Abstract

Surface defect inspection based on deep learning has demonstrated outstanding performance in improving detection accuracy and model generalization. However, the small scale of defect datasets always limits the application of deep models in industry. Generative models can obtain realistic samples in a very cheap way, which can effectively solve this problem and thus has received widespread attention in recent years. This paper provides a comprehensive analysis and summary of the current studies of surface defect inspection methods proposed between 2022 and 2024. First, according to the use of generative models, these methods are classified into four categories: Variational Auto-Encoders (VAEs), Generative Adversarial Networks (GANs), Diffusion Models (DMs), and multi-models. Second, the research status of surface defect inspection based on generative models in recent years is discussed from four aspects: sample generation, detection objective, inspection task, and learning model. Then, the public datasets and evaluation metrics that are commonly used for surface defect inspection are discussed, and a comparative evaluation of defect inspection methods based on generative models is provided. Finally, this study discusses the existing challenges for the defect inspection methods based on generative models, providing insights for future research.

1. Introduction

The manufacturing industry is the foundation of national economic development, directly reflecting the productivity level and international competitiveness of this country. To maintain competitiveness in the international market, excellent product quality is key. In the actual production process, it is inevitable that various defects appear on the surface of the product due to the difficulty in controlling the quality of raw materials, complex production technology, etc. Therefore, surface defect inspection, as an important component of quality production, plays a crucial role.

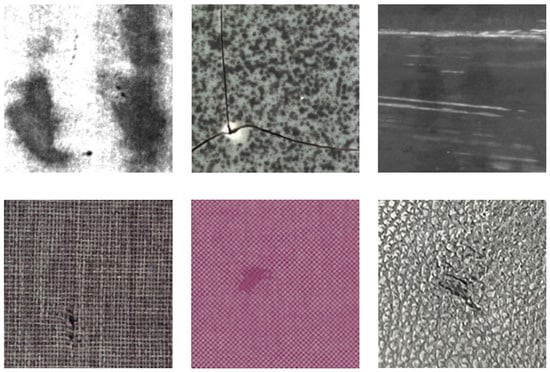

Generally, surface defects can be defined as the areas with local texture colors or structures that are inconsistent with the normal background surfaces []. According to the difference in material stiffness of a product, there are two types of surface defects in industry, i.e., the defects on rigid material surfaces, e.g., metal, wood, and ceramics, etc., and the defects on flexible material surfaces, e.g., fabric, leather, and rubber, etc. []. Visually, the former show irregular cracks, chipping inclusions, and stripe scratches, whereas the latter present bubbles, and dot or short-line type defects. Figure 1 shows the examples of two types of surface defects. Regardless of either type of surface defects, they not only influence the appearance of a product but also always become the starting point of physical damage or chemical corrosion, which can affect its quality and performance []. However, traditional defect inspection is performed by human vision, which is time-consuming, hard sledding, and inefficient []. The studies [,,] reported the drawbacks of the manual inspection in details. It is necessary to develop an automatic defect inspection system to replace the unreliable manual inspection.

Figure 1.

Examples of surface defect images. Upper row: examples of defects on rigid surfaces (https://pan.baidu.com/s/1l_RjTP7aTwr57ahcwelTpA, accessed on 25 July 2024). Bottom row: examples of defects on flexible surfaces (https://ibug.doc.ic.ac.uk/resources/fabrics/, accessed on 25 July 2024).

To achieve this, automatic defect inspection schemes were proposed in the 1980s []. Continuously, with the wide applications of vision sensors, more and more inspection methods based on machine learning (ML) and image processing techniques have emerged, mainly during the period 1981–2010. Usually, these methods extract well-designed handcraft features and then feed them into a pattern recognizer, hence also known as feature engineering. In past decades, related works have been reported. The surveys [,,] summarized the surface defect inspection methods in the 1980s, 1990s, and 2000s, respectively. Commonly, the traditional ML-based methods can be divided into four types: statistical methods, structural methods, filter-based methods, and model-based methods. However, no matter which kind of method of those mentioned above, the key to success is to design appropriate handcraft features, resulting in the inspection system having poor generalization and universality.

In 2012, AlexNet [] achieved great success in the visual recognition competition, attracting the world’s attention to the deep learning (DL) technique, especially the convolutional neural network (CNN). These models adopt neural networks with multiple convolutional layers to learn the high-level features with the powerful knowledge representation ability. In various computer vision tasks, e.g., image classification and object detection, a CNN has shown higher accuracy, better generalization, and less sensitivity to application conditions than traditional ML methods [,,]. It is natural that such models are employed in surface defect inspection and have become the most popular tools until now. Understandably, there are many reviews, such as focused on the DL-based defect inspection methods proposed in 2013–2023 [,,,,,,]. According to their summaries, the published methods can intuitively be divided into two stages with the gradual development of a CNN. The earlier stage is to combine CNNs and traditional ML pattern recognizers, such as [], which uses the former to extract features and the latter to perform vision tasks. Essentially, this mode still follows the solutions of feature engineering and thus fails to solve the problem of poor generalization. The latter stage is the end-to-end inspection methods, such as [], which can perform inspection tasks on different kinds of surfaces, regardless of rigid or flexible ones. The methods proposed during this period are indeed effective, however, their successes are based on an implicit assumption: the training samples are enough. Unlike common objects, the collection of defect samples is very different in industry. If training data is limited, the CNNs may not converge and achieve excellent results. To alleviate the requirements for defect samples, the previous methods as in [] reduced the size of a baseline CNN, which can also decrease the representation power of the model. The methods proposed in [,] adopted the pre-trained models for fine-tuning strong CNN models. Although this scheme can reduce the original sample requirement of the model, it cannot work well when there is a large gap between the target data distribution and source data distribution. Therefore, in the deep learning period, inspection methods pay more attention to solving the problem of lacking enough samples instead of how to design a model or an algorithm absorbedly, which is the fundamental difference from the traditional ML-based methods. Table 1 provides a concise summary of the reviewed research on surface defect detection based on deep learning.

Table 1.

Summary of reviewed studies based on deep learning for surface defect inspection.

For the data-limited defect inspection, the most intuitive solution is to generate new defect samples. Traditional data augmentation tricks, such as image rotations and flips, can simply expand the number of samples but cannot provide new knowledge, which is unable to assist a CNN in finishing feature learning under insufficient samples. In recent years, the sample generation paradigm has attracted much attention and provided a new solution for this problem. It can synthesize new samples by generative models, such as the Variational Auto-Encoders (VAEs), Generative Adversarial Networks (GANs), and Diffusion Models (DMs). The literature [,,,] summarized the generative models and their applications in other fields. In 2022, He et al. [] reviewed the defect detection methods based on GAN. Zhong et al. [] investigated and analyzed the image generation of surface defects in 2023. The generative models are also in the domain of the DL. The above-mentioned literature [,,,,] involved several defect inspection methods based on generative models, in which the papers were mainly published before 2022, but they did not focus on such methods. Therefore, this paper conducts a review of the generative models-based methods for the application of surface defect inspection that have been proposed in 2022–2024. In this paper, we categorized the popular generative models, i.e., the AE, GAN, and DM, and discussed their principles, properties, as well as advantages and disadvantages for industrial applications. Subsequently, we systematically summarized the related methods based on the three generative models. This paper also provides information about the common evaluation measures and public defect datasets. Finally, we discussed the key challenges and explored future work on the application of generative models in defect inspection.

The structure of this study is as follows: Section 2 outlines the popular generative models that can be used for inspection tasks. Section 3 presents a detailed overview of the generative model-based methods for surface defect inspection, where the papers are selected since 2022. Section 4 provides an introduction to the public datasets used in surface defect detection and the popular metrics used to evaluate surface defect detection models. The performance of the selected methods is also presented in this section. Section 5 concludes this study and offers a thorough discussion of the main challenges and future research directions for surface defect detection.

2. Overview of Generative Models

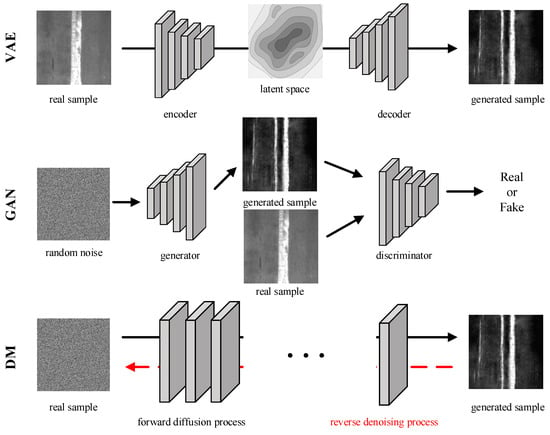

Conventional methods can generate defect images by using computer-aided design [] or three-dimensional modeling []. However, this strategy has limitations: it requires additional ray-tracing, consumes extensive computational resources, and fails to generate defect objects with irregular shapes []. With the development of the architecture of deep neural networks, deep generative models are being widely used in defect inspection and gradually replacing the traditional methods. Generative models for surface defect inspection can be broken up into three kinds of network architectures: VAEs, GANs, and DMs, illustrated in Figure 2. Each architecture differs in the strategy that is used to learn a latent representation of the feature. Both VAEs and DMs learn to maximize the likelihood of the input data. In contrast, GANs utilize a minimax game between their two subnetworks, which can be implemented in any form of a differentiable system that maps input data from one space to another. In this section, we only briefly describe the working principle and recent application of these generative models. Readers can refer to the previous reviews and resources for more details on generative models, such as mathematical formulations.

Figure 2.

Comparison of major generative models used in defect inspection.

2.1. Variational Auto-Encoder

VAEs are generative models that intend to learn both an encoder and a decoder to map input data to values in a continuous latent space []. Consider defect generation: the encoder learns to map a defect sample into a continuous embedding that can be interpreted as a latent variable in a probabilistic model, while the decoder learns to reconstruct the defect sample from its learned embedding. The loss function of a VAE consists of two terms. One is the reconstruction loss term that forces the decoder to recover the original image x from its embedding . The other is the regularization term that aims to make the distribution of learned embedding conform to the standard normal distribution as much as possible, which measures the Kullback–Leibler (KL) divergence between these two distributions. The loss function is defined as in Equation (1).

where λ is the weight of the regularization term, which is used to balance the importance between the reconstruction loss and the regularization term. In the context of sample generation, VAEs can be used for signal generation [,], image generation [,], and text generation [,].

2.2. Generative Adversarial Network

GANs [] are the deep generative models that consist of two neural networks: a generator G and a discriminator D. The G learns to create an image by sampling from a noise distribution , i.e., transform the noise z into G(z), with the aim to make the ideal converge to the real data distribution . Meanwhile, the D learns to distinguish whether the input sample x is real or fake. The optimization of a GAN can be viewed as a mini-max problem with value function V (G, D) that is written as in Equation (2).

where is the empirical estimate of the expected value of the probability. In the optimization process, G and D compete with each other until reaching the Nash equilibrium []. At that point, G considers the generated samples to be realistic enough. GANs have been widely used in many fields, such as face recognition [,], video prediction [,], and natural language processing [,], etc. In the field of defect inspection, GANs are the most popular generative model to address the issues of data limitation, where more related details can be found in the next section.

2.3. Diffusion Model

DMs [] are a family of probabilistic generative models that progressively destroy data by injecting noise and then learn to recover the data by reducing noise, in which the latter can be regarded as a sample generation process. Several methods make use of DMs for various tasks, such as super-resolution [,], image inpainting [,], and image translation [,], etc.

In computer vision tasks, the denoising diffusion probabilistic model (DDPM) is the commonly used diffusion model for image synthesis []. The DDPM can be viewed as a hierarchical Markov VAE with a fixed encoder. Specifically, the forward process of DDPM works as the encoder, but unlike VAE, this process is a linear Gaussian model. On the other hand, the reverse process of DDPM corresponds to the decoder shared between multiple decoding steps. Given that step t, x0~q(x0) represents the input data and its distribution, the forward process can be defined as the Markov chain where xt is the sample after injecting t-step noise to x0. In contrast, for the prior distribution p(x), the reverse process can be represented as , where θ denotes model parameters. The loss function of DDPM is defined in Equation (3).

3. Defect Inspection Based on Generative Models

In defect inspection, recent methods obtain generated samples through four types of generative models: VAEs, GANs, DMs, and multi-models, which combine with multiple models for sample generation. In addition, defect inspection tasks can be divided into three basic vision tasks: defect classification that identifies the defect class of a sample, defect detection that classifies and localizes each defect instance in a sample, and defect segmentation that divides a sample into regions with consistent characteristics pixel by pixel. In this section, we provide a technical review of the generative model-based defect inspection methods that are proposed between 2022 and 2024.

3.1. Defect Inspection Based on VAEs

VAEs have been widely used for image generation of surface defect inspection []. A simple way to use VAEs is for data augmentation, and then the generated samples are fed into a classifier or a detector. For instance, Xiang et al. [] proposed the convolutional AE (CAE) for generating fabric defect samples and a defect detection algorithm based on Fourier convolution. Zhang et al. [] designed the AE5-SSIM to reconstruct tinfoil images. This model is based on structural similarity reconstruction AE, whose encoder and decoder networks have five sub-encoder blocks and five sub-decoder blocks, respectively. Sae-ang et al. [] introduced an auto-encoder to extract useful information from unlabeled data and then performed semantic anomaly detection on the samples. Si et al. [] reconstructed images by a VAE model and analyzed the detection performance using various image gradient filters on the surface of wooden broads. Shi et al. [] proposed a lightweight surface defect detection network based on the CAE to solve the problem of shortage of defective samples in the industry.

The data augmentation strategy is simple but limited application due to the generation and representation processes being separate. Two different learning stages may result in differences in feature learning and waste the opportunity to learn the correlation between them. Therefore, more researchers choose to establish defect inspection systems in end-to-end learning schemes. For VAE-based defect methods, Zhang et al. [] proposed an attention-based vector quantization VAE (AVQ-VAE) for detecting defects in colored patterned fabrics, which adopts autoregressive modeling of discrete variables and attention mechanisms to enhance the detection performance. Zhang et al. [] presented a multi-scale U-shaped denoising CAE (MSUDCAE) model for fabric defect detection, which was trained on defect-free samples and calculated residual maps between the original image and the corresponding reconstructed image to improve detection results. Tao et al. [] presented an unsupervised detection method based on a dual-Siamese network. This framework tackled the problems that persist in the discriminative embedding-based methods and achieved state-of-the-art anomaly inspection performance on four public defect datasets. Min et al. [] proposed a two-stage architecture including the railway cropping network and defects removal VAE (DR-VAE). The former extracted railroad surface and the latter carried out image reconstruction and defect detection on railway surfaces. Lu et al. [] introduced a semantic label-enhanced (LE) VAE for generating defect examples and exploited semantic label information to improve classification performance. Fang et al. [] proposed a sample-less anomaly detection strategy called FastRecon that works in low-data environments and is able to generalize across products at no additional cost. Li et al. [] presented an introspective self-supervised reconstruction model (ISRM), which only used normal samples for training and integrated self-supervised learning into an introspective auto-encoder to address the problems of sample imbalance and complex background interference. Yang et al. [] established the Fs-CAE network by adding frequency shift operation based on the CAE network. The method only needs samples without defects for model training and does not require labels, thus reducing manual labeling time. Yang et al. [] proposed an unsupervised defect detection method based on the Vision Transformer (ViT), which utilizes a transformer encoder to capture global contextual information, thereby enhancing detailed image understanding and detection performance.

Table 2 presents the key features of the selected papers that are based on VAEs for defect inspection. Due to the lack of defect images and manual annotations, these studies had to perform defect inspection in the modes of unsupervised learning or weakly-supervised learning. In 2022–2024, most methods focused on the challenging defect segmentation tasks. However, VAEs-based methods are only suitable for simple situations, for example, each image containing only one defect. VAEs generate samples by an encoding-decoding process, which assumes input samples follow a Gaussian distribution and maps them to the continuous data distribution []. Therefore, VAEs are good at reconstructing features with regular patterns but fail to learn complex and random features, resulting in the problem of generating blurry images []. Comparatively, GANs and DMs have more complex latent priors for data assumption, and thus have the ability to deal with a complex defect dataset [].

Table 2.

Summary of studies based on VAEs for surface defect inspection.

3.2. Defect Inspection Based on GANs

GANs are the most popular generative model used in defect inspection. There are two main network architectures used for defect sample generation. The one is the classical GAN architecture that samples from the random noise distribution and generates samples unconditionally. Among the most representative models are standard GAN [], DCGAN (deep convolutional GAN) [], and WGAN (Wasserstein GAN) [], etc. Existing inspection methods utilize these generative models for data augmentation or modify the output layer of the discriminator according to the type of inspection task. Table 3 summarizes the selected methods which are based on classical GAN architecture for defect inspection.

Table 3.

Summary of studies based on typical GANs for surface defect inspection.

For example, He et al. [] designed a customized GAN to generate unlabeled samples and performed label assignment for unlabeled samples to enable them to participate in semi-supervised training. Liu et al. [] introduced a triple-attention semantic segmentation network for surface defect detection, which utilized the GAN-based data augmentation (DA-GAN) method to exaggerate defect images and capture contextual information to improve segmentation results. Murase et al. [] proposed the Anomalous Latent Variable Generating Adversarial Networks (ALGAN) that only used normal data for training and introduced latent variables in anomalous states to generate pseudo data. Gan et al. [] used a GAN to generate pseudo-defect images and mixed them into real images in a pre-trained CNN for defect classification. For defect classification tasks, Li et al. [] introduced the DefectGAN, which equipped fully convolutional networks and Markov discriminators to reduce the risk of pattern collapse and used a novel sampling strategy to balance memory consumption and training quality. Hao et al. [] adopted the WGAN to generate new defect samples and integrated attention mechanisms into a CNN model to recognize defects on a hot-rolled strip steel surface. Song et al. [] constructed a mapping network for the latent space, which made it possible to compose defect images of various sizes and optimized the proposed method in terms of convergence and computational cost. Jin et al. [] replaced the activation functions DCGAN with ELUs (EDCGAN) for sample generation and adopted the MobileNet for steel surface defect classification. Liu et al. [] modified the traditional GAN with two dual discriminators and introduced a regularization technique into GAN for generating high-quality and diverse surface defect images. Zhao et al. [] presented a semi-supervised detection method of the metal product surface, which incorporated the Visual Transformer (ViT) into GAN and extracted multi-scale mask features for capturing rich semantic information. Wei et al. [] proposed a multi-stage detection framework by transforming the defect detection task of fabrics into an unsupervised task based on DCGAN, which only required a few number of normal samples and achieved competitive results. Luo et al. [] introduced the ADRGAN (attentive dual residual GAN) which uses the channel-wise and spatial-wise attention mechanisms to track and recover raindrop-like pseudo-defects. The method is able to locate and remove these pseudo-defects more accurately while retaining the real defect features, thus improving the accuracy and efficiency of defect detection. Ma et al. [] constructed the adaptive GAN (AGAN) that generates defects similar in style to the background of the defect-free samples and designed the self-attentive encoder and spatial-aware decoder modules for obtaining the final prediction results. Xu et al. [] proposed an unsupervised learning method for recognizing steel surface defects with fewer labeled samples, which generated defect images using a diverse generative adversarial network (DGAN) and learned the representation using flexible contrast to improve the semantic information of samples. Li et al. [] proposed the Defect Location Sensitive GAN (DLS-GAN) for data augmentation, which used two encoder–decoders to help synthesize defects on the object and improve the synthesis quality. Wang et al. [] modified the auxiliary classifier GAN (ACGAN) by applying the Wasserstein distance and spectral normalized strategy, which obtained high-quality generation and reduced the cost of detection. He et al. [] proposed the perceptually constrained single image GAN (PCSGAN) to solve the problem posed by small numbers of defect images, which can train generators and discriminators at each scale. KU et al. [] developed a defect-background separated GAN to enhance the accuracy of battery exterior defect inspection, which contributes to constructing a balanced dataset by increasing the overall quantity of the defect segmentation dataset, addressing the shortage of defect instances. Noor et al. [] proposed a DCGAN-based method for the automatic generation of image synthesis of apparel stitching defects.

The other type of GAN architecture is based on image-to-image translation, which generates samples conditioned on input images, such as CycleGAN [], StyleGAN [], and SinGAN [], etc. Using these generative models for constructing defect inspection methods can not only solve the issue of limited samples but also guide the learning mode of GANs due to the constraints on input samples. The selected methods that are based on image-to-image translation GAN architecture are presented in Table 4. For instance, Niu et al. [] introduced a weakly-supervised defect segmentation method that adopted the CycleGAN to generate defect-free templates through image-level annotation training and designed an attention module to enhance the ability to eliminate defective regions. Wen et al. [] presented an unsupervised learning method suitable for defect detection with small samples, which expands the dataset by generating defective images and utilizes the attention mechanism to highlight key features in the images as a way to improve the accuracy of defect classification. Yi et al. [] combined the SinGAN with the channel attention mechanism to generate high-quality and diverse defect images and improved classification accuracy by an image cutting and fusion method. Ren et al. [] proposed an improved StyleGAN model that actively places different emphases on images of different resolutions to enhance the generation quality and employed different CNNs for classification. Hu et al. [] proposed a structural defect detection algorithm based on the pix2pix network and migration learning using CGAN to reconstruct the defective region, calculate the difference between the reconstructed image and the defective image, and perform segmentation tasks on fabric surfaces. Wang et al. [] introduced the foreground perception cycle-consistent adversarial network (FCGAN), which combines an attention network with a generator and a discriminator to recognize discriminative foregrounds and synthesizes coordinated and realistic pseudo-defect images. He et al. [] designed a data augmentation module and a self-attention mechanism into the progressive GAN (Pro-GAN) to generate high-quality and high-diversity surface defect images. Xu et al. [] combined dual U-Net networks with the pix2pix network to generate defect localization maps, and then employed the YOLOv3 for fabric defect detection. Ran et al. [] proposed a new GAN for image-to-image translation to achieve high-quality synthesis from masked images to defect images of steel strips and validated the effectiveness of the synthesized data for data augmentation in YOLOv8. He et al. [] proposed the production-and-elimination GAN (PE-GAN) for high-quality defect sample generation, which guides the learning direction of generative models by simulating the formation of defects on the surface of steel plates.

Table 4.

Summary of studies based on image-to-image translation GANs for surface defect inspection.

3.3. Defect Inspection Based on DMs

Although it has been proven that the generation quality of DMs outperforms that of GANs and VAEs, the manufacturing field seems to pay little attention to DM-based defect inspection and sample generation. Tang et al. [] presented an unsupervised learning defect detection method on fabric surfaces, which improves the quality of image generation by optimizing the time step and utilizes the simplex noise DDPM (SN-DDPM) to reconstruct defect images, thus realizing accurate segmentation of defects. Huang et al. [] proposed a hybrid DL framework based on DDPM for data enhancement and a deep residual neural network (DenseNet) for defect classification on composite panel surfaces. Tao et al. [] generated diverse defective images by training a DDPM model with limited samples for generalized surface defect inspection. In this method, an erasing–inpainting mechanism is proposed to promote the recombination of real features and learned features, thus fully using the limited defect samples. Liang et al. [] introduced a stabilized diffusion enhancement method based on the improved YOLOv5 model for defect detection in metal stamping parts. This method introduces a lightweight bottleneck transformer structure and a multi-head self-attention mechanism to increase detection speed and accuracy.

Table 5 summarizes the DM-based studies conducted for surface defect inspection. Although DMs have strong performance and can generate realistic images, the network structure of DMs is too heavy and the sampling time is too long, which requires a significant amount of computation resources and training time. There is room to reduce training difficulty and model complexity for DMs, resulting in applicability for industrial applications in the future.

Table 5.

Summary of studies based on DMs for surface defect inspection.

3.4. Defect Inspection Based on Multi-Models

A new trend builds generative models based on multiple models, e.g., the combination of a GAN and a VAE. Zhao et al. [] introduced the channel attention mechanism into AE generator network and Combine with the Wasserstein GAN (WGAN) for image restoration, which can achieve good results in removing the oil droplets from the image and restoring the texture information of the oil droplet region. Yang et al. [] introduced the Mask2Defect that utilizes priori knowledge to data augmentation and has the ability to use generated samples to fine-tune the inspection model. The Mask2Defect consists of three generative models: the IPK-Encoder (industrial prior knowledge encoder) that obtains teacher masks for semi-supervised training, the M2DCNet (mask-to-defect construction network) that renders the defect details based on teacher masks, and the F2RDT-GAN (fake-to-real domain transformation GAN) that transforms the rendered samples to real defect domain for guaranteeing realistic background textures. Yu et al. [] proposed a weakly-supervised learning method for fabric defect detection, which replaces the generator of GAN with an AE architecture to generate samples. Then, the single-shot multi-box detector network is adopted for multi-scale defect detection. Ferrari et al. [] introduced an anomaly detection architecture that combines a GAN and a residual AE, which improves the accuracy of detecting and localizing surface anomalies by focusing on specific regions of the image. Dai et al. [] combined an attention feature fusion module and a residual banalization module through an encoder–decoder–encoder network structure to perform defect detection and segmentation based on defect-free samples. Bu et al. [] combined the deep conditional VAE (DCCVAE) and auxiliary conditional Wasserstein GAN with gradient penalty (ACWGAN-GP) to gradually expand and generate various coating defect images for solving the overfitting problem due to unbalanced data and finally adopted a CNN for defect classification based on generated samples.

Table 6 presents a summary of selected papers that combine multiple generative models for surface defect inspection. The commonly used combination is to integrate a VAE and a GAN, which can combine their advantages and achieve outperformance.

Table 6.

Summary of studies based on multi-models for surface defect inspection.

4. Datasets and Metrics

In this section, we provide a summary of public industrial defect datasets that are widely used for surface defect inspection. Then, we introduce the standard metrics for the industrial inspection methods that are based on generative models. Finally, by these metrics, the comparison results obtained from the selected papers are presented for the public defect datasets.

4.1. Surface Defect Datasets

In the field of industry, a dataset plays a crucial role in the research of generative model-based defect inspection methods. Unlike common detection datasets, defect datasets have smaller sample sizes with fewer categories and prefer to use grayscale images. According to the summary of the selected methods in the last section, the extensively used defect datasets are summarized in Table 7, specifically as follows: AITEX [], DAGM [], KolektorSDD1 [], KolektorSDD2 [], MT (Magnetic Tile) [], MVTec [], NEU series (NEU-CLS [], NEU-DET [], and NEU-CLS-64 []), RSDDs [], X-SDD [], and YDFID-1 []. These datasets cover a wide range of defect inspection scenarios of manufacturing product surfaces.

Table 7.

Summary of public surface defect datasets.

4.2. Metrics

Metrics are very important and necessary which can guide model design and demonstrate the effectiveness and superiority of the proposed methods. For surface inspection, it is desirable first to evaluate the accuracy of the inspection methods. The most basic indicators are accuracy (ACC), precision, recall, and F1-score, where the definitions of these indicators are defined in Equations (4)–(7).

where TP, TN, FP, and FN indicate a situation in which the model correctly predicts a positive sample as a positive case, the model correctly predicts a negative sample as a negative case, the model incorrectly predicts a negative sample as a positive case, and the model incorrectly predicts a positive sample as a negative case, respectively.

Additionally, in order to reasonably evaluate the prediction effect of methods, the indicators mAP (mean Average Precision) and mIoU (mean Intersection over Union) are always used for surface defect detection and segmentation tasks. For k-class defect inspection, they are calculated as in Equations (8) and (9).

where X denotes the predictions and Y denotes the ground-truths. Similar to mAP, AUROC is also a common indicator for surface defect inspection. The AUROC means the area under the receiver operating characteristic (ROC) curve, where the calculation formula is as Equation (10).

where represents the summation of the order number of positive samples. refers to rank the positive samples according to the probability scores. M and N represent the order number of positive and negative samples, respectively. There are two kinds of AUROC indicators: the image-level AUROC for evaluating classification performance and the pixel-level AUROC for evaluating segmentation performance.

The generated samples are fake images synthesized by generative models, whose quality can greatly affect the performance of inspection models. The Fréchet Inception Distance (FID) is the popular metric for evaluating the generation quality by comparing the feature distribution difference between generated samples and real samples. The definition of FID is shown in Equation (11).

where and are the real and the generated samples, respectively. The notions μ,, and represent the mean, the covariance matrix, and the trace of a matrix.

4.3. Comparisons on Public Defect Datasets

Table 8 summarizes the comparison results of selected methods on the public defect datasets which have been mentioned in Section 4.1. Specifically, the comparison performance of the AITEX, DAGM, KolektorSDD1, KolektorSDD2, MT, MVTec, NEU-CLS, NEU-DET, NEU-CLS-64, RSDDs, X-SDD, and YDFID-1 datasets are shown in Table 8 (a)–(k).

Table 8.

Comparison results of selected methods on the public defect datasets.

Overall, the surface inspection methods based on generative models have made significant achievements since 2022, especially the defect classification tasks. However, the defect detection and segmentation performance still face challenges due to instable generation quality and having to train models in unsupervised learning or weakly-supervised learning manners. It is worth noting that most inspection methods do not open source code for its potential for industrial applications in the future, and thus it is impossible to reproduce them.

5. Discussion and Conclusions

Generative models maintain rapid development as a powerful tool for defect inspection on manufacturing product surfaces. In this paper, we have conducted a comprehensive review of the recent defect inspection methods that were proposed between 2022 and 2024. Specifically, we focus on the generative models-based methods because there is generally a shortage of defect samples in the industrial field. Furthermore, we introduce the public defect datasets and the comparison results of the selected methods. Finally, we discuss the challenges that still need to be addressed in this area. The goal of this review is to offer readers a greater understanding of the present research status on surface defect inspection for industrial products, to serve as a reference for future research in this area.

5.1. Challenges and Opportunities

Although generative models have been widely used in the field of defect inspection, there are some challenges with both the model itself and its application to the task of sample generation of surface defects.

- Small-scale defect datasets. Due to the difficulty in collecting defect samples, existing industrial surface defect datasets are relatively small scale. For deep neural networks, the larger model size brings stronger representability that can achieve better inspection results. However, the model size is positively correlated with sample requirements. A small training set limits the application of large models in industrial inspection tasks. Therefore, it is very cheap to obtain samples through generative models, which have been the research hotspot in the field of industrial inspection.Not only in terms of the number of defect samples, manual annotations are also insufficient due to the lack of simple and reliable labeling methods []. Undoubtedly, inspection methods can achieve excellent accuracy under the supervision of manual labels. However, industrial labeling is highly professional and heavy work, resulting in most existing defect datasets only having image-level labels. Meanwhile, the generated samples are unlabeled, and inspection models can hardly be constructed in a supervised learning manner with these samples. Therefore, current methods can only utilize generated samples for defect inspection tasks, especially for defect detection and segmentation tasks, in weakly-supervised learning and unsupervised learning manners. The accuracy obtained in these ways cannot meet the actual levels of industrial inspection.Furthermore, the small scale of a dataset can lead to an imbalance in representation learning during the process of sample generation []. For large-scale datasets, it is not necessary to require equal sample sizes between classes, which means class imbalance can slightly affect the training of deep models. However, defect datasets are all small-scale, in which the number of defect-free samples is usually bigger than that of defect samples. If training on such a class-imbalanced dataset, the model tends to learn features in features of categories with larger sample sizes. Although it is easy to recover the balance of a dataset by adding generated samples, these samples are essentially fake images, which may not necessarily have a positive impact on generation learning.

- Difficulties in training of generative models. Advanced generative models have their own difficulties in training. The goal of training a GAN is to reach Nash equilibrium, but it is difficult to achieve because the adversarial nature of a GAN cannot guarantee convergence, and thus training usually occurs in oscillations with gradually increasing amplitudes []. Moreover, GANs may suffer from mode collapse, which causes the generator to only learn simple features and fail to learn complex features, and thus GANs only produce duplicate or similar images []. For the DMs, the sampling time as well as the training time are too long, and their model structures are too complex and heavy. Moreover, generative models are also deep neural networks, which require a certain number of samples for model training. The aim of generative models is to generate images as realistically as possible. Therefore, generative models need to train on real samples, which in some cases cannot be achieved when the number of initial defect samples is extremely small. A method that allows training models on a small number of samples urgently needs to be developed.

- How to improve generation quality. The performance of inspection models is highly dependent on the quality of generation samples. The quality not only refers to the clarity of the generated image but also to the diversity of generated defect features. It is necessary to design a learning mechanism to guide generative models to focus on defect areas and ignore background areas. Moreover, many product surfaces can produce defects of small size. For example, a defect target only occupies 32 × 32 pixels area in a 512 × 512 pixels defect image. Generative models are essentially deep neural networks in which each convolutional layer is equivalent to a filter. It is very challenging for generative models to learn and generate such a small target that only has a few details. Feature fusion techniques can bring more details to feature representation, which boosts the recognition of small defect targets []. However, this method is not always effective. A better method for discovering target details needs to be studied for the further improvement of the accuracy of detecting small defect targets. The background texture can also interfere with the generation quality. Many semi-finished products without surface treatment, e.g., hot-rolled steel plates, also need surface defect inspection to ensure production quality. Sometimes background textures may confuse a detector’s cognition and be identified as defects, while subtle defects may be identified as background textures. In addition, many industrial production environments are extremely harsh, resulting in oil contamination or dust appearing on the surface of the product. These objects are generally not included in defect datasets and can therefore be misclassified as existing defect classes in the dataset, causing generative models to perform incorrect feature learning.

- Real-time inspection. The primary objective of industrial inspection is undoubtedly the pursuit of high precision. The design of defect inspection methods should also satisfy the requirements of industrial real-time performance. However, the reality is current methods, especially based on deep learning, are involved in the trade-off of inspection accuracy and speed. Although computer hardware has developed rapidly and model lightweight technology has made some progress, accuracy and real-time performance still cannot be balanced for industrial inspection.

5.2. Future Research Directions

- A generative model with high generation quality. Generative models are not intended as a means of data augmentation. If the generated samples are not clear enough, it will have a negative impact on feature learning. For defect inspection methods based on generative models, a training set always contains a much larger number of generated samples than real ones. Only increasing the number of samples cannot improve the final detection accuracy. DM is currently the most advanced and powerful generative model, which holds great potential in defect detection. However, this model still needs improvements due to difficulties in training, slow sampling speed, and other reasons. An important research direction will be to solve the problems of DMs and design inspection methods based on these models.

- Knowledge transferring. The distribution differences exist between the generated sample and the real sample. Due to the difficulty in obtaining new samples, the differences can seriously affect the quality of generation and inspection results. A promising research direction is to mine common knowledge and suppress special knowledge across different defect datasets. For example, both steel and aluminum plates have scratch defects that have similar features. The scratch features are common knowledge, and correspondingly different surface textures are their special knowledge. If aluminum plate datasets have a few samples, common knowledge from steel plate datasets can be transferred to boost sample generation. The most commonly used knowledge-transferring method is the cross-domain adaptation []. The effectiveness of mining knowledge from fake data is disappointing, which is a research problem that needs to be investigated.

- Accurate defect detection or segmentation in the weakly-supervised learning mode. Due to generated samples being unlabeled, most defect inspection methods are in the weakly-supervised learning mode. Although effective at defect classification, the detection and segmentation accuracy is far inferior to supervised learning methods. On one hand, it is because of the limitations of weakly-supervised learning itself; on the other hand, it is due to the lack of reliable label assignment methods, which are worth studying in future work.

- Lightweight model design. There are successful lightweight design cases in convolutional neural networks, e.g., the MobileNet []. However, these schemes are unable to integrate into generative models. To obtain high generation quality, powerful generative models require a complex learning process, such as the adversarial learning of GANs and the diffusion-and-denoising process of DMs, which depends on a heavy network architecture. Finally, the generation process is always time consuming. To meet real-time inspecting, generative models require lightweight design, which can also reduce the sample demand.

Author Contributions

Conceptualization, Y.H. and X.W.; methodology, Y.H. and J.X.; software, Y.H. and S.L.; validation, S.L. and X.W.; investigation, S.L.; resources, Y.H.; data curation X.W.; writing—original draft preparation, Y.H.; writing—review and editing, X.W. and J.X.; visualization, Y.H.; project administration, Y.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (62306186), the Technology Plan Joint Foundation of Liaoning Province (2023-BSBA-238), and the Technology Plan Joint Foundation of Liaoning Province (2023-MSLH-246).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chen, Y.; Ding, Y.; Zhao, F.; Zhang, E.; Wu, Z.; Shao, L. Surface Defect Detection Methods for Industrial Products: A Review. Appl. Sci. 2021, 11, 7657. [Google Scholar] [CrossRef]

- Tang, B.; Chen, L.; Sun, W.; Lin, Z. Review of surface defect detection of steel products based on machine vision. IET Image Process. 2023, 17, 303–322. [Google Scholar] [CrossRef]

- Hütten, N.; Gomes, M.A.; Hölken, F.; Andricevic, K.; Meyes, R.; Meisen, T. Deep Learning for Automated Visual Inspection in Manufacturing and Maintenance: A Survey of Open- Access Papers. Appl. Syst. Innov. 2024, 7, 11. [Google Scholar] [CrossRef]

- Neogi, N.; Mohanta, D.K.; Dutta, P.K. Review of vision-based steel surface inspection systems. EURASIP J. Image Video Process. 2014, 50, 1–19. [Google Scholar] [CrossRef]

- Neogi, N.; Mohanta, D.K.; Dutta, P.K. Machine Vision Algorithms and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Sheehan, J.; Drury, C. The analysis of industrial inspection. Appl. Ergon. 1971, 2, 74–78. [Google Scholar] [CrossRef] [PubMed]

- Chiang, H.-Q.; Hwang, S.-L. Human performance in visual inspection and defect diagnosis tasks: A case study. Int. J. Ind. Ergon. 1988, 2, 235–241. [Google Scholar] [CrossRef]

- Ren, Z.; Fang, F.; Yan, N.; Wu, Y. State of the Art in Defect Detection Based on Machine Vision. Int. J. Precis. Eng. Manuf. Technol. 2022, 9, 661–691. [Google Scholar] [CrossRef]

- Chin, R.T. Automated visual inspection: 1981 to 1987. Comput. Vis. Graph. Image Process. 1988, 41, 346–381. [Google Scholar] [CrossRef]

- Newman, T.S.; Jain, A.K. A Survey of Automated Visual Inspection. Comput. Vis. Image Underst. 1995, 61, 231–262. [Google Scholar] [CrossRef]

- Xie, X. A Review of Recent Advances in Surface Defect Detection using Texture analysis Techniques. ELCVIA Electron. Lett. Comput. Vis. Image Anal. 2008, 7, 1–22. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. In Proceedings of the Neural Information Processing Systems (NIPS), Lake Tahoe, NV, USA, 3–6 December 2012. [Google Scholar]

- Voulodimos, A.; Doulamis, N.; Doulamis, A.; Protopapadakis, E. Deep Learning for Computer Vision: A Brief Review. Comput. Intell. Neurosci. 2018, 2018, 7068349. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Wang, Z.; Liu, X.; Zeng, N.; Liu, Y.; Alsaadi, F.E. A survey of deep neural network architectures and their applications. Neurocomputing 2017, 234, 11–26. [Google Scholar] [CrossRef]

- Liu, L.; Ouyang, W.; Wang, X.; Fieguth, P.; Chen, J.; Liu, X.; Pietikäinen, M. Deep learning for generic object detection: A survey. Int. J. Comput. Vis. 2020, 128, 261–318. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Malhan, R.K.; Rajendran, P.; Shah, B.C.; Thakar, S.; Yoon, Y.J.; Gupta, S.K. Image-Based Surface Defect Detection Using Deep Learning: A Review. J. Comput. Inf. Sci. Eng. 2021, 21, 040801. [Google Scholar] [CrossRef]

- Czimmermann, T.; Ciuti, G.; Milazzo, M.; Chiurazzi, M.; Roccella, S.; Oddo, C.M.; Dario, P. Visual-based defect detection and classification approaches for industrial applications—A survey. Sensors 2020, 20, 1459. [Google Scholar]

- Wen, X.; Shan, J.; He, Y.; Song, K. Steel Surface Defect Recognition: A Survey. Coatings 2022, 13, 17. [Google Scholar] [CrossRef]

- Gao, Y.; Li, X.; Wang, X.V.; Wang, L.; Gao, L. A Review on Recent Advances in Vision-based Defect Recognition towards In-dustrial Intelligence. J. Manuf. Syst. 2022, 62, 753–766. [Google Scholar] [CrossRef]

- Saberironaghi, A.; Ren, J.; El-Gindy, M. Defect Detection Methods for Industrial Products Using Deep Learning Techniques: A Review. Algorithms 2023, 16, 95. [Google Scholar] [CrossRef]

- Jha, S.B.; Babiceanu, R.F. Deep CNN-based visual defect detection: Survey of current literature. Comput. Ind. 2023, 148, 103911. [Google Scholar] [CrossRef]

- Ameri, R.; Hsu, C.-C.; Band, S.S. A systematic review of deep learning approaches for surface defect detection in industrial applications. Eng. Appl. Artif. Intell. 2024, 130, 107717. [Google Scholar] [CrossRef]

- Ghorai, S.; Mukherjee, A.; Gangadaran, M.; Dutta, P.K. Automatic Defect Detection on Hot-Rolled Flat Steel Products. IEEE Trans. Instrum. Meas. 2013, 62, 612–621. [Google Scholar] [CrossRef]

- He, Y.; Song, K.; Meng, Q.; Yan, Y. An End-to-End Steel Surface Defect Detection Approach via Fusing Multiple Hierarchical Features. IEEE Trans. Instrum. Meas. 2020, 69, 1493–1504. [Google Scholar] [CrossRef]

- Jiang, M. An end-to-end steel strip surface defects recognition system based on convolutional neural networks. Steel Res. Int. 2017, 88, 1600068. [Google Scholar]

- Huang, H.; Li, Q.; Zhang, D. Deep learning based image recognition for crack and leak-age defects of metro shield tunnel. Tunn. Undergr. Space Technol. 2018, 77, 166–176. [Google Scholar] [CrossRef]

- Ren, R.; Hung, T.; Tan, K.C. A Generic Deep-Learning-Based Approach for Automated Surface Inspection. IEEE Trans. Cybern. 2018, 48, 929–940. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Guo, W. Auto-Encoders in Deep Learning—A Review with New Perspectives. Mathematics 2023, 11, 1777. [Google Scholar] [CrossRef]

- Creswell, A.; White, T.; Dumoulin, V.; Arulkumaran, K.; Sengupta, B.; Bharath, A.A. Generative Adversarial Networks: An Overview. IEEE Signal Process. Mag. 2018, 35, 53–65. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, Z.; Song, Y.; Hong, S.; Xu, R.; Zhao, Y.; Zhang, W.; Cui, B.; Yang, M.-H. Diffusion Models: A Comprehensive Survey of Methods and Applications. ACM Comput. Surv. 2023, 56, 1–39. [Google Scholar] [CrossRef]

- Bond-Taylor, S.; Leach, A.; Long, Y.; Willcocks, C.G. Deep Generative Modelling: A Comparative Review of VAEs, GANs, Normalizing Flows, Energy-Based and Autoregressive Models. IEEE Trans. Pattern Anal. Mach. Intell. 2022, 44, 7327–7347. [Google Scholar] [CrossRef]

- He, X.; Chang, Z.; Zhang, L.; Xu, H.; Chen, H.; Luo, Z. A Survey of Defect Detection Applications Based on Generative Ad-versarial Networks. IEEE Access 2022, 10, 113493–113512. [Google Scholar] [CrossRef]

- Zhong, X.; Zhu, J.; Liu, W.; Hu, C.; Deng, Y.; Wu, Z. An Overview of Image Generation of Industrial Surface Defects. Sensors 2023, 23, 8160. [Google Scholar] [CrossRef] [PubMed]

- Mery, D.; Hahn, D.; Hitschfeld, N. Simulation of defects in aluminium castings using CAD models of flaws and real X-ray images. Insight Non Destr. Test. Cond. Monit. 2005, 47, 618–624. [Google Scholar] [CrossRef]

- Boikov, A.; Payor, V.; Savelev, R.; Kolesnikov, A. Synthetic Data Generation for Steel Defect Detection and Classification Using Deep Learning. Symmetry 2021, 13, 1176. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Q.; Zhu, G.; Sun, G. Utilizing VQ-VAE for End-to-End Health Indicator Generation in Predicting Rolling Bearing RUL. Meas. Sci. Technol. 2023, 35, 6106. [Google Scholar] [CrossRef]

- Kaur, D.; Islam, S.N.; Mahmud, M.A.; Haque, M.E.; Anwar, A. A VAE-Bayesian deep learning scheme for solar power gener-ation forecasting based on dimensionality reduction. Energy AI 2023, 14, 100279. [Google Scholar] [CrossRef]

- Wu, Y.; Xu, L. Image Generation of Tomato Leaf Disease Identification Based on Adversarial-VAE. Agriculture 2021, 11, 981. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y. Remote Sensing Image Generation Based on Attention Mechanism and VAE-MSGAN for ROI Extraction. IEEE Geosci. Remote Sens. Lett. 2021, 19, 1–5. [Google Scholar] [CrossRef]

- Chen, R.; Wang, J.; Yu, L.C.; Zhang, X. Decoupled variational autoencoder with interactive attention for affective text gener-ation. Eng. Appl. Artif. Intell. 2023, 123, 106447. [Google Scholar] [CrossRef]

- Duan, D.; Zhang, Q.; Han, Z.; Xiong, H. Enhancing Text Generation via Parse Tree Embedding. Comput. Intell. Neurosci. 2022, 23, 1–9. [Google Scholar] [CrossRef]

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative adversarial nets. In Proceedings of the Neural Information Processing Systems (NIPS), Montreal, QC, Canada, 8 December 2014. [Google Scholar]

- Antipov, G.; Baccouche, M.; Dugelay, J.-L. Face aging with conditional generative adversarial networks. In Proceedings of the 2017 IEEE International Conference on Image Processing (ICIP), Beijing, China, 17–20 September 2017; pp. 2089–2093. [Google Scholar]

- Choi, Y.; Choi, M.; Kim, M.; Ha, J.; Kim, S.; Choo, J. Stargan: Unified generative adversarial networks for multi-domain image-to-image translation. In Proceedings of the Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–22 June 2018. [Google Scholar]

- Xiao, J.; Bi, X. Multi-Scale Attention Generative Adversarial Networks for Video Frame Interpolation. IEEE Access 2020, 8, 94842–94851. [Google Scholar] [CrossRef]

- Liu, M.-Y.; Huang, X.; Yu, J.; Wang, T.-C.; Mallya, A. Generative Adversarial Networks for Image and Video Synthesis: Algorithms and Applications. Proc. IEEE 2021, 109, 839–862. [Google Scholar] [CrossRef]

- Nie, W.; Narodytska, N.; Patel, A. Relgan: Relational generative adversarial networks for text generation. In Proceedings of the The International Conference on Learning Representations (ICLR), Vancouver, BC, Canada, 30 April–3 May 2018. [Google Scholar]

- Li, J.; Monroe, W.; Shi, T.; Jean, S.; Ritter, A.; Jurafsky, D. Adversarial Learning for Neural Dialogue Generation. arXiv 2017, arXiv:1701.06547. [Google Scholar]

- Ho, J.; Saharia, C.; Chan, W.; Fleet, D.J.; Norouzi, M.; Salimans, T. Cascaded Diffusion Models for High Fidelity Image Gen-eration. J. Mach. Learn. Res. 2022, 23, 1–33. [Google Scholar]

- Saharia, C.; Ho, J.; Chan, W.; Salimans, T.; Fleet, D.J.; Norouzi, M. Image Super-Resolution Via Iterative Refinement. IEEE Trans. Pattern Anal. Mach. Intell. 2023, 45, 4713–4726. [Google Scholar] [CrossRef] [PubMed]

- Saharia, C.; Chan, W.; Chang, H.; Lee, C.; Ho, J.; Salimans, T.; Fleet, D.; Norouzi, M. Palette: Image-to-image diffusion models. In Proceedings of the Special Interest Group on Computer Graphics and Interactive Techniques Conference, Vancouver, BC, Canada, 7–11 August 2022. [Google Scholar]

- Lugmayr, A.; Danelljan, M.; Romero, A.; Yu, F.; Timofte, R.; VanGool, L. Repaint: Inpainting using denoising diffusion proba-bilistic models. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops (CVPRW), Salt Lake City, UT, USA, 18–22 June 2018. [Google Scholar]

- Meng, C.; He, Y.; Song, Y.; Song, J.; Wu, J.; Zhu, J.Y.; Ermon, S. Sdedit: Guided Image Synthesis and Editing with Stochastic Differential Equations. arXiv 2021, arXiv:2108.01073. [Google Scholar]

- Isola, P.; Zhu, J.-Y.; Zhou, T.; Efros, A.A. Image-to-image translation with conditional adversarial networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017. [Google Scholar]

- Ho, J.; Jain, A.; Abbeel, P. Denoising diffusion probabilistic models. In Proceedings of the Neural Information Processing Systems (NIPS), Virtual, Brooklyn, NY, USA, 2–8 December 2020. [Google Scholar]

- Xiang, J.; Pan, R.; Gao, W. Yarn-dyed fabric defect detection based on an improved autoencoder with Fourier convolution. Text. Res. J. 2023, 93, 1153–1165. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, L.; Zhang, D.; Huang, Y.; Kan, S.; Cen, Y. AE5-SSIM: A Novel Unsupervised Tinfoils Defect Detection Model with Deep Autoencoder. In Proceedings of the 2022 16th IEEE International Conference on Signal Processing (ICSP), Beijing, China, 21–24 October 2022. [Google Scholar]

- Sae-Ang, B.-I.; Kumwilaisak, W.; Kaewtrakulpong, P. Semi-Supervised Learning for Defect Segmentation with Autoencoder Auxiliary Module. Sensors 2022, 22, 2915. [Google Scholar] [CrossRef] [PubMed]

- Si, J.; Kim, S. Defect Detection of Wood Grain Images with Image Gradient Applied to AE-based generation. In Proceedings of the 2023 IEEE 6th International Conference on Knowledge Innovation and Invention (ICKII), Sapporo, Japan, 11–13 August 2023. [Google Scholar]

- Shi, H.; Li, G.; Bao, H. Lightweight Reconstruction Network for Surface Defect Detection Based on Texture Complexity Analysis. Electronics 2023, 12, 3617. [Google Scholar] [CrossRef]

- Zhang, H.; Qiao, G.; Liu, S.; Yu, Y.; Yao, L.; Ge, Z. Attention-based vector quantisation variational autoencoder for colour-patterned fabrics defect detection. Color. Technol. 2023, 139, 223–238. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, S.; Tan, Q.; Lu, S.; Yao, L.; Ge, Z. Colour-patterned fabric defect detection based on an unsupervised multi-scale U-shaped denoising convolutional autoencoder model. Color. Technol. 2022, 138, 522–537. [Google Scholar] [CrossRef]

- Tao, X.; Zhang, D.; Ma, W.; Hou, Z.; Lu, Z.; Adak, C. Unsupervised Anomaly Detection for Surface Defects With Dual-Siamese Network. IEEE Trans. Ind. Inform. 2022, 18, 7707–7717. [Google Scholar] [CrossRef]

- Min, Y.; Li, Y. Self-Supervised Railway Surface Defect Detection with Defect Removal Variational Autoencoders. Energies 2022, 15, 3592. [Google Scholar] [CrossRef]

- Lu, T.; Wang, Z.; Shen, Y.; Shao, X.; Tang, Y. DefVAE: A Defect Detection Method for Catenary Devices Based on Variational Autoencoder. IEEE Trans. Instrum. Meas. 2023, 72, 1–12. [Google Scholar] [CrossRef]

- Fang, Z.; Wang, X.; Li, H.; Liu, J.; Hu, Q.; Xiao, J. Fastrecon: Few-shot industrial anomaly detection via fast feature recon-struction. In Proceedings of the IEEE/CVF International Conference on Computer Vision (ICCV), Paris, France, 2–6 October 2023. [Google Scholar]

- Li, Y.; Min, Y.; Yue, B. ISRM: Introspective Self-Supervised Reconstruction Model for Rail Surface Defect Detection and Seg-mentation. Meas. Sci. Technol. 2024, 35, 5208. [Google Scholar]

- Yang, Z.; Zhang, M.; Chen, Y.; Hu, N.; Gao, L.; Liu, L.; Ping, E.; Song, J.I. Surface defect detection method for air rudder based on positive samples. J. Intell. Manuf. 2024, 35, 95–113. [Google Scholar] [CrossRef]

- Yang, Q.; Guo, R. An Unsupervised Method for Industrial Image Anomaly Detection with Vision Transformer-Based Auto-encoder. Sensors 2024, 24, 2440. [Google Scholar] [CrossRef] [PubMed]

- Alec, R.; Metz, L.; Chintala, S. Unsupervised representation learning with deep convolutional generative adversarial networks. arXiv 2015, arXiv:1511.06434. [Google Scholar]

- Adler, J.; Lunz, S. Banach Wasserstein GAN. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–22 June 2018. [Google Scholar]

- He, Y.; Wen, X.; Xu, J. A Semi-Supervised Inspection Approach of Textured Surface Defects under Limited Labeled Samples. Coatings 2022, 12, 1707. [Google Scholar] [CrossRef]

- Liu, T.; He, Z. TAS2-Net: Triple-Attention Semantic Segmentation Network for Small Surface Defect Detection. IEEE Trans. Instrum. Meas. 2022, 71, 1–12. [Google Scholar] [CrossRef]

- Murase, H.; Fukumizu, K. ALGAN: Anomaly Detection by Generating Pseudo Anomalous Data via Latent Variables. IEEE Access 2022, 10, 44259–44270. [Google Scholar] [CrossRef]

- Gan, Y.; Liong, S.-T.; Wang, S.-Y.; Cheng, C.T. An improved automatic defect identification system on natural leather via generative adversarial network. Int. J. Comput. Integr. Manuf. 2022, 35, 1378–1394. [Google Scholar] [CrossRef]

- Li, J.; Zheng, Y.; You, Z.; Le, X. DefectGAN: Generate Industrial Defects from Extremely Few Samples. Int. J. Artif. Intell. Tools 2022, 31, 2240021. [Google Scholar] [CrossRef]

- Hao, Z.; Li, Z.; Ren, F.; Lv, S.; Ni, H. Strip Steel Surface Defects Classification Based on Generative Adversarial Network and Attention Mechanism. Metals 2022, 12, 311. [Google Scholar] [CrossRef]

- Song, S.; Chang, K.; Yun, K.; Jun, C.; Baek, J.-G. Defect Synthesis Using Latent Mapping Adversarial Network for Automated Visual Inspection. Electronics 2022, 11, 2763. [Google Scholar] [CrossRef]

- Jin, G.; Liu, Y.; Qin, P.; Hong, R.; Xu, T.; Lu, G. An End-to-End Steel Surface Classification Approach Based on EDCGAN and MobileNet V2. Sensors 2023, 23, 1953. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Zhang, T.; Yu, Y.; Miao, L. A data generation method with dual discriminators and regularization for surface defect detection under limited data. Comput. Ind. 2023, 151, 103963. [Google Scholar] [CrossRef]

- Zhao, L.; Zheng, Y.; Peng, T.; Zheng, E. Metal Surface Defect Detection Based on a Transformer with Multi-Scale Mask Feature Fusion. Sensors 2023, 23, 9381. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Liang, J.; Liu, H.; Hou, Z.; Huan, Z. Multi-stage unsupervised fabric defect detection based on DCGAN. Vis. Comput. 2022, 39, 6655–6671. [Google Scholar] [CrossRef]

- Luo, Q.; He, H.; Liu, K.; Yang, C.; Silvén, O.; Liu, L. Rain-Like Layer Removal From Hot-Rolled Steel Strip Based on Attentive Dual Residual Generative Adversarial Network. IEEE Trans. Instrum. Meas. 2023, 72, 1–15. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, E.; Chen, Y.; Duan, J.; Shao, L. SIA-net: Structural information awareness network based on normal samples for surface defect detection. Eng. Appl. Artif. Intell. 2023, 126, 107131. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, J.; Liang, Y.; Zhai, Y.; Ying, Z.; Zhou, W.; Genovese, A.; Piuri, V.; Scotti, F. Flexible and Diverse Contrastive Learning for Steel Surface Defect Recognition With Few Labeled Samples. IEEE Trans. Instrum. Meas. 2023, 72, 1–14. [Google Scholar] [CrossRef]

- Li, W.; Gu, C.; Chen, J.; Ma, C.; Zhang, X.; Chen, B.; Wan, S. DLS-GAN: Generative Adversarial Nets for Defect Location Sensitive Data Augmentation. IEEE Trans. Autom. Sci. Eng. 2023, 1–17. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Z.; Sun, H.; Zhou, Q.; Yang, Z. AC-SNGAN: Multi-class data augmentation for damage detection of conveyor belt surface using improved ACGAN. Measurement 2024, 224, 113814. [Google Scholar] [CrossRef]

- He, S.; Jian, Z.; Liu, S.; Liu, J.; Fang, Y.; Hu, J. PCSGAN: A Perceptual Constrained Generative Model for Railway Defect Sample Expansion From a Single Image. IEEE Trans. Intell. Transp. Syst. 2024, 1–11. [Google Scholar] [CrossRef]

- Ku, D.; Pahk, H.J. Enhancing Battery Exterior Defect Inspection Accuracy Through Defect-Background Separated GAN De-velopment. IEEE Access 2024, 12, 44286–44305. [Google Scholar] [CrossRef]

- Ul-Huda, N.; Ahmad, H.; Banjar, A.; Alzahrani, A.O.; Ahmad, I.; Naeem, M.S. Image synthesis of apparel stitching defects using deep convolutional generative adversarial networks. Heliyon 2024, 10, e26466. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.-Y.; Park, T.; Isola, P.; Efros, A.A. Unpaired image-to-image translation using cycle-consistent adversarial networks. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017. [Google Scholar]

- Karras, T.; Laine, S.; Aila, T. A style-based generator architecture for generative adversarial networks. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Long Beach, CA, USA, 15–20 June 2019. [Google Scholar]

- Shaham, T.R.; Dekel, T.; Michaeli, T. SinGAN: Learning a Generative Model from a Single Natural Image. In Proceedings of the 2019 IEEE/CVF International Conference on Computer Vision (ICCV), Seoul, Republic of Korea, 27 October–2 November 2019. [Google Scholar]

- Niu, S.; Li, B.; Wang, X.; He, S.; Peng, Y. Defect attention template generation cycleGAN for weakly supervised surface defect segmentation. Pattern Recognit. 2022, 123, 108396. [Google Scholar] [CrossRef]

- Wen, L.; Wang, Y.; Li, X. A New Cycle-consistent Adversarial Networks With Attention Mechanism for Surface Defect Clas-sification With Small Samples. IEEE Trans. Ind. Inform. 2022, 18, 8988–8998. [Google Scholar] [CrossRef]

- Yi, C.; Chen, Q.; Xu, B.; Huang, T. Steel Strip Defect Sample Generation Method Based on Fusible Feature GAN Model under Few Samples. Sensors 2023, 23, 3216. [Google Scholar] [CrossRef]

- Ren, X.; Lin, W.; Yang, X.; Yu, X.; Gao, H. Data Augmentation in Defect Detection of Sanitary Ceramics in Small and Non-i.i.d Datasets. IEEE Trans. Neural Networks Learn. Syst. 2023, 34, 8669–8678. [Google Scholar] [CrossRef]

- Hu, F.; Gong, J.; Fu, H.; Liu, W. Fabric Defect Detection Method Using SA-Pix2pix Network and Transfer Learning. Appl. Sci. 2023, 14, 41. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, W.; Wen, L.; Gao, L. A New Foreground-Perception Cycle-Consistent Adversarial Network for Surface Defect Detection With Limited High-Noise Samples. IEEE Trans. Ind. Inform. 2023, 19, 11742–11751. [Google Scholar] [CrossRef]

- He, X.; Luo, Z.; Li, Q.; Chen, H.; Li, F. DG-GAN: A High Quality Defect Image Generation Method for Defect Detection. Sensors 2023, 23, 5922. [Google Scholar] [CrossRef]

- Xu, Y.; Zhi, C.; Wang, S.; Chen, J.; Sun, R.; Dong, Z.; Yu, L. FabricGAN: An enhanced generative adversarial network for data augmentation and improved fabric defect detection. Text. Res. J. 2024, 35, 5408. [Google Scholar] [CrossRef]

- Ran, G.; Yao, X.; Wang, K.; Ye, J.; Ou, S. Sketch-guided spatial adaptive normalization and high-level feature constraints based GAN image synthesis for steel strip defect detection data augmentation. Meas. Sci. Technol. 2024, 35, 045408. [Google Scholar] [CrossRef]

- He, Y.; Li, S.; Wen, X.; Xu, J. A High-Quality Sample Generation Method for Improving Steel Surface Defect Inspection. Sensors 2024, 24, 2642. [Google Scholar] [CrossRef]

- Tang, S.; Jin, Z.; Zhang, Y.; Lu, J.; Li, H.; Yang, J. A Timestep-Adaptive-Diffusion-Model-Oriented Unsupervised Detection Method for Fabric Surface Defects. Processes 2023, 11, 2615. [Google Scholar] [CrossRef]

- Huang, T.; Gao, Y.; Li, Z.; Hu, Y.; Xuan, F. A Hybrid Deep Learning Framework Based on Diffusion Model and Deep Residual Neural Network for Defect Detection in Composite Plates. Appl. Sci. 2023, 13, 5843. [Google Scholar] [CrossRef]

- Tao, H. Erasing-inpainting-based data augmentation using denoising diffusion probabilistic models with limited samples for generalized surface defect inspection. Mech. Syst. Signal Process. 2024, 208, 111082. [Google Scholar] [CrossRef]

- Liang, Y.; Feng, S.; Zhang, Y.; Xue, F.; Shen, F.; Guo, J. A stable diffusion enhanced YOLOV5 model for metal stamped part defect detection based on improved network structure. J. Manuf. Process. 2024, 111, 21–31. [Google Scholar] [CrossRef]

- Zhao, M.; Song, K.K.; Tian, X.; Liao, X.; Xiao, J. A Method of Removing Oil Droplets from Bearing Image Based on a Two-stage Neural Network. In Proceedings of the 2022 7th International Conference on Signal and Image Processing (ICSIP), Suzhou, China, 20–22 July 2022. [Google Scholar]

- Yang, B.; Liu, Z.; Duan, G.; Tan, J. Mask2Defect: A Prior Knowledge-Based Data Augmentation Method for Metal Surface Defect Inspection. IEEE Trans. Ind. Inform. 2022, 18, 6743–6755. [Google Scholar] [CrossRef]

- Yu, Z.; Sheng, X.; Xie, G.; Xu, Y.; Sun, Y. Online Fabric Defects Detection Using Convolutional Neural Networks with Two Frameworks. AATCC J. Res. 2023, 10, 356–366. [Google Scholar] [CrossRef]

- Ferrari, N.; Fraccaroli, M.; Lamma, E. GRD-Net: Generative-Reconstructive-Discriminative Anomaly Detection with Region of Interest Attention Module. Int. J. Intell. Syst. 2023, 2023, 1–18. [Google Scholar] [CrossRef]

- Dai, Y.; Zhang, L.; Wu, Y. F-GAN: A fusion algorithm for surface defect detection based on generative adversarial network. In Proceedings of the 2023 8th International Conference on Intelligent Computing and Signal Processing (ICSP), Xi’an, China, 21–23 April 2023. [Google Scholar]

- Bu, H.; Yang, T.; Hu, C.; Zhu, X.; Ge, Z.; Zhou, H. An Image Classification Method of Unbalanced Ship Coating Defects Based on DCCVAE-ACWGAN-GP. Coatings 2024, 14, 288. [Google Scholar] [CrossRef]

- Silvestre-Blanes, J.; Albero-Albero, T.; Miralles, I.; Pérez-Llorens, R.; Moreno, J. A Public Fabric Database for Defect Detection Methods and Results. Autex Res. J. 2019, 19, 363–374. [Google Scholar] [CrossRef]

- Jager, M.; Knoll, C.; Hamprecht, F.A. Weakly Supervised Learning of a Classifier for Unusual Event Detection. IEEE Trans. Image Process. 2008, 17, 1700–1708. [Google Scholar] [CrossRef] [PubMed]

- Tabernik, D.; Šela, S.; Skvarč, J.; Skočaj, D. Segmentation-based deep-learning approach for surface-defect detection. J. Intell. Manuf. 2020, 31, 759–776. [Google Scholar] [CrossRef]

- Božič, J.; Tabernik, D.; Skočaj, D. Mixed supervision for surface-defect detection: From weakly to fully supervised learning. Comput. Ind. 2021, 129, 103459. [Google Scholar] [CrossRef]

- Huang, Y.; Qiu, C.; Yuan, K. Surface Defect Saliency of Magnetic Tile. Vis. Comput. 2020, 36, 85–96. [Google Scholar] [CrossRef]

- Bergmann, P.; Batzner, K.; Fauser, M.; Sattlegger, D.; Steger, C. The MVTec Anomaly Detection Dataset: A Comprehensive Real-World Dataset for Unsupervised Anomaly Detection. Int. J. Comput. Vis. 2021, 129, 1038–1059. [Google Scholar] [CrossRef]

- Song, K.; Yan, Y. A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl. Surf. Sci. 2013, 285, 858–864. [Google Scholar] [CrossRef]

- Gan, J.; Li, Q.; Wang, J.; Yu, H. A Hierarchical Extractor-Based Visual Rail Surface Inspection System. IEEE Sensors J. 2017, 17, 7935–7944. [Google Scholar] [CrossRef]

- Feng, X.; Gao, X.; Luo, L. X-SDD: A New Benchmark for Hot Rolled Steel Strip Surface Defects Detection. Symmetry 2021, 13, 706. [Google Scholar] [CrossRef]

- Zhang, H.; Tan, Q.; Lu, S.; Ge, Z.; Gu, D. Yarn-dyed Fabric Defect Detection using U-shaped De-noising Convolutional Au-to-Encoder. In Proceedings of the IEEE 9th Data Driven Control and Learning Systems Conference (DDCLS), Liuzhou, China, 20–22 November 2020. [Google Scholar]

- He, Y.; Song, K.; Dong, H.; Yan, Y. Semi-supervised defect classification of steel surface based on multi-training and generative adversarial network. Opt. Lasers Eng. 2019, 122, 294–302. [Google Scholar] [CrossRef]

- Salimans, T.; Goodfellow, I.; Zaremba, W.; Cheung, V.; Radford, A.; Chen, X. Improved techniques for training GANs. In Proceedings of the 30th International Conference on Neural Information Processing Systems, Barcelona, Spain, 5–10 December 2016. [Google Scholar]

- Ma, S.; Song, K.; Niu, M.; Tian, H.; Wang, Y.; Yan, Y. Shape-Consistent One-Shot Unsupervised Domain Adaptation for Rail Surface Defect Seg-mentation. IEEE Trans. Ind. Inform. 2023, 19, 9667–9679. [Google Scholar] [CrossRef]

- Howard, A.G.; Zhu, M.; Chen, B.; Kalenichenko, D.; Wang, W.; Weyand, T.; Andreetto, M.; Adam, H. MobileNets: Efficient Convolutional Neural Networks for Mobile Vision Applications. arXiv 2017, arXiv:1704.04861. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).