Field Test and Numerical Simulation Study on Water Pressure Distribution and Lining Deformation Law in Water-Rich Tunnel Crossing Fault Zones

Abstract

:Featured Application

Abstract

1. Introduction

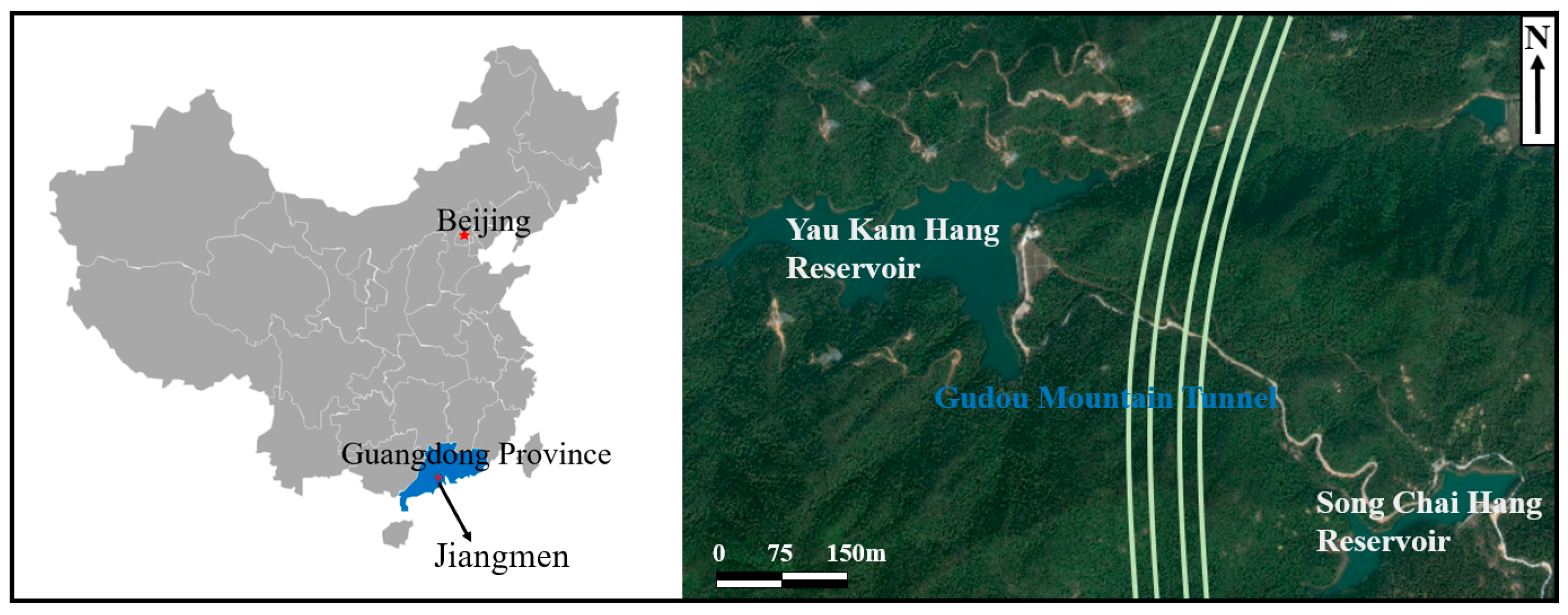

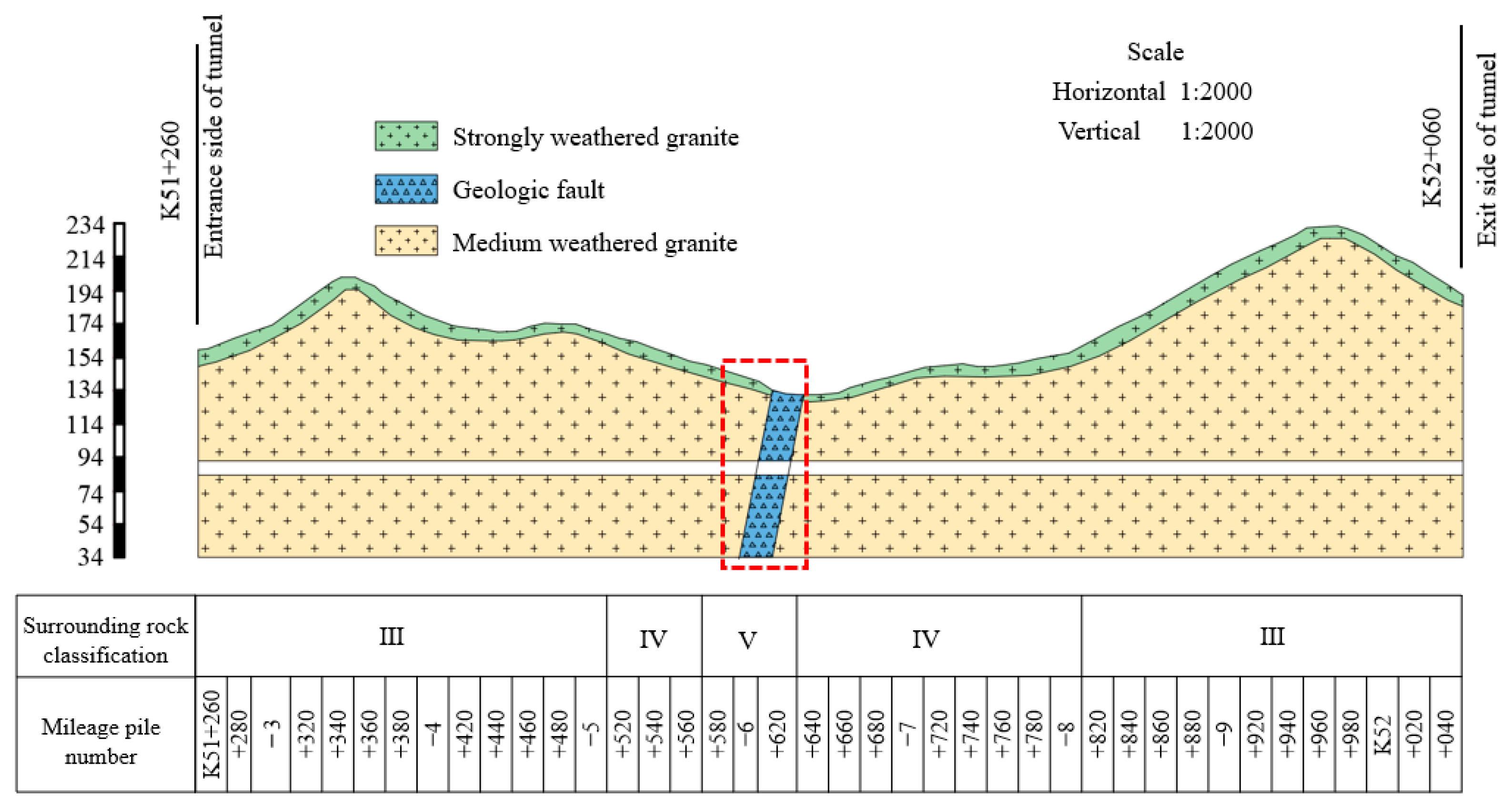

2. Overview of the Project

3. Field Test of Water Pressure around the Tunnel

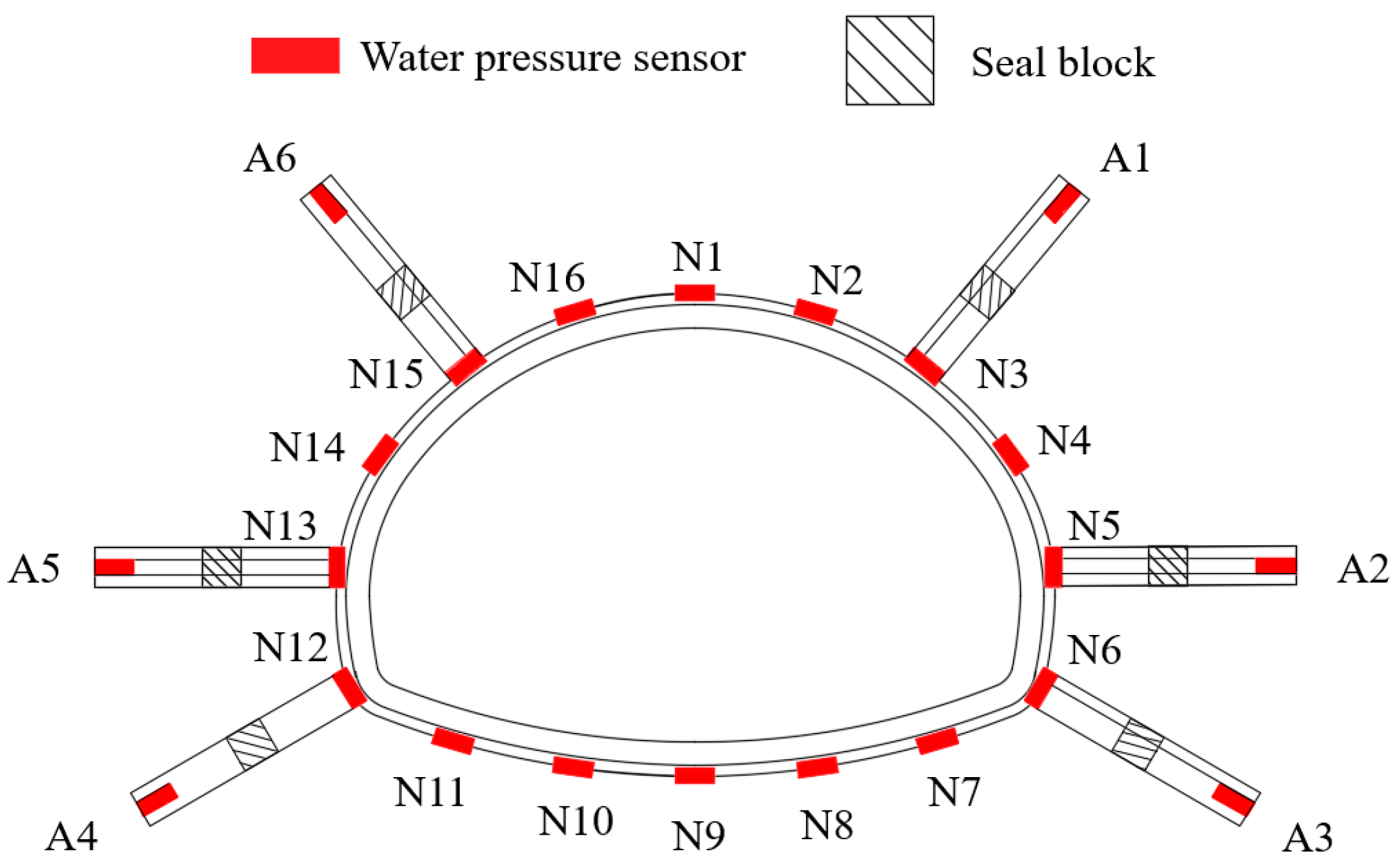

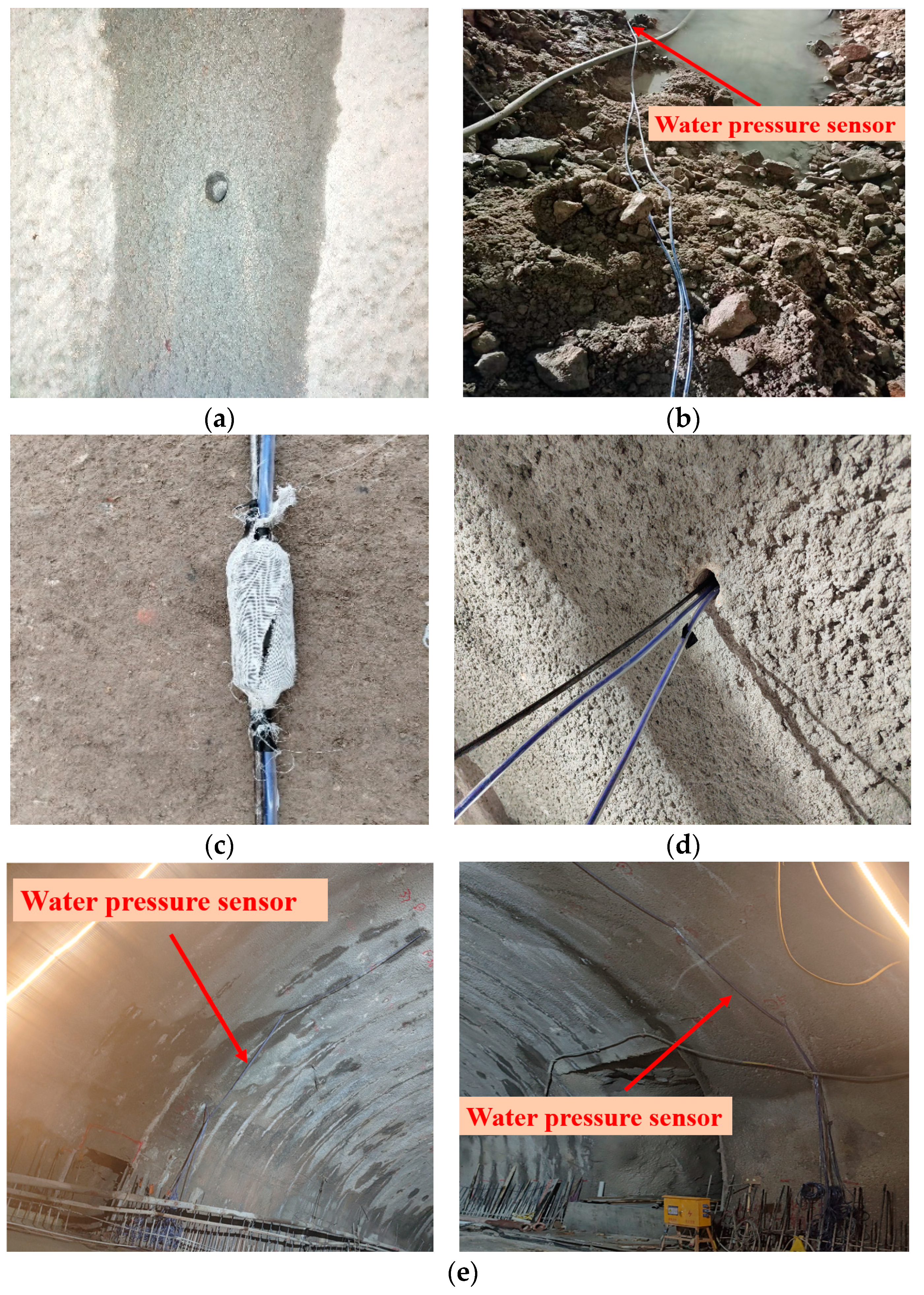

3.1. Test Equipment and Parameters

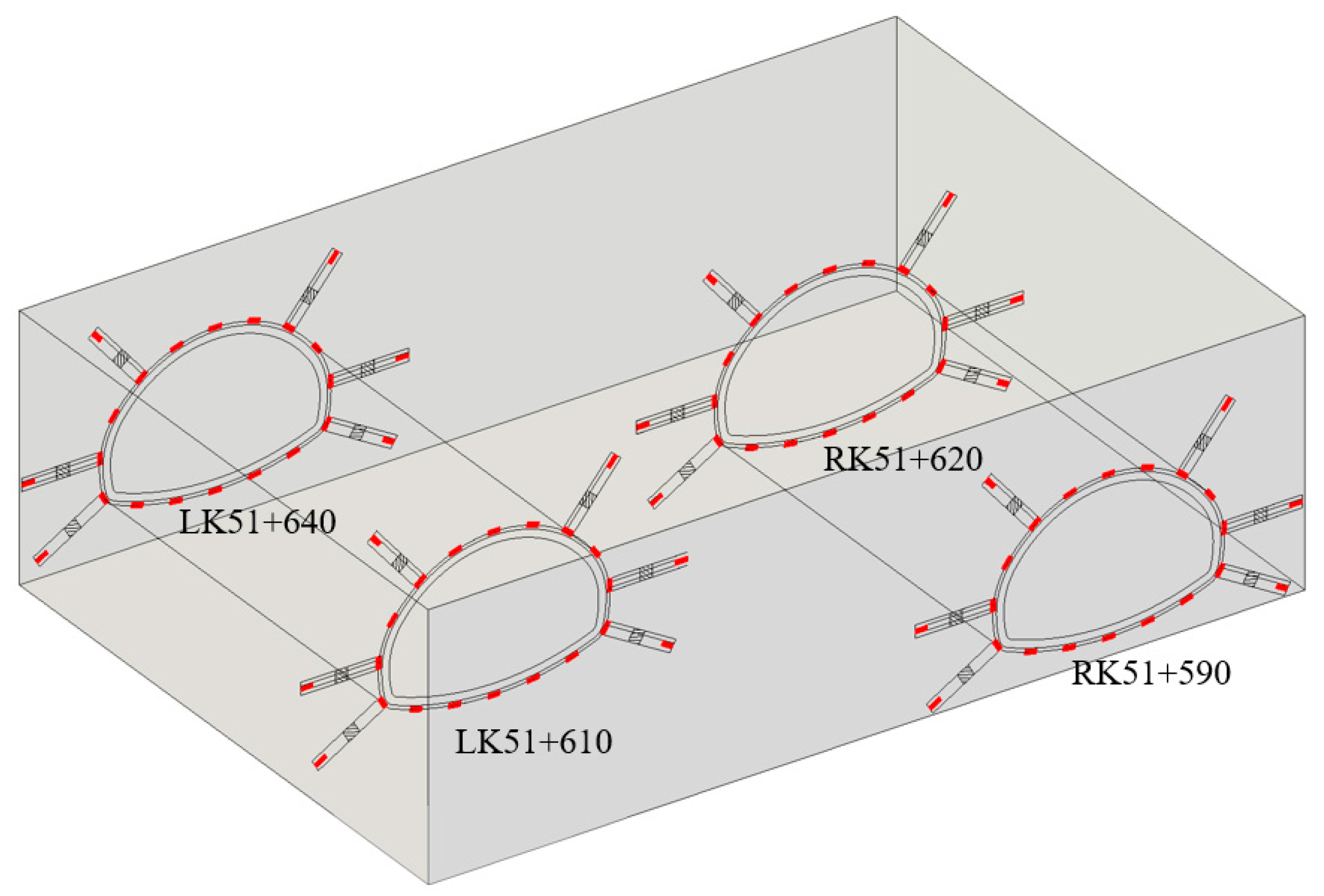

3.2. Test Section and Equipment Layout

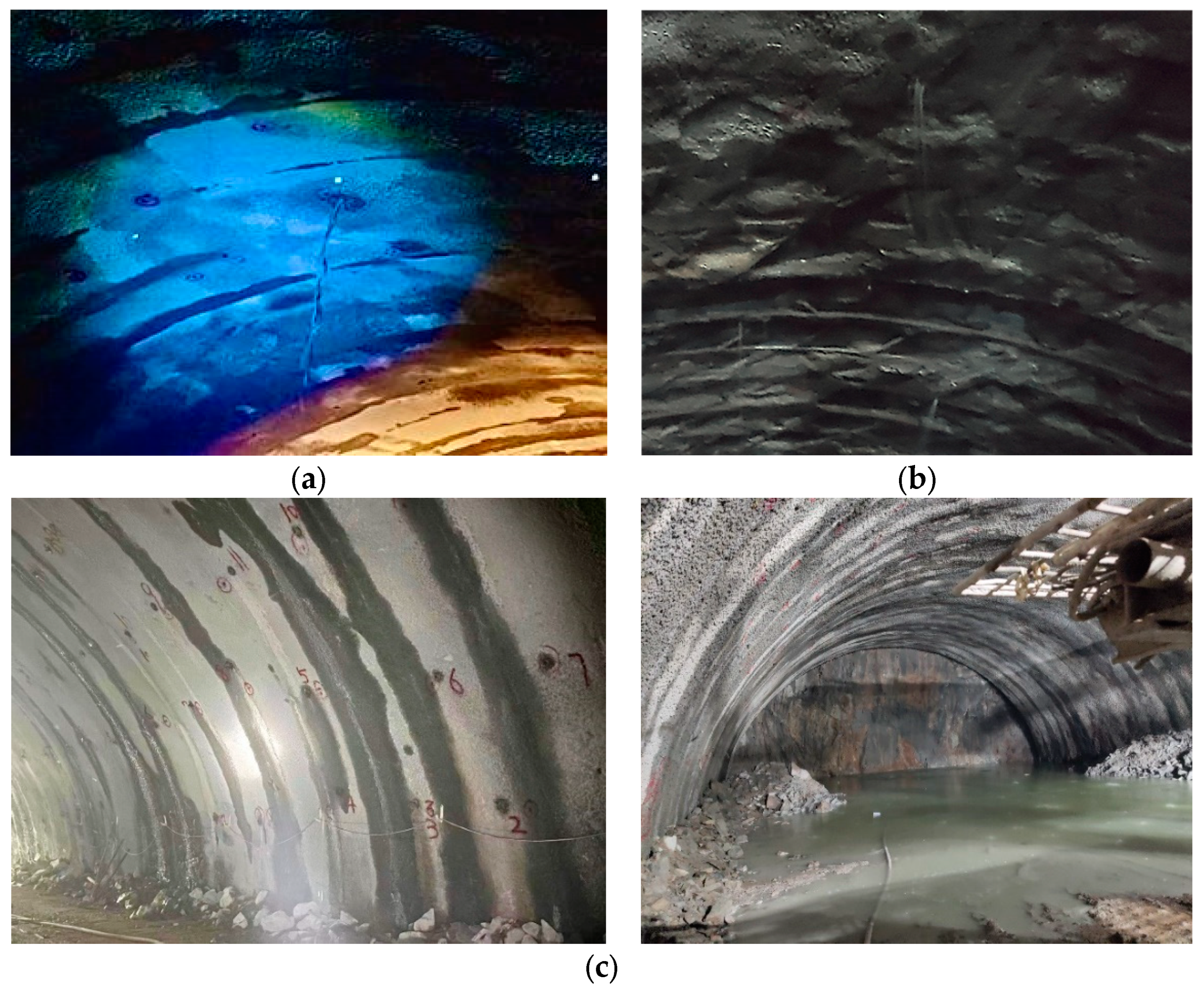

3.3. Test Process

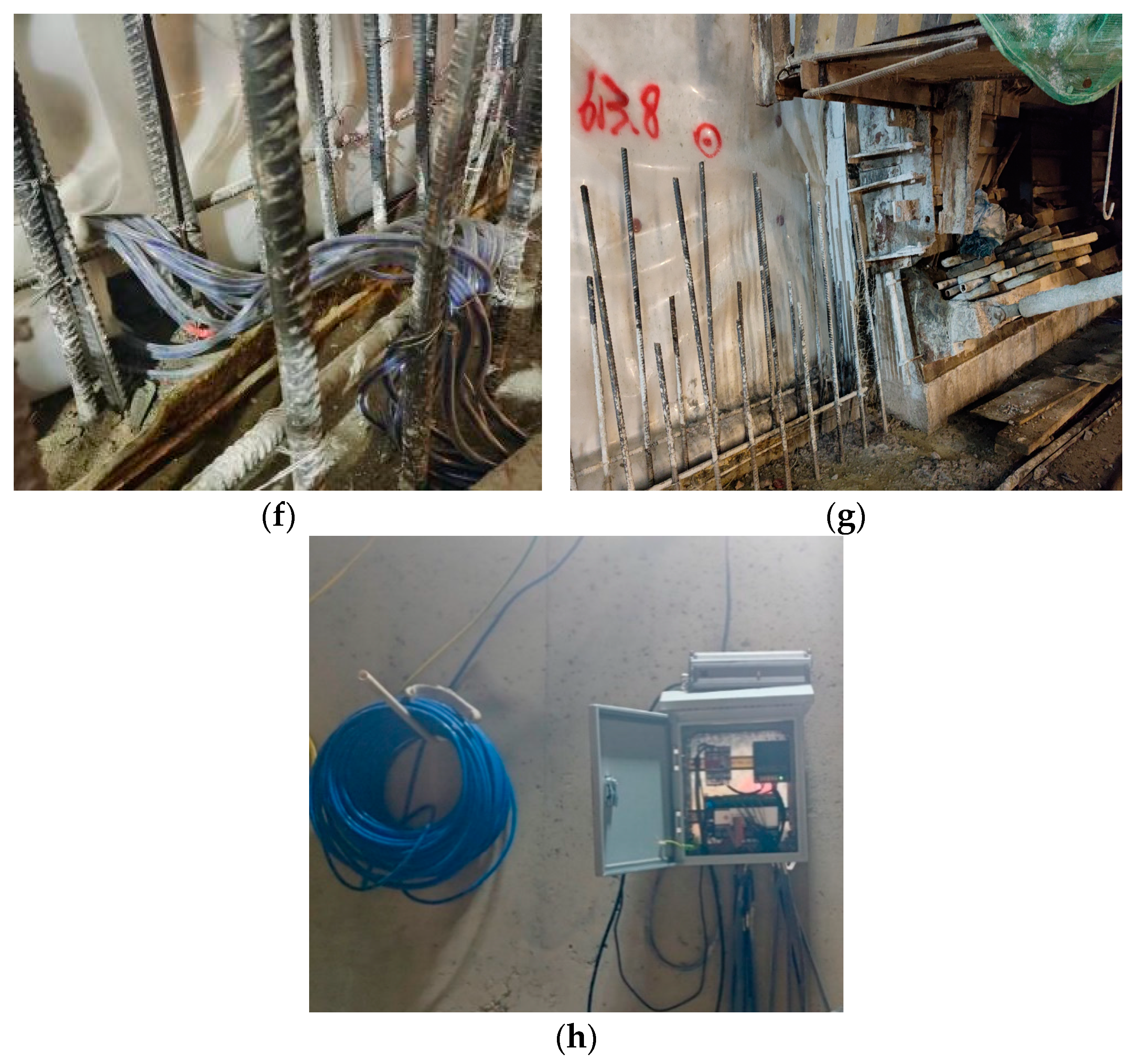

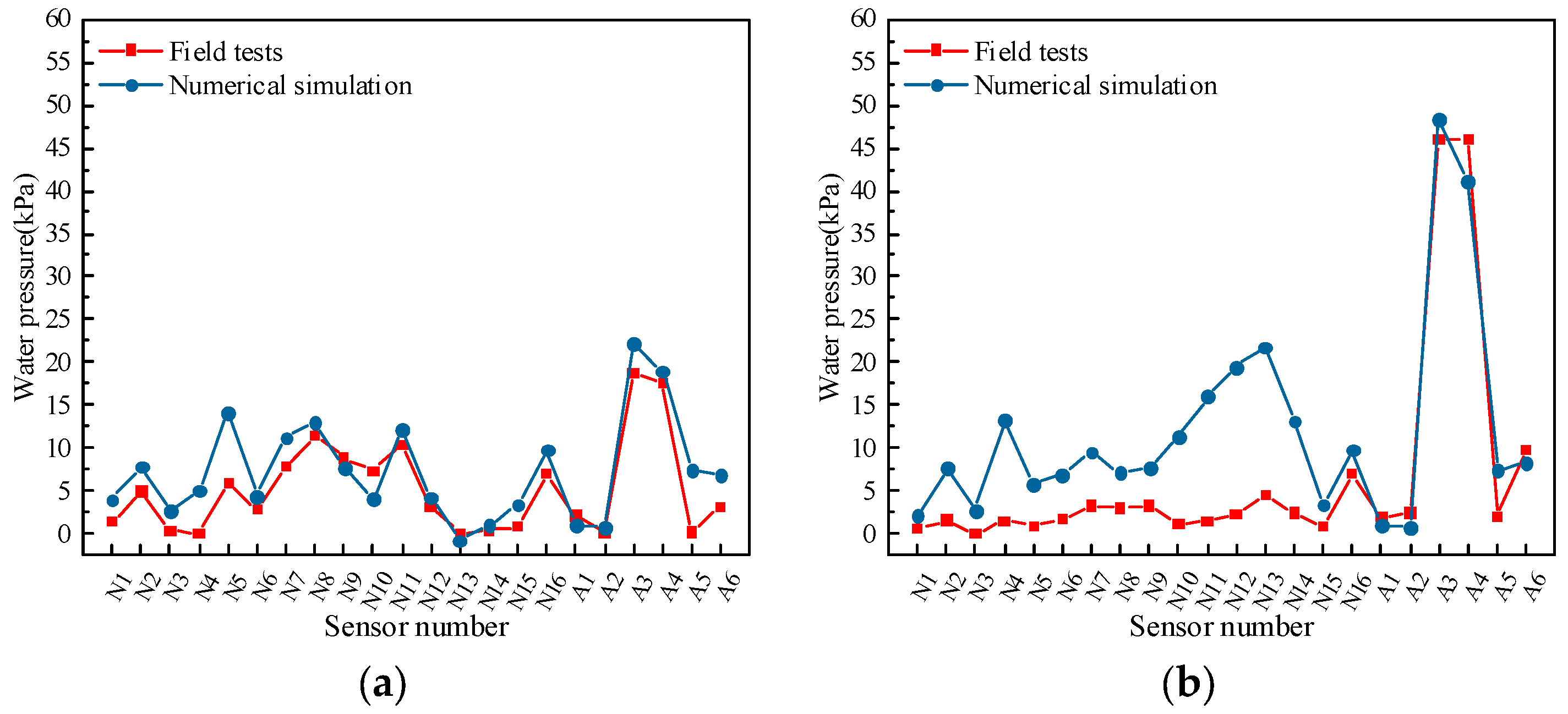

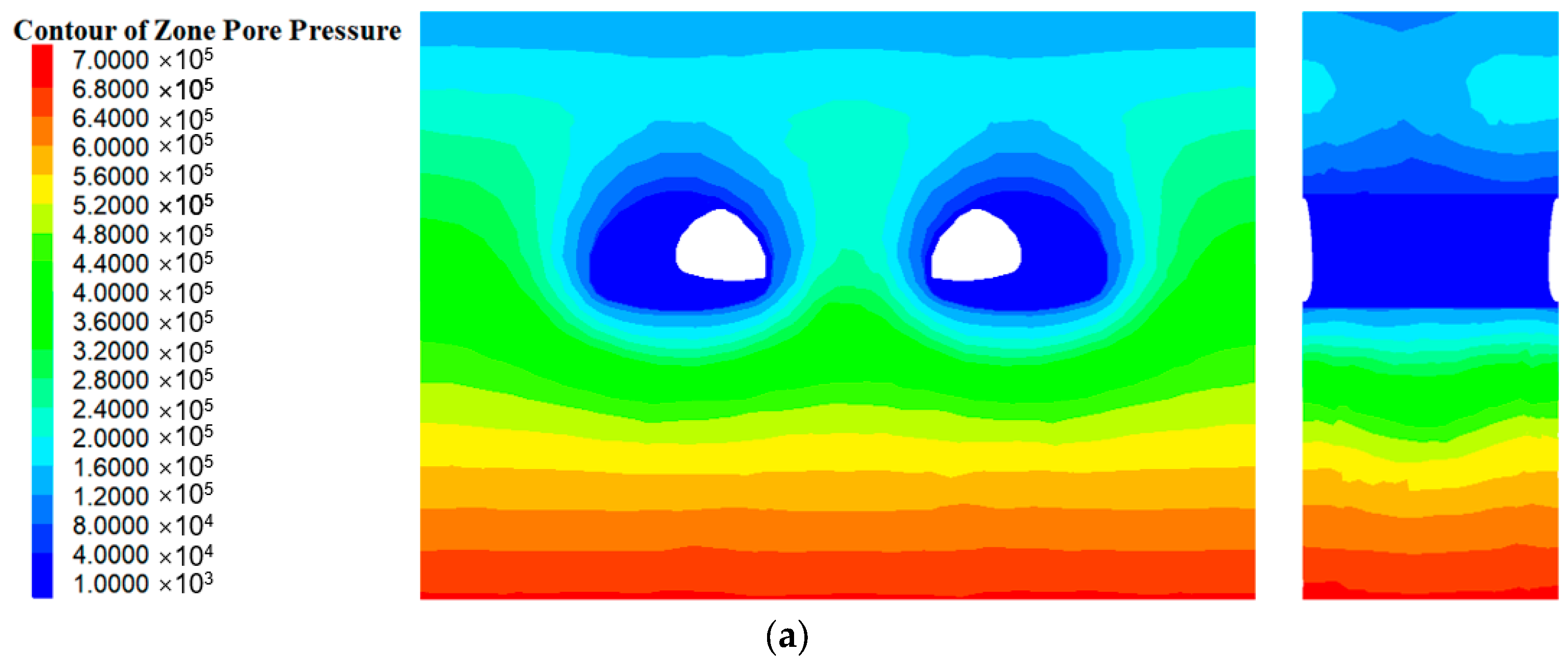

3.4. Analysis of Test Results

4. Numerical Simulation

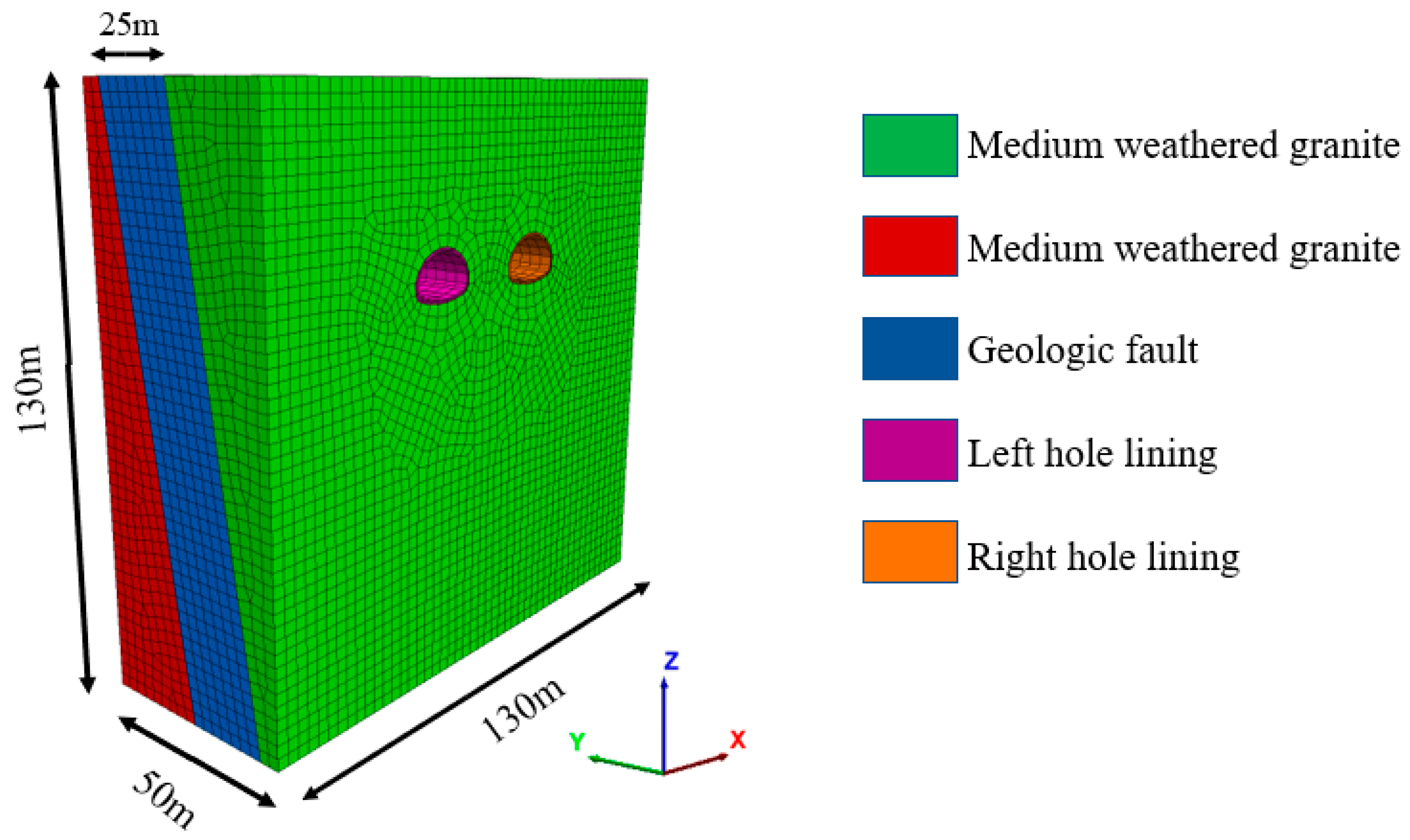

4.1. Numerical Model and Boundary Conditions

4.2. Numerical Simulation Process and Working Conditions

4.3. Analysis of Simulation Results

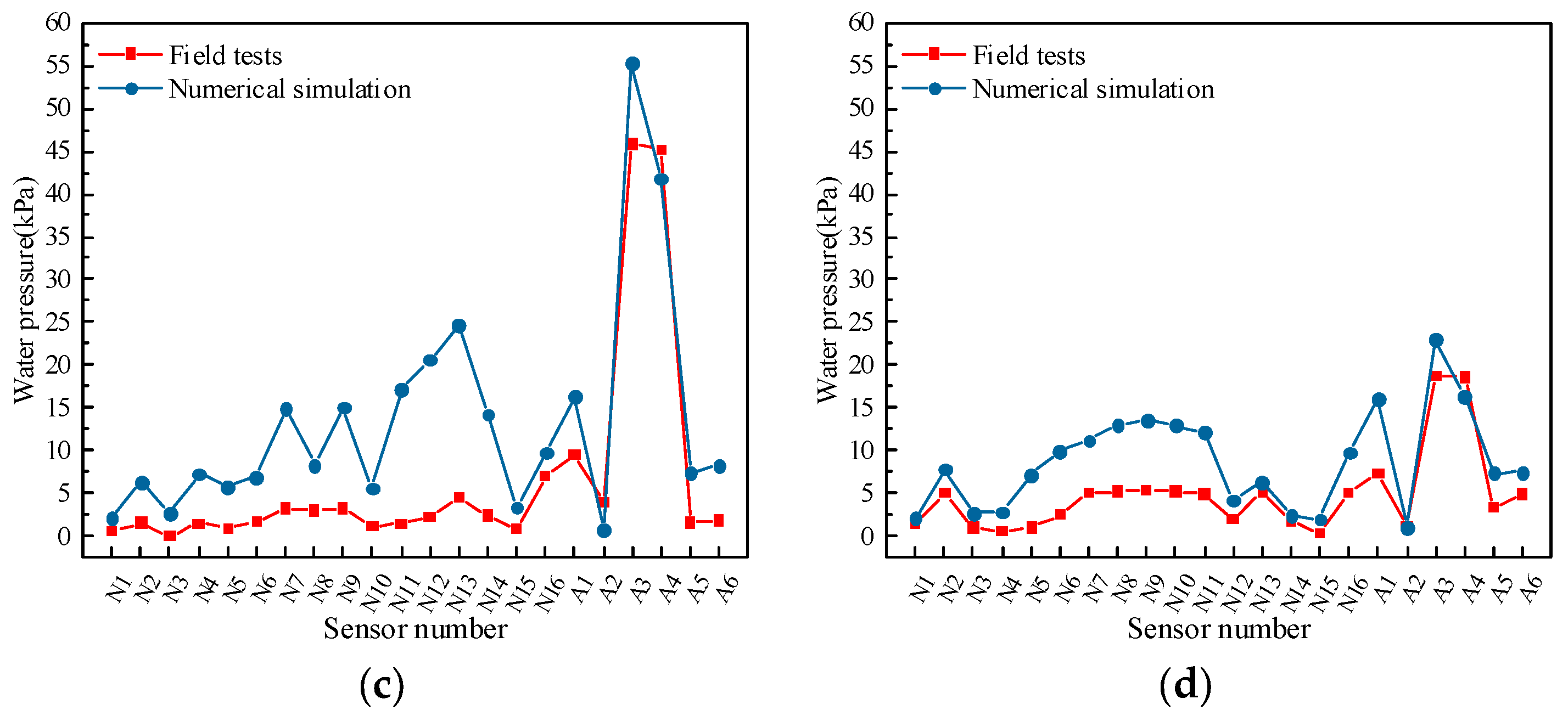

4.3.1. Water Pressure Distribution Patterns around the Tunnel

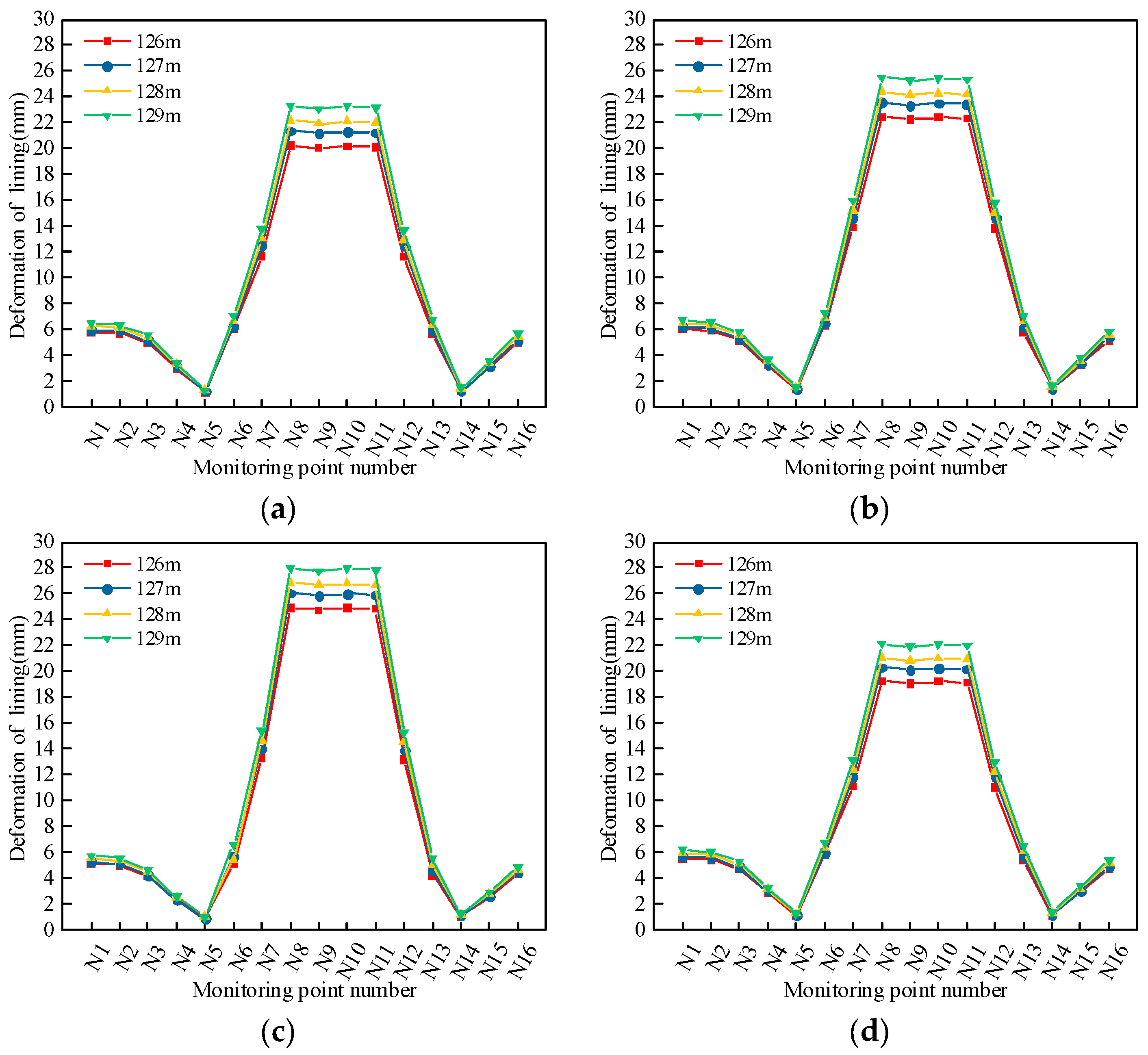

4.3.2. Deformation Patterns of Tunnel Lining Structures

5. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peng, L. Existing Operational Railway Tunnel Water Leakage Causes and Remediation Technologies. Adv. Mater. Res. 2014, 1004–1005, 1444–1449. [Google Scholar] [CrossRef]

- Li, S.C.; Zhou, Z.Q.; Li, L.P.; Xu, Z.H.; Zhang, Q.Q.; Shi, S.S. Risk assessment of water inrush in karst tunnels based on attribute synthetic evaluation system. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2013, 38, 50–58. [Google Scholar] [CrossRef]

- Gao, C.L.; Zhou, Z.Q.; Yang, W.M.; Lin, C.J.; Lia, L.P.; Wang, J. Model test and numerical simulation research of water leakage in operating tunnels passing through intersecting faults. Tunn. Undergr. Space Technol. 2019, 94, 13. [Google Scholar] [CrossRef]

- Liu, T.J.; Zhu, H.H.; Xia, C.C.; Li, Z.H.; Li, G.F. Analysis of site investigation of cracking and leakage on arcade tunnel lining of Yunnan province. China J. Highw. Transp. 2004, 17, 64–67. (In Chinese) [Google Scholar]

- Zou, Y.L.; He, C.; Zhou, Y.; Zhang, Z.; Fu, J.K. Statistics and Cause Analysis of Leakage Diseases in Operating Expressway Tunnels in Chongqing. J. Highw. Transp. Res. Dev. 2013, 30, 86–93. (In Chinese) [Google Scholar]

- Zarei, H.R.; Uromeihy, A.; Sharifzadeh, M. Evaluation of high local groundwater inflow to a rock tunnel by characterization of geological features. Tunn. Undergr. Space Technol. 2011, 26, 364–373. [Google Scholar] [CrossRef]

- He, H.; Tang, X.; Lin, S.; Yan, Z.; Li, D. Field experiments and numerical simulations for two types of steel tube lining structures under high internal pressure. Tunn. Undergr. Space Technol. 2022, 120, 104272. [Google Scholar] [CrossRef]

- Chen, Z.Q.; Li, Z.; He, C.; Ma, C.C.; Li, X.; Chen, K.; Zhang, H.; Liu, M. Investigation on seepage field distribution and structural safety performance of small interval tunnel in water-rich region. Tunn. Undergr. Space Technol. 2023, 138, 105172. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Z.Q.; He, C.; Chen, K.P.; Zhang, H.; Ma, C.C.; Li, X.; Liu, M.Y. Experimental simulation of seepage field distribution for small interval tunnel under varying-head infiltration. Transp. Geotech. 2023, 41, 22. [Google Scholar] [CrossRef]

- Li, Z.; He, C.; Chen, Z.Q.; Yang, S.Z.; Ding, J.J.; Pen, Y. Study of seepage field distribution and its influence on urban tunnels in water-rich regions. Bull. Eng. Geol. Environ. 2019, 78, 4035–4045. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, X.Y.; Yang, J.S.; Zhang, J.; Huang, L.C. Analysis of ground collapse caused by shield tunnelling and the evaluation of the reinforcement effect on a sand stratum. Eng. Fail. Anal. 2020, 115, 13. [Google Scholar] [CrossRef]

- Li, D.; Cheng, S.; Liu, N.; Liu, Z.; Sun, Y. Numerical Simulation Study on the Distribution Characteristics of Precipitation Seepage Field in Water-Rich Ultra-Thick Sand and Gravel Layer. Water 2023, 15, 3720. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Z.Q.; He, C.; Ma, C.C.; Duan, C.R. Seepage field distribution and water inflow laws of tunnels in water-rich regions. J. Mt. Sci. 2022, 19, 591–605. [Google Scholar] [CrossRef]

- Mei, Y.; Luo, Z.; Jiang, H.Y.; Gong, H.; Hou, Y.D.; Wang, X.F. Study on the Floating Law of Metro Segments in Water-Rich Sandy Silt and Silty Clay Strata. KSCE J. Civ. Eng. 2022, 26, 2979–2991. [Google Scholar] [CrossRef]

- Shi, J.K.; Wang, F.; Zhang, D.M.; Huang, H.W. Refined 3D modelling of spatial-temporal distribution of excess pore water pressure induced by large diameter slurry shield tunneling. Comput. Geotech. 2021, 137, 18. [Google Scholar] [CrossRef]

- He, B.G.; Xue, R.H.; Zhang, Z.Q.; Feng, X.T.; Wu, C. A novel method of imposing external water pressure to explore the failure behavior of railway tunnel linings. Tunn. Undergr. Space Technol. 2023, 133, 15. [Google Scholar] [CrossRef]

- Yang, F.J.; Zhou, H.; Zhang, C.Q.; Lu, J.J.; Lu, X.J.; Geng, Y.J. An analysis method for evaluating the safety of pressure water conveyance tunnel in argillaceous sandstone under water-weakening conditions. Tunn. Undergr. Space Technol. 2020, 97, 15. [Google Scholar] [CrossRef]

- Huang, M.; Huang, M.; Yang, Z. Large-Scale Model Test on Water Pressure Resistance of Lining Structure of Water-Rich Tunnel. Materials 2023, 16, 440. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.M.; Yang, H.P.; Huang, M.Q.; Wang, L. External hydraulic pressure and invert uplift study in a non-circular shallow tunnel. Tunn. Undergr. Space Technol. 2022, 122, 13. [Google Scholar] [CrossRef]

- Wang, T.; Yan, C.Z. Investigating the influence of water on swelling deformation and mechanical behavior of mudstone considering water softening effect. Eng. Geol. 2023, 318, 20. [Google Scholar] [CrossRef]

- Zhang, W.J.; Wang, J.H.; Jin, M.M.; Koizumi, A. Numerical analysis of DRC segment under inner water pressure based on full-scale test verification for shield tunnel. Tunn. Undergr. Space Technol. 2016, 56, 157–167. [Google Scholar] [CrossRef]

- Xie, Q.; Cao, Z.L.; Sun, W.C.; Fumagalli, A.; Fu, X.; Wu, Z.H.; Wu, K. Numerical simulation of the fluid-solid coupling mechanism of water and mud inrush in a water-rich fault tunnel. Tunn. Undergr. Space Technol. 2023, 131, 22. [Google Scholar] [CrossRef]

- Luo, S.; Xu, M.; Kang, X.B.; Li, X.X.; Rao, L.F. Analytical solution of external water pressure on deep tunnel lining in horizontally layered hydrogeological structures. Bull. Eng. Geol. Environ. 2022, 81, 13. [Google Scholar] [CrossRef]

- Jiang, C.; Xie, H.S.; He, J.L.; Wu, W.Y.; Zhang, Z.C. Analytical Solution of Seepage Field in Karst Tunnel. Adv. Civ. Eng. 2018, 2018, 9. [Google Scholar] [CrossRef]

- Zhao, N.; Wang, Y.C.; Meng, B.; Luo, N. Numerical Simulation on the Seepage Properties of Soil-Rock Mixture. Adv. Mater. Sci. Eng. 2018, 2018, 10. [Google Scholar] [CrossRef]

- Li, S.; Liu, H.L.; Li, L.-P.; Zhang, Q.-Q.; Kai, W.; Wang, K. Large scale three-dimensional seepage analysis model test and numerical simulation research on undersea tunnel. Appl. Ocean. Res. 2016, 59, 510–520. [Google Scholar] [CrossRef]

- GB 50010-2010; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Code for Design of Concrete Structures. Chinese Standard: Beijing, China, 2011.

| Physical–Mechanical Parameter | Surrounding Rock | Geologic Fault |

|---|---|---|

| Hydraulic conductivity (10−5 cm/s) | 0.612 | 8.06 |

| Porosity (%) | 0.5 | 0.73 |

| Modulus of elasticity (GPa) | 25 | 11 |

| Poisson’s ratio | 0.35 | 0.45 |

| Internal friction angle (°) | 30 | 29 |

| Cohesion (MPa) | 0.25 | 0.01 |

| Volumetric weight (kN/m3) | 22 | 17.8 |

| Water Pressure Sensor Parameters | Parameter Values |

|---|---|

| Maximum diameter (mm) | 28 |

| Length (mm) | 135 |

| Maximum pressure measurement range (MPa) | 1 |

| Resolution (%F·S) | 0.008 |

| Measurement accuracy (%F·S) | ±0.1 |

| Output signal | RS485, Modbus protocol |

| Protection class | IP68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Z.; Li, D.; Wang, F.; Zhang, L.; Wang, S. Field Test and Numerical Simulation Study on Water Pressure Distribution and Lining Deformation Law in Water-Rich Tunnel Crossing Fault Zones. Appl. Sci. 2024, 14, 7110. https://doi.org/10.3390/app14167110

Feng Z, Li D, Wang F, Zhang L, Wang S. Field Test and Numerical Simulation Study on Water Pressure Distribution and Lining Deformation Law in Water-Rich Tunnel Crossing Fault Zones. Applied Sciences. 2024; 14(16):7110. https://doi.org/10.3390/app14167110

Chicago/Turabian StyleFeng, Zhongju, De Li, Fuchun Wang, Liang Zhang, and Siqi Wang. 2024. "Field Test and Numerical Simulation Study on Water Pressure Distribution and Lining Deformation Law in Water-Rich Tunnel Crossing Fault Zones" Applied Sciences 14, no. 16: 7110. https://doi.org/10.3390/app14167110

APA StyleFeng, Z., Li, D., Wang, F., Zhang, L., & Wang, S. (2024). Field Test and Numerical Simulation Study on Water Pressure Distribution and Lining Deformation Law in Water-Rich Tunnel Crossing Fault Zones. Applied Sciences, 14(16), 7110. https://doi.org/10.3390/app14167110