Research on the Migration and Settlement Laws of Backflow Proppants after Fracturing Tight Sandstone

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. Distribution Characteristics of Backflow Proppants in Tight Sandstone

3.2. Research on the Influencing Factors of the Sedimentation Rates of Proppants

3.3. Distribution Characteristics of Support Agents for Tight Sandstone Backflow

3.4. Mechanism of Free Settling of Proppants under Multi-Fluid Conditions

4. Results and Analysis

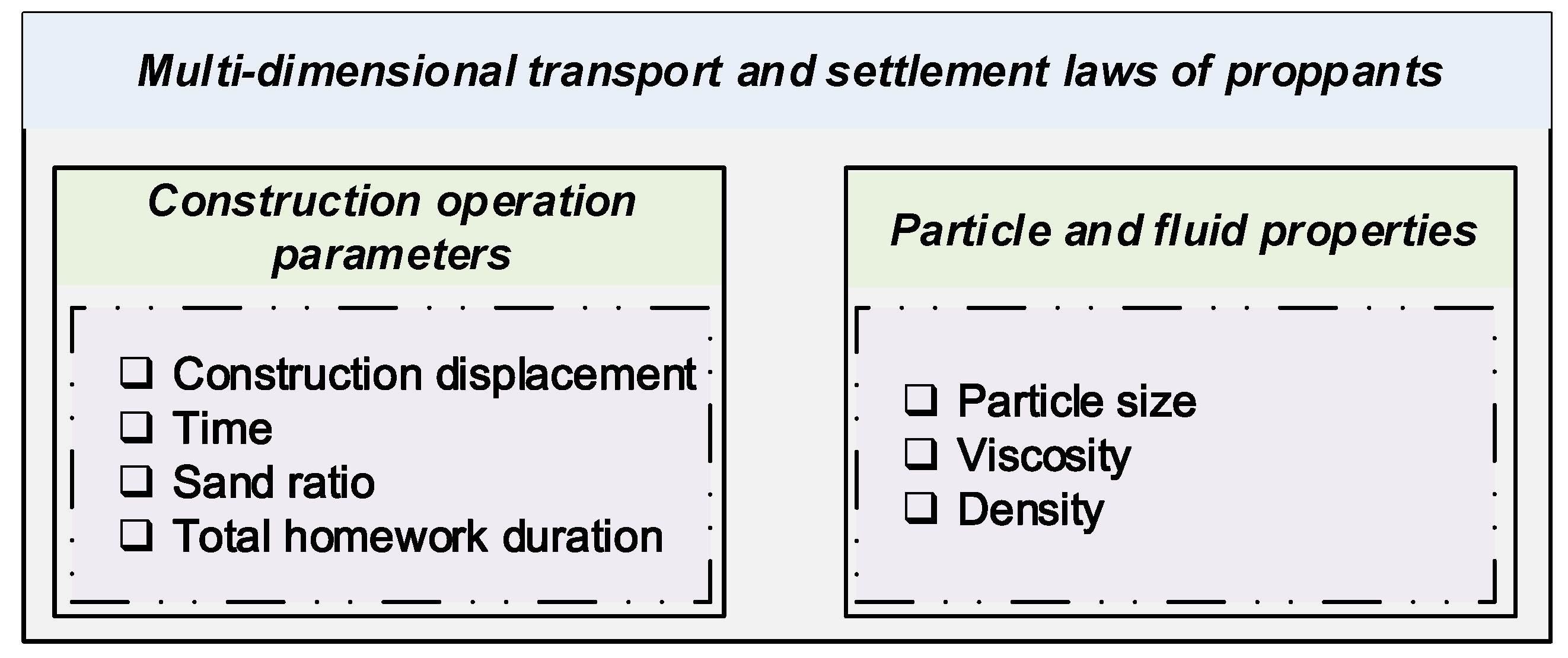

4.1. Multi-Dimensional Transport and Settlement Laws of Proppants

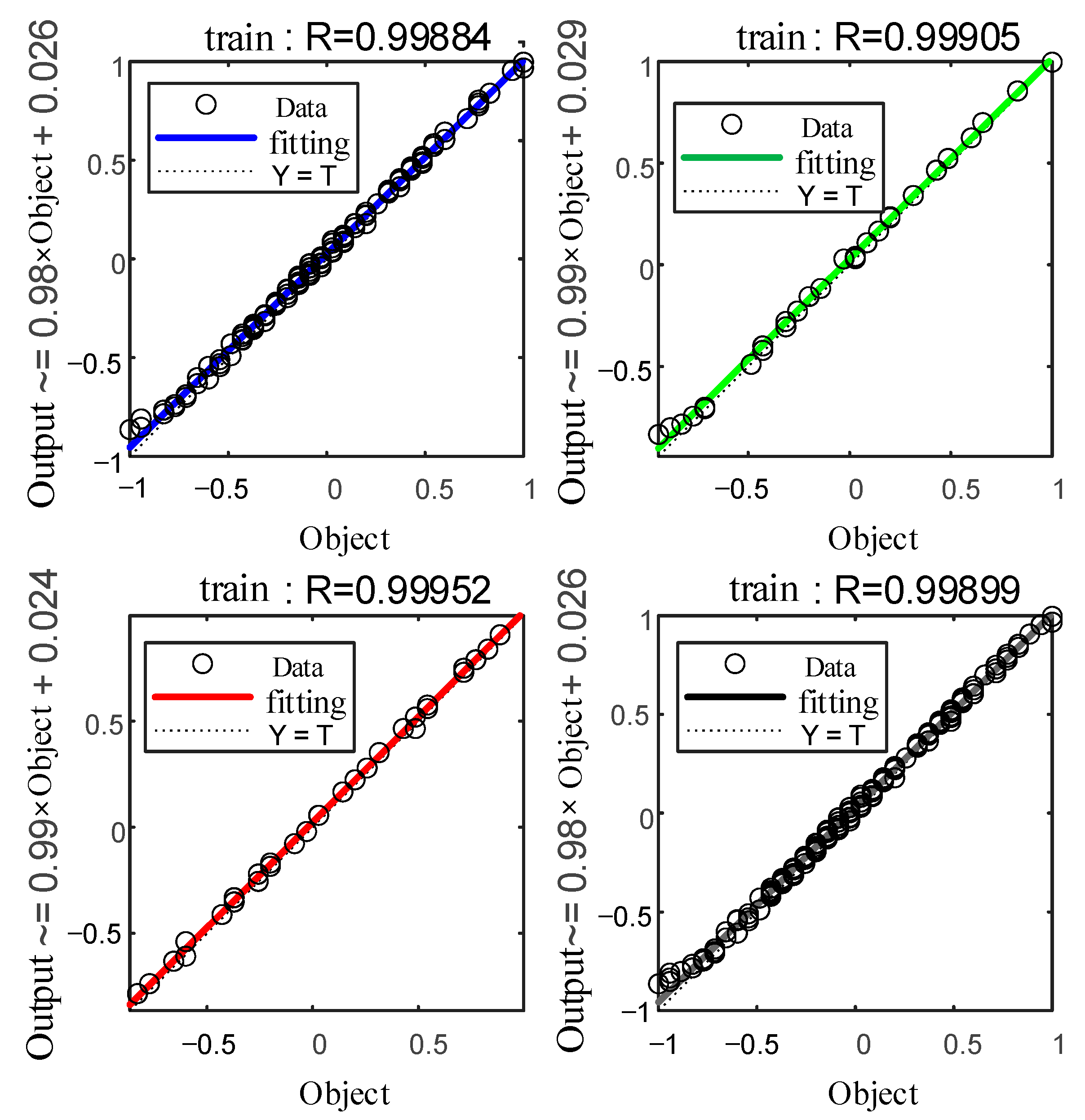

4.2. Exploration of the Transport and Settlement Laws of Proppant Based on Artificial Intelligence

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, M.; Guo, T.; Jia, X.; Wen, D.; Chen, M.; Wang, Y.; Qu, Z.; Ma, D. Study on the pump schedule impact in hydraulic fracturing of unconventional reservoirs on proppant transport law. Energy 2024, 286, 129569. [Google Scholar] [CrossRef]

- He, X.; Pang, Z.; Ren, L.; Zhao, L.; Lu, X.; Wang, Y.; Liu, P. A critical review on analysis of sand producing and sand-control technologies for oil well in oilfields. Front. Energy Res. 2024, 12, 1399033. [Google Scholar] [CrossRef]

- Toupchian, A.; Mahani, H.; Ayatollahi, S. The impact of grain size heterogeneity on the performance of low-salinity waterflooding in carbonate formations. Fuel 2024, 356, 129513. [Google Scholar] [CrossRef]

- Eyitayo, S.I.; Talal, G.; Kolawole, O.; Okere, C.J.; Ispas, I.; Arbad, N.; Emadibaladehi, H.; Watson, M.C. Experimental Investigation of the Impact of CO2 Injection Strategies on Rock Wettability Alteration for CCS Applications. Energies 2024, 17, 2600. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, M.; Liu, J.; Zhang, Y.; Gao, M.; Song, X.; Emadibaladehi, H.; Dai, C. Study on formation process and reservoir damage mechanism of blockages caused by polyacrylamide fracturing fluid in production wells. Fuel 2024, 358, 130154. [Google Scholar] [CrossRef]

- Chen, L.; Gong, R.; Wang, J.; Xu, H.; Zhang, L. Influence of reservoir physical properties on guar gum fracturing fluid damage in unconventional tight reservoirs. Phys. Fluids 2024, 36, 046608. [Google Scholar] [CrossRef]

- Celis, S.A.; García-García, F.; Rodríguez-Tovar, F.J.; Giraldo-Villegas, C.A.; Pardo-Trujillo, A. Coarse-grained submarine channels: From confined to unconfined flows in the Colombian Caribbean (late Eocene). Sediment. Geol. 2024, 459, 106550. [Google Scholar] [CrossRef]

- Winkler, W. The North Penninic Bündnerschiefer and Flysch of the Prättigau (Swiss Alps) revisited. Swiss J. Geosci. 2024, 117, 4. [Google Scholar] [CrossRef]

- Shen, W.; Ma, T.; Zuo, L.; Yang, X.; Cai, J. Advances and Prospects of Supercritical CO2 for Shale Gas Extraction and Geological Sequestration in Gas Shale Reservoirs. Energy Fuels 2024, 38, 789–805. [Google Scholar] [CrossRef]

- Guo, J.; Lu, Q.; Liu, Z.; Zeng, F.; Guo, T.; Liu, Y.; Liu, L.; Qiu, L. Concept and key technology of “multi-scale high-density” fracturing technology: A case study of tight sandstone gas reservoirs in the western Sichuan Basin. Nat. Gas Ind. B 2023, 10, 283–292. [Google Scholar] [CrossRef]

- Ma, K.; Li, D.; Liang, D. Reservoir stimulation technologies for natural gas hydrate: Research progress, challenges, and perspectives. Energy Fuels 2023, 37, 10112–10133. [Google Scholar] [CrossRef]

- Tan, J.; Li, C.; Zhou, J.Q.; Tang, H. On non-Darcian flow behavior in a rough-walled fracture filled with a porous medium. J. Hydrol. 2023, 616, 128778. [Google Scholar] [CrossRef]

- Chen, D.; Sun, Z. Numerical Simulation of the Proppant Settlement in SC-CO2 Sand-Carrying Fluid in Fracturing Fractures. Energies 2022, 16, 11. [Google Scholar] [CrossRef]

- Lupo, M.; Barletta, D.; Sofia, D.; Poletto, M. Calibration of DEM for Cohesive Particles in the SLS Powder Spreading Process. Processes 2021, 9, 1715. [Google Scholar] [CrossRef]

- Yao, S.; Chang, C.; Hai, K.; Huang, H.; Li, H. A review of experimental studies on the proppant settling in hydraulic fractures. J. Pet. Sci. Eng. 2022, 208, 109211. [Google Scholar] [CrossRef]

- Wang, F.; Chen, Q.; Lyu, X.; Zhang, S. Fracturing-fluid flowback simulation with consideration of proppant transport in hydraulically fractured shale wells. ACS Omega 2020, 5, 9491–9502. [Google Scholar] [CrossRef]

- Qu, Z.; Wang, J.; Guo, T.; Shen, L.; Liao, H.; Liu, X.; Fan, J.; Hao, T. Optimization on fracturing fluid flowback model after hydraulic fracturing in oil well. J. Pet. Sci. Eng. 2021, 204, 108703. [Google Scholar] [CrossRef]

- Liu, Y.; Sharma, M.M. Effect of fracture width and fluid rheology on proppant settling and retardation: An experimental study. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. SPE-96208-MS. [Google Scholar] [CrossRef]

- Liao, Z.; Li, X.; Ge, L.; Yang, Z.; Zhu, J.; Xue, Q.; Wang, H. Lightweight proppants in unconventional oil and natural gas development: A review. Sustain. Mater. Technol. 2022, 33, e00484. [Google Scholar] [CrossRef]

- Guo, T.; Wang, Y.; Du, Z.; Chen, M.; Liu, D.; Liu, X.; Rui, Z. Evaluation of coated proppant unconventional performance. Energy Fuels 2021, 35, 9268–9277. [Google Scholar] [CrossRef]

- Lee, J.; Babadagli, T. Effect of roughness on fluid flow and solute transport in a single fracture: A review of recent developments, current trends, and future research. J. Nat. Gas Sci. Eng. 2021, 91, 103971. [Google Scholar] [CrossRef]

- Xie, W.; Chen, S.; Wang, M.; Yu, Z.; Wang, H. Progress and prospects of supercritical CO2 application in the exploitation of shale gas reservoirs. Energy Fuels 2021, 35, 18370–18384. [Google Scholar] [CrossRef]

- Wyatt, G.R.; Huppert, H.E. Dense Suspension Flow in a Penny-Shaped Crack, Part I: Theory. J. Mech. Phys. Solids 2021, 152, 104417. [Google Scholar] [CrossRef]

- Zhao, J.; Ren, L.; Jiang, T.; Hu, D.; Wu, L.; Wu, J.; Yin, C.; Li, Y.; Hu, Y.; Lin, R.; et al. Ten years of gas shale fracturing in China: Review and prospect. Nat. Gas Ind. B 2022, 9, 158–175. [Google Scholar] [CrossRef]

- Kogler, K.; Langbauer, C. BEER® Bio Enhanced Energy Recovery–Development of a new Stimulation Technology. Oil Gas Eur. Mag. 2021, 2021, 43–51. [Google Scholar]

- Li, Z.; Kang, W.; Zhao, Y.; Yang, H.; Li, M.; Kang, X.; Zhou, T.; Zhou, B.; Sarsenbekuly, B.; Aidarova, S. Organic acid-enhanced viscoelastic surfactant and its application in fracturing fluids. Energy Fuels 2021, 35, 3130–3139. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Zhao, W.; Liu, Y.; Liu, H. Modeling and Experimental Study of Self-Suspension Fracking Liquid Containing Nanoparticles. Chem. Technol. Fuels Oils 2021, 57, 335–357. [Google Scholar] [CrossRef]

- Yao, E.; Bai, H.; Zhou, F.; Zhang, M.; Wang, J.; Li, F. Performance evaluation of the multifunctional variable-viscosity slick water for fracturing in unconventional reservoirs. ACS Omega 2021, 6, 20822–20832. [Google Scholar] [CrossRef]

- Yao, L.; Liu, Y.; Liu, J.; Xiao, Z.; Xie, K.; Cao, H.; Zhang, H. An optimized CFD-DEM method for particle collision and retention analysis of two-phase flow in a reduced-diameter pipe. Powder Technol. 2022, 405, 117547. [Google Scholar] [CrossRef]

- Di Vaira, N.; Leonardi, C.; Johnson, R., Jr. Modelling micro-proppant transport in stress-sensitive naturally-fractured reservoirs. In Proceedings of the SPE Europec Featured at EAGE Conference and Exhibition, Virtual, 1–3 December 2020; p. D021S016R003. [Google Scholar] [CrossRef]

- Chernov, D.; Sornette, D.; Chernov, D.; Sornette, D. Specific features of risk management in the industrial and agricultural sectors. In Critical Risks of Different Economic Sectors: Based on the Analysis of More Than 500 Incidents 2020, Accidents and Disasters; Springer: Berlin/Heidelberg, Germany, 2020; pp. 13–145. [Google Scholar]

| Cd | Re |

|---|---|

| ≤1 | |

| 1~500 | |

| 0.44 | 500~200,000 |

| Number of Groups | i1 | i2 | i3 | i4 | i5 | i6 | i7 | o1 | o2 |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.5 | −0.9 | −0.7 | 0.3 | −0.7 | 0.9 | −0.1 | 0.7 | −0.9 |

| 2 | −0.3 | 0.1 | 0.4 | −0.5 | 0.2 | −0.4 | 0.8 | −0.4 | 0.6 |

| 3 | 0.1 | −0.3 | −0.8 | 0.9 | −0.9 | 0.6 | −0.7 | 0.9 | −0.3 |

| 4 | −0.8 | 0.7 | 0.2 | −0.8 | 0.5 | −0.2 | 0.4 | −0.6 | 0.7 |

| 5 | 0.1 | −0.6 | −0.6 | 0.6 | −0.3 | 0.3 | −0.5 | 0.2 | −0.5 |

| 6 | −0.9 | 0.8 | 0.9 | −0.2 | 0.8 | −0.8 | 0.2 | −0.8 | 0.2 |

| 7 | 0.6 | −0.5 | −0.3 | 0.7 | −0.6 | 0.7 | −0.3 | 0.3 | −0.8 |

| 8 | −0.5 | 0.4 | 0.5 | −0.1 | 0.1 | −0.5 | 0.9 | −0.1 | 0.1 |

| 9 | 0.2 | −0.2 | −0.1 | 0.4 | −0.4 | 0.1 | −0.6 | 0.5 | −0.4 |

| 10 | −0.7 | 0.6 | 0.7 | −0.6 | 0.7 | −0.6 | 0.1 | −0.3 | 0.8 |

| 11 | 0.4 | −0.7 | 0.6 | 0.8 | −0.4 | 0.8 | 0.8 | 0.7 | −0.9 |

| 12 | −0.7 | 0.3 | −0.8 | −0.7 | 0.9 | −0.6 | −0.6 | −0.4 | 0.6 |

| 13 | 0.9 | −0.5 | 0.4 | 0.6 | −0.7 | 0.4 | 0.4 | 0.8 | −0.3 |

| 14 | −0.2 | 0.8 | −0.5 | −0.4 | 0.3 | −0.7 | −0.7 | −0.2 | 0.7 |

| 15 | 0.6 | −0.2 | 0.2 | −0.8 | −0.5 | 0.2 | 0.2 | 0.9 | −0.5 |

| 16 | −0.3 | 0.9 | −0.9 | 0.2 | 0.8 | −0.9 | −0.9 | −0.5 | 0.2 |

| 17 | 0.8 | −0.4 | 0.1 | 0.2 | −0.2 | 0.1 | 0.1 | 0.6 | −0.8 |

| 18 | −0.5 | 0.6 | −0.3 | 0.5 | 0.6 | −0.3 | −0.3 | −0.3 | 0.1 |

| 19 | 0.1 | −0.1 | 0.7 | −0.6 | −0.1 | 0.5 | 0.5 | 0.1 | −0.4 |

| 20 | −0.8 | 0.7 | −0.6 | 0.1 | 0.7 | −0.8 | −0.8 | −0.6 | 0.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, H.; Qin, Q. Research on the Migration and Settlement Laws of Backflow Proppants after Fracturing Tight Sandstone. Appl. Sci. 2024, 14, 7746. https://doi.org/10.3390/app14177746

Cheng H, Qin Q. Research on the Migration and Settlement Laws of Backflow Proppants after Fracturing Tight Sandstone. Applied Sciences. 2024; 14(17):7746. https://doi.org/10.3390/app14177746

Chicago/Turabian StyleCheng, Hanlie, and Qiang Qin. 2024. "Research on the Migration and Settlement Laws of Backflow Proppants after Fracturing Tight Sandstone" Applied Sciences 14, no. 17: 7746. https://doi.org/10.3390/app14177746

APA StyleCheng, H., & Qin, Q. (2024). Research on the Migration and Settlement Laws of Backflow Proppants after Fracturing Tight Sandstone. Applied Sciences, 14(17), 7746. https://doi.org/10.3390/app14177746