Abstract

For many years, structural health monitoring (SHM) has held significant importance across diverse engineering sectors. The main aim of SHM is to assess the health status and understand distinct features of structures by analyzing real-time data from physical measurements. The dynamic response (DR) is a significant tool in SHM studies. This response is used primarily to detect variations or damage by examining the vibration signals of DR. Numerous scholarly articles and reviews have discussed the phenomenon and importance of using DR to predict damages in uniform thickness (UT) plate structures. However, previous reviews have predominantly focused on the UT plates, neglecting the equally important varying thickness (VT) plate structures. Given the significance of VT plates, especially for academic researchers, it is essential to compile a comprehensive review that covers the vibration of both the UT and VT cracked plate structures and their identification methods, with a special emphasis on VT plates. VT plates are particularly significant due to their application in critical components of various applications where optimizing the weight, aerodynamics, and dimensions is crucial to meet specific design specifications. Furthermore, this review critically evaluates the damage identification methods, focusing on their accuracy and applicability in real-world applications. This review revealed that current research studies are inadequate in describing crack path identification; they have primarily focused on predicting the quantification of cracks in terms of size or possible location. Identifying the crack path is crucial to avoid catastrophic failures, especially in scenarios where the crack may propagate in critical dimensions of the plate. Therefore, it can be concluded that an accurate analytical and empirical study of crack path and damage identification in these plates would be a novel and significant contribution to the academic field.

1. Introduction

A plate represents a structural component characterized by its three-dimensional solid geometry with a significantly thin thickness in relation to its other dimensions [1]. In various engineering applications [2,3,4], plates serve to offer structural reinforcement and assist in the distribution of loads and stresses throughout the construction [5].

Over time, plates are subject to extreme events, persistent ambient oscillations, and natural incidents like earthquakes, corrosion, traffic-induced pressures, and material degradation, which cause damage to their microstructure [6]. Cracks can seriously damage structural effectiveness. Even minor damages can disrupt a plate’s function, potentially resulting in structural breakdowns [7]. As a result, the consistent evaluation of the plates’ performance has become vital to ensure structural robustness and safety [8,9]. In other words, developing methods for early crack detection and accurate localization has become essential for the continuous operation and longevity of machinery and infrastructure [10].

Over the years, SHM and methodologies for identifying damage in plate structures have grown prominently in disciplines such as aerospace, civil, and mechanical engineering [11,12,13]. Specialists in damage identification have made efforts to develop cost-effective and reliable monitoring methods. Emphasis in their research has been placed on utilizing the DR to determine plate deterioration [14,15,16,17,18]. This technique is effective for detecting hidden damage in a plate’s interior, as evidenced by variations in characteristics such as stiffness detectable through vibration analyses. Additionally, this approach allows for inspections during active operations, reducing the potential downtime and associated expenses [19,20].

Numerous scholarly articles and reviews have been written to explain the phenomenon and significance of using the DR to predict the damages in UT plates [19,21,22,23,24,25,26]. Nevertheless, despite the significant progress achieved, a research gap still exists in the context of damage detection in VT plates. Plates characterized by a VT hold substantial significance, as they find application in critical components such as aircraft wings, automobile chassis, vessels, buildings, and more, where the optimization of weight, aerodynamics, and dimensions is essential to meet specific design specifications [27].

Additionally, the critical review showed that the current research studies and their findings are insufficient in describing how to identify the crack path. Researchers have rarely studied the crack path in beams in the literature [28,29], and for plates, they only predict the size or potential location of the crack [30,31,32,33,34,35]. Identifying the crack path direction is crucial for several reasons such as preventing catastrophic failures because it may move in a direction where the size of the plate is critical, helping engineers to design structures that are more resistant to cracking, and can be used to develop methods for repairing and monitoring structures that have cracked.

Addressing these research gaps, therefore, represents an opportunity for further investigation. By doing so, a comprehensive understanding of the challenges and prospects associated with monitoring techniques for detecting damage in VT plates and crack paths can be obtained, which will streamline the processes associated with the inspection of engineering structures, thereby reducing the time, effort, and associated costs.

The subsequent sections of this paper are structured as follows. A general background and the fundamentals of the vibration of plates are presented in Section 2. In Section 3, vibration-based damage identification for cracked plates in forward and inverse research is discussed and reviewed. A general discussion of all sections is presented in Section 4. Conclusions are drawn, and gaps are listed in Section 5.

2. Fundamentals of Plate Structural Vibration

Using DR to identify damage in plate structures relies heavily on a thorough understanding of their vibrational behavior. This section provides an overview of essential plate vibration theories and details how the crack term is formalized to achieve precise vibration characteristics, which is critical for accurate damage identification.

2.1. Plate Theories

The study of plate vibrations began with the development of linear models. These models have gradually progressed to address the complexities of real-world applications. The initial work by Euler and Bernoulli in 1766 and 1789 provided the foundation by modeling plates as two-dimensional membranes. This work led to the derivation of the first differential equations describing the vibrational behavior of thin plates, as illustrated in Equation (1) [36]. These models serve as a reference point for identifying irregularities caused by structural damage.

After that, Lagrange [37] formulated the first true equation governing the free vibration of plates by integrating the effects of bending stiffness into the vibration equations. Navier, in 1823, further enhanced the theory by considering the molecular structure of the plate. This approach enabled the derivation of a comprehensive differential equation for lateral loading, as shown in Equation (2) [36].

Later, in 1887, Kirchhoff re-evaluated this equation using an alternative energy method [36]. However, significant developments were made between 1877 and 1945 by Rayleigh [38,39] and Timoshenko [40]. These improvements included the effects of transverse shear deformation and rotary inertia, expanding the usefulness of classical theories to higher frequencies. These led to studies on rectangular plate (RP) vibrations using the Rayleigh–Ritz method (RRM) [41,42,43].

Subsequent developments came from Reissner (1945) [44] and Mindlin (1951) [45] by introducing the first-order shear deformation theory (FSDT). This theory is used when a shear correction factor is required to reconcile the actual stress state with the assumed normal stress state [46].

Building upon Mindlin’s work, higher-order shear deformation theories (HSDTs) were developed in the 1960s and 1970s. These theories incorporate higher-order terms in the displacement fields, leading to better accuracy for thick plates without the need for a shear correction factor [47,48,49]. Reddy (1984) [50] made significant contributions in this area by developing a third-order theory that accurately predicted displacements and stresses while ensuring zero transverse shear stress on the plate surfaces.

More recently, Neves et al. (2012) [51] developed a quasi-3D sinusoidal shear deformation theory for functionally graded plates (FGPs) based on Carrera’s unified formulation (CUF). This theory improves the accuracy of static and free vibration analyses by accounting for thickness stretching. Building on these advancements, Ghazwani et al. (2024) [52] further refined these theories, increasing the accuracy of plate analysis, especially for thick and complex structures. This improvement was achieved by enhancing the displacement fields and eliminating the need for shear correction factors.

2.2. Nonlinear Deflection Theory

The concept of nonlinear theory in DR relates to systems displaying nonlinear vibration behaviors in their reactions to external excitation. Such nonlinear systems challenge the principle of superposition, where combining individual inputs does not accurately predict the overall system response; especially when dealing with deflections, approximately one-tenth of a plate’s thickness, structural stiffening occurs, a phenomenon not accounted for by linear theory [53,54,55].

Nonlinear vibration behaviors have been studied in many research studies [56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72]. However, the pioneering contributions in nonlinear theory include Kirchhoff’s description of plate bending and elongation [73], Von Karman’s publication of the final form of nonlinear differential equations for statically deflected plates with moderate deflections in 1910 [74], and Bromberg and Stoker’s development of nonlinear theories for plane and curved shells while neglecting bending in 1945 [75].

Later, in 1955, Berger [76] simplified a set of equations that explained the significant deformation of plates. Chu and Hermann (1956) [77] employed a perturbation theory to address the nonlinear free vibrations of the RP. Casado-Pascual et al. (2003) [78] introduced a simplified two-state model to explain the nonlinear dynamics of bistable systems. Liu et al. (2013) [79] developed an analytical theory for characterizing nonlinear DR of waveguide-cavity structures. Liu et al. (2017) [80] developed nonlinear theories for laminated plates and casings, highlighting the classical nonlinear large deformation theory. Yang and Xiang (2022) [81] suggested a thorough response function theory, showing microscopic nonlinear dynamic processes in molecular vibrational polaritons.

2.3. Equation of Motion of Cracked Plates

Based on previous plate theories, the governing equations were developed and utilized to comprehend the behavior of plates under various loading conditions and boundary constraints. Leissa [82] and Szilard [37] deeply analyzed the governing equation of the RP in its traditional form. They proposed the governing equation of an intact isotropic and orthotropic RP with the UT and VT based on classical plate theory. Their works serve as a reference point for developing the governing equations to identify irregularities caused by structural damage.

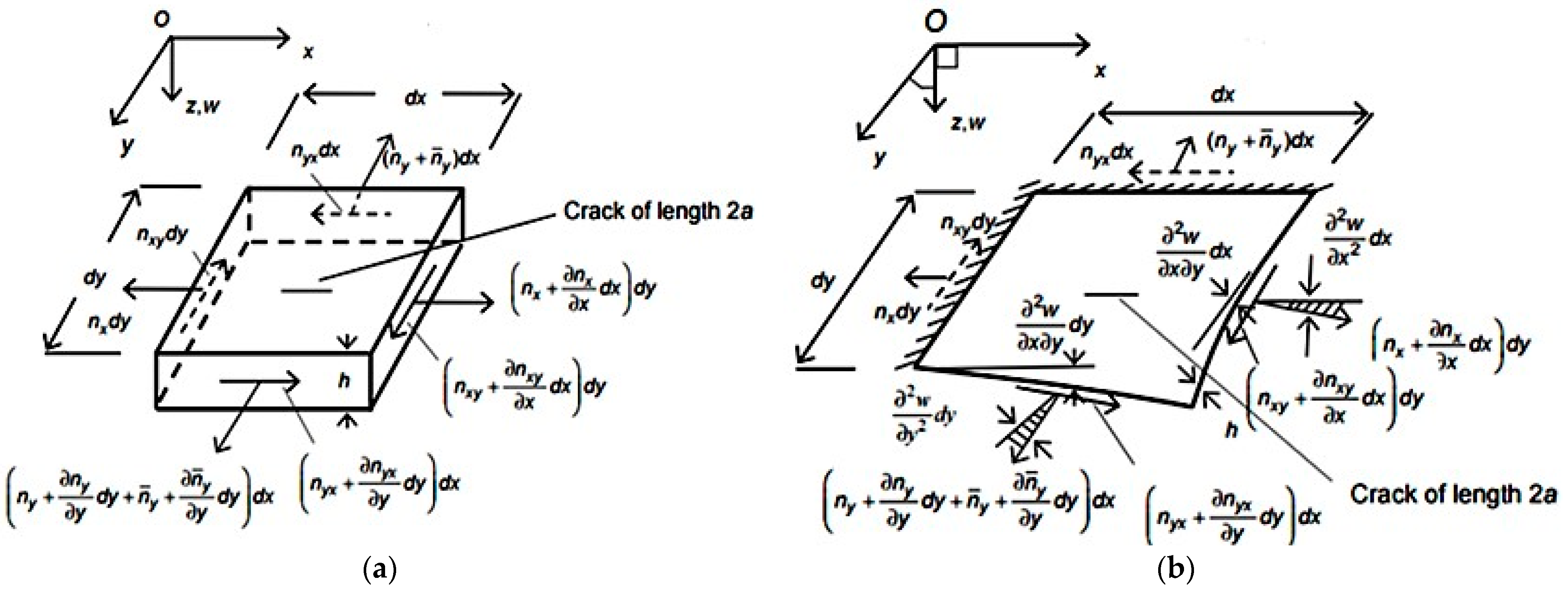

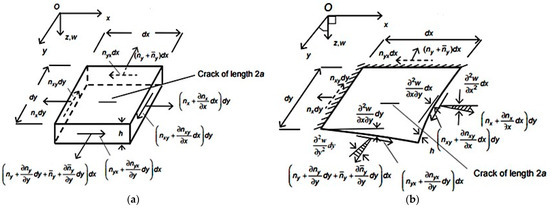

Building upon these works, Israr et al. (2011) [83] developed a governing equation for RP with UT featuring a central crack (a). They utilized the approximate relationship between nominal tensile and bending stresses at the crack location, as shown in Figure 1, to enhance the model’s accuracy, as shown in Equation (3). Ismail and Cartmell (2012) [84] extended Israr’s work by formulating a governing equation that accounts for a crack inclined at an angle on the top surface of the plate, subjected to bending moments and tension, as shown in Equation (4). Compliance coefficients tt, bb, and bt = tb are recognized from Rice and Levy’s paper [85]. Meanwhile, the Ctt, Cbb, and Cbt = Ctb coefficients can be found in the paper by Joseph and Erdogan [86].

Figure 1.

(a) In-plane forces acting on the plate, and (b) cracked plate deformation and two-sided constraints [83].

Gupta et al. (2018) [27] further expanded this area of study by deriving equations of motion for partially cracked isotropic and FGM plates with both linear and parabolically varying thicknesses (LVT and PVT). They developed the crack terms using the line spring model (LSM) for plates with VT, making them dependent on the plate thickness. Their analysis, based on classical plate theory, assumed that the volumes of the plates with the VT and the UT were identical to enable a comparison of dynamic properties. For simplification, they disregarded the normal stress, shear deformation, and rotary inertia, as shown in Equation (5). Chandrakar et al. (2022) [87] continued this research by focusing on cracked orthotropic plates with VT under different boundary conditions and incorporated crack terms using the LSM. The study also explored the impact of in-plane forces on frequency response by analyzing nonlinearity using multiple scales.

3. Crack Detection in Plates Using Dynamic Response (DR)

In SHM studies, examining the DR is essential for detecting changes or damage in dynamic systems using vibration signal analysis. This analysis aims to identify, locate, and measure any structural damages present. Notably, a crack in a structure increases the flexibility locally, affecting its static and dynamic behaviors. Engineers have worked extensively to understand and model the changes caused by cracks and their effects on the structure’s dynamic properties. It is important to mention that most models have been developed to explore changes in DR due to crack damage, addressing a forward problem. However, damage detection through vibration measurements, which is an inverse problem, is challenging and sometimes impractical. This discussion will further explore both forward and inverse problem research, with attention to the VT configurations in the following sections.

3.1. Forward Problem for the DR of the Cracked Plate

Various research initiatives have been conducted to examine changes in the DR of plate structures due to damage caused by cracks, a situation identified as a forward problem. These studies can be systematically divided into two categories, depending on the thickness of the plates being analyzed.

3.1.1. Plate of the Uniform Thickness (UT)

Numerous researchers have focused on studying the dynamic behaviors of UT plates with cracks, developing various analytical approaches. Before the widespread use of the FE method, mathematical techniques were essential for understanding the vibration dynamics of these plates [88].

Early significant contributions to this field, dating back to 1967 by Lynn and Kumbasar [89], involved using Green’s function to formulate a Fredholm integral equation of the first kind to analyze vibrations in cracked RP. This equation was designed for mixed edge conditions influenced by the crack’s presence. The Krylov and Bogoliubov method was later used to solve this equation, particularly for cases involving narrow cracks and plates with fully supported boundaries. The outcomes of this solution were observed as frequency changes corresponding to different crack sizes. Stahq and Keer (1972) [90] studied the vibrations and stability of cracked RP using dual-series equations, resulting in a second kind of homogeneous Fredholm integral equation. Joseph et al. (1988) used the LSM to analyze part-through cracks in shells under mixed loading, and found that shell curvature minimally affected the stress intensity factors for superficial cracks [91]. Maruyama and Ichinomya (1989) investigated the free vibration dynamics of the RP with straight slits, using holographic interferometry to study the effect of slit dimensions, positions, and angles on natural frequencies and related modal shapes. Their experiments included different slit positions and angles, showing a decrease in natural frequencies with increasing slit dimensions and angles [92]. Liew et al. (1994) [93] aimed to understand the vibration characteristics of cracked RP by employing the domain decomposition method. Their study was divided into two specific cases, cracks originating from the edge and cracks located in the center. Their findings revealed that the presence of cracks reduced the plates’ flexural rigidity, resulting in lower vibrational frequencies in both cases. Khadem et al. (2000) [94] created and utilized modified comparison functions to analyze vibrations in the SS, cracked RP. This method provided benefits like not being restricted by specific types of functions, having higher accuracy, and being easier to use compared to eigenfunctions. The researchers used these modified functions to determine the natural frequencies of cracked plates via the RRM, with variations in frequencies based on crack depth, length, and position.

Pia et al. (2002) [95] used the scanning laser vibrometer technique to study the dynamics of damaged CP and successfully identified minor defects through the analysis of modal shapes and frequencies. Wu et al. (2005) [96] utilized the incremental harmonic balance (IHB) method to examine the dynamic instability and nonlinear responses of cracked plates under periodic forces, illustrating instability regions and exploring the effects of different parameters on the instability and nonlinear behaviors of these plates. Salehi-Khojin et al. (2006) [97] used both experimental and analytical techniques to study the effects of patch layers and loading frequencies on the fatigue fracture behaviors of aluminum plates, focusing on variations in key fracture mechanics parameters. In the same year, Israr et al. (2006) [98] presented approximate solutions for plate vibrations related to cracks, developing an analytical equation for the dynamics of edge-loaded plates with various boundary conditions. They later expanded the applications of their research, providing relationship information between forces and moments at crack tips and plate edges, significantly advancing the study of vibrations in plates with partial cracks. Their findings highlighted the impact of cracks on natural frequencies, where the frequency of damaged plate dropped, as shown in Table 1 [7]. In 2011 [83], they introduced a model to analyze the vibration dynamics of damaged isotropic plates, with the results aligning well with other research in the field.

Table 1.

Natural frequencies of a damaged plate under various boundary conditions [7].

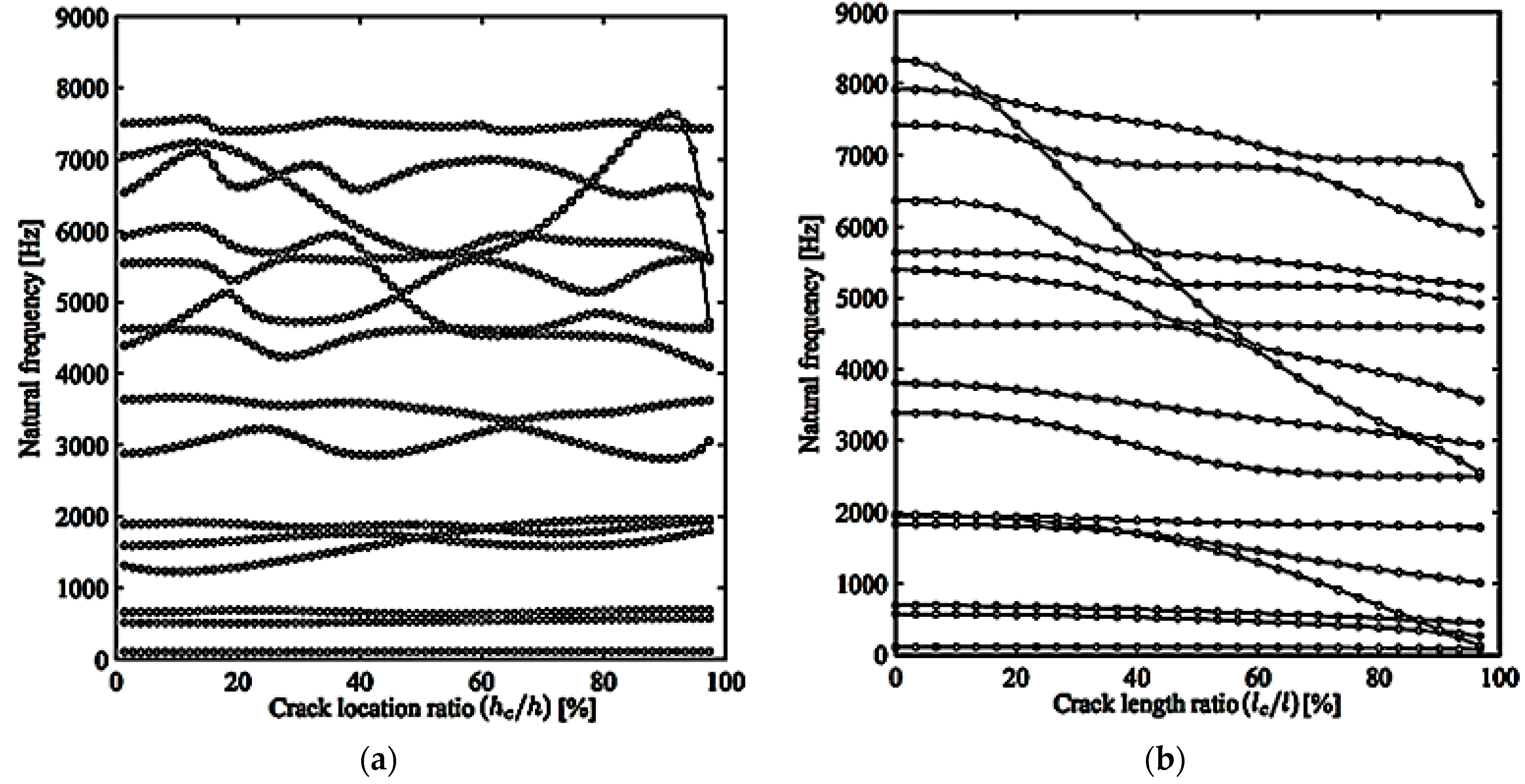

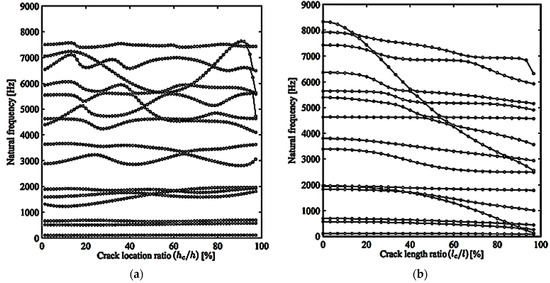

In addition, Saito et al. (2008) [99] examined the vibration behaviors of cracked cantilevered plates by considering changes in crack location and length, using FEM and the hybrid frequency/time (HFT) method. The study focused on nonlinearity due to crack closing effects, particularly near veerings. The research highlighted the effect of crack location and length on the first 15 natural frequencies, as shown in Figure 2. Natarajan et al. (2011) [100] studied the vibration characteristics of cracked FGM plates by considering various parameters and observed a decrease in natural frequency with increasing temperature gradients, crack lengths, and gradient indices. Huang et al. (2011) [101] used the RRM to analyze vibrations in plates with internal disruptions, introducing functions that accurately represented stress near crack tips and discontinuity across cracks. A 2018 study built on this presented a refined method for analyzing plates with through-cracks, concentrating on how crack parameters influence frequency variations, mode transition, and localization [102]. Soon after, Ismail and Cartmell (2012) [84] explored how crack orientation influenced the base frequency of partially cracked isotropic plates using both analytical and experimental methods. Bose et al. (2013) [103] conducted a comprehensive investigation into the impact of crack orientation and position on the natural frequency of cracked plates by employing the LSM. Their findings unveiled an inverse correlation between the natural frequency and crack length, independent of the plate’s boundary constraints. Moreover, for SS or CS plates, an increase in crack angle up to 45 degrees induced a reduction in the natural frequency. Conversely, the natural frequency exhibited an upward trend with increasing crack eccentricity. In 2016, Bose et al. [104] extended their research to include mobility analysis, which provided a deeper understanding of side cracks within the RP. In their analysis, the RRM has demonstrated its effectiveness in providing valuable insights into the dynamics of forced vibration, showing the connections between normalized mobility, crack length ratios, and crack angles. Jung et al. (2014) [105] developed a bending and vibration analysis model for specific microplates, while Khalili et al. (2014) [106] examined the responses of cracked aluminum plates repaired with composite patches. Beigi et al. (2014) [107] conducted a study using the FEM to understand the impact of various crack parameters such as crack orientation, length, and position on plate vibrations. Joshi et al., working from 2014 to 2017 [108,109,110,111,112], extensively used the LSM to explore the effects of cracks on the vibration dynamics of various plate types, highlighting the decline in the base frequency with rising temperatures. Their results shed light on the vibrational changes caused by cracks and the comprehensive impacts of thermal moments and in-plane forces on plates of different materials including isotropic and FGM plates. They also explored the thermal effects on these plates using the modified couple stress theory in later studies [113].

Figure 2.

Variation of the first 15 natural frequencies with respect to crack (a) location ratio and (b) length ratio [99].

Moreover, Akgoz and Civalek (2015) [114] introduced a novel sinusoidal plate model that was founded on the modified strain gradient theory. Using Hamilton’s principle, they derived the governing equations and their associated boundary conditions, enabling a more precise analysis of free vibrations in microplates. Gupta et al., in 2015 and 2016, developed a framework highlighting the influence of microstructure and fiber orientation on vibrational characteristics of different cracked plates [115,116]. Gao et al. (2017) [117] and Ghadiri et al. (2017) [118] analyzed the nonlinear dynamic properties and stability of plates, revealing relationships between different parameters including temperature, crack length, and boundary conditions. Shojaeefard et al. (2017) examined the free vibration of specific FG porous CP under nonlinear thermal loads. In 2018, their study used the FSDT to analyze the vibration of rotating nano/micro-CP made from FG materials [119,120]. Mahinzare et al., in 2017 and 2018, utilized FSDT to investigate the vibration of various rotating CP, focusing on the relationship between variables such as angular velocity, size, and external electric voltage on the vibrational behavior of cracked plates [121,122].

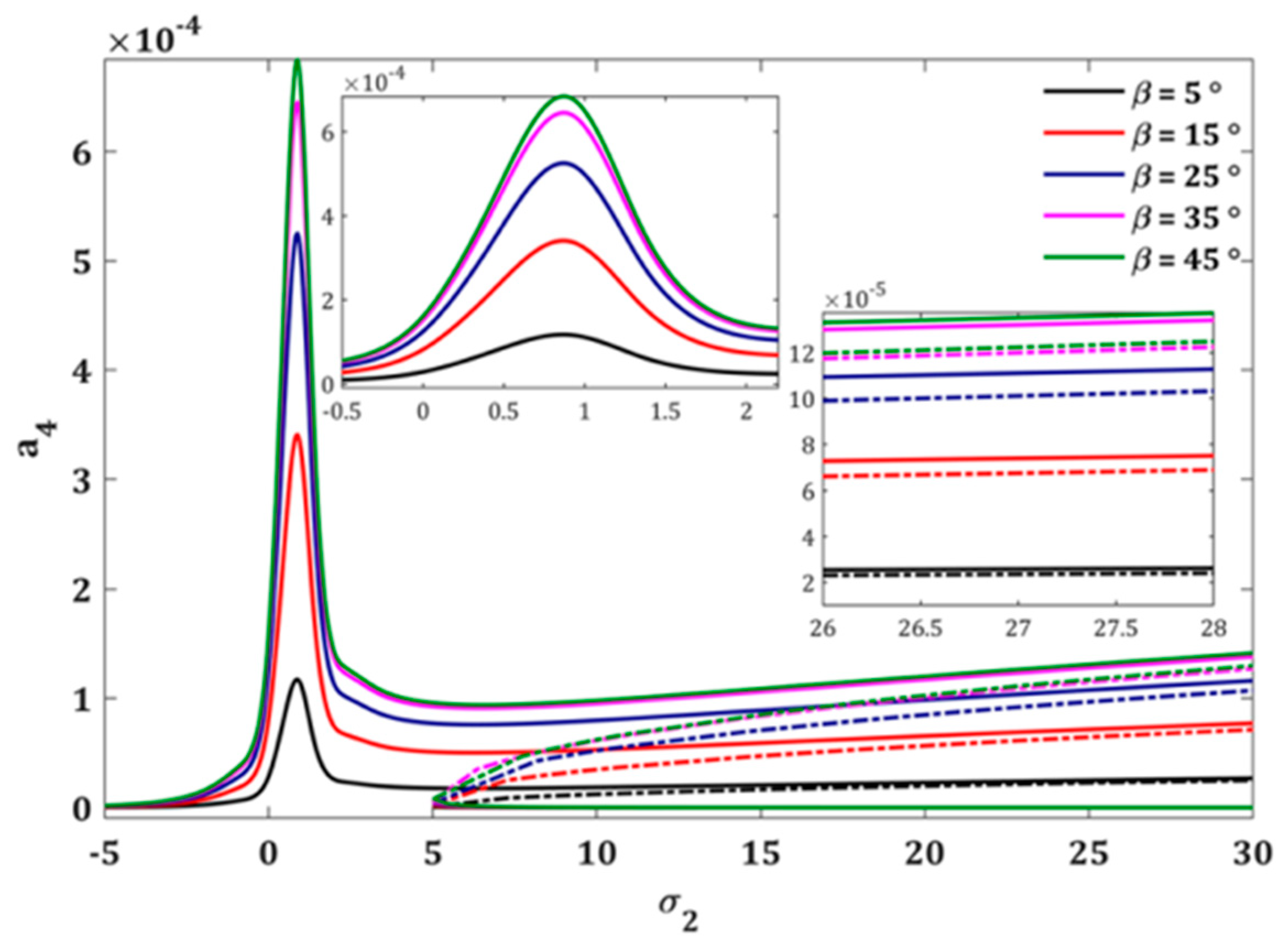

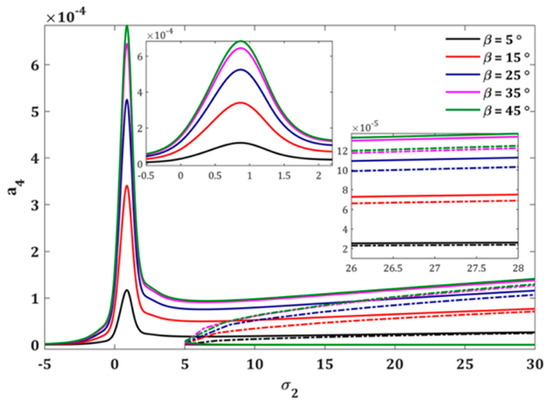

Research by Chouiyakh et al. (2018) [123] and Moradi et al. (2018) [124] presented the Hilbert transform and Mindlin theory to detect and study the characteristics of cracks on plates, focusing on structural deterioration and the impact of load. Guptal et al. (2018) [125] investigated the damage location effects on the primary frequency of plates in thermal environments, emphasizing temperature and damage-related factors. From 2018 to 2020, Soni et al. [126,127,128,129,130,131] conducted a series of studies on cracked plates, focusing on vibration analysis and the influence of various factors such as temperature, immersion depth, and internal material length scale. Their research investigated the dynamics of different types of plates with cracks, providing analytical models for submerged, thermally influenced plates, and exploring the influence of crack length and microstructure on frequency. Meanwhile, Mashrouteh et al. (2019) [132] explored the vibration characteristics of a uniquely cracked plate, offering new understandings of frequency responses related to crack angle. Their findings indicate an inverse relationship between crack angle and frequency response, as shown in Figure 3.

Figure 3.

Frequency response curve at different crack angles, where a4 is the peak amplitude at mode 4, and σ2 is the second perturbation parameter [132].

Recently, Ranjbaran and Seifi (2020) [133] introduced an analytical approach based on Kirchhoff’s theory to investigate the natural vibrational characteristics of isotropic plates with surface or internal cracks, focusing on how various crack and boundary condition parameters affect natural frequencies. They concluded that the presence of internal cracks significantly altered the natural frequencies of a structure compared to surface cracks. Additionally, the longer the crack, the lower the natural frequencies. Dean et al. (2020) [134] utilized a multi-phase field approach to address the initiation of intra-laminar cracking in long fiber-reinforced composites. However, these studies did not offer any models or methodologies for examining buckling and free vibration issues, which are commonly encountered in practical applications. To address this gap, Dean et al. (2021) [135] applied phase-field theory to analyze multi-crack plates using Mindlin plate theory, where each layer contains a crack that extends through the layer’s thickness according to the angle-ply orientation, but does not penetrate the entire plate thickness. In developing this theory, multiple phase-field variables were introduced, with each variable representing the crack in a specific layer.

Furthermore, Gonenli and Das (2021) [136] developed a mathematical model to explore the impact of through-thickness damage on thin plate frames of different configurations, highlighting how much the location of damage affects the strength of the structure. Aftab et al. initiated a two-phase investigation into breathing cracks in plate-like structures in 2021, using DR analysis and Hilbert transform to assess crack severity [137]. Their follow-up study in 2022 presented a crack identification technique based on instantaneous frequency ratio (IFR), highlighting the importance of different excitation types for damage indication and severity estimation. Nikkhoo et al. (2022) [138] analyzed thin RP with cracks under moving masses ad found that the mass weight and velocity, crack dimensions, angular orientations, and plate aspect ratios significantly influenced the dynamic outcomes. They noted that moving masses affected the plates’ dynamics more than moving loads. Song et al. (2022) [139] established a methodology for analyzing the free vibrations of hexagonal plates, both intact and cracked, focusing on the impact of crack length and inclination on their natural frequencies and mode configurations under various boundary conditions. Al-shammari et al. (2022) [140] examined the vibrational effects of central apertures and cracks on the RP, observing a correlation between fundamental frequency and aperture diameter, with cracks reducing the frequency. Migot et al. (2023) [141] focused on fatigue crack detection using local vibration techniques, validated by scanning laser Doppler vibrometer (SLDV) and electromechanical impedance spectroscopy (EMIS). Wang et al. (2023) [142] investigated the vibration of cracked ferromagnetic plates subjected to in-plane forces and a magnetic field, focusing on the first mode of natural frequency. Finally, the damage and DR of structures subjected to impact or blast loads have been extensively discussed in numerous studies [143,144,145,146]. For example, Wang et al. (2024) [147] investigated the damage and the DR of rectangular steel plates under near-surface blast conditions. Their study combined full-scale tests and numerical simulations to analyze how factors like explosion yield, height, angle, and steel plate thickness affected structural integrity. Finally, Table 2 summarizes significant forward research investigations related to damage identification in UT plates.

Table 2.

Summary of forward studies that discuss the detection of damage in UT plates.

3.1.2. Plate of Thickness (VT)

A few studies have focused on the oscillatory behavior of cracked plates of VT. Wang et al. (2008) [158] examined the dynamics of viscoelastic RP with VT and the impact of cracks on their vibrational properties by applying the differential quadrature methodology. The study established differential equations to describe the motion of a viscoelastic plate whose thickness varies linearly and contains part-through cracks. These equations include terms for the additional rotation caused by the cracks. The study revealed that the dimensionless complex frequencies, which describe the vibrational properties of a system, are influenced by the material’s non-dimensional delay time, the plate’s aspect and thickness ratio, and the characteristics of any cracks present. The research shows that cracks impact vibration by changing these frequencies, particularly when they are closer to the plate’s center, which decreases the rigidity of the plate. Moreover, a higher number of cracks leads to a significant decrease in frequency, whereas an increase in the plate’s aspect and thickness ratios results in a considerable increase in frequency. Gupta et al. (2018) [27] combined classical plate theory with modified couple stress theory to develop an analytical model to understand the nonlinear vibration dynamics of cracked RP with LVT and PVT. In Table 3, their research showed that the fundamental frequency rose as the taper parameter increased in both one and two directions, with a more pronounced effect in the latter. Furthermore, the fundamental frequency increased with the taper parameter more significantly in PVT than in LVT. Additionally, an increase in crack length and gradient index resulted in a reduction in the fundamental frequency. The impact of boundary conditions on the fundamental frequency was also significant. Importantly, their results revealed similar vibrational behaviors between the UT and VT plates affected by cracks, though the magnitudes of influence differed.

Table 3.

Impact of varying thickness gradient index, crack size, and taper factor on the basic vibration frequency of a FGM plate with all edge simply supported (SSSS) boundary conditions, taking into account both one-dimensional and two-dimensional models [27].

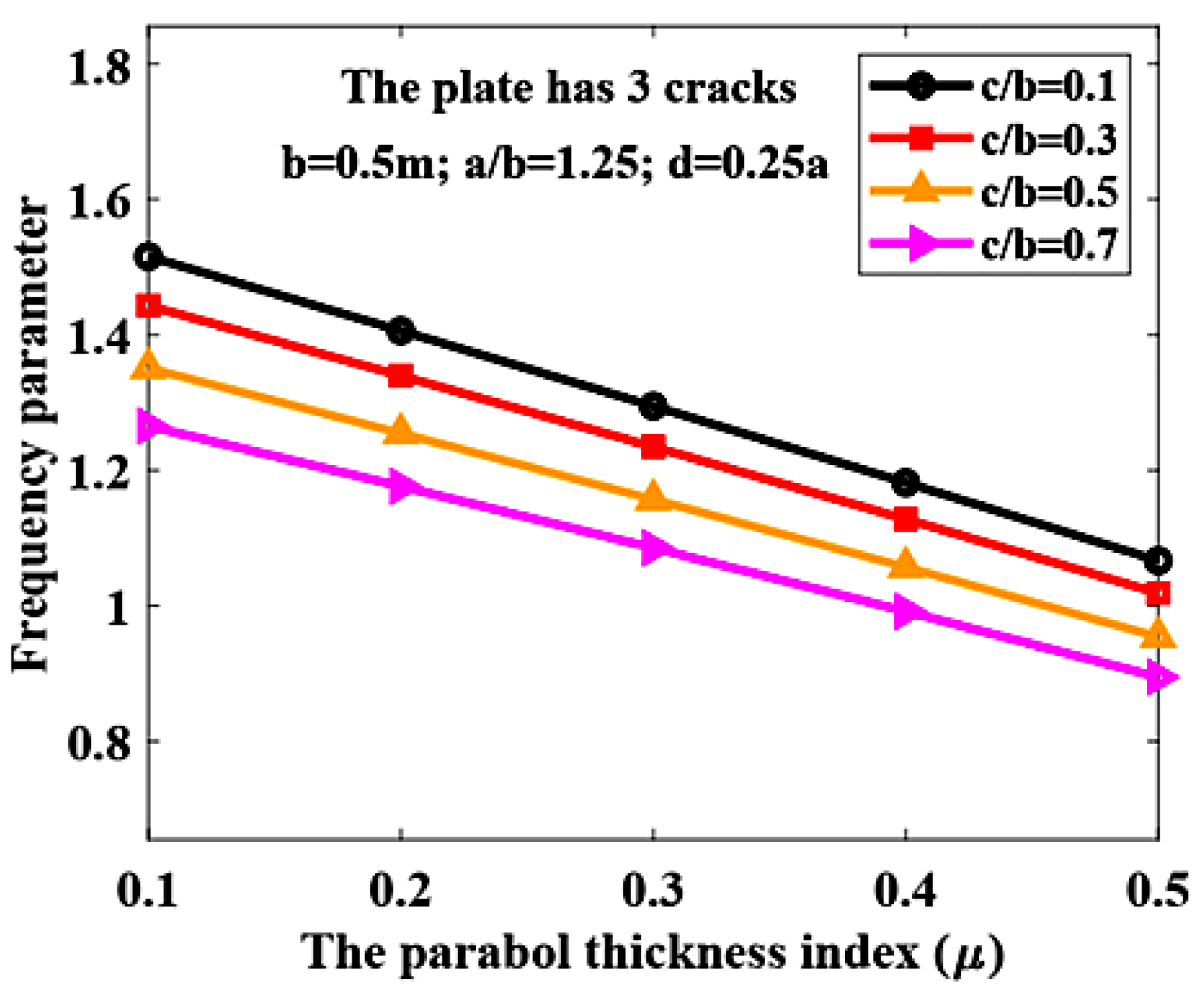

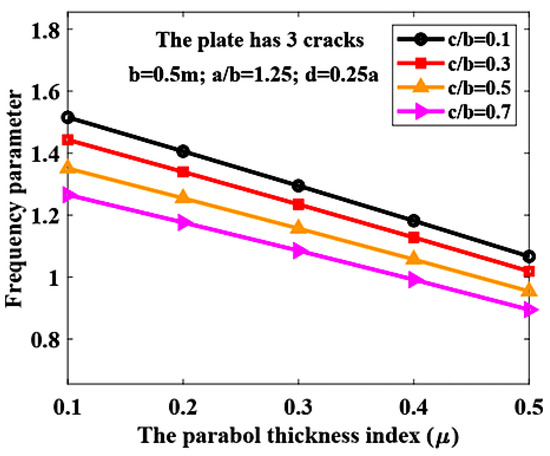

From 2019 to 2021, Minh et al. [159,160,161,162,163,164] conducted a series of studies on FGM plates with LVT and central cracks, investigating the effects of crack dimensions, material volume fraction exponents, and plate thickness on vibration frequencies. They used various shear deformation theories to analyze stability and vibrational parameters, considering factors like temperature, boundary conditions, and plate geometry. The study’s findings indicated that several factors contributed to reduced vibration frequency in plates. An increase in crack length, length-to-width ratio, and power-law index all led to decreased plate stiffness and vibration frequency. Additionally, plates with a higher ratio of initial to final thickness (h0/ha) exhibited a more significant reduction in vibration frequency. In 2020, Heo et al. [165] examined the free vibration of cracked plates of LVT, employing the peridynamics (PD) approach. They found that thicker plates had higher natural frequency values, while longer cracks led to lower frequencies. Interestingly, larger crack orientation resulted in higher frequencies, and plates with LVT showed mode shapes favouring their thinner ends. Chandrakar et al. (2021 and 2022) [87,166] studied the nonlinear vibrations of cracked isotropic and orthotropic plates with LVT and PVT. They observed that the nonlinearity of the plate increased with the increasing or decreasing value of the taper parameter. A plate with PVT was more nonlinear compared to LVT cases. Additionally, the presence of a crack further increased the nonlinearity of the plate. Le et al. (2023) [167] combined the FSDT and FE methods to study the vibrational properties of the RP with PVT and multi cracks. Their results showed that when a plate’s crack length increases or the number of cracks grows, its stiffness decreases, leading to a lower free vibration frequency. Similarly, an increase in the sheet thickness ratio or the plate length ratio, which makes the plate thinner, also resulted in a reduction in the vibration frequency, as shown in Figure 4.

Figure 4.

The correlation between the frequency parameter and the index of parabolic varying thickness (PVT) contains 3 cracks, where (c) crack length, (d) distance between cracks, and (a and b) plate length and width, respectively [167].

3.2. Inverse Problem for the DR of the Cracked Plate

Employing the DR measurements to identify the crack location and size is known as an inverse problem. The primary theory of vibration-based damage detection is based on the dependency of modal parameters on the physical properties of the structure under inspection. Damage-caused changes in the structure’s physical properties lead to clear changes in modal parameters (including natural frequencies, modal damping, and mode shapes). Research effectively substantiates the application of DR measurements for damage detection in plate structures; however, compared with the forward problem, there is much less research on the inverse problem.

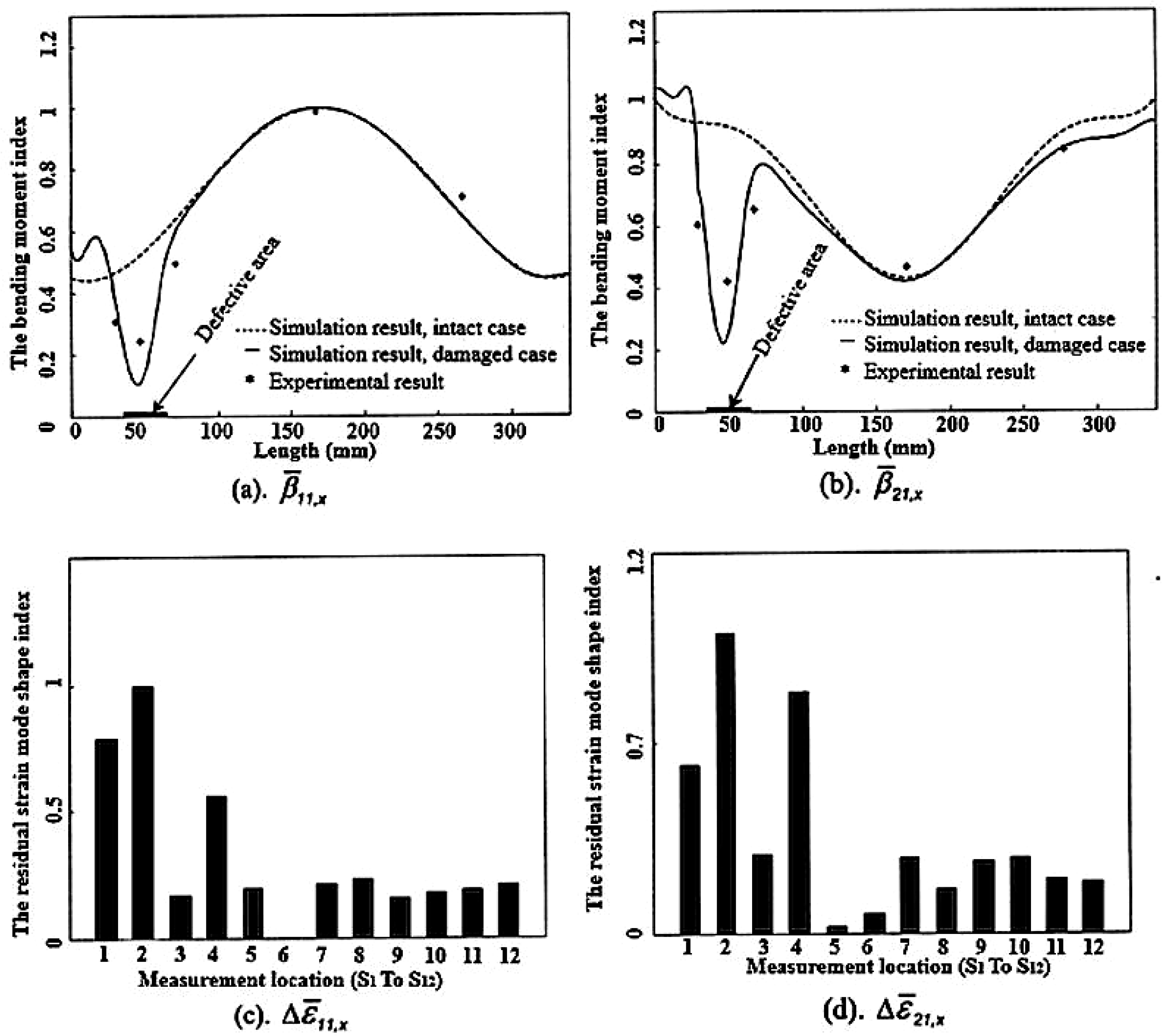

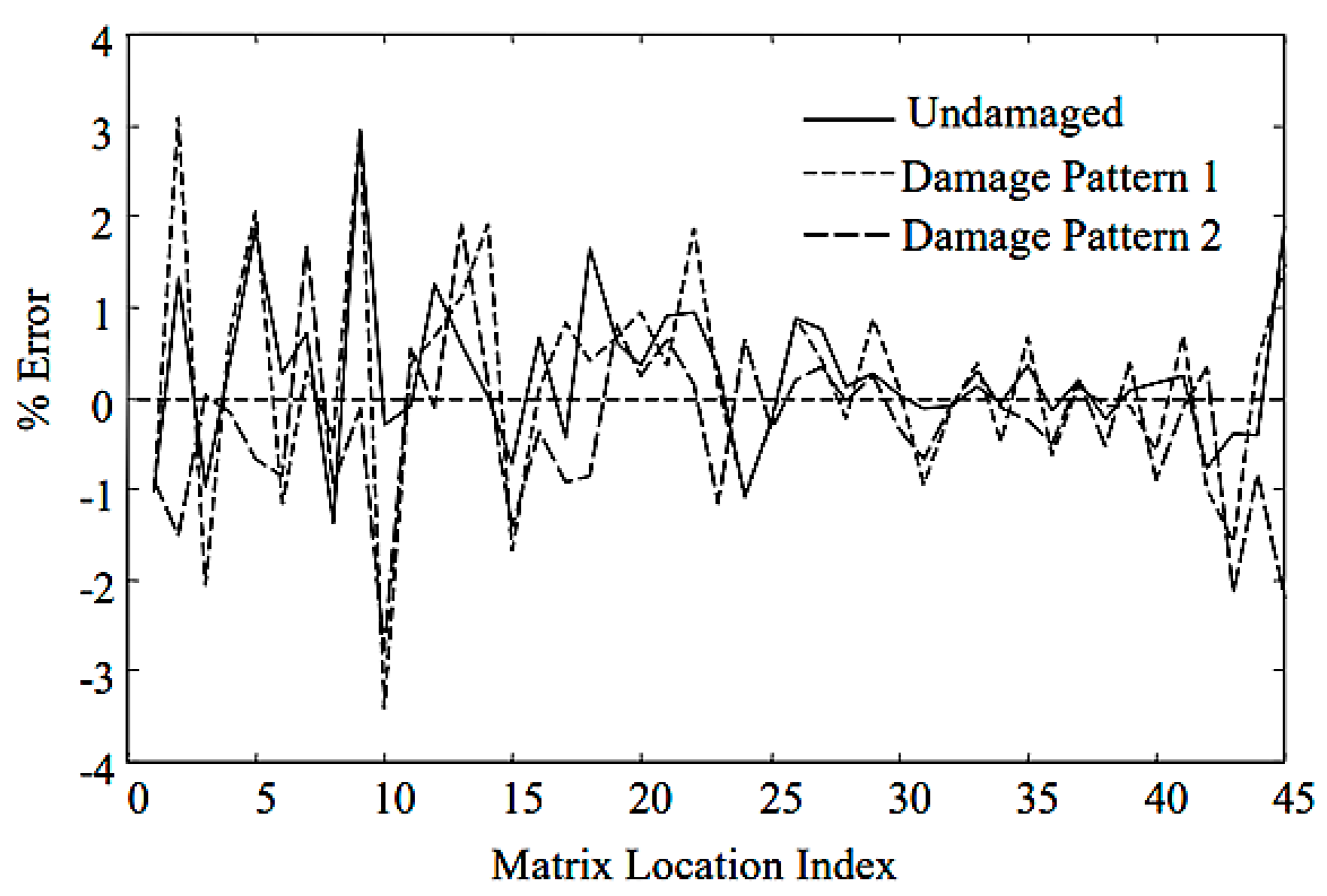

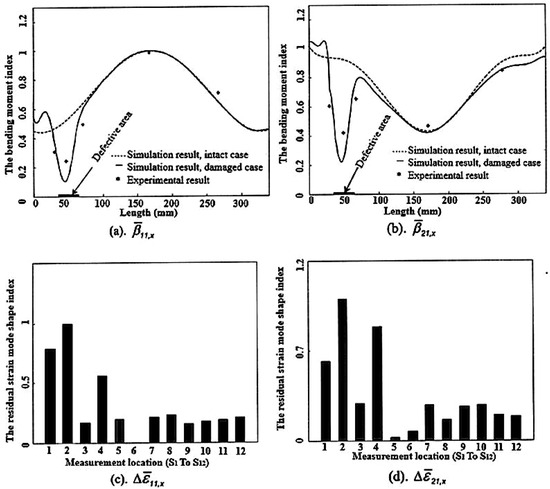

The study of this type of inverse problem began in 1978, when Adams et al. [168] introduced a methodology to identify damage in a one-dimensional structure by analyzing the changes in its longitudinal vibration frequencies. Lee et al. (1997, 2001, 2003) [169,170,171] developed a series of crack models and damage detection techniques for plate structures. Their initial crack model, introduced in 1997, used the strain energy equivalence principle (SEEP) to detect damage in elliptical through-cracks in 2D and 3D elastic solids [169]. In 2001, they developed a novel structural damage identification method for plate structures, utilizing frequency response functions (FRFs) as its foundation. This method, rooted in the principles of the dynamic equation of motion, employed a damage distribution function to effectively characterize the extent and location of damage within the structure [170]. In 2003, they developed a new damage identification theory for thin plates with line micro-cracks using the effective stiffness model and the FRF. However, this theory, limited to micro-cracked plates not close to boundaries, requires experimental validation, as it has only been demonstrated numerically [171]. Cornwell et al. (1999) [172] explored the effectiveness of strain energy-based methods for damage detection in plate-like structures through a comprehensive research program encompassing both experimental and numerical studies. These methods efficiently localized areas of reduced stiffness down to 10% accuracy with the use of limited modes. This technique only needed the comparison of the structure’s mode shapes pre- and post-damage. Li et al. (2002) [173] implemented the strain mode technique through numerical simulations and experiments to pinpoint damage locations in plate-like structures, utilizing an aluminum plate with free boundary conditions as their test subject. Their findings, detailed in Figure 5, revealed a consistent correlation between the simulation and experimental results. This was particularly evident in identifying areas of damage based on the bending moment index r,x. This index proved to be a reliable indicator for locating damage, as evidenced by the congruence of the major maximum of residual strain r,x at the damaged area and minor maxima near it.

Figure 5.

The bending moment index (r,x) results for (a) modes (1,1) and (b) mode (2,1), along with the residual strain mode shape index (r,x) results for (c) modes (1,1) and (d) mode (2,1) [173].

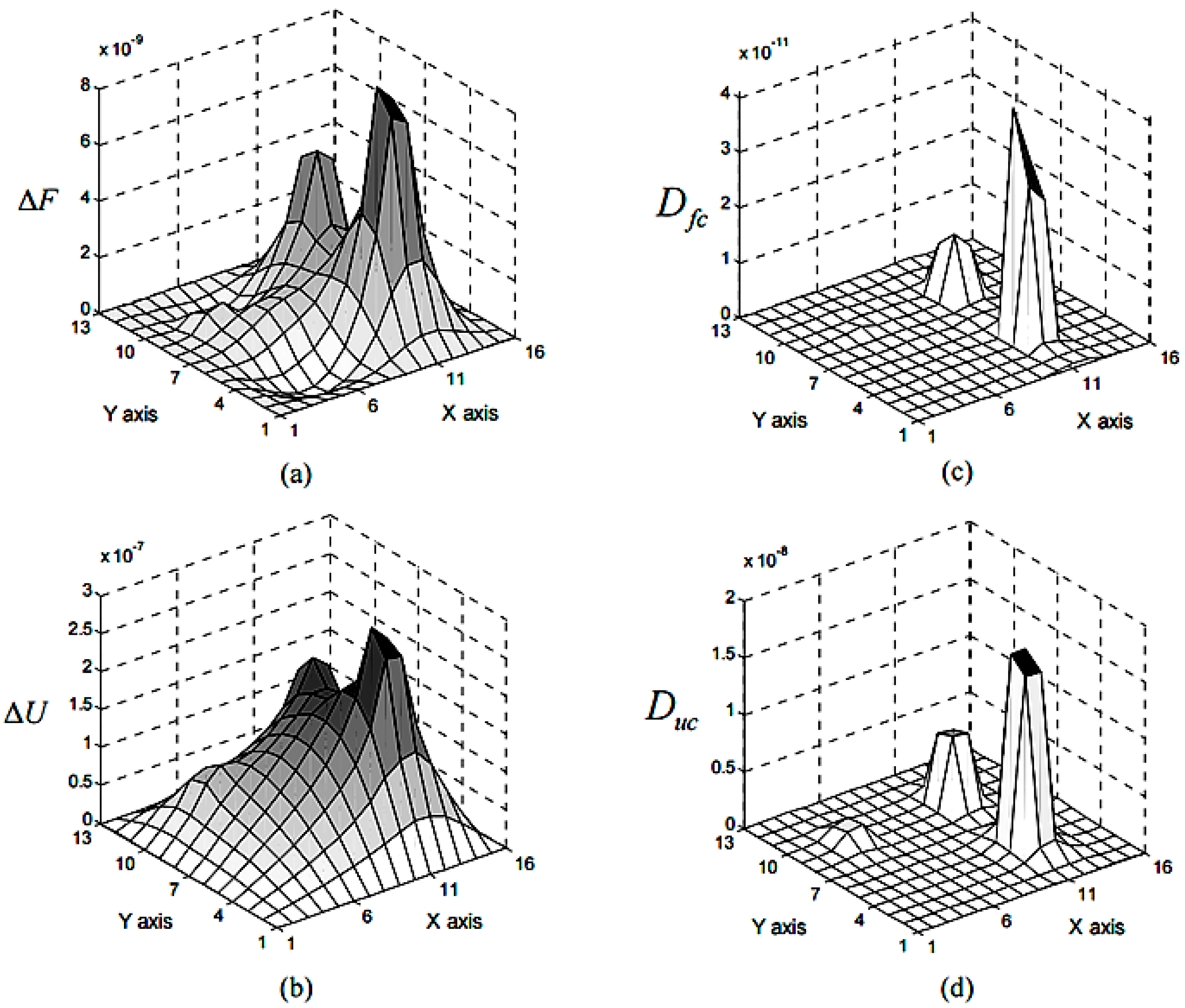

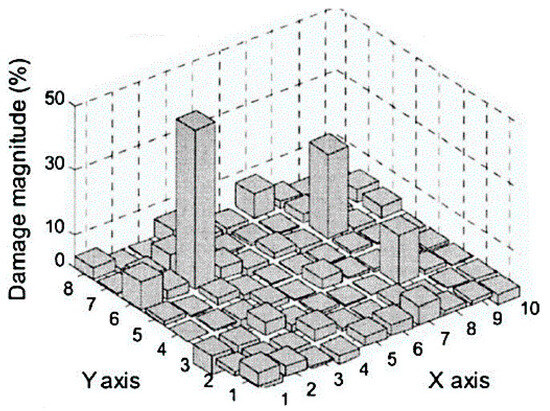

After that, Wu and Law (2004–2005) [174,175,176,177,178,179] made significant contributions to the field of damage identification in plate structures and developed various methods for locating and quantifying damage using vibration measurements. The authors conducted a comprehensive comparison of various damage localization techniques. Their findings revealed that uniform load surface (ULS) curvature surpassed other methods in terms of damage localization sensitivity, particularly under conditions of incomplete and noisy measurements, as demonstrated in Figure 6 [174]. Additionally, they proposed an anisotropic damage model to detect edge-parallel cracks in thin RP and compared their results with Lee’s 1997 [169] model [175]. Additionally, the researchers proposed a novel damage localization technique for two-dimensional plate structures, employing changes in ULS curvature as the primary indicator [176]. Additionally, they developed a new method for damage localization in two-dimensional plate structures based on changes in the ULS curvature [177]. Subsequently, they improved their previous study to identify the specific location and measure the severity of damage in two-dimensional plate structures using a sensitivity-based method with ULS curvature, effectively showing the damage location and magnitude, as seen in Figure 7 [178]. Their work was further extended by proposing a new anisotropic damage model for detecting cracks in plates with edge-parallel cracks [179]. Their work has been experimentally and numerically validated, and their methods have demonstrated their ability to identify a variety of damage types including cracks, delamination, and stiffness reductions.

Figure 6.

Comparison between different methods for locating damage based on changes in the modal flexibility: (a) index of flexibility change; (b) index of uniform load surface (ULS) change; (c) index of flexibility curvature; (d) index of ULS curvature [174].

Figure 7.

Damage magnitude percentage for the two-dimensional cracked plate [178].

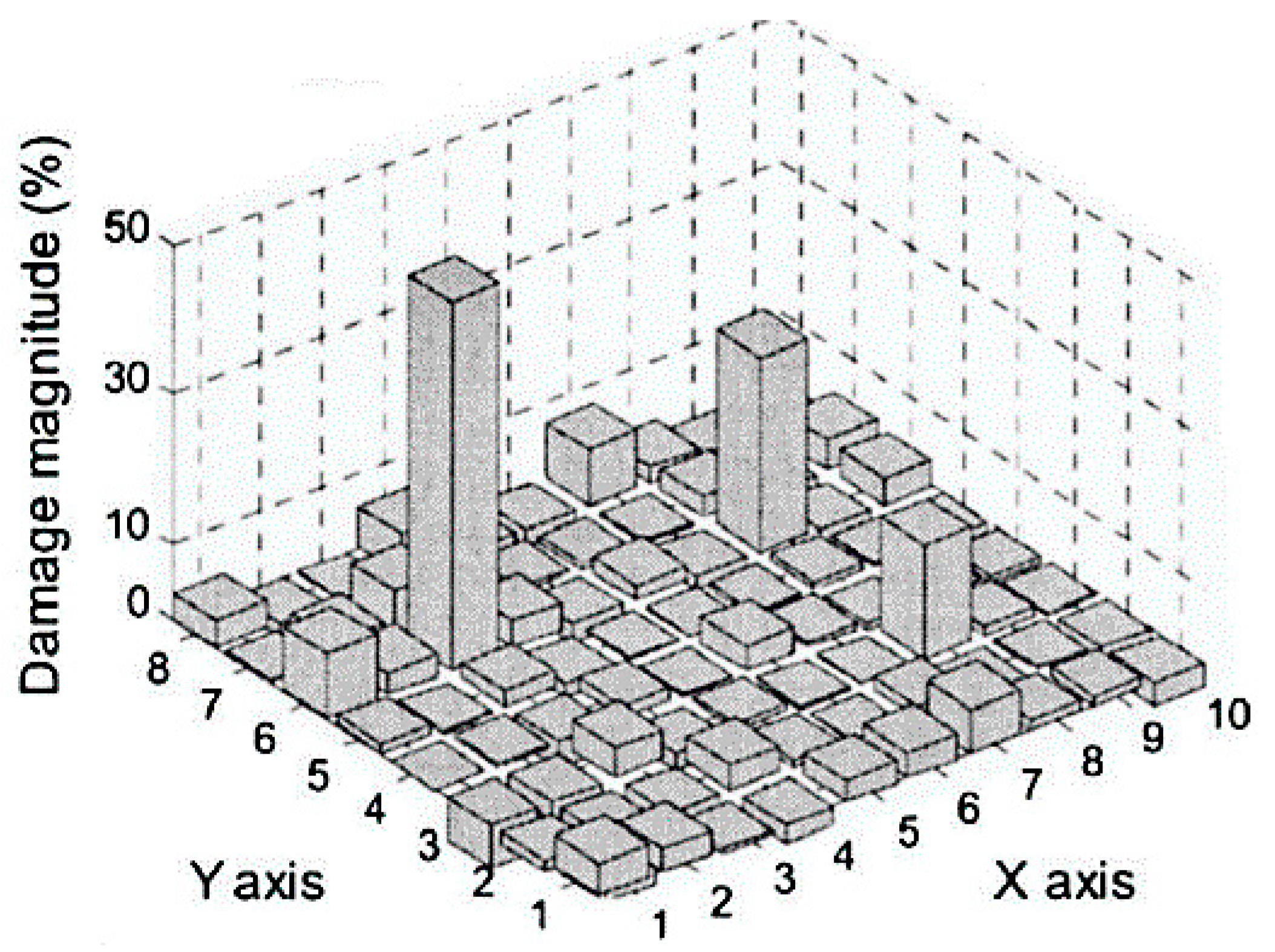

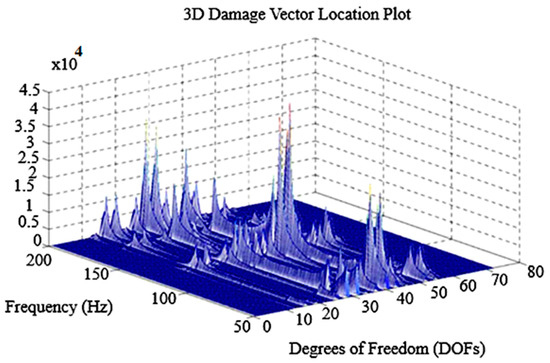

In 2004, Yam et al. [180] developed a strategy for detecting damage in structures using vibration analysis on a honeycomb sandwich plate and identified future research areas despite experimental errors. Subsequently, in 2005, Yam et al. examined damage in composite plates with internal cracks and delamination, using piezoelectric devices for measurements. This study found a relationship between damage characteristics and changes in modal parameters, with delamination locations identifiable through damping and strain energy changes [181]. The technique by Huynh et al. (2004) [182] used non-destructive vibration tests for damage identification in plate structures. By employing the FEM data of an intact structure and its FRF, they formulated a damage location vector (DLV). This DLV method effectively located and assessed the damage, even with noisy and incomplete data. Furthermore, in 2005 [183], the authors proposed another method for early-stage damage detection where there was no substantial change in mass or damping. The method related alterations in FRFs to shifts in the structural stiffness matrix, with the DLV evaluation showcasing this relationship. An experiment was conducted where element 11 was altered to mimic internal damage. Analysis of the FRF data via the DLV identified element 11 and its neighboring nodes as damaged, with the impact on neighboring nodes being significantly lesser and decreasing with distance from element 11, as shown in Figure 8.

Figure 8.

Damage detection in element 11 by the damage location vector method [183].

Moreover, Qiao and Lestari (2008) [184] developed a novel method that combined static/dynamic approaches to improve damage detection in composite plates. This technique, identifying changes in the DR due to damage, used two actuator-sensor systems to measure the DR and utilized both experimental and numerical mode shapes to detect delamination. The researchers successfully identified, located, and quantified the extent of delamination and the effect of static load on the DR. The researchers concluded that this method effectively enhanced damage detection by amplifying the damage’s impact. Ramos et al. (2010) [185] explored dynamic-based methods for damage identification in arched structures using ambient and random impact vibrations. They applied stochastic subspace identification (SSI), the mode shape curvature method (MSCM), and FEM updating to detect and assess structural damage. The study found that while some methods successfully identified damage, others struggled due to noise and sensitivity to geometric changes. They concluded that a combination of methods provided the most reliable results, emphasizing the need for robust techniques in early damage detection for historical structures. Trana (2010) [186] introduced a new technique for detecting cracks in different structures including metallic and reinforced concrete under real-world conditions. The study compared the DLV and Maia FRF curvature difference (MFCD) methods. While MFCD, working solely with FRF, was specialized for beams, the DLV offered a more comprehensive application but required a dynamic stiffness matrix. Xu et al. (2013) [187] presented a technique for detecting plate damage using two-dimensional Gaussian wavelets, laser-scanned deflection shapes, and focused on harmonic excitation-induced vibrations, with data collected via a scanning laser vibrometer.

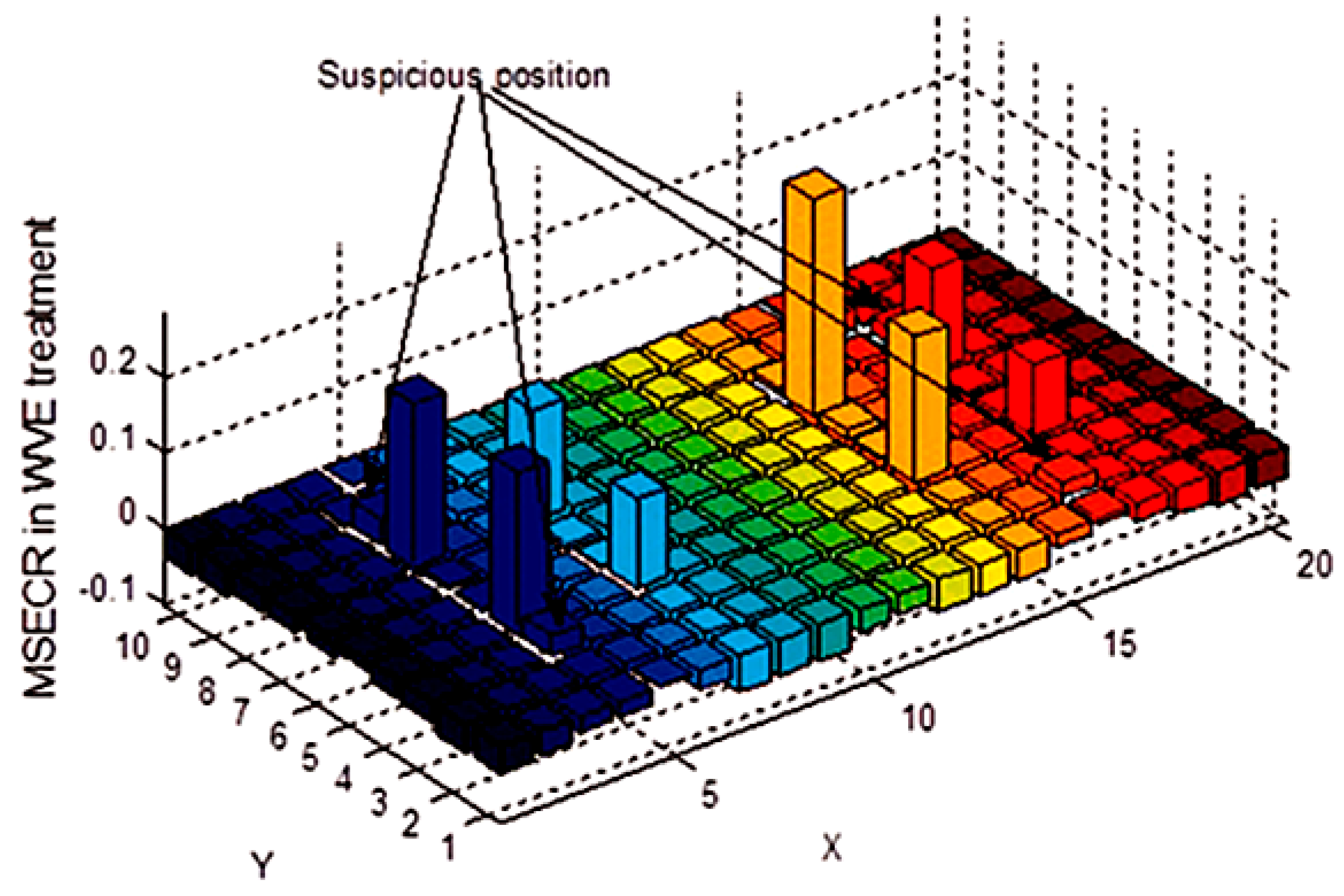

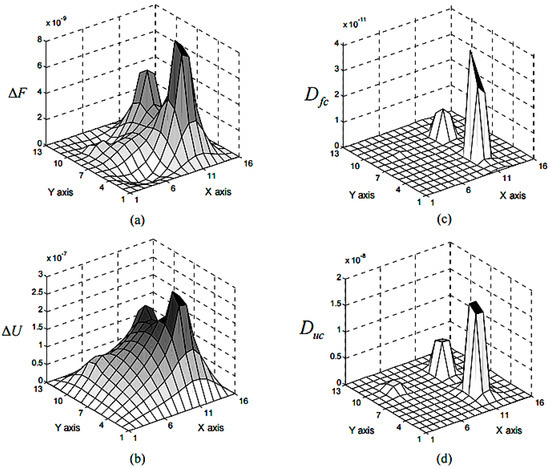

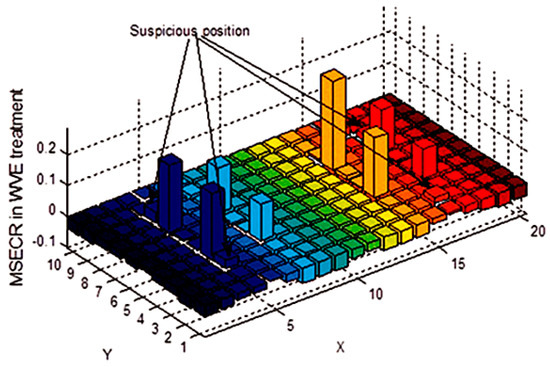

Furthermore, Fu et al. (2013) [188] introduced a novel damage detection technique for plate structures using dynamic response sensitivity-based finite element model updating (DRSBFEMU). While this method effectively identified local damage in plates from a small number of acceleration measurements, it became computationally expensive and less accurate in scenarios with large finite element discretization. To address this limitation, Fu et al. (2016) [189] proposed a two-stage damage identification method. The first stage utilizes the modal strain energy change ratio (MSECR) to identify potential damage locations, along with a method to minimize false alarms caused by the “vicinity effect”. These identified elements are then considered suspicious for further investigation. In the second stage, the DRSBFEMU method quantifies the extent of damage for these suspicious elements, reducing the number of unknowns and significantly decreasing the computational time. The effectiveness and efficiency of the proposed method were demonstrated using a cantilevered plate and a two-span continuous plate. The results confirm the method’s ability to identify damage in plates from a few acceleration measurements. However, as shown in Figure 9, noise interference can lead to false alarms in the damaged locations identified using the improved MSECR method.

Figure 9.

Enhanced modal strain energy change ratio (MSECR) method localization of multiple defects in a two-span plate with 2% noise [189].

Recently, Al-agamy et al. (2019) [190] explored damage detection in composite plates through a theoretical and experimental study using the DLV method. The FEM was employed for theoretical simulation of a damaged plate, followed by a shaker test on a centrally damaged plate under two different boundary conditions. The DLV method successfully identified intentionally damaged elements in the plate, with primary data peaks pinpointing the damage and secondary peaks showing affected neighboring nodes, though the impact on these was less significant. The study concluded that the DLV method could effectively locate damage. Huang et al. (2019) [191] investigated the geometric features of phase diagrams for cantilever beams with breathing cracks and proposed a novel method for crack identification based on these features. The study emphasized how the presence of a crack influenced the dynamics of the system, particularly under primary and super-harmonic resonance conditions. The authors introduced multiple identification indices, such as quasi-standard deviation and vertical segmentation methods, which are used to analyze changes in the phase diagram’s area due to variations in crack depth and location. Their findings suggest that phase diagrams, especially under super-harmonic resonance, are highly sensitive to crack parameters, making the proposed method both feasible and effective to accurately determine crack characteristics in engineering structures. Duvnjak et al. (2021) [192] successfully employed the mode shape damage index (MSDI) to detect discrete damage in plate-like structures. Experimental validation demonstrated the MSDI method’s capability to identify the presence of damage, pinpoint single or multiple damage locations, and assess damage severity in cases of single discrete damage. Finally, Table 4 summarizes significant research investigations related to damage identification in UT plates.

Table 4.

Summary of damage identification research in plates of uniform thickness (UT).

4. Discussion

This section offers an in-depth analysis of plate theories, with a focus on modeling cracks and thickness variation in governing equations of plates and exploring damage detection methods in plate structure. The discussion aims to methodically evaluate the benefits, constraints, and complexities inherent in these areas.

Plate theories provide a fundamental framework for understanding the behavior of thin plates under various loading conditions and boundary constraints. These theories are essential for designing safe and efficient plate structures in a wide range of engineering applications. However, these theories have both advantages and disadvantages that need to be carefully considered when selecting the most appropriate theory for a specific application. Classical plate theories, such as the Euler–Bernoulli, Lagrange, Navier, and Kirchhoff theories, provide valuable tools for analyzing thin plates under static loading, but they have limitations. These theories cannot accurately predict the behavior of thick plates, plates with large deflections, or plates made of nonlinear or anisotropic materials. Additionally, they are not suitable for analyzing plates subjected to shear loads, dynamic loads, or three-dimensional effects. Additionally, the Rayleigh plate theory further restricts its applicability to thin plates with small deflections and linear elastic, homogeneous, and isotropic materials. To address these limitations, more sophisticated plate theories have been developed. The MR plate theory relaxes the assumption of negligible shear strains, allowing for the modeling of transverse shear deformation and stresses. This theory provides more accurate predictions for thick plates or plates with high aspect ratios. However, its ability to handle nonlinear materials or dynamic loads is still limited. For even more complex behaviors, such as three-dimensional effects and nonlinear material properties, HSDT incorporates additional terms in the governing equations. These theories provide the most accurate predictions but are computationally more demanding and may not be necessary for all applications. Generally, the selection of plate theory depends on the specific characteristics of the plate, the loading conditions, and the required level of accuracy. Classical plate theories are suitable for simple plate geometries and moderate loading conditions. For more complex problems or situations where high accuracy is required, more advanced plate theories, such as the MR or HSDT, should be used.

The governing equations differ for damaged and undamaged plates in accounting for the presence of damage. In an undamaged plate, the material properties are assumed to be uniform throughout the plate. This means that the governing equations can be expressed in a relatively simple form. However, in a damaged plate, the material properties are no longer uniform. This is because the damage has caused a change in the stiffness, mass, and damping properties of the plate. As a result, the governing equations for a damaged plate must be more complex in order to account for these changes. Modeling the behavior of damaged plates requires modifying the governing equations to account for the changes in material properties caused by the damage. Two main approaches exist, explicit damage modeling, which directly incorporates the damage characteristics into the equations [207,208,209,210,211], and implicit damage modeling, which utilizes a damage parameter to represent the overall impact on the plate’s behavior [212,213,214,215]. The selection of the approach depends on the damage complexity and desired accuracy. Explicit modeling is suitable for simple damage types, while implicit modeling is more appropriate for complex damage scenarios. Generally, governing equations for damaged plates are more intricate and computationally demanding due to the introduction of additional unknowns, necessitating the use of numerical methods for solutions. Moreover, the governing equations for plates of UT are relatively simple and can be derived using classical plate theories, while those for plates of VT are more complex and require additional considerations. This is primarily due to the presence of thickness variation in VT plates, which leads to more intricate behavior and necessitates the incorporation of a thickness function into the governing equations. The analysis of VT plates is consequently more challenging than that of UT plates.

The forward problem shows that an increase in crack length, size, depth, and angle typically leads to a decrease in the natural frequencies, a common observation in vibration characteristics. The growth or reorientation of a crack reduces the plate’s overall stiffness, which in turn lowers the natural frequencies, causing the plate to vibrate at slower speeds for the same mode shapes. Moreover, the presence of cracks can alter the modal shapes, introducing localized flexibility and leading to more significant vibrations in certain areas, resulting in distortions or asymmetries compared to an uncracked plate. The location of a crack also significantly affects the vibration characteristics. Internal cracks, for example, have a more pronounced impact on natural frequencies than surface cracks. Because the internal cracks cut deeper into the plate, effectively removing material and reducing its overall stiffness, this drop in stiffness significantly lowers the natural frequencies, as the plate vibrates slower with less rigidity. Additionally, the shape of the plate influences its frequencies, which is a complex interplay of various factors. For instance, the CP under SSSS and CCCC boundary conditions with UT generally exhibited the lowest frequency compared to other shapes [216]. Plates with higher aspect ratios also tend to have higher fundamental frequencies due to their reduced bending capacity. The boundary conditions and material properties of the cracked plate are crucial in determining the vibrational characteristics, with different boundary conditions and materials significantly affecting the natural frequencies. Finally, the type of excitation condition can significantly influence the frequency response of a vibrating system. The nature of vibration affects the plate’s frequency response by determining which natural frequencies are excited and to what extent based on the frequency content, duration, and damping of the excitation.

In the field of inverse damage detection, numerous DR techniques have been utilized. Each of these techniques comes with its own set of advantages and disadvantages. For instance, vibration-based monitoring is a promising technique for structural damage detection due to its ability to identify damage by analyzing changes in the dynamic properties of a structure [217]. These dynamic properties, such as natural frequencies, mode shapes, and damping ratios, are sensitive to changes in stiffness caused by structural damage. Various methods have been developed to detect damage based on these properties including methods based on changes in natural frequencies [218], mode shapes [219,220], and their derivatives [221,222,223,224,225,226]. Additionally, non-modal methods, such as the FRF method [227] and guided waves approach [228], can also be used for damage detection but often require additional algorithms to enhance their effectiveness. Furthermore, the DRSBFEMU method has shown promise in real-world applications [188]. This was compared to methods used in [229,230,231] and found to be more accurate in identifying simulated damage in a plate. The DRSBFEMU method was particularly close to the true values in its identification results and is a promising tool for practical damage identification applications. However, it is important to note that none of these methods can predict the exact crack size.

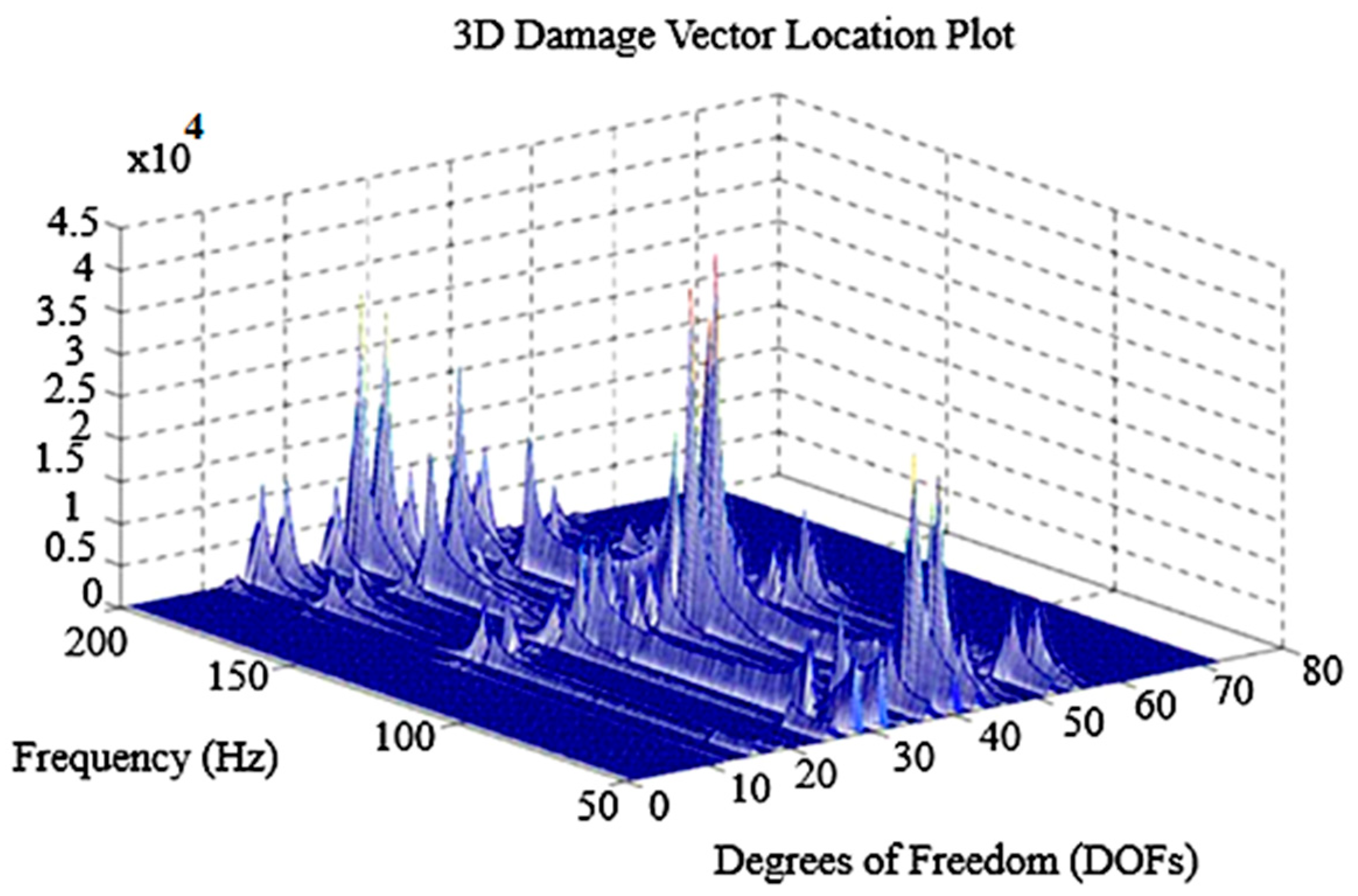

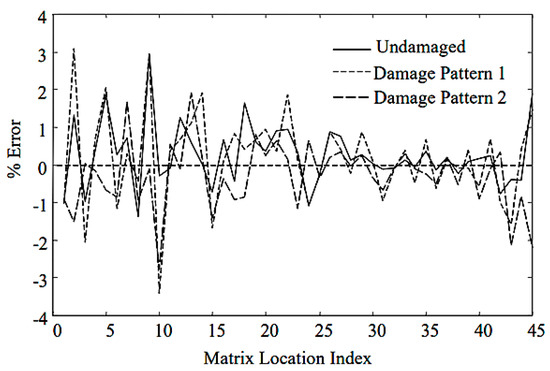

The DLV method is a valuable tool for the SHM and has been widely used in various research projects [190,232,233,234]. It can successfully detect damage using only a limited number of sensors and truncated modes [235]. However, the method has some limitations [235,236,237]. First, it is sensitive to noise in the measured data. This is because the method relies on the difference in flexibility between a damaged structure and an undamaged structure. If the measured data are noisy, the difference in flexibility may be difficult to distinguish, as shown in Bernal’s research, where the DLV error was around 1.5%, as shown in Figure 10 [237]. Second, the scalar proves to be inconsequential for localization purposes and is only of secondary importance in quantification, as reductions in stiffness can be calculated in percentages without reference to specific values. Moreover, the method is not always able to accurately identify the location and extent of damage. This is because it is based on the assumption that damaged elements are completely stiff. In reality, damaged elements may still have some stiffness, making it difficult to identify them using the DLV method. Finally, the method can be computationally expensive. This is because it requires the calculation of the flexibility matrix of the structure. The flexibility matrix is a large matrix, and its calculation can be time-consuming.

Figure 10.

Damage location vector (DLV) method error [237].

The phase diagram-based method offers several advantages including its high sensitivity to nonlinear dynamic behaviors, which are often more indicative of cracks than linear parameters [238,239,240,241]. This method allows for the detailed analysis of crack characteristics such as location and depth. by using various indices like quasi-standard deviation and vertical segmentation to provide quantitative insights. It is effective under both primary and super-harmonic resonance conditions, with the latter being particularly sensitive to crack parameters [191]. Additionally, the method holds the potential for real-time monitoring, enabling continuous crack detection without interrupting the operation of the structure. However, the method has limitations including the complexity of nonlinear dynamics, which can be challenging to implement and interpret, and its sensitivity to noise and measurement errors, which may affect accuracy [242,243]. The method also relies on achieving specific resonance conditions, which can be difficult in practical applications, and it is currently more suited to simpler structures like cantilever beams. Furthermore, it depends on accurate knowledge of the system’s dynamic parameters and crack characteristics, which might not always be readily available [244,245,246].

Artificial neural networks (ANN) are a powerful tool in structural health monitoring, particularly for detecting cracks and other forms of damage in composite structures, due to their ability to model complex nonlinear relationships between input data such as vibration signals, and output predictions including the presence, location, and severity of cracks [247,248,249]. One of the significant advantages of ANN is its capacity to handle the nonlinear relationships inherent in the data, which is particularly relevant in complex materials like composites where crack severity often exhibits nonlinear patterns [250,251]. Moreover, ANN models are robust against noise, making them effective even with noisy input data, a common scenario in real-world applications [251]. Once trained on a sufficiently diverse dataset, ANN can generalize well, enabling it to detect cracks in previously unseen structures, thus offering versatility across various applications [251]. However, challenges remain such as the need for large datasets to train the models effectively, which can be costly and time-consuming to acquire, and the difficulty in understanding the internal decision-making process of ANNs, which poses challenges in critical applications where transparency and interpretability are crucial [250].

Detecting damage in plates with VT using their DR presents several challenges. The DR of a plate with VT is more complex than that of a UT because the propagation of waves, such as stress waves or vibration waves, is influenced by the changing thickness, leading to variations in wave speed, attenuation, and mode conversion. These complexities make it challenging to interpret the DR signals and accurately identify the location and severity of damage. Additionally, the DR of a plate including its natural frequencies and mode shapes is significantly affected by thickness variations. This can lead to ambiguities in interpreting the DR, making it difficult to distinguish between damage-induced changes and inherent variations due to thickness variations. Moreover, the material properties of the plate of VT, such as its density, stiffness, and damping, along with its geometric features, such as curvature, holes, and other irregularities, can further complicate the DR and make damage detection more challenging. Furthermore, in some cases, damage in plates can lead to nonlinear behavior in the DR, making it difficult to model and analyze the system using conventional linear methods. In addition, environmental factors, such as temperature fluctuations and external noise, can also influence the DR of the plate, adding additional challenges to damage detection. Similarly, the DR signals obtained from damaged plates may be contaminated by noise from various sources such as background vibrations or measurement errors. Effective noise reduction techniques are crucial for accurate damage detection. Finally, analyzing the DR of plates with varying thicknesses can be computationally demanding, especially for complex geometries or high-frequency excitations. This can limit the real-time applicability of damage detection methods based on the DR. Despite these challenges, DR-based damage detection methods have been actively researched and developed, and they continue to show promise in various applications. However, research must aim to improve the accuracy, robustness, and applicability of these methods by addressing the challenges above-mentioned.

5. Conclusions

In conclusion, this comprehensive review has focused on research efforts related to the fundamentals of vibration and damage detection in plate structures using DR analysis, especially for the challenge of crack location and path identification. It has been established that damage can indeed be detected through vibration tests because the existence of cracks in structural elements results in the introduction of local flexibility, which modifies the vibration responses of the members. However, several research gaps and promising directions for future investigation have been identified:

- Most research on damage detection in plates has focused on the forward problem, which is to study how crack damage affects the DR of plates. This work has provided valuable insights and developed various models for different structures. However, there is a need to apply these models to the inverse problem, which is to detect damage from vibration measurements.

- Additionally, most research on the inverse problem has focused on plates with the UT, even though plates with VT are important in many applications. This oversight needs to be addressed to comprehensively address the challenges of damage detection in the VT plates.

- Moreover, many studies on the inverse problem have not been able to accurately identify crack parameters such as size, length, and propagation rate. They often only pinpoint the damage location in plates with UT based on changes in vibration responses. Future research should focus on improving the accuracy of these parameters.

- Finally, crack path identification, a critical area of research for beam structures, has yet to be studied in plate structures. This important gap in the literature needs to be addressed.

In summary, there is a need for more research on damage detection in VT plates and crack path identification. This research is important to improve the efficiency and cost-effectiveness of structural inspections in engineering applications.

Author Contributions

Conceptualization, Y.L.A.A., F.H. and M.K.; Methodology, Y.L.A.A., F.H. and M.K.; Formal analysis, Y.L.A.A.; Investigation, Y.L.A.A.; Resources, Y.L.A.A.; Data curation, Y.L.A.A.; Writing—original draft preparation, Y.L.A.A.; Writing—review and editing, Y.L.A.A., F.H., A.A.A., and M.K.; Visualization, Y.L.A.A.; Supervision, M.K. and F.H.; Project administration, Y.L.A.A.; Funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at Northern Border University, Arar, Saudi Arabia.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| A and B | A and B are constants |

| SSSS | All edges simply supported |

| ∇4 | Biharmonic operator |

| CP | Circular plates |

| CS | clamped supported |

| Coefficients at the center of crack | |

| Compliance of stretching-bending | |

| DLV | Damage location vector |

| ρ | Density |

| q | Distributed transverse loading |

| DR | Dynamic response |

| B(x,y) | Effective torsional rigidity |

| FE | Finite element |

| D | Flexural rigidity |

| DRSBFEMU | Dynamic response sensitivity-based finite element model updating |

| FD | Fractal dimension |

| FRF | Frequency response function |

| FGM | Functionally graded material |

| FSDT | First-order shear deformation theory |

| a | Half-crack length |

| HSDT | higher-order shear deformation theory |

| nx | In-plane or membrane force per unit length |

| LSM | Line spring model |

| LVT | Linear varying thickness |

| Pz | Load acting at the surface per unit area |

| MR | Mindlin–Reissner |

| E | Modulus of elasticity |

| Moment | |

| NDT | Non-destructive testing |

| Nondimensional bending compliance | |

| PVT | Parabolically varying thickness |

| υ | Poisson’s ratio |

| RP | Rectangular plates |

| RRM | Rayleigh–Ritz method |

| SPT | Signal processing technique |

| SS | Simply supported |

| SP | Squire plate |

| Stretching compliance | |

| SHM | Structural health monitoring |

| h | Thickness |

| 3D | Three dimensions |

| Dt | Torsional rigidity |

| w | Transverse deflection |

| CCFF | Two edges clamped and two free supported |

| CCSS | Two edges clamped and two simply supported |

| 2D | Two dimensions |

| ULS | Uniform load surface |

| UT | Uniform thickness |

| VT | Varying thickness |

| WT | Wavelet transformation |

References

- Dai, H.H.; Song, Z. On a Consistent Finite-Strain Plate Theory Based on Three-Dimensional Energy Principle. Proc. R. Soc. A Math. Phys. Eng. Sci. 2014, 470, 20140494. [Google Scholar] [CrossRef]

- Sanders Robert, E.; Marshall, G.J. Chapter 14. Aluminum in Marine Transportation. In Aluminium-Technology, Industry, and Applications; ASM International: Materials Park, OH, USA, 2023. [Google Scholar]

- Sanders Robert, E.; Marshall, G.J. Chapter 13. Aluminum in Ground Transportation. In Aluminium-Technology, Industry, and Applications; ASM International: Materials Park, OH, USA, 2023. [Google Scholar]

- Sanders Robert, E.; Marshall, G.J. Chapter 11. Aluminum in Aircraft and Space Applications. In Aluminium-Technology, Industry, and Applications; ASM International: Materials Park, OH, USA, 2023. [Google Scholar]

- Zhang, Y.; Du, J. Dynamic Analysis of Two Parallel Rectangular Plates Coupled with Mechanical Links. Int. J. Struct. Stab. Dyn. 2021, 21, 2150157. [Google Scholar] [CrossRef]

- Lu, C. 7.2.1 Damaged Plate. In Damage and Repair of Aerospace Composite Materials; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Israr, A.; Cartmell, M.P.; Manoach, E.; Trendafilova, I.; Ostachowicz, W.; Krawczuk, M.; Zak, A. Analytical Modeling and Vibration Analysis of Partially Cracked Rectangular Plates with Different Boundary Conditions and Loading. J. Appl. Mech. Trans. ASME 2009, 76, 011005. [Google Scholar] [CrossRef]

- Obenchain, M.B.; Nadella, K.S.; Cesnik, C.E.S. Hybrid Global Matrix/Local Interaction Simulation Approach for Wave Propagation Simulation in Composite Laminates. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 2013. [Google Scholar]

- Goetz, J.; Tan, H.; Tovvar, A.; Renaud, J. Multi-Material Structural Topology Optimization for Blast Mitigation Using Hybrid Cellular Automata. In Proceedings of the 51st AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Orlando, FL, USA, 12–15 April 2010; American Institute of Aeronautics and Astronautics (AIAA): Reston, VA, USA, 2010. [Google Scholar]

- Israr, A. Vibration Analysis of Cracked Aluminium Plates; University of Glasgow: Glasgow, UK, 2008. [Google Scholar]

- Dimarogonas, A.D. Vibration of Cracked Structures: A State of the Art Review. Eng. Fract. Mech. 1996, 55, 831–857. [Google Scholar] [CrossRef]

- Qiu, Z.; Wu, H.; Ye, C. Acceleration Sensors Based Modal Identification and Active Vibration Control of Flexible Smart Cantilever Plate. Aerosp. Sci. Technol. 2009, 13, 277–290. [Google Scholar] [CrossRef]

- Khan, S.Z.; Khan, T.M.; Joya, Y.F.; Khan, M.A.; Ahmed, S.; Shah, A. Assessment of Material Properties of AISI 316L Stainless Steel Using Non-Destructive Testing. Nondestruct. Test. Eval. 2016, 31, 360–370. [Google Scholar] [CrossRef]

- Chen, Z.; Gui, H.; Liao, X.; Du, M. Dynamic Response Analysis of a Bulk Carrier by Nonlinear Hydroelastic Method. J. Mar. Sci. Eng. 2021, 9, 877. [Google Scholar] [CrossRef]

- Hairer, M.; Majda, A.J. A Simple Framework to Justify Linear Response Theory. Nonlinearity 2010, 23, 909–922. [Google Scholar] [CrossRef]

- Spann, F. A Procedure for Comparing Dynamic Test Severities Based on Equipment Response Characteristics. J. IEST 1988, 31, 62–66. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, X.; Geng, Y.; Zhang, X. Effect of Clogging on the Permeability of Porous Asphalt Pavement. Adv. Mater. Sci. Eng. 2020, 2020, 4851291. [Google Scholar] [CrossRef]

- He, X.; Fulton, R.E. Nonlinear Dynamics Analysis of a Laminated Printed Wiring Board. J. Electron. Packag. 2002, 124, 77–84. [Google Scholar] [CrossRef]

- Zai, B.A.; Khan, M.; Khan, K.A.; Mansoor, A.; Shah, A.; Shahzad, M. The Role of Dynamic Response Parameters in Damage Prediction. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4620–4636. [Google Scholar] [CrossRef]

- Limongelli, M.P.; Manoach, E.; Quqa, S.; Giordano, P.F.; Bhowmik, B.; Pakrashi, V.; Cigada, A. Vibration Response-Based Damage Detection. In Structural Health Monitoring Damage Detection Systems for Aerospace; Springer: Cham, Switzerland, 2021; pp. 133–173. [Google Scholar]

- Fan, W.; Qiao, P. Vibration-Based Damage Identification Methods: A Review and Comparative Study. Struct. Health Monit. 2011, 10, 83–111. [Google Scholar] [CrossRef]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Gabbouj, M.; Inman, D.J. A Review of Vibration-Based Damage Detection in Civil Structures: From Traditional Methods to Machine Learning and Deep Learning Applications. Mech. Syst. Signal Process. 2021, 147, 107077. [Google Scholar] [CrossRef]

- Zai, B.A.; Khan, M.A.; Khan, S.Z.; Asif, M.; Khan, K.A.; Saquib, A.N.; Mansoor, A.; Shahzad, M.; Mujtaba, A. Prediction of Crack Depth and Fatigue Life of an Acrylonitrile Butadiene Styrene Cantilever Beam Using Dynamic Response. J. Test. Eval. 2020, 48, 20180674. [Google Scholar] [CrossRef]

- Alotaibi, M.; Honarvar Shakibaei Asli, B.; Khan, M. Non-Invasive Inspections: A Review on Methods and Tools. Sensors 2021, 21, 8474. [Google Scholar] [CrossRef]

- Zai, B.A.; Khan, M.A.; Khan, K.A.; Mansoor, A. A Novel Approach for Damage Quantification Using the Dynamic Response of a Metallic Beam under Thermo-Mechanical Loads. J. Sound Vib. 2020, 469, 115134. [Google Scholar] [CrossRef]

- Alshammari, Y.L.A.; He, F.; Khan, M.A. Modelling and Investigation of Crack Growth for 3D-Printed Acrylonitrile Butadiene Styrene (ABS) with Various Printing Parameters and Ambient Temperatures. Polymers 2021, 13, 3737. [Google Scholar] [CrossRef]

- Gupta, A.; Jain, N.K.; Salhotra, R.; Joshi, P.V. Effect of Crack Location on Vibration Analysis of Partially Cracked Isotropic and FGM Micro-Plate with Non-Uniform Thickness: An Analytical Approach. Int. J. Mech. Sci. 2018, 145, 410–429. [Google Scholar] [CrossRef]

- Francese, A.; Khan, M.; He, F. Role of Dynamic Response in Inclined Transverse Crack Inspection for 3D-Printed Polymeric Beam with Metal Stiffener. Materials 2023, 16, 3095. [Google Scholar] [CrossRef]

- Yang, Z.; He, F.; Khan, M. An Empirical Torsional Spring Model for the Inclined Crack in a 3D-Printed Acrylonitrile Butadiene Styrene (ABS) Cantilever Beam. Polymers 2023, 15, 496. [Google Scholar] [CrossRef] [PubMed]

- Aravanis, T.-C.I.; Sakellariou, J.S.; Fassois, S.D. Damage Precise Localization under Varying Operating Conditions via the Vibration-Data-Based Functional Model Method: Formulation and Experimental Validation. J. Sound Vib. 2022, 535, 117078. [Google Scholar] [CrossRef]

- Zhang, Y.; Bernal, D. Damage Localization from Projections of Free Vibration Signals. J. Sound Vib. 2017, 394, 146–154. [Google Scholar] [CrossRef]

- Xu, W.; Zhu, W.; Cao, M.; Wu, H.; Zhu, R. A Novel Damage Index for Damage Detection and Localization of Plate-Type Structures Using Twist Derivatives of Laser-Measured Mode Shapes. J. Sound Vib. 2020, 481, 115448. [Google Scholar] [CrossRef]

- Tondreau, G.; Deraemaeker, A. Automated Data-Based Damage Localization under Ambient Vibration Using Local Modal Filters and Dynamic Strain Measurements: Experimental Applications. J. Sound Vib. 2014, 333, 7364–7385. [Google Scholar] [CrossRef][Green Version]

- Haywood-Alexander, M.; Dervilis, N.; Worden, K.; Dobie, G.; Rogers, T.J. Informative Bayesian Tools for Damage Localisation by Decomposition of Lamb Wave Signals. J. Sound Vib. 2022, 535, 117063. [Google Scholar] [CrossRef]

- Manoach, E.; Trendafilova, I. Large Amplitude Vibrations and Damage Detection of Rectangular Plates. J. Sound Vib. 2008, 315, 591–606. [Google Scholar] [CrossRef]

- Timoshenko, S. History of Strength of Materials: With a Brief Account of the History of Theory of Elasticity and Theory of Structures; Dover Publications: Mineola, NY, USA, 1983; ISBN 0486611876. [Google Scholar]

- Szilard, R. Theories and Applications of Plate Analysis: Classical, Numerical and Engineering Methods; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Rayleigh, J.W.S.B. The Theory of Sound; Cambridge University Press: Cambridge, UK, 1877; ISBN 9781108032209. Available online: https://books.google.co.uk/books/about/The_Theory_of_Sound.html?id=v4NSAlsTwnQC&redir_esc=y (accessed on 1 September 2024).

- Rayleigh, J.W.S.B. The Theory of Sound; Dover Publications, Inc.: New York, NY, USA, 1945; Volume 2, Available online: https://books.google.co.uk/books/about/The_Theory_of_Sound.html?id=Frvgu1wSFfUC&redir_esc=y (accessed on 1 September 2024).

- Timoshenko, S.P. On the Correction for Shear of the Differential Equation for Transverse Vibrations of Prismatic Bars. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1921, 41, 744–746. [Google Scholar] [CrossRef]

- Tomotika, S. The Transverse Vibration of a Square Plate Clamped at Four Edges. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1936, 21, 745–760. [Google Scholar] [CrossRef]

- Young, D. Vibration of Rectangular Plates by the Ritz Method. J. Appl. Mech. 1950, 17, 448–453. [Google Scholar] [CrossRef]

- Warburton, G.B. The Vibration of Rectangular Plates. Proc. Inst. Mech. Eng. 1954, 168, 371–384. [Google Scholar] [CrossRef]

- Reissner, E. The Effect of Transverse Shear Deformation on the Bending of Elastic Plates. J. Appl. Mech. 1945, 12, A69–A77. [Google Scholar] [CrossRef]

- Mindlin, R.D. Influence of Rotatory Inertia and Shear on Flexural Motions of Isotropic, Elastic Plates. J. Appl. Mech. 1951, 18, 31–38. [Google Scholar] [CrossRef]

- Chen, H.; Kumar, A.V. Implicit Boundary Approach for Reissner-Mindlin Plates. In Proceedings of the Volume 2A: 33rd Computers and Information in Engineering Conference, Portland, OR, USA, 4–7 August 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013. [Google Scholar]

- Lo, K.H.; Christensen, R.M.; Wu, E.M. A High-Order Theory of Plate Deformation—Part 1: Homogeneous Plates. J. Appl. Mech. 1977, 44, 663–668. [Google Scholar] [CrossRef]

- Lo, K.H.; Christensen, R.M.; Wu, E.M. A High-Order Theory of Plate Deformation—Part 2: Laminated Plates. J. Appl. Mech. 1977, 44, 669–676. [Google Scholar] [CrossRef]

- Challamel Noël, K.J.T.I. 2.3.2 Reduction of the Governing Equations by Mathematical Techniques. In Modern Trends in Structural and Solid Mechanics 2: Vibrations; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Reddy, J.N. A Simple Higher-Order Theory for Laminated Composite Plates. J. Appl. Mech. 1984, 51, 745–752. [Google Scholar] [CrossRef]

- Neves, A.M.A.; Ferreira, A.J.M.; Carrera, E.; Roque, C.M.C.; Cinefra, M.; Jorge, R.M.N.; Soares, C.M.M. A Quasi-3D Sinusoidal Shear Deformation Theory for the Static and Free Vibration Analysis of Functionally Graded Plates. Compos. B Eng. 2012, 43, 711–725. [Google Scholar] [CrossRef]

- Ghazwani, M.H.; Alnujaie, A.; Van Vinh, P.; Sedighi, H.M. Effects of Porosity and Nonlocality on the Low- and High-Frequency Vibration Characteristics of Al/Si3N4 Functionally Graded Nanoplates Using Quasi-3D Theory. Arch. Civ. Mech. Eng. 2024, 24, 49. [Google Scholar] [CrossRef]

- Li, R.; Yang, Z.; Chen, G.; Wu, B. Analytical Solutions for Nonlinear Deflections of Corner-Fillet Leaf-Springs. Mech. Mach. Theory 2021, 157, 104182. [Google Scholar] [CrossRef]

- Akhavan, H.; Ribeiro, P.; de Moura, M.F.S.F. Large Deflection and Stresses in Variable Stiffness Composite Laminates with Curvilinear Fibres. Int. J. Mech. Sci. 2013, 73, 14–26. [Google Scholar] [CrossRef]

- Karagiozova, D.; Yu, T.X.; Shi, S.Y.; Zhu, L. On the Influence of Elasticity on the Large Deflections Response of Circular Plates to Uniform Quasi-Static Pressure. Int. J. Mech. Sci. 2017, 131–132, 894–907. [Google Scholar] [CrossRef]

- Yamaki, N. Influence of Large Amplitudes on Flexural Vibrations of Elastic Plates. ZAMM Z. Angew. Math. Mech. 1961, 41, 501–510. [Google Scholar] [CrossRef]

- Wah, T. Large Amplitude Flexural Vibration of Rectangular Plates. Int. J. Mech. Sci. 1963, 5, 425–438. [Google Scholar] [CrossRef]

- SRINIVASAN, A.V. Large Amplitude-Free Oscillations of Beams and Plates. AIAA J. 1965, 3, 1951–1953. [Google Scholar] [CrossRef]

- Stanišić, M.M.; Payne, J.G. A Rapidly Converging Technique for Vibration Analysis of Plates with a Discrete Mass Distribution. Ing. Arch. 1968, 37, 189–195. [Google Scholar] [CrossRef]

- Rehfield, L.W. Nonlinear Free Vibrations of Elastic Structures. Int. J. Solids Struct. 1973, 9, 581–590. [Google Scholar] [CrossRef]

- Mei, C. Finite Element Displacement Method for Large Amplitude Free Flexural Vibrations of Beams and Plates. Comput. Struct. 1973, 3, 163–174. [Google Scholar] [CrossRef]

- Mazumdar, J.; Jones, R. A Simplified Approach to the Large Amplitude Vibration of Plates and Membranes. J. Sound Vib. 1977, 50, 389–397. [Google Scholar] [CrossRef]

- Karmakar, B.M. Amplitude-Frequency Characteristics of Non-Linear Vibrations of Clamped Elliptic Plates Carrying a Concentrated Mass. Int. J. Non-Linear Mech. 1978, 13, 351–359. [Google Scholar] [CrossRef]

- Benamar, R.; Bennouna, M.M.K.; White, R.G. The Effects of Large Vibration Amplitudes on the Fundamental Mode Shape of a Fully Clamped, Symmetrically Laminated Rectangular Plate. In Proceedings of the 4th International Conference on Recent Advances in Structural Dynamics, Southampton, UK, 15–18 July 1991; pp. 749–760. Available online: https://ui.adsabs.harvard.edu/abs/1991sdra.proc..749B/abstract (accessed on 1 September 2024).

- Benamar, R.; Bennouna, M.M.K.; White, R.G. The Effects of Large Vibration Amplitudes on the Mode Shapes and Natural Frequencies of Thin Elastic Structures, Part II: Fully Clamped Rectangular Isotropic Plates. J. Sound Vib. 1993, 164, 295–316. [Google Scholar] [CrossRef]

- Benamar, R.; Bennouna, M.M.K.; White, R.G. The Effects of Large Vibration Amplitudes on the Mode Shapes and Natural Frequencies of Thin Elastic Structures Part I: Simply Supported and Clamped-Clamped Beams. J. Sound Vib. 1991, 149, 179–195. [Google Scholar] [CrossRef]

- Abdelali, H.M.; Bikri, K.E.; Benamar, R. The Effects of Large Vibration Amplitudes on the Mode Shapes and Natural Frequencies of Thin Isotropic Skew Plates; EDP Sciences: Ulis, France, 2012. [Google Scholar]

- Lacarbonara, W. Nonlinear Structural Mechanics; Springer: Boston, MA, USA, 2013; ISBN 978-1-4419-1275-6. [Google Scholar]

- Tang, D.; Zhao, M.; Dowell, E.H. Inextensible Beam and Plate Theory: Computational Analysis and Comparison with Experiment. J. Appl. Mech. 2014, 81, 061009. [Google Scholar] [CrossRef]