Identification of Moving Train Axle Loads for Simply Supported Composite Beam Bridges in Urban Rail Transit

Abstract

:1. Introduction

2. Structure Characterization and Field Measurement Scheme of an In-Service Simply Supported Composite Beam Bridge in Urban Rail Transit

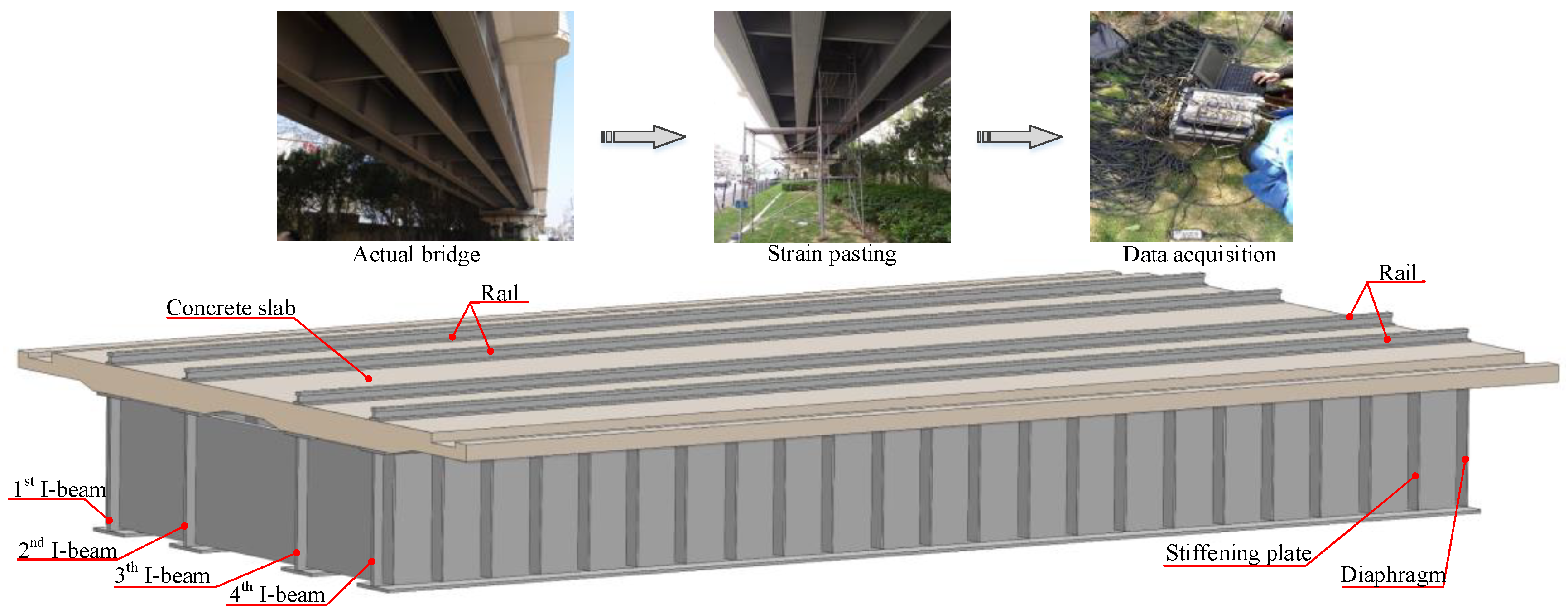

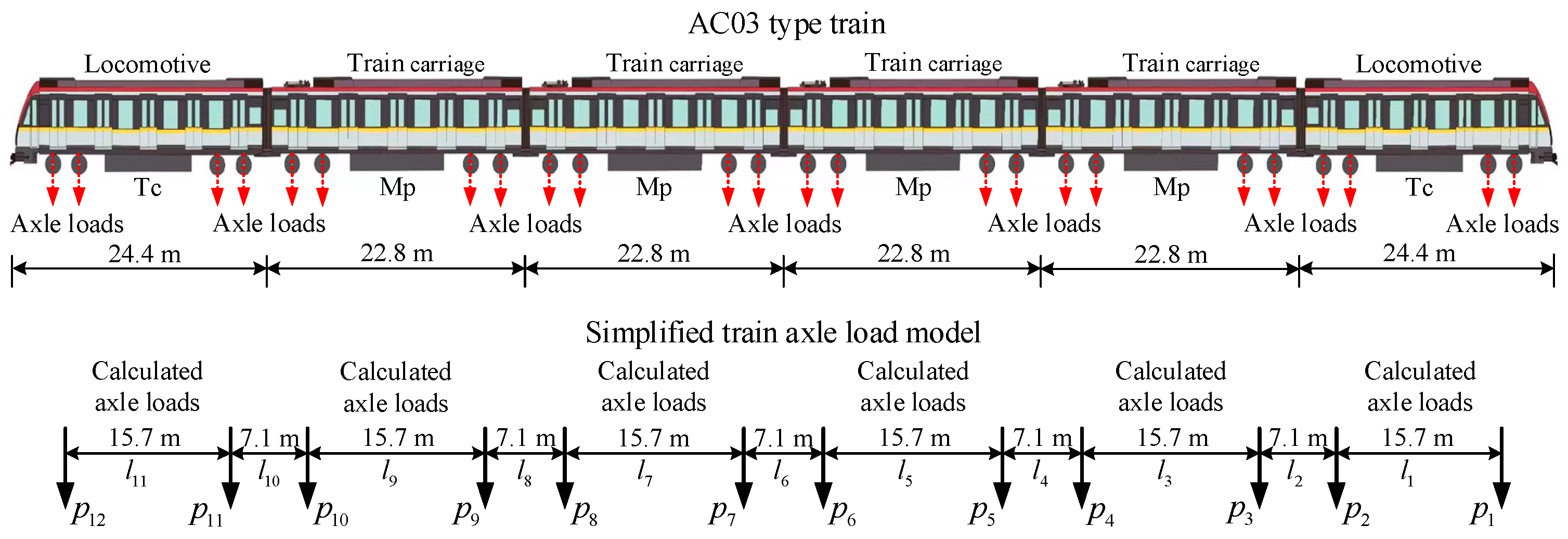

2.1. Structure Characterization of a Simply Supported Composite Beam Bridge

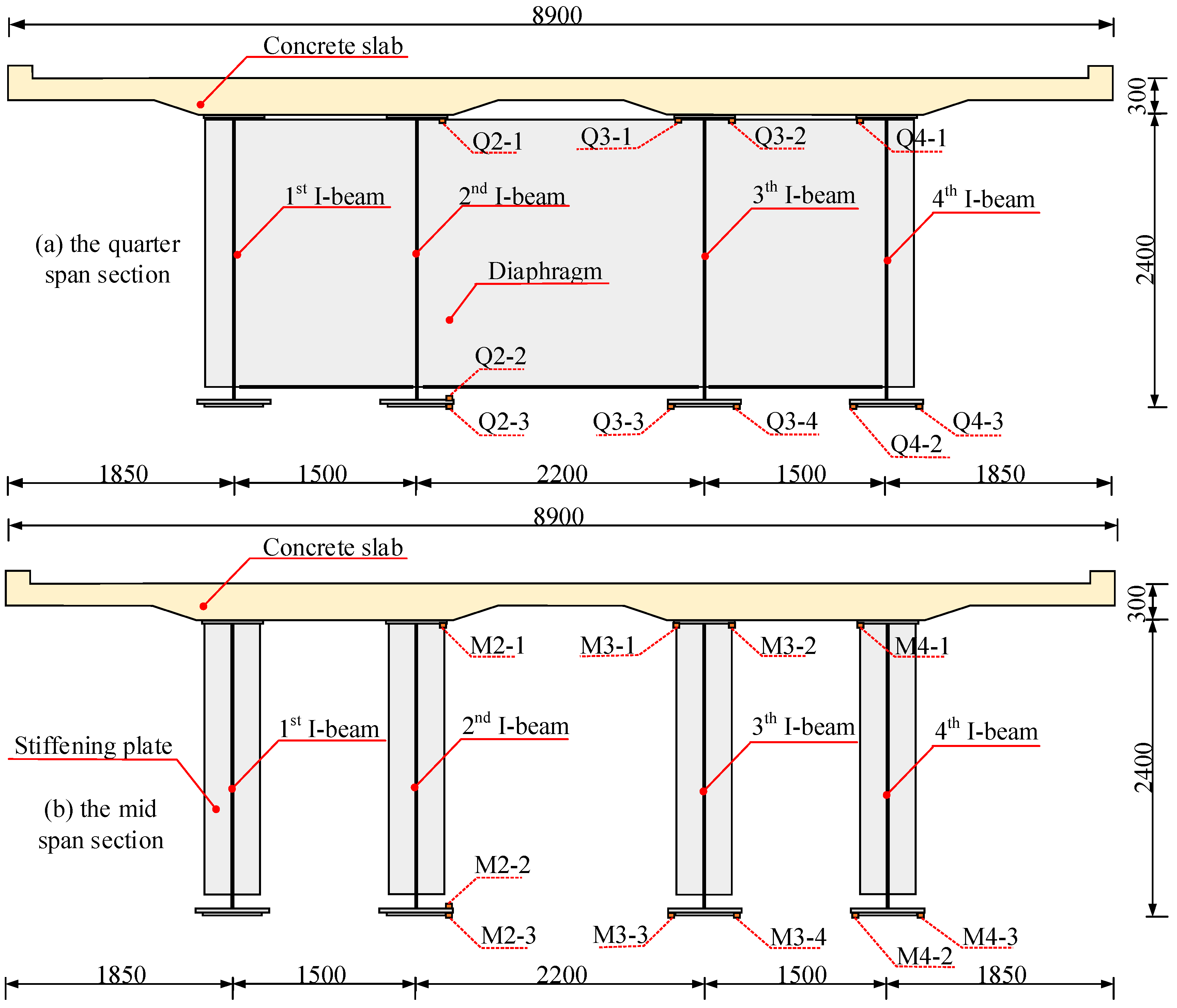

2.2. Strain Field Measurement Scheme of a Simply Supported Composite Beam Bridge

3. Numerical Modeling, Validation, and Strain Influence Lines Calculation of an In-Service Simply Supported Composite Beam Bridge

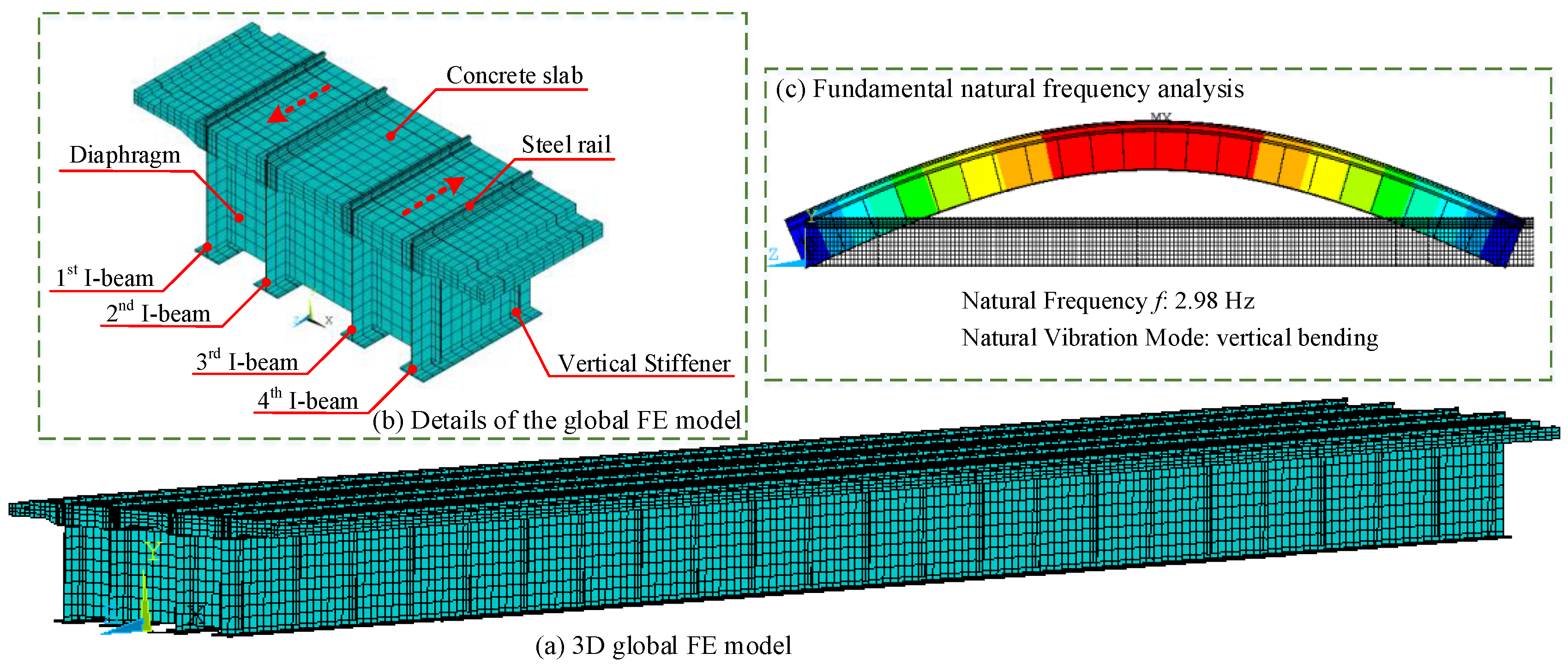

3.1. Numerical Modeling of the Simply Supported Composite Beam Bridge

3.2. Validation of the Global FE Model of the Simply Supported Composite Beam Bridge

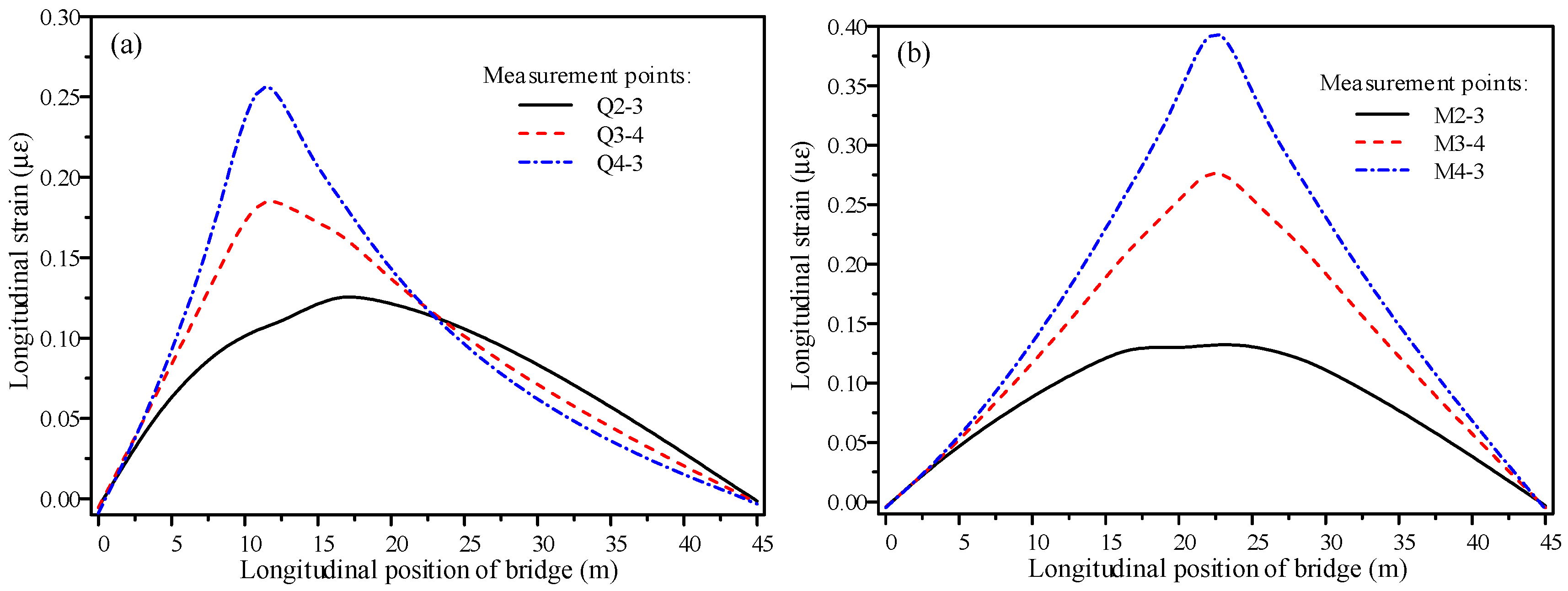

3.3. Numerical Calculation of Strain Influence Lines

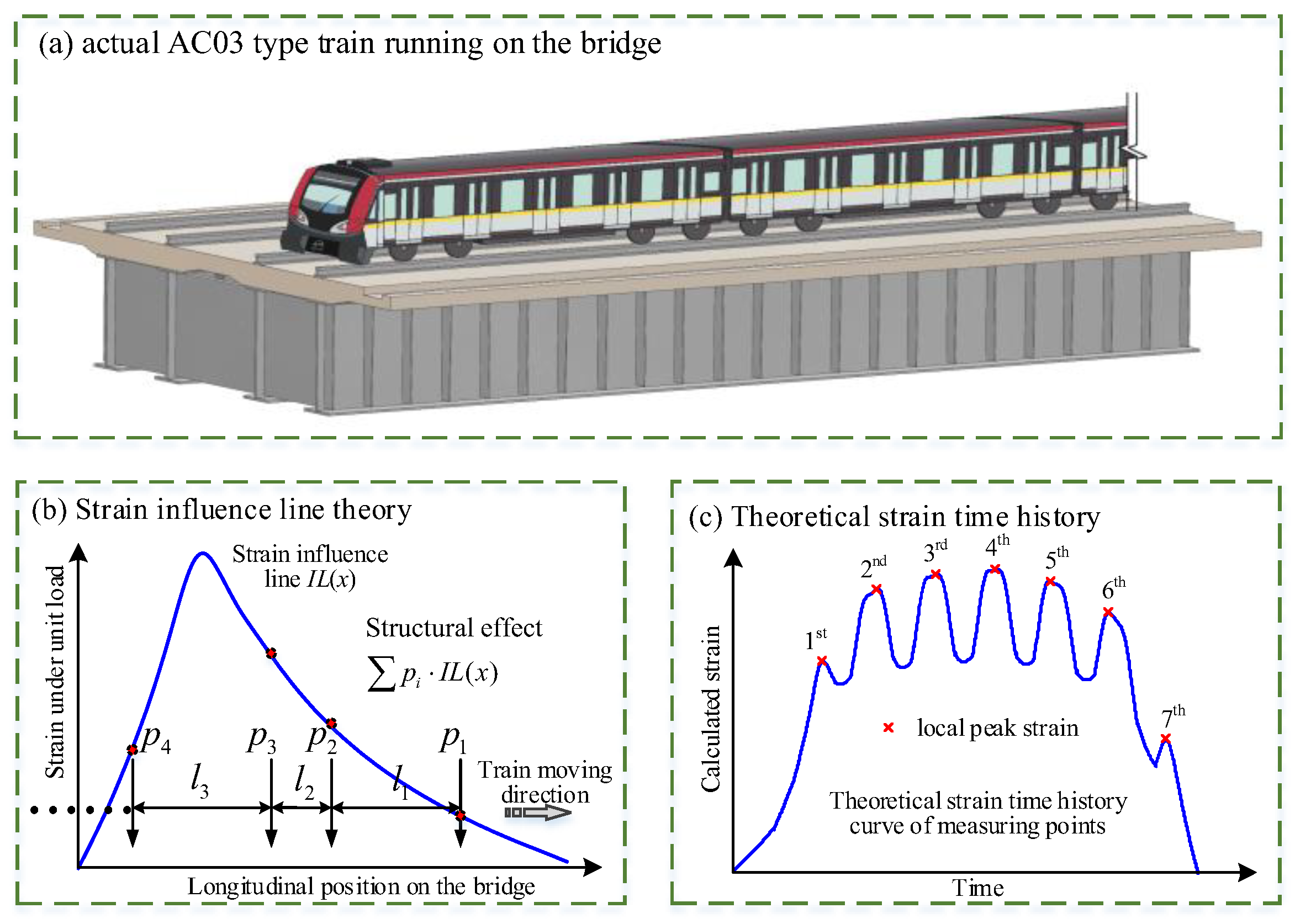

4. Identification Method of Train Axle Loads Using Strain Influence Line Theory with Mathematical Optimization Techniques

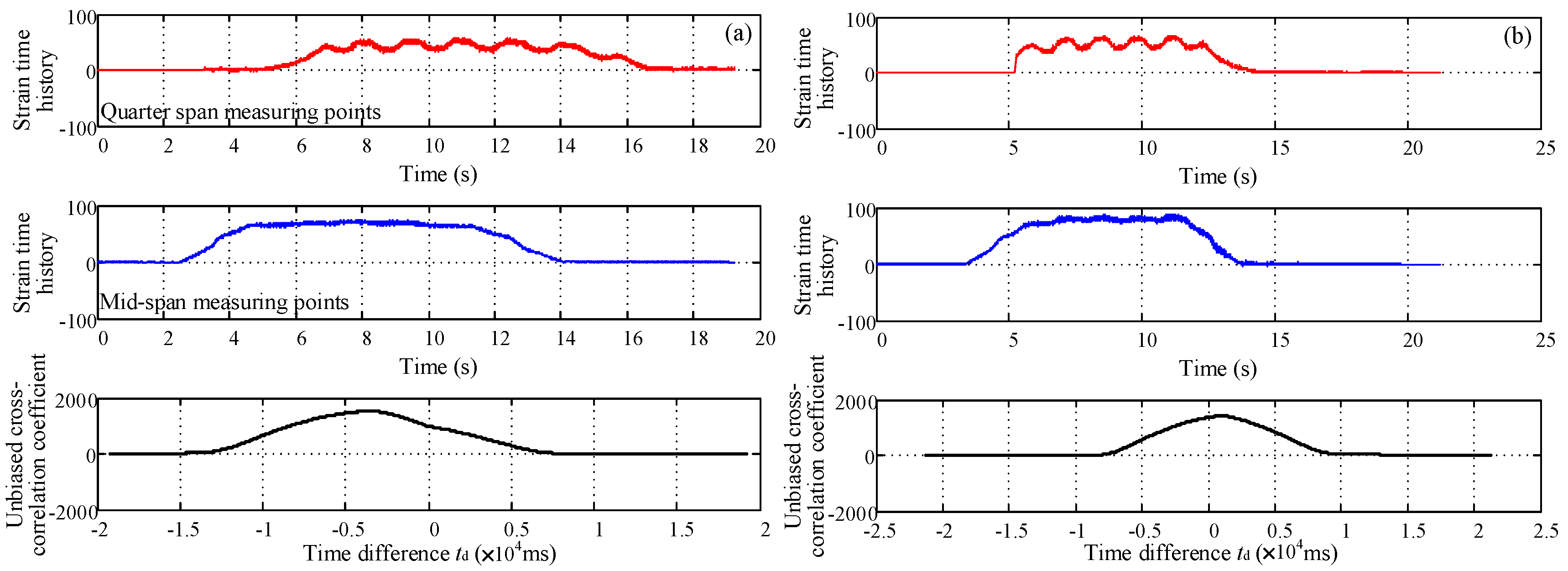

4.1. Train Speed Estimation

4.2. Train Axle Loads Identification

5. Application of Train Axle Loads Identification Method

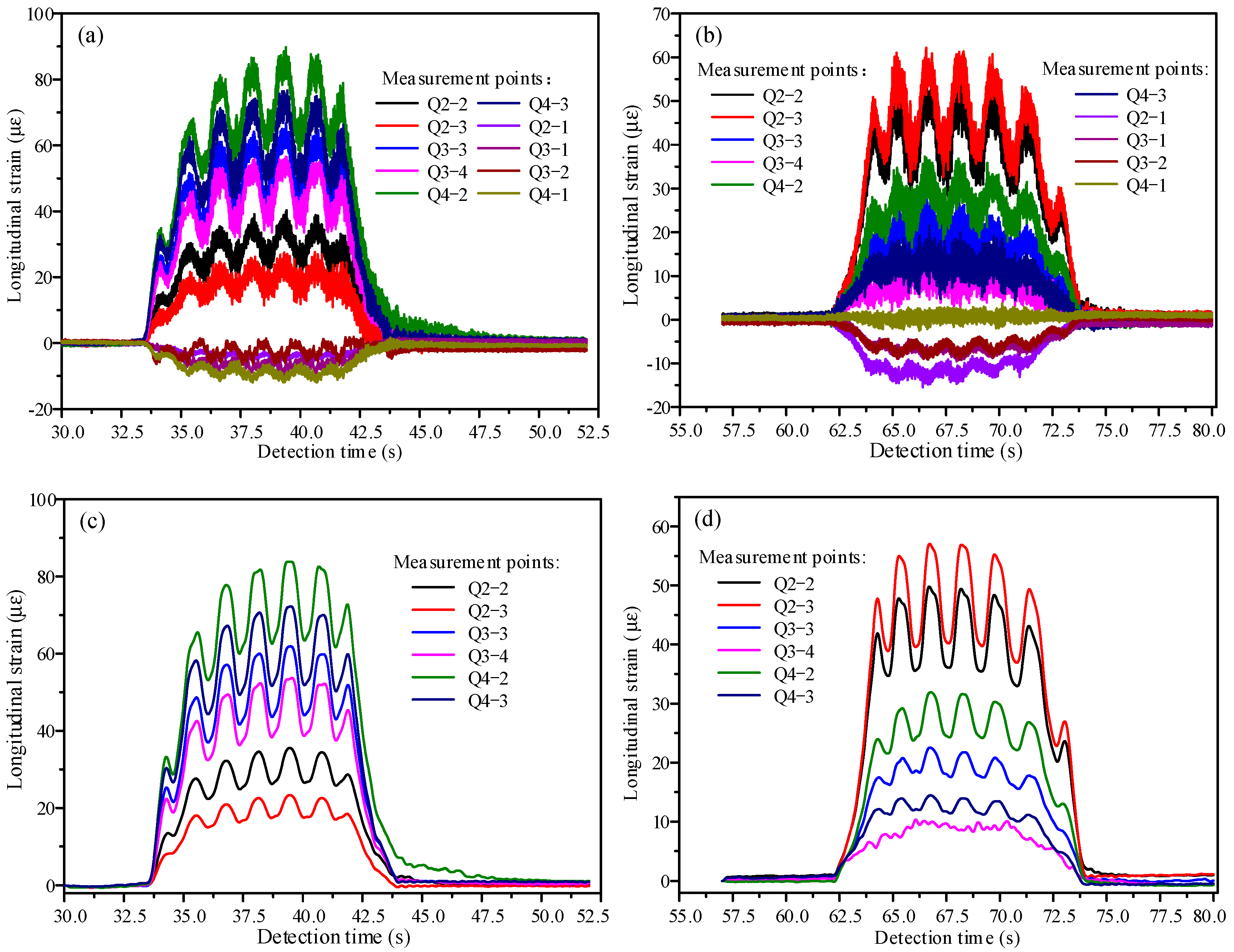

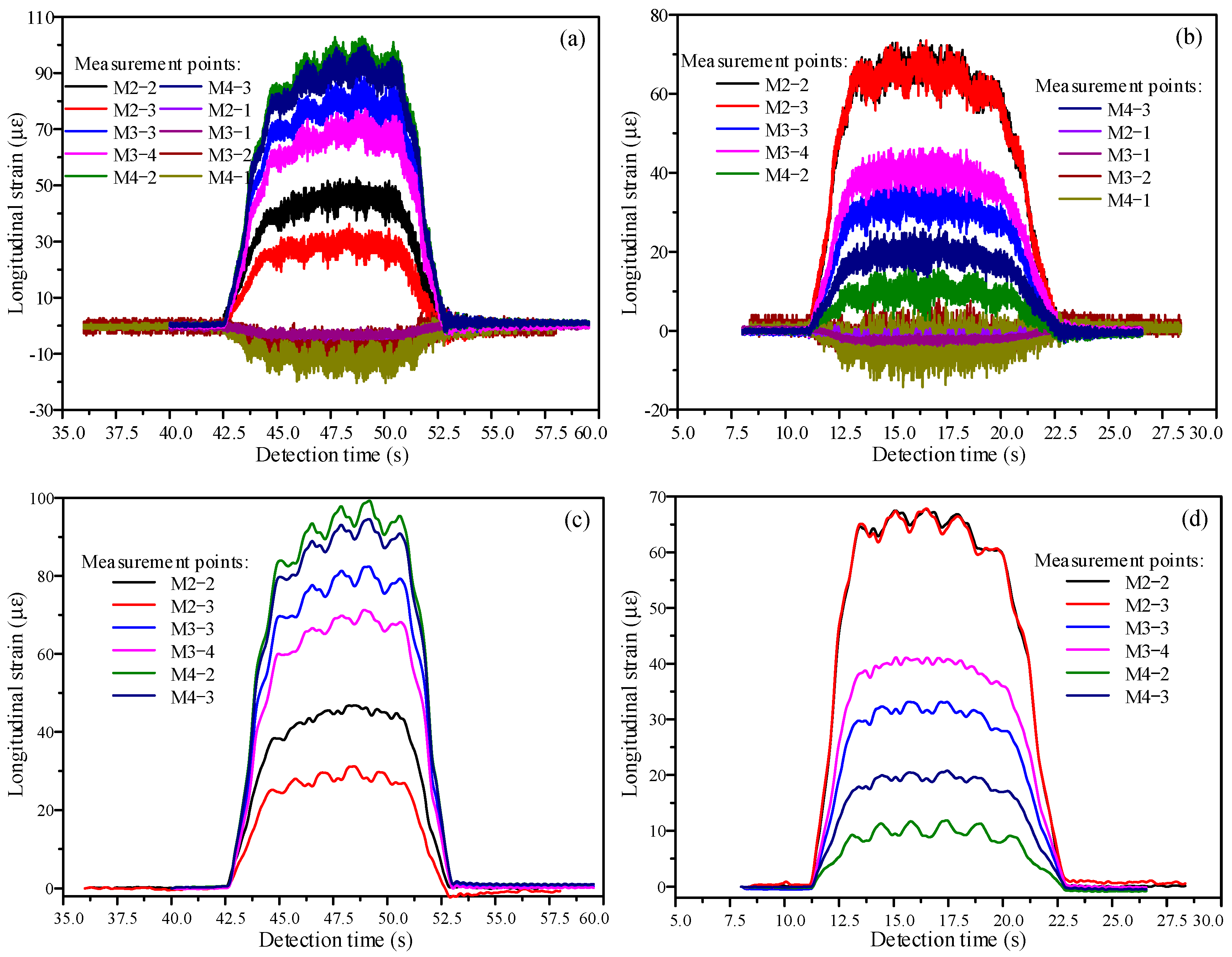

5.1. Pre-Processing of Strain Measurement Data

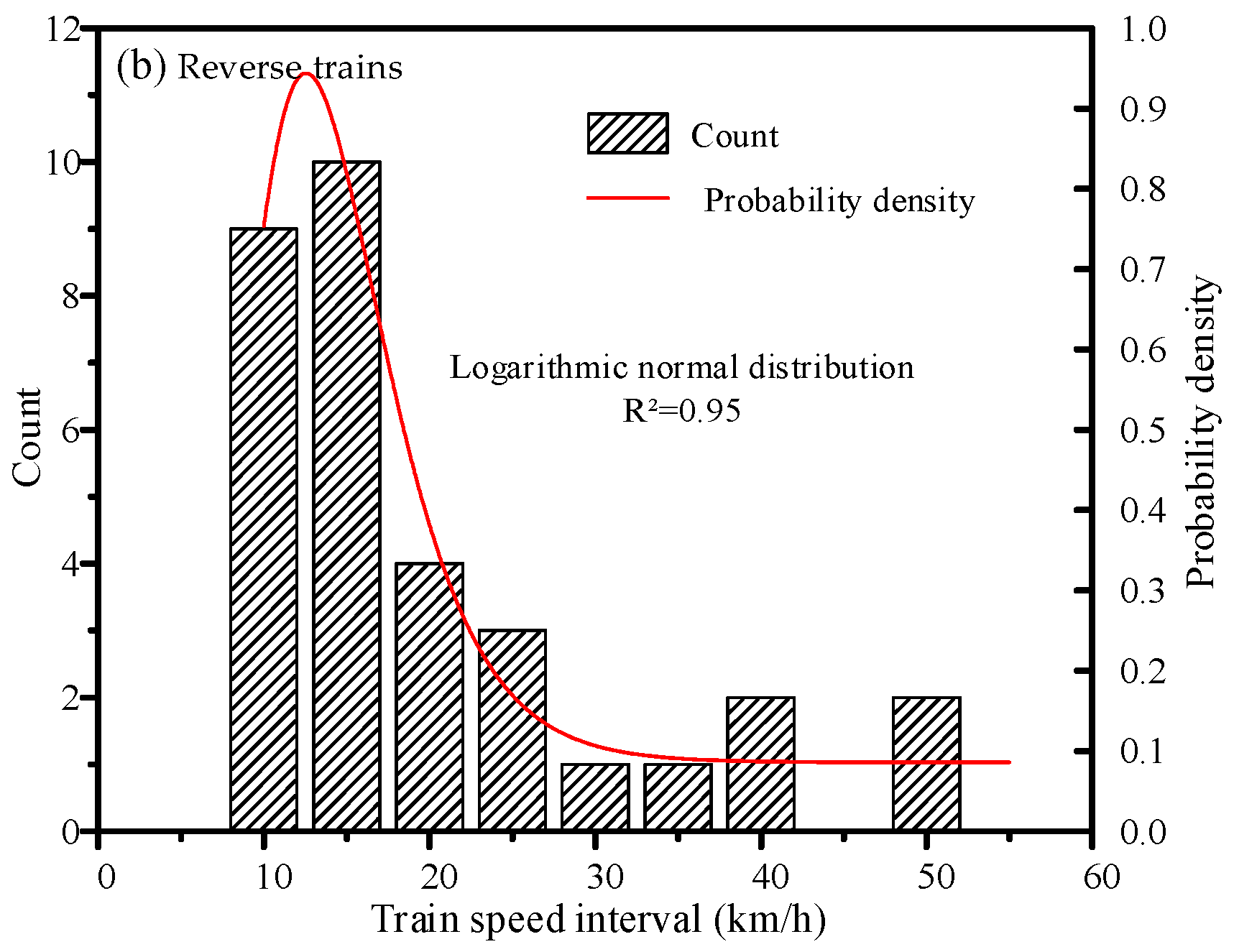

5.2. Train Speed Analysis for Urban Rail Transit

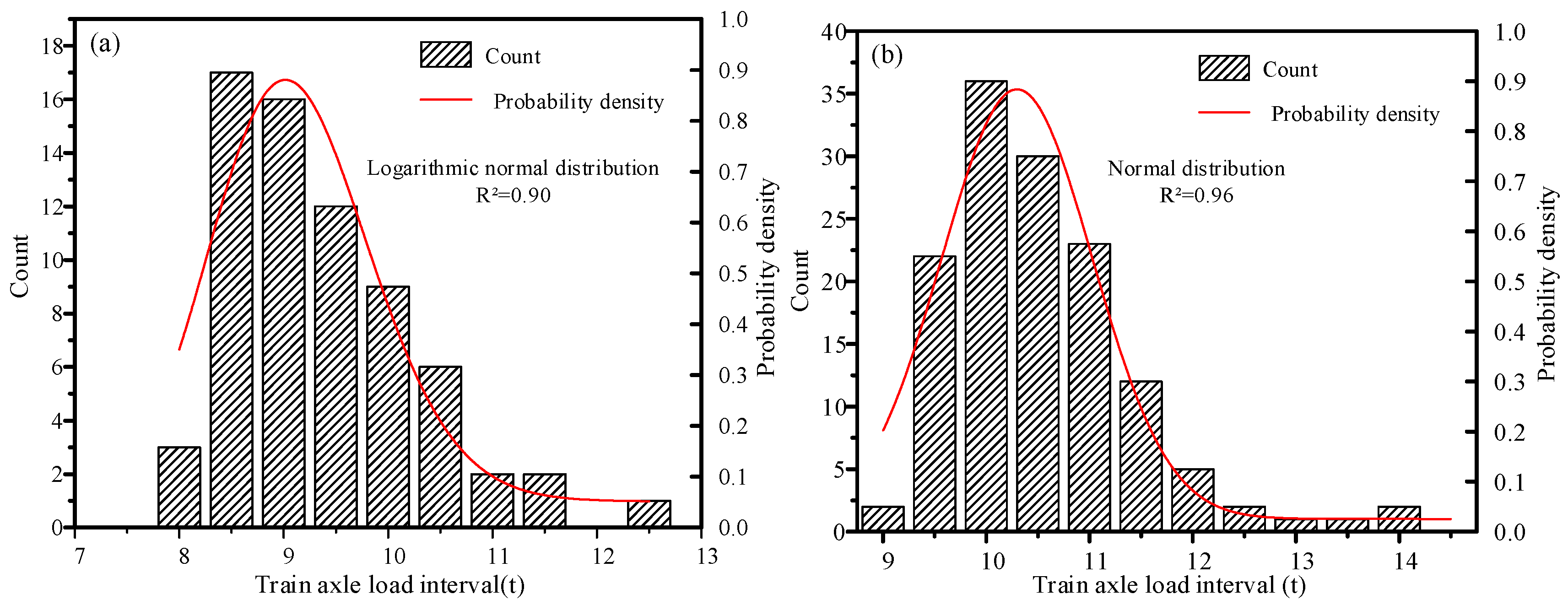

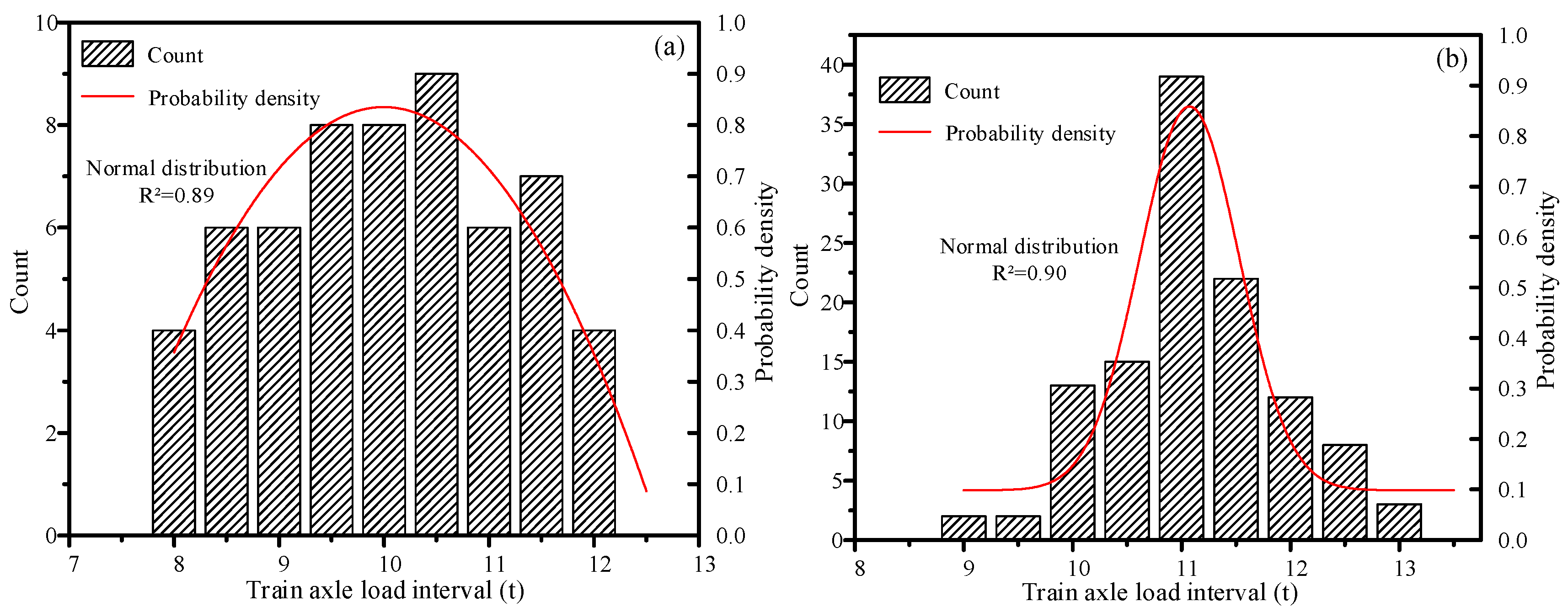

5.3. Train Axle Load Analysis for Urban Rail Transit

6. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, P.B.; Zhang, F.B.; Wang, J.B.; Wei, L.; Huo, W.B. Review of wheel-rail forces measuring technology for railway vehicles. Adv. Mech. Eng. 2023, 15, 1–15. [Google Scholar] [CrossRef]

- Chen, Q.H.; Gong, J.C.; Ge, X.; Chen, S.Q.; Wang, K.Y. Estimation of wheel-rail forces based on the STF-SCKF-NE algorithm. Measurement 2024, 236, 114974. [Google Scholar] [CrossRef]

- Mao, J.X.; Zhu, X.J.; Wang, H.; Guo, X.M.; Pang, Z.H. Train Load Identification of the Medium-Small Railway Bridge using Virtual Axle Theory and Bayesian Inference. Int. J. Struct. Stab. Dyn. 2024, 24, 2450193. [Google Scholar] [CrossRef]

- Kanehara, H.; Fujioka, T. Measuring rail/wheel contact points of running railway vehicles. Wear 2002, 253, 275–283. [Google Scholar] [CrossRef]

- Matsumoto, A.; Sato, Y.; Ohno, H.; Tomeoka, M.; Matsumoto, K.; Kurihara, J.; Ogino, T.; Tanimoto, M.; Kishimoto, Y.; Sato, Y.; et al. A new measuring method of wheel–rail contact forces and related considerations. Wear 2008, 265, 1518–1525. [Google Scholar] [CrossRef]

- Gullers, P.; Andersson, L.; Lundén, R. High-frequency vertical wheel-rail contact forces-field measurements and influence of track irregularities. Wear 2008, 265, 1472–1478. [Google Scholar] [CrossRef]

- Urda, P.; Muñoz, S.; Aceituno, J.F.; Escalona, J.L. Wheel-rail contact contact force measurement using strain gauges and distance lasers on a scaled railway vehicle. Mech. Syst. Signal Process. 2019, 138, 106555. [Google Scholar] [CrossRef]

- Jin, X.C. A measurement and evaluation method for wheel-rail contact forces and axle stresses of high-speed train. Measurement 2020, 149, 106983. [Google Scholar] [CrossRef]

- Zhou, W.; Abdulhakeem, S.; Fang, C.C.; Han, T.H.; Li, G.F.; Wu, Y.T.; Faisal, Y. A new wayside method for measuring and evaluating wheel-rail contact forces and positions. Measurement 2020, 166, 108244. [Google Scholar] [CrossRef]

- Peng, X.Y.; Zeng, J.; Wang, J.B.; Wang, Q.S.; Li, D.D.; Liang, S.K. Wayside wheel-rail vertical contact force continuous detecting method and its application. Measurement 2022, 193, 110975. [Google Scholar] [CrossRef]

- Roveri, N.; Carcaterra, A.; Sestieri, A. Real-time monitoring of railway infrastructures using fibre bragg grating sensors. Mech. Syst. Signal Process. 2015, 60–61, 14–28. [Google Scholar] [CrossRef]

- Gao, L.; Zhou, C.Y.; Xiao, H.; Chen, Z.P. Continuous vertical wheel-rail force reconstruction method based on the distributed acoustic sensing technology. Measurement 2022, 197, 111297. [Google Scholar] [CrossRef]

- Uhl, T. The inverse identification problem and its technical application. Arch. Appl. Mech. 2007, 77, 325–337. [Google Scholar] [CrossRef]

- Pau, A.; Vestroni, F. Weigh-in-motion of train loads based on measurements of rail strains. Struct. Control Health Monit. 2021, 28, e2818. [Google Scholar] [CrossRef]

- Marques, F.; Moutinho, C.; Hu, W.H.; Cunha, A.; Caetano, E. Weigh-in-motion implementation in an old metallic railway bridge. Eng. Struct. 2016, 123, 15–29. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Q.X.; Li, J.; Mao, J.X.; Hu, S.T.; Zhao, X.X. Identification of moving train loads on railway bridge based on strain monitoring. Smart Struct. Syst. 2019, 23, 263–278. [Google Scholar]

- Deepthi, T.M.; Saravanan, U.; Prasad, A.M. Algorithms to determine wheel loads and speed of trains using strains measured on bridge girders. Struct. Control Health Monit. 2019, 26, e2282. [Google Scholar] [CrossRef]

- Wang, Y.; Qu, W.L. Moving train loads identification on a continuous steel truss girder by using dynamic displacement influence line method. Int. J. Steel Struct. 2011, 11, 109–115. [Google Scholar] [CrossRef]

- Wang, Y.; Qu, W.L.; Xiao, C. Moving train loads and parameters identification on a steel truss girder model. Int. J. Steel Struct. 2015, 15, 165–173. [Google Scholar] [CrossRef]

- Sekuła, K.; Kołakowski, P. Piezo-based weigh-in-motion system for the railway transport. Struct. Control Health Monit. 2012, 19, 199–215. [Google Scholar] [CrossRef]

- Pimentel, R.; Ribeiro, D.; Matos, L.; Mosleh, A.; Calçada, R. Bridge weigh-in-motion system for the identification of train loads using fiber-optic technology. Structures 2021, 30, 1056–1070. [Google Scholar] [CrossRef]

- Wu, B.T.; Lin, Z.C.; Liang, Y.X.; Zhou, Z.W.; Lu, H.X. An effective prediction method for bridge long-gauge strain under moving trainloads with experimental verification. Mech. Syst. Signal Process. 2023, 186, 109855. [Google Scholar] [CrossRef]

- Thomoglou, A.K.; Falara, M.G.; Voutetaki, M.E.; Fantidis, J.G.; Tayeh, B.A.; Chalioris, C.E. Electromechanical properties of multi-reinforced self-sensing cement-based mortar with MWCNTs, CFs, and PPs. Constr. Build. Mater. 2023, 400, 132566. [Google Scholar] [CrossRef]

- Silva, I.J.G.; Karoumi, R. Traffic monitoring using a structural health monitoring system. Bridge Eng. 2015, 168, 13–23. [Google Scholar] [CrossRef]

- Thomoglou, A.K.; Rousakis, T.; Karabinis, A. Numerical Modeling of Shear Behavior of Urm Strengthened with Frcm or Frp Subjected to Seismic Loading. In Proceedings of the 16th European Conference on Earthquake Engineering (16ECEE), Thessaloníki, Greece, 18–21 June 2018. [Google Scholar]

- JTG D60–2015; General Design Specification for Highway Bridges and Culverts. China Communication Press: Beijing, China, 2015.

- Ditommaso, R.; Mucciarelli, M.; Ponzo, F.C. Analysis of non-stationary structural systems by using a band-variable filter. Bull. Earthq. Eng. 2012, 10, 895–911. [Google Scholar] [CrossRef]

- He, L.S.; Feng, B. Correlation Analysis of Signals. In Fundamentals of Measurement and Signal Analysis; Springer: Singapore, 2022. [Google Scholar]

- TB 10002–2017; Code for Design on Railway Bridges and Culverts. National Railway Administration; China Railway Press: Beijing, China.

- Sun, H.H.; Chen, W.Z.; Cai, S.Y.; Zhang, B.S. Tracking time-varying structural responses of in-service cable-stayed bridges with model parameter errors and concrete time-dependent effects. Structures 2022, 37, 819–832. [Google Scholar] [CrossRef]

- Maurya, S.P.; Singh, N.P.; Singh, K.H. Optimization Methods for Nonlinear Problems. In Seismic Inversion Methods: A Practical Approach; Springer Geophysics; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Ye, Q.Z.; Luo, Q.; Feng, G.S.; Wang, T.F.; Xie, H.W. Stress distribution in roadbeds of slab tracks with longitudinal discontinuities. Railw. Eng. Sci. 2023, 31, 61–74. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Peng, X.; Xu, J.; Tu, H. Identification of Moving Train Axle Loads for Simply Supported Composite Beam Bridges in Urban Rail Transit. Appl. Sci. 2024, 14, 8310. https://doi.org/10.3390/app14188310

Sun H, Peng X, Xu J, Tu H. Identification of Moving Train Axle Loads for Simply Supported Composite Beam Bridges in Urban Rail Transit. Applied Sciences. 2024; 14(18):8310. https://doi.org/10.3390/app14188310

Chicago/Turabian StyleSun, Huahuai, Xiyang Peng, Jun Xu, and Hongkai Tu. 2024. "Identification of Moving Train Axle Loads for Simply Supported Composite Beam Bridges in Urban Rail Transit" Applied Sciences 14, no. 18: 8310. https://doi.org/10.3390/app14188310

APA StyleSun, H., Peng, X., Xu, J., & Tu, H. (2024). Identification of Moving Train Axle Loads for Simply Supported Composite Beam Bridges in Urban Rail Transit. Applied Sciences, 14(18), 8310. https://doi.org/10.3390/app14188310