Highly Photoresponsive Vertically Stacked Silicon Nanowire Photodetector with Biphasic Current Stimulator IC for Retinal Prostheses

Abstract

1. Introduction

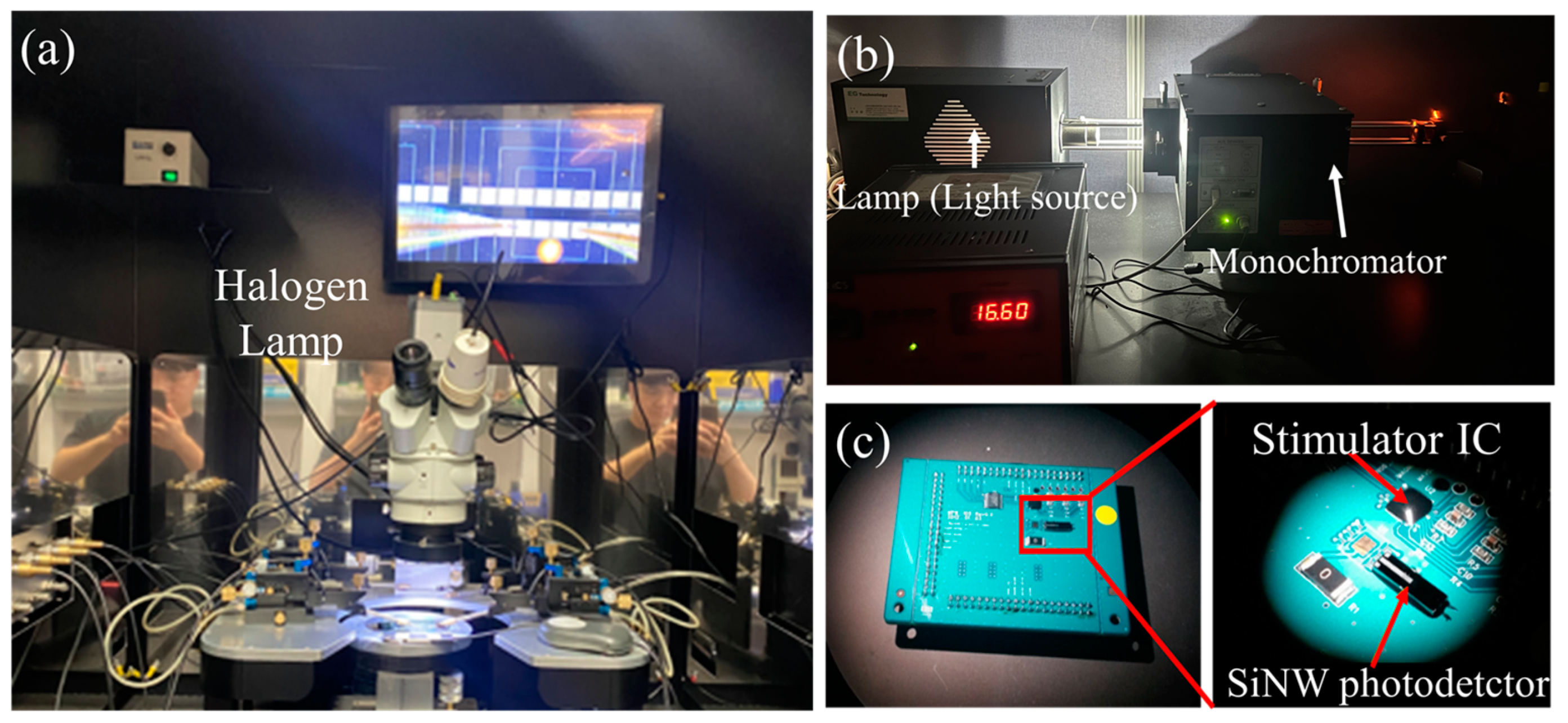

2. Materials and Methods

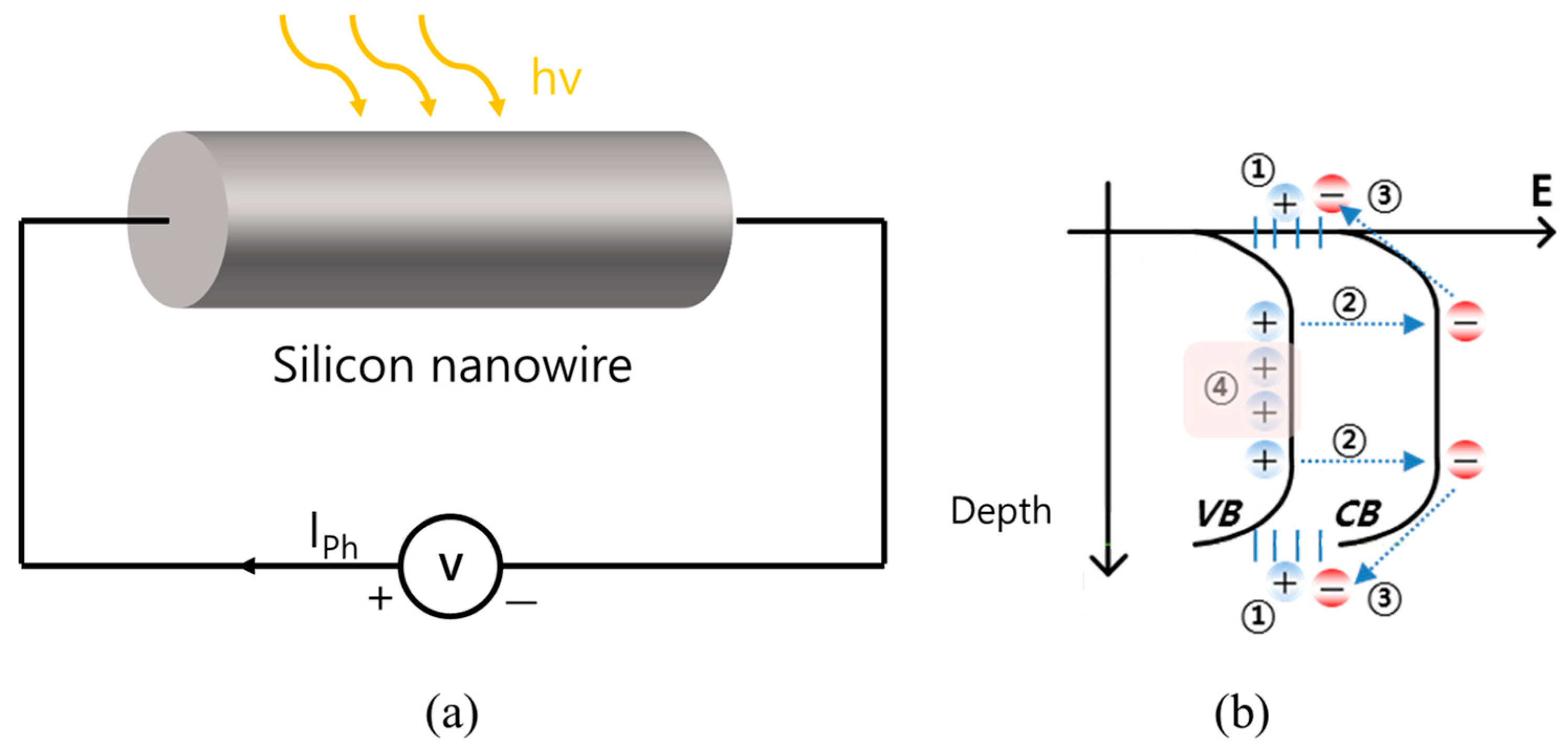

2.1. Theoretical Consideration: Photoresponsivity of SiNW Photodetector

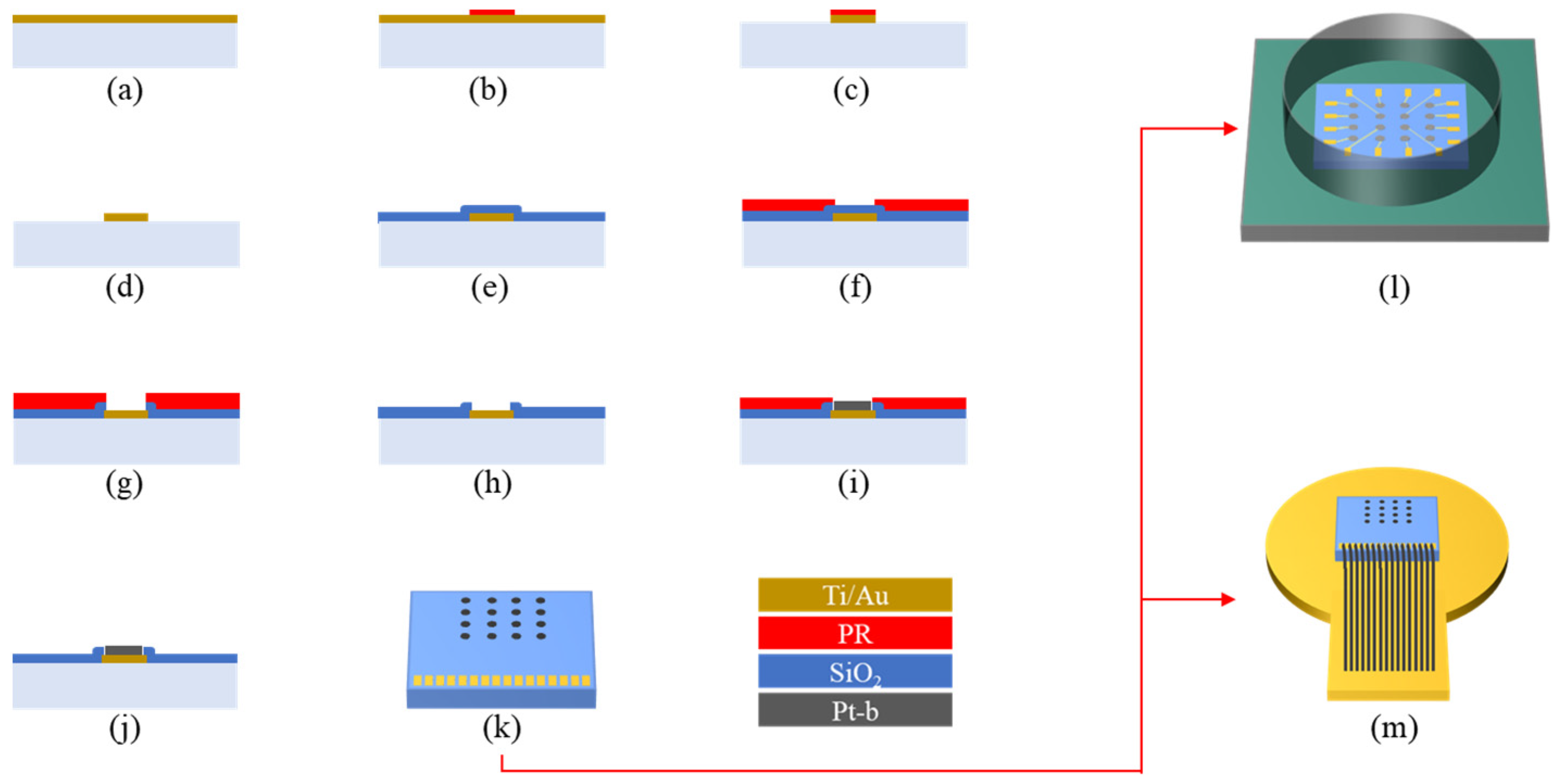

2.2. Fabrication of Vertically Stacked SiNW Photodetector

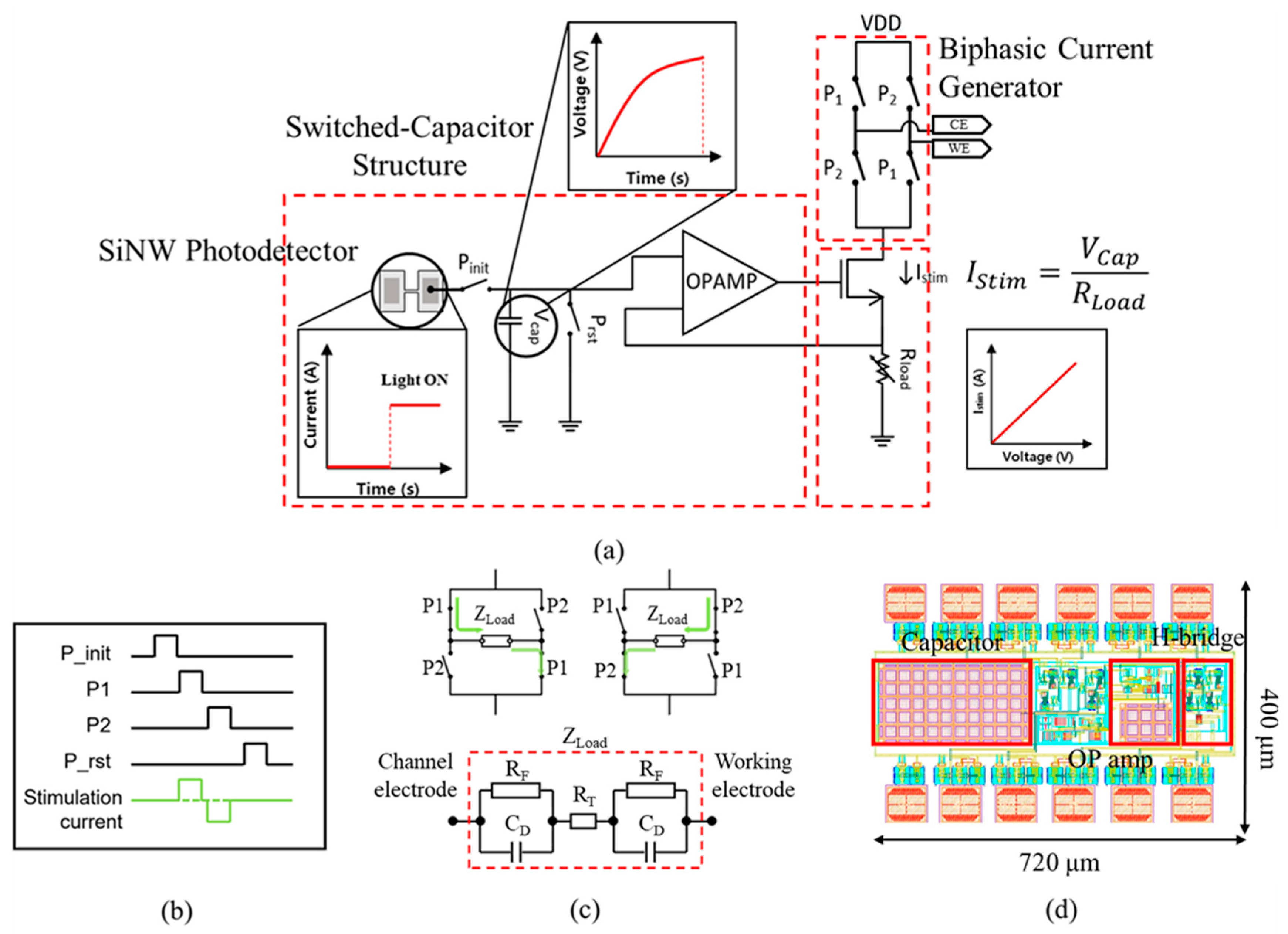

2.3. Switched Capacitor Biphasic Current Stimulator

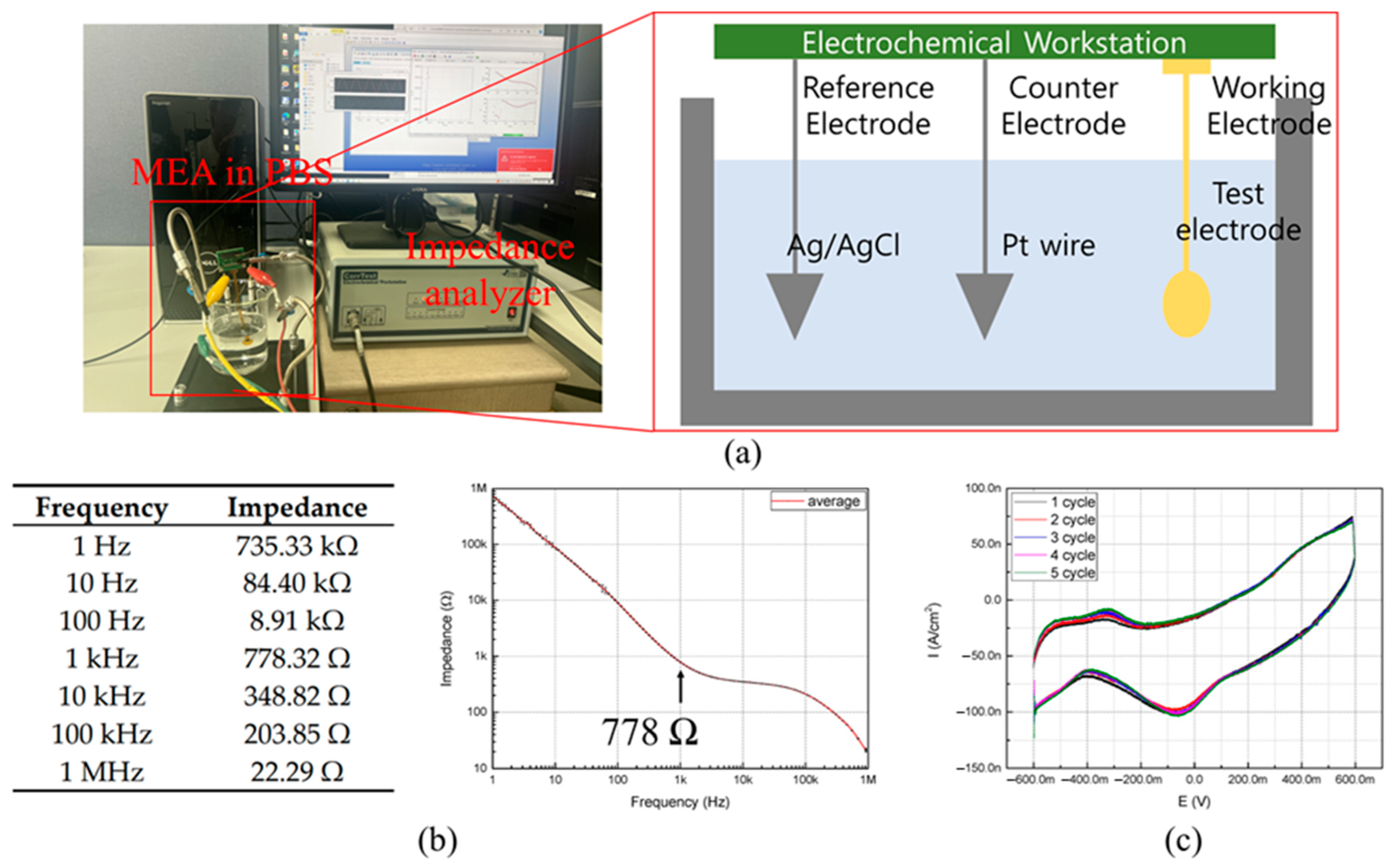

2.4. Fabrication of Nanostructured Platinum-Black MEA

3. Results

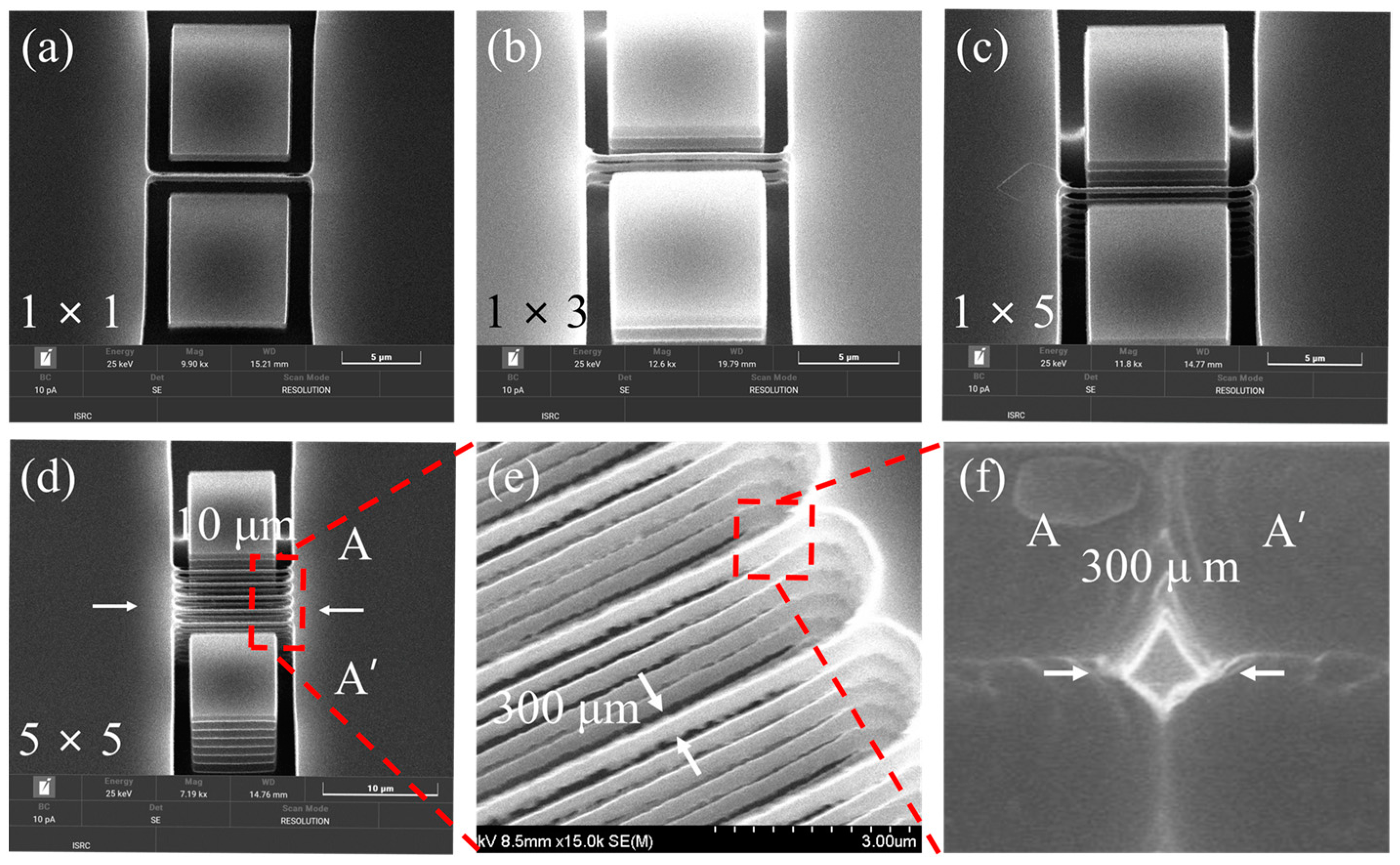

3.1. Fabrication Results of Vertically Stacked SiNW Photodetector

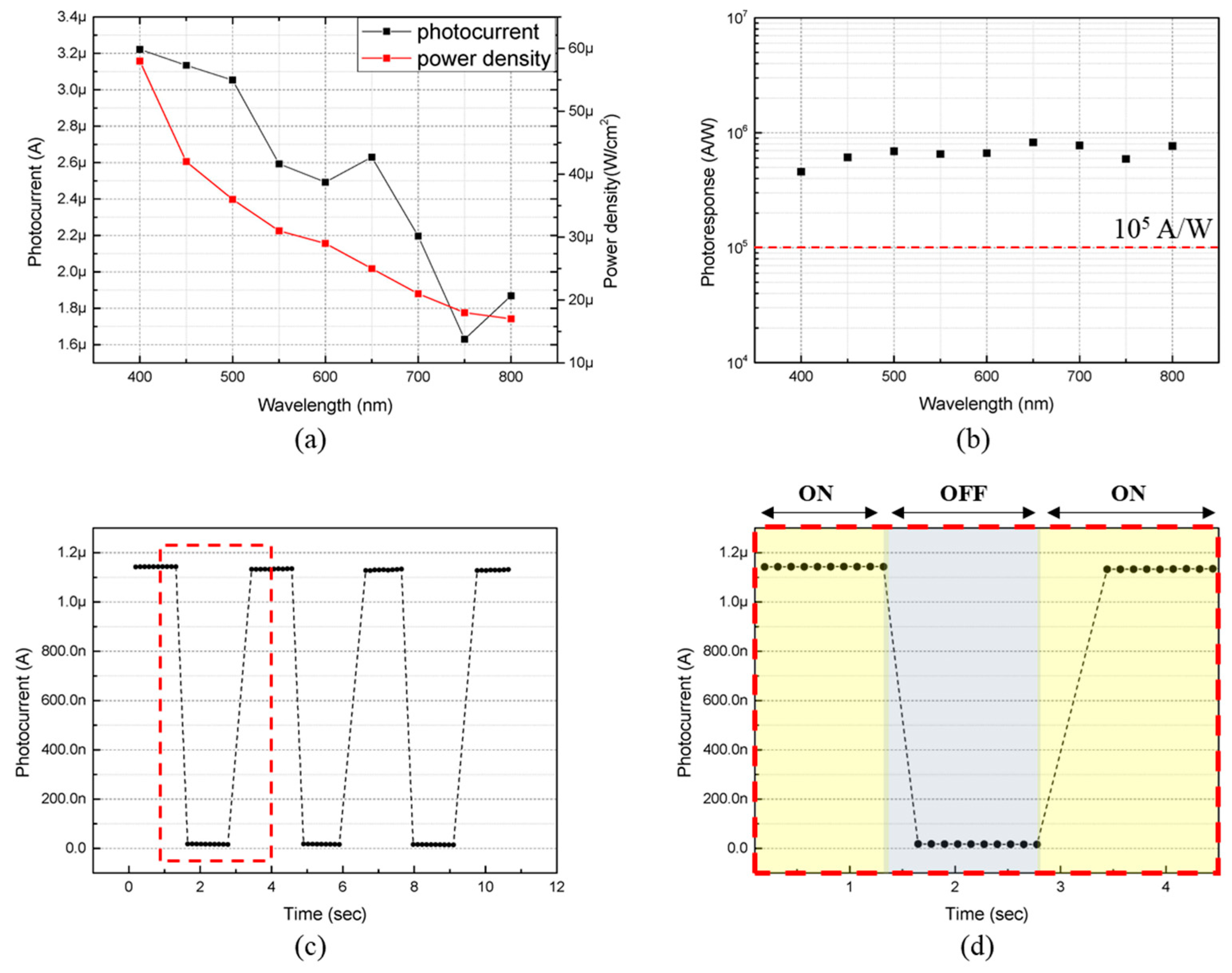

3.2. Electrical and Optical Characteristics of SiNW Photodetector

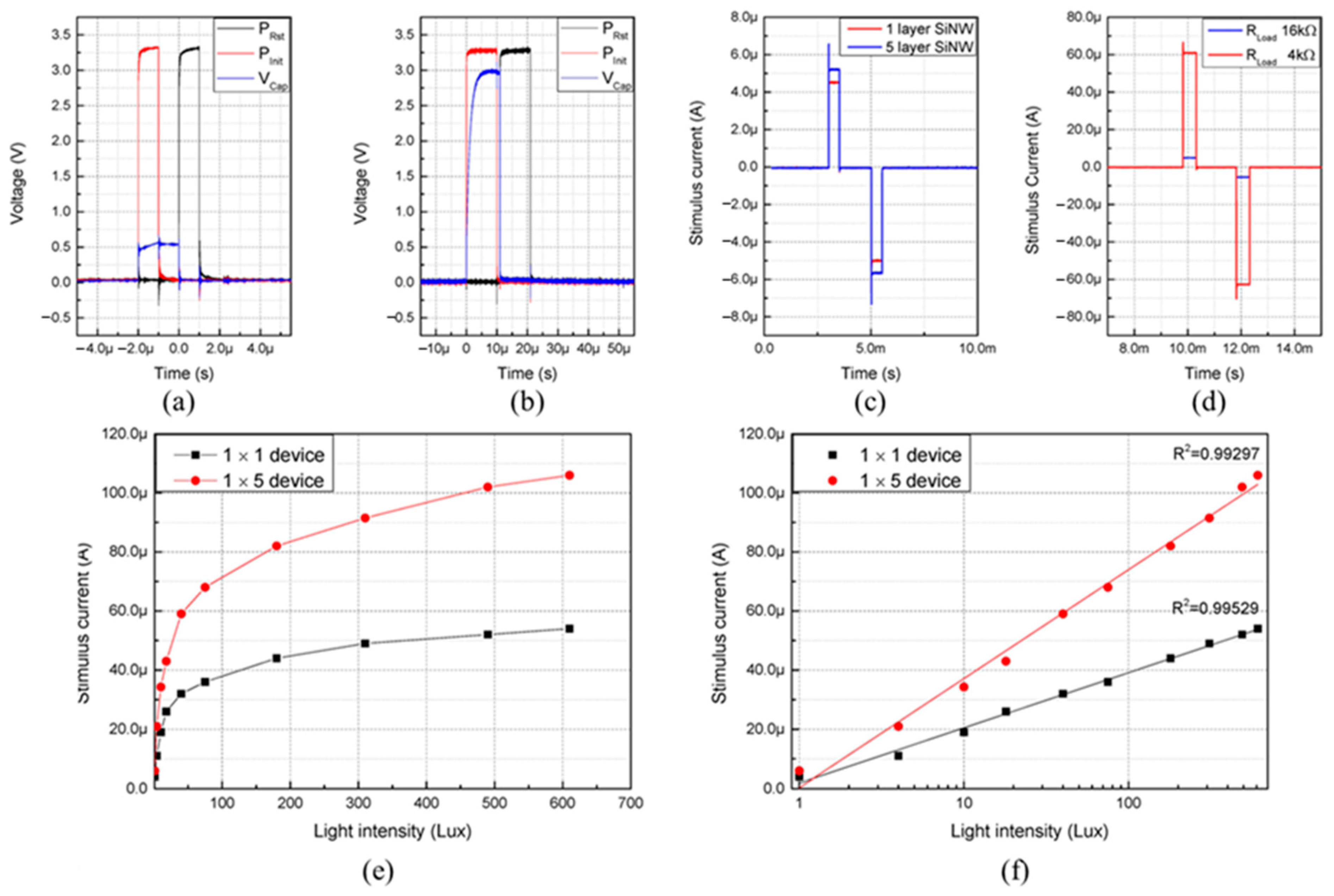

3.3. Evaluation of SiNW Photodetector-Integrated Stimulator Circuit

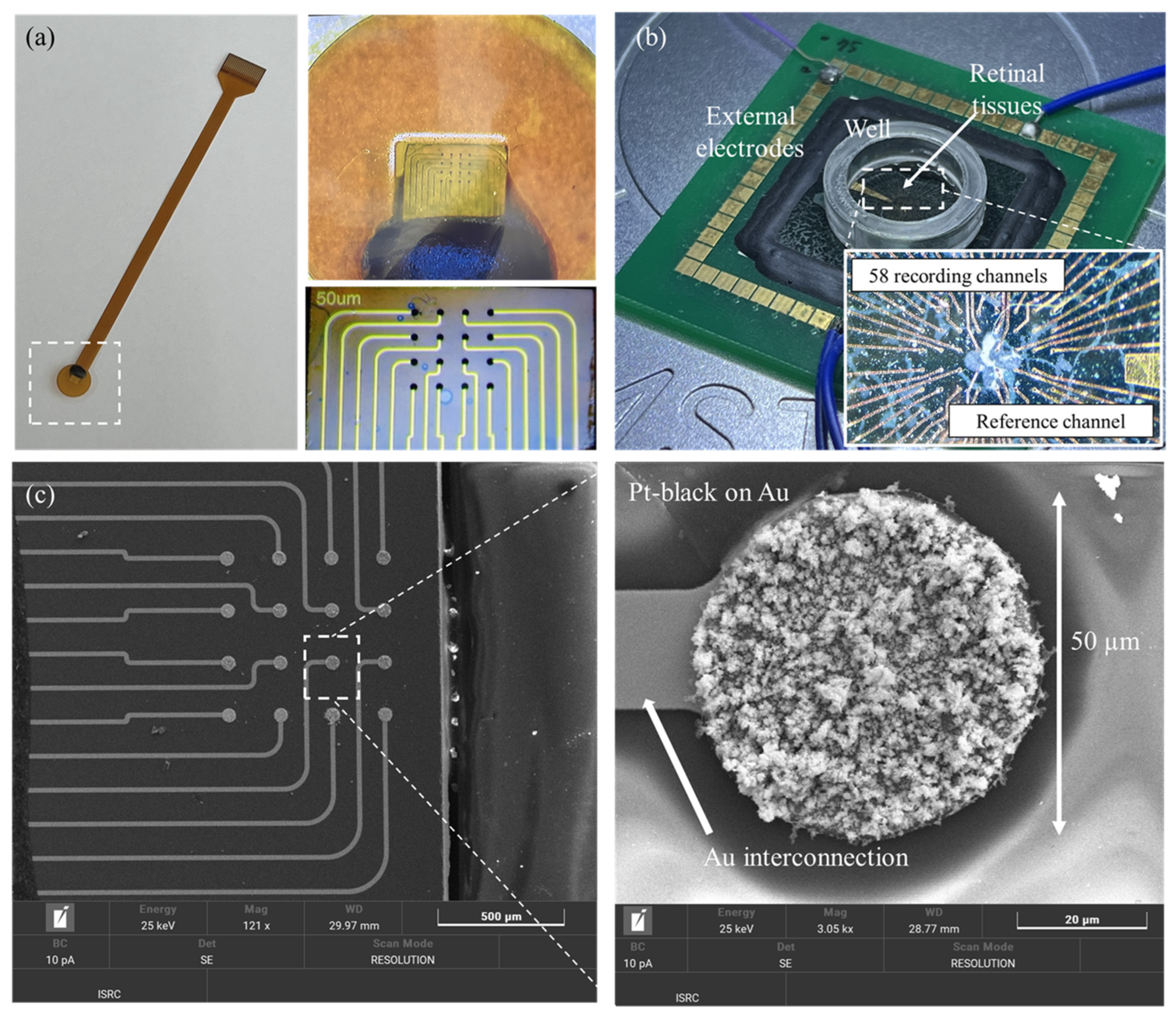

3.4. Fabrication Results of Pt-Black MEA

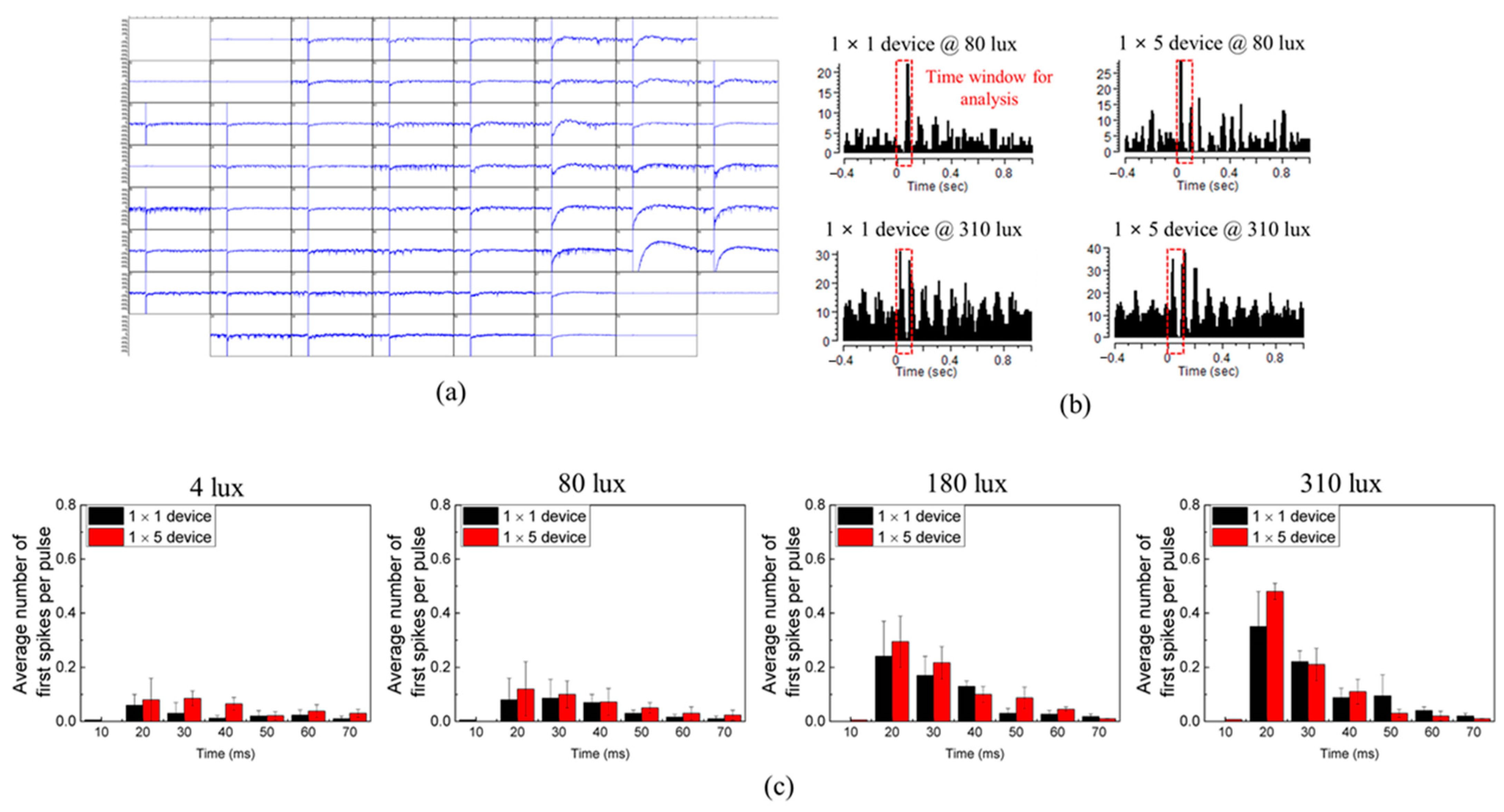

3.5. In Vitro Experiment

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hartong, D.T.; Berson, E.L.; Dryja, T.P. Retinitis Pigmentosa. Lancet 2006, 368, 1795–1809. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Qiao, L.; Du, M.; Qu, C.; Wan, L.; Li, J.; Huang, L. Age-Related Macular Degeneration: Epidemiology, Genetics, Pathophysiology, Diagnosis, and Targeted Therapy. Genes Dis. 2022, 9, 62–79. [Google Scholar] [CrossRef]

- Congdon, N.; O’Colmain, B.; Klaver, C.C.W.; Klein, R.; Muñoz, B.; Friedman, D.S.; Kempen, J.; Taylor, H.R.; Mitchell, P. Causes and prevalence of visual impairment among adults in the Unites States. Arch. Ophthalmol. 2004, 122, 477–485. [Google Scholar]

- Jones, B.W.; Marc, R.E. Retinal Remodeling during Retinal Degeneration. Exp. Eye Res. 2005, 81, 123–137. [Google Scholar] [CrossRef] [PubMed]

- Marc, R.E.; Jones, B.W.; Watt, C.B.; Strettoi, E. Neural Remodeling in Retinal Degeneration. Prog. Retin. Eye Res. 2003, 22, 607–655. [Google Scholar] [CrossRef]

- Luo, Y.H.L.; da Cruz, L. The Argus® II Retinal Prosthesis System. Prog. Retin. Eye Res. 2016, 50, 89–107. [Google Scholar] [CrossRef] [PubMed]

- Scribner, D.; Johnson, L.; Klein, R.; Bassett, W.; Howard, J.; Skeath, P.; Wassetman Humayun, L.B.; Perkins, F.; Peckerar, M.; Finch, B.J.; et al. A Retinal Prosthesis Device Based on an 80 × 40 Hybrid Microelectronic-Microwire Glass Array. In Proceedings of the IEEE 2003 Custom Integrated Circuits Conference, San Jose, CA, USA, 24 September 2003. [Google Scholar]

- Stingl, K.; Schippert, R.; Bartz-Schmidt, K.U.; Besch, D.; Cottriall, C.L.; Edwards, T.L.; Gekeler, F.; Greppmaier, U.; Kiel, K.; Koitschev, A.; et al. Interim Results of a Multicenter Trial with the New Electronic Subretinal Implant Alpha AMS in 15 Patients Blind from Inherited Retinal Degenerations. Front. Neurosci. 2017, 11, 445. [Google Scholar] [CrossRef]

- Wu, C.Y.; Tseng, C.K.; Liao, J.H.; Chiao, C.C.; Chu, F.L.; Tsai, Y.C.; Ohta, J.; Noda, T. CMOS 256-Pixel/480-Pixel Photovoltaic-Powered Subretinal Prosthetic Chips with Wide Image Dynamic Range and Bi/Four-Directional Sharing Electrodes and Their Ex Vivo Experimental Validations with Mice. IEEE Trans. Circuits Syst. I Regul. Pap. 2020, 67, 3273–3283. [Google Scholar] [CrossRef]

- Tomioka, K.; Toyoda, K.; Ishizaki, T.; Noda, T.; Ohta, J.; Kimura, M. Retinal Prosthesis Using Thin-Film Devices on a Transparent Substrate and Wireless Power Transfer. IEEE Trans. Electron Devices 2020, 67, 529–534. [Google Scholar] [CrossRef]

- Park, J.H.; Tan, J.S.Y.; Wu, H.; Dong, Y.; Yoo, J. 1225-Channel Neuromorphic Retinal-Prosthesis SoC with Localized Temperature-Regulation. IEEE Trans. Biomed. Circuits Syst. 2020, 14, 1230–1240. [Google Scholar] [CrossRef]

- Muqit, M.M.K.; Hubschman, J.P.; Picaud, S.; McCreery, D.B.; Van Meurs, J.C.; Hornig, R.; Buc, G.; Deterre, M.; Nouvel-Jaillard, C.; Bouillet, E.; et al. PRIMA Subretinal Wireless Photovoltaic Microchip Implantation in Non-Human Primate and Feline Models. PLoS ONE 2020, 15, e023071. [Google Scholar] [CrossRef] [PubMed]

- Daschner, R.; Rothermel, A.; Rudorf, R.; Rudorf, S.; Stett, A. Functionality and Performance of the Subretinal Implant Chip Alpha AMS. Sens. Mater. 2018, 30, 179–192. [Google Scholar] [CrossRef]

- Cha, K.; Horch, K.; Normann, R.A. Simulation of a Phosphene-Based Visual Field: Visual Acuity in a Pixelized Vision System. Ann. Biomed. Eng. 1992, 20, 439–449. [Google Scholar] [CrossRef]

- Tong, W.; Meffin, H.; Garrett, D.J.; Ibbotson, M.R. Stimulation Strategies for Improving the Resolution of Retinal Prostheses. Front. Neurosci. 2020, 14, 262. [Google Scholar] [CrossRef]

- Lee, S.; Jung, S.W.; Park, S.; Ahn, J.; Hong, S.J.; Yoo, H.J.; Lee, M.H.; Cho, D.I.D. Fabrication and evaluation of silicon nanowire photodetectors on flexible substrate for retinal prosthetic system. Sens. Mater. 2012, 24, 205–220. [Google Scholar]

- Lo Faro, M.J.; Leonardi, A.A.; D’Andrea, C.; Morganti, D.; Musumeci, P.; Vasi, C.; Priolo, F.; Fazio, B.; Irrera, A. Low Cost Synthesis of Silicon Nanowires for Photonic Applications. J. Mater. Sci. Mater. Electron. 2020, 31, 34–40. [Google Scholar] [CrossRef]

- Kochylas, I.; Dimitriou, A.; Apostolaki, M.A.; Skoulikidou, M.C.; Likodimos, V.; Gardelis, S.; Papanikolaou, N. Enhanced Photoluminescence of R6G Dyes from Metal Decorated Silicon Nanowires Fabricated through Metal Assisted Chemical Etching. Materials 2023, 16, 1386. [Google Scholar] [CrossRef] [PubMed]

- Soci, C.; Zhang, A.; Bao, X.Y.; Kim, H.; Lo, Y.; Wang, D. Nanowire Photodetectors. J. Nanosci. Nanotechnol. 2010, 10, 1430–1449. [Google Scholar] [CrossRef]

- Zhang, A.; Kim, H.; Cheng, J.; Lo, Y.-H. Ultrahigh Responsivity Visible and Infrared Detection Using Silicon Nanowire Phototransistors. Nano Lett. 2010, 10, 2117–2120. [Google Scholar] [CrossRef]

- Yang, X.; Gao, A.; Wang, Y.; Li, T. Wafer-Level and Highly Controllable Fabricated Silicon Nanowire Transistor Arrays on (111) Silicon-on-Insulator (SOI) Wafers for Highly Sensitive Detection in Liquid and Gaseous Environments. Nano Res. 2018, 11, 1520–1529. [Google Scholar] [CrossRef]

- Tintelott, M.; Pachauri, V.; Ingebrandt, S.; Vu, X.T. Process Variability in Top-down Fabrication of Silicon Nanowire-based Biosensor Arrays. Sensors 2021, 21, 5153. [Google Scholar] [CrossRef] [PubMed]

- Park, I.; Li, Z.; Pisano, A.P.; Williams, R.S. Top-down Fabricated Silicon Nanowire Sensors for Real-Time Chemical Detection. Nanotechnology 2010, 21, 015501. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Lee, J.K.; Han, S.J.; Lee, S. A Novel Top-down Fabrication Process for Vertically-Stacked Silicon-Nanowire Array. Appl. Sci. 2020, 10, 1146. [Google Scholar] [CrossRef]

- Gong, X.; Zhao, R.; Yu, X. A 3-D-Silicon Nanowire FET Biosensor Based on a Novel Hybrid Process. J. Microelectromech. Syst. 2018, 27, 164–170. [Google Scholar] [CrossRef]

- Zhang, A. SiNW Phototransistor: Designing, Fabricating and Characterizing a High Responsibility, Broadband Photodetector. Ph.D. Thesis, University of California, San Diego, CA, USA, 2010. [Google Scholar]

- Kim, C.; Han, S.; Kim, T.; Lee, S. Implantable pH Sensing System Using Vertically Stacked Silicon Nanowire Arrays and Body Channel Communication for Gastroesophageal Reflux Monitoring. Sensors 2024, 24, 861. [Google Scholar] [CrossRef]

- Nam, K.; Choi, G.; Kim, H.; Yoo, M.; Ko, H. A Potentiostat Readout Circuit with a Low-Noise and Mismatch-Tolerant Current Mirror Using Chopper Stabilization and Dynamic Element Matching for Electrochemical Sensors. Appl. Sci. 2021, 11, 8287. [Google Scholar] [CrossRef]

- Dommel, N.B.; Wong, Y.T.; Lehmann, T.; Dodds, C.W.; Lovell, N.H.; Suaning, G.J. A CMOS Retinal Neurostimulator Capable of Focussed, Simultaneous Stimulation. J. Neural Eng. 2009, 6, 035006. [Google Scholar] [CrossRef]

- Han, S.; Kim, C.; Kim, K.; Lee, S. Implantable Nanostructured MEA with Biphasic Current Stimulator for Retinal Prostheses. Technol. Health Care 2023, 31, 1981–1995. [Google Scholar] [CrossRef]

- Das, K.; Mukherjee, S.; Manna, S.; Ray, S.K.; Raychaudhuri, A.K. Single Si Nanowire (Diameter ≤ 100 Nm) Based Polarization Sensitive near-Infrared Photodetector with Ultra-High Responsivity. Nanoscale 2014, 6, 11232–11239. [Google Scholar] [CrossRef]

- Soci, C.; Zhang, A.; Xiang, B.; Dayeh, S.A.; Aplin, D.P.R.; Park, J.; Bao, X.Y.; Lo, Y.H.; Wang, D. ZnO Nanowire UV Photodetectors with High Internal Gain. Nano Lett. 2007, 7, 1003–1009. [Google Scholar] [CrossRef]

- Sekirnjak, C.; Hottowy, P.; Sher, A.; Dabrowski, W.; Litke, A.M.; Chichilnisky, E.J. Electrical Stimulation of Mammalian Retinal Ganglion Cells with Multielectrode Arrays. J. Neurophysiol. 2006, 95, 3311–3327. [Google Scholar] [CrossRef] [PubMed]

- Boinagrov, D.; Pangratz-Fuehrer, S.; Goetz, G.; Palanker, D. Selectivity of Direct and Network-Mediated Stimulation of the Retinal Ganglion Cells with Epi-, Sub- and Intraretinal Electrodes. J. Neural Eng. 2014, 11, 026008. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Jung, S.W.; Park, S.; Ahn, J.; Hong, S.J.; Yoo, H.J.; Lee, M.H.; Cho, D.I. Ultra-high responsivity, silicon nanowire photodetectors for retinal prosthesis. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.; Han, S.; Lee, S. Highly Photoresponsive Vertically Stacked Silicon Nanowire Photodetector with Biphasic Current Stimulator IC for Retinal Prostheses. Appl. Sci. 2024, 14, 8831. https://doi.org/10.3390/app14198831

Kim T, Han S, Lee S. Highly Photoresponsive Vertically Stacked Silicon Nanowire Photodetector with Biphasic Current Stimulator IC for Retinal Prostheses. Applied Sciences. 2024; 14(19):8831. https://doi.org/10.3390/app14198831

Chicago/Turabian StyleKim, Taehwan, Seungju Han, and Sangmin Lee. 2024. "Highly Photoresponsive Vertically Stacked Silicon Nanowire Photodetector with Biphasic Current Stimulator IC for Retinal Prostheses" Applied Sciences 14, no. 19: 8831. https://doi.org/10.3390/app14198831

APA StyleKim, T., Han, S., & Lee, S. (2024). Highly Photoresponsive Vertically Stacked Silicon Nanowire Photodetector with Biphasic Current Stimulator IC for Retinal Prostheses. Applied Sciences, 14(19), 8831. https://doi.org/10.3390/app14198831