Application of the Extension Strain Criterion for Sandstone Failure Evaluation under Tension and Shear Stress Conditions

Abstract

:1. Introduction

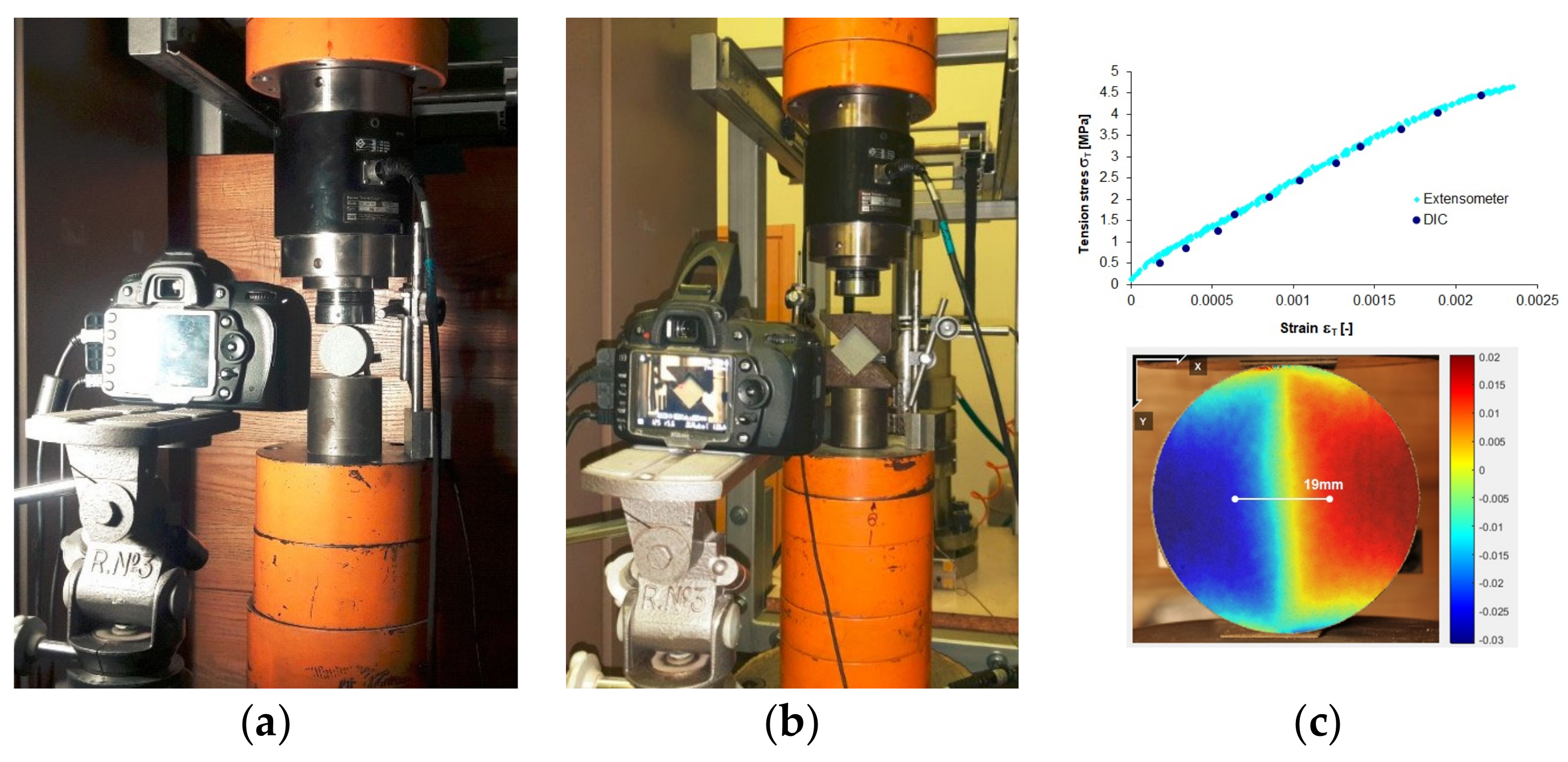

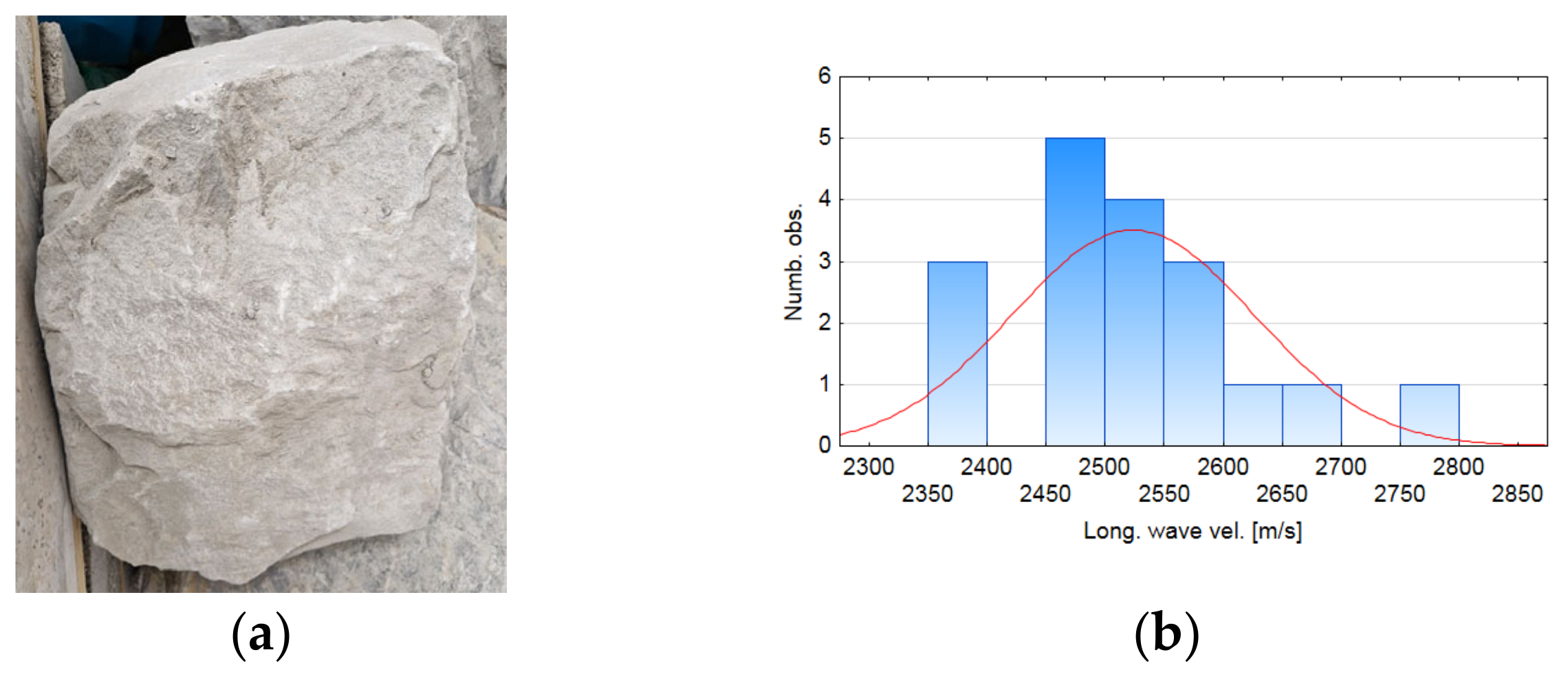

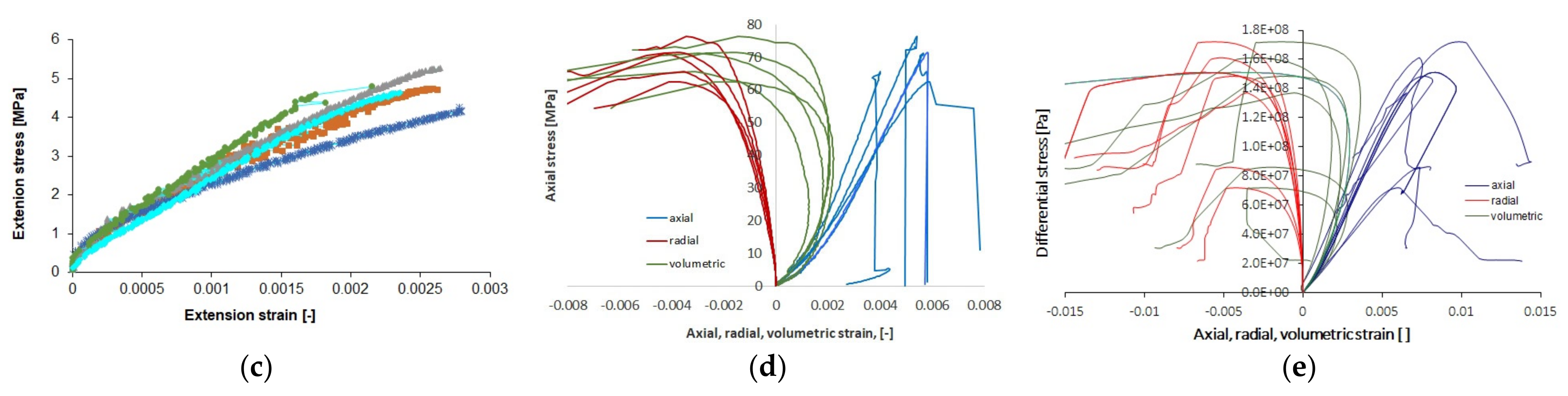

2. Methods and Materials

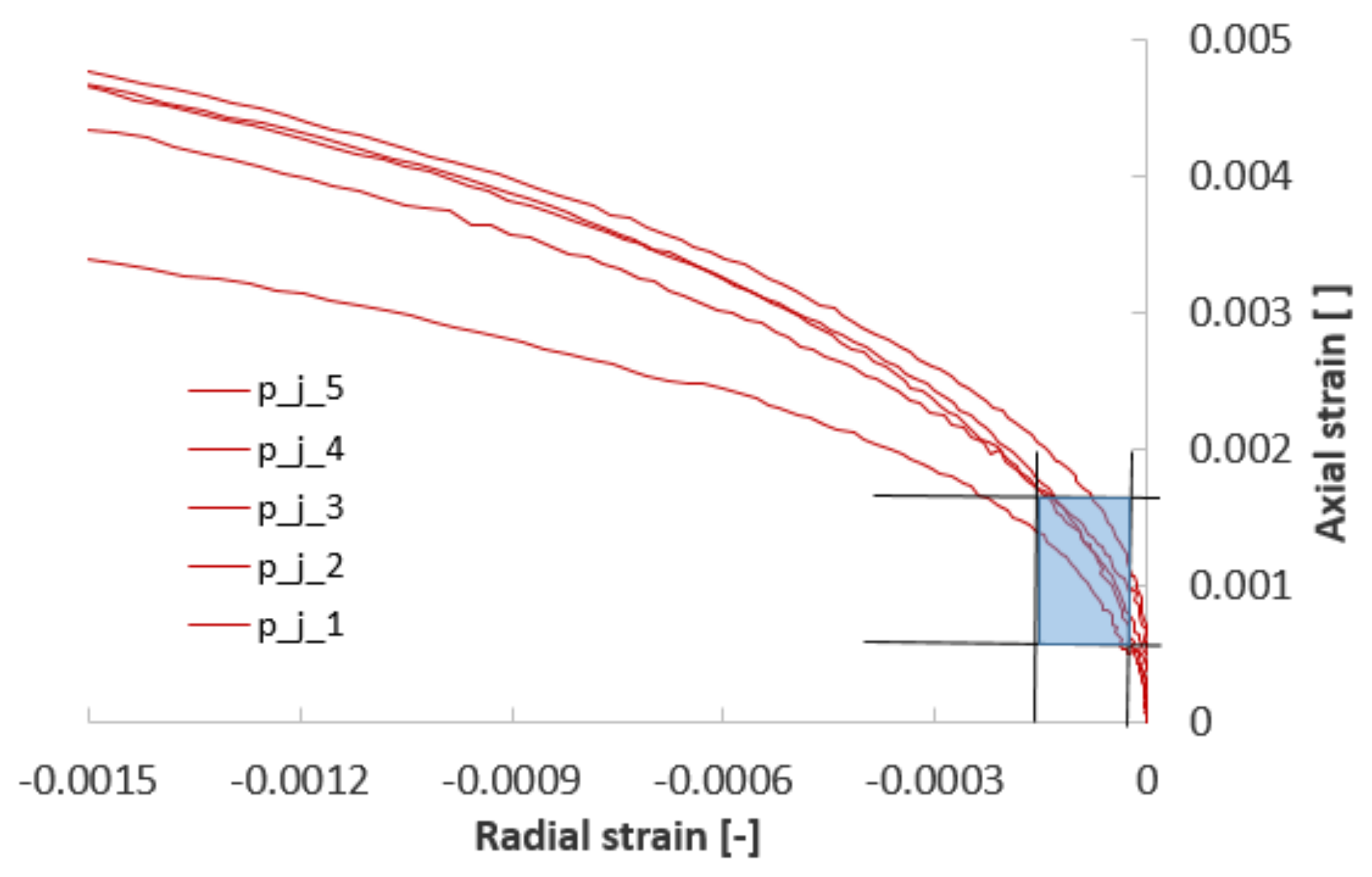

2.1. Methods

2.2. Materials and Preliminary Results

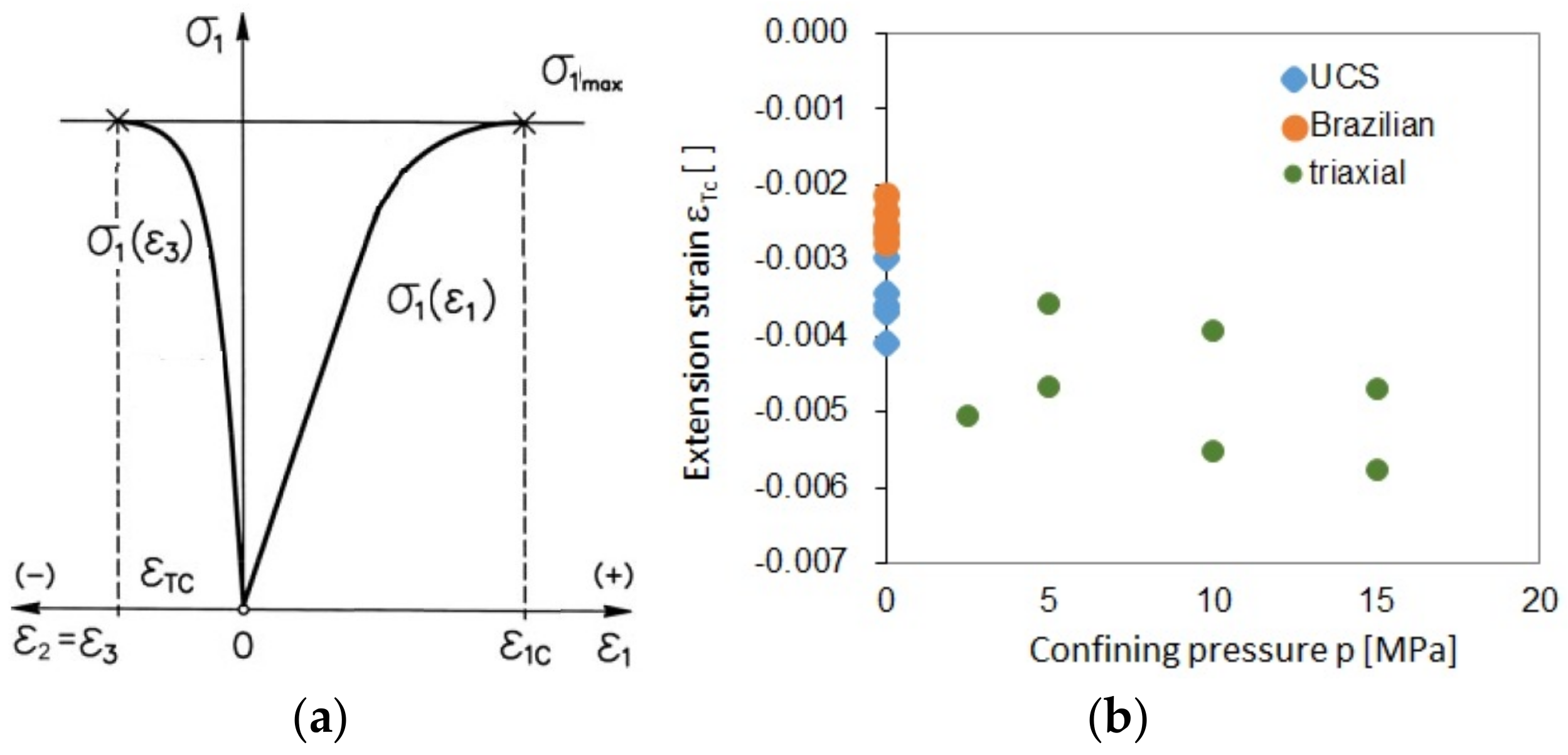

3. Stacey’s Extension Strain Criterion

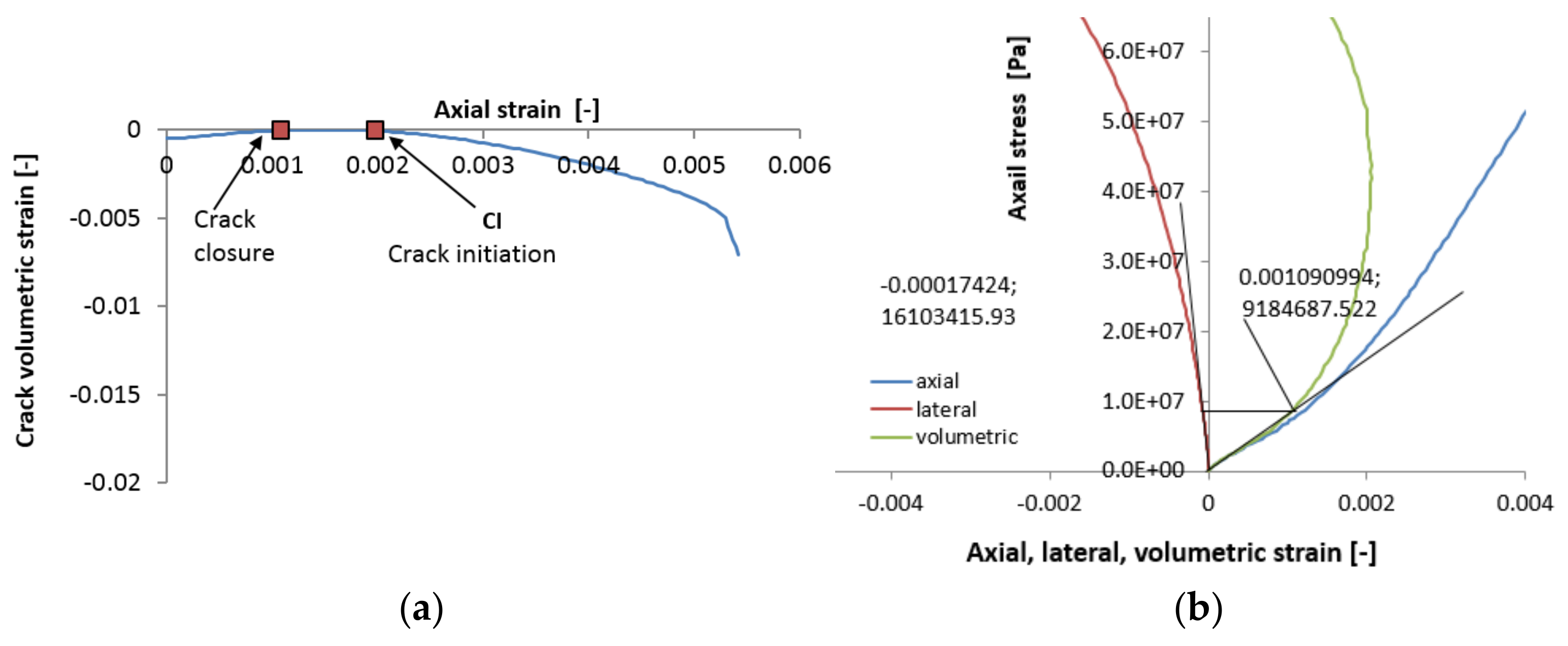

4. The Crack Initiation Threshold as an Extension Strain Criterion in Uniaxial Compression Tests

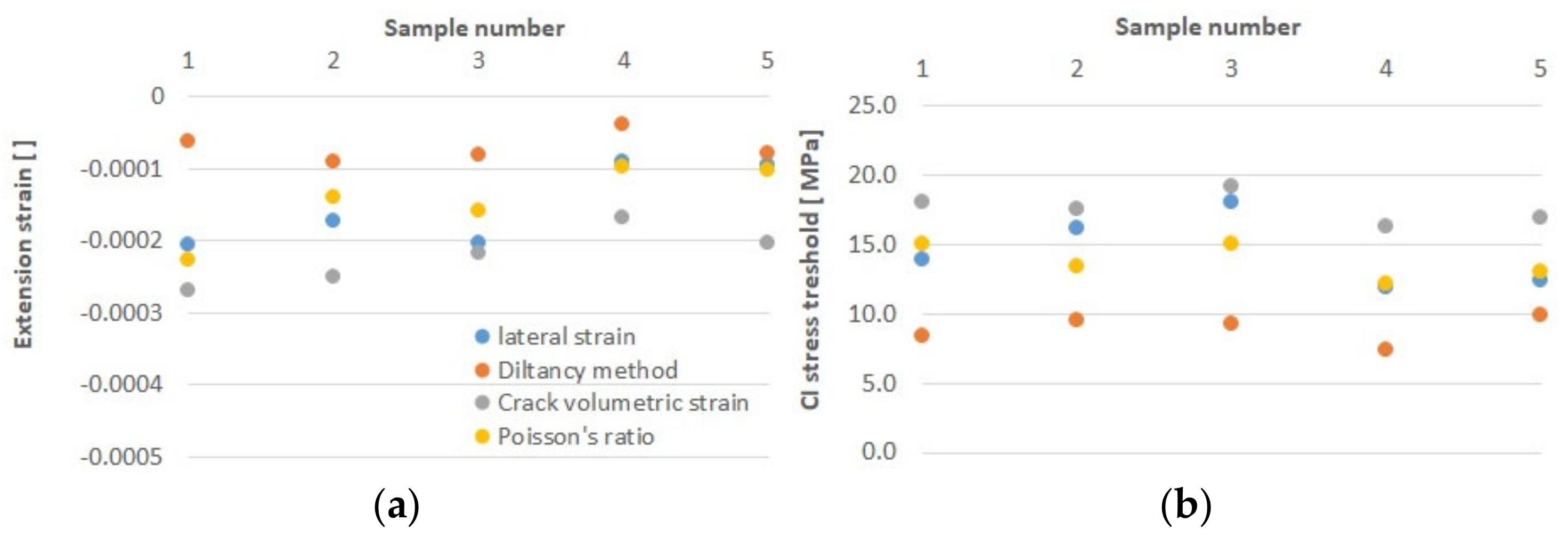

4.1. Assumptions of the Analyses

4.2. Discussion of the Results

5. The Application of Tensile Strength Tests’ Results to Determine the Extension Strain Criterion

5.1. Assumptions of the Analyses

5.2. Discussion of the Results

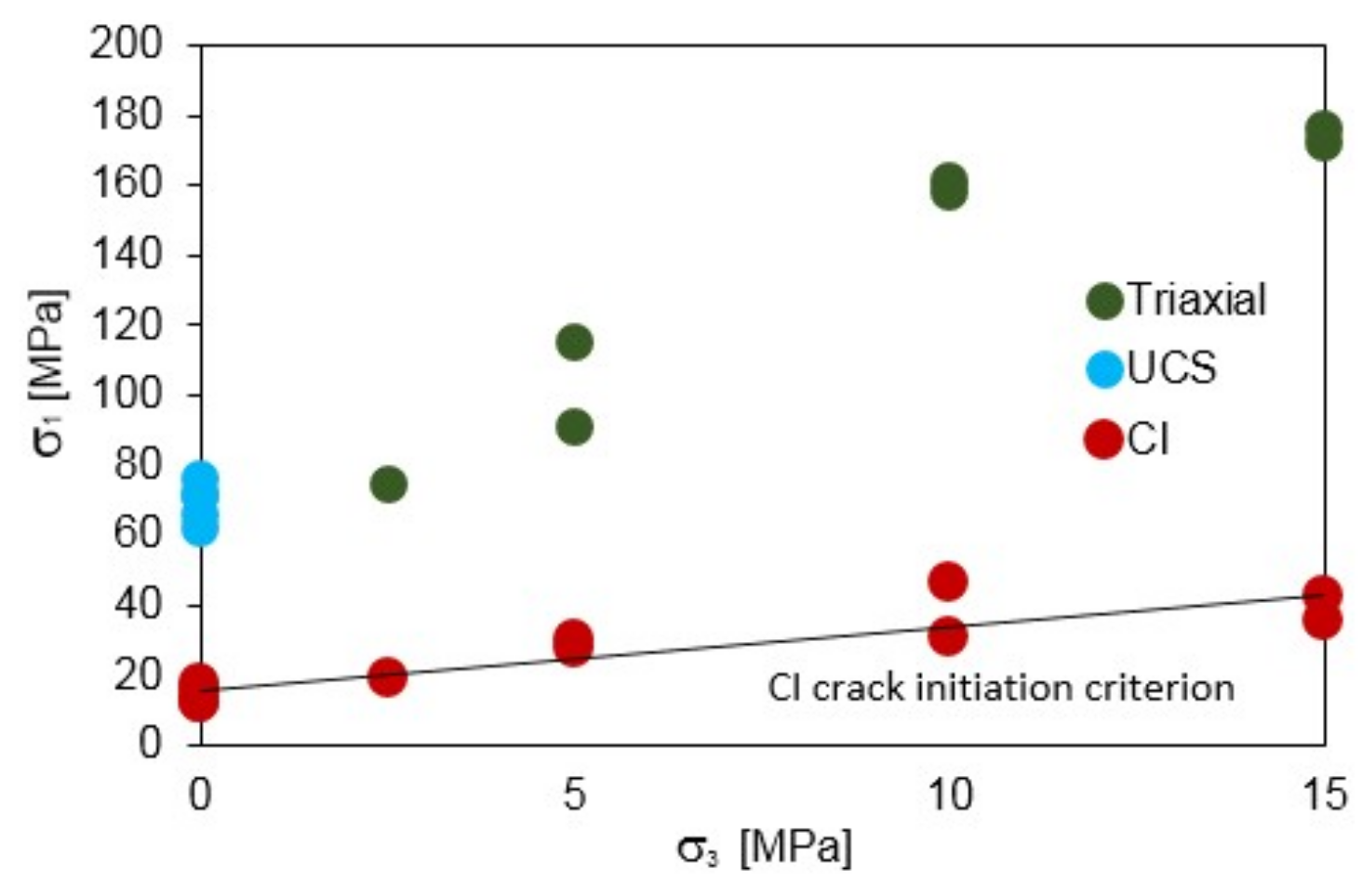

6. The Extension Strain Criterion as a Macroscopic Rock Sample Failure Condition

6.1. Assumptions of the Analyses

6.2. Discussion of the Results

7. The Use of the Extension Strain Criterion to Evaluate the Fracture Initiation in a Sandstone Sample Subjected to Tension in the Brazilian Test

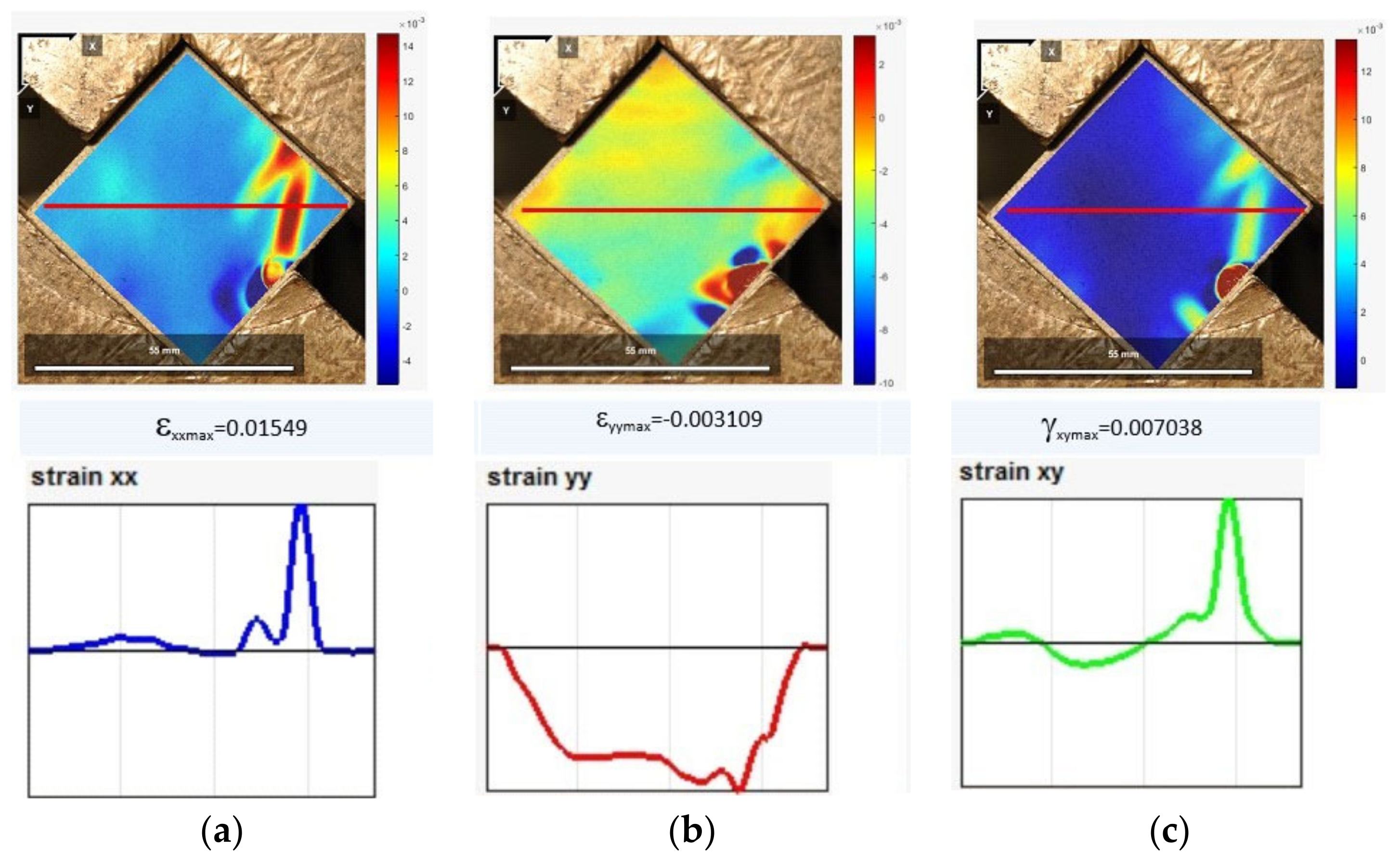

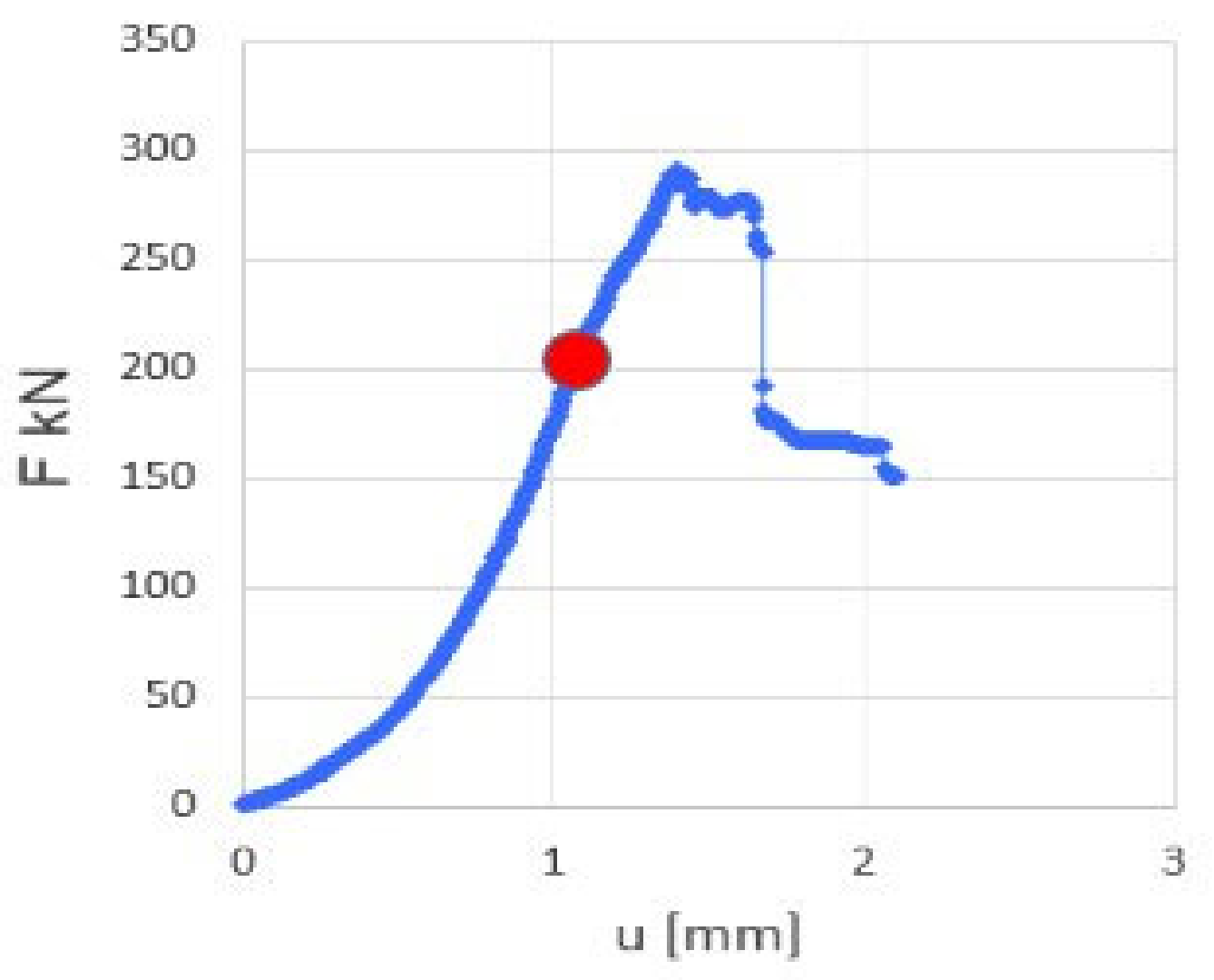

8. The Application of the Extension Strain Criterion to Evaluate the Microscopic Failure of a Rock Sample in the Simple Shear Test

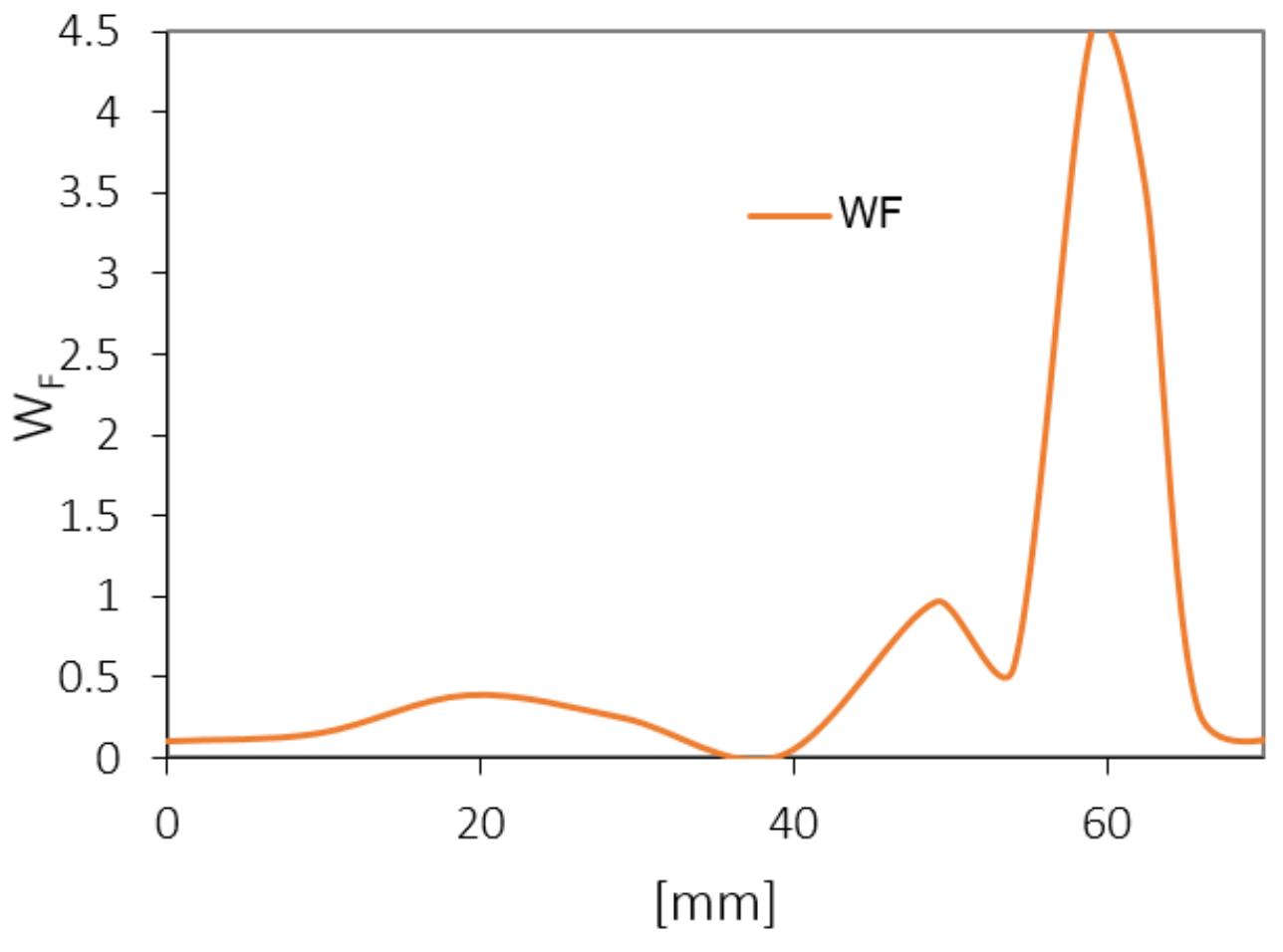

9. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stacey, T.R. A simple extension strain criterion for fracture of brittle rock. Int. J. Rock Mech. Min. Sci. 1981, 18, 469–474. [Google Scholar] [CrossRef]

- Wesseloo, J.; Stacey, T.R. A Reconsideration of the Extension Strain Criterion for Fracture and Failure of Rock. Rock Mech. Rock Eng. 2016, 49, 4667–4679. [Google Scholar] [CrossRef]

- Barton, N.; Shen, B. Risk of shear failure and extensional failure around overstressed excavations in brittle rock. J. Rock Mech. Geotech. Eng. 2017, 9, 210–225. [Google Scholar] [CrossRef]

- Shen, B.; Barton, N. Rock fracturing mechanisms around underground openings. Geomech. Eng. 2018, 16, 35–47. [Google Scholar]

- Andersson, J.C.; Martin, C.D.; Stille, H. The Aspo Pillar Stability Experiment: Part II—Rock mass response to coupled excavation-induced and thermal induced stresses. Int. J. Rock Mech. Min. Sci. 2009, 46, 879–895. [Google Scholar] [CrossRef]

- Barton, N.; Shen, B. Extension failure mechanisms explain failure initiation in deep tunnels and critical heights of cliff faces and near-vertical mountain walls. In Proceedings of the 51st US Rock Mechanics Geomechanics Symposium, San Francisco, CA, USA, 25–28 June 2017. [Google Scholar]

- Martin, C.D.; Kaiser, P.K.; McCreath, D.R. Hoek–Brown parameters for predicting the depth of brittle failure around tunnels. Can. Geotech. J. 1999, 36, 136–151. [Google Scholar] [CrossRef]

- Diederichs, M.S. Rock fracture and collapse under low confinement conditions. Rock Mech. Rock Eng. 2003, 36, 339–381. [Google Scholar] [CrossRef]

- Diederichs, M.S.; Kaiser, P.K. Tensile strength and abutment relaxation as failure control mechanics in underground excavations. Int. J. Rock Mech. Min. Sci. 1999, 36, 69–96. [Google Scholar] [CrossRef]

- Diederichs, M.S.; Kaiser, P.K.; Eberhardt, E. Damage initiation and propagation in hard rock tunnelling and the influence of near-face stress rotation. Int. J. Rock Mech. Min. Sci. 2004, 41, 785–812. [Google Scholar] [CrossRef]

- Shen, B.; Khanal, M.; Shi, J.; Mallants, D. Modelling geomechanical stability of a large deep borehole in shale for radioactive waste disposal. Tunn. Undergr. Space Technol. 2024, 145, 105606. [Google Scholar] [CrossRef]

- Shi, J.; Shen, B.; Khanal, M.; Mallants, D. Analytical and Numerical Estimation of Fracture Initiation and Propagation Regions around Large-Diameter, Deep Boreholes for Disposal of Long-Lived Intermediate-LevelWaste. Energies 2022, 15, 2445. [Google Scholar] [CrossRef]

- Louchnikov, V. Simple calibration of the extension strain criterion for its use in numerical modelling. In Strategic versus Tactical Approaches in Mining 2011; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2011; ISBN 978-0-9806154-6-3. [Google Scholar]

- Fujii, Y.; Kiyama, T.; Ishijima, Y.; Kodama, J. Examination of a Rock Failure Criterion Based on Circumferential Tensile Strain. Pure Appl. Geophys. 1998, 152, 551–577. [Google Scholar] [CrossRef]

- Kwaśniewski, M.; Takahashi, M. Strain-based failure criteria for rocks: State of the art and recent advances. In Proceedings of the ISRM International Symposium—EUROCK 2010, Lausanne, Switzerland, 15–18 June 2010; Taylor & Francis Group: London, UK, 2010. [Google Scholar]

- Staat, M. An Extension Strain Type Mohr–Coulomb Criterion. Rock Mech. Rock Eng. 2021, 54, 6207–6233. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stead, D.; Stimpson, B.; Read, R.S. Identifying crack initiation and propagation thresholds in brittle rock. Can. Geotech. J. 1998, 35, 222–233. [Google Scholar] [CrossRef]

- Nicksiar, M.; Martin, C.D. Evaluation of Methods for Determining Crack Initiation in Compression Tests on Low-Porosity Rocks. Rock Mech. Rock Eng. 2012, 45, 607–617. [Google Scholar] [CrossRef]

- Brace, W.F.; Paulding, B.; Scholz, C. Dilatancy in the fracture of crystalline rocks. J. Geophys. Res. 1966, 71, 3939–3953. [Google Scholar] [CrossRef]

- Perras, M.A.; Diederichs, M.S. A Review of the Tensile Strength of Rock: Concepts and Testing. Geotech. Geol. Eng. 2014, 32, 525–546. [Google Scholar] [CrossRef]

- Li, D.Y.; Ngai, L.; Wong, Y. The Brazilian disc test for rock mechanics applications: Review and new insights. Rock Mech. Rock Eng. 2013, 46, 269–287. [Google Scholar] [CrossRef]

- ISRM. Suggested methods for determining tensile strength of rock materials. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 99–103. [Google Scholar] [CrossRef]

- ASTM D2936-08; Standard Test Method for Direct Tensile Strength of Intact Rock Core Specimens. ASTM International: West Conshohocken, PA, USA, 2008.

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-source 2D digital image correlation Matlab software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Diederichs, M.S. The 2003 Canadian Geotechnical Colloquium: Mechanistic interpretation and practical application of damage and spalling prediction criteria for deep tunnelling. Can. Geotech. J. 2007, 44, 1082–1116. [Google Scholar] [CrossRef]

- Diederichs, M.S.; Martin, C.D. Measurement of spalling parameters from laboratory testing. In Proceedings of the ISRM International Symposium—EUROCK 2010, Lausanne, Switzerland, 15–18 June 2010. [Google Scholar]

- Hondros, G. The evaluation of Poisson’s ratio and the modulus of materials of a low tensile resistance by the Brazilian (indirect tensile) test with particular reference to concrete. Aust. J. Appl. Sci. 1959, 10, 243–268. [Google Scholar]

- Fairhurst, C. On the validity of the ‘Brazilian’ test for brittle materials. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1964, 1, 535–546. [Google Scholar] [CrossRef]

- Hudson, J.A.; Brown, E.T.; Rummel, F. The controlled failure of rock discs and rings loaded in diametral compression. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 241–248. [Google Scholar] [CrossRef]

- Li, X.; Takahashi, M.; Wu, Z.; Xu, D. An experimental study on the failure criteria based on strain. Hokkaido Geotech. 1999, 87–93. (In Japanese) [Google Scholar]

| Copression | Tension | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Samlpe | Conf. σ2 = σ3 | Density | Long. Wave Vel. | σ1 | ε1c | εTc | E | Sample | Density | Long. Wave Vel. | σT | εTc | |

| MPa | kg/m3 | m/s | MPa | [-] | [-] | GPa | [-] | kg/m3 | m/s | MPa | [–] | ||

| p_j_1 | - | 2320.8 | 2565.8 | 71.15 | 0.0049 | −0.0041 | 16.33 | 0.35 | p_r_1 | 2270.66 | 2373.74 | 4.64 | −0.0026 |

| p_j_2 | - | 2351.6 | 2511.1 | 65.68 | 0.0033 | −0.0030 | 14.30 | 0.33 | p_r_2 | 2378.14 | 2474.92 | 4.74 | −0.0026 |

| p_j_3 | - | 2338.4 | 2468.4 | 76.30 | 0.0054 | −0.0034 | 16.92 | 0.24 | p_r_3 | 2289.07 | 2692.31 | 5.27 | −0.0028 |

| p_j_4 | - | 2337.0 | 2555.6 | 71.53 | 0.0058 | −0.0037 | 15.40 | 0.26 | p_r_4 | 2266.47 | 2864.72 | 4.26 | −0.0021 |

| p_j_5 | - | 2278.4 | 2543.3 | 62.50 | 0.0059 | −0.0036 | 13.03 | 0.21 | p_r_5 | 2344.97 | 2472.60 | 4.80 | −0.0028 |

| Average | 2325.2 | 69.4 | 0.0051 | -0.0036 | 15.2 | 0.3 | 2309.9 | 2575.7 | 4.7 | −0.0026 | |||

| Stand. dev. | 25.4 | 4.8 | 0.0009 | 0.0004 | 1.4 | 0.1 | 44.2 | 178.2 | 0.3 | 0.0002 | |||

| p_t_1 | 2.5 | 2327.1 | 2611.84 | 74.54 | 0.0099 | −0.0050 | 9.10 | 0.20 | |||||

| p_t_2 | 5 | 2298.1 | 2569.44 | 91.10 | 0.0082 | −0.0047 | 12.68 | 0.26 | |||||

| p_t_3 | 5 | 2312.3 | 2392.64 | 115.00 | 0.0065 | −0.0036 | 25.38 | 0.20 | |||||

| p_t_4 | 10 | 2321.2 | 2516.13 | 158.50 | 0.0098 | −0.0039 | 23.16 | 0.28 | |||||

| p_t_5 | 10 | 2287.8 | 2363.64 | 161.17 | 0.0073 | −0.0055 | 26.24 | 0.30 | |||||

| p_t_6 | 15 | 2293.4 | 2392.64 | 176.21 | 0.0072 | −0.0047 | 29.79 | 0.25 | |||||

| p_t_7 | 15 | 2334.9 | 2600 | 172.07 | 0.0094 | −0.0058 | 23.43 | 0.27 | |||||

| Average | 2310.7 | 2507.5 | |||||||||||

| Stand. dev. | 16.7 | 99.2 | |||||||||||

| Sample | Lateral Strain | Diltancy Method | Crack Volumetric Strain | Poisson’s Ratio | ||||

|---|---|---|---|---|---|---|---|---|

| εext [] | CI [MPa] | εext [] | CI [MPa] | εext [] | CI [MPa] | εext [] | CI [MPa] | |

| p_j_1 | −0.000207 | 13.84 | −0.000063 | 8.28 | −0.000271 | 17.99 | −0.000228 | 15.00 |

| p_j_2 | −0.000174 | 16.10 | −0.000092 | 9.52 | −0.000250 | 17.53 | −0.000141 | 13.36 |

| p_j_3 | −0.000204 | 17.99 | −0.000081 | 9.18 | −0.000218 | 19.06 | −0.000160 | 14.97 |

| p_j_4 | −0.000091 | 11.83 | −0.000039 | 7.39 | −0.000169 | 16.21 | −0.000099 | 12.09 |

| p_j_5 | −0.000095 | 12.36 | −0.000079 | 9.85 | −0.000204 | 16.89 | −0.000103 | 12.94 |

| Average | −0.000154 | 14.42 | −0.000071 | 8.85 | −0.000222 | 17.54 | −0.000146 | 13.67 |

| Stand. dev. | 0.000051 | 2.32 | 0.000018 | 0.89 | 0.000035 | 0.97 | 0.000047 | 1.15 |

| Sample | σT | εext |

|---|---|---|

| MPa | [–] | |

| p_r_1 | 4.64 | 0.00058 |

| p_r_2 | 4.74 | 0.00059 |

| p_r_3 | 5.27 | 0.00066 |

| p_r_4 | 4.26 | 0.00053 |

| p_r_5 | 4.80 | 0.00060 |

| Average | 4.74 | 0.00059 |

| St. Dev. | 0.32 | 0.00004 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cieślik, J. Application of the Extension Strain Criterion for Sandstone Failure Evaluation under Tension and Shear Stress Conditions. Appl. Sci. 2024, 14, 8953. https://doi.org/10.3390/app14198953

Cieślik J. Application of the Extension Strain Criterion for Sandstone Failure Evaluation under Tension and Shear Stress Conditions. Applied Sciences. 2024; 14(19):8953. https://doi.org/10.3390/app14198953

Chicago/Turabian StyleCieślik, Jerzy. 2024. "Application of the Extension Strain Criterion for Sandstone Failure Evaluation under Tension and Shear Stress Conditions" Applied Sciences 14, no. 19: 8953. https://doi.org/10.3390/app14198953