The Influence of Selected Parameters of Recycled Polyvinyl Butyral on the Sustainable Filament Extrusion Process

Abstract

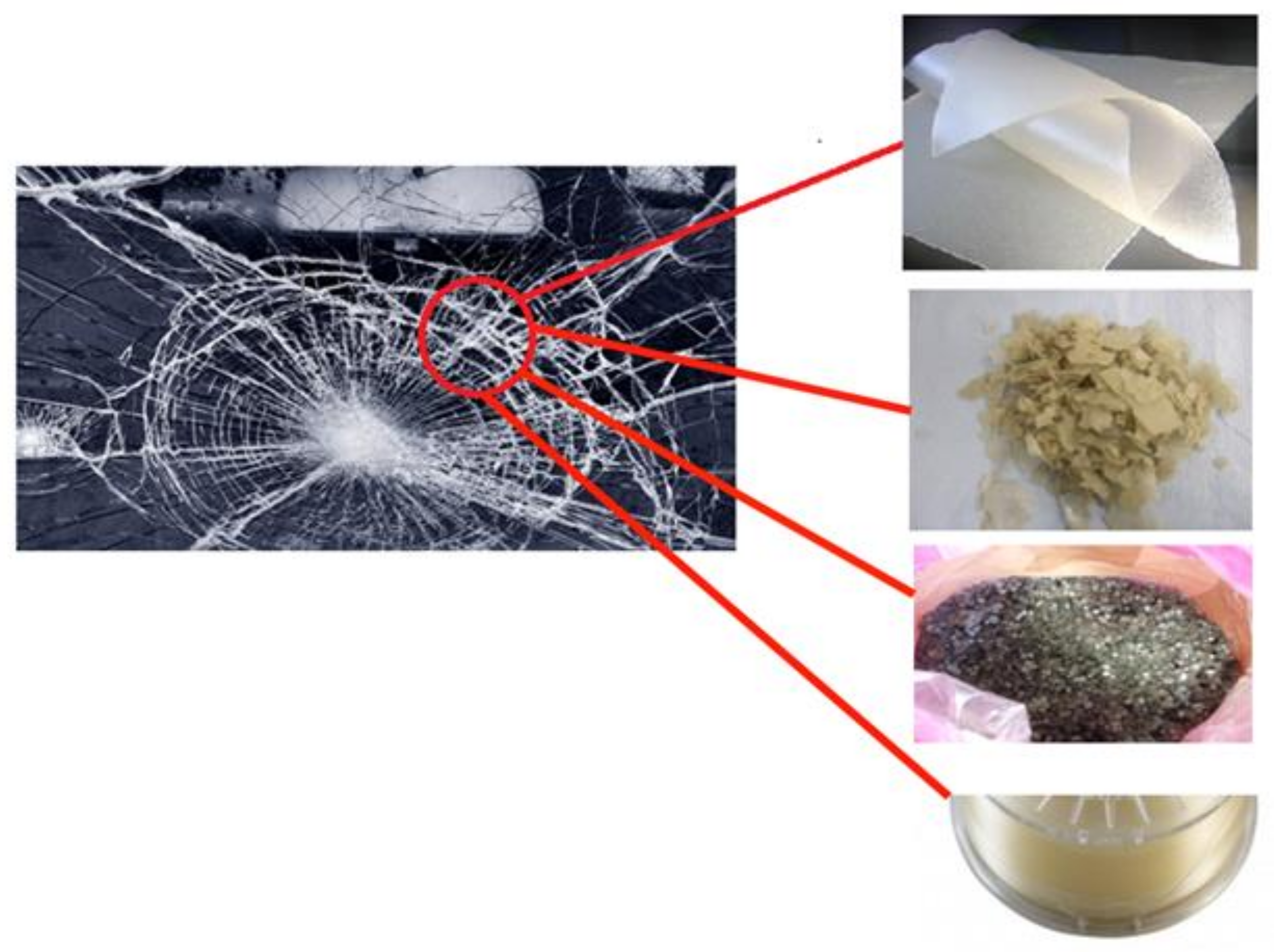

:1. Introduction

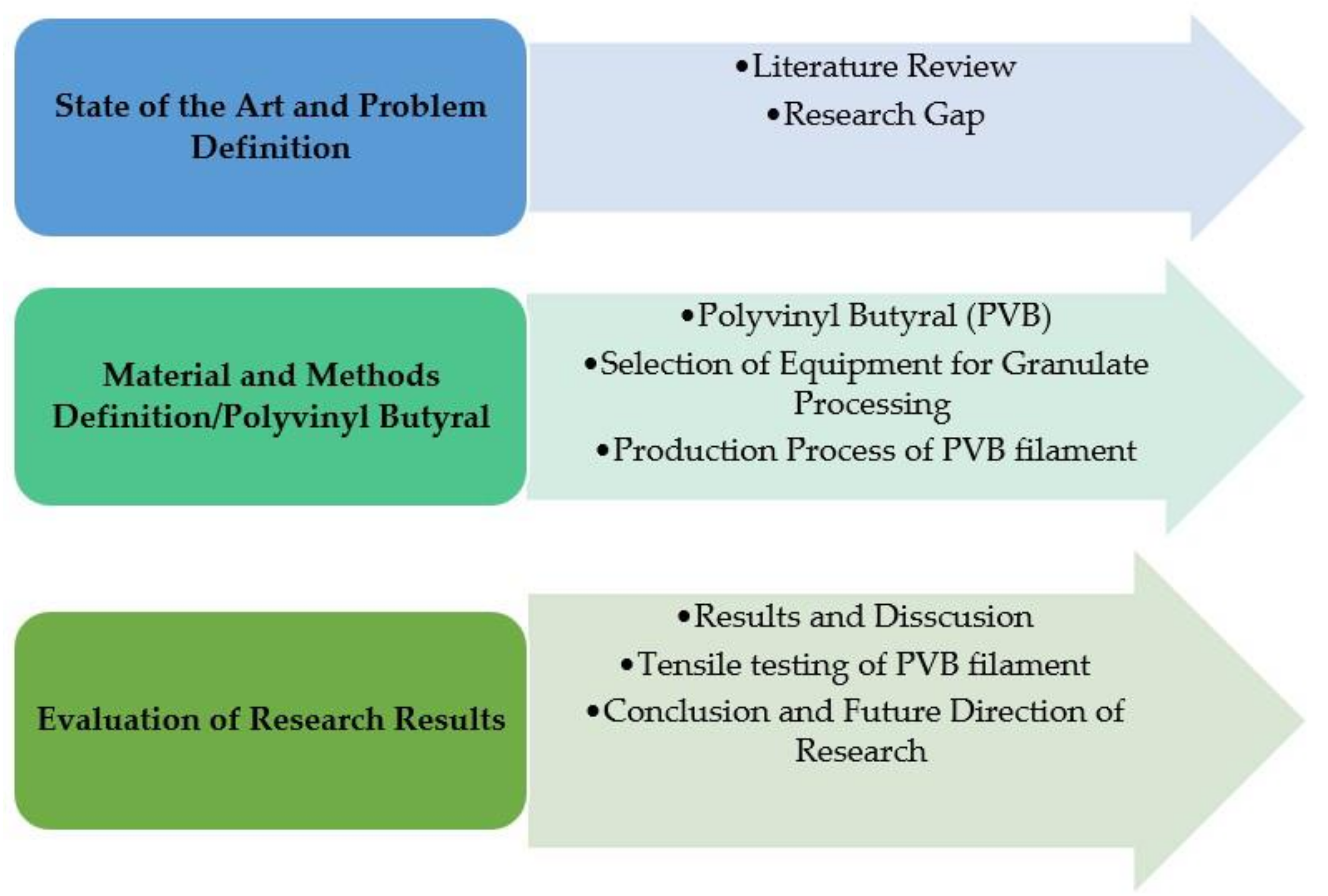

Work Methodology and Research Gap Identification

2. Materials and Methods

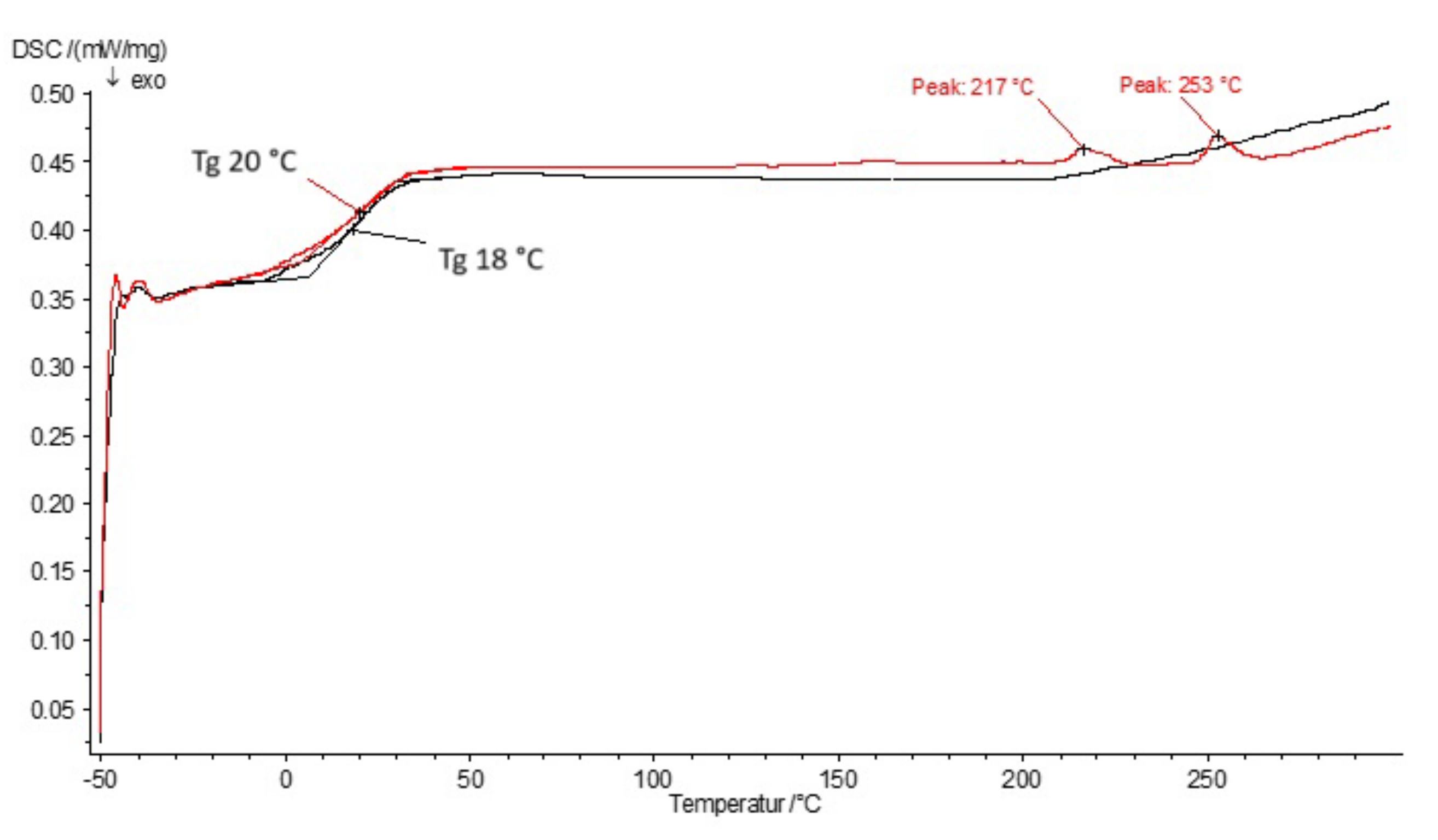

2.1. Differential Scanning Calorimetry

2.2. Selection of Equipment for Granulate Processing

- Nodules or particles in the fiber.

- Insufficient diameter of the extruded fiber.

- High speed of the feeder.

- Low outlet temperature.

- High outlet temperature.

3. Results and Discussion

3.1. Extrusion of Filament from Polyvinyl Butyral Granulates

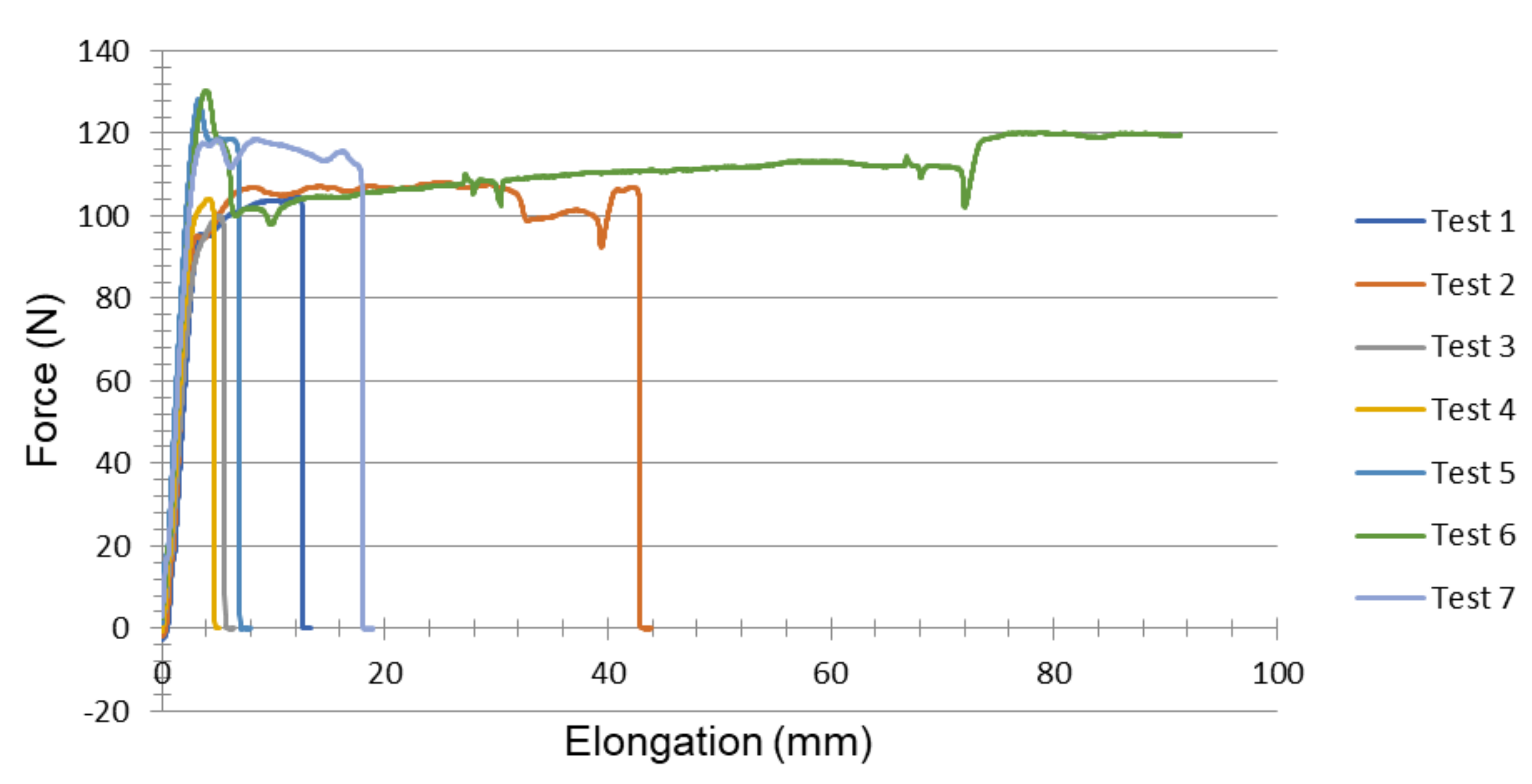

3.2. Tensile Test of Extruded PVB Filament

- if the body breaks outside the marked working part;

- a tear occurs within 10 mm of the jaw.

- frequency and load status of the tested recycled polyvinyl butyral (PVB);

- the magnitude of the mean stress when loading the polyvinyl butyral;

- state of tension of the recycled polyvinyl butyral;

- aggressiveness and temperature of the environment in which the measurement takes place;

- the shape tested from recycled polyvinyl butyral;

- test sample recycled polyvinyl butyral;

- the existence or assumption of cracks in materials (PVB recycled);

- surface properties of the recycled PVB;

- method of preparing the tested sample (use of material processing technology).

- chemical composition of the recycled PVB;

- structural changes in the recycled PVB;

- method of recycled PVB processing (use of material processing technology, as in the case of external factors).

4. Conclusions

- Create a stable environment or one with a constant temperature. Ideally, the location and design of the extrusion equipment should be changed;

- Using a different arrangement of cooling unit fans and increasing their performance or alternative cooling methods;

- Support of circular economy in the manufacturing process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Butyral, P. Handbook of Thermoplastics; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- DePalma, K.; Walluk, M.R.; Murtaugh, A.; Hilton, J.; McConky, S.; Hilton, B. Assessment of 3D printing using fused deposition modeling and selective laser sintering for a circular economy. J. Clean. Prod. 2020, 264, 121567. [Google Scholar] [CrossRef]

- Straka, M.; Taušová, M.; Rosová, A.; Cehlár, M.; Kačmáry, P.; Sisol, M.; Ignácz, P.; Farkas, C. Big data analytics of a waste recycling simulation logistics system. Pol. J. Environ. Stud. 2020, 29, 2355–2364. [Google Scholar] [CrossRef] [PubMed]

- Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on End-Of Life Vehicles. Available online: https://eur-lex.europa.eu/eli/dir/2000/53 (accessed on 30 June 2024).

- Behún, M.; Behúnová, A. Advanced Innovation Technology of BIM in a Circular Economy. Appl. Sci. 2023, 13, 7989. [Google Scholar] [CrossRef]

- Bustos Seibert, M.; Mazzei Capote, G.A.; Gruber, M.; Volk, W.; Osswald, T.A. Manufacturing of a PET filament from recycled material for material extrusion (MEX). Recycling 2022, 7, 69. [Google Scholar] [CrossRef]

- Królikowski, M.; Żach, P.; Kalestyński, M. Selection of Conditions in PVB Polymer Dissolution Process for Laminated Glass Recycling Applications. Polymers 2022, 14, 5119. [Google Scholar] [CrossRef]

- Balint, T.; Živčák, J.; Kohan, M.; Lancoš, S.; Ondrejová, B. Optimization of parameters during filament extrusion. Exp. Mech. 2023, 30, 1. [Google Scholar]

- Hartig, S.; Hildebrandt, L.; Fette, M.; Meyer, T.; Musienko, E.; Redlich, T.; Wulfsberg, J. Process parameter determination for small recycling plants for the production of filament for FFF printing using the Taguchi method. Prog. Addit. Manuf. 2021, 7, 87–97. [Google Scholar] [CrossRef]

- Turku, I.; Kasala, S.; Kärki, T. Characterization of Feedstock Filament Extruded from Secondary Sources of PS, ABS and PVC. Recycling 2018, 3, 57. [Google Scholar] [CrossRef]

- Šooš, Ľ.; Matúš, M.; Pokusová, M.; Čačko, V.; Bábics, J. The recycling of waste laminated glass through decomposition technologies. Recycling 2021, 6, 26. [Google Scholar] [CrossRef]

- McCaw, J.C.S.; Cuan-Urquizo, E. Mechanical characterization of 3D printed, non-planar lattice structures under quasi-static cyclic loading. Rapid Prototyp. J. 2019, 26, 707–717. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Liu, B.; Zhu, M.; Ge, D. Experimental study on mechanical behavior of PVB laminated glass under quasi-static and dynamic loadings. Compos. Part B Eng. 2011, 42, 302–308. [Google Scholar] [CrossRef]

- Xu, D.; Yang, W.; Fan, H.; Liu, J.; Duan, X.; Xu, W.; Liu, K. Comparative Analysis on Strength Properties of Fabric Using Intra-layer Polyvinyl Butyral-paste Spinning. Fibers Polym. 2021, 22, 2027–2035. [Google Scholar] [CrossRef]

- Dou, H.; Cheng, Y.; Ye, W.; Zhang, D.; Li, J.; Miao, Z.; Rudykh, S. Effect of process parameters on tensile mechanical properties of 3D printing continuous carbon fiber-reinforced PLA composites. Materials 2020, 13, 3850. [Google Scholar] [CrossRef] [PubMed]

- Rypl, R.; Chudoba, R.; Mörschel, U.; Stapleton, S.E.; Gries, T.; Sommer, G. A novel tensile test device for effective testing of high-modulus multi-filament yarns. J. Ind. Text. 2015, 44, 934–947. [Google Scholar] [CrossRef]

- Rodrigues, S.; Miri, S.; Cole, R.G.; Postigo, A.A.; Saleh, M.A.; Dondish, A.; Melenka, G.W.; Fayazbakhsh, K. Towards optimization of polymer filament tensile test for material extrusion additive manufacturing process. J. Mater. Res. Technol. 2023, 24, 8458–8472. [Google Scholar] [CrossRef]

- DIN 53015; Viscometry—Measurement of viscosity using the Hoeppler Falling-Ball Viscometer. European Standards: Plzen, Czech Republic, 2019.

- DIN ISO 11465-1996-12; Soil quality—Determination of Dry Matter and Water Content on a Mass Basis. European Standards: Plzen Czech Republic, 1996.

- Grabowik, C.; Kalinowski, K.; Ćwikła, G.; Paprocka, I.; Kogut, P. Tensile tests of specimens made of selected group of the filament materials manufactured with FDM method. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 112, p. 04017. [Google Scholar]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties. ISO: Genewa, Switzerland, 2019.

- Wu, S.; Bhat, G.S. Inorganic fullerene-like tungsten disulfide/waterborne polyurethane reinforced Spectra® composites with improved mechanical properties and tensile energy absorption. Results Mater. 2023, 18, 100389. [Google Scholar] [CrossRef]

- Aggromito, D.; Pascoe, L.; Klimenko, J.; Farley, J.; Tatarsky, M.; Wholey, W. Simulation of PVB-glass adhesion and its influence on the blast protection properties of laminated safety glass. Int. J. Impact Eng. 2022, 170, 104372. [Google Scholar] [CrossRef]

- Liu, B.; Sun, Y.; Li, Y.; Wang, Y.; Ge, D.; Xu, J. Systematic experimental study on mechanical behavior of PVB (polyvinyl butyral) material under various loading conditions. Polym. Eng. Sci. 2012, 52, 1137–1147. [Google Scholar] [CrossRef]

- Cherif, C.; Seidel, A.; Younes, A.; Hausding, J. Evaluation of a tensile test for the determination of the material behaviour of filament yarns under high strain rates. AUTEX Res. J. 2010, 10, 88–94. [Google Scholar] [CrossRef]

- Kliment, M.; Trebuna, P.; Pekarcikova, M.; Straka, M.; Trojan, J.; Duda, R. Production Efficiency Evaluation and Products Quality Improvement Using Simulation. Int. J. Simul. Model. 2020, 19, 470–481. [Google Scholar] [CrossRef]

- Židek, K.; Piteľ, J.; Adámek, M.; Lazorík, P.; Hošovský, A. Digital Twin of Experimental Smart Manufacturing Assembly System for Industry 4.0 Concept. Sustainability 2020, 12, 3658. [Google Scholar] [CrossRef]

- Knapčíková, L.; Behúnová, A.; Kaščak, J.; Husár, J. Polyvinyl Butyral (PVB) as a Significant Material Used by Additive Manufacturing. In 6th EAI International Conference on Management of Manufacturing Systems. EAI/Springer Innovations in Communication and Computing; Knapčíková, L., Peraković, D., Eds.; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Dhaliwal, A.K.; Hay, J.N. The characterization of polyvinyl butyral by thermal analysis. Thermochim. Acta 2002, 391, 245–255. [Google Scholar] [CrossRef]

- Török, J.; Törökova, M.; Duplakova, D.; Murcinkova, Z.; Duplak, J.; Kascak, J.; Karkova, M. Advanced Configuration Parameters of Post Processor Influencing Tensile Testing PLA and Add-Mixtures in Polymer Matrix in the Process of FDM Technology. Appl. Sci. 2021, 11, 6212. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Kabir, A.M.; Malhan, K.R.; Shah, B.; Shembekar, A.V.; Yoon, Y.J.; Gupta, S.K. A Robotic Cell for Multi-Resolution Additive Manufacturing. In Proceedings of the International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 2800–2807. [Google Scholar] [CrossRef]

- Ismail Mourad, A.-H.; Idrisi, A.H.; Christy, J.V.; Thekkuden, D.T.; Al Jassmi, H.; Ghazal, A.M.; Syam, M.M.; Ali Ahmed Al Qadi, O.D. Mechanical Performance Assessment of Internally-Defected Materials Manufactured Using Additive Manufacturing Technology. J. Manuf. Mater. Process. 2019, 3, 74. [Google Scholar] [CrossRef]

- Vasilescu, M.D.; Fleser, T. Influence of Technological Parameters on the Dimension of GEAR Parts Generated with PLA Matherial by FDM 3D Printing. Mater. Plast. 2018, 55, 247–251. [Google Scholar] [CrossRef]

- Little, H.A.; Tanikella, N.G.; Reich, J.M.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks. Materials 2020, 13, 4273. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.; Liebscher, M.; Mechtcherine, V. Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes. Sustainability 2021, 13, 159. [Google Scholar] [CrossRef]

- Ahlers, D.; Wasserfall, F.; Hendrich, N.; Zhang, J. 3D printing of nonplanar layers for smooth surface generation. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 1737–1743. [Google Scholar] [CrossRef]

- Wielki, J.; Grabara, J. The Impact of Ad-Blocking on the Sustainable Development of the Digital Advertising Ecosystem. Sustainability 2018, 10, 4039. [Google Scholar] [CrossRef]

- Kleijnen, J. Supply chain simulation tools and techniques: A survey. Int. J. Simul. Process Model. 2005, 1, 82. [Google Scholar] [CrossRef]

- Straka, M.; Khouri, S.; Rosova, A.; Caganova, D.; Culkova, K. Utilization of Computer Simulation for Waste Separation Design as a Logistics System. Int. J. Simul. Model. 2018, 17, 583–596. [Google Scholar] [CrossRef]

- Gil Muñoz, V.; Muneta, L.M.; Carrasco-Gallego, R.; de Juanes Marquez, J.; Hidalgo-Carvajal, D. Evaluation of the Circularity of Recycled PLA Filaments for 3D Printers. Appl. Sci. 2020, 10, 8967. [Google Scholar] [CrossRef]

| Material PVB—Polyvinyl Butyral, Recycled | |

|---|---|

| Form | Flakes |

| Melting temperature | 130–170 °C |

| Color | Transparent |

| Viscosity | 100–175 m Pa·s (DIN 53015) |

| Melt volume rate (MVR) | 6–7 cm3/10 min |

| Melt flow rate (MFR) | 5–6 g/10 min |

| PLA (z) | PVB (z) | PLA (x,y) | PVB (x,y) | |

|---|---|---|---|---|

| Tensile Yield Strength [MPa] | 51 ± 3 | 50 ± 5 | 59 ± 2 | 49 ± 5 |

| Tensile Modulus [GPa] | 2.3 ± 0.1 | 1.7 ± 0.1 | 2.4 ± 0.1 | 1.7 ± 0.1 |

| Elongation at Yield Point [%] | 2.9 ± 0.3 | 4.6 ± 0.7 | 3.2 ± 1 | 4.4 ± 0.7 |

| Flexural Strength [MPa] | 83 ± 6 | 72 ± 1 | 99 ± 1 | 73 ± 3 |

| Flexural Modulus [GPa] | 3.1 ± 0.1 | 2.2 ± 0.1 | 3.2 ± 0.1 | 2.3 ± 0.1 |

| Deflection at Flexural Strength [mm] | 7.5 ± 0.2 | 8.4 ± 0.4 | 8.3 ± 0.2 | 8.5 ± 0.3 |

| Impact Strength Charpy [kJ/m2] | 13 ± 1 | 55 ± 7 | 14 ± 1 | 59 ± 12 |

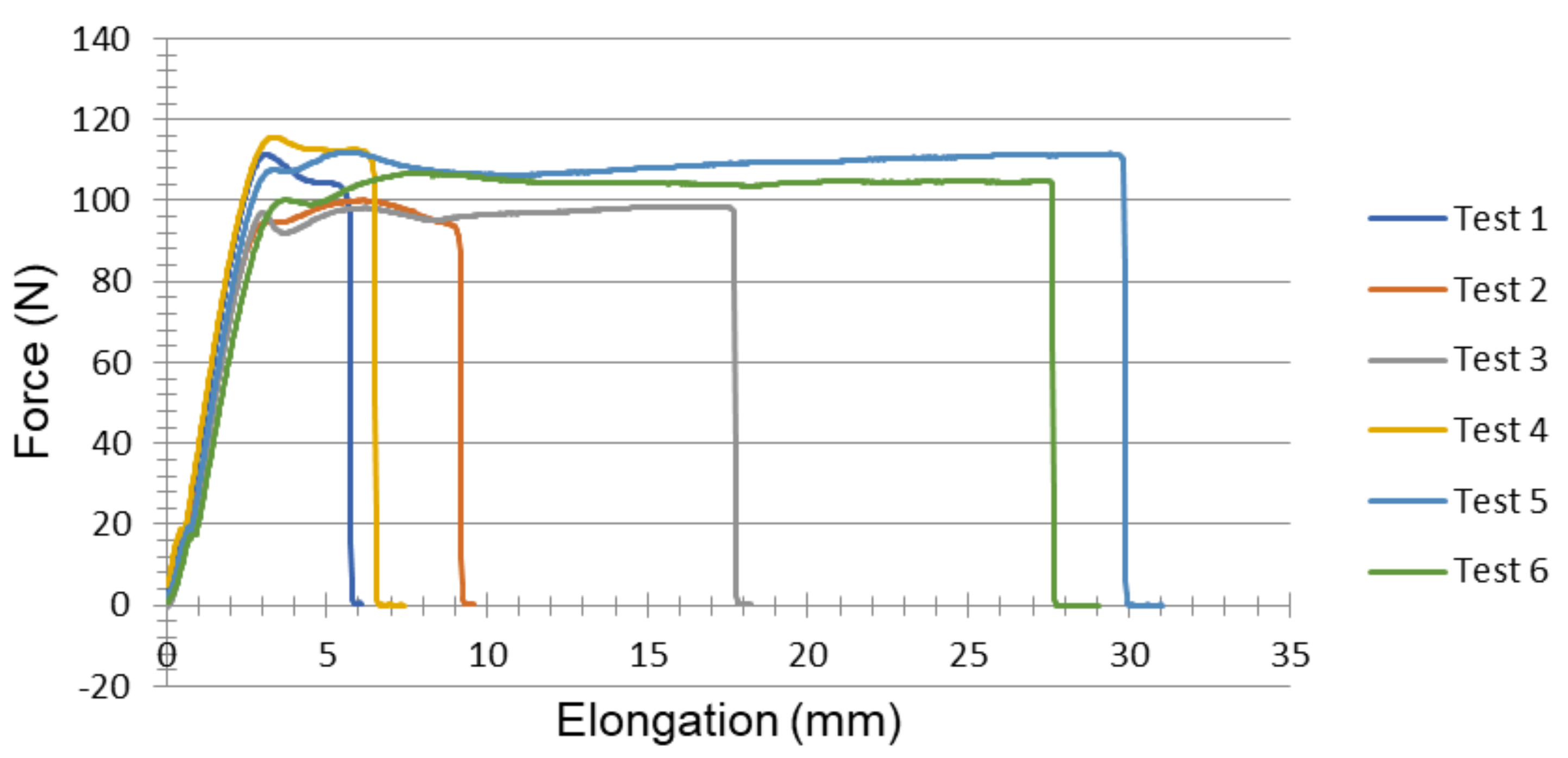

| Test No | Temperature | Force Peak (N) | Elongation at Break (%) | Elong. Peak (mm) | Strain Peak (%) | Tensile Stress (MPa) | Stress Yield (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 140 | 104.53 | 43.459 | 12.327 | 12.327 | 0.020 | 43.454 |

| 2 | 140 | 108.19 | 44.98 | 25.187 | 25.187 | 0.021 | 44.959 |

| 3 | 140 | 100.08 | 41.608 | 5.165 | 5.165 | 0.025 | 41.588 |

| 4 | 140 | 104.05 | 43.259 | 4.197 | 4.197 | 0.017 | 43.255 |

| 5 | 140 | 128.27 | 53.328 | 3.328 | 3.328 | 0.021 | 53.312 |

| 6 | 140 | 118.54 | 49.283 | 8.549 | 8.549 | 0.037 | 49.221 |

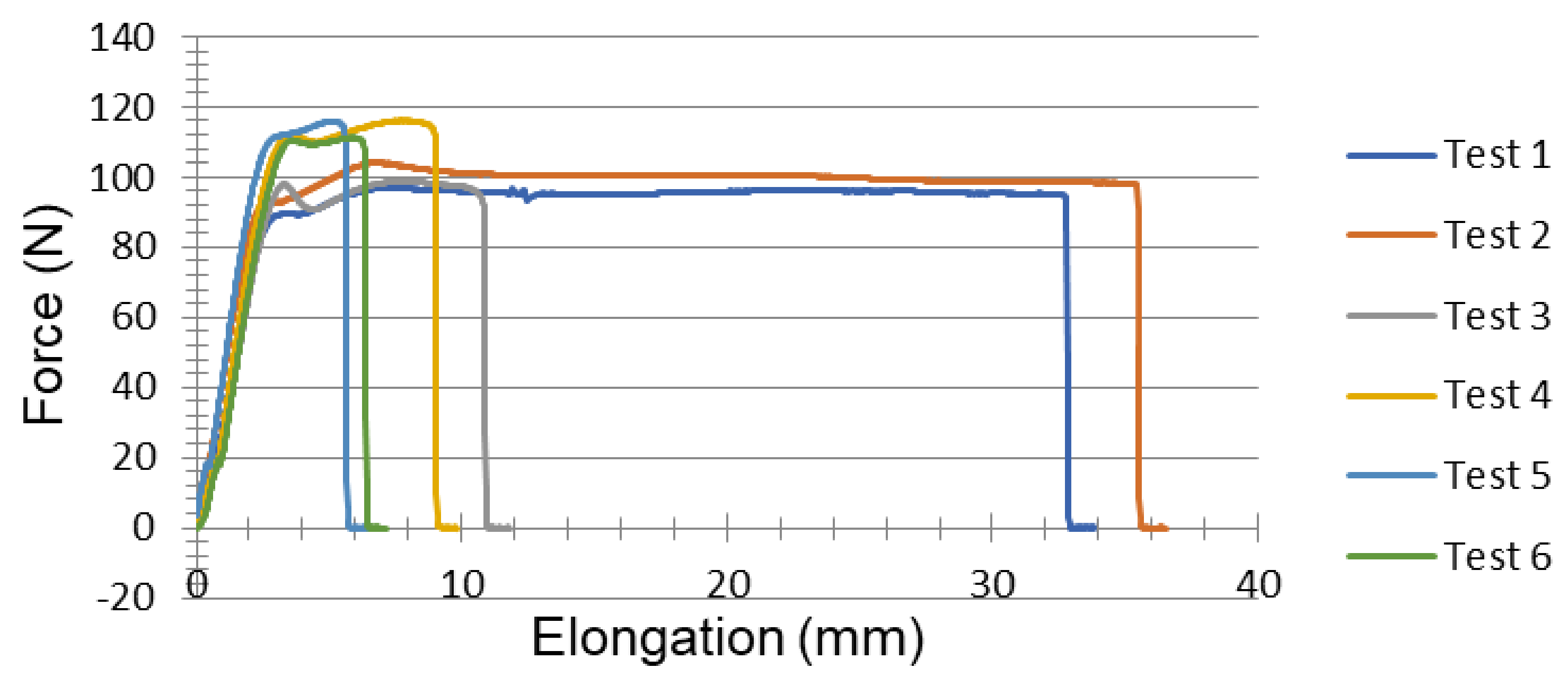

| Test No | Temperature | Force Peak (N) | Elongation at Break (%) | Elong. Peak (mm) | Strain Peak (%) | Tensile Stress (MPa) | Stress Yield (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 150 | 90.88 | 37.784 | 5.438 | 5.438 | 0.037 | 37.771 |

| 2 | 150 | 100.88 | 41.941 | 3.012 | 3.012 | 0.025 | 41.916 |

| 3 | 150 | 105.87 | 44.016 | 3.18 | 3.18 | 0.029 | 43.995 |

| 4 | 150 | 108.27 | 45.013 | 50.434 | 50.434 | 0.054 | 44.244 |

| 5 | 150 | 97.28 | 40.444 | 5.67 | 5.67 | 0.017 | 40.415 |

| 6 | 150 | 96.81 | 40.249 | 5.165 | 5.165 | 0.017 | 40.241 |

| Test No | Temperature | Force Peak (N) | Elongation at Break (%) | Elong. Peak (mm) | Strain Peak (%) | Tensile Stress (MPa) | Stress Yield (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 155 | 111.3 | 46.273 | 3.096 | 3.096 | 0.158 | 46.257 |

| 2 | 155 | 100.03 | 41.588 | 6.104 | 6.104 | 0.187 | 41.579 |

| 3 | 155 | 98.56 | 40.976 | 16.725 | 16.725 | 0.158 | 40.336 |

| 4 | 155 | 115.68 | 48.094 | 3.362 | 3.362 | 0.025 | 48.073 |

| 5 | 155 | 111.96 | 46.548 | 5.56 | 5.56 | 0.029 | 46.539 |

| 6 | 155 | 106.71 | 44.365 | 7.659 | 7.659 | 0.008 | 44.357 |

| Test No | Temperature | Force Peak (N) | Elongation at Break (%) | Elong Peak (mm) | Strain Peak (%) | Tensile Stress (MPa) | Stress Yield (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 160 | 96.88 | 40.278 | 7.576 | 7.576 | 0.025 | 40.27 |

| 2 | 160 | 104.18 | 43.313 | 6.94 | 6.94 | 0.021 | 43.301 |

| 3 | 160 | 98.98 | 41.151 | 7.752 | 7.752 | 0.071 | 40.719 |

| 4 | 160 | 116.1 | 48.269 | 7.747 | 7.747 | 0.017 | 48.26 |

| 5 | 160 | 115.83 | 48.157 | 5.155 | 5.155 | 0.008 | 48.14 |

| 6 | 160 | 111.18 | 46.223 | 5.9 | 5.9 | 0.008 | 46.207 |

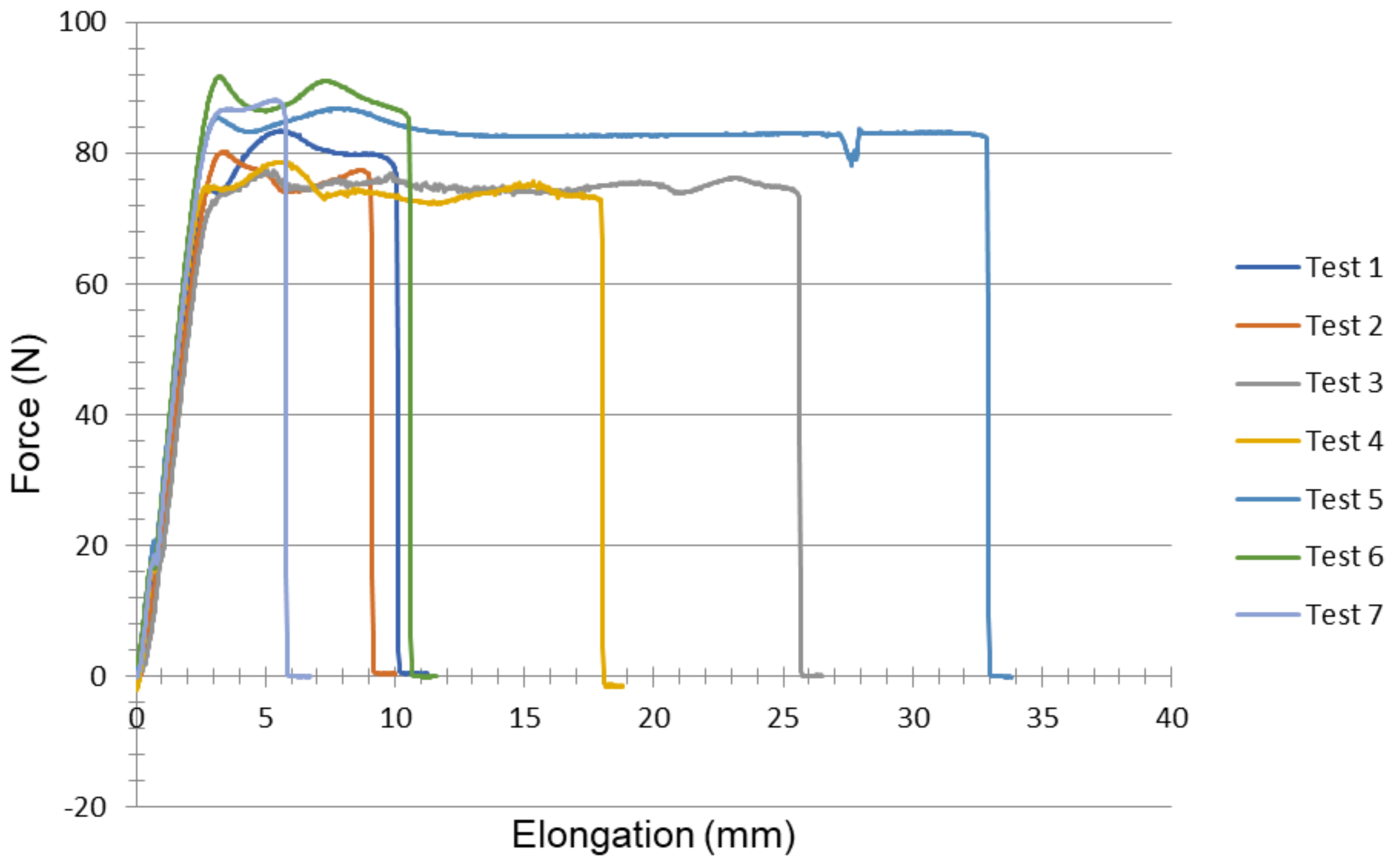

| Test No | Temperature | Force Peak (N) | Elongation at Break (%) | Elong Peak (mm) | Strain Peak (%) | Tensile Stress (MPa) | Stress Yield (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 175 | 83.4 | 34.674 | 5.552 | 5.552 | 0.183 | 34.657 |

| 2 | 175 | 80.14 | 33.318 | 3.353 | 3.353 | 0.146 | 33.314 |

| 3 | 175 | 77.4 | 32.179 | 4.879 | 4.879 | 0.017 | 32.009 |

| 4 | 175 | 78.6 | 32.678 | 5.525 | 5.525 | 0.582 | 32.67 |

| 5 | 175 | 86.81 | 36.091 | 7.905 | 7.905 | 0.021 | 36.079 |

| 6 | 175 | 91.63 | 38.095 | 3.212 | 3.212 | 0.033 | 38.075 |

| 7 | 175 | 88.08 | 36.619 | 5.31 | 5.31 | 0.008 | 36.615 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martiček, M.; Tauberová, R.; Kaščak, J.; Vandžura, R.; Sukić, E.; Knapčíková, L. The Influence of Selected Parameters of Recycled Polyvinyl Butyral on the Sustainable Filament Extrusion Process. Appl. Sci. 2024, 14, 9752. https://doi.org/10.3390/app14219752

Martiček M, Tauberová R, Kaščak J, Vandžura R, Sukić E, Knapčíková L. The Influence of Selected Parameters of Recycled Polyvinyl Butyral on the Sustainable Filament Extrusion Process. Applied Sciences. 2024; 14(21):9752. https://doi.org/10.3390/app14219752

Chicago/Turabian StyleMartiček, Matúš, Rebeka Tauberová, Jakub Kaščak, Radoslav Vandžura, Enes Sukić, and Lucia Knapčíková. 2024. "The Influence of Selected Parameters of Recycled Polyvinyl Butyral on the Sustainable Filament Extrusion Process" Applied Sciences 14, no. 21: 9752. https://doi.org/10.3390/app14219752

APA StyleMartiček, M., Tauberová, R., Kaščak, J., Vandžura, R., Sukić, E., & Knapčíková, L. (2024). The Influence of Selected Parameters of Recycled Polyvinyl Butyral on the Sustainable Filament Extrusion Process. Applied Sciences, 14(21), 9752. https://doi.org/10.3390/app14219752