Abstract

This study aims to incorporate building and demolition waste, including lime and crushed granite, as partial alternatives for cement and fine aggregates, respectively, and to devise a plan to reduce their environmental effect resulting from their extensive prevalence in substantial amounts. The use of lime in paste, mortar, and concrete has become a common practice to regulate the environment, save resources, and improve performance in various settings. The first stage of this study investigated the effects of replacing different proportions (0%, 15%, 25%, 35%, and 50%) of lime powder with cement on the physical and mechanical properties of mortar specimens over 7, 28, and 90 days. The next phase of the research examined the impacts of substituting varying quantities (ranging from 10% to 100%) of granite powder in 15 different mixes, while keeping a consistent water-to-binder ratio of 0.45. The last part of the study consisted of an examination of data from previous research on cement mortar and lime-modified cement mortar. This included testing on flowability, standard consistency, setting time, flexural strength, and compressive strength. The acquired data underwent a statistical analysis, which resulted in the development of equations that may predict the mechanical characteristics of changed cement mortar mixes. These equations also highlight the impact of certain physical qualities on compressive and flexural strength.

1. Introduction

In the cement industry, there is a pressing need to enhance sustainability by minimizing energy consumption and CO2 emissions. This is particularly crucial for the European sector, which heavily relies on imported raw materials, thereby exacerbating energy use and emissions [1]. To address this, ongoing research is being conducted to explore alternative fuels derived from waste materials, improve material efficiency, and develop manufacturing methods with near-zero emissions, all aimed at reducing costs and environmental impacts [2]. Furthermore, stakeholders across the value chain can leverage the environmental benefits of cement production to support the principles of a circular economy [3,4].

Lime-based building materials, such as lime mortar, have a rich historical legacy spanning centuries or even millennia. Lime, an inorganic substance containing calcium in the form of carbonates, oxides, and hydroxides, is typically derived from chalk or limestone. It can be processed by cutting, grinding, or pulverizing before undergoing chemical treatment. Lime contributes to material workability, cohesion, adhesion, air content, and moisture levels. Broadly, there are three lime categories, including fat lime, hydraulic lime, and poor lime, each serving distinct purposes.

Presently, lime mortar finds application primarily in the ongoing maintenance of ancient historical structures and temples. Combining lime mortar with pozzolanic materials can lead to enhanced strength and reduced setting times due to the formation of calcium silicate hydrate (C-S-H) gel upon exposure to water [5,6]. However, it is worth noting that lime mortar requires more time to set and achieve strength compared to cement mortar. The process of carbonation, involving the transformation of calcium hydroxide (CaOH2) into calcium carbonate (CaCO3) in the presence of carbon dioxide and air, is responsible for setting and strength development in pure lime. In contrast, cement’s strength primarily arises from hydration, the interaction between bogue compounds in cement and water [7,8,9].

Granite, an igneous rock formed when magma cools beneath the Earth’s surface, can undergo contact metamorphism when it encounters limestone, leading to the creation of metamorphic rock known as skarn [10]. This transformation is a consequence of the high heat and pressure experienced by rocks, causing mineral components to rearrange or new minerals to form [11]. Recycling granite fragments serves as an environmentally friendly and cost-effective solution, preventing waste from being sent to landfills and offering a versatile solid stone [12].

Research has explored the use of granite in high-performance concrete, particularly granite powder as a partial substitute for sand. These investigations have demonstrated its positive impact on mechanical properties, with concrete containing 25% granite powder (GP25) proving superior to other mix ratios and even ordinary concrete [13]. Singh et al. [14] discovered that substituting 10–20% granite cutting waste (GCW) for fine aggregate in concrete enhanced compressive strength by 11.8–14.2% and split tensile strength by 13.5–16.7%. Water absorption reduced by 7.4–9.2%, hence augmenting durability nonetheless, performance deteriorated as GCW replacement reached above 30%. According to research by Singh et al. [15], high-strength concrete’s compressive strength was raised by 12–16% and split tensile strength by 10–15% when 10–20% granite cutting waste (GCW) was used as a substitute for fine aggregate. There was an improvement in durability due to a 5–8% reduction in water absorption, although performance dropped when replacement levels were over 30%.

Studies, such as those conducted by Upadhyaya et al. [16], have evaluated the feasibility of incorporating granite dust as a partial replacement for natural sand in reinforced concrete, concluding that up to 15% of natural river sand can be substituted with granite dust in the construction of reinforced concrete structures. Furthermore, investigations by Ahmed and Tobbala [17] have shown that ECC blends with up to 10% sand replaced by granite dust exhibit improved compressive, flexural, and bond strength properties compared to control ECC blends. Additionally, granite dust has a positive influence on the microstructure of ECC, reducing the number of pores. Suresh et al.’s research has explored the use of waste granite dust particles as a substitute for finer sand particles in concrete mixtures, resulting in enhanced compression, failure, and bending properties of conventional concrete [18].

The inclusion of amorphous silica is essential for improving durability. Amorphous silica, especially in the forms of silica fume or nanoparticles, interacts with calcium hydroxide in cement to produce supplementary calcium silicate hydrate (C-S-H). This response enriches the microstructure by closing capillary holes, hence reducing permeability and improving the concrete’s durability against environmental assaults such as chloride penetration [19].

This research intends to accomplish three primary goals due to the accumulation of building debris stemming from the conflict in Mosul. The primary objective is to integrate lime waste into the formulation of cement–lime mortar at ratios of 10%, 25%, 35%, and 50% as a partial replacement of cement to produce mortar with satisfactory properties for construction purposes, while simultaneously mitigating environmental waste and contributing to the reduction in cement consumption, whic substantially affects the emission of significant volumes of carbon dioxide (CO2) into the atmosphere. The second purpose is to analyze the characteristics of cement–lime mortar including granite powder as a partial replacement for fine aggregates by assessing its physical and mechanical qualities. The third purpose is to establish nonlinear connections for predicting certain physical attributes and estimating compressive and flexural strength, using statistical analysis of the experimental findings from this study in conjunction with data gathered from prior research in this field.

2. Materials

2.1. Cement

Throughout the experimental work, Ordinary Portland Cement (OPC) of grade 32.5 according to ASTM C150 [20] was utilized. Table 1 shows the various physical properties of the used cement. The data in Table 1 were acquired from tests carried out during this study.

Table 1.

Physical properties of OPC (32.5 grade).

2.2. Lime

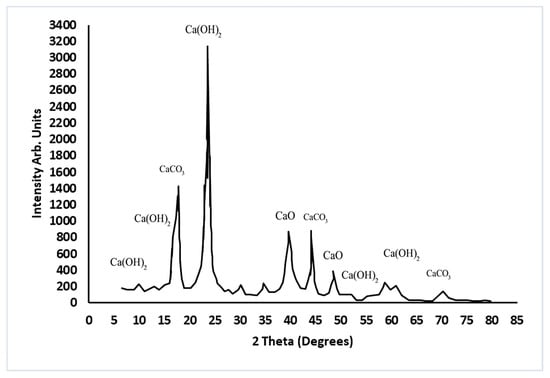

To produce cement–lime mortar, high calcium hydraulic lime according to ASTM C141 [21] was used as a binder and as a partial replacement for cement. In this investigation, the percentage of lime utilized was 0, 15, 25, 35, and 50% by weight of cement. The physical and chemical properties of the used lime are presented in Table 2. The data in Table 2 were acquired from tests carried out during this study. The XRD results were acquired following the analysis of the lime samples conducted in a local laboratory, as shown in Figure 1, which demonstrates that hydraulic lime contains a lot of Ca(OH)2.

Table 2.

Physical and chemical properties of used lime.

Figure 1.

XRD lime analysis.

2.3. Fine Aggregate

Sand extracted from the local river-bed having maximum a size of 4.5 mm was evaluated in accordance with ASTM C33 [22] and utilized as fine aggregate. The specific gravity of the sand was 2.62, unit weight was 1683 kg/m3, and the fineness modulus was 2.84.

2.4. Granite Powder

Granite powder is a fine residue derived from the crushing and processing of granite rocks. It mostly consists of quartz, feldspar, and other minerals typically present in granite. Granite powder has several advantages when used as a partial substitute for cement in mortar formulations: Granite powder has a tiny particle size, often passing through a No. 325 sieve, facilitating its effective integration with other constituents in the mixture. The fineness enhances the packing density of the particles, possibly increasing the mechanical qualities of the mortar.

Pozzolanic activity: While granite powder is not a conventional pozzolanic substance, it may demonstrate modest pozzolanic activity owing to the presence of reactive silica. This may enhance strength growth over time, especially during prolonged curing. Physical properties like specific gravity, water absorption, and bulk density of granite powder are shown in Table 3.

Table 3.

Physical properties of granite.

3. Methodology

In order to reach the best results, the experimental work was divided into two parts. The first part aims to find the optimal ratio to replace cement with lime in masonry mortar. To achieve this goal, five mortar mixtures (1:2.75) were prepared, containing 10% silica fume as an additive with replacement ratios of 0, 15, 25, 35, and 50% of lime as a partial replacement of cement. A total of 45 cubes (50 × 50 mm) for compressive strength were tested at 7, 28, and 90 days according to ASTM C109/C109M [26]; 15 prisms (40 × 40 × 160 mm) for flexural strength at age 28 days according to ASTM C348 [27]; and 10 cylinders (100 × 200 mm) for splitting strength at age 28 days according to ASTM C496/C496M [28]. Dry density and water absorption tests were carried out according to ASTM C642 [29]. The mix containing 25% lime as a partial replacement of cement was chosen as an economical mix as well as meeting the structural requirements of cement–lime mortar to be used as a masonry mortar.

The second part included ten mixes: 90 cubes (50 × 50 mm) according to ASTM C109/C109M, 30 prisms (40 × 40 × 160 mm) according to ASTM C348, and 30 cylinders (100 × 200 mm) according to ASTM C496/C496M containing 25% lime as a partial replacement of cement, as well as different percentages of granite powder (10, 20, 30, 40, 50, 60, 70, 80, 90, and 100%) as a partial replacement for fine aggregate. The ideal combination was identified based on the findings of the physical and mechanical characteristics, featuring the most effective ratio of granite powder as a partial replacement for fine aggregate. Table 4 represents the mixing proportions of cement–lime mortars.

Table 4.

Mix proportions of cement–lime mortar.

Curing and testing parameters: Following the mixing process, all samples were enclosed in a plastic bag for a duration of 48 h. specimens were removed from molds and immersed in water at a temperature of 23 ± 2 °C until the testing commenced. Testing occurred at 7, 28, and 90 days. This process aims to assess the mechanical and physical characteristics of mortar mixes to enhance the durability and performance of masonry mortar, using lime and granite powder as sustainable ingredients.

4. Results and Discussion

4.1. Flowability

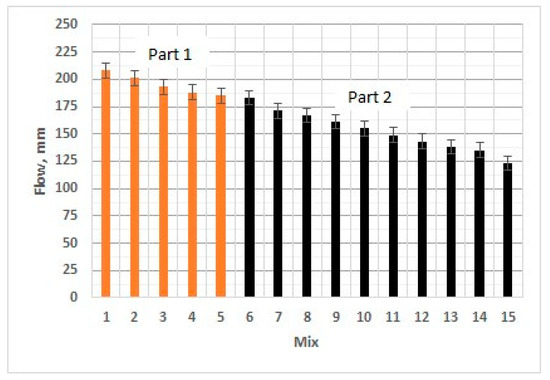

In its fresh state, the mortar’s flowability is the most important factor. To determine the flowability of mortar, the flow table test was utilized according to [30]. This involves placing the material in two layers and compacting it without segregation or bleeding. The flow values of various mixes are represented in Figure 2. Incorporating 15, 25, 35, and 50% lime as a partial replacement for cement significantly reduced the flowability of the cement-lime mortar. Also, a significant reduction was observed in mortar flowability when 25% lime was used as a partial replacement for cement and 10% to 100% granite powder was used as a partial replacement for fine aggregate. Figure 2, part 1 demonstrates a decline in the flowability of the cement–lime mortar as the replacement ratios of lime (15%, 25%, 35%, and 50%) for cement increase. Moreover, in Figure 2, part 2 of the mixtures, a consistent reduction in flowability is seen as the granite powder replacement ratios escalate in the presence of 25% lime. The data indicate that greater replacements lead to a significant decrease in flowability, due to elevated viscosity and cohesion in the mixture. This conduct is wholly consistent with the findings of [31].

Figure 2.

Flow of various mixes.

4.2. Compressive Strength

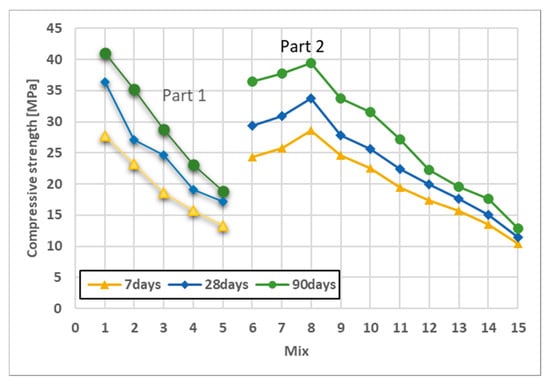

Figure 3 depicts the results of replacing a portion of 0, 15, 25, 35, and 50% cement with lime. In the first part, represented by mixtures (1, 2, 3, 4, and 5), it was demonstrated that an increase in the percentage of lime replacement for cement results in a significant decrease in compressive strength at ages 7, 28, and 90 days. This is due to the fact that lime has a lower compressive strength than cement. As the percentage of lime in the mixture increased, the overall strength of the mortar decreased [32]. Such behavior is consistent with many studies ([33,34,35]). In the second part, the use of 25% lime as a partial replacement for cement, along with 10%, 20%, and 30% granite powder as a partial replacement for fine aggregate in mixes 6, 7, and 8, resulted in a significant improvement in compressive strength. This enhancement results from the synergistic actions of lime, which facilitates the pozzolanic reaction and improves binding characteristics, and granite powder, which serves as a filler, refining the concrete’s microstructure [36].

Figure 3.

Compressive strength for various mixes at ages 7, 28, and 90 days.

Mix no. 8, containing 25% lime as a partial replacement for cement and 30% granite powder as a replacement for fine aggregate, gave better results than the rest of the mixes. Mix no. 8 was characterized by an intense increase in compressive strength and a combination of viscous consistency as well as an increase in the density of the microstructure due to the increase in hydration products. Increasing the proportion of fine aggregate replaced with granite powder to more than 30% has an important adverse effect on the loss in compressive strength.

4.3. Flexural Strength

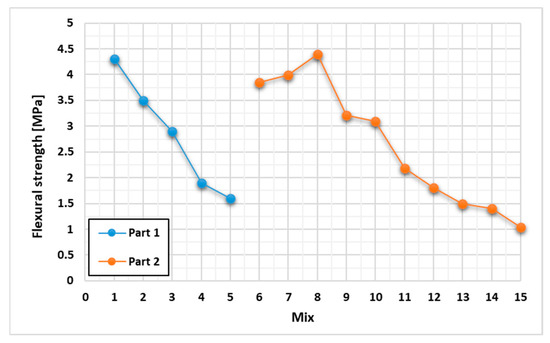

Figure 4 illustrates the flexural strength of mortars formed using a single binder over a 28-day period. In the initial segment, the cement mortar with the standard composition displayed the highest strength, followed by a notable reduction in strength as the proportion of lime increased. Specifically, mortars containing 15%, 25%, 35%, and 50% lime experienced a decline in flexural strength by 19%, 32%, 56%, and 63%, respectively. Comparable results can be found in existing scientific literature concerning both hydrated lime and cement mortars [37,38].

Figure 4.

Flexural strength for various mixes at age of 28 days.

Concerning the latter part of Figure 4, mixtures featuring granitic aggregates as a partial replacement for sand at ratios of 10%, 20%, and 30%, while maintaining a fixed cement replacement rate of 25%, exhibited an enhancement in flexural strength upon the introduction of fine granitic aggregates. Subsequently, there was a substantial reduction in flexural strength, reaching 76% when 100% granite aggregate was employed as a partial substitute for sand. Consistent with the findings of Torgal et al. [39,40], it is advisable to avoid employing cement contents at or below 25% in lime–cement mortars, as this may adversely affect strength. This may be attributed to the improved mechanical properties of the mixture containing 25% lime as a partial replacement for cement and 30% fine granite aggregate as a substitute for sand, as evident in the latter segment of Figure 4, a consequence of the use of flexible additives that reduce pore size.

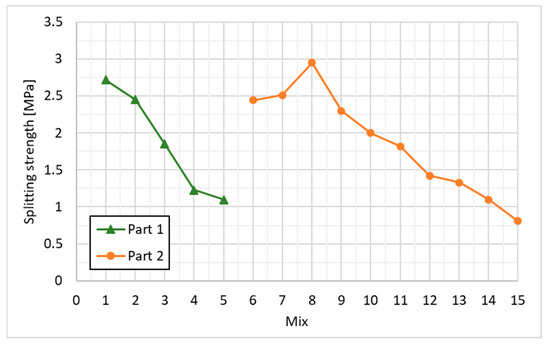

4.4. Splitting Tensile Strength

The tensile strength of concrete or mortar is closely related to its compressive strength. Analysis of the first part of Figure 5 shows that the splitting strength decreases significantly as the ratio of cement replacement lime increases. In the second half of Figure 5, mix no. 8 is 30% fine granite aggregate instead of fine aggregate, 25% lime as a partial replacement of cement, and 10% silica fume, at a constant water–cement ratio of 0.45. After that, the splitting strength was significantly reduced, which was due to the increased replacement of cement with lime.

Figure 5.

Splitting strength for various mixes at age of 28 days.

5. Data Collected and Statistical Analysis

In order to investigate and assess the impact of lime content on properties of cement–lime mortar, such as density and flowability, as well as the hardened properties of compressive, direct tensile, splitting, and flexural strength, more than 600 data from various research studies were analyzed in this study. These data are summarized in Table 5.

Table 5.

A summary of cement–lime mortar’s mechanical properties from several studies.

5.1. Water-to-Binder Ratio

According to the previous studies (Table 5), a statistical study of the water-to-cement ratio (w/c) for cement mortar reveals a range that extends from 0.3 to 0.74%, with values falling somewhere in the middle. The average is 0.467%, which corresponds to a standard deviation of 0.11 percent, and the coefficient of variation (COV) is around 23.9%. Figure 6 demonstrates that between 0.4 and 0.6% of the entire volume of cement mortar accounts for more than 72 percent of the overall volume. In addition, an examination of the water-to-binder ratio (w/b) data for lime-modified cement mortars, which was also obtained from the literature (Table 5), reveals that the ratio may vary anywhere from 0.3 to 0.52%, with an average of 0.44%. The coefficient of variation is 17.65%, while the standard deviation is 0.072%.

Figure 6.

Lime content % vs. consistency of modified cement-lime mortar.

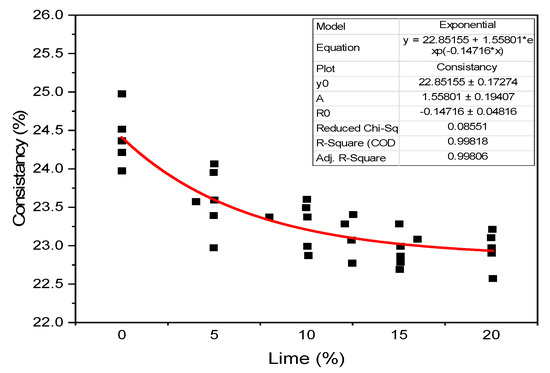

5.2. Consistency

As the lime percentage rises, the fluidity of cement mortar tends to diminish. Lime decreases the consistency of cement. The Vipulanandan correlation model Equation (1) was used to forecast the consistency of the cement–lime mixture. The model parameters, together with an R2 value of 0.998, are shown in Figure 6. Figure 6 demonstrates that the addition of 20% lime resulted in a 6% decrease in the consistency of the cement.

where represents the consistency of modified cement–lime mortar and represents lime content %.

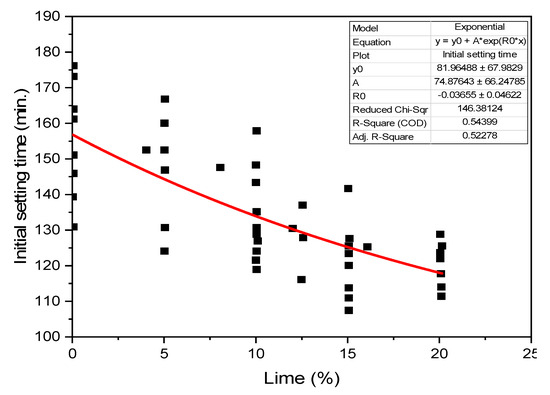

5.3. Setting Time

The presence of lime was discovered to expedite both the initial and final settling period of cement. The Vipulanandan correlation model Equation (2) was used to forecast the fluctuation in the initial and final setting time of modified cement–lime mortar. The model parameters included the coefficient of determination R2 = 0.54399. The addition of 20% lime resulted in a decrease of 27% in the initial setting times, respectively, as seen in Figure 7. The decrease in hydration rate of C-S-H cement may be attributed to the function of lime as a C-S-H nucleation substrate. In addition, the presence of a crystalline core in lime may have had a role in speeding up the early-stage hydration of tricalcium silicate (C3S).

where , , and are as demonstrated in Figure 6, = lime content %.

Figure 7.

Lime content % vs. setting time of modified cement-lime mortar.

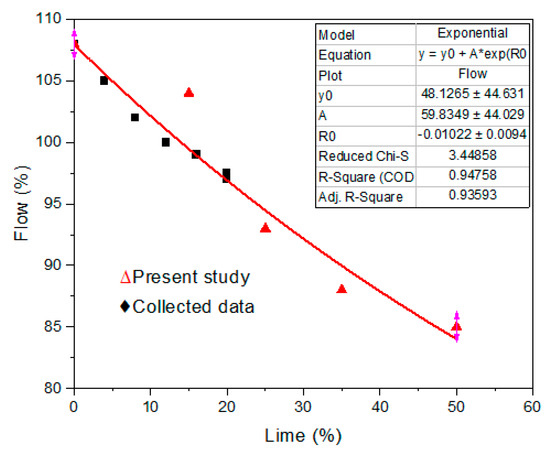

5.4. Flowability

The flow table test was used to ascertain the impact of lime on the viscosity of cement mortar. As the proportion of lime increased, the fluidity of cement decreased. The Vipulanandan correlation model, represented by Equation (3), accurately estimated the variation in the flow of cement mortar mixed with lime. The model achieved a high level of accuracy, with an R2 value of 0.947. According to Figure 8, the addition of 50% lime resulted in a 20% drop in the fluidity of cement mortar. The reduced rate of cement mortar flow might be attributed to the superior dispersion of cement particles by lime. The reason for this capability is likely due to lime’s reduced reactivity compared to cement, as well as the limited formation of gel.

where , , and are as demonstrated in Figure 9 and = lime content %.

Figure 8.

Lime content % vs. flow % of modified cement-lime mortar.

Figure 9.

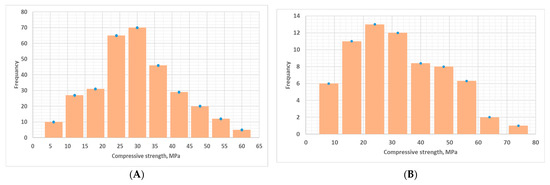

Normal distribution of compressive strength for (A) cement mortar and (B) modified cement-lime mortar.

5.5. Compressive Strength

An analysis of 300 compressive strength point values for cement mortar, gathered from the published literature (Table 5), reveals that the compressive strength ranges from 3 MPa to 65 MPa after 28 days of curing. The mean value is 33 MPa, with a standard deviation of 17.23 MPa and a coefficient of variation (COV) of 43%. Various distribution tests were conducted to assess the compressive strength of the cement mortar. Figure 9A demonstrates that the Anderson–Darling statistic (AD) and p-value, which are used for hypothesis testing, indicate that the Weibull frequency distribution is a good match for the compressive strength of cement mortar.

Modified cement–lime mortar: A dataset including compressive strength values of lime-reinforced cement mortars was compiled from several literature sources (Table 5). The compressive strength varied between 6.7 MPa and 65 MPa, with an average of 37.5 MPa. The standard deviation was 21 MPa, and the coefficient of variation (COV) was 49.7%. By using Anderson–Darling (AD) statistics and p-values for hypothesis testing, it was determined that the compressive strength data adhere to a Weibull distribution, as seen in Figure 9B.

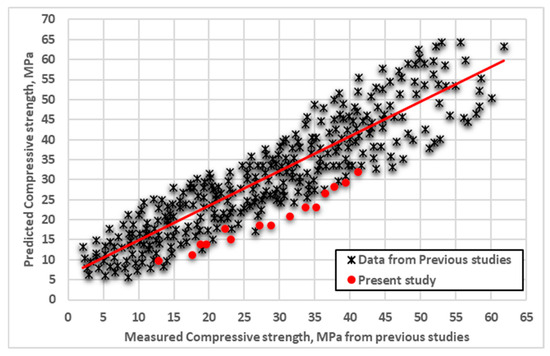

A multiple regression analysis was conducted to examine the impact of lime on the compressive strength of cement mortar. Figure 10 demonstrates that the compressive strength was influenced by independent factors such as water–cement ratio, curing time, and lime via nonlinear interactions. In Equation (4), the value d = −0.28 represents the nonlinear model and indicates that lime has a more significant impact on diminishing the compressive strength of cement mortar compared to the water–cement ratio and setting time.

with R2 = 0.82.

Figure 10.

Measured vs. predicted compressive strength of modified cement-lime mortar.

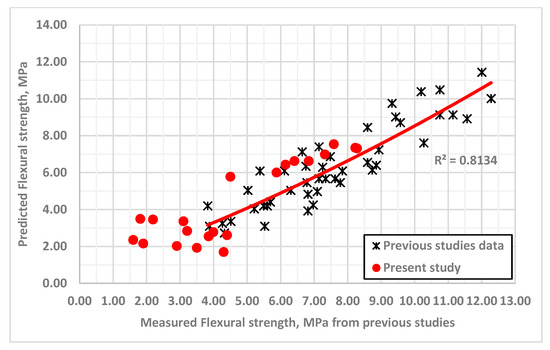

5.6. Flexural Strength

For the purpose of determining how lime influences the flexural strength of cement mortar, a nonlinear regression analysis was developed and used. Figure 11 illustrates a nonlinear connection that exists between flexural strength and independent factors such as the ratio of water to cement, the amount of time it takes for the material to cure, and the amount of lime it contains. Equation parameters are derived using numerous regression analyses using the least squares approach. These analyses are performed using the equation. Lime has the most significant impact on lowering the flexural strength of cement mortar according to water/water ratio and hardening time, as shown by the nonlinear model parameter (d = −0.04) in Equation (5). Lime also has the most significant influence on the ratio of water to water.

with R2 = 0.81.

Figure 11.

Measured vs. predicted flexural strength of modified cement–lime mortar.

6. Conclusions

This research sought to investigate the utilization of building and demolition waste, particularly lime and granite powder, in the production of cement–lime mortar. The main goal was to determine the optimal ratio of lime and integrate granite powder in order to develop a mortar with mechanical and physical characteristics appropriate for structural applications in masonry and construction. The research evaluated the impact of lime on hardening time, consistency, workability, and the strength properties of cement–lime mortar. The following results were derived from experimental data:

The results indicated that lime waste and granite powder are suitable components for producing cement–lime mortar, exhibiting satisfactory physical and mechanical properties.

The research presents a viable solution for the environmental challenges associated with extensive building and demolition waste in Mosul, especially in the aftermath of considerable combat devastation.

The addition of lime (up to 25%) in lime-modified mortar, when compared to standard cement mortar, led to a 15% decrease in compressive strength and a 33% decrease in workability.

The use of lime resulted in a reduction of 16% in mortar consistency and a 30% decrease in setting time.

A 25% lime component led to reduced compressive strength during various curing durations (3, 7, and 28 days), with lime content having the most significant impact on the decrease in compressive strength relative to water–cement ratio and curing time.

The ideal blend, consisting of 25% lime and 30% granite powder as a substitute for fine aggregate, demonstrated enhanced physical and mechanical characteristics.

Nonlinear models were created to forecast the consistency, setting time, and compressive and flexural strength of cement–lime modified mortar, revealing that curing time significantly influenced compressive strength more than the water–cement ratio or lime amount.

Author Contributions

J.M.A.: writing—original draft preparation, conceptualization, data curation, methodology, software, supervision; M.A.-G.: writing—original draft preparation, visualization, writing—reviewing and editing; A.A.: writing—reviewing and editing, validation, and investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yagüe, S.; Rosales-Prieto, V.; Sánchez-Lite, A.; González-Gaya, C. Properties of Green Mortar Containing Granite Sawmill. Appl. Sci. 2021, 11, 2136. [Google Scholar] [CrossRef]

- Pooja, K.; Shreelaxmi, P. Recent Advances in Construction of Masonry Structure by Waste Materials. In Lecture Notes in Civil Engineering; Springer: Singapore, 2022; Volume 2826, pp. 541–549. [Google Scholar] [CrossRef]

- Woźniak, Z.Z.; Chajec, A.; Sadowski, Ł. Effect of the Partial Replacement of Cement with Waste Granite Powder on the Properties of Fresh and Hardened Mortars for Masonry Applications. Materials 2022, 15, 9066. [Google Scholar] [CrossRef] [PubMed]

- Grist, E.R.; Paine, K.A.; Heath, A.; Norman, J.; Pinder, H. Structural and Durability Properties of Hydraulic Lime-Pozzolan Concretes. Cem. Concr. Compos. 2015, 62, 212–223. [Google Scholar] [CrossRef]

- Kadum, N.; Al-Attar, T.; Al-Azzawi, Z. Evaluation of Pozzolime Mixtures as a Sustainable Binder to Replace Portland Cement in Structural Concrete. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 120, p. 16. [Google Scholar] [CrossRef]

- Raeis Samiei, R.; Daniotti, B.; Pelosato, R.; Dotelli, G. Properties of Cement-Lime Mortars vs. Cement Mortars Containing Recycled Concrete Aggregates. Constr. Build. Mater. 2015, 84, 84–94. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Influence of Natural Hydraulic Lime Content on the Properties of Aerial Lime-Based Mortars. Constr. Build. Mater. 2014, 72, 208–218. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, J.; Wang, D.; Xu, C.; Zhai, M.; Ma, X. Comparative Study on the Properties of Three Hydraulic Lime Mortar Systems: Natural Hydraulic Lime Mortar, Cement-Aerial Lime-Based Mortar and Slag-Aerial Lime-Based Mortar. Constr. Build. Mater. 2018, 186, 42–52. [Google Scholar] [CrossRef]

- Pavlík, V.; Užáková, M. Effect of Curing Conditions on the Properties of Lime, Lime-Metakaolin and Lime-Zeolite Mortars. Constr. Build. Mater. 2016, 102, 14–25. [Google Scholar] [CrossRef]

- Zou, C. Oil and Gas in Metamorphic Reservoirs. In Unconventional Petroleum Geology; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Selley, R.C.; Plimer, I.R.; Cocks, L.R.M. Encyclopedia of Geology. Elsevier: Amsterdam, The Netherlands, 2004. Available online: https://www.sciencedirect.com/referencework/9780123693969/encyclopedia-of-geology#book-info (accessed on 4 September 2024).

- Ghannam, S.; Najm, H.; Vasconez, R. Experimental Study of Concrete Made with Granite and Iron Powders as Partial Replacement of Sand. Sustain. Mater. Technol. 2016, 9, 1–9. [Google Scholar] [CrossRef]

- Kala, D.T. Effect of Granite Powder on Strength Properties of Concrete. Int. J. Eng. Sci. 2013, 2, 36–50. Available online: http://www.researchinventy.com/papers/v2i12/F0212036050.pdf (accessed on 4 September 2024).

- Singh, S.; Khan, S.; Khandelwal, R.; Chugh, A.; Nagar, R. Performance of Sustainable Concrete Containing Granite Cutting Waste. J. Clean. Prod. 2016, 119, 86–98. [Google Scholar] [CrossRef]

- Singh, S.; Nagar, R.; Agrawal, V.; Rana, A.; Tiwari, A. Sustainable Utilization of Granite Cutting Waste in High Strength Concrete. J. Clean. Prod. 2016, 116, 223–235. [Google Scholar] [CrossRef]

- Upadhyaya, S.; Nanda, B.; Panigrahi, R. Effect of Granite Dust as Partial Replacement to Natural Sand on Strength and Ductility of Reinforced Concrete Beams. J. Inst. Eng. Ser. A 2020, 101, 669–677. [Google Scholar] [CrossRef]

- Ahmed, T.I.; Tobbala, D.E. The Role of Granite Dust in Engineered Cement Composites as a Partial Replacement of Fine Aggregate. Innov. Infrastruct. Solut. 2022, 7, 104. [Google Scholar] [CrossRef]

- Suresh, C.; Sivaramakrishnan, S.; Siddharthan, P.; Vinay Babu, S.; Sai Neeraja, V.; Arockia Dhanraj, J. Study on the Characteristics of the Ordinary Concrete with the Granite Dust as a Substitute for the Fine Aggregates. Mater. Today Proc. 2022, 69, 739–743. [Google Scholar] [CrossRef]

- Sumathi, A.; Arthika, J. Study on Properties of High Strength Concrete Using Silica Fume and Rice Husk Ash. In Advances in Structural Mechanics and Applications, Proceedings of the ASMA 2021, Structural Integrity, Denver, CO, USA, 29 August–2 September 2021; Springer: Cham, Switzerland, 2022; Volume 19. [Google Scholar] [CrossRef]

- ASTM C150/C150M-21; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C141/C141M-14; Standard Test Method for the Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM C33/C33M-16; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2016. Available online: https://www.astm.org/c0033_c0033m-16.html (accessed on 21 October 2024).

- ASTM C188; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM C1585; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- ASTM C430; Standard Test Method for the Fineness of Hydraulic Cement by the 45-μm (No. 325) Sieve. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 50 mm [2 in.] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM C348; Standard Test Method for Flexural Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/c1437-20.html (accessed on 4 September 2024).

- Lin, W.-T.; Cheng, A.; Černý, R. Effect of limestone powder on strength and permeability of cementitious mortars. MATEC Web Conf. 2020, 322, 01009. [Google Scholar] [CrossRef]

- De Bem, D.H.; Trentin, P.O.; Medeiros-Junior, R.A. Effect of Hydrated Lime on Efflorescence Formation. Int. J. Build. Pathol. Adapt. 2022, 40, 775–790. [Google Scholar] [CrossRef]

- Alake, O. Compressive Strength of Termite Mound and Lime Blended Cement Mortar Subjected to Acidic Environment. FUTA J. Eng. Eng. Technol. 2022, 16, 1–8. [Google Scholar] [CrossRef]

- Kandhan, K.M.; Karunakaran, V. Study on Behaviour and Durability Properties of Concrete and Mortar by the Influence of Lime as Partial Replacement of Cement. Int. Res. J. Eng. Technol. 2021, 8, 272–275. Available online: https://www.irjet.net/archives/V8/i1/IRJET-V8I152.pdf (accessed on 4 September 2024).

- Olaniyi, A.; Olaniyi, U.a.a. Influence of Curing Media on the Compressive Strength of Termite Mound-Lime Blended Cement Mortar. Int. Res. J. Eng. Technol. 2014, 26, 349–365. [Google Scholar]

- Singh, P.; Saha, S.; Samanta, A.K. An Experimental Investigation on the Properties of Concrete Using Natural Soil Deposit. In Technologies for Sustainable Buildings and Infrastructure, Proceedings of the SIIOC 2023, Mangalore, India, 20–21 April 2023; Jayalekshmi, B.R., Rao, K.S.N., Pavan, G.S., Eds.; Lecture Notes in Civil Engineering; Springer: Singapore, 2024; Volume 528. [Google Scholar] [CrossRef]

- Lanas, J.; Bernal, J.L.P.; Bello, M.A.; Galindo, J.I.A. Mechanical Properties of Natural Hydraulic Lime-Based Mortars. Cem. Concr. Res. 2004, 34, 1–8. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Aggelakopoulou, E.; Anagnostopoulou, S. Strength Development and Lime Reaction in Mortars for Repairing Historic Masonries. Cem. Concr. Compos. 2005, 27, 289–294. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Faria, J.; Jalali, S. Some Considerations about the Use of Lime–Cement Mortars for Building Conservation Purposes in Portugal: A Reprehensible Option or a Lesser Evil? Constr. Build. Mater. 2012, 30, 488–494. [Google Scholar] [CrossRef]

- Arizzi, A.; Viles, H.; Cultrone, G. Experimental Testing of the Durability of Lime-Based Mortars Used for Rendering Historic Buildings. Constr. Build. Mater. 2012, 28, 807–818. [Google Scholar] [CrossRef]

- Nehdi, M.; Mindess, S.; Aïtcin, P.-C. Optimization of High Strength Limestone Filler Cement Mortars. Cem. Concr. Res. 1996, 26, 883–893. [Google Scholar] [CrossRef]

- Uk, S.; Urkel, T.; Git, Y.; Altuntaş, A. The Effect of Limestone Powder, Fly Ash and Silica Fume on the Properties of Self-Compacting Repair Mortars. Sadhana 2009, 34, 331–343. [Google Scholar] [CrossRef]

- Qadir, W.; Ghafor, K.; Mohammed, A. Evaluation of the Effect of Lime on the Plastic and Hardened Properties of Cement Mortar and Quantified Using Vipulanandan Model. Open Eng. 2019, 9, 468–480. [Google Scholar] [CrossRef]

- Gudissa, W.; Abebe, D. The Use of Limestone Powder as an Alternative Cement Replacement Material: An Experimental Study. Zede J. 2010, 27, 33–43. Available online: https://www.ajol.info/index.php/zj/article/view/120814 (accessed on 4 September 2024).

- Corinaldesi, V.; Mazzoli, A.; Moriconi, G.; Claisse, P.; Naik, T. Mechanical and Physical Properties of Cement Mortars Containing Plastic Waste Particles. J. Mater. Des. 2010, 32, 1646–1650. Available online: https://api.semanticscholar.org/CorpusID:54649608 (accessed on 4 September 2024). [CrossRef]

- Yang, H.S.; Fang, K.H.; Tu, S.J. The Influence of Limestone Powder on Fluidity, Strength and Hydration of Cement Mortar. In Advanced Materials Research; Trans Tech Publications: Stafa, Switzerland, 2011; Volume 168, pp. 512–517. [Google Scholar] [CrossRef]

- Sezer, G.İ. Compressive Strength and Sulfate Resistance of Limestone and/or Silica Fume Mortars. Constr. Build. Mater. 2012, 26, 613–618. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Z. Impact of the Limestone Powder on the Properties of Cement Paste and Mortar. In Applied Mechanics and Materials; Trans Tech Publications: Stafa, Switzerland, 2012; Volume 174, pp. 236–240. [Google Scholar] [CrossRef]

- Zelić, J.; Rušić, D.; Veža, D.; Krstulović, R. The Role of Silica Fume in the Kinetics and Mechanisms During the Early Stage of Cement Hydration. Cem. Concr. Res. 2000, 30, 1655–1662. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Han, C.S.; Yin, X. Influence of Limestone Powder on Performance of the Pre-Mixed Cement Mortar. In Advanced Materials Research; Trans Tech Publications: Stafa, Switzerland, 2011; Volume 306, pp. 1096–1100. [Google Scholar] [CrossRef]

- De Weerdt, K.; Haha, M.B.; Le Saout, G.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration Mechanisms of Ternary Portland Cements Containing Limestone Powder and Fly Ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Xu, G.Q.; You, Z.G.; Gao, L.; Han, D.L. The Influence of Combined Admixture of Super-Fine Limestone Powder and Low Quality Fly Ash on the Performance of Cement Mortar. In Advanced Materials Research; Trans Tech Publications: Stafa, Switzerland, 2013; Volume 652, pp. 1181–1184. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).