Robotized Mobile Platform for Non-Destructive Inspection of Aircraft Structures

Abstract

:1. Introduction

2. Structural Design and Control System

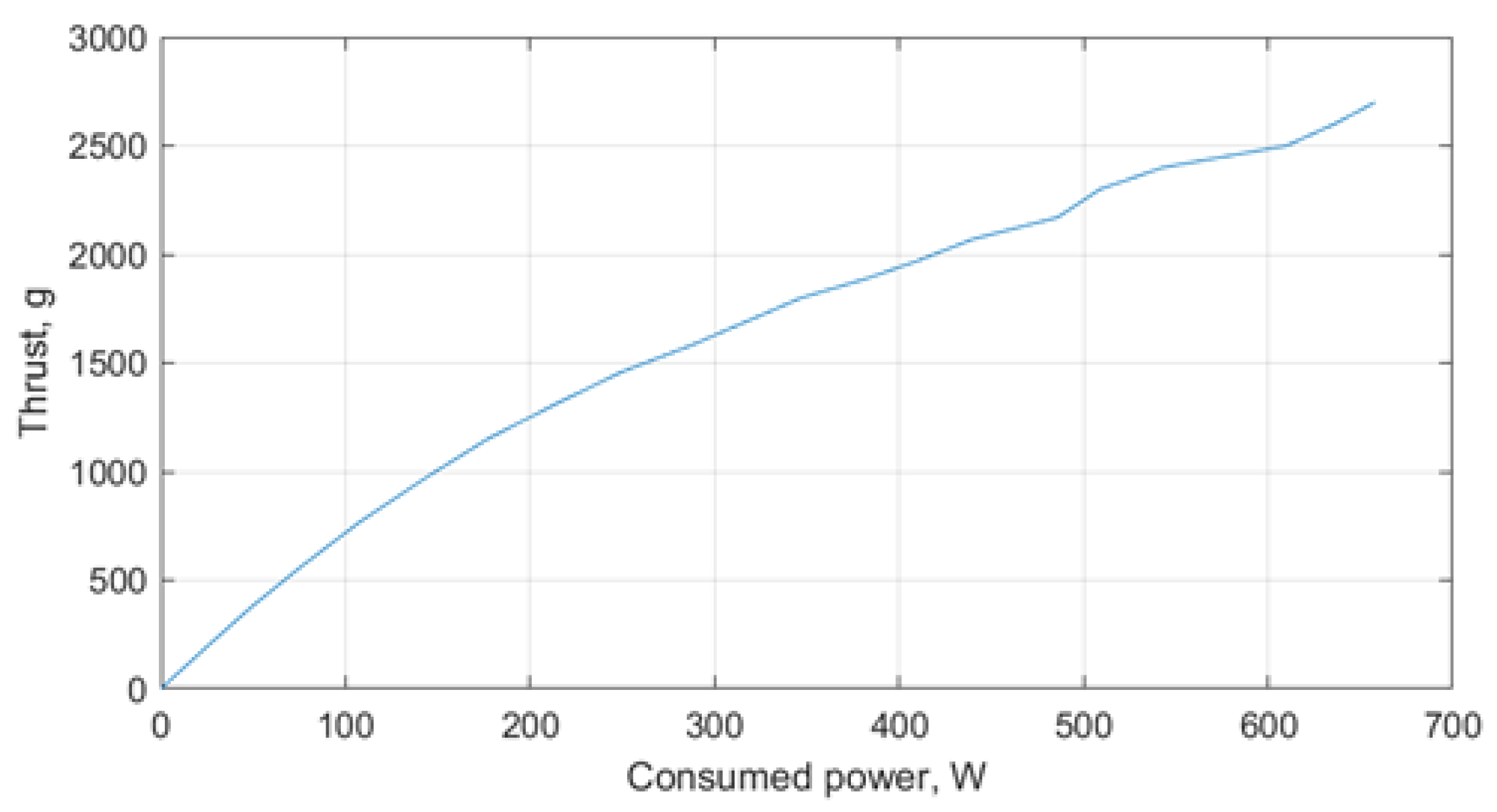

2.1. Assumptions and Initial Calculations

- The classical propeller drive or electric ducted fan (EDF) was assumed to be used for the generation of a payload by creating a negative pressure. This approach allows for appropriate adhesion of the MP for various curvatures of the tested surfaces. These types of driver ensure high efficiency and low weight in relation to the power output.

- The body in the form of a shell structure is to be made of glass-epoxy laminate. This design allows for a compact structure, and the use of a glass-epoxy laminate allows for low weight and high durability.

- The MP should be equipped with a four-wheel chassis, which usually ensures vehicle stability and good traction.

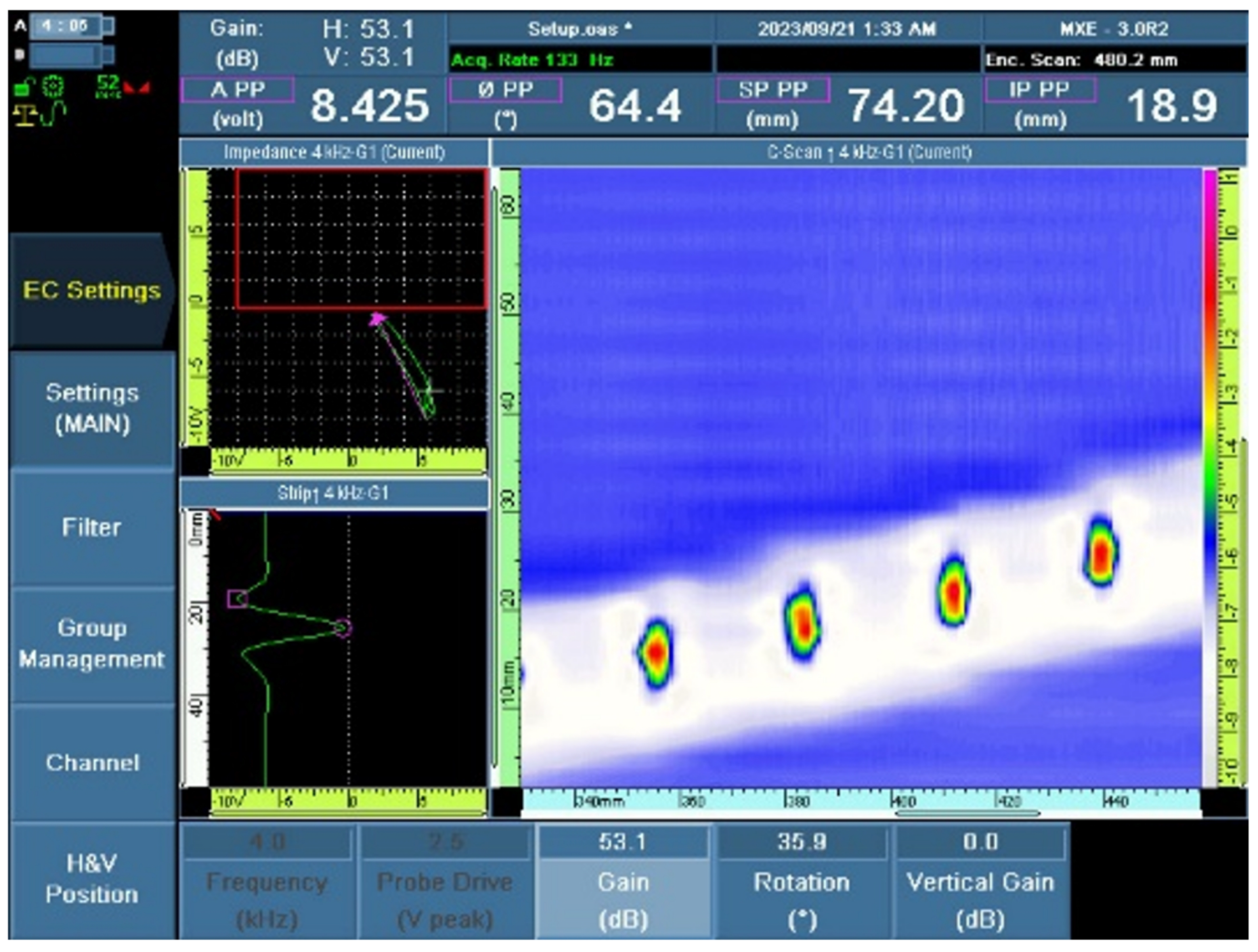

- The minimum speed was assumed considering the speed to scanning with the selected testing system: Olympus OmniScan MX with eddy current array (ECA) testing technique, which is typically used for inspection of aircraft. Measurements are to be made using the SAB-067-005-032 low-frequency eddy current array probe, for which the scan speed is 0.1 m/s. The MP should mimic the movement of the ECA probe during inspection by following the predefined trajectories.

- The speed during idle travel of MP is assumed to be not less than 0.5 m/s.

- The assumption for wheels were the following: diameter of 70–100 mm, tread made of a material with a high friction coefficient (rubber, polyurethane or silicone) close to 1. Higher friction coefficient will allow to obtain a greater lifting capacity of the entire MP with the same propeller drive thrust.

- Wheel drive is to be implemented with DC motors with integrated gear to minimize the mass of the MP.

- The weight of the whole MP is assumed to be up to 2 kg, including ECA probes and cabling, which was estimated after a preliminary review of available components, propeller drive performance, and price.

- DC power supply with a voltage in the range of 12–48 V is provided via converter from the power grid, which is governed by the selected ECA system, where the probe is connected to the defectoscope by wire.

2.2. Selection of Components

- power supply from the vehicle’s built-in lithium-polymer battery,

- power supply via a converter from the power grid. In this case, energy is supplied to the vehicle through a two-core cable with an appropriate cross-section.

2.3. Development of the Control System

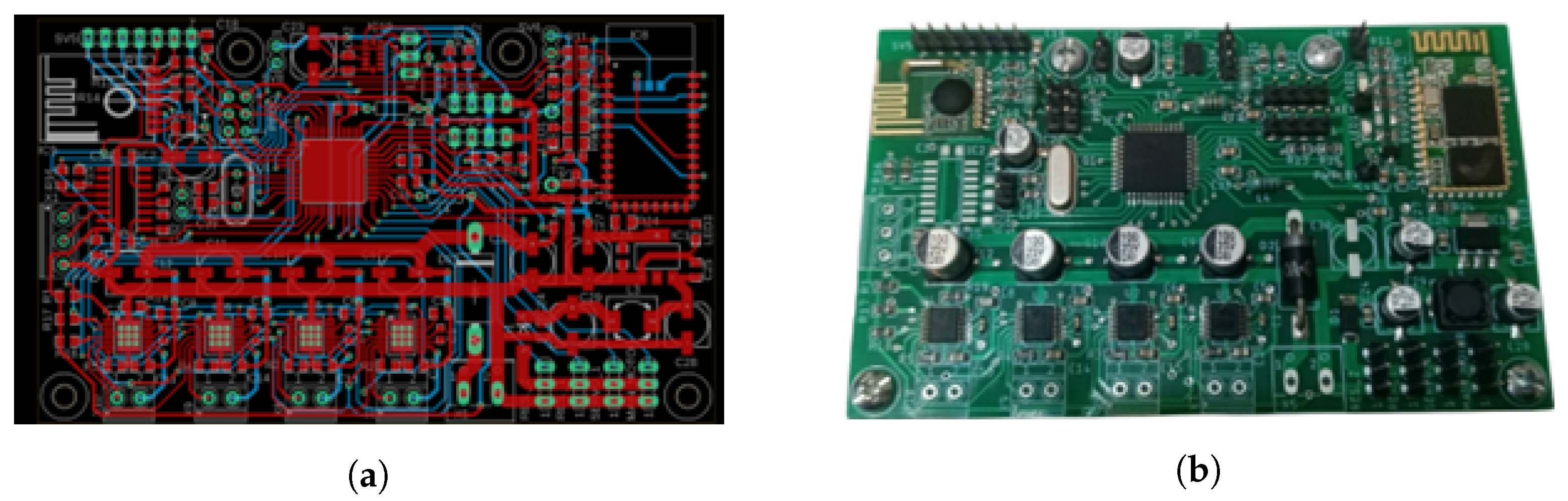

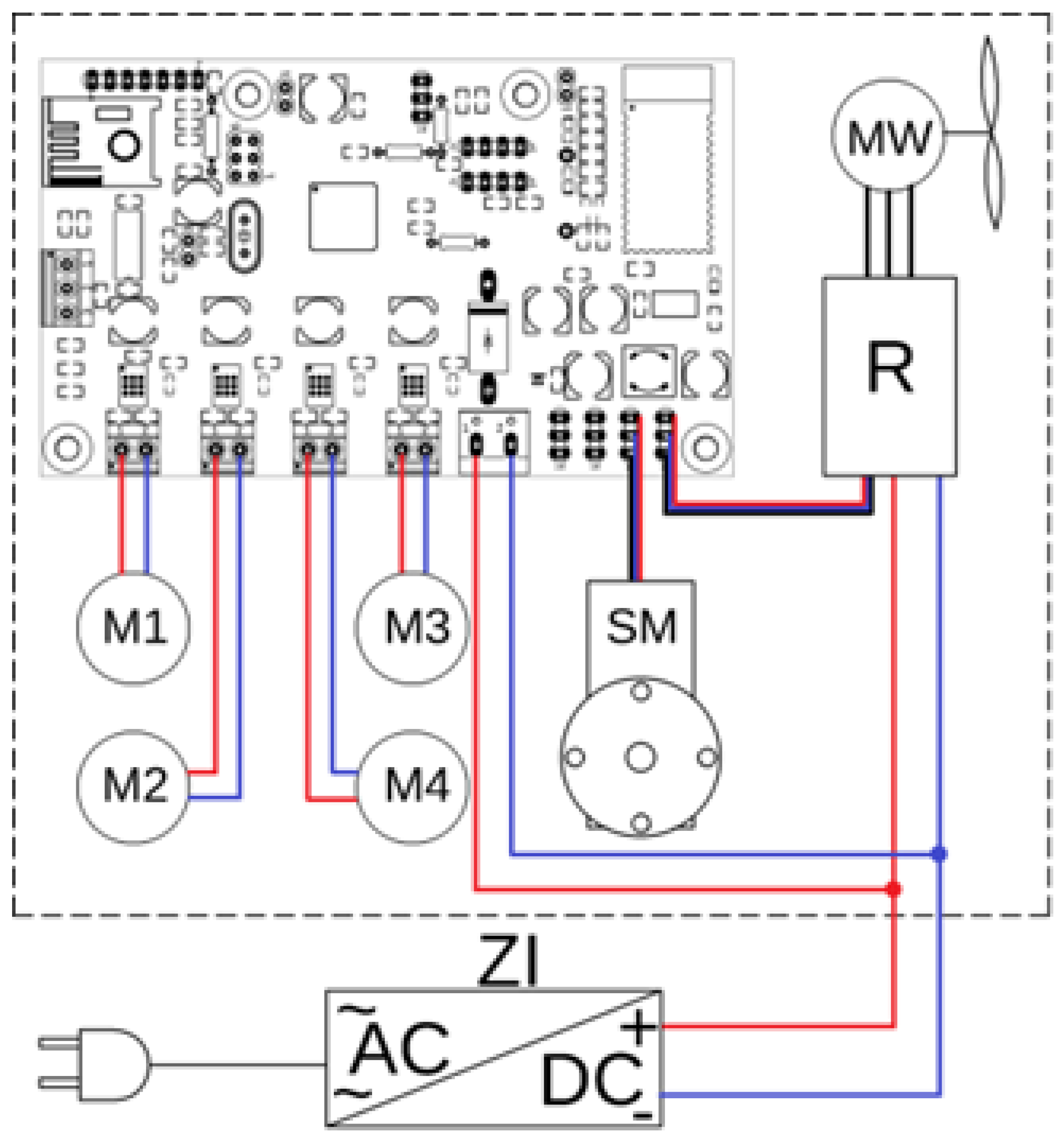

2.4. Hardware

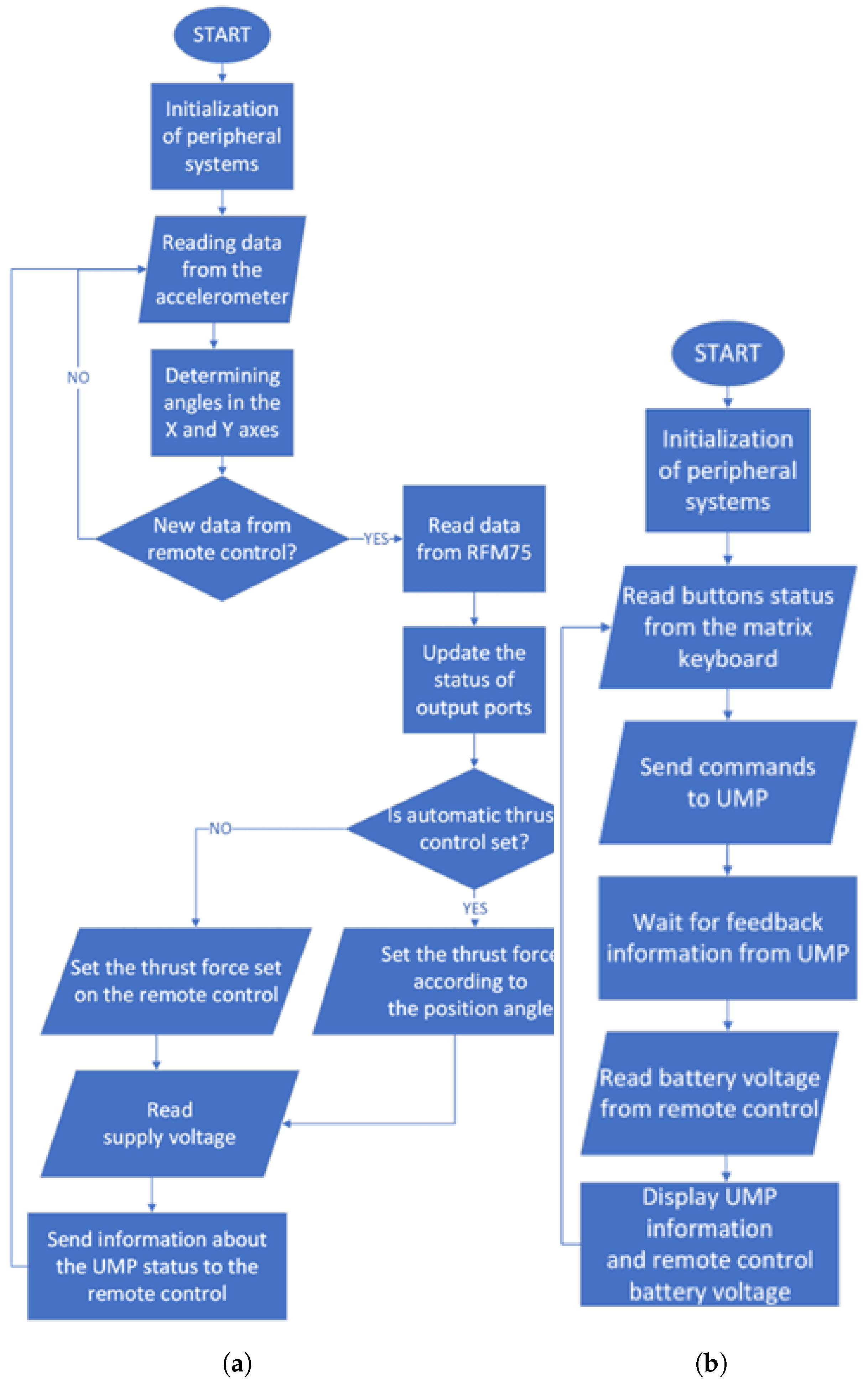

2.5. Software

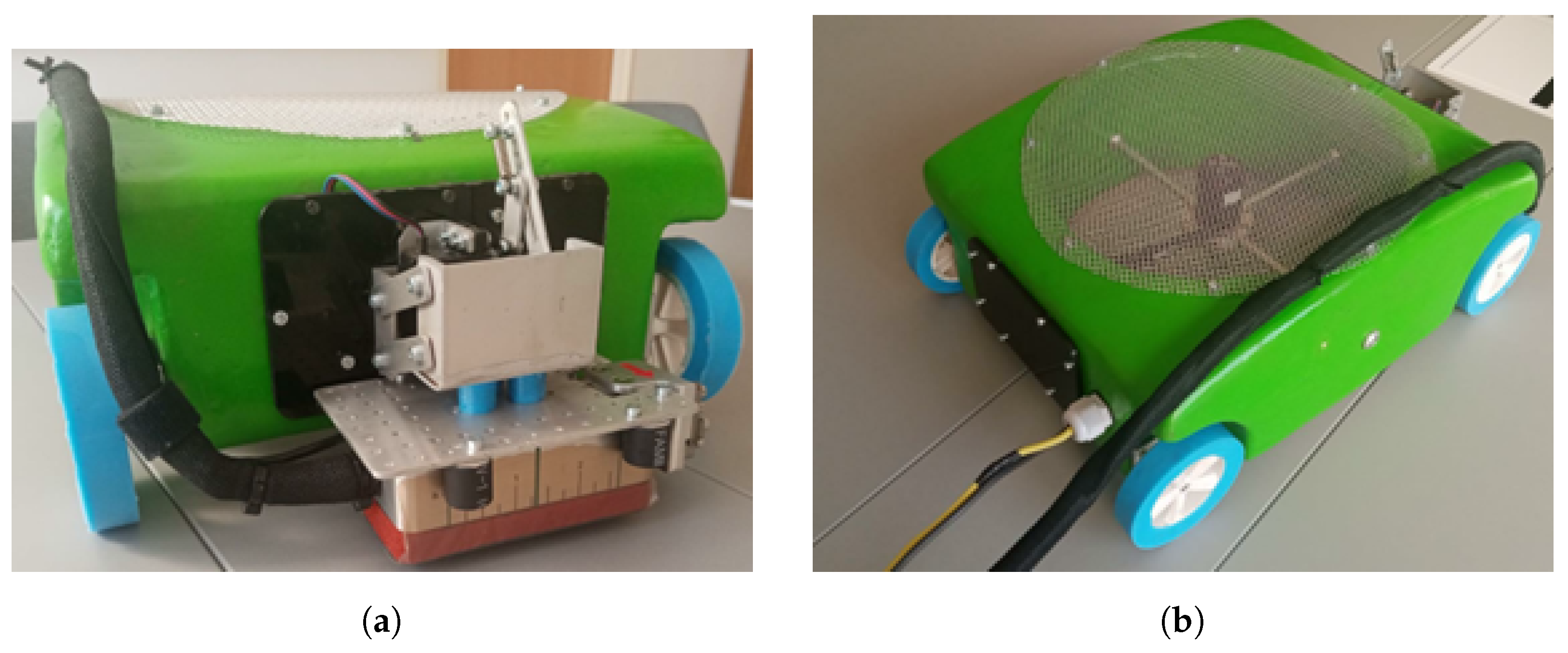

2.6. Mechanical Design and the Prototype of the Mobile Platform

3. Testing and Experimental Validation

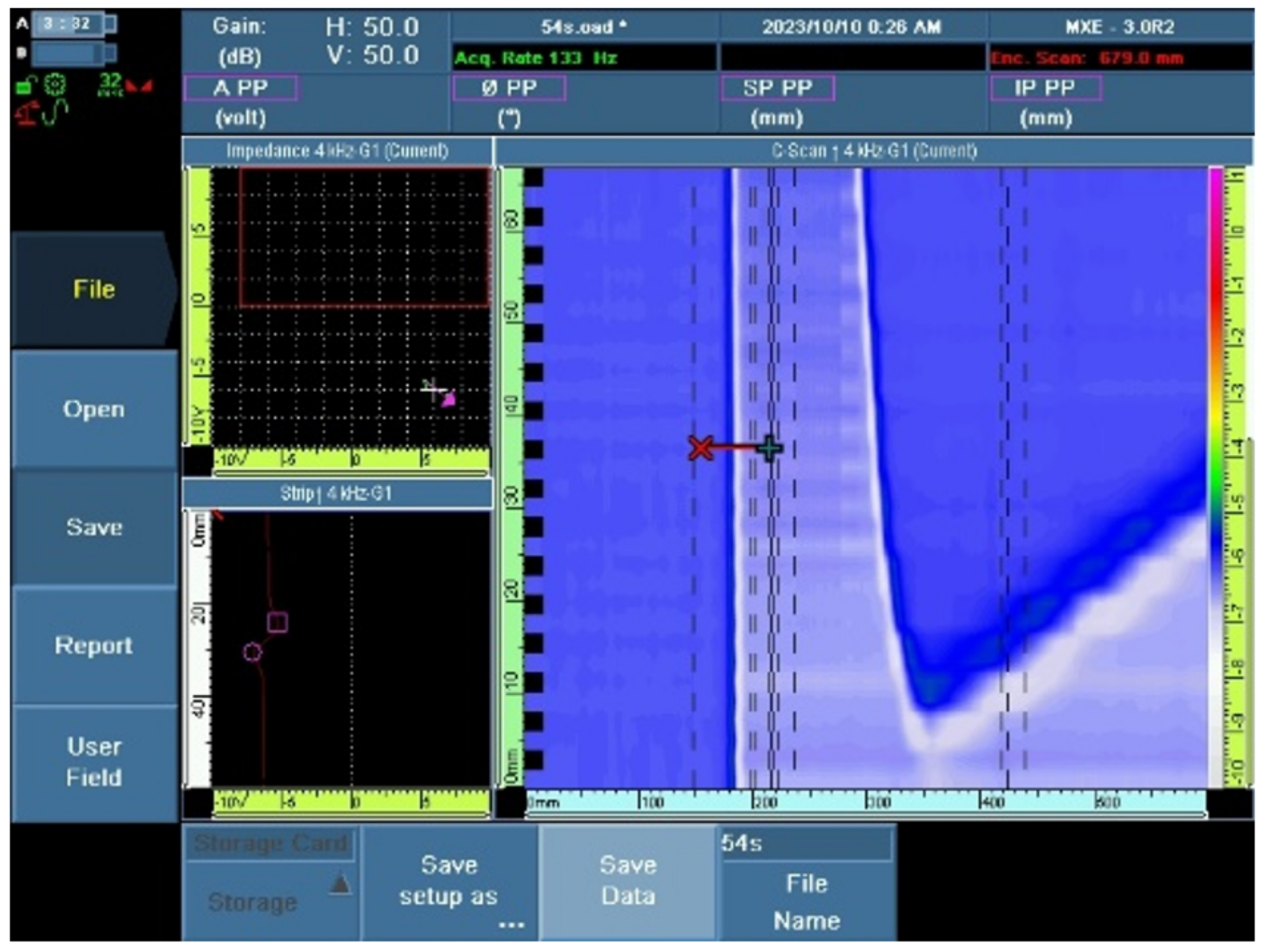

3.1. ECA Testing System

3.2. Initial and Laboratory Tests

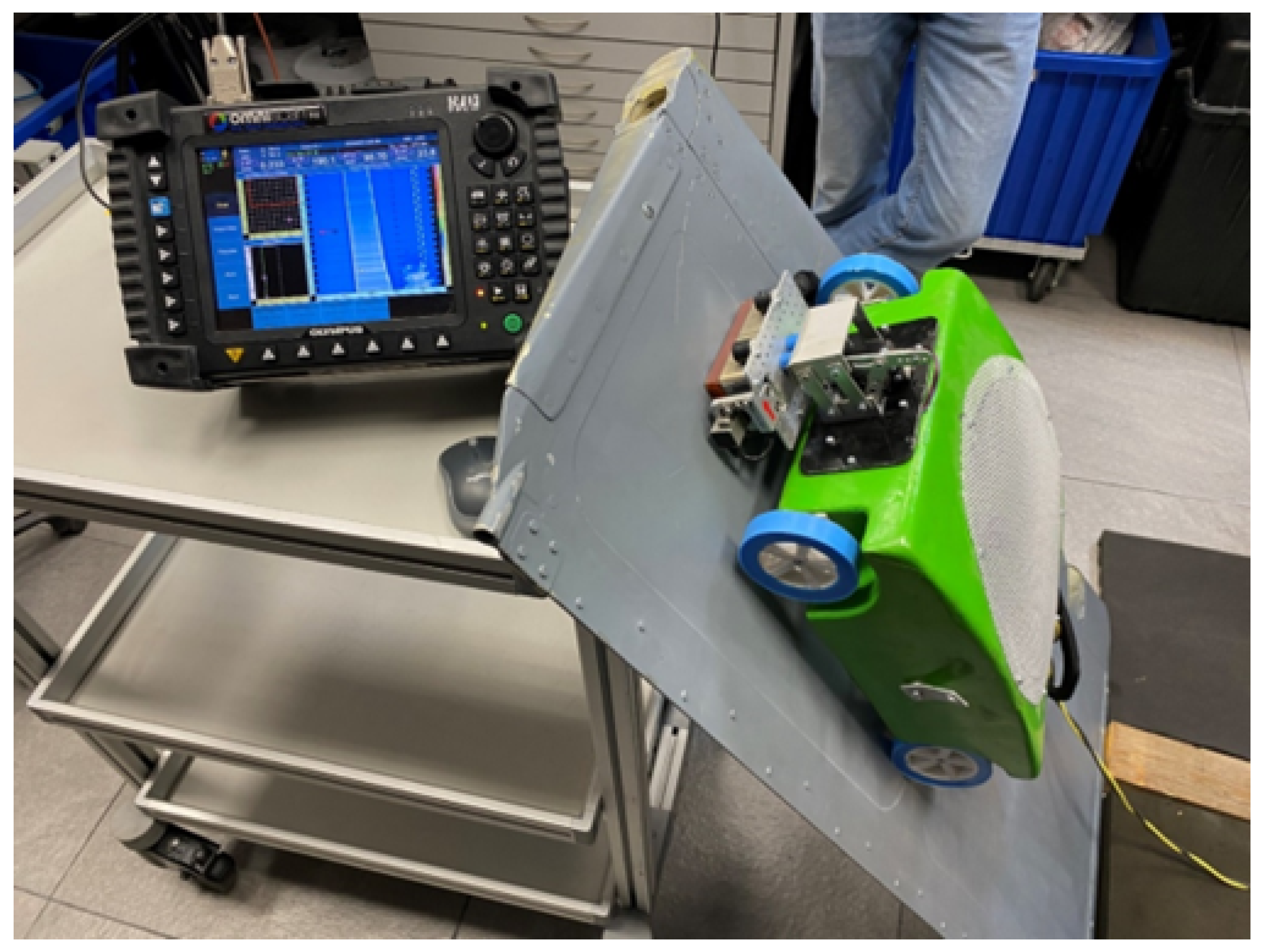

3.3. Testing of Aircraft Structures

3.4. Inspection Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- NDT and Inspection Market by Technique (Ultrasonic Testing, Visual, Magnetic Particle, Liquid Penetration, Eddy-Current, Radiographic, Acoustic Emission), Service, Method, Vertical, Application and Region-Global Forecast to 2029. Market Research Report SE 2860. 2024. Available online: https://www.marketsandmarkets.com/Market-Reports/non-destructive-testing-ndt-equipment-services-market-882.html?srsltid=AfmBOoqaX449ZXqSqonsymf0u28QrQBdG9m-fo5iY88uDutuR-WfGhtc (accessed on 3 November 2024).

- Vrana, J.; Singh, R. NDE 4.0—A design thinking perspective. J. Nondestruct. Eval. 2021, 40, 8. [Google Scholar] [CrossRef] [PubMed]

- Meyendorf, N.; Ida, N.; Singh, R.; Vrana, J. NDE 4.0: Progress, promise, and its role to industry 4.0. NDT&E Int. 2023, 140, 102957. [Google Scholar]

- Prakash, N.; Nieberl, D.; Mayer, M.; Schuster, A. Learning defects from aircraft NDT data. NDT&E Int. 2023, 138, 102885. [Google Scholar]

- Kostopoulos, V.; Psarras, S.; Loutas, T.; Sotiriadis, G.; Gray, I.; Padiyar, M.J.; Petrunin, I.; Raposo, J.; Fragonara, L.Z.; Tzitzilonis, V.; et al. Autonomous inspection and repair of aircraft composite structures. IFAC-PapersOnLine 2018, 51, 554–557. [Google Scholar] [CrossRef]

- Fernandez, R.F.; Keller, K.; Robins, J. Design of a system for Aircraft Fuselage Inspection. In Proceedings of the 2016 IEEE Systems and Information Engineering Design Symposium (SIEDS), Charlottesville, VA, USA, 29 April 2016; pp. 283–288. [Google Scholar]

- Mineo, C.; Pierce, S.G.; Nicholson, P.I.; Cooper, I. Robotic path planning for non-destructive testing—A custom MATLAB toolbox approach. Robot. Comput.-Integr. Manuf. 2016, 37, 1–12. [Google Scholar] [CrossRef]

- Morozov, M.; Pierce, S.G.; MacLeod, C.N.; Mineo, C.; Summan, R. Off-line scan path planning for robotic NDT. Measurement 2018, 122, 284–290. [Google Scholar] [CrossRef]

- Zhou, B.; Tian, T.T.; Zhu, G.; Zhao, J.B.; Liu, D.H. An ultrasonic testing method for wall thickness of turbine blades. Measurement 2022, 198, 111357. [Google Scholar] [CrossRef]

- Zimermann, R.; Mohseni, E.; Vasilev, M.; Loukas, C.; Vithanage, R.K.W.; Macleod, C.N.; Lines, D.; Javadi, Y.; Silva, M.P.E.E.; Fitzpatrick, S.; et al. Collaborative robotic wire + arc additive manufacture and sensor-enabled in-process ultrasonic non-destructive evaluation. Sensors 2022, 22, 4203. [Google Scholar] [CrossRef]

- Foster, E.A.; Bolton, G.; Bernard, R.; McInnes, M.; McKnight, S.; Nicolson, E.; Loukas, C.; Vasilev, M.; Lines, D.; Mohseni, E.; et al. Automated real-time eddy current array inspection of nuclear assets. Sensors 2022, 22, 6036. [Google Scholar] [CrossRef]

- Dhoot, M.K.; Fan, I.S.; Skaf, Z. Review of robotic systems for aircraft inspection. In Proceedings of the 9th International Conference on Through-Life Engineering Service, Cranfield, UK, 7–9 November 2022. [Google Scholar] [CrossRef]

- Rashed, M.A.; Kimball, M.; Vega, L.; Vera, D.; Soler, J.; Correa, M.; Garcia, A.; Virk, G.S.; Sattar, T.P. Climbing robots for NDT applications, Human-Centric Robotics. In Proceedings of the 20th International Conference on CLAWAR 2017, Guedes, Porto, 11–13 September 2017; pp. 285–292. [Google Scholar] [CrossRef]

- Papa, U.; Ponte, S. Preliminary design of an unmanned aircraft system for aircraft general visual inspection. Electronics 2018, 7, 435. [Google Scholar] [CrossRef]

- Tzitzilonis, V.; Malandrakis, K.; Fragonara, L.Z.; Domingo, J.A.G.; Avdelidis, N.P.; Tsourdos, A.; Forster, K. Inspection of aircraft wing panels using unmanned aerial vehicles. Sensors 2019, 19, 1824. [Google Scholar] [CrossRef] [PubMed]

- Hruz, M.; Bugaj, M.; Novak, A.; Kandera, B.; Badanik, B. The Use of UAV with infrared camera and RFID for airframe condition monitoring. Appl. Sci. 2021, 11, 3737. [Google Scholar] [CrossRef]

- Zhang, D.; Watson, R.; MacLeod, C.; Dobie, G.; Galbraith, W.; Pierce, G. Implementation and evaluation of an autonomous airborne ultrasound inspection system. Nondestruct. Test. Eval. 2022, 37, 1–21. [Google Scholar] [CrossRef]

- Bogue, R. The role of robotics in non-destructive testing. Ind. Robot 2010, 37, 421–426. [Google Scholar] [CrossRef]

- Andrikopoulos, G.; Papadimitriou, A.; Brusell, A.; Nikolakopoulos, G. On Model-Based Adhesion Control of a Vortex Climbing Robot. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 4–8 November 2019; pp. 1460–1465. [Google Scholar]

- Shin, H.J.; Park, J.Y.; Hong, S.C.; Lee, J.R. In situ non-destructive evaluation of an aircraft UHF antenna radome based on pulse-echo ultrasonic propagation imaging. Compos. Struct. 2017, 160, 16–22. [Google Scholar] [CrossRef]

- Rochat, F.; Hirschmann, V.; Barras, T.; Bleuer, H.; Mondada, F.; Sti, E.; Lsro, I.M.T. Climbing robot with thermal glue. In Proceedings of the 14th International Conference on Climbing and Walking Robots, CLAWAR, Paris, France, 6–8 September 2011; pp. 409–416. [Google Scholar]

- Li, H.; Sun, X.; Chen, Z.; Zhang, L.; Wang, H.; Wu, X. Design of a wheeled wall climbing robot based on the performance of bio-inspired dry adhesive material. Robotica 2022, 40, 611–624. [Google Scholar] [CrossRef]

- Sabermand, V.; Ghorbanirezaei, S.; Hojjat, Y. Testing the application of Free Flapping Foils (FFF) as a method to improve adhesion in an electrostatic wall-climbing robot. J. Adhes. Sci. Technol. 2019, 33, 2579–2594. [Google Scholar] [CrossRef]

- Alkalla, M.G.; Fanni, M.A.; Mohamed, A.F.; Hashimoto, S.; Sawada, H.; Miwa, T.; Hamed, A. EJBot-II: An optimized skid-steering propeller-type climbing robot with transition mechanism. Adv. Robot. 2019, 33, 1042–1059. [Google Scholar] [CrossRef]

- Zhao, J.; Li, X. Development of Wall-Climbing Robot Using Vortex Suction Unit and Its Evaluation on Walls with Various Surface Conditions. In Intelligent Robotics and Applications. ICIRA 2017. Lecture Notes in Computer Science; Huang, Y., Wu, H., Liu, H., Yin, Z., Eds.; Springer: Cham, Switzerland, 2017; Volume 10464. [Google Scholar] [CrossRef]

- Andrikopoulos, G.; Nikolakopoulos, G. Vortex Actuation via Electric Ducted Fans: An Experimental Study. J. Intell. Robot Syst. 2019, 95, 955–973. [Google Scholar] [CrossRef]

- Altaf, M.; Ahmad, E.; Xu, Y.; Liu, R.; Li, Y.; Na, H. Design of a climbing robot platform with protection device. Int. J. Adv. Robot. Syst. 2017, 14, 1729881417716382. [Google Scholar] [CrossRef]

- Xiao, J.; Li, B.; Ushiroda, K.; Song, Q. Rise-Rover: A wall-climbing robot with high reliability and load-carrying capacity. In Proceedings of the 2015 IEEE International Conference on Robotics and Biomimetics (ROBIO), Zhuhai, China, 6–9 December 2015; pp. 2072–2077. [Google Scholar] [CrossRef]

- Božić, M.; Jerbić, B.; Švaco, M. Development of a Mobile Wall-Climbing Robot with a Hybrid Adhesion System. In Proceedings of the 2021 44th International Convention on Information, Communication and Electronic Technology (MIPRO), Opatija, Croatia, 27 September–1 October 2021; pp. 1136–1142. [Google Scholar] [CrossRef]

- Peters, G.; Pagano, D.; Liu, D.K.; Waldron, K. A prototype climbing robot for inspection of complex ferrous structures. In Proceedings of the 13th International Conference on Climbing and Walking Robots, CLAWAR, Nagoya, Japan, 31 August–3 September 2010; pp. 150–156. [Google Scholar]

- Qian, Z.; Xia, H. Study of a wall-climbing robot based on chain feet with negative pressure adhesion. Discov. Appl. Sci. 2024, 6, 132. [Google Scholar] [CrossRef]

- Rajendran, R.; Dhanraj, J.A. A comparative survey on weight & payload of wall climbing robot (WCR) using magnetic adhesive, suction adhesive and fusion type adhesive. Proc. Mater. Today 2023, in press. [Google Scholar] [CrossRef]

- Schmidt, D.; Berns, K. Climbing robots for maintenance and inspections of vertical structures—A survey of design aspects and technologies. Robot. Auton. Syst. 2013, 61, 1288–1305. [Google Scholar] [CrossRef]

- Li, M.; Yin, C. Axial flow impeller design and simulation for negative pressure adsorption climbing robot. J. Phys. Conf. Ser. 2024, 2785, 012026. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, S.; Cui, D.; Bi, Q.; Jiang, R.; Yan, C. Design and optimization of wall-climbing robot impeller by genetic algorithm based on computational fluid dynamics and kriging model. Sci. Rep. 2022, 12, 9571. [Google Scholar] [CrossRef]

- Hernando, M.; Gomez, V.; Brunete, A.; Gambao, E. CFD modelling and optimization procedure of an adhesive system for a modular climbing robot. Sensors 2021, 21, 1117. [Google Scholar] [CrossRef]

- Gu, J.; Wang, C.; Wu, X. Self-adjusted adsorption strategy for an aircraft skin inspection robot. J. Mech. Sci. Technol. 2018, 32, 2867–2875. [Google Scholar] [CrossRef]

- Shi, X.; Xu, L.; Xu, H.; Jiang, C.; Zhao, Z.; Guo, Y.; Chen, X. A 6-DOF humanoid wall-climbing robot with flexible adsorption feet based on negative pressure suction. Mechatronics 2022, 87, 102889. [Google Scholar] [CrossRef]

- Pham, V.H.; Nguyen, H.C.; Nguyen, N.D.; Mach, B.N.; Nguyen, T.Q. Design and simulation of a wall-climbing robot car using 3D printing technology and the vacuum method. Adv. Mech. Eng. 2023, 15, 16878132231186277. [Google Scholar] [CrossRef]

- Liang, P.; Gao, X.; Zhang, Q.; Gao, R.; Li, M.; Xu, Y.; Zhu, W. Design and stability analysis of a wall-climbing robot using propulsive force of propeller. Symmetry 2020, 13, 37. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, X. Experimental investigation on climbing robot using rotation-flow adsorption unit Rob. Auton. Syst. 2018, 105, 112–120. [Google Scholar] [CrossRef]

- Guo, T.; Deng, Z.D.; Liu, X.; Song, D.; Yang, H. Development of a new hull adsorptive underwater climbing robot using the Bernoulli negative pressure effect. Ocean Eng. 2022, 243, 110306. [Google Scholar] [CrossRef]

- Shang, J.; Sattar, T.; Chen, S.; Bridge, B. Design of a climbing robot for inspecting aircraft wings and fuselage. Ind Robot 2007, 34, 495–502. [Google Scholar] [CrossRef]

- Qin, G.; Li, C.; Wu, H.; Ji, A. Wall-Climbing Mobile Robot for Inspecting DEMO Vacuum Vessel. Appl. Sci. 2022, 12, 9260. [Google Scholar] [CrossRef]

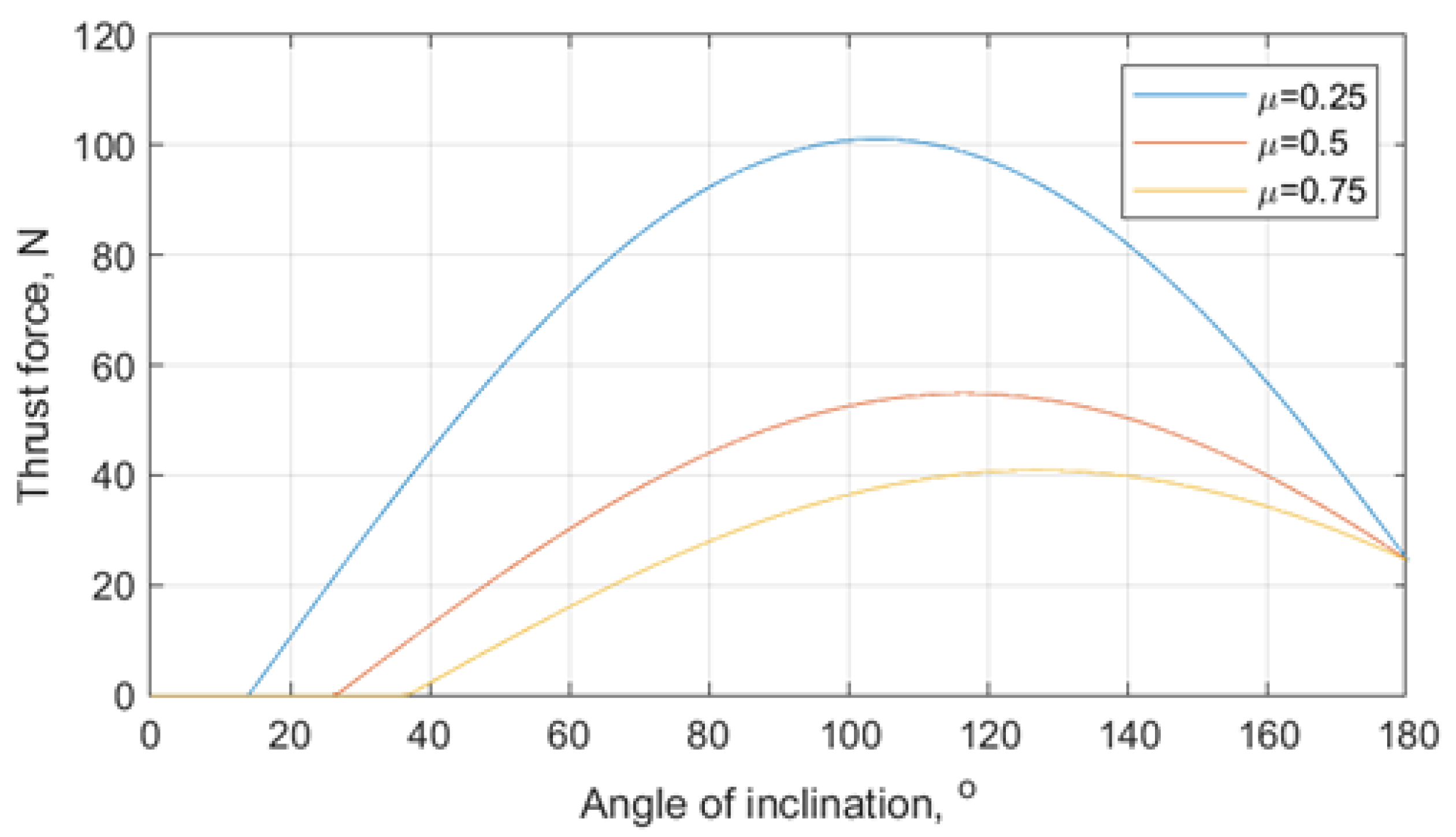

| Friction Coefficient, – | Angle of Inclination, ° | Thrust Force, N |

|---|---|---|

| 0.25 | 104 | 80.9 |

| 0.5 | 116.6 | 43.8 |

| 0.75 | 126.9 | 32.7 |

| Name Year Source | Presented MP 2024 | Rise-Rover 2015 [28] | Vortexbot 2017 [25] | 2017 [27] | 2007 [43] | 2024 [31] | EJBot II 2019 [22] | 2021 [29] | VCR 2019 [24] | 2022 [44] |

|---|---|---|---|---|---|---|---|---|---|---|

| Adhesion type | Neg. pressue thrust obtained by propulsion impeller | Vaccum suction cups embedded in the wheel track | Vortex suction unit for generation of negative pressure | Centrifugal impeller to generate negative pressure suction | Vacuum suction cups for adhesion | Vacuum suction cups for adhesion | Neg. pressure thrust obtained by propeller | Neg. pressure thrust obtained by electric ducted fans EDF | Vortex technique obtained by electric ducted fan | Vortex technique and bionic material on wheels |

| Locomotion type | Four independent electric wheel drives | Two electric rotors of tracked wheels | Electrical drives for three wheels | Two servo motor | Two pairs of pneumatic cylinders to drive positions of partial cups | Electric drive for changing the positions of suction cups attached to the chain belt | Two DC motors for separated two tracks | Two propulsion impeller units | Electrical drives of wheels | Electrically driven wheels |

| Application | NDT inspections for aircraft fuselages | Test of MB planned for NDT | Test of MB | Video inspection | NDT for aircraft | Test of MB | laboratory MB tested, planned for vessels surfaces in the petro- chemical industry | Test of MB planned for NDT | Test of MB planned for inspection and maintenance | Test of MB planned for NDT of vessels |

| Idle speed scan speed mm/s | 500 100 | 500 | [-] | 100 | 600 | [-] | [-] | [-] | [-] | [-] |

| Size L,W,H mm | 479 324 154 | 533 203 140 | [-] | 330 330 85 frame size | 518 518 180 | 650 530 260 | [-] | 347 320 218 | 272 288 150 | 250 130 20 |

| Umbilical weight of MP kg | 2 | 11 | 2.4 | 3 | [-] | 10.5 | [-] | 2.7 | 2.2 | 1.5 |

| Payload kg | 0.7 | 7.2 | 2.5 | 8 | 18 (including umbilical weight) | [-] | [-] | 1.9 | 8.1 | 2 * |

| P/W | 0.35 Up to 0.55 ** | 0.65 | 1.04 | 2.66 | [-] | [-] | [-] | 0.7 | 3.7 | 1.33 * |

| Total maximum power kW | 0.7 | 4 | [-] | [-] | [-] | [-] | [-] | 1.5 | 1.17 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toman, R.; Rogala, T.; Synaszko, P.; Katunin, A. Robotized Mobile Platform for Non-Destructive Inspection of Aircraft Structures. Appl. Sci. 2024, 14, 10148. https://doi.org/10.3390/app142210148

Toman R, Rogala T, Synaszko P, Katunin A. Robotized Mobile Platform for Non-Destructive Inspection of Aircraft Structures. Applied Sciences. 2024; 14(22):10148. https://doi.org/10.3390/app142210148

Chicago/Turabian StyleToman, Rafał, Tomasz Rogala, Piotr Synaszko, and Andrzej Katunin. 2024. "Robotized Mobile Platform for Non-Destructive Inspection of Aircraft Structures" Applied Sciences 14, no. 22: 10148. https://doi.org/10.3390/app142210148

APA StyleToman, R., Rogala, T., Synaszko, P., & Katunin, A. (2024). Robotized Mobile Platform for Non-Destructive Inspection of Aircraft Structures. Applied Sciences, 14(22), 10148. https://doi.org/10.3390/app142210148