A Rectangular Spiral Inward–Outward Alternating-Flow Polymer Thermal Collector for a Solar Water Heating System—A Preliminary Investigation in the Climate of Seri Iskandar, Malaysia

Abstract

:1. Introduction

2. Materials and Methods

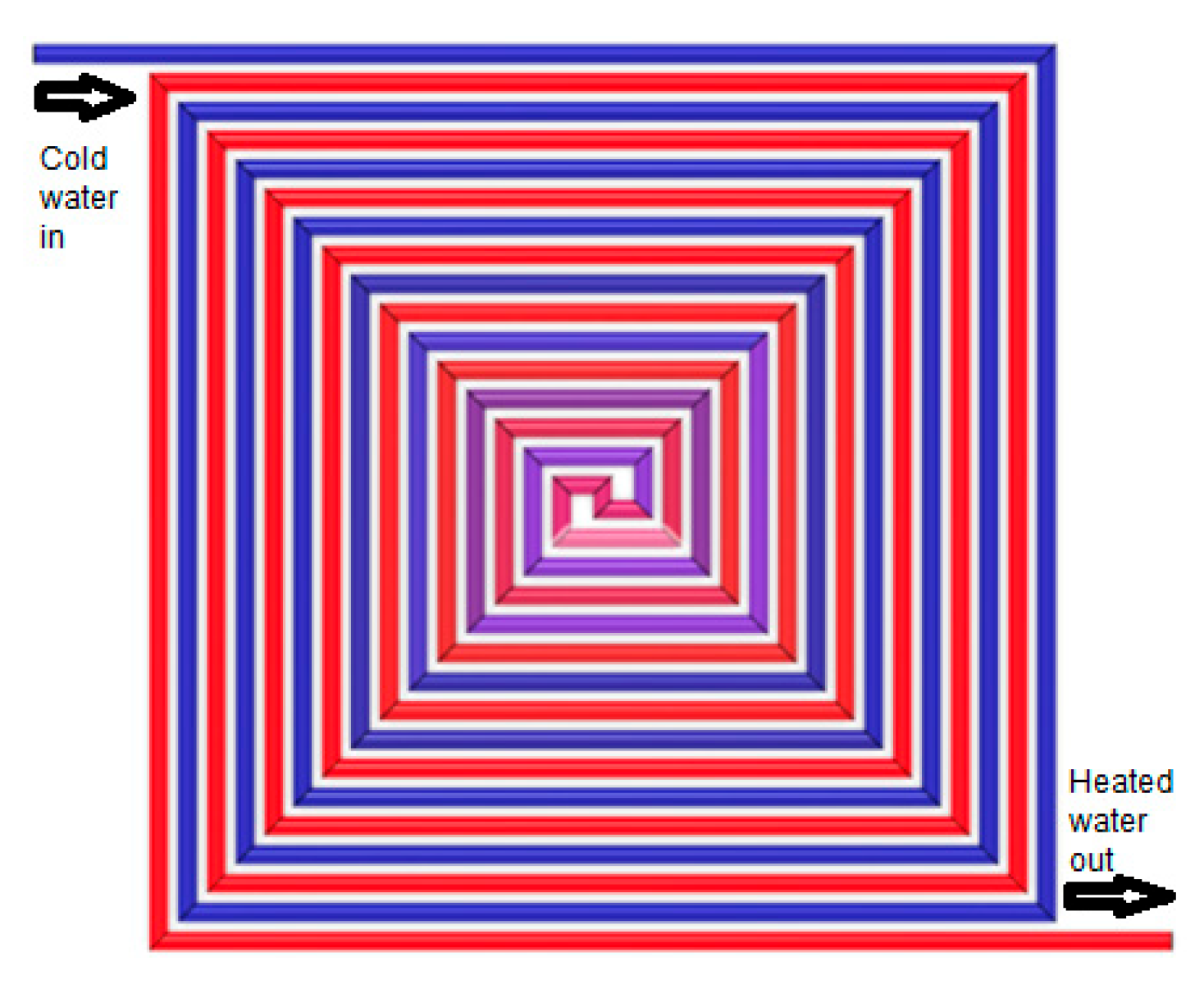

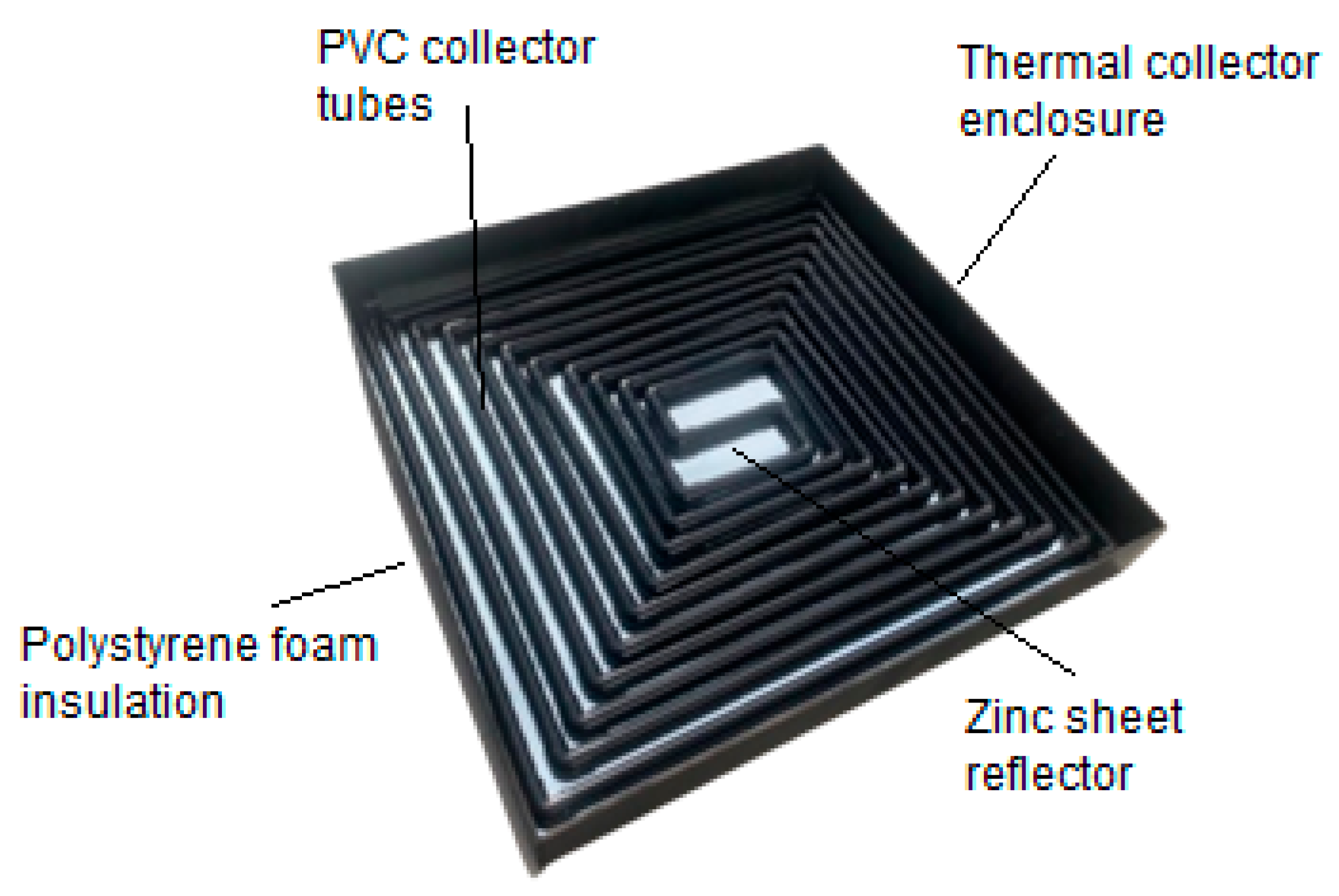

2.1. RSioaf Polymer Thermal Collector

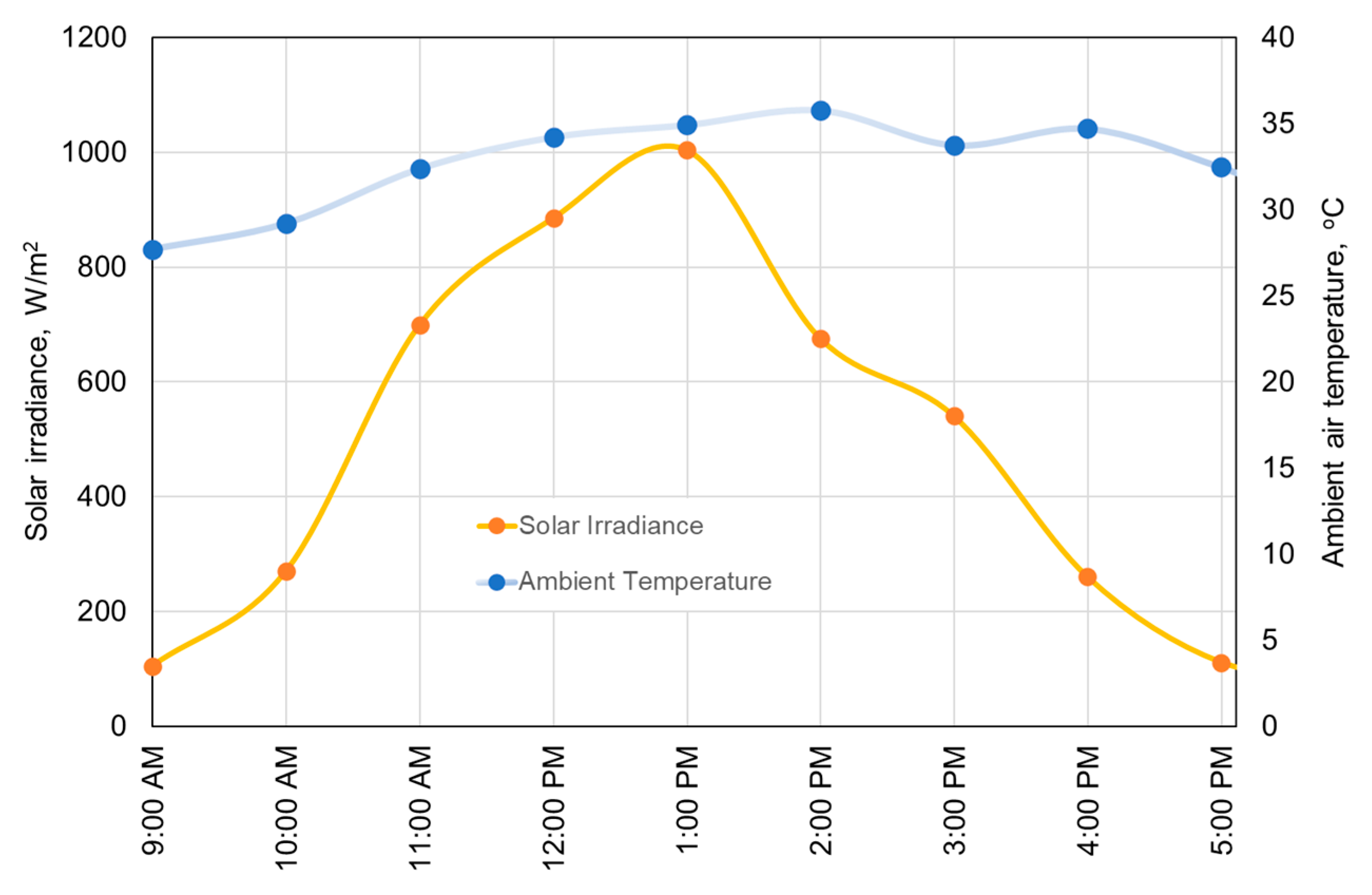

2.2. Experimental Setup and Procedures

2.3. Energy Model

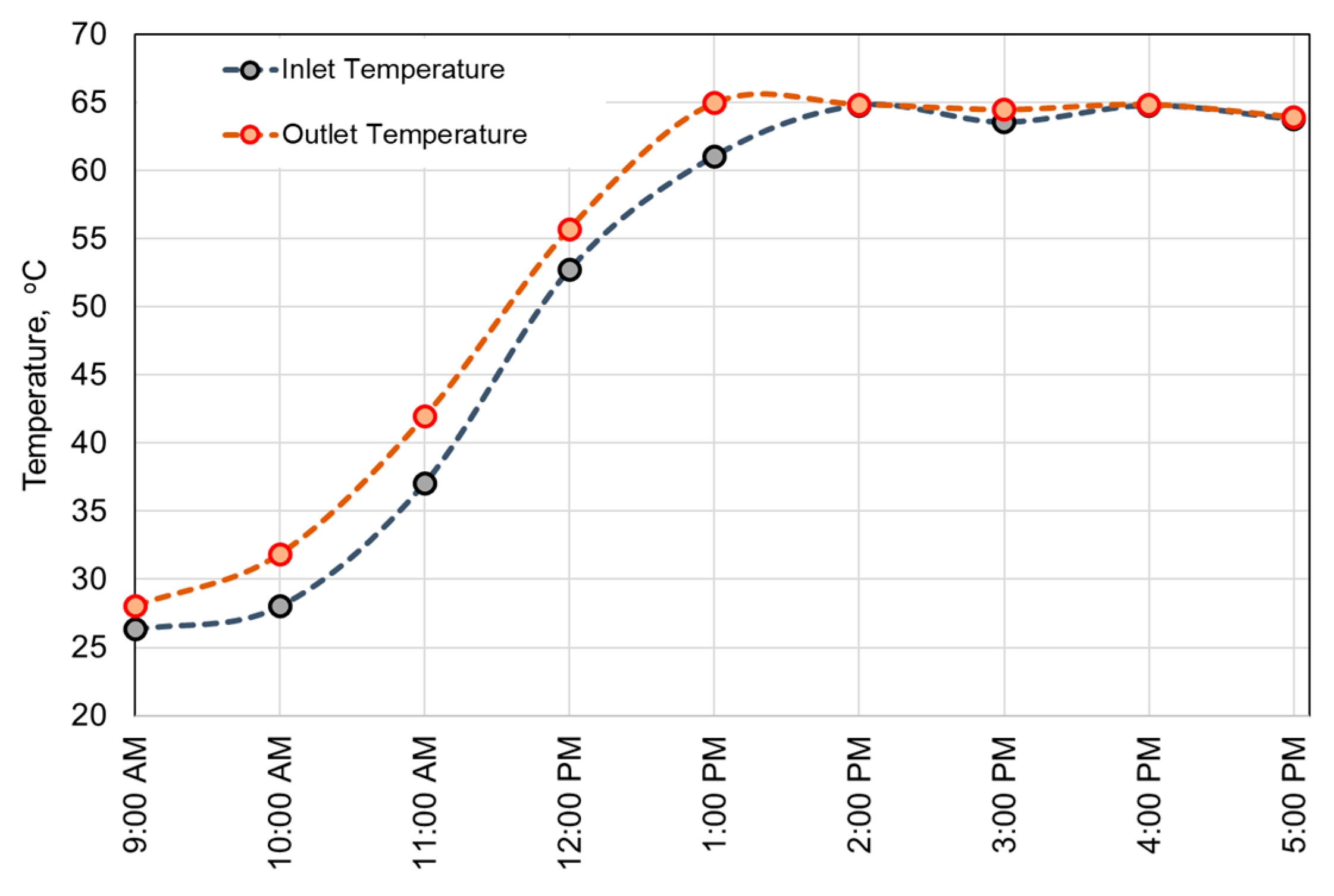

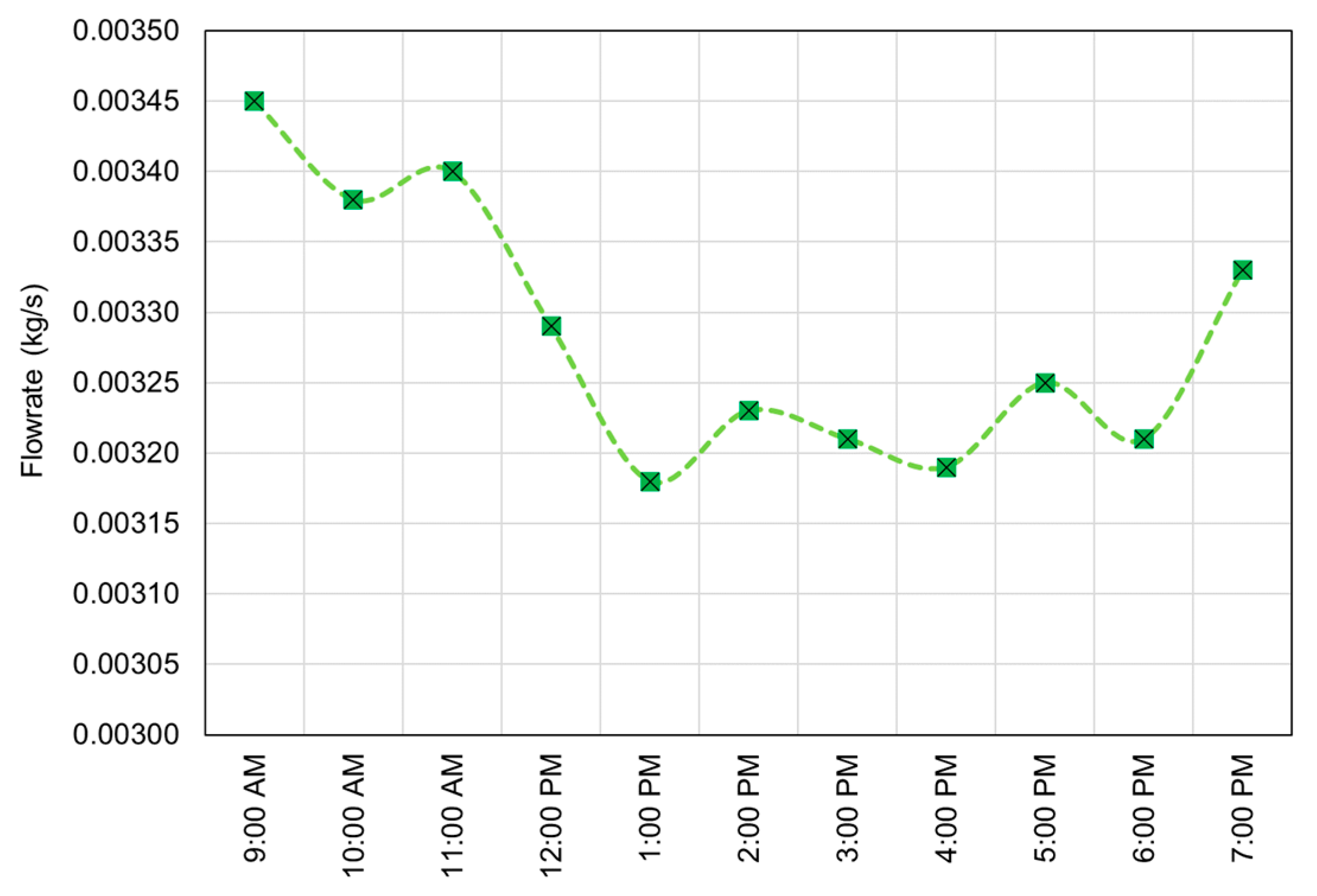

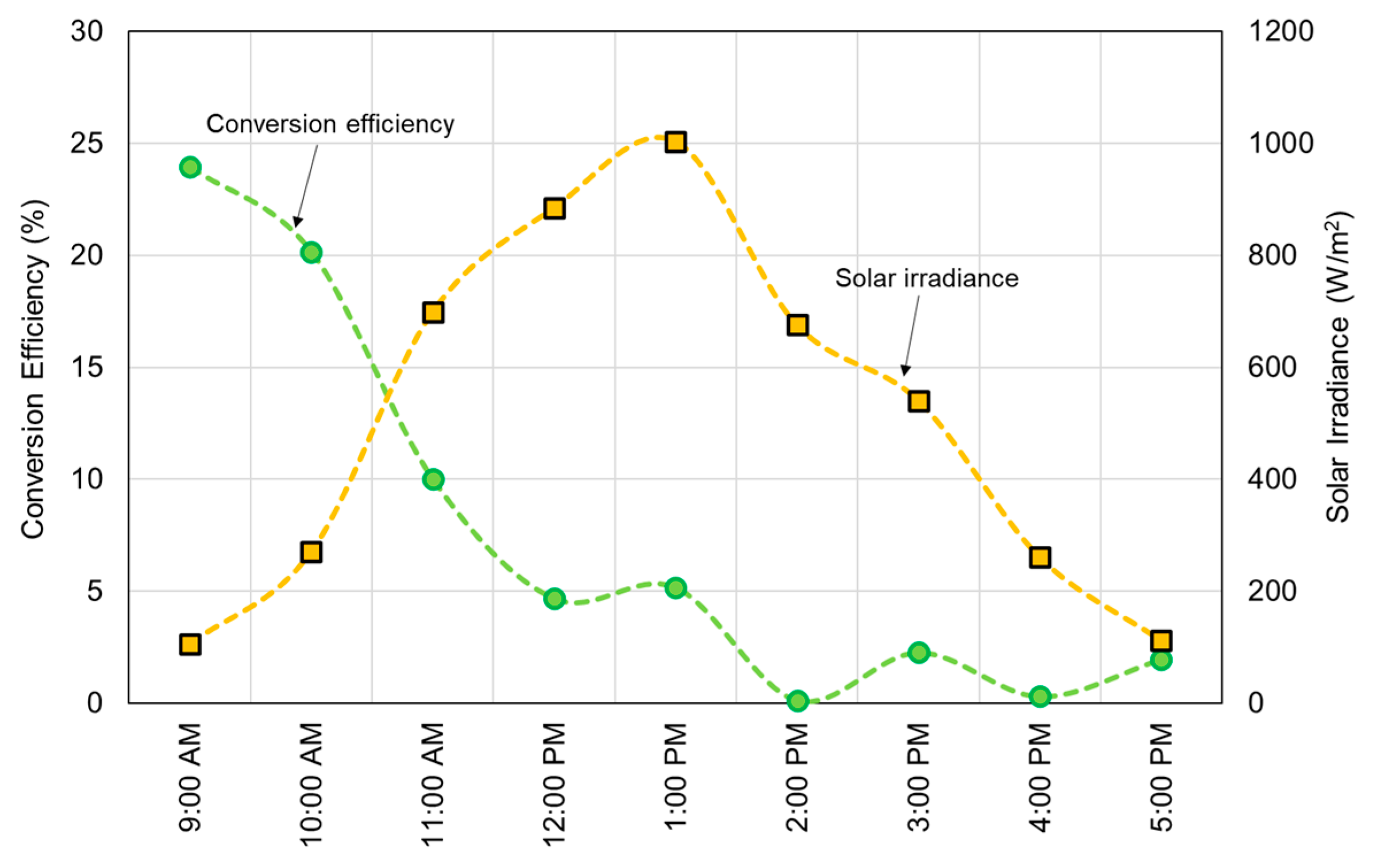

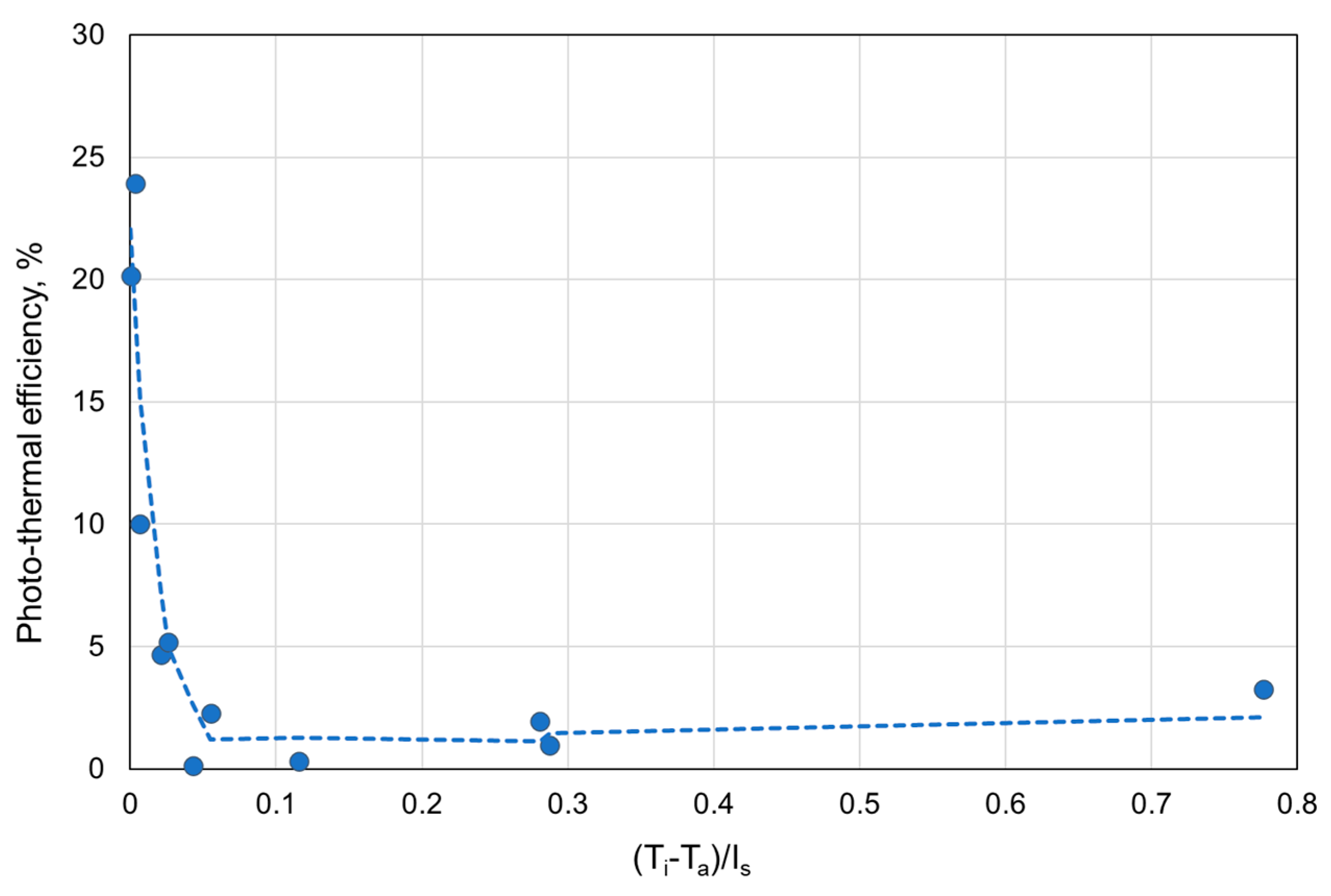

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Smil, V. General Energetics Energy in the Biosphere and Civilization; John Wiley: New York, NY, USA, 1991. [Google Scholar]

- Huang, G.; Wang, K.; Markides, C.N. Efficiency limits of concentrating spectral-splitting hybrid photovoltaic-thermal (PV-T) solar collectors and systems. Light Sci. Appl. 2021, 10, 28. [Google Scholar] [CrossRef] [PubMed]

- Nanda, I.R.; Pambudi, N.A.; Aziz, M. Review on the Progress of Solar Water Heaters and Their Future Perspectives. Energy Technol. 2023, 11, 2300191. [Google Scholar] [CrossRef]

- Dwivedi, P.; Sudhakar, K.; Soni, A.; Solomin, E.; Kirpichnikova, I. Advanced cooling techniques of P.V. modules: A state of art. Case Stud. Therm. Eng. 2020, 21, 100674. [Google Scholar] [CrossRef]

- Sadhishkumar, S.; Balusamy, T. Performance improvement in solar water heating systems—A review. Renew. Sustain. Energy Rev. 2014, 37, 191–198. [Google Scholar] [CrossRef]

- Clift, D.H.; Stanley, C.; Hasan, K.N.; Rosengarten, G. Assessment of advanced demand response value streams for water heaters in renewable-rich electricity markets. Energy 2023, 267, 126577. [Google Scholar] [CrossRef]

- Thakur, A.; Kumar, R.; Kumar, S.; Kumar, P. Review of developments on flat plate solar collectors for heat transfer enhancements using phase change materials and reflectors. Mater. Today Proc. 2021, 45, 5449–5455. [Google Scholar] [CrossRef]

- Nižetić, S.; Jurčević, M.; Čoko, D.; Arıcı, M.; Hoang, A.T. Implementation of phase change materials for thermal regulation of photovoltaic thermal systems: Comprehensive analysis of design approaches. Energy 2021, 228, 120546. [Google Scholar] [CrossRef]

- Suman, S.; Khan, M.K.; Pathak, M. Performance enhancement of solar collectors—A review. Renew. Sustain. Energy Rev. 2015, 49, 192–210. [Google Scholar] [CrossRef]

- Kizildag, D.; Castro, J.; Kessentini, H.; Schillaci, E.; Rigola, J. First test field performance of highly efficient flat plate solar collectors with transparent insulation and low-cost overheating protection. Sol. Energy 2022, 236, 239–248. [Google Scholar] [CrossRef]

- Eswara, C.A.C.S.P. Global Solar Water Heater Market Size, Share, Competitive Landscape and Trend Analysis Report by Type, Capacity and End User: Opportunity Analysis and Industry Forecast, 2020–2027; A07957; 2020; p. 301. Available online: https://www.alliedmarketresearch.com/solar-water-heater-market-A07957 (accessed on 21 October 2024).

- Sopian, K.; Zulkifli, R.; Sahari, J.; Othman, M.Y. Thermal performance of thermoplastic natural rubber solar collector. J. Mater. Process. Technol. 2002, 123, 179–184. [Google Scholar] [CrossRef]

- Frank, C.O.; Bernim, B.; Gowan, J.G. Performance of non-metallic flate plate solar collectors. Sol. Energy 1984, 33, 305–309. [Google Scholar]

- De la Peña, J.L.; Aguilar, R. Polymer Solar Collectors. A Better Alternative to Heat Water in Mexican Homes. Energy Procedia 2014, 57, 2205–2210. [Google Scholar] [CrossRef]

- Selikhov, Y.; Klemeš, J.J.; Kapustenko, P.; Arsenyeva, O. The study of flat plate solar collector with absorbing elements from a polymer material. Energy 2022, 256, 124677. [Google Scholar] [CrossRef]

- García, A.; Vicente, P.G.; Viedma, A. Experimental study of heat transfer enhancement with wire coil inserts in laminar-transition-turbulent regimes at different Prandtl numbers. Int. J. Heat Mass Transf. 2005, 48, 4640–4651. [Google Scholar] [CrossRef]

- García, A.; Martin, R.H.; Pérez-García, J. Experimental study of heat transfer enhancement in a flat-plate solar water collector with wire-coil inserts. Appl. Therm. Eng. 2013, 61, 461–468. [Google Scholar] [CrossRef]

- Jaisankar, S.; Radhakrishnan, T.K.; Sheeba, K.N. Experimental studies on heat transfer and friction factor characteristics of forced circulation solar water heater system fitted with helical twisted tapes. Sol. Energy 2009, 83, 1943–1952. [Google Scholar] [CrossRef]

- Kim, S.i.; Kissick, J.; Spence, S.; Boyle, C. Design, analysis and performance of a polymer–carbon nanotubes based economic solar collector. Sol. Energy 2016, 134, 251–263. [Google Scholar] [CrossRef]

- Hasan, M.F.; Mahadi, M.S.U.R.; Miyazaki, T.; Koyama, S.; Thu, K. Exergy Analysis of Serpentine Thermosyphon Solar Water Heater. Appl. Sci. 2018, 8, 391. [Google Scholar] [CrossRef]

- Available online: https://pvcfittingsdirect.com/does-sunlight-harm-pvc/#:~:text=PVC%20pipe%20and%20fitting%20exposure,minimal%20effects%20to%20these%20qualities (accessed on 21 October 2024).

- Wallner, G.M.; Povacz, M.; Hausner, R.; Lang, R.W. Lifetime modeling of polypropylene absorber materials for overheating protected hot water collectors. Sol. Energy 2016, 125, 324–331. [Google Scholar] [CrossRef]

| Parameter | Polymer Tube | Metal Tube 1 |

|---|---|---|

| Absorber tube material | Polyvinyl chloride | Copper |

| Absorber tube design | Rectangular spiral inward–outward alternating flow | Serpentine |

| Dimension of absorber plate | 1.0 m2 | 0.6 m2 |

| Pipe inner diameter | 14 mm | 10 mm |

| Pipe thickness | 3 mm | 1.5 mm |

| Glazing material | None | Tempered glass |

| Insulation | PVC foam | Glass wool and cork sheet |

| Collector tilt angle | 4.5° | 27° |

| Absorber thermal conductivity | 0.19 W·m−1·K−1 | 401 W·m−1·K−1 |

| Ambient temperature | 27–36 °C | 30 °C |

| Solar irradiance | 105–1004 W·m−2 | 900 W·m−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamad, T.I.; Mohd Shaifudeen, M.D.S. A Rectangular Spiral Inward–Outward Alternating-Flow Polymer Thermal Collector for a Solar Water Heating System—A Preliminary Investigation in the Climate of Seri Iskandar, Malaysia. Appl. Sci. 2024, 14, 11045. https://doi.org/10.3390/app142311045

Mohamad TI, Mohd Shaifudeen MDS. A Rectangular Spiral Inward–Outward Alternating-Flow Polymer Thermal Collector for a Solar Water Heating System—A Preliminary Investigation in the Climate of Seri Iskandar, Malaysia. Applied Sciences. 2024; 14(23):11045. https://doi.org/10.3390/app142311045

Chicago/Turabian StyleMohamad, Taib Iskandar, and Mohammad Danish Shareeman Mohd Shaifudeen. 2024. "A Rectangular Spiral Inward–Outward Alternating-Flow Polymer Thermal Collector for a Solar Water Heating System—A Preliminary Investigation in the Climate of Seri Iskandar, Malaysia" Applied Sciences 14, no. 23: 11045. https://doi.org/10.3390/app142311045

APA StyleMohamad, T. I., & Mohd Shaifudeen, M. D. S. (2024). A Rectangular Spiral Inward–Outward Alternating-Flow Polymer Thermal Collector for a Solar Water Heating System—A Preliminary Investigation in the Climate of Seri Iskandar, Malaysia. Applied Sciences, 14(23), 11045. https://doi.org/10.3390/app142311045