Bluesil FLD 550 HT Silicone Oil as Heat Transfer Fluid for Power Plant Applications: Thermal Stability Properties

Abstract

1. Introduction

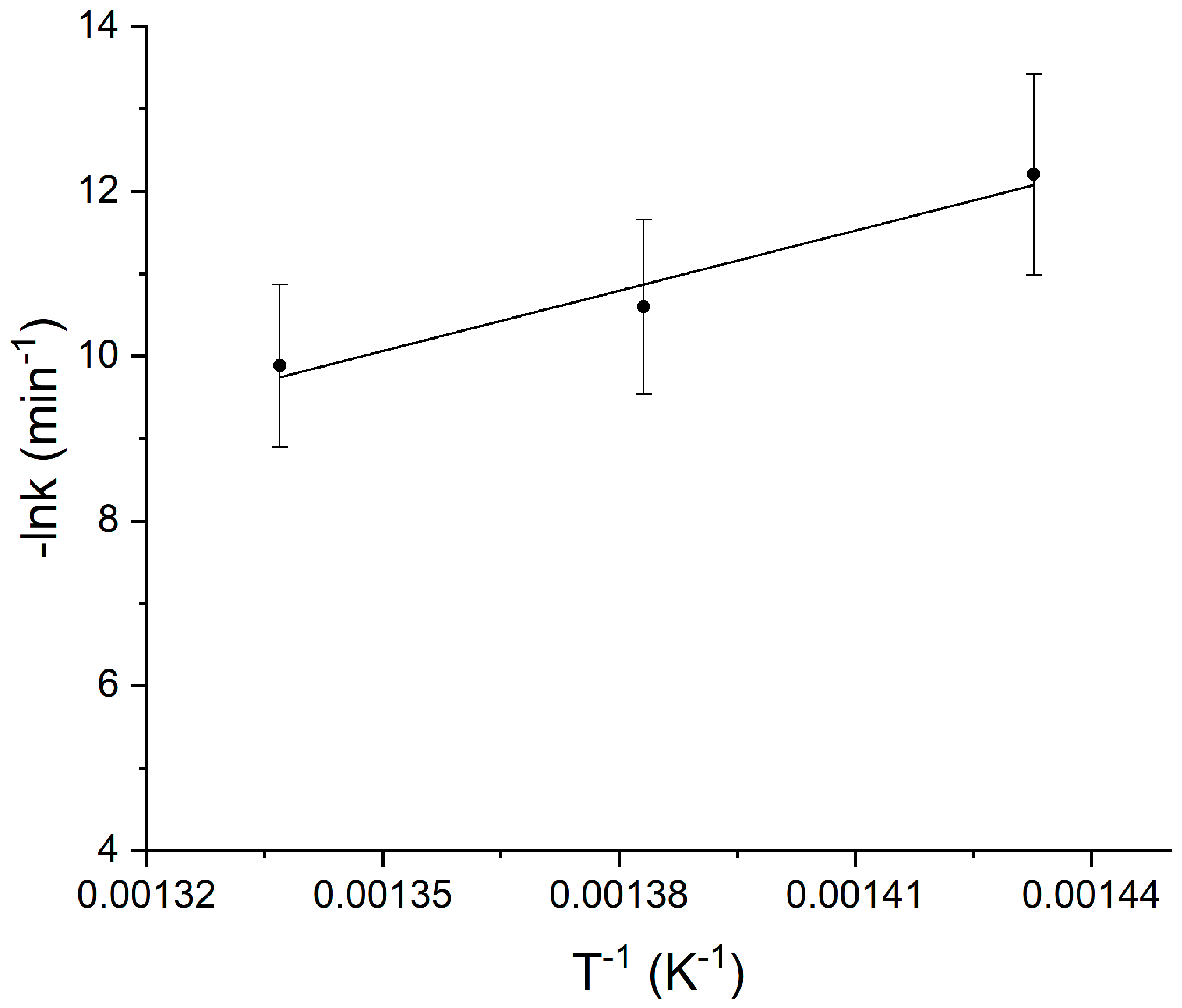

2. Materials and Methods

- Co = initial terphenyl concentration [mol/L]

- Vo = oil volume [L]

- Ct = terphenyl concentration [mol/L]

- Vhs = head space volume [L]

- CH2 = Hydrogen concentration [mol/L]

- K = Arrhenius constant

- t = time [min]

- T = temperature [K]

- A = pre-exponential factor

- Ea = activation energy [kJ/mol]

- R = 8.314 [J/mol K]

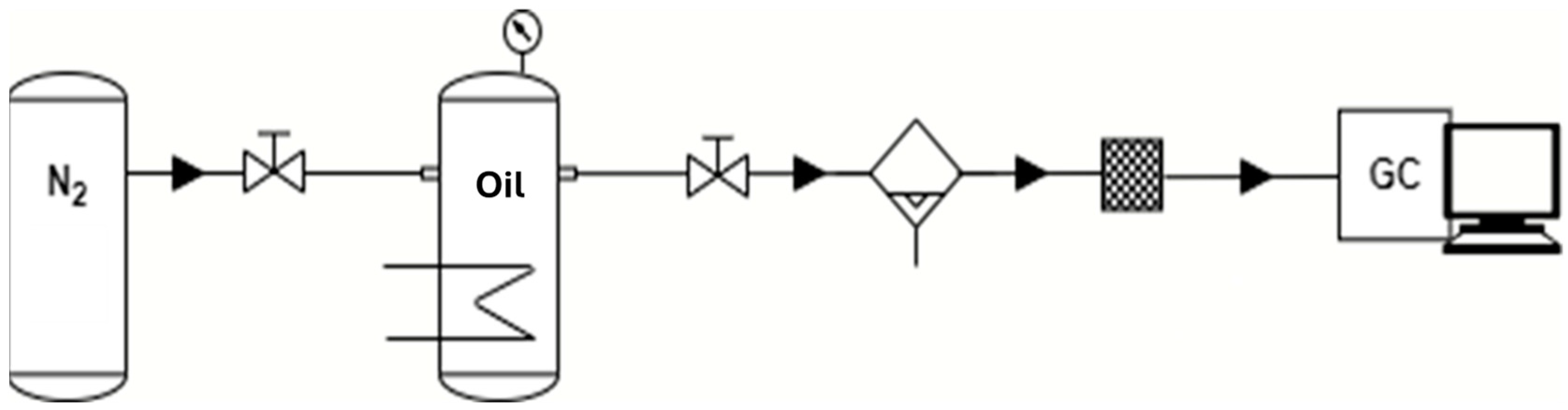

Instrumentation

- Xm = average measured value [J/g*K]

- Xi = measured values [J/g*K]

- N = measurements number

- σ = standard deviation

- Errm = mean error

- Err% = precision percentage error

- Xm = average measured value [Pa*s]

- XTh = value from technical data sheet [Pa*s]

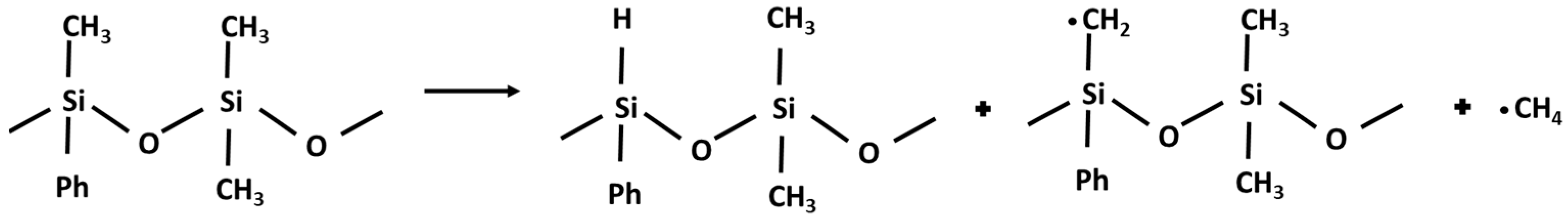

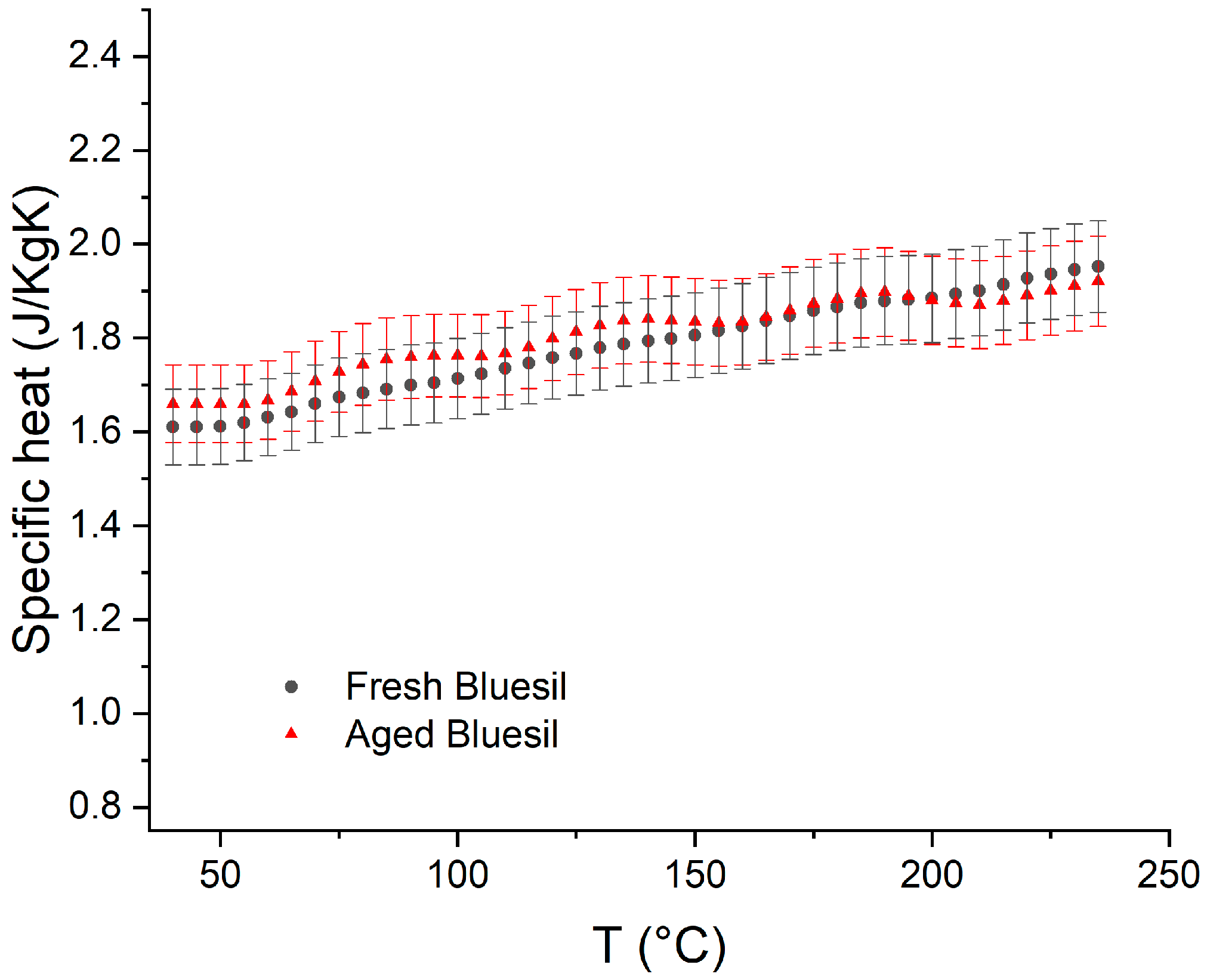

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HTF | Heat transfer fluid |

| HT | Heat transfer |

| GC | Gas chromatograph |

| TCD | Thermal conductivity detector |

| GC-MS | Gas chromatography coupled to mass spectrometry |

| TGA | Thermo gravimetric analysis |

| DSC | Differential scanning calorimetry |

References

- Krishna, Y.; Faizal, M.; Saidur, R.; Ng, K.; Aslfattahi, N. State-of-the-Art Heat Transfer Fluids for Parabolic Trough Collector. Int. J. Heat Mass Transf. 2020, 152, 119541. [Google Scholar] [CrossRef]

- El-Genk, M.S.; Tournier, J.-M. On the Use of Noble Gases and Binary Mixtures as Reactor Coolants and CBC Working Fluids. Energy Convers. Manag. 2008, 49, 1882–1891. [Google Scholar] [CrossRef]

- Lorenzin, N.; Abánades, A. A Review on the Application of Liquid Metals as Heat Transfer Fluid in Concentrated Solar Power Technologies. Int. J. Hydrogen Energy 2016, 41, 6990–6995. [Google Scholar] [CrossRef]

- Benoit, H.; Spreafico, L.; Gauthier, D.; Flamant, G. Review of Heat Transfer Fluids in Tube-Receivers Used in Concentrating Solar Thermal Systems: Properties and Heat Transfer Coefficients. Renew. Sustain. Energy Rev. 2016, 55, 298–315. [Google Scholar] [CrossRef]

- Giaconia, A.; Tizzoni, A.C.; Sau, S.; Corsaro, N.; Mansi, E.; Spadoni, A.; Delise, T. Assessment and Perspectives of Heat Transfer Fluids for CSP Applications. Energies 2021, 14, 7486. [Google Scholar] [CrossRef]

- Vutukuru, R.; Pegallapati, A.S.; Maddali, R. Suitability of Various Heat Transfer Fluids for High Temperature Solar Thermal Systems. Appl. Therm. Eng. 2019, 159, 113973. [Google Scholar] [CrossRef]

- Campuzano, F.; Ordoñez, J.; Martínez, J.D.; Agudelo, A.F.; Sarathy, S.M.; Roberts, W.L. Thermal Decomposition Characteristics of the Tire Pyrolysis Oil Derived from a Twin-Auger Reactor: Study of kinetics and Evolved Gases. Fuel 2023, 338, 127248. [Google Scholar] [CrossRef]

- Santos, J.C.O.; dos Santos, I.M.G.; Souza, A.G.; Sobrinho, E.V.; Fernandes, V.J., Jr.; Silva, A.J.N. Thermoanalytical and Rheological Characterization of Automotive Mineral Lubricants after Thermal Degradation. Fuel 2004, 83, 2393–2399. [Google Scholar] [CrossRef]

- Ikonen, E.; Liukkonen, M.; Hansen, A.H.; Edelborg, M.; Kjos, O.; Selek, I.; Kettunen, A. Fouling Monitoring in a Circulating Fluidized Bed Boiler Using Direct and Indirect Model-Based Analytics. Fuel 2023, 346, 128341. [Google Scholar] [CrossRef]

- Yang, Q.; Tong, S.; Tong, Z.; Wang, H.; Cao, X.E. Ash Fouling Characteristic Analysis and Prediction for Pillow Plate Heat Exchanger in Waste Heat Recovery Based on Attentive-Feature Decision Algorithm. Fuel 2024, 372, 132133. [Google Scholar] [CrossRef]

- Wang, F.-L.; Tang, S.-Z.; He, Y.-L.; Kulacki, F.A.; Yu, Y. Heat Transfer and Fouling Performance of Finned Tube Heat Exchangers: Experimentation via on Line Monitoring. Fuel 2019, 236, 949–959. [Google Scholar] [CrossRef]

- Cellini, R.F. JEN Research Programme on Organic Moderator-Coolants. In Proceedings of the Panel on the Use of Organic Liquids as Reactor Coolants and Moderators, Vienna, Austria, 9–13 May 1966; pp. 67–93. Available online: http://www.iaea.org/inis/collection/NCLCollectionStore/_Public/34/065/34065185.pdf (accessed on 25 January 2025).

- Smee, J.L.; Puttagunta, V.R.; Robertson, R.F.S.; Hatcher, R. Organic Coolant Summary Report (No. AECL–4922); Atomic Energy of Canada Ltd.: Chalk River, ON, Canada, 1975. [Google Scholar]

- Grirate, H.; Zari, N.; Elmchaouri, A.; Molina, S.; Couturier, R. Life Time Analysis of Thermal Oil Used as Heat Transfer Fluid in CSP Power Plant. In Proceedings of the SOLARPACES 2015: International Conference on Concentrating Solar Power and Chemical Energy Systems, Cape Town, South Africa, 13–16 October 2015. [Google Scholar] [CrossRef]

- Cheng, W.; Chen, M.; Ouyang, D.; Weng, J.; Zhao, L.; Chen, Y. Investigation of the Thermal Performance and Heat Transfer Characteristics of the Lithium-Ion Battery Module Based on an Oil-Immersed Cooling Structure. J. Energy Storage 2024, 79, 110184. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Kang, S.-W.; Wu, T.-Y. Fabrication of Polydimethylsiloxane (PDMS) Pulsating Heat Pipe. Appl. Therm. Eng. 2009, 29, 573–580. [Google Scholar] [CrossRef]

- Silicones, Organo Functional. 2011. ‘BLUESIL’. Available online: https://www.bag-distribution.com/Files/108113/16311264463191.pdf (accessed on 12 January 2025).

- Dow. n.d. SYLTHERMTM XLT Heat Transfer Fluid Technical Data Sheet. Available online: http://www.dowtherm.com (accessed on 12 January 2025).

- Thermal Expansion of SYLTHERM HF Fluid. n.d. Available online: www.dowtherm.com (accessed on 12 January 2025).

- Typical Properties of SYLTHERM 800 Fluid 1. n.d. Available online: www.dowtherm.com (accessed on 12 January 2025).

- Jung, C.; Dersch, J.; Nietsch, A.; Senholdt, M. Technological Perspectives of Silicone Heat Transfer Fluids for Concentrated Solar Power. Energy Procedia 2015, 69, 663–671. [Google Scholar] [CrossRef]

- Chainet, F.; Le Meur, L.; Lienemann, C.-P.; Ponthus, J.; Courtiade, M.; Donard, O.F.X. Characterization of Silicon Species Issued from PDMS Degradation Under Thermal Cracking of Hydrocarbons: Part 1—Gas Samples Analysis by Gas Chromatography-time of Flight Mass Spectrometry. Fuel 2013, 111, 519–527. [Google Scholar] [CrossRef]

- Chainet, F.; Le Meur, L.; Lienemann, C.-P.; Ponthus, J.; Courtiade, M.; Donard, O.F.X. Characterization of Silicon Species Issued from PDMS Degradation Under Thermal Cracking of Hydrocarbons: Part 2—Liquid Samples Analysis by a Multi-Technical Approach Based on Gas Chromatography and Mass Spectrometry. Fuel 2014, 116, 478–489. [Google Scholar] [CrossRef]

- Dai, X.; Shi, L.; Qian, W. Thermal Stability of hexamethyldisiloxane (MM) as a Working Fluid for Organic Rankine Cycle. Int. J. Energy Res. 2019, 43, 896–904. [Google Scholar] [CrossRef]

- Gallarini, S.; Spinelli, A.; Lietti, L.; Guardone, A. Thermal Stability of Linear Siloxanes and Their Mixtures. Energy 2023, 278, 127687. [Google Scholar] [CrossRef]

- Keulen, L.; Gallarini, S.; Landolina, C.; Spinelli, A.; Iora, P.; Invernizzi, C.; Lietti, L.; Guardone, A. Thermal Stability of Hexamethyldisiloxane and Octamethyltrisiloxane. Energy 2018, 165, 868–876. [Google Scholar] [CrossRef]

- Di Marcoberardino, G.; Invernizzi, C.M.; Iora, P.; Arosio, L.; Canavese, M.; Lunghi, A.; Mazzei, A. Thermal Stability and Thermodynamic Performances of Pure Siloxanes and Their Mixtures in Organic Rankine Cycles. Energies 2022, 15, 3498. [Google Scholar] [CrossRef]

- Wang, W.; Dai, X.; Shi, L. Influence of Thermal Stability on Organic Rankine Cycle Systems Using Siloxanes as Working Fluids. Appl. Therm. Eng. 2022, 200, 117639. [Google Scholar] [CrossRef]

- Mansi, E.; Sau, S.; Balog, I.; Caputo, G.; Corsaro, N.; Tiranti, G.; Filippi, F.; Panza, F.; Ratto, N.; Simonetti, A.; et al. High Temperature Stability of a Commercial Terphenyl-Based Thermal Oil. Prog. Nucl. Energy 2021, 140, 103900. [Google Scholar] [CrossRef]

- Mansi, E.; Sau, S.; Balog, I.; Cemmi, A.; Ciotti, M.; Corsaro, N.; Caputo, G.; Filippi, F.; Panza, F.; Ratto, N.; et al. Oil Testing for Intense Use in CSP Applications. In Proceedings of the SOLARPACES 2020: 26th International Conference on Concentrating Solar Power and Chemical Energy Systems, Freiburg, Germany, 28 September–2 October 2020. [Google Scholar]

- Bluesil Safety Data Sheet. 2016, pp. 1–16. Available online: https://www.siliconiitalia.it/public/schede/318/bluesil%20fld%20604v50%20in.pdf (accessed on 12 January 2025).

- NIST. NIST Mass Spectral Database for NIST/EPA/NIH and Mass Spectral Search Program (Version 2.3). The National Institute of Standards and Technology NIST. Nist 17; 2017; pp. 1–73. Available online: http://www.nist.gov/srd/ (accessed on 8 January 2025).

- Mettler. Thermal Analysis Specific Heat. 2003. Available online: http://www.mt.com/ta (accessed on 8 January 2025).

- Taylor, J.R. Introduction to Error Analysis: The Study of Uncertain; University Science Books: Sausalito, CA, USA, 1997. [Google Scholar]

- Cannon Instrument Company®. Viscosity & Flash Point Standards for Reference, Validation, and Calibration. n.d. Available online: www.cannoninstrument.com (accessed on 8 January 2025).

- Zhou, W.; Yang, H.; Guo, X.; Lu, J. Thermal Degradation Behaviors of Some Branched and Linear Polysiloxanes. Polym. Degrad. Stab. 2006, 91, 1471–1475. [Google Scholar] [CrossRef]

- Camino, G.; Lomakin, S.; Lageard, M. Thermal Polydimethylsiloxane Degradation. Part 2. The Degradation Mechanisms. Polymer 2002, 43, 2011–2015. [Google Scholar] [CrossRef]

- Arkles, B. Silicone Fluids: Stable Inert Media. 1–30 January 2013. 2012. Available online: https://www.researchgate.net/publication/277313694_Silicone_Fluids_Stable_Inert_Media (accessed on 11 January 2025).

- Bond Dissociation Energies Table. Available online: https://labs.chem.ucsb.edu/zakarian/armen/11---bonddissociationenergy.pdf (accessed on 11 January 2025).

| Thermophysical Characteristics | |

|---|---|

| Composition | Methyl Phenyl siloxane co-polymer |

| Color | colorless |

| Viscosity at 25 °C, mm2/s, approx | 125 |

| Specific gravity at 25 °C, approx | 1.065 |

| Flash point, °C, approx | 300 |

| Freezing point, °C | −50 |

| Refractive index at 25 °C, approx | 1.495 |

| Surface tension at 25 °C, mN/m, approx | 24.5 |

| Vapor pressure at 200 °C, mbar, approx | 1.33 × 10−2 |

| Expansion coefficient between 25 °C and 100 °C, approx | 7.5 × 10−4 |

| Specific heat between 40 °C and 200 °C J/gK approx | 1.50 |

| Thermal conductivity, W/mK approx | 0.15 |

| Viscosity, mm2/s, approx.: | |

| at 100 °C | 20 |

| at 35 °C | 84 |

| at 25 °C | 125 |

| at −30 °C | 22,000 |

| Tset (°C) | Toil (°C) | H2 (µmol/g) | CH4 (µmol/g) |

|---|---|---|---|

| 425 | 403 | 27 | 26 |

| 450 | 428 | 85 | 37 |

| 475 | 453 | 529 | 79 |

| Tested Oil | Temperature Range Tested | Overheating Temperature | Partial Pressure Reached | Amount of Condensable Production |

|---|---|---|---|---|

| °C | °C | bar | mL | |

| Therminol66 [29] | 350–415 | 430 | 9 | 35 |

| Therminol SP [30] | 350–390 | 405 | 12 | 25 |

| Bluesil | 400–475 | 475 | 8 | 8 |

| Tested Oil | Fresh Oil Onset Temperature (°C) | Aged Oil Onset Temperature (°C) |

|---|---|---|

| Therminol 66 [29] | 215 | 223 |

| Therminol SP [30] | 244 | 177 |

| Bluesil | 376 | 185 |

| Thermally Stressed Oils | Fresh Oil Onset Fitting Equations | Aged Oil Onset Fitting Equations |

|---|---|---|

| Therminol 66 [29] | Cp [KJ/Kg K] = 1.55 + 3.34 × 10−3 T [°C] | Cp [KJ/Kg K] = 1.54 + 3.21 × 10−3 T [°C] |

| Therminol SP [30] | Cp [KJ/Kg K] = 1.91 + 3.04 × 10−3 T [°C] | Cp [KJ/Kg K] = 1.96 + 3.47 × 10−3 T [°C] |

| Bluesil | Cp [KJ/Kg K] = 1.53 + 1.81 × 10−3 T [°C] | Cp [KJ/Kg K] = 1.62 + 1.36 × 10−3 T [°C] |

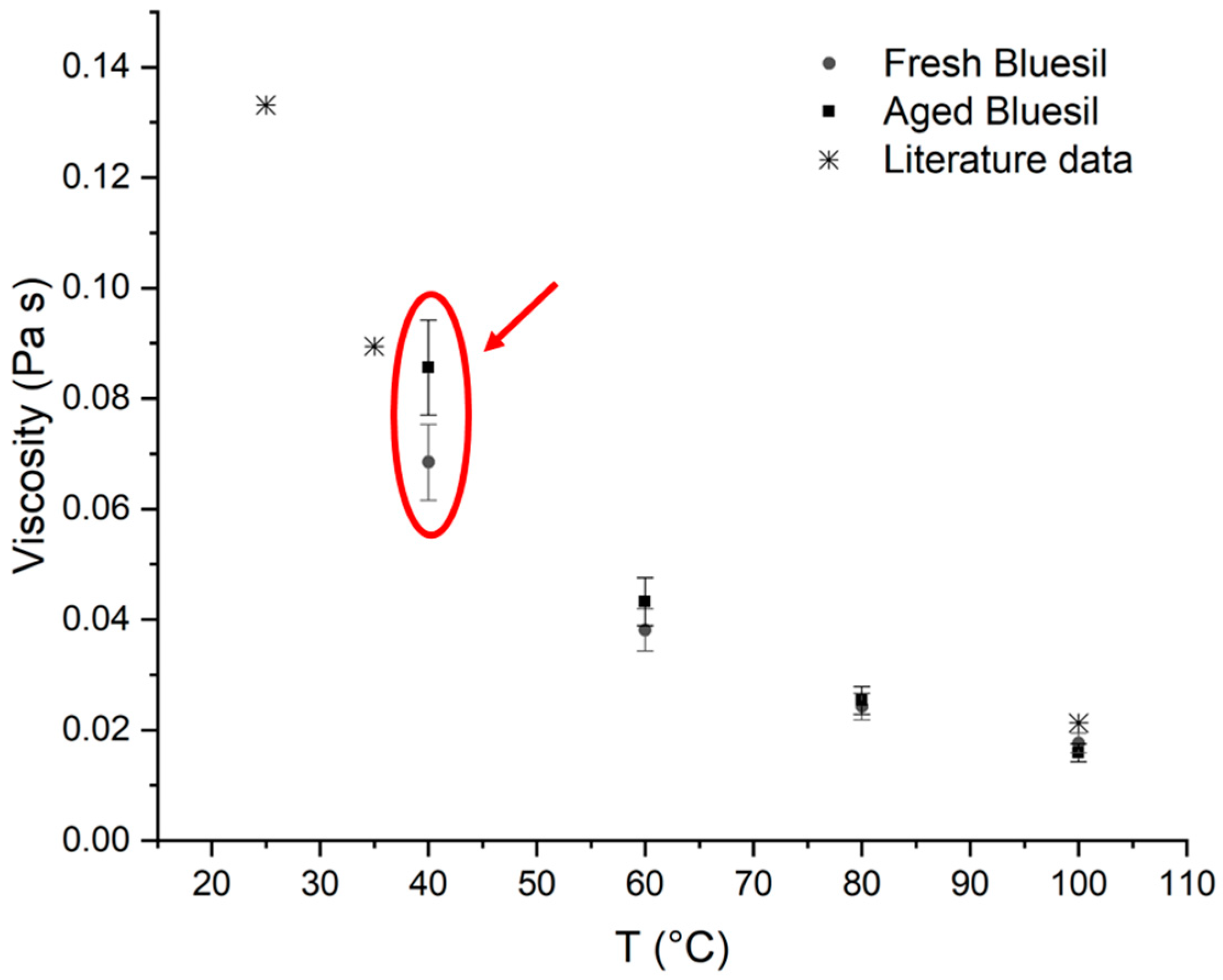

| T | Fresh_Bluesil | Aged_Bluesil | Diff |

|---|---|---|---|

| °C | Pa*s | Pa*s | % |

| 40 | 6.85 × 10−2 | 8.56 × 10−2 | 20.0 |

| 60 | 3.81 × 10−2 | 4.33 × 10−2 | 11.9 |

| 80 | 2.43 × 10−2 | 2.54 × 10−2 | 4.30 |

| 100 | 1.77 × 10−2 | 1.59 × 10−2 | 11.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mansi, E.; Balog, I.; Caputo, G.; Corsaro, N.; Di Sarcina, I.; Tiranti, G.; Filippi, F.; Panza, F.; Ratto, N.; Sau, S.; et al. Bluesil FLD 550 HT Silicone Oil as Heat Transfer Fluid for Power Plant Applications: Thermal Stability Properties. Appl. Sci. 2025, 15, 2340. https://doi.org/10.3390/app15052340

Mansi E, Balog I, Caputo G, Corsaro N, Di Sarcina I, Tiranti G, Filippi F, Panza F, Ratto N, Sau S, et al. Bluesil FLD 550 HT Silicone Oil as Heat Transfer Fluid for Power Plant Applications: Thermal Stability Properties. Applied Sciences. 2025; 15(5):2340. https://doi.org/10.3390/app15052340

Chicago/Turabian StyleMansi, Emiliana, Irena Balog, Giampaolo Caputo, Natale Corsaro, Ilaria Di Sarcina, Giuliano Tiranti, Francesco Filippi, Fabio Panza, Nicolò Ratto, Salvatore Sau, and et al. 2025. "Bluesil FLD 550 HT Silicone Oil as Heat Transfer Fluid for Power Plant Applications: Thermal Stability Properties" Applied Sciences 15, no. 5: 2340. https://doi.org/10.3390/app15052340

APA StyleMansi, E., Balog, I., Caputo, G., Corsaro, N., Di Sarcina, I., Tiranti, G., Filippi, F., Panza, F., Ratto, N., Sau, S., Simonetti, A., Spadoni, A., Tizzoni, A. C., Cemmi, A., & Ciotti, M. (2025). Bluesil FLD 550 HT Silicone Oil as Heat Transfer Fluid for Power Plant Applications: Thermal Stability Properties. Applied Sciences, 15(5), 2340. https://doi.org/10.3390/app15052340