Impact of Temperature and Humidity on Key Mechanical Properties of Corrugated Board

Abstract

1. Introduction

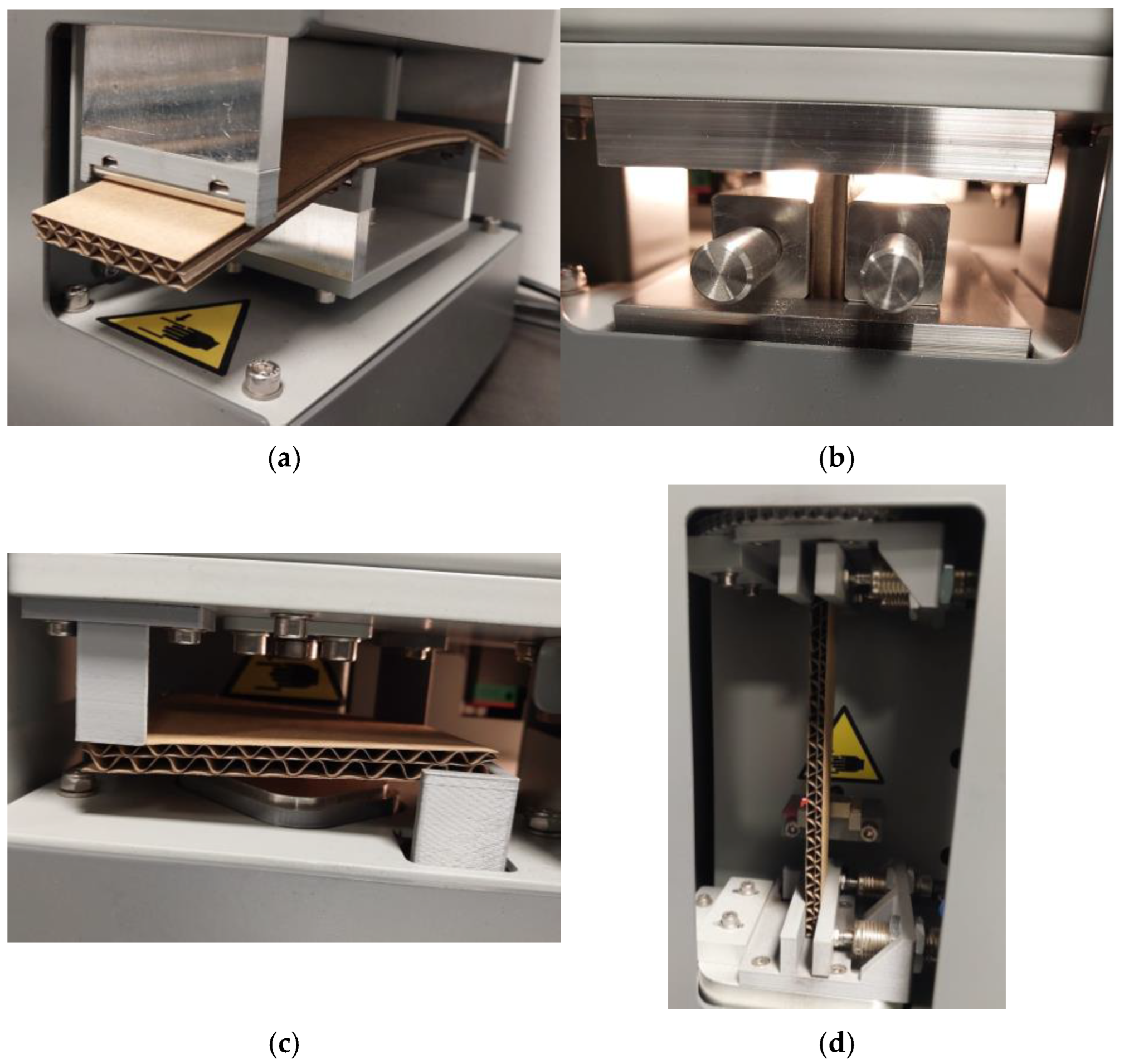

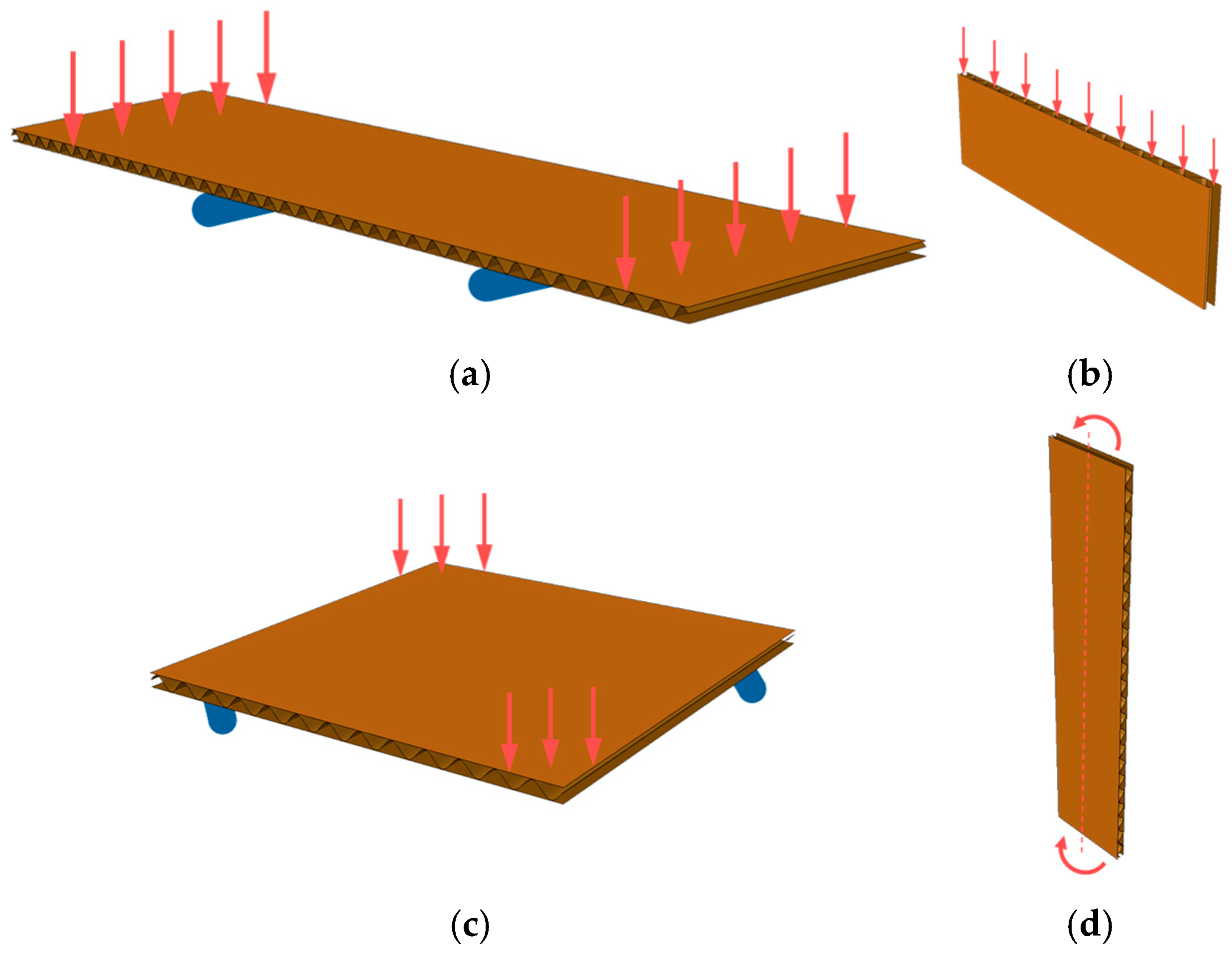

2. Materials and Methods

- the Shear Stiffness Test (SST), using a square 85 × 85 mm sample;

- the Torsion Stiffness Test (TST) in both MD and CD, using a rectangular 150 × 30 mm sample.

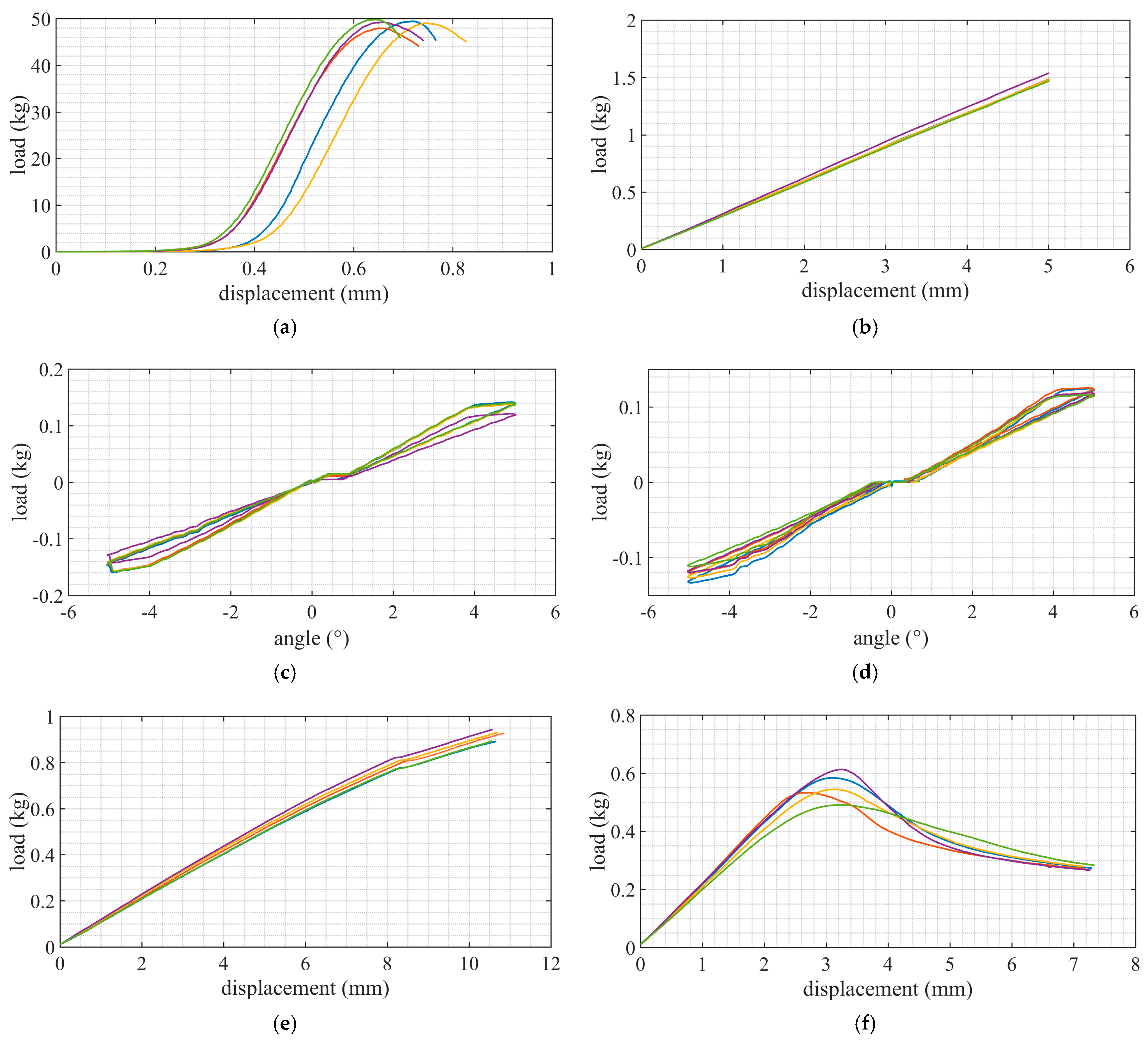

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| E Flute Cardboard | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness (mm) | |||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 504 | 507 | 509 | 512 | 520 | 531 | 555 | 10 | 1.72 | 1.72 | 1.73 | 1.73 | 1.74 | 1.75 | 1.76 | ||

| 20 | 500 | 503 | 507 | 510 | 519 | 527 | 551 | 20 | 1.71 | 1.73 | 1.72 | 1.73 | 1.74 | 1.74 | 1.76 | ||

| 30 | 499 | 504 | 506 | 509 | 516 | 522 | 544 | 30 | 1.71 | 1.72 | 1.71 | 1.73 | 1.73 | 1.74 | 1.75 | ||

| 40 | 495 | 498 | 507 | 505 | 510 | 514 | 523 | 40 | 1.72 | 1.72 | 1.72 | 1.73 | 1.73 | 1.73 | 1.74 | ||

| 50 | 490 | 493 | 495 | 501 | 503 | 510 | 518 | 50 | 1.71 | 1.71 | 1.71 | 1.71 | 1.73 | 1.72 | 1.73 | ||

| 60 | 488 | 489 | 493 | 493 | 500 | 506 | 514 | 60 | 1.70 | 1.71 | 1.72 | 1.71 | 1.71 | 1.71 | 1.73 | ||

| B flute cardboard | |||||||||||||||||

| grammage | thickness (mm) | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 411 | 411 | 417 | 418 | 420 | 426 | 439 | 10 | 2.96 | 2.95 | 2.96 | 2.97 | 2.97 | 2.98 | 2.95 | ||

| 20 | 409 | 410 | 414 | 415 | 419 | 425 | 440 | 20 | 2.97 | 2.94 | 2.96 | 2.97 | 2.97 | 2.98 | 2.98 | ||

| 30 | 407 | 411 | 411 | 412 | 415 | 420 | 426 | 30 | 2.96 | 2.96 | 2.97 | 2.96 | 2.96 | 2.97 | 2.97 | ||

| 40 | 402 | 408 | 409 | 408 | 410 | 414 | 416 | 40 | 2.95 | 2.96 | 2.96 | 2.96 | 2.97 | 2.96 | 2.97 | ||

| 50 | 399 | 400 | 401 | 402 | 408 | 409 | 411 | 50 | 2.96 | 2.96 | 2.94 | 2.94 | 2.96 | 2.96 | 2.96 | ||

| 60 | 395 | 396 | 399 | 401 | 403 | 404 | 409 | 60 | 2.94 | 2.95 | 2.95 | 2.95 | 2.96 | 2.96 | 2.96 | ||

| C flute cardboard | |||||||||||||||||

| grammage | thickness (mm) | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 453 | 451 | 458 | 459 | 464 | 474 | 498 | 10 | 4.02 | 4.02 | 4.03 | 4.05 | 4.04 | 4.03 | 4.02 | ||

| 20 | 450 | 452 | 456 | 457 | 461 | 469 | 490 | 20 | 4.02 | 4.03 | 4.04 | 4.02 | 4.04 | 4.04 | 4.01 | ||

| 30 | 449 | 450 | 452 | 456 | 457 | 461 | 466 | 30 | 4.01 | 4.02 | 4.00 | 4.02 | 4.03 | 4.03 | 4.02 | ||

| 40 | 442 | 446 | 447 | 450 | 451 | 452 | 456 | 40 | 4.01 | 4.00 | 4.01 | 4.01 | 4.04 | 4.02 | 4.01 | ||

| 50 | 437 | 439 | 436 | 442 | 443 | 445 | 447 | 50 | 4.02 | 4.01 | 4.00 | 4.02 | 4.02 | 4.01 | 4.01 | ||

| 60 | 435 | 432 | 437 | 439 | 440 | 443 | 445 | 60 | 4.00 | 4.00 | 4.00 | 4.00 | 4.01 | 4.00 | 3.98 | ||

| EE flue cardboard | |||||||||||||||||

| grammage | thickness (mm) | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 651 | 648 | 656 | 658 | 664 | 672 | 693 | 10 | 2.78 | 2.78 | 2.80 | 2.78 | 2.80 | 2.83 | 2.82 | ||

| 20 | 642 | 648 | 653 | 654 | 661 | 667 | 687 | 20 | 2.78 | 2.78 | 2.79 | 2.79 | 2.79 | 2.80 | 2.83 | ||

| 30 | 639 | 644 | 647 | 652 | 655 | 660 | 665 | 30 | 2.77 | 2.77 | 2.78 | 2.77 | 2.80 | 2.78 | 2.80 | ||

| 40 | 635 | 639 | 641 | 645 | 643 | 648 | 659 | 40 | 2.75 | 2.77 | 2.78 | 2.78 | 2.77 | 2.78 | 2.78 | ||

| 50 | 627 | 627 | 628 | 630 | 636 | 636 | 641 | 50 | 2.74 | 2.75 | 2.77 | 2.81 | 2.79 | 2.79 | 2.79 | ||

| 60 | 624 | 621 | 625 | 628 | 627 | 633 | 633 | 60 | 2.76 | 2.76 | 2.77 | 2.78 | 2.78 | 2.75 | 2.76 | ||

| EB flute cardboard | |||||||||||||||||

| grammage | thickness (mm) | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 579 | 577 | 582 | 583 | 588 | 602 | 635 | 10 | 4.15 | 4.17 | 4.19 | 4.19 | 4.22 | 4.25 | 4.20 | ||

| 20 | 570 | 572 | 579 | 580 | 586 | 594 | 619 | 20 | 4.19 | 4.22 | 4.21 | 4.21 | 4.21 | 4.23 | 4.21 | ||

| 30 | 564 | 572 | 573 | 578 | 580 | 586 | 593 | 30 | 4.18 | 4.19 | 4.17 | 4.22 | 4.20 | 4.22 | 4.19 | ||

| 40 | 562 | 566 | 570 | 573 | 575 | 578 | 580 | 40 | 4.20 | 4.17 | 4.21 | 4.20 | 4.20 | 4.21 | 4.17 | ||

| 50 | 556 | 561 | 558 | 561 | 565 | 569 | 567 | 50 | 4.16 | 4.13 | 4.16 | 4.19 | 4.21 | 4.21 | 4.20 | ||

| 60 | 553 | 552 | 558 | 560 | 559 | 562 | 563 | 60 | 4.14 | 4.17 | 4.14 | 4.17 | 4.21 | 4.18 | 4.17 | ||

| BC flute cardboard | |||||||||||||||||

| grammage | thickness (mm) | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 801 | 797 | 809 | 809 | 815 | 833 | 861 | 10 | 6.74 | 6.72 | 6.75 | 6.74 | 6.74 | 6.74 | 6.74 | ||

| 20 | 789 | 794 | 800 | 806 | 811 | 823 | 852 | 20 | 6.73 | 6.70 | 6.73 | 6.73 | 6.74 | 6.71 | 6.74 | ||

| 30 | 787 | 788 | 795 | 799 | 806 | 811 | 817 | 30 | 6.71 | 6.71 | 6.68 | 6.77 | 6.76 | 6.77 | 6.76 | ||

| 40 | 780 | 786 | 789 | 792 | 795 | 798 | 807 | 40 | 6.71 | 6.67 | 6.69 | 6.72 | 6.68 | 6.74 | 6.71 | ||

| 50 | 773 | 774 | 777 | 781 | 784 | 787 | 787 | 50 | 6.63 | 6.66 | 6.71 | 6.71 | 6.70 | 6.69 | 6.68 | ||

| 60 | 769 | 768 | 774 | 776 | 774 | 779 | 778 | 60 | 6.70 | 6.68 | 6.67 | 6.67 | 6.69 | 6.71 | 6.72 | ||

References

- Mordor Intelligence. Global Paper And Paperboard Packaging Market Size & Share Analysis—Growth Trends & Forecasts (2024–2029). Available online: https://www.mordorintelligence.com/industry-reports/global-paper-and-paperboard-packaging-market (accessed on 19 October 2024).

- Nienke, T.; Kwade, A.; Eggerath, D. Influence of moisture, temperature and bleaching on the mechanical properties of coated fiber-based substrates. Coatings 2022, 12, 1287–1299. [Google Scholar] [CrossRef]

- Wang, D. Elastic Modulus Prediction of Corrugating Medium under Different Temperature and Relative Humidity. IOP Conf. Ser. Mater. Sci. Eng. 2018, 439, 042043. [Google Scholar] [CrossRef]

- Fadiji, T.; Berry, T.M.; Coetzee, C.J.; Opara, U.L. Mechanical design and performance testing of corrugated paperboard packaging for the postharvest handling of horticultural produce. Biosyst. Eng. 2018, 171, 220–244. [Google Scholar] [CrossRef]

- Berry, T.M.; Ambaw, A.; Defraeye, T.; Coetzee, C.; Opara, U.L. Moisture adsorption in palletised corrugated fibreboard cartons under shipping conditions: A CFD modelling approach. Food Bioprod. Process. 2019, 114, 43–59. [Google Scholar] [CrossRef]

- Niini, A.; Tanninen, P.; Laukala, T.; Varis, J.; Leminen, V. A folding method to increase the rigidity of paperboard tray packages. BioResources 2022, 17, 1427–1441. [Google Scholar] [CrossRef]

- Kaeppeler, U.; Hünniger, J.; Hofmann, A.; Berlich, A.; Engisch, L. Thermal influence on the mechanical properties of cardboard during an ultrasonic-assisted embossing process. BioResources 2020, 15, 5110–5121. [Google Scholar] [CrossRef]

- Cornaggia, A.; Gajewski, T.; Knitter-Piątkowska, A.; Garbowski, T. Influence of Humidity and Temperature on Mechanical Properties of Corrugated Board—Numerical Investigation. BioResources 2023, 18, 7490–7509. [Google Scholar] [CrossRef]

- Su, H.; Huang, C.; Li, C.; Zhao, Y.; Zheng, D.; Duan, Q. Failure mechanism of the corrugated medium under simulated cold chain logistics. ACS Omega 2023, 8, 23673–23682. [Google Scholar] [CrossRef]

- Niini, A.; Tanninen, P.; Varis, J.; Leminen, V. Effects of press-forming parameters on the dimensional stability of paperboard trays. BioResources 2021, 16, 4876–4890. [Google Scholar] [CrossRef]

- Cataldi, P.; Profaizer, M.; Bayer, I.S. Preventing water-induced mechanical deterioration of cardboard by a sequential polymer treatment. Ind. Eng. Chem. Res. 2019, 58, 6456–6465. [Google Scholar] [CrossRef]

- Marinelli, A.; Diamanti, M.V.; Lucotti, A.; Pedeferri, M.P.; Del Curto, B. Evaluation of coatings to improve the durability and water-barrier properties of corrugated cardboard. Coatings 2022, 12, 10–24. [Google Scholar] [CrossRef]

- Beck, M.; Fischerauer, G. Modeling Warp in Corrugated Cardboard Based on Homogenization Techniques for In-Process Measurement Applications. Appl. Sci. 2022, 12, 1684. [Google Scholar] [CrossRef]

- Nordstrand, T.M. Parametric study of the post-buckling strength of structural core sandwich panels. Compos. Struct. 1995, 30, 441–451. [Google Scholar] [CrossRef]

- Nordstrand, T. Analysis and testing of corrugated board panels into the post-buckling regime. Compos. Struct. 2004, 63, 189–199. [Google Scholar] [CrossRef]

- Mrówczyński, D.; Knitter-Piątkowska, A.; Garbowski, T. Numerical Homogenization of Single-Walled Corrugated Board with Imperfections. Appl. Sci. 2022, 12, 9632. [Google Scholar] [CrossRef]

- Mrówczyński, D.; Garbowski, T. Influence of Imperfections on the Effective Stiffness of Multilayer Corrugated Board. Materials 2023, 16, 1295. [Google Scholar] [CrossRef]

- Cillie, J.; Coetzee, C. Experimental and Numerical Investigation of the In-Plane Compression of Corrugated Paperboard Panels. Math. Comput. Appl. 2022, 27, 108. [Google Scholar] [CrossRef]

- Archaviboonyobul, T.; Chaveesuk, R.; Singh, J.; Jinkarn, T. An analysis of the influence of hand hole and ventilation hole design on compressive strength of corrugated fiberboard boxes by an artificial neural network model. Packag. Technol. Sci. 2020, 33, 171–181. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.J.; Opara, U.L. Compression strength of ventilated corrugated paperboard packages: Numerical modelling, experimental validation and effects of vent geometric design. Biosyst. Eng. 2016, 151, 231–247. [Google Scholar] [CrossRef]

- Giampieri, A.; Perego, U.; Borsari, R. A constitutive model for the mechanical response of the folding of creased paperboard. Int. J. Solids Struct. 2011, 48, 2275–2287. [Google Scholar] [CrossRef]

- Beex, L.A.A.; Peerlings, R.H.J. An experimental and computational study of laminated paperboard creasing and folding. Int. J. Solids Struct. 2009, 46, 4192–4207. [Google Scholar] [CrossRef]

- Garbowski, T.; Knitter-Piątkowska, A.; Mrówczyński, D. Numerical Homogenization of Multi-Layered Corrugated Cardboard with Creasing or Perforation. Materials 2021, 14, 3786. [Google Scholar] [CrossRef] [PubMed]

- Gallo, J.; Cortés, F.; Alberdi, E.; Goti, A. Mechanical behavior modeling of containers and octabins made of corrugated cardboard subjected to vertical stacking loads. Materials 2021, 14, 2392. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.-L.; Chen, J.; Wu, Y.; Sun, J. Analysis of hazard factors of the use of corrugated carton in packaging low-temperature yogurt during logistics. Procedia Environ. Sci. 2011, 10, 968–973. [Google Scholar] [CrossRef]

- Kim, S.; Horvath, L.; Molina, E.; Frank, B.; Johnson, S.; Johnson, A. Predicting the effect of pallet overhang on the box compression strength. Packag. Technol. Sci. 2023, 36, 927–939. [Google Scholar] [CrossRef]

- Garbowski, T.; Gajewski, T.; Mrówczyński, D.; Jędrzejczak, R. Crushing of Single-Walled Corrugated Board during Converting: Experimental and Numerical Study. Energies 2021, 14, 3203. [Google Scholar] [CrossRef]

- Yoshihara, H.; Yoshinobu, M.; Maruta, M. Bending stiffness and moment capacity of cardboard obtained from three-point and elastica bending tests. Nord. Pulp Pap. Res. J. 2022, 38, 73–85. [Google Scholar] [CrossRef]

- Buannic, N.; Cartraud, P.; Quesnel, T. Homogenization of corrugated core sandwich panels. Compos. Struct. 2003, 59, 299–312. [Google Scholar] [CrossRef]

- Garbowski, T.; Gajewski, T. Determination of transverse shear stiffness of sandwich panels with a corrugated core by numerical homogenization. Materials 2021, 14, 1976. [Google Scholar] [CrossRef]

- Nordstrand, T. On buckling loads for edge-loaded orthotropic plates including transverse shear. Compos. Struct. 2004, 65, 1–6. [Google Scholar] [CrossRef]

- Popil, R.E. Overview of recent studies at IPST on corrugated board edge compression strength: Testing methods and effects of interflute buckling. BioResources 2012, 7, 2553–2581. [Google Scholar] [CrossRef][Green Version]

- Åslund, P.E.; Hägglund, R.; Carlsson, L.A.; Isaksson, P. Modeling of global and local buckling of corrugated board panels loaded in edge-to-edge compression. J. Sandw. Struct. Mater. 2014, 16, 272–292. [Google Scholar] [CrossRef]

- Mrówczyński, D.; Pozorska, J.; Garbowski, T.; Pozorski, Z. Bending stiffness of unsymmetrical multilayered corrugated board: Influence of boundary conditions. BioResources 2023, 18, 7611–7628. [Google Scholar] [CrossRef]

- Błaszczuk, J.; Pozorski, Z. The analysis of the influence of core compression effect on the determination of the shear modulus of sandwich panel core. Sci. Res. Inst. Math. Comput. 2012, 11, 5–13. [Google Scholar] [CrossRef]

- Pozorska, J.; Pozorski, Z. The comparison of numerical models of a sandwich panel in the context of the core deformations at the supports. AIP Conf. Proc. 2018, 1922, 050007. [Google Scholar]

- ISO 187:2022; Paper, Board And Pulps—Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples. International Standard; ISO: Geneva, Switzerland, 2022.

- TAPPI T402 sp-21; Standard Conditioning and Testing Atmospheres for Paper, Board, Pulp Handsheets, and Related Products, Test Method TAPPI/ANSI T 402 sp-21. TAPPI: Atlanta, GA, USA, 2021.

- FEMat Systems: BSE System. Available online: http://fematsystems.pl/bse-system_en/ (accessed on 19 October 2024).

- ISO 5628:2019; Paper and Board—Determination of Bending Stiffness—General Principles for Two-Point, Three-Point and Four-Point Methods. International Standard. ISO: Geneva, Switzerland, 2019.

- TAPPI T836 om-20; Bending Stiffness, Four Point Method, Test Method TAPPI/ANSI T 836 om-20. TAPPI: Atlanta, GA, USA, 2020.

- ISO 3037:2022; Corrugated Fibreboard—Determination of Edgewise Crush Resistance (Non-Waxed Edge Method). International Standard. ISO: Geneva, Switzerland, 2022.

- ISO 13821:2020; Corrugated Fibreboard—Determination of Edgewise Crush Resistance—Waxed Edge Method. ISO: Geneva, Switzerland, 2020.

- FEFCO Testing Method No. 8, Edgewise Crush Resistance of Corrugated Fiberboard; European Federation of Corrugated Board Manufacturers: Brussels, Belgium, 1997.

- TAPPI T839 om-24; Edgewise Compressive Strength of Corrugated Fiberboard Using the Clamp Method (Short Column Test), Test Method TAPPI T 839 om-24. TAPPI: Atlanta, GA, USA, 2024.

| Cardboard | Grammage | Grammage of Papers (g/m2) | Thickness |

|---|---|---|---|

| (g/m2) | (mm) | ||

| E flute | 508 | 170–135–170 | 1.73 |

| B flute | 415 | 125–120–125 | 2.97 |

| C flute | 456 | 125–130–130 | 4.02 |

| EE flute | 653 | 125–120–80–120–125 | 2.77 |

| EB flute | 578 | 125–90–80–90–125 | 4.19 |

| BC flute | 803 | 170–135–80–135–170 | 6.72 |

| ECT (%) [* 6.36 kN/m] | SST (%) [* 0.92 Nm] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 115% | 109% | 93% | 81% | 77% | 58% | 34% | 10 | 111% | 112% | 100% | 90% | 75% | 51% | 28% | ||

| 20 | 118% | 106% | 98% | 99% | 85% | 64% | 36% | 20 | 112% | 112% | 101% | 103% | 85% | 60% | 28% | ||

| 30 | 123% | 111% | 108% | 98% | 92% | 77% | 49% | 30 | 115% | 110% | 109% | 105% | 89% | 73% | 46% | ||

| 40 | 125% | 123% | 109% | 109% | 103% | 92% | 78% | 40 | 117% | 112% | 112% | 103% | 99% | 84% | 71% | ||

| 50 | 131% | 134% | 131% | 125% | 110% | 96% | 82% | 50 | 127% | 108% | 114% | 112% | 104% | 90% | 74% | ||

| 60 | 137% | 140% | 131% | 129% | 119% | 108% | 85% | 60 | 125% | 114% | 113% | 112% | 108% | 103% | 84% | ||

| (%) [* 0.38 Nm] | (%) [* 0.38 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 105% | 103% | 95% | 97% | 89% | 71% | 47% | 10 | 105% | 105% | 103% | 97% | 92% | 74% | 53% | ||

| 20 | 105% | 105% | 97% | 100% | 92% | 74% | 45% | 20 | 113% | 105% | 105% | 103% | 95% | 74% | 47% | ||

| 30 | 111% | 108% | 103% | 100% | 87% | 76% | 50% | 30 | 111% | 108% | 105% | 100% | 89% | 79% | 53% | ||

| 40 | 108% | 103% | 103% | 95% | 89% | 79% | 70% | 40 | 111% | 105% | 105% | 100% | 95% | 84% | 71% | ||

| 50 | 103% | 103% | 103% | 97% | 92% | 84% | 70% | 50 | 111% | 108% | 105% | 100% | 97% | 87% | 79% | ||

| 60 | 108% | 103% | 103% | 100% | 95% | 87% | 79% | 60 | 108% | 105% | 105% | 103% | 100% | 92% | 79% | ||

| (%) [* 0.60 Nm] | (%) [* 1.87 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 95% | 107% | 92% | 90% | 78% | 62% | 33% | 10 | 103% | 102% | 101% | 93% | 88% | 74% | 49% | ||

| 20 | 102% | 100% | 103% | 97% | 85% | 68% | 32% | 20 | 106% | 103% | 103% | 101% | 93% | 78% | 50% | ||

| 30 | 110% | 105% | 98% | 97% | 83% | 67% | 42% | 30 | 114% | 109% | 105% | 102% | 91% | 80% | 56% | ||

| 40 | 105% | 100% | 107% | 90% | 85% | 78% | 65% | 40 | 109% | 108% | 102% | 98% | 91% | 89% | 76% | ||

| 50 | 108% | 103% | 103% | 95% | 83% | 82% | 72% | 50 | 114% | 111% | 106% | 104% | 98% | 93% | 81% | ||

| 60 | 105% | 103% | 103% | 97% | 90% | 87% | 73% | 60 | 113% | 109% | 107% | 107% | 100% | 93% | 82% | ||

| ECT (%) [* 4.51 kN/m] | SST (%) [* 1.06 Nm] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 108% | 111% | 97% | 90% | 80% | 63% | 41% | 10 | 105% | 106% | 97% | 97% | 84% | 69% | 43% | ||

| 20 | 119% | 107% | 95% | 103% | 93% | 76% | 45% | 20 | 109% | 106% | 102% | 99% | 92% | 75% | 43% | ||

| 30 | 124% | 118% | 114% | 104% | 95% | 88% | 73% | 30 | 108% | 107% | 104% | 96% | 92% | 83% | 72% | ||

| 40 | 118% | 123% | 111% | 106% | 113% | 106% | 97% | 40 | 112% | 105% | 103% | 102% | 99% | 95% | 77% | ||

| 50 | 137% | 134% | 125% | 118% | 112% | 120% | 108% | 50 | 113% | 110% | 113% | 106% | 107% | 103% | 100% | ||

| 60 | 137% | 119% | 133% | 124% | 120% | 123% | 113% | 60 | 114% | 109% | 111% | 109% | 108% | 107% | 101% | ||

| (%) [* 0.75 Nm] | (%) [* 0.65 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 101% | 111% | 92% | 93% | 87% | 69% | 47% | 10 | 103% | 108% | 102% | 95% | 92% | 77% | 58% | ||

| 20 | 108% | 111% | 108% | 96% | 96% | 77% | 56% | 20 | 112% | 106% | 103% | 100% | 95% | 82% | 58% | ||

| 30 | 115% | 103% | 97% | 103% | 93% | 87% | 73% | 30 | 112% | 102% | 100% | 103% | 94% | 85% | 77% | ||

| 40 | 112% | 103% | 99% | 101% | 96% | 92% | 87% | 40 | 111% | 109% | 105% | 100% | 103% | 97% | 94% | ||

| 50 | 104% | 111% | 99% | 105% | 97% | 101% | 93% | 50 | 106% | 102% | 100% | 103% | 100% | 98% | 98% | ||

| 60 | 105% | 111% | 107% | 101% | 100% | 96% | 97% | 60 | 108% | 105% | 102% | 102% | 100% | 100% | 88% | ||

| (%) [* 1.54 Nm] | (%) [* 3.39 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 106% | 105% | 98% | 98% | 88% | 75% | 54% | 10 | 101% | 109% | 94% | 97% | 93% | 84% | 63% | ||

| 20 | 113% | 110% | 108% | 105% | 95% | 78% | 55% | 20 | 108% | 103% | 102% | 105% | 95% | 84% | 67% | ||

| 30 | 115% | 106% | 102% | 100% | 94% | 81% | 65% | 30 | 105% | 104% | 101% | 101% | 96% | 89% | 77% | ||

| 40 | 113% | 105% | 105% | 99% | 102% | 93% | 81% | 40 | 109% | 104% | 103% | 101% | 104% | 97% | 89% | ||

| 50 | 114% | 110% | 108% | 108% | 106% | 102% | 92% | 50 | 103% | 113% | 104% | 105% | 107% | 99% | 88% | ||

| 60 | 114% | 110% | 110% | 110% | 105% | 101% | 90% | 60 | 104% | 109% | 104% | 101% | 99% | 101% | 83% | ||

| ECT (%) [* 5.75 kN/m] | SST (%) [* 1.78 Nm] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 100% | 98% | 81% | 78% | 67% | 48% | 23% | 10 | 99% | 104% | 93% | 92% | 76% | 60% | 28% | ||

| 20 | 112% | 105% | 94% | 91% | 79% | 60% | 34% | 20 | 104% | 104% | 102% | 99% | 87% | 70% | 40% | ||

| 30 | 118% | 110% | 105% | 97% | 91% | 78% | 75% | 30 | 110% | 107% | 102% | 97% | 88% | 77% | 70% | ||

| 40 | 122% | 113% | 111% | 103% | 107% | 100% | 91% | 40 | 113% | 103% | 104% | 101% | 100% | 97% | 92% | ||

| 50 | 130% | 129% | 126% | 123% | 116% | 111% | 113% | 50 | 112% | 112% | 111% | 106% | 103% | 103% | 102% | ||

| 60 | 135% | 131% | 128% | 125% | 120% | 119% | 113% | 60 | 112% | 111% | 107% | 108% | 107% | 99% | 99% | ||

| (%) [* 1.37 Nm] | (%) [* 0.80 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 92% | 99% | 85% | 82% | 65% | 62% | 33% | 10 | 90% | 99% | 91% | 89% | 80% | 69% | 48% | ||

| 20 | 104% | 97% | 95% | 92% | 82% | 63% | 34% | 20 | 108% | 103% | 98% | 96% | 88% | 78% | 55% | ||

| 30 | 105% | 101% | 92% | 87% | 89% | 71% | 66% | 30 | 104% | 103% | 98% | 93% | 86% | 83% | 75% | ||

| 40 | 103% | 102% | 94% | 93% | 92% | 85% | 87% | 40 | 103% | 100% | 100% | 98% | 94% | 85% | 85% | ||

| 50 | 109% | 98% | 100% | 95% | 91% | 92% | 95% | 50 | 101% | 98% | 95% | 95% | 94% | 91% | 94% | ||

| 60 | 101% | 104% | 103% | 94% | 96% | 92% | 94% | 60 | 101% | 94% | 95% | 93% | 91% | 90% | 90% | ||

| (%) [* 3.43 Nm] | (%) [* 4.65 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 99% | 104% | 91% | 88% | 80% | 63% | 30% | 10 | 110% | 104% | 104% | 102% | 89% | 84% | 48% | ||

| 20 | 108% | 107% | 105% | 98% | 86% | 69% | 37% | 20 | 112% | 101% | 117% | 109% | 98% | 89% | 58% | ||

| 30 | 114% | 106% | 102% | 99% | 88% | 76% | 67% | 30 | 112% | 107% | 106% | 107% | 98% | 96% | 85% | ||

| 40 | 113% | 108% | 103% | 97% | 101% | 92% | 86% | 40 | 105% | 107% | 99% | 104% | 110% | 105% | 98% | ||

| 50 | 114% | 115% | 114% | 108% | 106% | 103% | 99% | 50 | 98% | 112% | 105% | 106% | 110% | 106% | 93% | ||

| 60 | 116% | 112% | 112% | 110% | 109% | 107% | 99% | 60 | 105% | 104% | 106% | 107% | 107% | 100% | 97% | ||

| ECT (%) [* 8.68 kN/m] | SST (%) [* 1.24 Nm] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 101% | 98% | 83% | 82% | 72% | 57% | 34% | 10 | 98% | 102% | 94% | 94% | 85% | 75% | 49% | ||

| 20 | 107% | 105% | 93% | 93% | 85% | 72% | 47% | 20 | 104% | 107% | 103% | 101% | 93% | 81% | 55% | ||

| 30 | 116% | 111% | 104% | 98% | 91% | 86% | 86% | 30 | 109% | 103% | 98% | 99% | 91% | 85% | 81% | ||

| 40 | 119% | 109% | 109% | 109% | 109% | 104% | 81% | 40 | 108% | 109% | 100% | 97% | 98% | 95% | 84% | ||

| 50 | 133% | 128% | 134% | 129% | 121% | 122% | 116% | 50 | 115% | 113% | 114% | 110% | 107% | 102% | 99% | ||

| 60 | 134% | 142% | 136% | 129% | 123% | 121% | 110% | 60 | 116% | 114% | 109% | 106% | 107% | 104% | 102% | ||

| (%) [* 0.90 Nm] | (%) [* 0.81 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 98% | 102% | 94% | 93% | 90% | 80% | 54% | 10 | 91% | 101% | 99% | 101% | 95% | 86% | 59% | ||

| 20 | 99% | 106% | 97% | 98% | 90% | 82% | 56% | 20 | 104% | 105% | 104% | 102% | 98% | 88% | 63% | ||

| 30 | 100% | 99% | 94% | 98% | 91% | 84% | 78% | 30 | 106% | 104% | 101% | 101% | 94% | 89% | 81% | ||

| 40 | 100% | 96% | 98% | 92% | 93% | 90% | 78% | 40 | 106% | 101% | 99% | 96% | 96% | 95% | 81% | ||

| 50 | 101% | 97% | 102% | 101% | 94% | 91% | 90% | 50 | 109% | 107% | 106% | 102% | 99% | 96% | 100% | ||

| 60 | 102% | 108% | 97% | 92% | 96% | 93% | 91% | 60 | 109% | 109% | 107% | 106% | 101% | 99% | 101% | ||

| (%) [* 1.55 Nm] | (%) [* 3.34 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 99% | 105% | 95% | 99% | 92% | 83% | 58% | 10 | 96% | 99% | 97% | 98% | 91% | 84% | 63% | ||

| 20 | 108% | 106% | 106% | 102% | 97% | 86% | 60% | 20 | 103% | 104% | 102% | 101% | 93% | 87% | 64% | ||

| 30 | 103% | 106% | 100% | 99% | 93% | 86% | 76% | 30 | 107% | 101% | 99% | 97% | 91% | 88% | 78% | ||

| 40 | 106% | 103% | 98% | 98% | 97% | 94% | 79% | 40 | 107% | 103% | 97% | 97% | 94% | 91% | 80% | ||

| 50 | 110% | 109% | 111% | 106% | 105% | 99% | 97% | 50 | 111% | 108% | 110% | 106% | 105% | 98% | 97% | ||

| 60 | 111% | 108% | 101% | 105% | 102% | 101% | 93% | 60 | 111% | 112% | 103% | 104% | 105% | 102% | 98% | ||

| ECT (%) [* 7.52 kN/m] | SST (%) [* 2.17 Nm] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 101% | 97% | 86% | 85% | 67% | 48% | 22% | 10 | 100% | 100% | 89% | 95% | 82% | 64% | 27% | ||

| 20 | 115% | 107% | 99% | 90% | 81% | 63% | 35% | 20 | 109% | 104% | 101% | 99% | 92% | 76% | 45% | ||

| 30 | 116% | 111% | 110% | 101% | 93% | 86% | 77% | 30 | 111% | 106% | 102% | 99% | 96% | 87% | 77% | ||

| 40 | 123% | 118% | 113% | 108% | 104% | 98% | 93% | 40 | 111% | 107% | 101% | 100% | 99% | 94% | 90% | ||

| 50 | 128% | 129% | 129% | 126% | 117% | 111% | 113% | 50 | 117% | 112% | 113% | 111% | 108% | 102% | 103% | ||

| 60 | 130% | 131% | 130% | 125% | 121% | 118% | 117% | 60 | 116% | 114% | 108% | 112% | 111% | 107% | 103% | ||

| (%) [* 1.49 Nm] | (%) [* 1.02 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 90% | 95% | 82% | 86% | 79% | 64% | 34% | 10 | 98% | 100% | 92% | 100% | 83% | 73% | 42% | ||

| 20 | 108% | 108% | 98% | 93% | 86% | 74% | 42% | 20 | 119% | 105% | 96% | 93% | 88% | 76% | 56% | ||

| 30 | 108% | 109% | 106% | 97% | 88% | 75% | 69% | 30 | 115% | 105% | 108% | 102% | 98% | 86% | 76% | ||

| 40 | 107% | 107% | 103% | 93% | 87% | 89% | 82% | 40 | 120% | 103% | 107% | 100% | 98% | 93% | 92% | ||

| 50 | 113% | 107% | 108% | 109% | 97% | 93% | 101% | 50 | 111% | 110% | 110% | 110% | 106% | 101% | 111% | ||

| 60 | 109% | 109% | 107% | 105% | 105% | 103% | 96% | 60 | 125% | 120% | 103% | 104% | 110% | 104% | 109% | ||

| (%) [* 3.53 Nm] | (%) [* 6.57 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 98% | 101% | 90% | 91% | 81% | 65% | 29% | 10 | 102% | 102% | 96% | 97% | 86% | 76% | 41% | ||

| 20 | 108% | 107% | 105% | 98% | 88% | 73% | 43% | 20 | 102% | 104% | 102% | 101% | 94% | 80% | 58% | ||

| 30 | 109% | 104% | 103% | 101% | 90% | 78% | 74% | 30 | 104% | 97% | 97% | 97% | 97% | 89% | 77% | ||

| 40 | 110% | 106% | 100% | 96% | 97% | 90% | 83% | 40 | 103% | 98% | 98% | 96% | 95% | 91% | 83% | ||

| 50 | 114% | 110% | 112% | 108% | 105% | 98% | 97% | 50 | 99% | 95% | 96% | 98% | 99% | 94% | 91% | ||

| 60 | 116% | 112% | 109% | 107% | 108% | 101% | 98% | 60 | 100% | 95% | 93% | 91% | 87% | 94% | 85% | ||

| ECT (%) [* 9.58 kN/m] | SST (%) [* 4.70 Nm] | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 106% | 99% | 88% | 89% | 71% | 60% | 34% | 10 | 103% | 100% | 92% | 89% | 81% | 65% | 41% | ||

| 20 | 116% | 103% | 98% | 99% | 92% | 73% | 46% | 20 | 102% | 105% | 103% | 95% | 92% | 77% | 59% | ||

| 30 | 109% | 107% | 106% | 99% | 94% | 86% | 81% | 30 | 113% | 104% | 105% | 98% | 96% | 88% | 84% | ||

| 40 | 115% | 114% | 108% | 105% | 109% | 102% | 98% | 40 | 113% | 108% | 109% | 105% | 97% | 95% | 96% | ||

| 50 | 124% | 122% | 125% | 122% | 116% | 112% | 117% | 50 | 113% | 111% | 116% | 111% | 107% | 108% | 105% | ||

| 60 | 125% | 127% | 126% | 118% | 115% | 117% | 118% | 60 | 114% | 113% | 115% | 112% | 115% | 116% | 108% | ||

| (%) [* 3.57 Nm] | (%) [* 1.87 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 97% | 103% | 93% | 96% | 82% | 69% | 44% | 10 | 94% | 103% | 100% | 101% | 93% | 82% | 53% | ||

| 20 | 111% | 108% | 103% | 97% | 92% | 76% | 57% | 20 | 111% | 108% | 104% | 107% | 100% | 85% | 63% | ||

| 30 | 112% | 112% | 106% | 98% | 94% | 86% | 78% | 30 | 104% | 105% | 101% | 101% | 98% | 93% | 84% | ||

| 40 | 111% | 111% | 110% | 104% | 91% | 90% | 84% | 40 | 111% | 108% | 107% | 105% | 99% | 103% | 93% | ||

| 50 | 107% | 108% | 107% | 104% | 98% | 95% | 88% | 50 | 113% | 109% | 106% | 98% | 101% | 98% | 102% | ||

| 60 | 108% | 101% | 106% | 99% | 106% | 95% | 94% | 60 | 107% | 100% | 106% | 107% | 104% | 106% | 99% | ||

| (%) [* 13.43 Nm] | (%) [* 17.78 Nm] | ||||||||||||||||

| RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | RH (%) | 30 | 40 | 50 | 60 | 70 | 80 | 90 | ||

| T (°C) | T (°C) | ||||||||||||||||

| 10 | 104% | 105% | 93% | 99% | 89% | 77% | 53% | 10 | 109% | 108% | 92% | 94% | 86% | 82% | 63% | ||

| 20 | 105% | 106% | 106% | 101% | 98% | 83% | 60% | 20 | 103% | 104% | 97% | 96% | 95% | 89% | 65% | ||

| 30 | 108% | 105% | 101% | 100% | 96% | 85% | 79% | 30 | 103% | 104% | 86% | 92% | 100% | 97% | 92% | ||

| 40 | 105% | 103% | 101% | 96% | 95% | 92% | 85% | 40 | 99% | 102% | 99% | 99% | 101% | 104% | 90% | ||

| 50 | 105% | 105% | 105% | 101% | 101% | 97% | 98% | 50 | 101% | 98% | 99% | 100% | 96% | 103% | 100% | ||

| 60 | 107% | 106% | 106% | 105% | 103% | 98% | 94% | 60 | 106% | 100% | 108% | 99% | 99% | 97% | 96% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mrówczyński, D.; Gajewski, T.; Cornaggia, A.; Garbowski, T. Impact of Temperature and Humidity on Key Mechanical Properties of Corrugated Board. Appl. Sci. 2024, 14, 12012. https://doi.org/10.3390/app142412012

Mrówczyński D, Gajewski T, Cornaggia A, Garbowski T. Impact of Temperature and Humidity on Key Mechanical Properties of Corrugated Board. Applied Sciences. 2024; 14(24):12012. https://doi.org/10.3390/app142412012

Chicago/Turabian StyleMrówczyński, Damian, Tomasz Gajewski, Aram Cornaggia, and Tomasz Garbowski. 2024. "Impact of Temperature and Humidity on Key Mechanical Properties of Corrugated Board" Applied Sciences 14, no. 24: 12012. https://doi.org/10.3390/app142412012

APA StyleMrówczyński, D., Gajewski, T., Cornaggia, A., & Garbowski, T. (2024). Impact of Temperature and Humidity on Key Mechanical Properties of Corrugated Board. Applied Sciences, 14(24), 12012. https://doi.org/10.3390/app142412012