Abstract

Stabilising the natural colour of wood species exposed to light in indoor conditions is a challenge that could be better addressed based on a deeper understanding of the occurring phenomena and influencing factors. This paper investigates comparatively the light-induced colour changes for three hardwood species, namely, European maple (Acer pseudoplatanus L.), European ash (Fraxinus excelsior L.) and European walnut (Juglans regia L.), as well as the influence of finishing with three types of clear, colourless waterborne lacquers: acrylic-polyurethane (F1), acrylic (F2) and polyurethane (F3) on their colour stability. Colour measurements in the CIELab system in conjunction with an artificial accelerated ageing test under the action of UV-VIS radiation, simulating natural light passing through window glass, and two types of test samples were employed to highlight the influence and contributions of the wood substrate and of the coating films to the global colour modifications. Coating films applied on 1 mm clear glass slides were employed as a sort of “detachable” finish for this purpose. Direct exposure to UV-VIS light caused visible colour changes for both uncoated and coated wood surfaces, the values of the calculated colour differences (ΔE) after a 72 h exposure being dependant on both the wood species and the coating material. Excepting two situations for walnut, statistically significantly higher colour differences were obtained for the uncoated samples: maple (9.36 units), ash (8.39 units), walnut (6.20 units), compared to the coated ones: maple (4.92–5.71 units), ash (2.25–3.94 units), walnut (4.74–7.70 units). The wood substrates underlying the coating films were found to bring the maximum contribution to the overall colour changes in the clear coated surfaces, while the coating films employed in this research demonstrated a fairly good colour stability to UV-VIS light exposure, with maximum colour changes (∆E) up to only 1.30 units. Overall, the wood species and the type of coating were found as influencing factors in interaction with the light-induced colour changes in wood surfaces in indoor conditions.

1. Introduction

Colour, alongside texture and grain, represent particular and valuable aesthetic features of the various wood species [1]. The coating of wood surfaces with transparent, colourless finishing materials is the usual treatment applied to highlight and preserve their beauty and natural aspect over time in various practical applications. Nevertheless, colour changes in both uncoated and coated wood surfaces occur over time when exposed to light/UV radiation, both indoors and outdoors. This practical issue has been only partly solved by the outcomes of extensive research worldwide, remaining an actual research topic [2,3,4,5,6,7].

Colour changes in wood surfaces exposed to light are primarily the result of a complex and dynamic photo-degradation process of the wood surface, having as main actors the UV radiation from the light source and the lignin in wood. The absorption of UV radiation by lignin results in chemical bond cleavage and the formation of reactive free radicals (e.g., phenoxyl), which are then transformed into carbonyl- and carboxyl-containing chromophores and quinoid structures, responsible for colour changes, especially yellowing of the exposed wood surfaces [8,9,10,11,12,13]. Not only UV light but also visible violet light and blue light up to 515 nm may cause surface and subsurface colour changes without affecting lignin [14,15]. Furthermore, a possible contribution of wavelengths in the visible-near infrared region was highlighted by hyperspectral imaging [16].

In addition to lignin, certain classes of wood extractives may play an important role in determining the natural colour of wood species and their behaviour when exposed to light. Poly-phenolic extractives, such as tannins, can absorb UV light, scavenge free radicals and undergo photo-oxidation, retarding the photo-degradation of lignin and wood [17,18,19,20]. On the other hand, extractives from dark coloured wood species are responsible for their sensitivity to visible light, resulting in a bleaching effect after longer exposure times [21].

The result is, therefore, that the light-induced colour changes in wood surfaces are significantly influenced by the wood species due to the differences in their chemical composition, as proven by comparative research on more than two different species [1,22,23,24]. Colour changes also depend on the type of light (natural/artificial), spectral range (wavelengths), type of light source, exposure conditions and duration [25,26,27]. Accordingly, data from different research publications are often difficult to compare.

The coating of wood can impart some protective effect against light-induced colour changes by reducing the amount of light/UV radiation reaching the underlying wood substrate [28], depending on the chemical structure of the film-forming resin and the specific additives in a certain formulation. The coating materials can also undergo photo-degradation processes (photolysis, photo-oxidation) under the action of UV light, resulting in property changes, including glass transition temperature, UV light transmittance, colour and their protective behaviour [29,30]. Different types of film-forming materials, such as: acrylic-polyurethanes [31], acrylics [28,29,32,33,34] and polyurethanes [35], as well as natural products [36], have been studied in terms of behaviour and protective effect against light/UV-induced colour changes in wood surfaces.

Due to their transparency for both visible and UV light, clear finishes offer generally less protection against the action of light/UV radiation, resulting in more pronounced colour changes [28,29,31,33,35], compared to semi-transparent and opaque finishes that contain colouring pigments with a UV protective effect.

The interaction of UV light with the underlying wood at the interface wood/coating material results in the photo-oxidation of lignin and associated colour changes, representing an important contribution to the overall colour changes in clear-coated wood surfaces [10,28,35]. Different principles for stabilising the colour of clear-coated wood have been in research focus: (i) pre-treatments of the wood substrate for an improved UV resistance, (ii) modification of the coating materials with additives for improved UV resistance and (iii) combined methods. Nanoparticles of TiO2 [5], ZnO [37], CeO2 [3], CH2O [38] or α/γ Fe2O3 [6], UV absorbers (benzotriazole, [39], benzophenone [40]), HALS (hindered amine light stabiliser), (Tinuvin 292, Tinuvin 293 [41], Tinuvin 5151 [39]), or chemical modification treatments with succinic anhydride [42], maleic anhydride [43] or soybean oil modified epoxy resins [40] were employed as pre-treatments. Organic UV absorbers and HALS stabilisers [34,36] and inorganic UV absorbers and nanoparticles [6,44] were employed as additives for clear coatings. Approaches combining the two principles were also tested [4,13,33,39,41].

Most of the studied references reporting light-induced colour changes in the coated wood surfaces refer strictly to the changes observed and measured on the directly exposed coated wood surface [1,5,17,22,45], without any information on the possible photo-degradation of the wood substrate under the coating film. However, colour changes in clear-coated wood may be caused by colour changes in both the clear-coating film and underlying wood, or either of them [35], and their contribution should be acknowledged and evaluated to deeper understand the occurring phenomena. References addressing this important issue are rather rare [35,36,46,47]. Uncoated wood specimens and free coating films were employed to simulate clear-coated wood. A light reflection model was used to elucidate separately the colour changes caused by the clear-coating film and the underlying wood, showing a major contribution of the underlying wood compared to the coating film for two types of polyurethanes (approx. 60%/40%; 95%/5%) [35]. Different research concluded that in the case of spruce wood clear coated with a water-borne acrylic, the colour changes after 200 h UV irradiation were due almost entirely to the wood substrate, as colour changes in the coating film were negligible [47].

More studies have focused on the exposure of wood in outdoor conditions where UV radiation acts in conjunction with rainwater [2,32,45], while the topic of light-induced colour changes in indoor conditions by the natural light passing through the window glass [1,22,23,36] or light from artificial sources [26,27] has been less addressed, especially for clear-coated wood with natural aspect [46,48].

All these point to the idea that stabilising the natural colour of wood species exposed to light in indoors conditions remains a challenge that could be better addressed based on a deeper understanding of the occurring phenomena and influencing factors.

In this context, the objectives of the present study were: to evaluate comparatively the light-induced colour changes for uncoated and clear-coated wood surfaces with natural aspect in indoor conditions by accelerated testing; to determine the influence of the species and type of coating on the colour changes; and to highlight the specific contributions of the wooden support and of the coating films to the total colour changes in the finished surfaces. A dedicated laboratory method was employed for this purpose [46].

2. Materials and Methods

2.1. Wooden Material

Three hardwood species: European maple (Acer pseudoplatanus L.), European ash (Fraxinus excelsior L.) and European walnut (Juglans regia L.), were employed. The wood material was sourced from the company “Craiul Munților SRL”, Stupărei village, Valcea county, Romania. These species were selected based on their aesthetic appearance and importance for furniture and other interior design element manufacturing, including wooden floors and panelling. These species differ in natural colour, anatomical structure, texture and the presence or not of colour-differentiated sapwood and heartwood areas, so that they can provide beautiful contrasts that can be valorised by design, while also representing a group with sufficient variability in structure and properties to provide useful research data. Moreover, the expected research results will add new information to a data base, including their ageing properties as bare substrates or coated surfaces with natural traditional finishing materials [24], allowing useful comparisons.

Test samples of a rectangular form of 120 × 80 × 8 (mm × mm × mm) with radial or semi-radial faces were prepared from air-dried wood material. All samples were sanded manually with abrasive paper (120 and 180 grit sizes).

2.2. Coating Materials

Three types of clear, waterborne, colourless lacquers, falling into the classes of acrylic-polyurethane F1 (YO 20-M702), acrylic F2 (YO 15-M864) and polyurethane F3 (YO 20-M838) coatings (Table 1), were employed for wood finishing with natural aspect. These are all products of Renner Italy (Minerbio, Italy) [49], commercialised in Romania by Kroncolor Brașov (Brașov, Romania) [50]. The selection of these materials took into account ecological aspects (preference for waterborne products instead of solvent-based), their market share as finishing materials, the quality of the cured coating films ensured by their chemistry, alongside the recommendation of the specialists from Kroncolor for transparent finishes with natural appearance.

Table 1.

Waterborne transparent coating materials and additives (Renner–Italy) employed in the experimental research.

2.3. Test Sample Preparation

Wood specimens (uncoated and coated) and clear microscopic slides (1 mm thickglass lamellae) as such and coated with the experimental finishing materials (F1, F2, F3 as 1k formulations) were employed in this research. The finishing of the wood samples was carried out in laboratory conditions, applying two successive layers of approximately 90–100 g/m2 (corresponding to an approximately 100 μm thickness as a liquid), at an interval of 2–4 h. The same finishing technology was applied for the glass lamellae, employing a special device for coating film application (2 layers of 100 μm), with the intention to ensure reproducible testing conditions such as film thicknesses for the test samples V1 (uncoated wood + coating film of glass lamella) and F2 (coated wood). It should be noted, however, that some differences resulted from the practical procedure and the variation in the solids content and viscosity of the three coating materials. Moreover, the differences in the anatomical features of the three wood species: maple—diffuse porous with small vessels not visible with the naked eye; walnut—diffuse porous with larger vessels visible with the naked eye; and ash—ring porous with distinctly larger vessels clearly visible in early-wood, resulted in different coating penetration and coverage of the wood grain. Accordingly, semi-filled/nearly filled grain finishes were obtained for maple, and open grain finishes for walnut and ash. The preliminary examination of the transversal cross-cut edges of the coated samples confirmed visual perception in terms of pores filling and highlighted the interaction between the coating and the wood substrate at the interface, resulting in different penetrations of the coatings into the wood substrates. It could be observed that strongly interconnected “composite coating layers”, including coating films on top of wood surfaces and impregnated sub-surfaces, were obtained.

The actual spread rates applied and the (average values), determined by weighing each sample immediately after coating application, as well as the theoretical thickness of the resulting cured coating films, calculated considering the average spread rates and the solids content of each coating material but no wood penetration, are summarised in Table 2, The actual thicknesses of the cured coating films applied on glass lamellas, determined with a precision of 0.001 mm, are also included.

Table 2.

Experimental values referring to the preparation of the coated wood samples and glass lamellae with the three types of coating materials: application rates, theoretical film thickness on wood samples, thickness film on glass lamellae, alongside the solids content and viscosity of the applied coating materials F1, F2, F3.

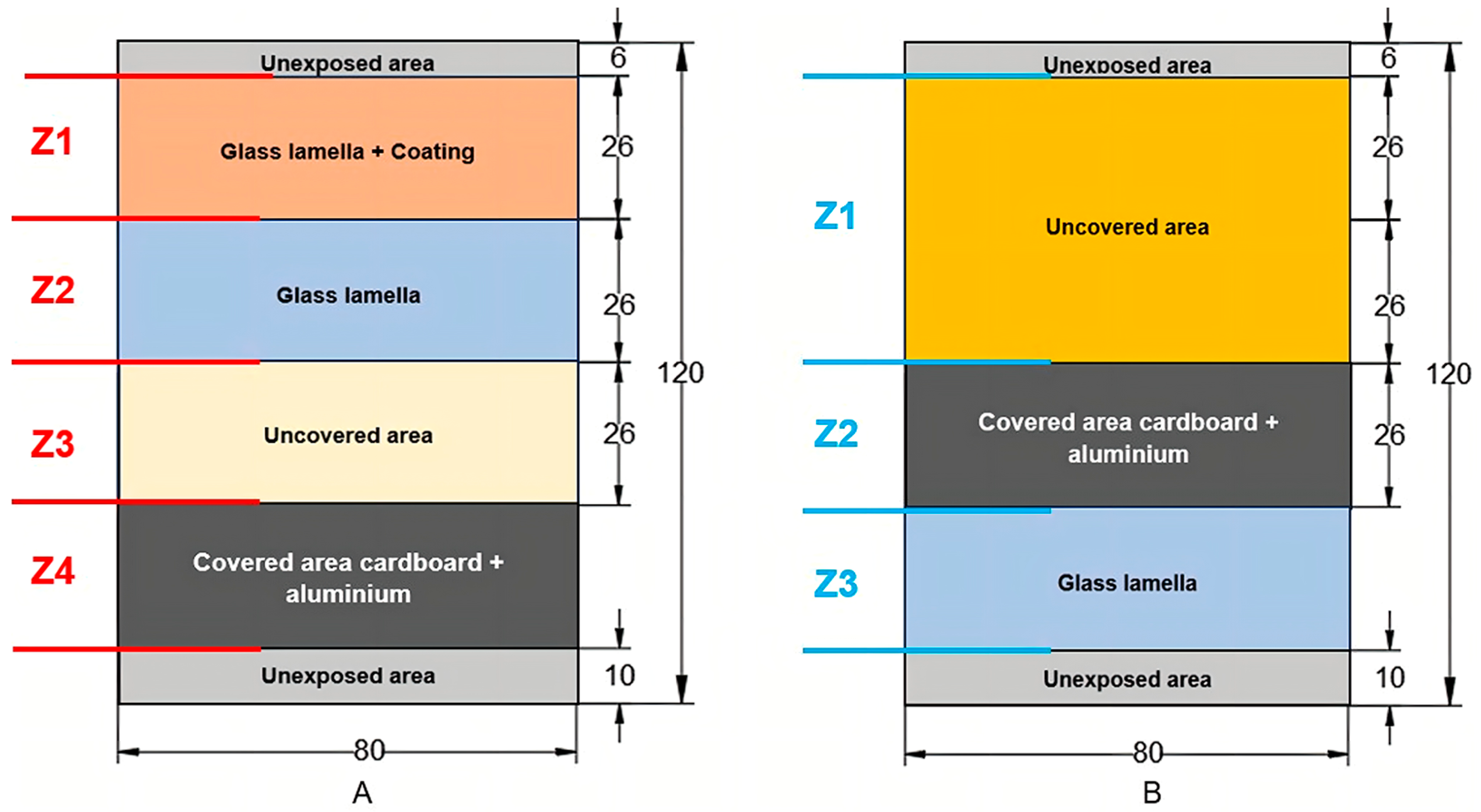

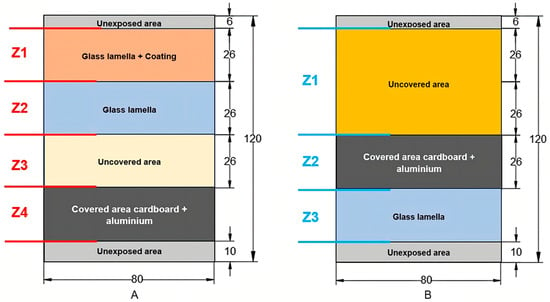

Two types of test samples for UV-VIS light exposure, coded V1 (uncoated wood support-Figure 1A) and V2 (coated wood support Figure 1B), resulted from assembling wood samples with glass lamellae, following an original concept [46]. This was developed to allow highlighting and measurement of the light-induced colour changes for the uncoated (V1/Z3) and coated wood surfaces (V2/Z1), the coating films (on glass lamellae) and the wood substrate under the coating film (simulated by V1/Z1, uncoated wood under coated glass lamella), in the various specific zones differentiated as exposure situations. Both types of test samples included a colour control area (V1/Z4, V2/Z2), tightly covered with black cardboard and aluminium foil to prevent the penetration and effect of light. The two types of test samples (V1, V2) were prepared in triplicate for each tested variant (wood species, type of coating), resulting in a number of 18 samples/species, respectively, 54 samples in total.

Figure 1.

Test samples: (A). V1—Uncoated wood support, coating on glass lamella: dimensions and various specific zones/light exposure situations (Z1–Z4); (B). V2—Coated wood support: dimensions and various specific zones/light exposure situations (Z1–Z3). (reproduced from [46] with permission).

2.4. Colour Measurements

Colour measurements in the CIELab reference system were performed using an Ava-spec-USB2 spectrometer from Avantes (Apeldoorn, The Netherlands) [51] equipped with an integration Ava Sphere with a diameter of 80 mm, with a circular measuring aperture of 8 mm in diameter. Measurements were carried out under a standard D65 illuminant and the measurement angle set at 10 degrees, according to the relevant standard methods [52]. The light connection to the sphere was via glass fibres and a COL-UV-VIS collimating lens connected to the light source. The colour data were processed employing Ava soft 7.0.

The measured colour parameters were: the lightness value (L*), varying from 0 for black to 100 for white; the degree of red (redness) on the green–red chromatic axis (−a*, +a*); and the degree of yellow (yellowness) on the blue–yellow colour axis (−b*, +b*). The colour measurements were performed on 12 fixed points (circular areas of 8 mm diameter) on each wood sample (uncoated or coated) and on 3 fixed points for the coated glass lamellae, prior to assembling the wood specimens with the glass lamellae. After each period of light exposure, the samples were disassembled and colour measurements repeated in the same areas on the wood substrate and the coated lamellae. The colour measuring points on the wood samples corresponded to 3 fixed locations on each zone of the test samples, excepting zones V2/Z1 with 6 measuring points. As the test samples were in triplicate, a minimum number of 9 and maximum 18 measurements resulted for each zone/exposure situation for each tested variant. All the colour data were collected and further processed in Excel to calculate the light-induced variation in colour coordinates (ΔL*, Δa* and Δb*) and the total (global) colour difference (ΔE) according to the relationships (1)–(4):

where: e—exposed; i—initial.

A series of ΔL*, Δa*, Δb* and ΔE values calculated for each measuring point of a certain area/exposure situation (9 or 18 values) and their means were employed for statistical analysis of the colour changes after 72 h of light/UV exposure.

2.5. Accelerated UV–VIS Light-Induced Ageing Procedure

A Feutron 400 FKS environmental climatic chamber (Feutron Klima Simulation–GmbH-Greiz, Germany), equipped with a UVA Spot 400 T lamp (Hoenle UV Technology–Gilching, Germany), fitted with a glass H2 filter, was employed to expose the wood samples to UV-VIS light in the range of 295 to 600 nm, simulating natural light filtered by window glass, similarly to the previously reported research [23,53]. Considering the maximum emission of the lamp in the UV range (mainly UV-A, as indicated also by its name), this type of radiation with higher energy was considered to be the main ageing factor causing colour and chemical changes in our experiments. However, the expression UV lamp and UV exposure were still employed in this paper, including the graphs, for commodity reasons. It should be acknowledged, however, that visible light with wavelengths up to 515 nm may contribute to the surface and sub-surface wood colour changes, while visible violet radiation up to 430 nm may have a contribution to lignin degradation [14]. Accordingly, the visible light emitted by the source employed might have had a contribution to the colour changes measured in this research.

The samples were placed vertically on a rack at a distance of 60 cm from the UVA light source. The actual irradiation procedure, similar to the previously reported research [53], included an initial conditioning of 0.5 h (20 °C, 55% RH, no light), followed by 3 cycles of 24 h UV exposure separated by conditioning phases of 24 h (20 °C, 55% RH, no light), inserted to allow the removal of samples for measurements. Each cycle of 24 h UV exposure consisted of four steps of 6 h UV irradiation at 40 °C, alternated with dark periods of 0.5 h. Cycles of 24 h UV exposure are in accordance with a standardised procedure of exposure to daylight behind window glass (method B) [54]. This procedure was repeated three times so that the data refer to samples exposed for 24, 48 and 72 h to UV radiation. All the samples were in triplicate and exposure was carried out in two series. The position of the samples on the rack was changed after each period of 24 h exposure in order to ensure a similar degree of irradiation.

2.6. Data Processing and Statistical Analysis

Microsoft Excel version 2019 and the operating system Windows11 was employed for data collection and their basic processing by calculation of the average values and standard deviations for each group of 9 or 18 measurements. One-way Anova test in conjunction with Tukey’s honestly significant difference (HSD) as post hoc tests were employed to check the significant differences between the means of different groups at a significance level α = 0.05. Two-way Anova with replication was employed to evaluate the statistical significance of the wood species, type of coating material or exposure situation (specific areas of the test samples) as influencing factors on the global colour changes ∆E after 72 h light/UV exposure. The data analysis tool-pack in Excel 2019 and Statistica 8 software were used for statistics.

3. Results and Discussion

3.1. Light-Induced Colour Changes in the Uncoated Wood Surfaces

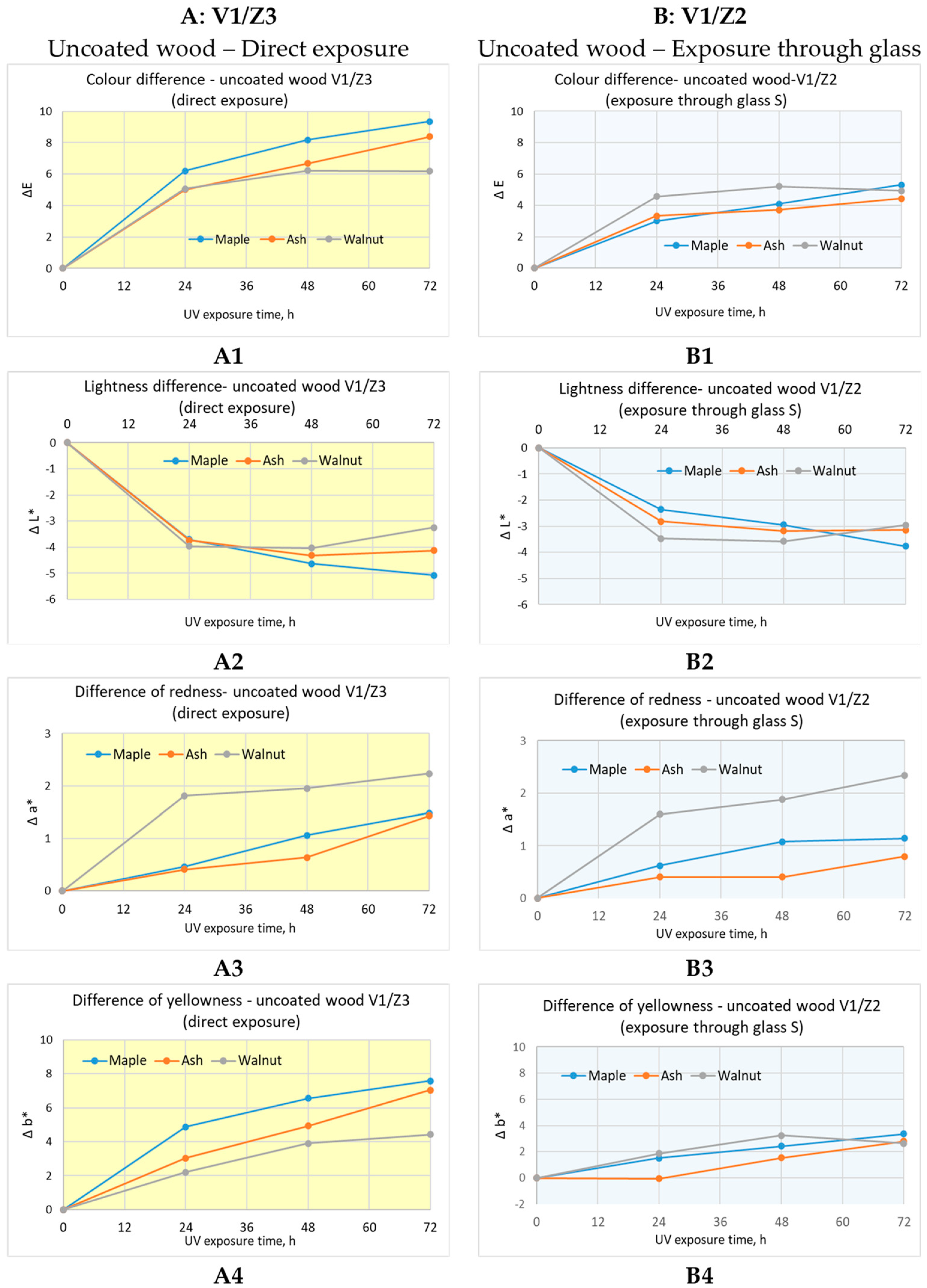

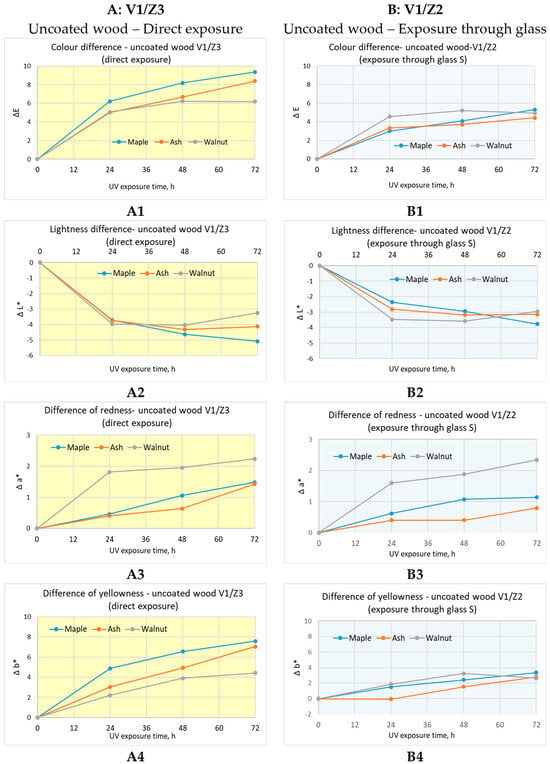

Light exposure of the uncoated wood surfaces (samples V1) resulted in progressive colour changes, visually perceived mostly as darkening, with some shade modifications, depending on the exposure situation and wood species. The evolution of these colour changes, expressed by the variation in the ∆E, ∆L*, ∆a*and ∆b* values as a function of the exposure time, is illustrated by the graphs in Figure 2, comparatively for the areas V1/Z3 directly exposed and the area V1/Z2 covered with a clear glass lamella.

Figure 2.

Comparative in-time evolution of light-induced colour changes (ΔE, ΔL*, Δa*, Δb*) for uncoated maple, ash and walnut wood surfaces (samples type V1) depending on the exposure situation: (A)—direct exposure to UV light (V1/Z3); (B)—exposure through a 1 mm thick clear glass lamella (V1/Z2).

The total colour changes (ΔE) in the unfinished wood support directly exposed to light/UV radiation (V1/Z3 areas) increased gradually during exposure, though these changes were more rapid in the first 24 h. The highest values after 72 h exposure were registered for maple (9.36 units), followed by ash (8.39 units) and then walnut (6.20 units). A similar order of light sensitivity for these three species was determined by [1], ΔE values of approximately 14.1 units, 12.5 units and 9.8 units resulting after longer exposure (600 h). Colour changes of 12.5 units for maple and 11.7 units for walnut were reported after 7 years exposure to natural light passing through the window glass [48].

The total colour changes resulted mostly from the decrease in lightness, highlighted by the negative ΔL* values evolving following a mirrored pattern when compared to ∆E and reaching the final values of (–5.07) units for maple, (−4.13) units for ash and (–3.25) units for walnut (Figure 2(A2)).

From a chromatic point of view, the positive Δa* values (up to 2.23 units) indicate only a slight increase in redness, while the positive Δb* values (up to 7.58 units) indicate a more important increase in the yellowness, specific to each wood species. The previous research and literature data indicated that the redness of wood, as well as UV/light-induced changes in redness, might be associated to the extractives [55], while the increase in yellowness can be correlated to UV-induced lignin degradation and formation of new quinones and stilbenes chromophores [8,9,11,12]. As lignin photo-degradation is the first and main photo-chemical process induced by UV light, higher changes in yellowness compared to redness are expected. In the present research, the highest increase in redness (Δa*) was determined in the case of walnut (2.23 units), followed by maple (1.48 units) and ash with quite similar values (1.43 units). Contrarily, the lowest change in yellowness was determined for walnut (Δb* = 4.42 units), compared to ash (7.05 units) and maple (7.58 units), with the highest value. This is in accordance with the previous research results and may be explained by the role of extractives [23,53]. Wood extractives may act as UV absorbers and free radical scavengers while themselves undergoing the photo-oxidation processes. All these effects result in retarding the photo-degradation of lignin in wood [18,19,20], which means less yellowing. A higher content of extractives in the walnut wood compared to maple and ash wood may explain both the darker natural colour of walnut and the reduced colour changes compared to maple following UV exposure, at least for the duration of the test carried out in this research (72 h).

The light-induced colour changes for the uncoated wood surfaces that were covered with a 1 mm thick clear glass slide (V1/Z2) are presented in Figure 2B. It can be observed that the total colour changes (ΔE) are smaller than those registered for surfaces directly exposed (V1/Z3) to UV light for all the three species, though the decrease in ∆E values varied among species, being higher for maple and ash (approximately −4 units) than for walnut (−1.24 units). This shows an effect of the glass by diminishing the intensity/energy and very likely the spectral distribution of light reaching the wood surface underneath. The literature data [56,57] and our own experience have shown reduced transmittance indexes of glass for UVB and UVA wavelength compared to visible radiation. The effect of glass is visible especially in the light-induced changes in lightness (∆L) and yellowness (∆b*), while it is almost absent in the case of redness (∆a*). This may support the assumption of selective partial blocking of UV radiation from the spectral distribution of the light emitted by the source, so that wood under the glass is exposed not only to light of lower intensity/energy but also to light with a different spectral distribution, with less UV radiation and more VIS radiation. This may also explain why the colour changes were less affected by the cover glass slide in the case of walnut, with a darker, reddish natural colour due to the extractives, which may absorb more visible radiation. The previously published research has demonstrated that dark natural wood species undergo intensive photo-bleaching when exposed to daylight, the most detrimental effect being caused by wavelengths of the visible spectral range, which affects mostly the low molecular extractives [21].

The glass effect is clearly a limitation of the method employed in this research in the attempt of highlighting and quantifying the colour changes in the wood substrate occurring under the coating film by simulating this situation with coated glass lamella on top of uncoated wood (V1/Z1).

3.2. Light-Induced Colour Changes in the Coated Wood Surfaces

Exposure of the coated wood surfaces to light (V2 samples) resulted generally in smaller colour changes, dependant on the wood species and the type of finishing material.

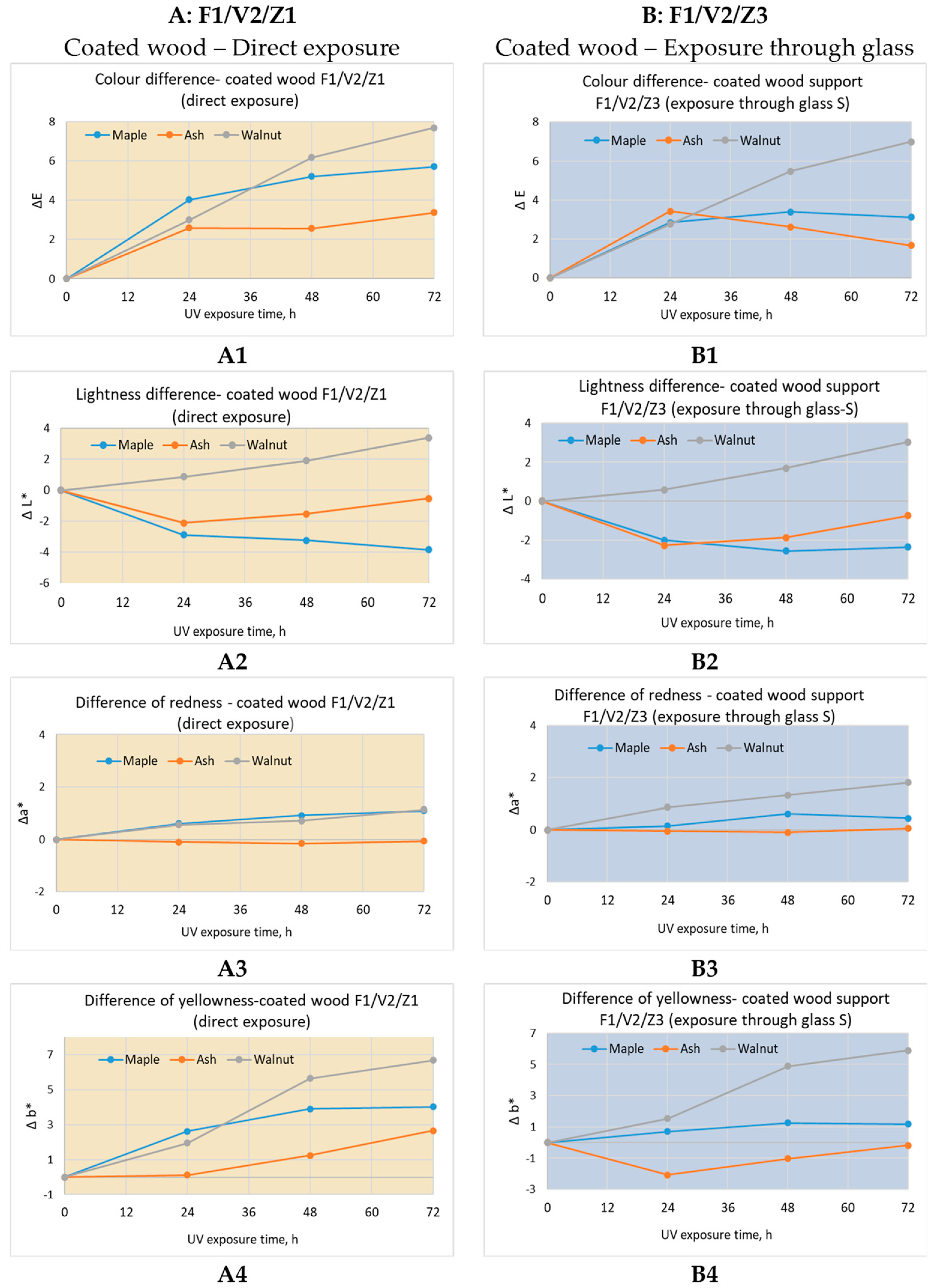

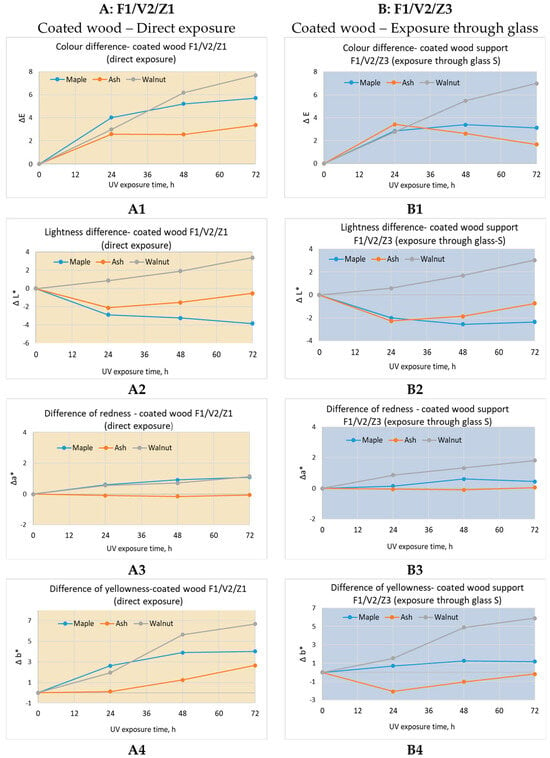

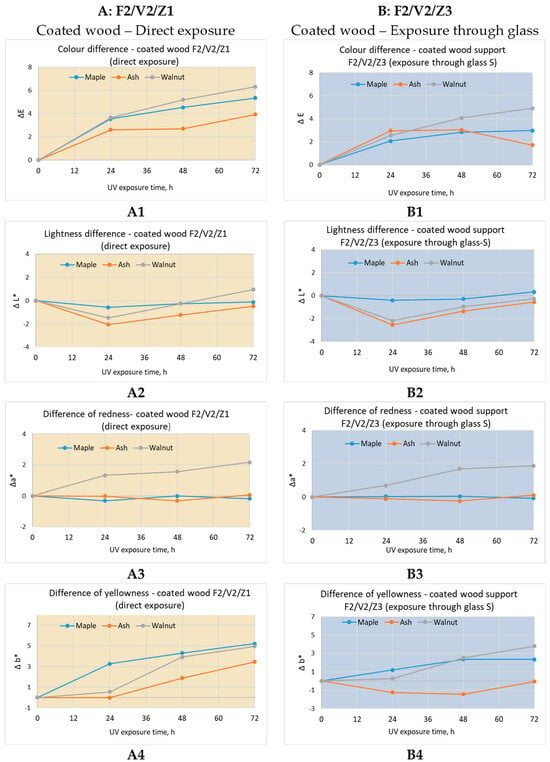

The graphs in (Figure 3A) represent the colour changes in the wood samples coated with the acrylic-polyurethane lacquer, coded F1, in the areas directly exposed to light/UV radiation (F1/V2/Z1) as a function of the exposure duration. The evolution of the global colour changes, expressed by the ΔE values, show a quite similar pattern for maple and ash, with maximum changes occurring during the first 24 h of exposure (3.96 units for maple and 2.16 units for ash), followed then by a slower increase up to the 5.71 units for maple and only 3.37 units for ash. The evolution of colour changes for the walnut samples was totally different, almost linear in time, reaching the highest value of 7.70 units after 72 h of light exposure.

Figure 3.

Comparative in-time evolution of light-induced colour changes (ΔE, ΔL*, Δa*, Δb*) for maple, ash and walnut wood surfaces coated with waterborne acrylic-polyurethane lacquer F1 (samples type V2), depending on the exposure situation: (A)—direct exposure to UV light (F1/V2/Z1); (B)—exposure through a 1 mm clear glass lamella (F1/V2/Z3).

The changes in lightness varied depending on the wood species: an increase in lightness, expressed by positive ΔL* values, reaching (+3.40) units after 72 h exposure was registered for walnut, whilst for the maple and ash coated specimens the lightness decreased, as shown by the negative ΔL* values, reaching (−3.83) units for maple and only (−0.52) units for ash following a reversed evolution after 24 h exposure.

From a chromatic point of view, only slight variations in redness were registered as positive, with Δa* values up to (1.09) units for maple and values up to (1.14) units walnut, while those measured for ash were negative but very close to zero (−0.06 units). Positive Δb* values indicated for all the coated wood species a continuous increase in yellowness, up to 2.65 units for ash, 4.03 units for maple and 6.69 units for walnut. To conclude, the colour stability of the wood samples coated with the acrylic-polyurethane water-based lacquer decreased in the following order: F1-ash > F1-maple > F1-walnut, which is different from that observed for the uncoated wood samples: walnut > ash > maple.

The light-induced colour changes for the same coated wood surfaces covered with 1 mm thick clear glass (V2/Z3) are shown in (Figure 3B). It can be seen that the total colour changes ΔE are smaller than those recorded on the surfaces directly exposed (V2/Z1) to light for all the three species, but to a different extent. The effect of covering glass in reducing the global colour changes (∆E) for the coated wood (Figure 3(B1)) was similar to uncoated wood, minimal for walnut and clearly more accentuated in the case of maple (maximum) and ash (medium). However, according to the graphs plotted in (Figure 3(B2–B4)), the effect of glass seemed to be more uniformly distributed on all the colour parameters L*, a*, b*, with some specificity related to the wood species. In the case of maple, for instance, it is clearly visible that the yellowness increase due to light exposure was considerably reduced (from approximately 4 units to approximately 1 unit) for the coated samples covered by glass. It is important to highlight that the order of colour stability among the F1 coated wood samples was not changed by the effect of glass cover.

A similar analysis of the light-induced colour changes for wood surfaces coated with the acrylic water-based lacquer, coded F2, is presented in (Figure 4), comparatively for the directly exposed areas (F2/V2/Z1) (Figure 4A) and areas exposed under a glass covering slide (F2/V2/Z3) (Figure 4B).

Figure 4.

Comparative in-time evolution of the light-induced colour changes (ΔE, ΔL*, Δa*, Δb*) for maple, ash and walnut wood surfaces coated with waterborne acrylic lacquer F2 (samples type V2), depending on the exposure situation: (A)—direct exposure to UV light (F2/V2/Z1); (B)—exposure through a 1 mm clear glass lamella (F2/V2/Z3).

For the directly exposed areas (F2/V2/Z1) (Figure 4A), the evolution of the global colour changes, expressed by the ΔE values, showed a quite similar pattern for maple and ash, with changes occurring rapidly during the first 24 h of exposure (3.34 units for maple and about 2 units for ash), followed then by a slower increase up to the 5.23 units for maple and 3.49 units for ash. The colour changes for the walnut samples evolved somehow differently, almost linearly in time, reaching the highest value of 5.53 units after 72 h of light exposure. A trend of darkening expressed by negative ΔL* values was registered for all wood species after the first 24 h of light exposure, but this trend was reversed by prolonged exposure. After 72 h light exposure, a slight increase in lightness was registered for walnut (ΔL* = +0.96 units), while the ΔL* values for ash (−0.12 units) and maple (−0.48 units) remained slightly negative but very close to zero.

From a chromatic point of view, the variation in redness ∆a* and yellowness ∆b* depended on the wood species. An increase in redness Δa* was determined only for walnut (2.16 units), the values for ash and maple being close to zero. Positive Δb* values indicated for all the coated wood species a continuous yellowing, following species dependant patterns, up to 3.45 units for ash, 4.96 units for walnut and 5.11 units for maple. To conclude, the colour stability of the wood samples coated with the acrylic water-based lacquer decreased in the following order: F2-ash > F2-maple ≅ F2-walnut. This is different from that observed for the uncoated wood samples (walnut > ash > maple) and those coated with the acrylic-polyurethane finish F1 (F1-ash > F1-maple > F1-walnut), pointing out that both the wood substrate and the coating film influence the colour light stability of the coated wood.

The light-induced colour changes for the same coated wood surfaces, covered with 1 mm thick transparent glass (F2/V2/Z3 areas), plotted in (Figure 4B), were again smaller than those determined for the directly exposed areas (Figure 4A), the influence of the covering glass being also dependant on the wood species. The highest decrease in the global colour changes (ΔE after 72 h of exposure) was observed again for maple (about −3 units), while the lowest was observed for walnut (about −0.5 units) (Figure 4(B1)). According to the graphs plotted in (Figure 4(B2–B4)), light exposure through the covering glass influenced mostly the evolution of the yellowness changes ∆b*, which were reduced for all species, with a more pronounced influence (about −3 units) for the maple and ash samples. It is important to highlight that the order of colour stability among the F2 coated wood samples was slightly changed by the effect of the glass cover (S), so that a clear difference could be observed between walnut and maple: S-F2-ash > S-F2-maple > S-F2-walnut.

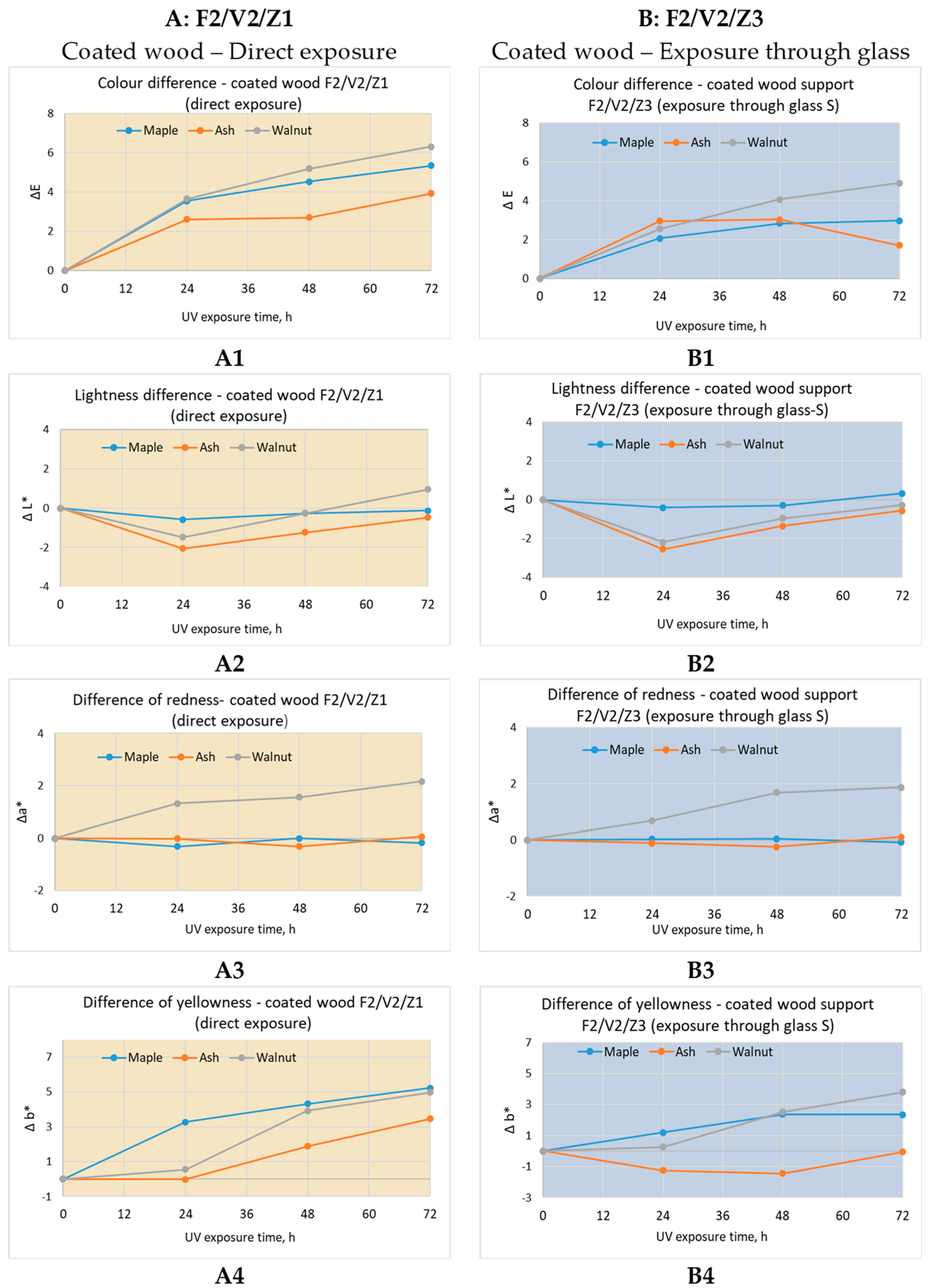

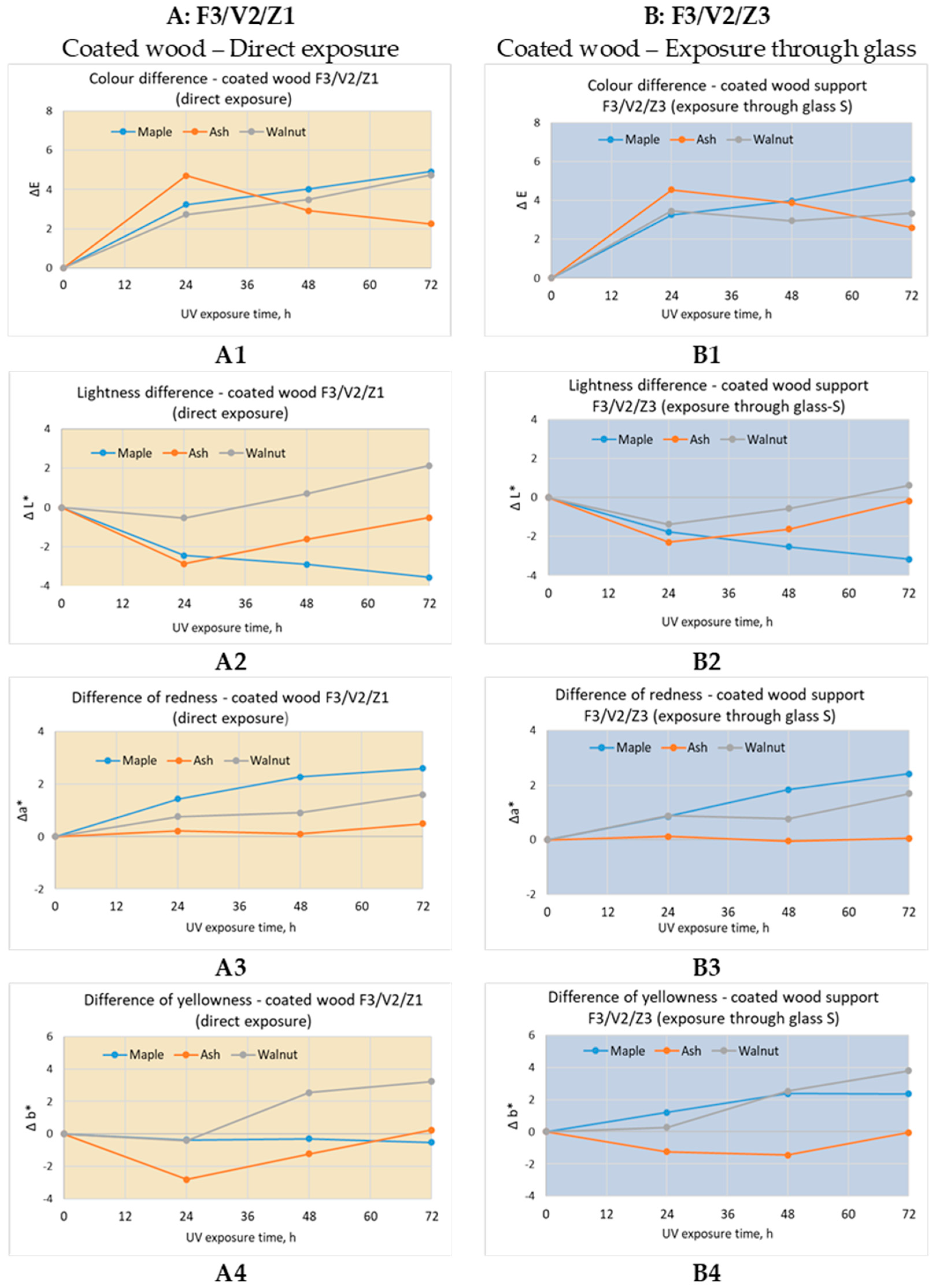

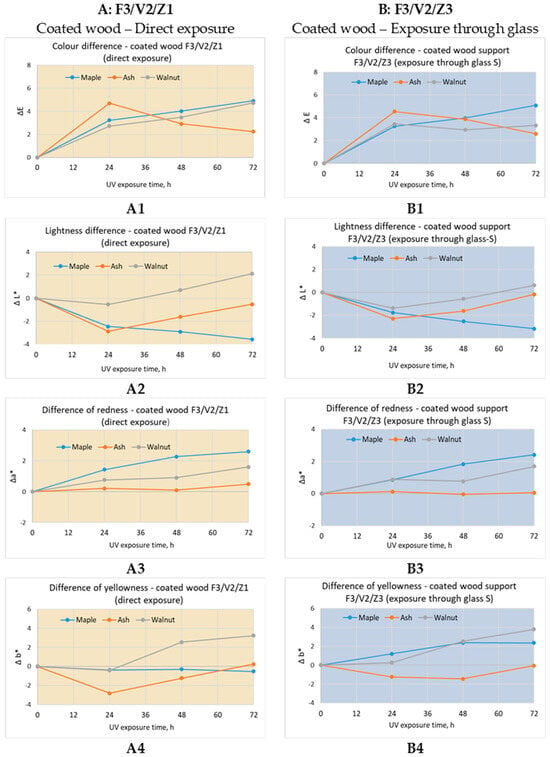

Finally, the light-induced colour changes for wood surfaces coated with the polyurethane water-based lacquer (1 K), coded F3, are presented in Figure 5 comparatively for the directly exposed areas (F3/V2/Z1) (Figure 5A) and areas exposed under a glass covering slide (F3/V2/Z3) (Figure 5B).

Figure 5.

Comparative in-time evolution of light-induced colour changes (ΔE, ΔL*, Δa*, Δb*) for maple, ash and walnut wood surfaces coated with water-based polyurethane lacquer F3 (samples type V2), depending on the exposure situation: (A)—direct exposure to UV light (F3/V2/Z1); (B)—exposure through a 1 mm clear glass lamella (F3/V2/Z3).

For the directly exposed areas (F3/V2/Z1) (Figure 5A), the evolution of the global colour changes, expressed by the ΔE values, show more specific wood species patterns. For ash (coated F3), fast and important colour changes occurred during the first 24 h, a maximum ∆E value of approximately 4 units being registered after this period. The process was reversed with about the same speed by continuing the light exposure, the ∆E values determined after 48 h and 72 h being considerably lower. The individual patterns for maple and walnut remained very similar to those presented for the samples coated with the other two finishes in Figure 3(A1)(F1) and Figure 4(A1)(F2), being characterised by: (i) changes occurring more rapidly during the first 24 h of exposure, followed then by a slower increase in the case of maple; (ii) changes increasing almost linearly in time in the case of walnut. After 72 h light exposure the measured ∆E values for the F3 coated samples, listed in increasing order, were: −2.25 for ash, 4.74 for walnut and 4.92 for maple.

A trend of darkening expressed by negative ΔL* values was registered after the first 24 h of light exposure, especially for ash and maple. This trend was reversed by continuing the light exposure in the case of ash but continued at a lower slope in the case of maple. In the case of walnut, only a very slight darkening was registered after 24 h light exposure and the further reversing of the process resulted in a lightening effect after 72 h, contrarily to the other two species. The comparative ∆L* values (glass/direct exposure) after 72 h were as follows: −3.17/−3.56 for maple, −0.17/−0.51 units for ash and +0.63/2.14 units for walnut.

From a chromatic point of view, the variation in redness ∆a* and yellowness ∆b* depended also on the wood species. A progressive increase in redness during light exposure was registered for maple (up to +2.60 units) and walnut (up to +1.61 units), while the values for ash had a slight wavy variation, resulting in only a very low increase (+0.49 units after 72 h).

The variation in the chromatic component b* was totally different. A trend of a very slight but continuous decrease in yellowness was registered for maple (up to about −0.5 units). A more advanced decrease in yellowness (up to approximately −3 units) was registered for ash samples but only during the first 24 h of exposure; afterwards, this trend was reversed so that after 72 h light exposure, almost no variation in yellowness could be observed any longer (∆b* = +0.24 units). An increase in yellowness after 72 h light exposure could be measured only for walnut (∆b* = +3.24 units).

Based on the global colour differences ∆E after 72 h light exposure, the colour stability of the wood samples coated with the waterborne polyurethane (1 K) lacquer F3 decreased in the following order: F3-ash > F3-walnut ≅ F3-maple. This is different from those observed for the uncoated wood samples (walnut > ash > maple) and those coated with the acrylic-polyurethane finish F1 (F1-ash > F1-maple > F1-walnut) but closer to those resulting for the samples coated with the acrylic finish F2 (F2-ash > F2-maple ≅ F2-walnut).

The light-induced colour changes for the same coated wood surfaces, exposed behind 1 mm thick clear glass (F3/V2/Z3 areas), plotted in Figure 5B, were again different but not always smaller than those determined for the directly exposed areas. Looking comparatively at the corresponding evolution patterns of the colour differences in the Figure 5(A1–A4,B1–B4), it can be observed that the most obvious pattern change due to the effect of the covering glass appeared for the yellowness variation (∆b*), especially for maple and ash. When exposed through the 1 mm clear cover glass, the F3 coated maple samples yellowed progressively, whilst when uncovered, there was a very slight trend of decrease. The pattern for ash was also different, with a less pronounced decrease in yellowness in the first 24 h, but finally after 72 h, there were no significant changes in yellowness, similarly to the uncovered samples. For walnut, the evolution pattern did not change shape, but the final increase in yellowness was slightly increased. Exposure through the covering glass reduced the variation in lightness to different extents depending on the wood species but did not change visibly the evolution patterns. It can be noted a smaller lightening for walnut, while the darkening effect for maple and ash seems less affected. Accordingly, there were some small differences in the evolution patterns of ∆E values for the three species and the final values recorded after 72 h light exposure. Based on these values, the colour stability of the wood samples coated with the waterborne polyurethane (1 K) lacquer F3 and covered by a 1 mm thick clear glass slide (S) decreased in the following order: S-F3-ash ≥ S-F3-walnut > S-F3-maple, which is slightly different from those observed earlier for direct exposure (F3-ash > F3-walnut ≅ F3-maple), especially as walnut is concerned. It has to be pointed out that for this type of finish (F3), the glass cover showed sort of a shielding effect only in the case of walnut, reducing the final ∆E value by 1.41 units, whilst the corresponding values for maple and ash substrates actually increased with 0.16, respectively, 0.35 units.

More research on an increased number of replicates and complementary investigation methods, including spectral analysis of the light emitted by the source and passing through the 1 mm thick clear glass cover, as well as the interaction of the respective light with the different wood substrates and the coating films in terms of absorption, reflection or transmittance are necessary to better understand and explain the experimental results obtained so far.

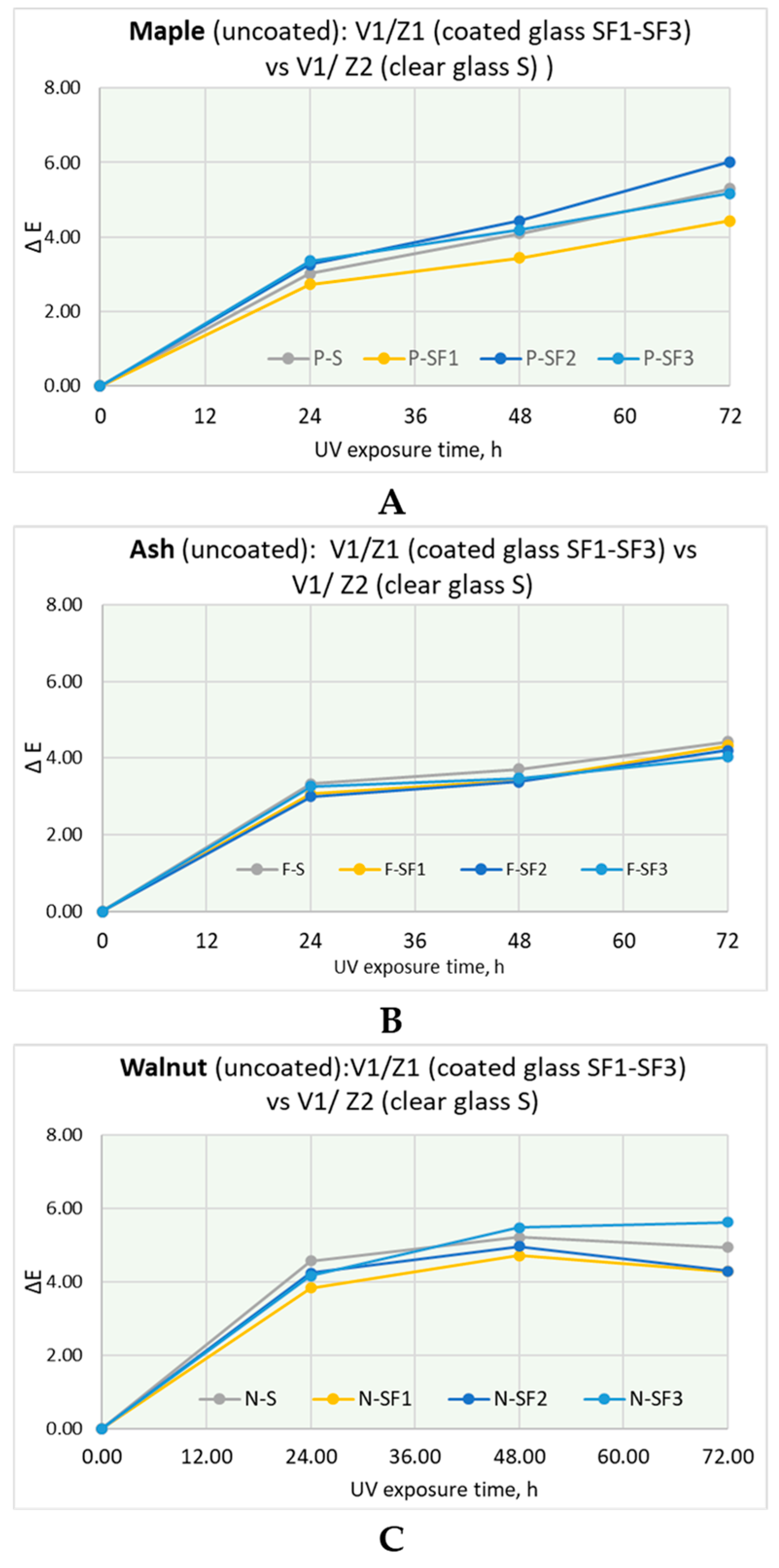

3.3. Light-Induced Colour Changes in the Wood Substrate under the Coating Film, Simulated by V1/Z1 Zones—Contribution of the Underlying Wood Substrate to Overall Colour Changes

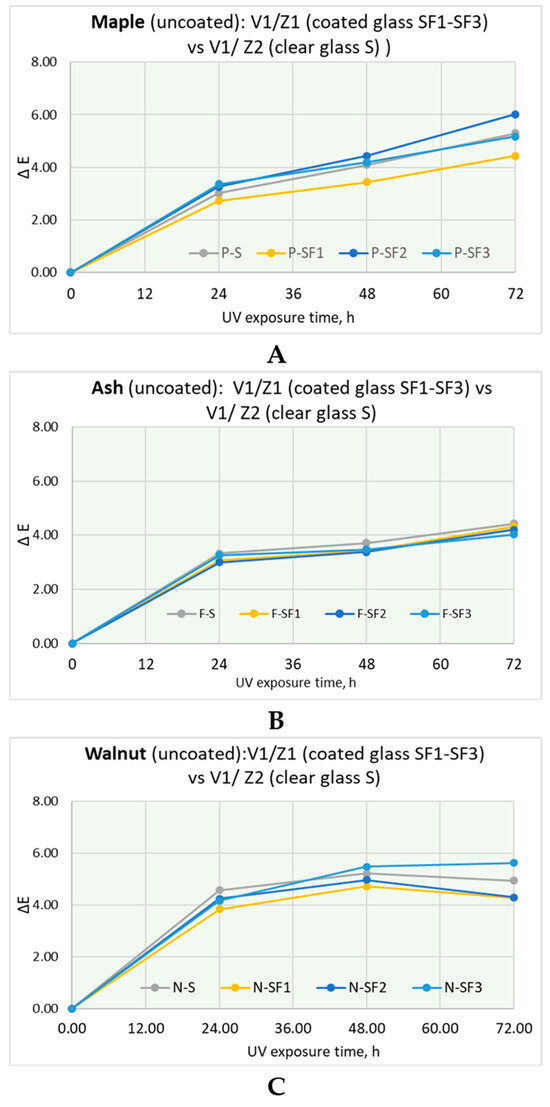

The experimental method employed in this research envisaged a possibility to highlight, measure and compare the light-induced colour changes in the wood substrate under the coating film and in the coating film itself. For this purpose, sort of a “detachable” coating film was necessary, and this goal was achieved by applying the coating films on 1 mm thick clear glass slides. These were tightly attached to the uncoated wood substrate during light exposure and removed after each exposure period to allow evaluation of the colour changes in the coating film (on glass slide) and in the substrate under the protective coating film (areas V1/Z1). As was already mentioned, the influence of the 1 mm thick clear glass slide was a limitation of this method and was considered by comparative evaluations with areas V1/Z2 (exposure through clear glass). The graphs plotted in (Figure 6) illustrate the in-time evolution of the global colour changes, expressed as ∆E values, for wood substrates exposed to light under the three different types of coating films: acrylic-polyurethane (F1), acrylic (F2), polyurethane (F3) applied on glass slides (SF1, SF2, SF3), alongside the control curves highlighting the effect of the clear glass (S). It can be clearly observed that light penetrated through the transparent coating film and the clear glass slide, reaching the wood substrate underneath and causing colour changes that evolved with the duration of exposure. The evolution patterns in the colour changes were very similar for exposure under clear glass (S) and exposure under coated glass (SF1–SF3), with only some small differences in the actual ∆E values. Slightly lower values under the coated glass may suggest some protective effect of the respective coating films, whilst slightly higher values may indicate an opposite effect. However, when compared to the colour differences for wood exposed under clear glass the differences brought about by the coatings applied on glass were very low, as can be observed in Table 3, where the average data after 72 h light exposure are presented.

Figure 6.

Light-induced colour changes in the wood substrate (uncoated) exposed under the protective effect of the three types of coatings (F1–F3) applied on clear glass slides (SF1, SF2, SF3), comparative to exposure through clear glass slides (S): (A)—maple; (B)—ash; (C)—walnut.

Table 3.

Comparative data of colour changes after 72 h light/UV exposure for wood substrate (maple, ash and walnut) under the coating films (coating materials F1, F2, F3), simulated in V1/Z1 areas by uncoated wood exposed under coated glass slides; the data on colour changes in the same substrates under clear glass slides (areas V1/Z2) are presented as reference values to evaluate the effect of the coatings.

Analysis of paired data by using the one-way Anova test at significance level α = 0.05 found no statistically significant differences between the mean ∆E values in the areas V1/Z1 and V1/Z2 (p values higher than 0.05), irrespective of the wood species and the type of coating material (F1, F2, F3). This means that no protective effect of the coating films on the colour changes in the wood substrate under the coating could be observed by the applied method. This statistics result was in good accordance with visual perception when analysing comparatively the light-induced colour changes in the areas V1/Z1 and V1/Z2 on the tested samples.

On the other hand, the fact that notable colour changes in the wood substrate occurring under the coated glass (V1/Z1) could be observed and quantified represents an important original contribution of this research. Moreover, the wood species and the type of coating were found as statistically significant influencing factors on the colour change values ∆E, determined for the V1Z1 areas after 72 h light/UV exposure, when the respective colour data were analysed by the Anova two-factor test with replication (summary in Table 4). The higher F value indicates wood species as a more important influencing factor than the coating film on the colour changes in the underlying substrate. The interaction of the two factors was not found statistically significant.

Table 4.

Summary of two-factor Anova test results with replication of the colour change values ∆E, after 72 h light exposure, in the areas V1/Z1, considering the wood species (1) and the type of coating (2) as influencing factors. (α-0.05).

The colour changes in the wood substrate due to light exposure under coated glass slides (V1/Z1) were determined as a simulation of the behaviour (contribution) of wood substrate under the coating films (V2/Z1), situations where there is no effect of the glass. Accordingly, the real colour changes in the substrates underneath the coating films and the associated chemical changes should be higher than those determined by the method applied in this research. This major contribution of the wood substrate to the total colour changes in the clear-coated wood surfaces is an important key point in understanding the occurring phenomena with the view of their correction, as also pointed out by the previous research [35,47]. For equivalence as exposure situations, the colour and related chemical changes in the substrate in the areas V1/Z1 should be comparable with the colour changes in a wood substrate under the coating film after exposure to light passing through a covering clear glass slide, respectively, areas (V2/Z3) in this research.

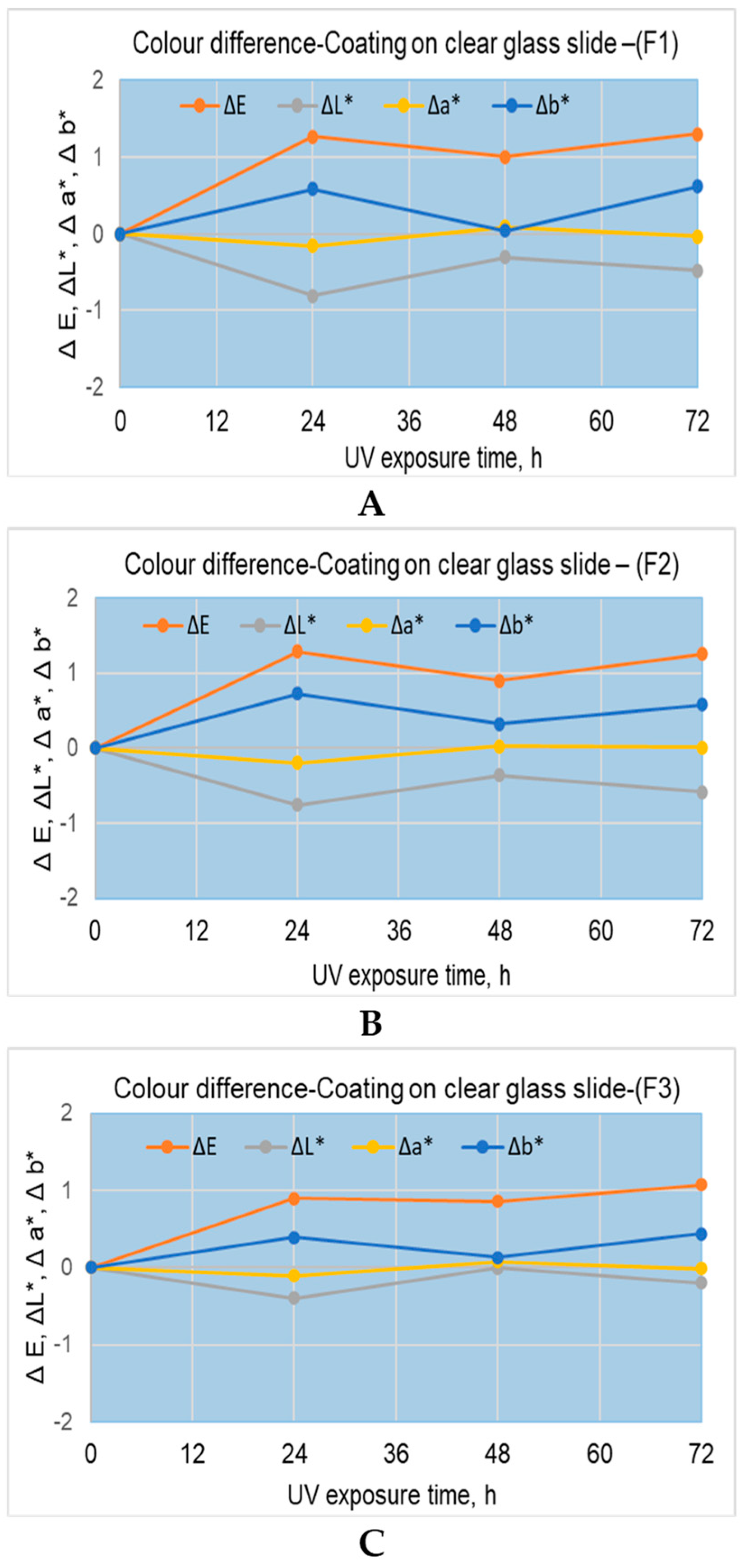

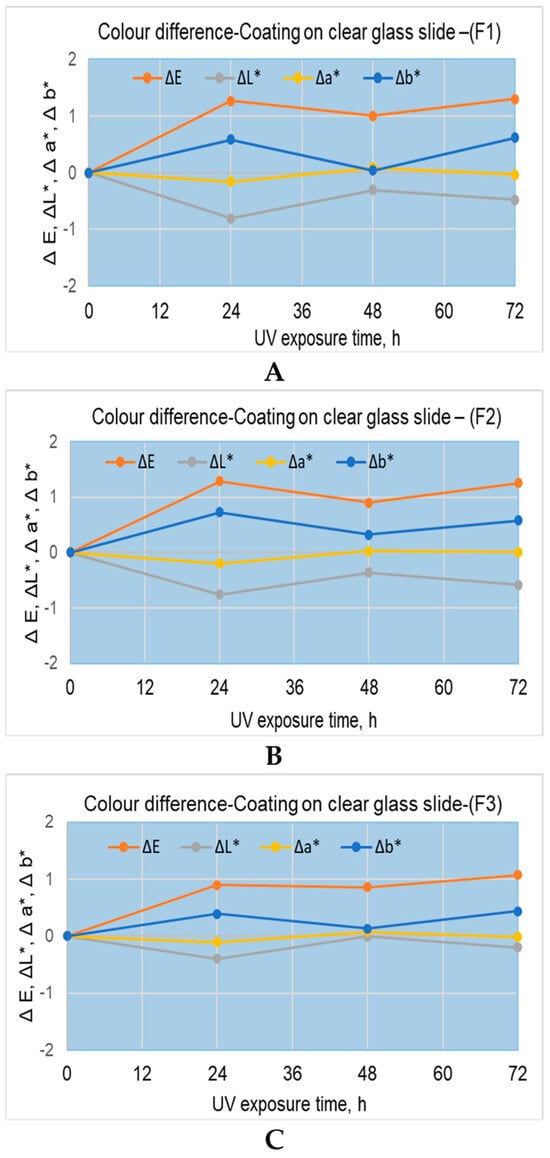

3.4. Light-Induced Colour Changes in the Coating Films—Contribution of Finishing Film to the Overall Colour Changes

The colour changes (ΔE, ΔL*, Δa*, Δb*) in the finishing films applied on 1 mm clear glass slides as a result of light exposure for different periods of time are presented in Figure 7. It can be easily observed that for all the three types of coatings, there were registered similar wavy patterns in colour changes. These were maximal after the first 24 h of exposure and consisted mainly in slight darkening (∆L* negative) and yellowing (∆b* positive). By further light exposure, the initial trend reversed twice. Redness evolved similarly but the changes were very low, close to zero. Consequently, the total colour changes (ΔE) after 72 h light exposure for the three types of finishing films were very low: 1.30 units for F1(acrylic-polyurethane), 1.25 units for F2 (acrylic) and 1.07 units for F3 (polyurethane). However, these differences in the means for the three types of coatings were not statistically significant when analysed by one-way Anova in conjunction with Tukey’s HSD post hoc test (p values higher than 0.05 at a significance level α = 0.05).

Figure 7.

Light-induced colour changes in coating films applied on clear glass slides: (A). acrylic-polyurethane lacquer F1; (B). acrylic lacquer F2; (C). polyurethane lacquer F3.

These low values demonstrate a fairly good colour stability to light exposure for all the tested coating materials. It would result, therefore, in a minimal contribution by the coating films to the overall colour changes in the wood coated surfaces, which strengthens the previous finding about the major contribution of the wood substrate to the total colour changes in the coated wood surfaces. However, the spectral properties of the coating films, meaning their specific capacity of absorbing, transmitting or reflecting/dispersing the UV-VIS radiation remain a key point in understanding and potentially controlling the colour changes in the substrate under the coating films and, finally, of the coated wood surfaces. These issues will be approached in future research.

3.5. Influence of Wood Species and Coating Materials on the Light-Induced Colour Changes in Wood Surfaces

The experimental results presented and discussed so far highlighted, in most cases, some protective effect of the three types of waterborne coatings (F1-acrylic-polyurethane, F2-acrylic, F3-polyurethane) against the UV-VIS light-induced colour changes in the wood substrates from the three wood species (maple, ash, walnut) under study. This protective effect was dependant on both the coating film and the wood species, which demonstrated different sensitivity to light-induced colour changes, in accordance with the previous research [22,24,53].

In order to have a cumulative and comparative image of the effect of clear coating on the colour stability of wood surfaces when exposed to light in indoor conditions, the data on the colour changes (∆E, ∆L*, ∆a*, ∆b*) after 72 h light exposure in the conditions of this research are cumulated in Table 5. The data for uncoated and coated samples (F1, F2, F3) of the three species were also included to allow a final discussion on the influence of both wood species and type of coating. Lower values in colour changes (∆E, ∆L*, ∆a*, ∆b*) mean better colour stability so that the effects of the above-mentioned influencing factors can be easily observed. The statistical significance of the differences between the mean values of the uncoated and coated specimens was tested by one-way Anova and Tukey’s HSD as post hoc test, and this information is included as superscript codes.

Table 5.

Comparative data of colour changes after 72 h light/UV exposure for uncoated and coated wood surfaces with the three finishing materials (F1, F2, F3).

Based on the comparative ∆E values, it can be observed that all the three coating materials F1, F2, F3 protected to some extent maple and ash wood substrates against the light-induced colour changes. This protective effect was higher for ash than maple. In the case of walnut, some protective effect was registered only for the coating F3. No effect was registered for the coating F2, while the samples finished with the coating F1 suffered colour changes slightly more intense (statistically significant) than uncoated walnut wood.

Differences in the protective effects of various waterborne clear coatings have been reported before. For instance, an increased protective effect of a 2 k polyurethane topcoat (based on hydroxyl-bearing polyacrylate and aliphatic poly-isocyanate) compared to an acrylic topcoat was reported for Radiata pine boards primed with a moisture curing isocyanate [58]. Colour change values ∆E varied in the range of approximately 2–10 units after 700 h light exposure (accelerated aging test simulating natural light passing through window glass) for spruce samples coated with four different three-layer coating systems (primer, middle layer, top layer) with waterborne coatings based on acryl/alkyd or polyurethane resins and their mixture [59].

The coated maple and ash samples exposed to light darkened less compared to the uncoated ones, as reflected by the comparative negative ∆L* values for all the three finishing materials. In the case of maple, this effect appeared to be highest for the F2 coating material, while in the case of ash, all the three coatings seemed to have a similar effect. Contrarily, the coated walnut samples became lighter following 72 h light exposure, this effect being more pronounced for the coatings F1 and F3 and minimal for F2. This particular behaviour of walnut is due to its darker colour compared to the other two species, respectively, to the role of extractives and visible light in the occurring colour changes, as reported in the literature [18,20,21].

The statistical significance of wood species (1) and type of coating (2) as influencing factors on the light-induced colour change values ∆E was verified by an Anova two-factor with replication test, at a significance level α = 0.05. According to the summary results presented in Table 6, respectively, the p values lower than 0.05, it can be stated that both the wood species (factor 1) and the type of coating (factor 2) are statistically significant influencing factors. Comparing the F values of the two factors, it results that wood species (F = 52.72) influence more the colour changes than the type of coating (F = 15.29). The test shows also that there is a significant two-way interaction between the two factors (p < 0.05; F = 3.31). This would mean a common and interconnected influence of the two factors for each wood species and type of coating. A significant impact of wood species and type of lacquer/coating system, alongside pre-treatments of wood surfaces and modification of coatings, on the light-induced colour changes in wood surfaces was previously reported [59].

Table 6.

Summary of two-way Anova results with replication of the colour change (∆E, after 72 h light exposure) in the coated wood surfaces (areas V2/Z1), considering the wood species (1) and the type of coating (2) as influencing factors.

The interaction of the coating material with the wood substrate at the interface level, consisting in wetting and penetration, depending on both the structural features and surface properties of the substrate and the coating material, might be part of this significant two-way influence on the UV-induced colour changes determined in this research. According to the literature data, a combination of the wood anatomy and the ability of the coatings to flow into the wood capillaries, influenced by the viscosity, solids content and type of solvent, govern the degree of coating penetration [60]. Generally, waterborne coatings penetrate less than the solvent-borne ones, though large variations might be among different formulations. In this context, binder type, pigmentation, solids content and drying time were found to be important. Acrylic waterborne dispersions have been found to have a low penetration compared to alkyd emulsions [61,62].

Differences in the colour changes in clear-coated pine wood after an artificial weathering test were associated with different penetrations of an acrylic coating system (primer and topcoat), increased colour changes being explained as possibly due to a reduced coating penetration. Increased penetrations were obtained in the same research for beech wood, but no final conclusion was drawn on the influence of coating penetration on the colour changes caused by weathering [63].

An interesting study on the degradative behaviour of coated-wood surfaces exposed to artificial weathering using Raman microspectroscopy was recently published. Chemical imaging pointed out different artificial weathering degradation patterns between wood specimens (Japanese cedar) that were clear-coated with impregnating materials and film-forming materials. For the impregnating systems, the surface-distributed coating gradually decreased during irradiation and lignin in the top surface cell walls degraded similarly to uncoated wood [64]. The result is, therefore, that both good penetration and the formation of a top film of the coating are beneficial for improved UV protection.

The preliminary microscopic investigation of our samples highlighted such “composite coating layers” with total thicknesses varying in the range of approximately 25–75 μm, while the top layer film included varied in the range 5–20 μm, with maximum thickness in ash early-wood (vessels). From the waterborne coating materials employed in this research, the polyurethane lacquer (F3) was the most fluid and ensured the best penetration into the wood substrate, approximated to around 50 μm for maple, 30–60 μm for ash (with the high values in early-wood vessels) and 25–60 μm for walnut (large values in vessels). This might explain, at least partially, the best protective effect against light-induced colour changes demonstrated in this research by the F3 finish for all the three wood species tested. However, more research and complementary methods are necessary for a conclusion with this respect.

4. Conclusions

The paper investigated comparatively the light-induced colour changes for three hardwood species, namely, European maple (Acer pseudoplatanus L.), European ash (Fraxinus excelsior L.) and European walnut (Juglans regia L.), as well as the influence of finishing with three types of clear, colourless waterborne lacquers (F1: acrylic-polyurethane, F2: acrylic, F3: polyurethane) on their colour stability.

Colour measurements in the CIELab system in conjunction with an artificial accelerated ageing test under the action of UV-VIS radiation, simulating natural light passing through window glass, and two types of test samples were employed to highlight the influence and contributions of the wood substrate and of the coating films to the global colour modifications.

Coating films applied on 1 mm clear glass slides were employed as a sort of “detachable” finish for this purpose. A different transmittance of the UV and VIS radiation from the artificial source through this glass support and a decrease in light intensity reaching the substrate is a limitation of the experimental method employed, which has to be considered in future research.

Direct exposure to UV-VIS light caused visible colour changes for both uncoated and coated wood surfaces, the values of the calculated colour differences (ΔE) after 72 h exposure being dependant on both the wood species and the coating material, which were found to be statistically significant influencing factors in interaction.

Excepting two situations for walnut, statistically significant higher colour differences were obtained for the uncoated samples: maple (9.36 units), ash (8.39 units), walnut (6.20 units), compared to the coated ones: maple (4.92–5.71 units), ash (2.25–3.94 units), walnut (4.74–7.70 units), depending on the type of coating.

From the three coating materials tested, the waterborne polyurethane lacquer represents a good option for all the wood species. The effect of each coating material tested depended on the wood species, as a more powerful influencing factor. The interaction between the wood substrate and the coating material at the interface level needs further investigation.

The wood substrate underlying the coating film was found to bring the maximum contribution to the overall colour changes in the clear-coated surfaces, the actual ∆E values being influenced by the wood species and the coating film as significant factors. The colour changes ∆E in the wood substrates under the simulated “detachable” coating films varied in the ranges 4.44–6.02 units for maple, 2.97–4.43 units for ash and 4.51–5.93 units for walnut.

The coating films employed in this research demonstrated a fairly good colour stability to UV-VIS light exposure, with colour changes (∆E) up to only 1.30 units, with no statistically significant differences.

These results will be employed as a basis for further research looking at efficient methods to stabilise the natural colour of the clear coated wood surfaces against the effect of light in indoor applications, considering the specific contributions of the wood substrate and of the coating films, as well as the particularities of each wood species in relation to their chemical composition.

Author Contributions

Conceptualisation: M.-J.T. and M.C.T.; methodology: M.-J.T. and M.C.T.; supervision: M.C.T., preparation of test samples: M.-J.T.; colour measurements: M.-J.T.; data processing: M.-J.T. and M.C.T.; graphs: M.-J.T.; writing and editing draft version: M.-J.T.; revisions: M.C.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research is part of a budget funded Ph.D. research project undertaken by the principal author within the Doctoral School of the Transilvania University of Brașov-Romania.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available within the article.

Acknowledgments

The authors would like to express their sincere thanks to the company “Craiul Muntilor SRL”, Stupărei village, Valcea county, Romania, for providing the wood material for this research. Furthermore, the authors would like to express their gratitude to the KronColoR company from Brasov, Romania for their professional advice and material support by providing the wood coating materials employed in this research. Special thanks are addressed to our colleague Bogdan Bedelean for advice and assistance in implementing the statistical analysis of data during the paper revision process. We also acknowledge the PRO-DD structural funds project (POS-CCE, O.2.2.1., ID 123, SMIS 2637, no. 11/2009) for providing the infrastructure used in this work at the ICDT Research Institute of the Transilvania University of Brasov-Romania.

Conflicts of Interest

The authors declare that there are no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Oltean, L.; Teischinger, A.; Hansmann, C. Wood surface discolouration due to simulated indoor sunlight exposure. Holz Als Roh-Und Werkst. 2007, 66, 51–56. [Google Scholar] [CrossRef]

- Kropat, M.; Hubbe, M.A.; Laleicke, F. Natural, Accelerated, and Simulated Weathering of Wodd: A Review. Bioresources 2020, 15, 9998–10062. [Google Scholar] [CrossRef]

- Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of Functional Treatments for Modified Wood. Coatings 2021, 11, 327. [Google Scholar] [CrossRef]

- Rajkovic, J.V.; Miklecic, J. Enhancing Weathering Resistance of Wood—A Review. Polymers 2021, 13, 1980. [Google Scholar] [CrossRef]

- Blanchet, P.; Pepin, S. Trends in Chemical Wood Surface Improvements and Modifications: A Review of the Last Five Years. Coatings 2021, 11, 1514. [Google Scholar] [CrossRef]

- Yi, T.; Morrell, J.J. Role of α/γ Fe2O3 and ZnO nano-particles in reducing photodegradation of wood components. Wood Sci. Technol. 2023, 57, 427–446. [Google Scholar] [CrossRef]

- Lee, H.-W.; Lee, E.-J.; Shin, Y.-J.; Jo, H.-Y.; Song, D.-Y. Surface Discoloration of Ultraviolet (UV)-Irradiated Phyllostachys bambusoides Bamboo. J. Korean Wood Sci. Technol. 2023, 51, 173–182. [Google Scholar] [CrossRef]

- Fengel, D.W.G.; de Gruyter, W. Wood—Chemistry, Ultrastructure, Reactions; Gruyter, W.D., Ed.; Walter de Gruyter: Berlin, Germany; New York, NY, USA, 1985. [Google Scholar] [CrossRef]

- Müller, U.; Rätzsch, M.; Schwanninger, M.; Steiner, M.; Zöbl, H. Yellowing and IR-changes of spruce wood as result of UV-irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar] [CrossRef]

- George, B.; Suttie, E.; Merlin, A.; Deglise, X. Photodegradation and photostabilisation of wood—The state of the art. Polym. Degrad. Stab. 2005, 88, 268–274. [Google Scholar] [CrossRef]

- Williams, R.S. Weathering of Wood. In Handbook of Wood Chemistry and Wood Composites; USDA, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2005. Available online: https://www.fs.usda.gov/research/treesearch/22122 (accessed on 8 September 2023).

- Evans, P.; Chowdhury, M.; Mathews, B.; Schmalzl, K.; Ayer, S.; Kiguchi, M.; Kataoka, Y. Weathering and Surface Protection of Wood. In Handbook of Environmental Degradation of Materials; William Andrew Inc.: New York, NY, USA, 2005; pp. 277–297. [Google Scholar] [CrossRef]

- Teacă, C.A.; Roşu, D.; Bodîrlău, R.; Roşu, L. Structural Changes in Wood under Artificial UV Light Irradiation Determined by FTIR Spectroscopy and Color Measurements—A Brief Review. BioResources 2013, 8, 1478–1507. [Google Scholar] [CrossRef]

- Kataoka, Y.; Kiguchi, M.; Williams, R.S.; Evans, P.D. Violet light causes photodegradation of wood beyond the zone affected by ultraviolet radiation. Holzforschung 2007, 61, 23–27. [Google Scholar] [CrossRef]

- Živković, V.; Arnold, M.; Radmanović, K.; Richter, K.; Turkulin, H. Spectral sensitivity in the photodegradation of fir wood (Abies alba Mill.) surfaces: Colour changes in natural weathering. Wood Sci. Technol. 2014, 48, 239–252. [Google Scholar] [CrossRef]

- Agresti, G.; Bonifazi, G.; Calienno, L.; Capobianco, G.; Lo Monaco, A.; Pelosi, C.; Picchio, R.; Serranti, S. Surface Investigation of Photo-Degraded Wood by Colour Monitoring, Infrared Spectroscopy, and Hyperspectral Imaging. J. Spectrosc. 2013, 2013, 380536. [Google Scholar] [CrossRef]

- Zahri, S.; Belloncle, C.; Charrier, F.; Pardon, P.; Quideau, S.; Charrier, B. UV light impact on ellagitannins and wood surface colour of European oak (Quercus petraea and Quercus robur). Appl. Surf. Sci. 2007, 253, 4985–4989. [Google Scholar] [CrossRef]

- Chang, T.-C.; Chang, H.-T.; Wu, C.-L.; Chang, S.-T. Influences of extractives on the photodegradation of wood. Polym. Degrad. Stab. 2010, 95, 516–521. [Google Scholar] [CrossRef]

- Chang, T.-C.; Chang, H.-T.; Wu, C.-L.; Lin, H.-Y.; Chang, S.-T. Stabilizing effect of extractives on the photo-oxidation of Acacia confusa wood. Polym. Degrad. Stab. 2010, 95, 1518–1522. [Google Scholar] [CrossRef]

- Chang, T.-C.; Lin, H.-Y.; Wang, S.-Y.; Chang, S.-T. Study on inhibition mechanisms of light-induced wood radicals by Acacia confusa heartwood extracts. Polym. Degrad. Stab. 2014, 105, 42–47. [Google Scholar] [CrossRef]

- Passauer, L.; Prieto, J.; Müller, M.; Rössler, M.; Schubert, J.; Beyer, M. Novel color stabilization concepts for decorative surfaces of native dark wood and thermally modified timber. Prog. Org. Coat. 2015, 89, 314–322. [Google Scholar] [CrossRef]

- Oltean, L.; Hansmann, C.; Németh, R.; Teischinger, A. Wood surface discolouration of three hungarian hardwood species due to simulated indoor sunlight exposure. Wood Res. 2010, 55, 49–58. Available online: https://www.researchgate.net/publication/299019578 (accessed on 11 October 2023).

- Timar, M.C.; Varodi, A.M.; Gurău, L. Comparative study of photodegradation of six wood species after short-time UV exposure. Wood Sci. Technol. 2016, 50, 135–163. [Google Scholar] [CrossRef]

- Liu, X.Y. Contributions to the Study of Ageing Phenomena of Wooden Substrate and Traditional Materials for Transparent Finishes—A Comparative Approach for Europe and China with Applicability in Furniture Conservation/Restoration. Ph.D. Thesis, Transilvania University, Brasov, Romania, 2017. [Google Scholar]

- Liu, R.; Zhu, H.; Li, K.; Yang, Z. Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light. Polymers 2019, 11, 709. [Google Scholar] [CrossRef] [PubMed]

- Cirule, D.; Kuka, E.; Sansonetti, E.; Hivrica, M.; Andersone, I.; Andersons, B. Wood photosensitivity to different artificial light sources. Eur. J. Wood Wood Prod. 2022, 80, 1507–1519. [Google Scholar] [CrossRef]

- Cirule, D.; Kuka, E.; Andersone, I.; Andersons, B. Wood discoloration patterns depending on the light source. Herit. Sci. 2022, 10, 158. [Google Scholar] [CrossRef]

- MacLeod, I.T.; Scully, A.D.; Ghiggino, K.P.; Ritchie, P.J.A.; Paravagna, O.M.; Leary, B. Photodegradation at the wood-clearcoat interface. Wood Sci. Technol. 1995, 29, 183–189. [Google Scholar] [CrossRef]

- Forsthuber, B.; Müller, U.; Teischinger, A.; Grüll, G. Chemical and mechanical changes during photooxidation of an acrylic clear wood coat and its prevention using UV absorber and micronized TiO2. Polym. Degrad. Stab. 2013, 98, 1329–1338. [Google Scholar] [CrossRef]

- Saha, S.; Kocaefe, D.; Boluk, Y.; Pichette, A. Surface degradation of CeO2 stabilized acrylic polyurethane coated thermally treated jack pine during accelerated weathering. Appl. Surf. Sci. 2013, 276, 86–94. [Google Scholar] [CrossRef]

- Aloui, F.; Ahajji, A.; Irmouli, Y.; George, B.; Charrier, B.; Merlin, A. Inorganic UV absorbers for the photostabilisation of wood-clearcoating systems: Comparison with organic UV absorbers. Appl. Surf. Sci. 2007, 253, 3737–3745. [Google Scholar] [CrossRef]

- Ncube, E.; Meincken, M. Surface characteristics of coated soft- and hardwoods due to UV-B ageing. Appl. Surf. Sci. 2010, 256, 7504–7509. [Google Scholar] [CrossRef]

- Rao, F.; Chen, Y.; Zhao, X.; Cai, H.; Li, N.; Bao, Y. Enhancement of bamboo surface photostability by application of clear coatings containing a combination of organic/inorganic UV absorbers. Prog. Org. Coat. 2018, 124, 314–320. [Google Scholar] [CrossRef]

- Esposito, C.C.; Frigione, M. Novel UV-Cured Nanocomposite Used for the Protection of Walnut Wood Artworks. Wood Res. 2014, 59, 229–244. Available online: https://www.researchgate.net/publication/287350116_Novel_UV-cured_nanocomposite_used_for_the_protection_of_walnut_wood_artworks (accessed on 22 October 2023).

- Chou, P.L.; Chang, H.T.; Yeh, T.F.; Chang, S.T. Characterizing the conservation effect of clear coatings on photodegradation of wood. Bioresour. Technol. 2008, 99, 1073–1079. [Google Scholar] [CrossRef]

- Capobianco, G.; Calienno, L.; Pelosi, C.; Scacchi, M.; Bonifazi, G.; Agresti, G.; Picchio, R.; Santamaria, U.; Serranti, S.; Monaco, A.L. Protective behaviour monitoring on wood photo-degradation by spectroscopic techniques coupled with chemometrics. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 172, 34–42. [Google Scholar] [CrossRef]

- Mahltig, B.; Swaboda, C.; Roessler, A.; Böttcher, H. Functionalising wood by nanosol application. J. Mater. Chem. 2008, 18, 3180–3192. [Google Scholar] [CrossRef]

- Wu, X.; Yang, F.; Gan, J.; Kong, Z.; Wu, Y. A Superhydrophobic, Antibacterial, and Durable Surface of Poplar Wood. Nanomaterials 2021, 11, 1885. [Google Scholar] [CrossRef]

- Panek, M.; Oberhofnerova, E.; Hysek, S.; Sedivka, P.; Zeidler, A. Colour Stabilization of Oak, Spruce, Larch and Douglas Fir Heartwood Treated with Mixtures of Nanoparticle Dispersions and UV-Stabilizers after Exposure to UV and VIS-Radiation. Materials 2018, 11, 1653. [Google Scholar] [CrossRef]

- Olsson, S.K.; Johansson, M.; Westin, M.; Östmark, E. Reactive UV-absorber and epoxy functionalized soybean oil for enhanced UV-protection of clear coated wood. Polym. Degrad. Stab. 2014, 110, 405–414. [Google Scholar] [CrossRef]

- Bielerman, J. Lackadditive; Wiley-VCH: Weinheim, Germany; New York, NY, USA; Chichester, UK; Brisbane, Australia; Singapore; Toronto, ON, Canada, 1998; p. 395. Available online: https://epdf.tips/lackadditive-german-edition.html (accessed on 19 September 2023).

- Rosu, D.; Teaca, C.A.; Bodirlau, R.; Rosu, L. FTIR and color change of the modified wood as a result of artificial light irradiation. J. Photochem. Photobiol. B 2010, 99, 144–149. [Google Scholar] [CrossRef]

- Essoua, G.G.E.; Blanchet, P.; Landry, V.; Beauregard, R. Maleic Anhydride Treated Wood: Effects of Drying Timeand Esterification Temperature on Properties. BioResources 2015, 10, 6830–6860. [Google Scholar] [CrossRef]

- Dong, Y.; Yan, Y.; Ma, H.; Zhang, S.; Li, J.; Xia, C.; Shi, S.Q.; Cai, L. In-Situ Chemosynthesis of ZnO Nanoparticles to Endow Wood with Antibacterial and UV-Resistance Properties. J. Mater. Sci. Technol. 2017, 33, 266–270. [Google Scholar] [CrossRef]

- Yuan, B.; Guo, M.; Huang, Z.; Naik, N.; Hu, Q.; Guo, Z. A UV-shielding and hydrophobic graphitic carbon nitride nanosheets/cellulose nanofibril (gCNNS/CNF) transparent coating on wood surface for weathering resistance. Prog. Org. Coat. 2021, 159, 106440. [Google Scholar] [CrossRef]

- Torcătoru, M.-J.; Timar, C.M. An experimental method to evaluate the contribution of the wood substrate and of the coating film in the global light in-duced colour changes of wood surfaces in indoors conditions. Bull. Transilv. Univ. Bras. Ser. II For.-Wood Ind.-Agric. Wood Eng. 2023, 16, 205–226. [Google Scholar] [CrossRef]

- Deka, M.; Petric, M. Photo-degradation of water borne acrylic coated modified and non-modified wood during artificial light exposure. BioResources 2008, 3, 346–362. [Google Scholar] [CrossRef]

- Liu, X.Y.; Timar, M.C.; Varodi, A.; Nedelcu, R.; Torcătoru, M.-J. Colour and Surface Chemistry Changes of Wood Surfaces Coated with Two Types of Waxes after Seven Years Exposure to Natural Light in Indoor Conditions. Coatings 2022, 12, 1689. [Google Scholar] [CrossRef]

- Available online: https://www.renneritalia.com/en/ (accessed on 13 October 2023).

- Available online: http://www.kroncolor.ro/contact.html (accessed on 18 October 2023).

- Available online: https://www.avantes.com/ (accessed on 27 October 2023).

- ISO-4582-2017; Plastics—Determination of Changes in Colour and Variations in Properties after Exposure to Glass-Filtered Solar Radiation, Natural Weathering or Laboratory Radiation Sources-Requirements. ISO: Geneva, Switzerland, 2017.

- Timar, M.C.; Beldean, E.C. Modification of Shellac with Clove (Eugenia caryophyllata) and Thyme (Satureja hortensis) Essential Oils: Compatibility Issues and Effect on the UV Light Resistance of Wood Coated Surfaces. Coatings 2022, 12, 1591. [Google Scholar] [CrossRef]

- ISO 16474-3:2013; Paints and Varnishes—Methods of Exposure to Laboratory Light Sources Part 3: Fluorescent UV Lamps. ISO: Geneva, Switzerland, 2013.

- Persze, L.; Tolvaj, L. Photodegradation of wood at elevated temperature: Colour change. J. Photochem. Photobiol. B Biol. 2012, 108, 44–47. [Google Scholar] [CrossRef]

- Duarte, I.; Rotter, A.; Malvestiti, A.; Silva, M. The role of glass as a barrier against the transmission of ultraviolet radiation: An experimental study. Photodermatol. Photoimmunol. Photomed. 2009, 25, 181–184. [Google Scholar] [CrossRef]

- Serrano, M.A.; Moreno, J.C. Spectral transmission of solar radiation by plastic and glass materials. J. Photochem. Photobiol. B 2020, 208, 111894. [Google Scholar] [CrossRef]

- Dawson, B.S.W.; Singh, A.P.; Kroese, H.W.; Schwitzer, M.A.; Gallagher, S.; Riddiough, S.J.; Wu, S. Enhancing exterior performance of clear coatings through photostabilization of wood. Part 2: Coating and weathering performance. J. Coat. Technol. Res. 2008, 5, 207–219. [Google Scholar] [CrossRef]

- Kúdela, J.; Sikora, A.; Gondáš, L. Wood Surface Finishing with Transparent Lacquers Intended for Indoor Use, and the Colour Resistance of These Surfaces during Accelerated Aging. Polymers 2023, 15, 747. [Google Scholar] [CrossRef]

- Meijer, D.M. A Review of Interfacial Aspects in Wood Coatings: Wetting, Surface Energy, Substrate Penetration and Adhesion; 2005. In Proceedings of the COST E18 FInal Seminar, Paris, France, 26–27 May 2005; Available online: https://www.researchgate.net/publication/260601859_A_review_of_interfacial_aspects_in_wood_coatings_wetting_surface_energy_substrate_penetration_and_adhesion (accessed on 7 December 2023).

- Meijer, D.M.; Thurich, K.; Militz, H. Comparative study on penetration characteristics of modern wood coatings. Wood Sci. Technol. 1998, 32, 347–365. [Google Scholar] [CrossRef]

- Meijer, D.M.; Thurich, K.; Militz, H. Quantitative measurements of capillary coating penetration in relation to wood and coating properties. Holz Als Roh-Und Werkst. 2001, 59, 35–45. [Google Scholar] [CrossRef]

- Özgenç, K.Ö.; Hiziroglu, S.; Yildiz, U. Weathering properties of wood species treated with different coating applications. BioResources 2012, 7, 4875–4888. [Google Scholar] [CrossRef]

- Kanbayashi, T.; Matsunaga, M.; Kobayashi, M.; Maeda, K. Elucidation of the degradative behavior of coated-wood surfaces exposed to artificial weathering using Raman microspectroscopy. Prog. Org. Coat. 2024, 187, 108184. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).