Selected Physical and Mechanical Properties of Subfossil Oak (Quercus spp.) Compared to Aged Oak and Recent Oak

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wood Material and Test Samples

2.2. Experimental Methods

2.2.1. Density and FSP

2.2.2. Swelling and Shrinkage

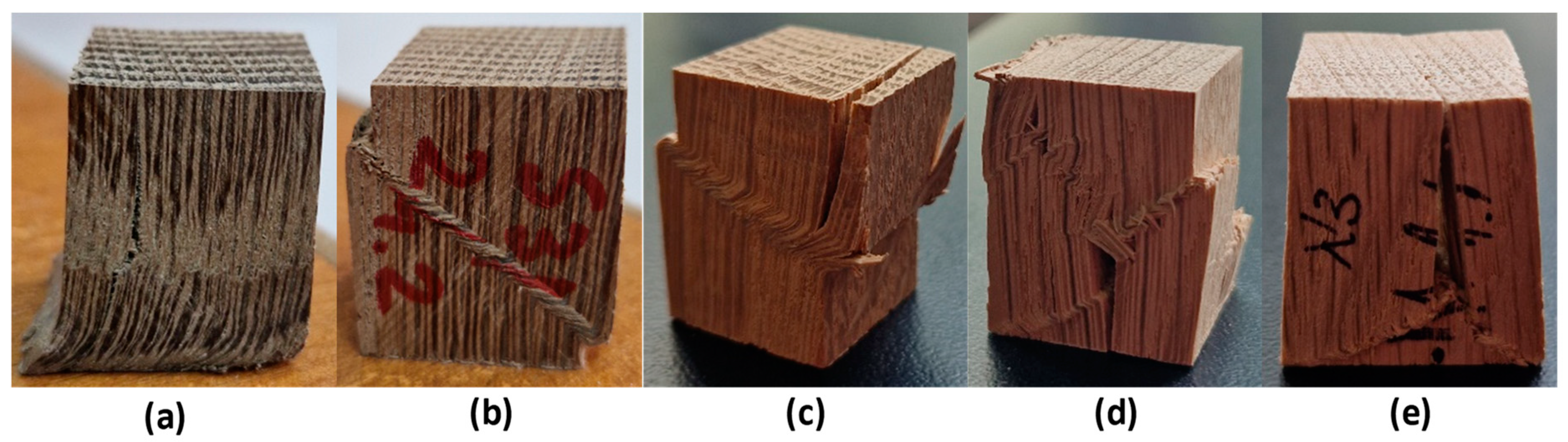

2.2.3. Compression Strength (Ultimate Stress in Compression Parallel to Grain)

2.3. Statistical Analysis

3. Experimental Results

3.1. Physical Properties of Subfossil Oak in Comparation with Aged Oak from Construction and Recent Oak

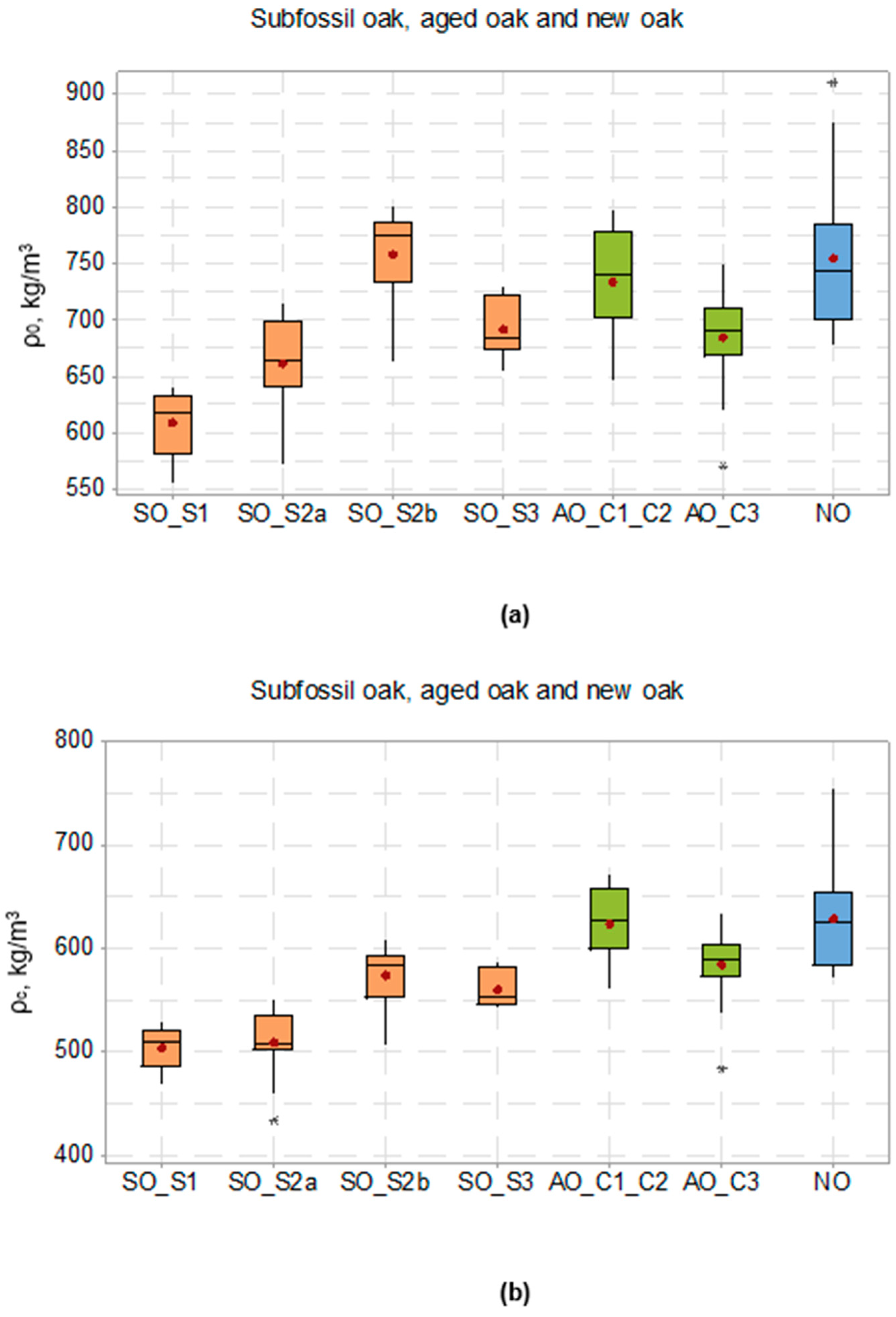

3.1.1. Wood Density

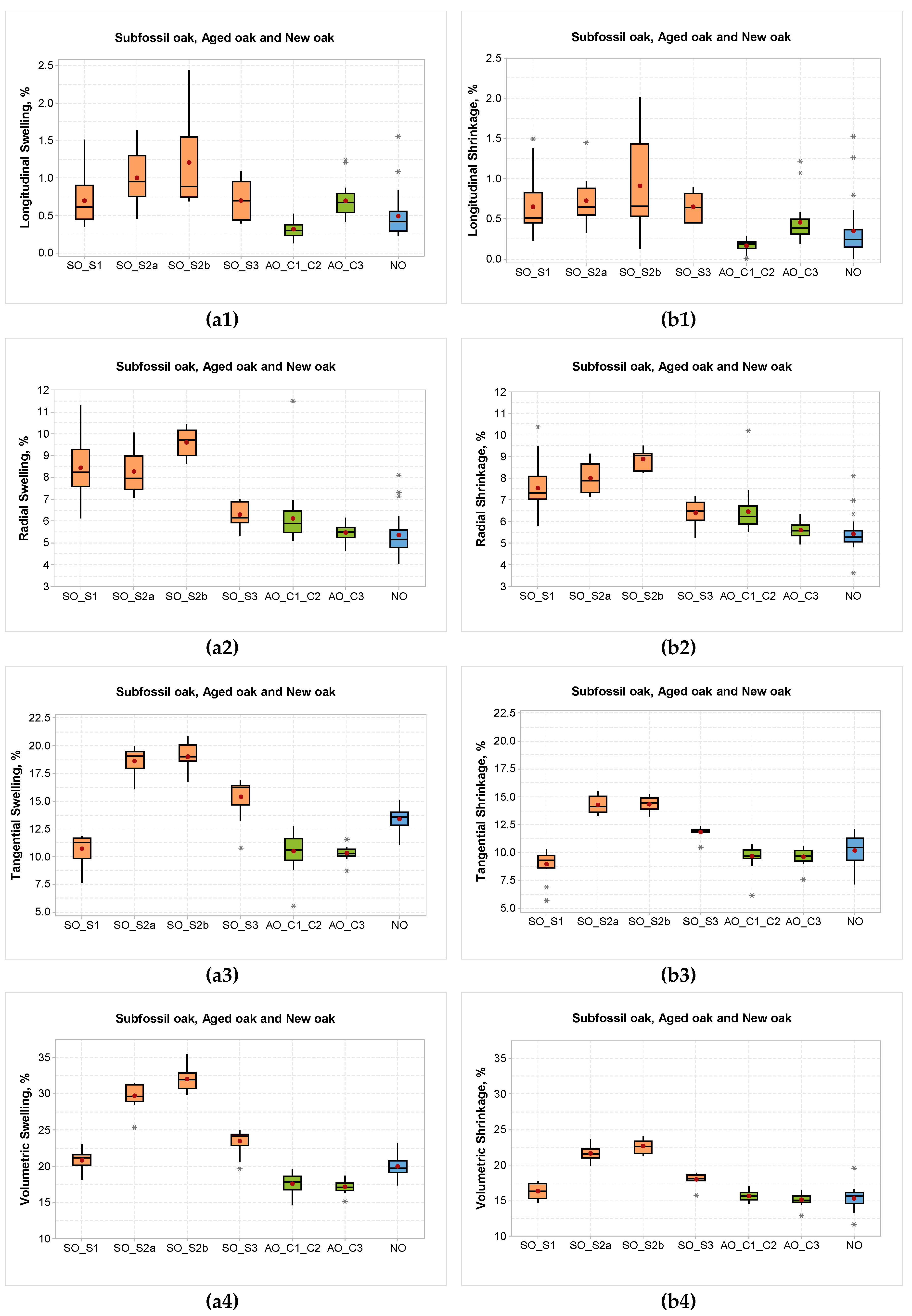

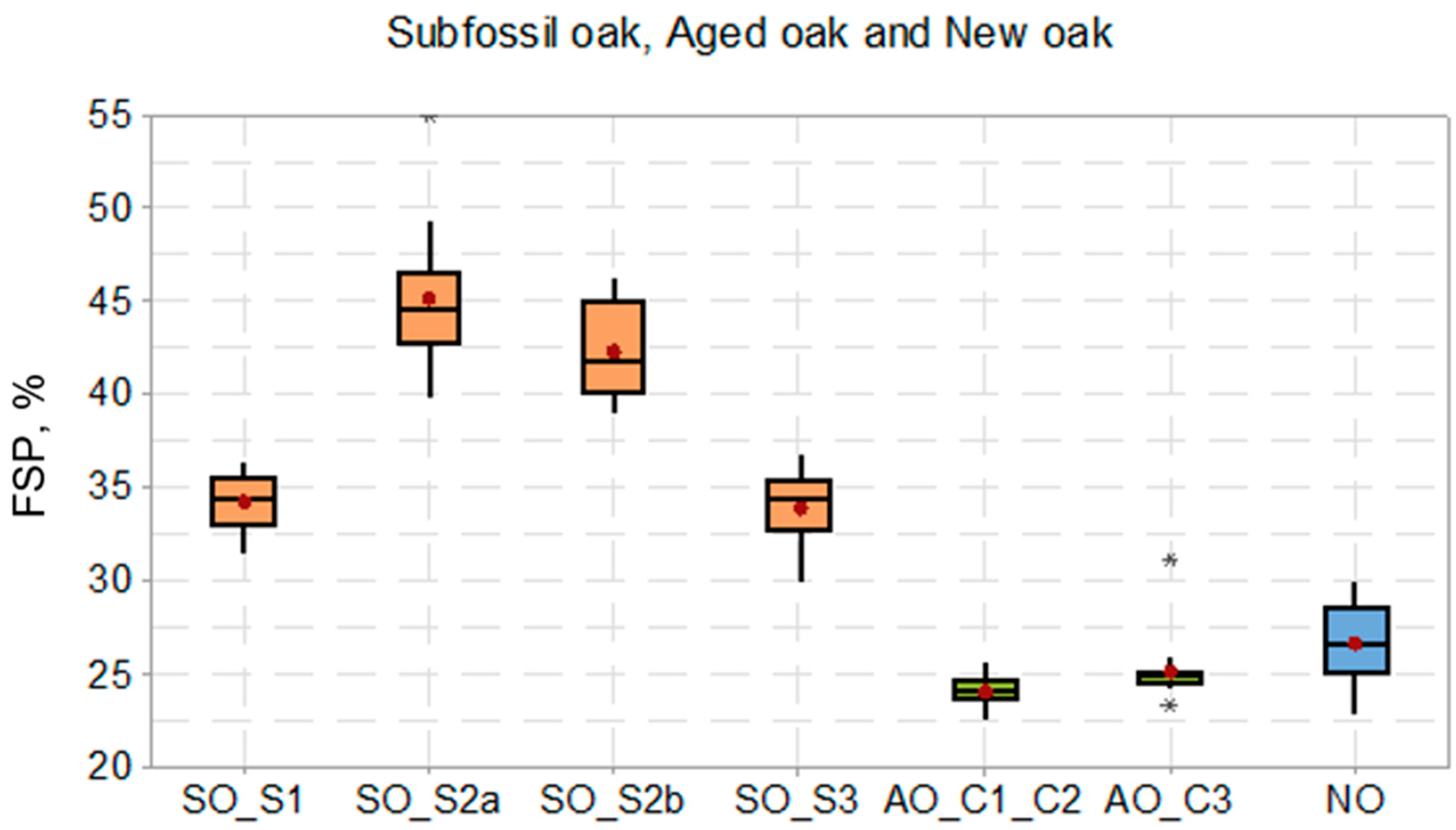

3.1.2. Swelling and Shrinkage, Anisotropy and FSP

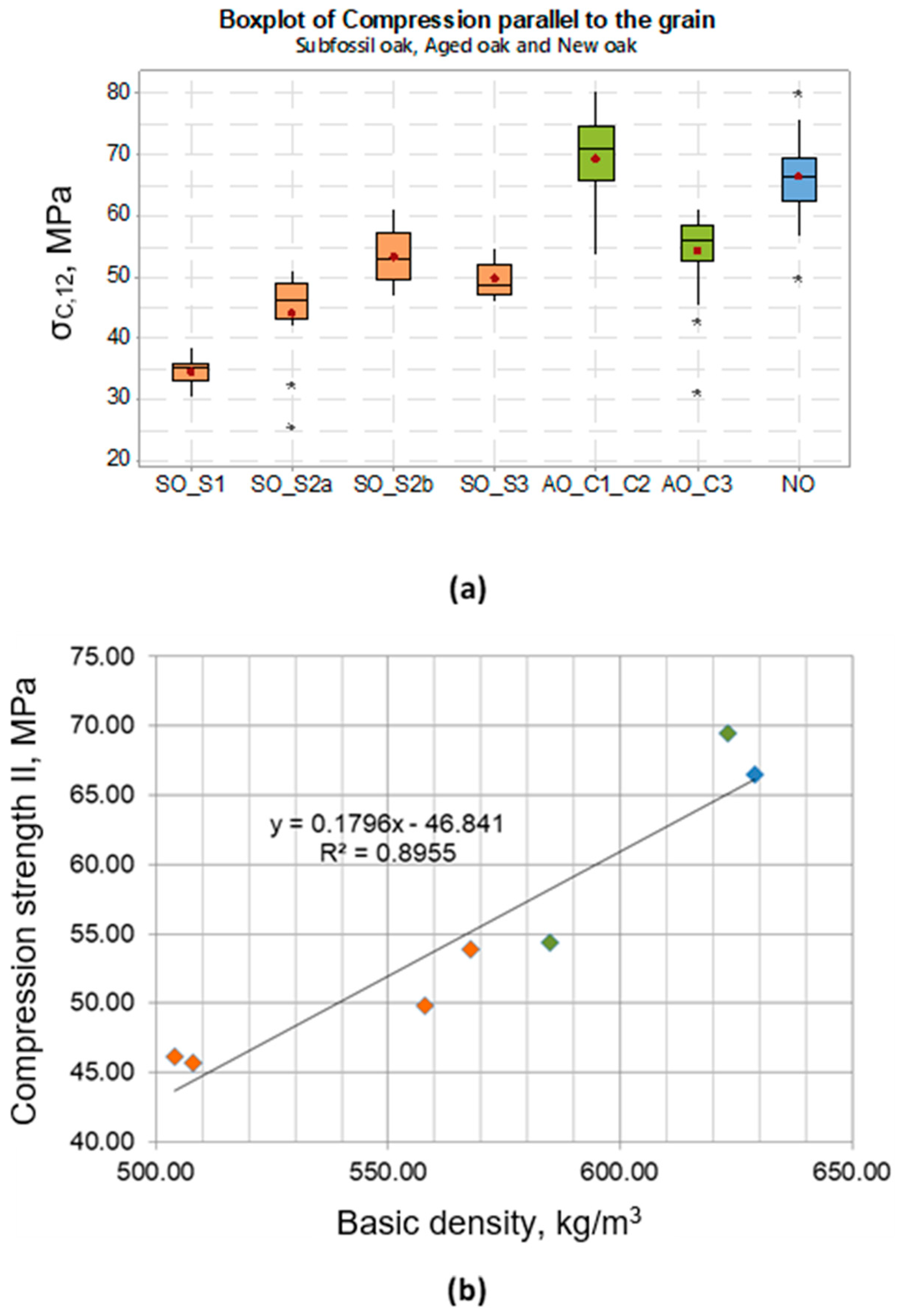

3.2. Mechanical Properties of Subfossil Oak Compared with Aged Oak from Construction and Recent Oak

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fengel, D. Aging and fossilisation of wood and its components. Wood Sci. Tehnol. 1991, 25, 153–177. [Google Scholar] [CrossRef]

- Kolář, T.; Rybníček, M. Phisical and mechanical properties of subfossil oak (Quercus, sp.) wood. Acta Univ. Agric. Silvic. Mendel. Brun. 2010, 58, 123–134. [Google Scholar] [CrossRef]

- Kolar, T.; Rybnícek, M.; Strelcová, M.; Hedbávný, J.; Vít, J. The changes in chemical composition and properties of subfossil oak deposited in holocene sediments. Wood Res. 2014, 59, 149–166. [Google Scholar]

- Baar, J.; Nevrly, O. Swelling of subfossil oak under different conditions. In Proceedings of the Iaws Plenary Meeting—Eco-Efficient Resource Wood with Special Focus on Hardwoods, Sopron, Hungary, 15–18 September 2014. [Google Scholar] [CrossRef]

- Rede, V.; Sara Essert, S.; Kocijan, M.; Dubravac, T. Influence of Ageing on Abrasion Volume Loss, Density, and Structural Components of Subfossil Oak. Appl. Sci. 2022, 12, 1814. [Google Scholar] [CrossRef]

- Ghavidel, A.; Hofmann, T.; Bak, M.; Sandu, I.; Vasilache, V. Comparative archaeometric characterization of recent and historical oak (Quercus spp.) wood. Wood Sci. Technol. 2020, 54, 1121–1137. [Google Scholar] [CrossRef]

- Kránitz, K.; Sonderegger, W.; Bues, C.T.; Niemz, P. Effects of aging on wood: A literature review. Wood Sci. Technol. 2016, 50, 7–22. [Google Scholar] [CrossRef]

- Liu, X.Y.; Timar, M.C.; Varodi, A.M.; Sawyer, G. An investigation of accelerated temperature induced ageing of four wood species: Colour and FTIR. Wood Sci. Technol. 2017, 51, 357–378. [Google Scholar] [CrossRef]

- Zisi, A. Forest Wood through the Eyes of a Cultural Conservator. Forests 2021, 12, 1001. [Google Scholar] [CrossRef]

- Ghavidel, A.; Bak, M.; Hofmann, T.; Vasilache, V.; Sandu, I. Evaluation of some wood-water relations and chemometric characteristics of recent oak and archaeological oak wood (Quercus robur) with archaeometric value. J. Cult. Herit. 2021, 51, 21–28. [Google Scholar] [CrossRef]

- Ghavidel, A.; Jorbandian, A.; Bak, M.; Gelbrich, J.; Morrell, J.J.; Sandu, I.; Hosseinpourpia, R. Degradation assessment of archaeological oak (Quercus spp.) buried under oxygen-limited condition. Holzforschung 2023, 77, 198–207. [Google Scholar] [CrossRef]

- Lisuzzo, L.; Hueckel, T.; Cavallaro, G.; Sacanna, S.; Lazzara, G. Pickering Emulsions based on Wax and Halloysite Nanotubes: An Ecofriendly Protocol for the Treatment of Archaeological Woods. CS Appl. Mater. Interfaces 2021, 13, 1651–1661. [Google Scholar] [CrossRef] [PubMed]

- Borgin, K.; Tsoumis, G.; Passialis, G. Density and shrinkage of old wood. Wood Sci. Tehnol. 1979, 13, 49–57. [Google Scholar] [CrossRef]

- Schwab, E. Holzeigenschaften einer Subfossile Eiche. Holz Als Roh-Und Werkst. 1994, 52, 210. [Google Scholar] [CrossRef]

- Krapiek, M. Holocene Dendrochronological standards for subfossil oaks from the area of Southern Poland. Stud. Quat. 2001, 18, 47–63. [Google Scholar]

- Klusek, M.; Pavelczyk, S. Stable carbon isotope analysis of subfossil wood from Austrian Alps. Geochronometria 2014, 41, 400–408. [Google Scholar] [CrossRef] [PubMed]

- Kolář, T. Oak Wood Properties Change on Ana Example of Subfossil Trunks. Dissertation, Mendel University, Brno, Czech Republic, 31 January 2012. [Google Scholar]

- Kolář, T.; Gryc, V.; Rybníček, M.; Vavrčík, H. Anatomical analysis and species identification of subfossil oak wood. Wood Res. 2012, 57, 251–264. [Google Scholar]

- Baar, J.; Paschová, Z.; Hofmann, T.; Kolář, T.; Koch, G.; Saake, B.; Rademacher, P. Natural durability of subfossil oak: Wood chemical composition changes through the ages. Holzforschung 2020, 74, 47–59. [Google Scholar] [CrossRef]

- Mañkowski, P.; Kozakiewicz, P.; Drodek, M. The selected properties of fossil oak wood from medieval burgh in P£oñsk. Wood Res. 2016, 61, 287–298. [Google Scholar]

- Veizović, M.; Popović, Z.; Todorović, N.; Milić, G. Drying quality and colour of subfossil oak from Central Serbia. Glasnik Sumarskog fakulteta 2018, 2018, 157–172. [Google Scholar] [CrossRef]

- Urso, T.; Martinelli, N.; Pignatelli, O.; Scortegagna, T. The subfossil trunk of Chiarano (TV). Conserv. Sci. Cult. Herit. 2018, 15, 41–52. [Google Scholar] [CrossRef]

- Meneghello, C. Bog Oak: Physico-mechanical and Chemical Characterization of Two Logs from Venetian Plan. In Proceedings of the XI Congresso Nazionale AIAr, Napoli, Italy, 28–30 July 2021. [Google Scholar] [CrossRef]

- Sinkovic, T.; Govorcin, S.; Dubravac, T.; Roth, V.; Sedlar, T. Comparison some physical and mechanical properties of abonos and recent oak (Quercus robur L.). Šumarski List 2009, 891, 605–611. [Google Scholar]

- Giagli, K.; Baar, J.; Fajstavr, M.; Gryc, V.; Vavrcik, H. Tree-ring width variation of wood density in Fraxinus excelsior L. and Quercus robur L. growing in Floodplain Forests. BioResources 2018, 13, 804–819. [Google Scholar] [CrossRef]

- Arvai, M.; Popa, I.; Mîndrescu, M.; Nagy, B.; Kern, Z. Dendrochronological assessment and radiocarbon dating of subfossil coniferous macroremains excavated from a peat bog, Maramures Mts, Romania. In Proceedings of the Late Pleistocene and Holocene Climatic Variability in the Carpathian Balkan Region, Cluj/Kolozsvár, Romania, 6–9 November 2014; Stefan cel Mare University Press: Suceava, Romania, 2014. [Google Scholar]

- Radoane, M.; Nechita, C.; Chiriloaei, F.; Rădoane, N.; Popa, I.; Roibu, C.; Robu, D. Late Holocene fluvial activity and correlations with dendrochronology of subfossil trunks: Case studies of north-eastern Romania. Geomorphology 2015, 239, 142–159. [Google Scholar] [CrossRef]

- Kern, Z.; Popa, I. Dendrochronological and radiocarbon analyses of subfossil oaks from the foothills of the Romanian Carpathian. Geochronometria 2016, 543, 113–120. [Google Scholar] [CrossRef]

- Ghavidel, A.; Gelbrich, J.; Ku, A.; Vasilache, V.; Sandu, I. Investigation of Archaeological European White Elm (Ulmus laevis) for Identifying and Characterizing the Kind of Biological Degradation. Heritage 2023, 3, 60. [Google Scholar] [CrossRef]

- EN 335:2013; Durability of Wood and Wood-Based Products—Use Classes: Definitions, Application to Solid Wood and Wood-Based Products. BSI Standards Publication: London, UK, 2013.

- Filipovici, J. Study of Wood, Vol II; Didactic Publishing House: Bucharest, Romania, 1965. (In Romanian) [Google Scholar]

- Deaconu, I.; Porojan, M.; Timar, M.C.; Bedelean, B.; Campean, M. Comparative Research on the Structure, Chemistry, and Physical Properties of Turkey Oak and Sessile Oak Wood. BioResources 2023, 18, 5724–5749. [Google Scholar] [CrossRef]

- ISO 13061-13:2016; Physical and Mechanical Properties of Wood. Test Methods for Small Clear Wood Specimens. Part 13: Deter. Determination of Radial and Tangential Shrinkage. ISO: Geneva, Switzerland, 2016.

- ISO 13061-14:2016; Physical and Mechanical Properties of Wood. Test Methods for Small Clear Wood Specimens. Part 14: Determination of Volumetric Shrinkage. ISO: Geneva, Switzerland, 2016.

- ISO 13061-15:2017; Physical and Mechanical Properties of Wood. Test Methods for Small Clear Wood Specimens. Part 15: Determination of Radial and Tangential Swelling. ISO: Geneva, Switzerland, 2016.

- ISO 13061-16:2017; Physical and Mechanical Properties of Wood. Test Methods for Small Clear Wood Specimens. Part 16: Determination of Volumetric Swelling. ISO: Geneva, Switzerland, 2016.

- ISO 13061-17:2017; Physical and Mechanical Properties of Wood. Test Methods for Small Clear Wood Specimens. Part 17: Determination of Ultimate Stress in Compression Parallel to Grain. ISO: Geneva, Switzerland, 2016.

- Wagenführ, R. Holzatlas (Wood atlas); Fachbuchverlag Leipzig im Carl Hanser Verlag: München, Germany, 2007; pp. 255–264. [Google Scholar]

- Kollmann, F.F.P.; Cote, W.A., Jr. Principles of Wood Science and Technology, Vol I. Solid Wood; Springer: Berlin/Heidelberg, Germany; GmbH & Co. KG: Hamburg, Germany, 2012; 592p, ISBN 9783642879302. [Google Scholar]

- Lucejko, J.J.; Tamburini, D.; Zborowska, M.; Babiński, L.; Modugno, F.; Colombini, M.P. Oak wood degradation processes induced by the burial environment in the archaeological site of Biskupin (Poland). Herit. Sci. 2020, 8, 44. [Google Scholar] [CrossRef]

- Clair, B.; Thibaut, B. Physical and Mechanical Properties of Reaction Wood. The Biology of Reaction Wood; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 2014; 249p, ISBN 978-3-642-10813-6. [Google Scholar] [CrossRef]

- Badel, E.; Bakour, R.; Perre, P. Investigation of the relationships between anatomical pattern, density and local swelling of oak wood. IAWA J. 2006, 27, 55–71. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, J.; Zhou, Y.; Zhao, Y.; Zhao, L. Compression strength and modulus of elasticity parallel to the grain of oak wood at ultra-low and high temperatures. BioResources 2014, 9, 3571–3579. [Google Scholar] [CrossRef]

| Wood Material | NOR | ρ0, kg/m3 | ρc, kg/m3 |

|---|---|---|---|

| SO_S1 | 15 | 609 ± 28 | 504 ± 19 |

| SO_S2a | 13 | 658 ± 48 | 508 ± 36 |

| SO_S2b | 12 | 752 ± 47 | 568 ± 32 |

| SO_S3 | 10 | 690 ± 29 | 558 ± 19 |

| AO_C1_C2 | 25 | 733 ± 47 | 623 ± 34 |

| AO_C3 | 20 | 685 ± 39 | 585 ± 32 |

| NO | 27 | 755 ± 63 | 629 ± 49 |

| Wood Material | Total Swelling | Total Shrinkage | ||||||

|---|---|---|---|---|---|---|---|---|

| σL max, | αRa max, | αTg max, | αV max, | βL max, | βRa max, | βTg max, | βV max, | |

| % | % | % | % | % | % | % | % | |

| SO_S1 | 0.7 ± 0.3 | 8.4 ± 1.5 | 10.7 ± 1.3 | 20.9 ± 1.4 | 0.7 ± 0.4 | 7.6 ± 1.2 | 9.0 ± 1.2 | 16.4 ± 1.0 |

| SO_S2a | 1.0 ± 0.3 | 8.5 ± 1.0 | 18.4 ± 1.2 | 29.6 ± 1.8 | 0.7 ± 0.3 | 8.0 ± 0.7 | 14.3 ± 0.8 | 21.7 ± 1.1 |

| SO_S2b | 1.2 ± 0.7 | 9.4 ± 0.7 | 19.5 ± 0.8 | 32.4 ± 1.7 | 0.9 ± 0.6 | 8.9 ± 0.5 | 14.4 ± 0.6 | 22.7 ± 1.0 |

| SO_S3 | 0.6 ± 0.3 | 6.4 ± 0.6 | 15.4 ± 2.1 | 23.6 ± 1.8 | 0.7 ± 0.2 | 6.4 ± 0.6 | 11.9 ± 0.5 | 18.0 ± 0.9 |

| AO_C1_C2 | 0.3 ± 0.1 | 6.1 ± 1.3 | 10.5 ± 1.5 | 17.6 ± 1.4 | 0.2 ± 0.1 | 6.5 ± 0.9 | 9.7 ± 0.9 | 15.6 ± 0.7 |

| AO_C3 | 0.7 ± 0.2 | 5.5 ± 0.4 | 10.3 ± 0.6 | 17.1 ± 0.8 | 0.5 ± 0.3 | 5.6 ± 0.4 | 9.7 ± 0.7 | 15.1 ± 0.8 |

| NO | 0.5 ± 0.3 | 5.4 ± 0.9 | 13.4 ± 1.0 | 20.0 ± 1.4 | 0.4 ± 0.4 | 5.4 ± 0.8 | 10.2 ± 1.3 | 15.3 ± 1.5 |

| Wood Material | FSP, % | Swelling Coefficients for 1% W Variation | Shrinkage Coefficients for 1% W Variation | |||||

|---|---|---|---|---|---|---|---|---|

| Kα,Ra, % | Kα,Tg, % | Kα,V, % | Kβ,L, % | Kβ,Ra, % | Kβ,Tg, % | Kβ,V, % | ||

| SO_S1 | 34 | 0.25 | 0.31 | 0.61 | 0.02 | 0.22 | 0.26 | 0.48 |

| SO_S2a | 45 | 0.19 | 0.41 | 0.66 | 0.02 | 0.18 | 0.32 | 0.48 |

| SO_S2b | 43 | 0.22 | 0.45 | 0.75 | 0.02 | 0.21 | 0.33 | 0.53 |

| SO_S3 | 34 | 0.19 | 0.45 | 0.69 | 0.02 | 0.19 | 0.35 | 0.53 |

| AO_C1_C2 | 24 | 0.25 | 0.44 | 0.73 | 0.01 | 0.27 | 0.40 | 0.65 |

| AO_C3 | 25 | 0.22 | 0.41 | 0.68 | 0.02 | 0.22 | 0.38 | 0.60 |

| NO | 27 | 0.20 | 0.50 | 0.75 | 0.01 | 0.20 | 0.38 | 0.58 |

| Wood Material | NOR | σc,12 | Strain at Break Point, | Modulus of Elasticity, Ec | ||

|---|---|---|---|---|---|---|

| Min | Mean | Max | ||||

| MPa | mm/mm | MPa | MPa | MPa | ||

| SO_S1 | 15 | 46 ± 3 | 0.020–0.023 | 3806 | 4144 | 4808 |

| SO_S2a | 13 | 46 ± 8 | 0.020–0.023 | 2937 | 3765 | 4494 |

| SO_S2b | 13 | 54 ± 5 | 0.023–0.027 | 3432 | 3523 | 3832 |

| SO_S3 | 12 | 50 ± 3 | 0.020–0.023 | 3197 | 3585 | 3708 |

| AO_C1_C2 | 31 | 69 ± 7 | 0.023–0.030 | 2236 | 4706 | 5334 |

| AO_C3 | 20 | 54 ± 7 | 0.020–0.033 | 1594 | 3854 | 4579 |

| NO_N | 29 | 66 ± 6 | 0.020–0.033 | 4680 | 4887 | 5114 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nedelcu, R.; Timar, M.C.; Porojan, M.; Beldean, E.C. Selected Physical and Mechanical Properties of Subfossil Oak (Quercus spp.) Compared to Aged Oak and Recent Oak. Appl. Sci. 2024, 14, 3294. https://doi.org/10.3390/app14083294

Nedelcu R, Timar MC, Porojan M, Beldean EC. Selected Physical and Mechanical Properties of Subfossil Oak (Quercus spp.) Compared to Aged Oak and Recent Oak. Applied Sciences. 2024; 14(8):3294. https://doi.org/10.3390/app14083294

Chicago/Turabian StyleNedelcu, Ruxandra, Maria Cristina Timar, Mihaela Porojan, and Emanuela Carmen Beldean. 2024. "Selected Physical and Mechanical Properties of Subfossil Oak (Quercus spp.) Compared to Aged Oak and Recent Oak" Applied Sciences 14, no. 8: 3294. https://doi.org/10.3390/app14083294

APA StyleNedelcu, R., Timar, M. C., Porojan, M., & Beldean, E. C. (2024). Selected Physical and Mechanical Properties of Subfossil Oak (Quercus spp.) Compared to Aged Oak and Recent Oak. Applied Sciences, 14(8), 3294. https://doi.org/10.3390/app14083294