Study on Gas Extraction Technology for Goaf Using L-Shaped Borehole on the Ground

Abstract

:1. Introduction

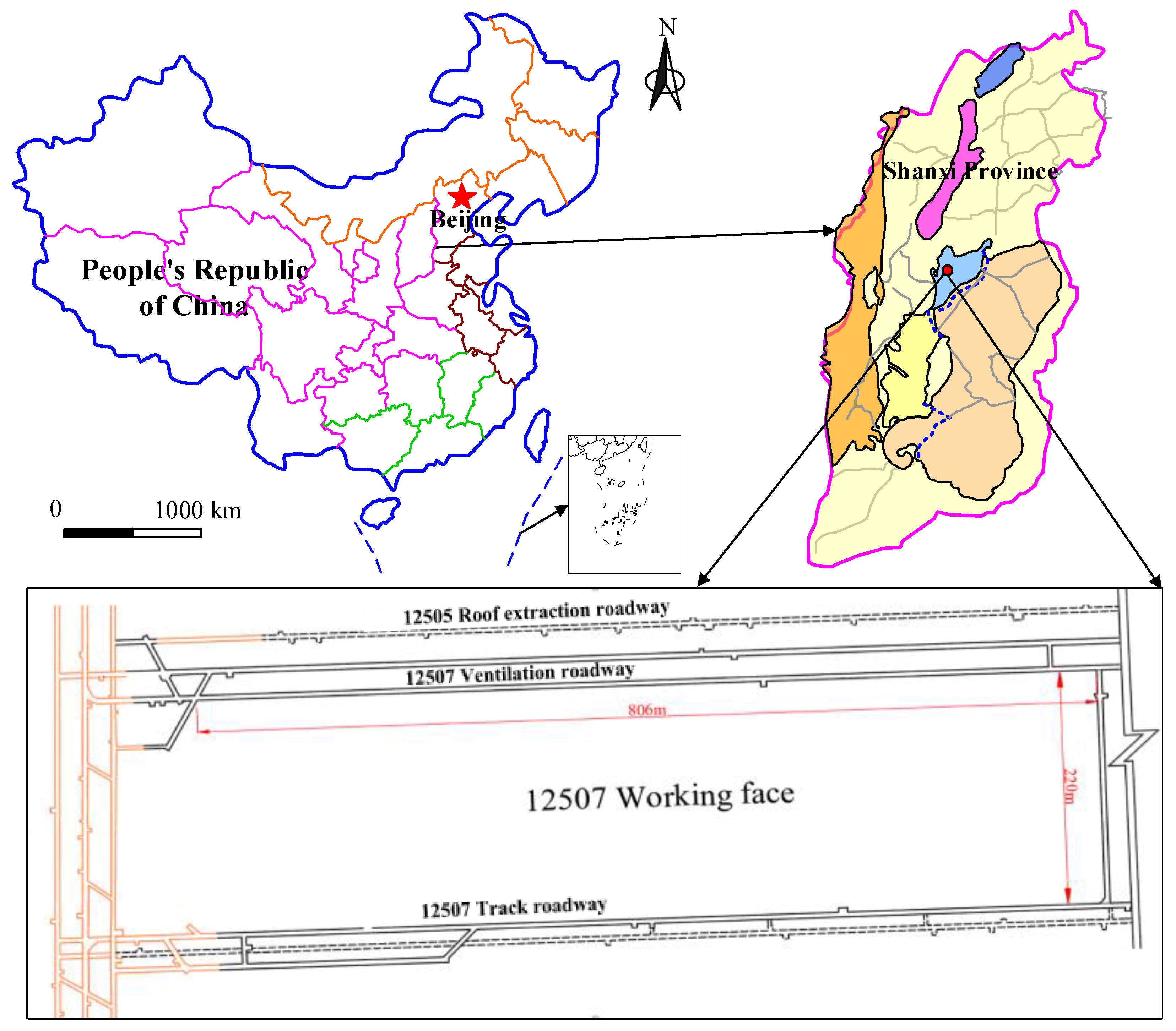

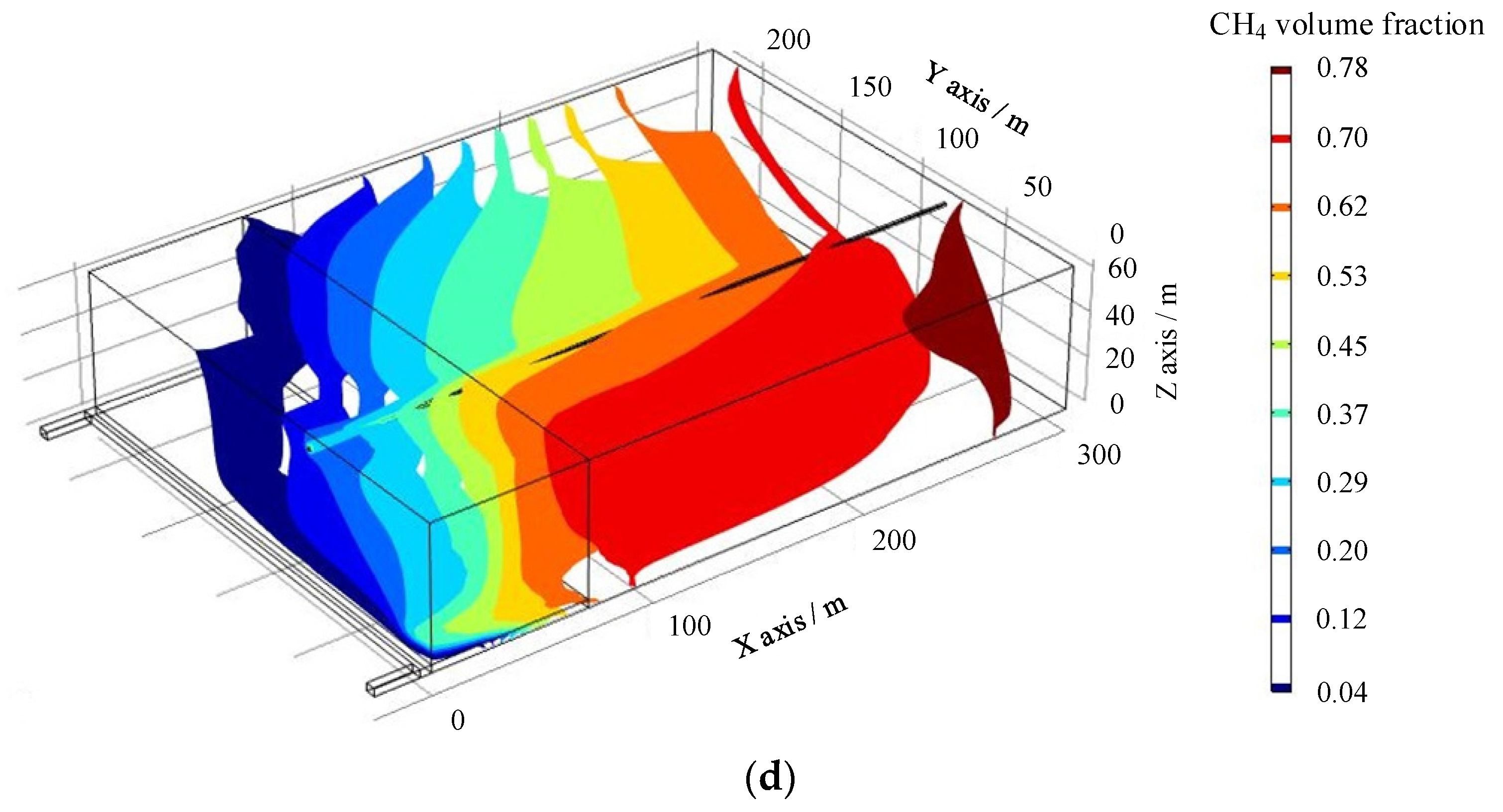

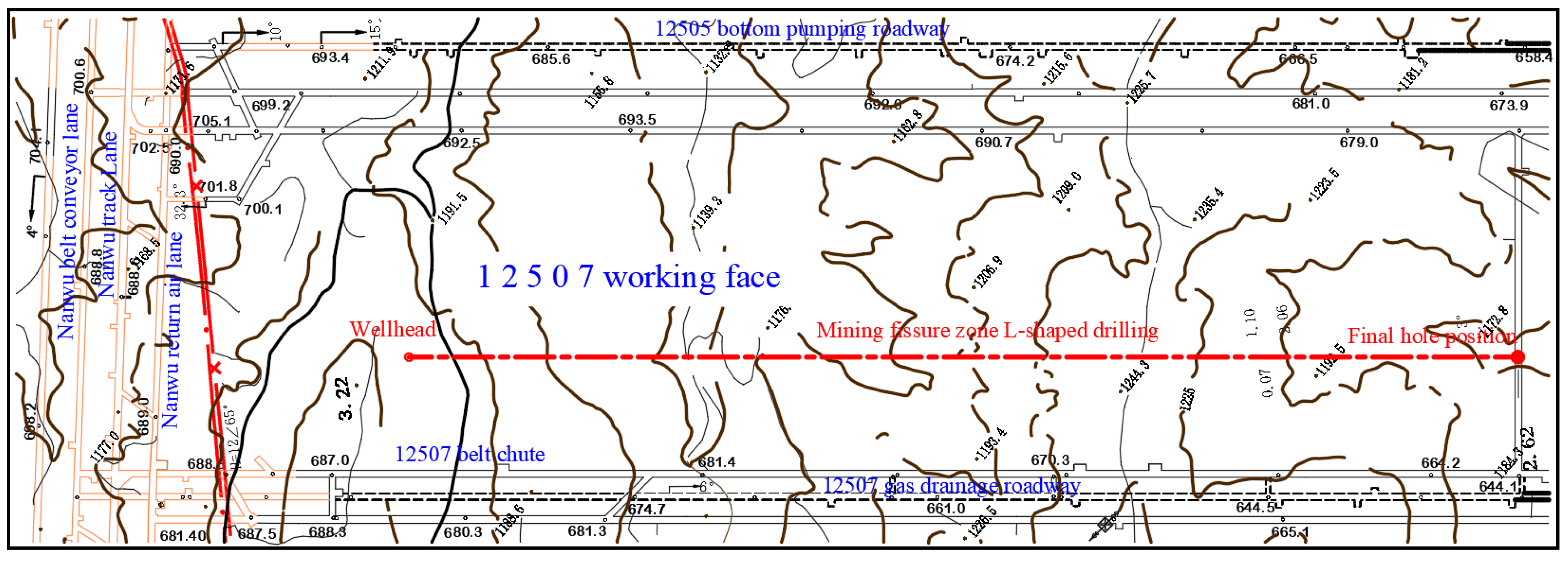

2. Overview of Mining Area

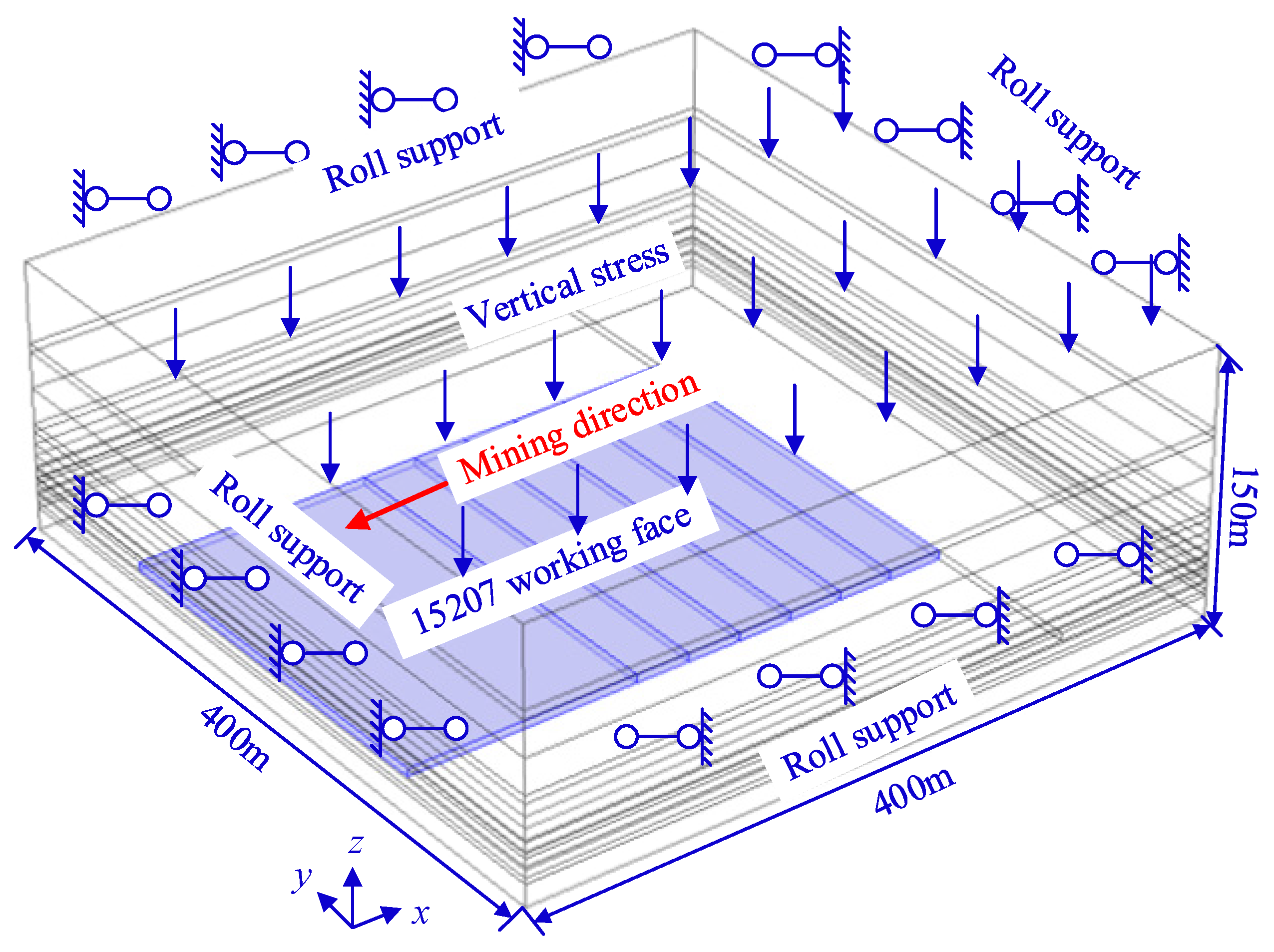

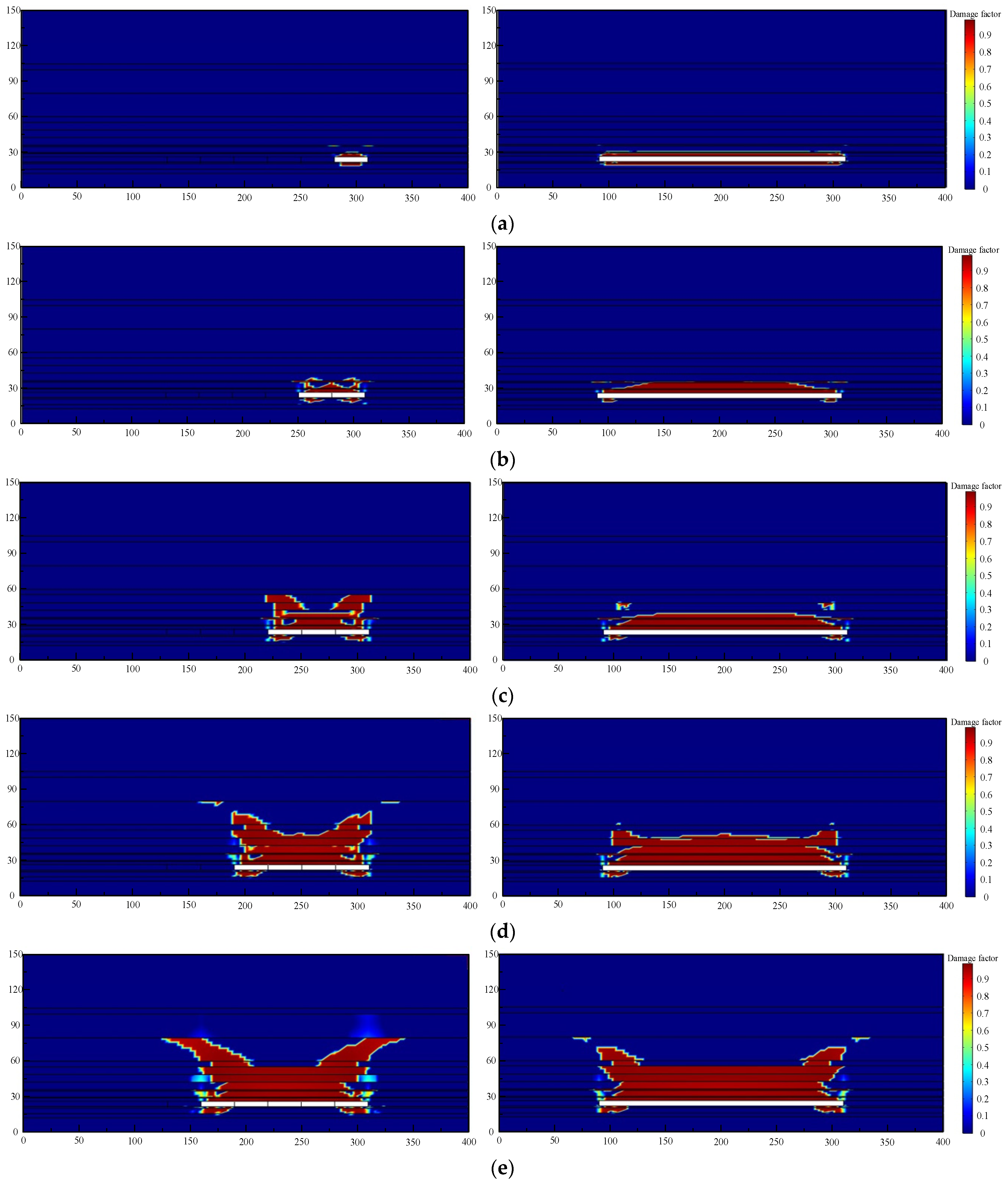

3. Study on the Failure Law of Mining Overburden

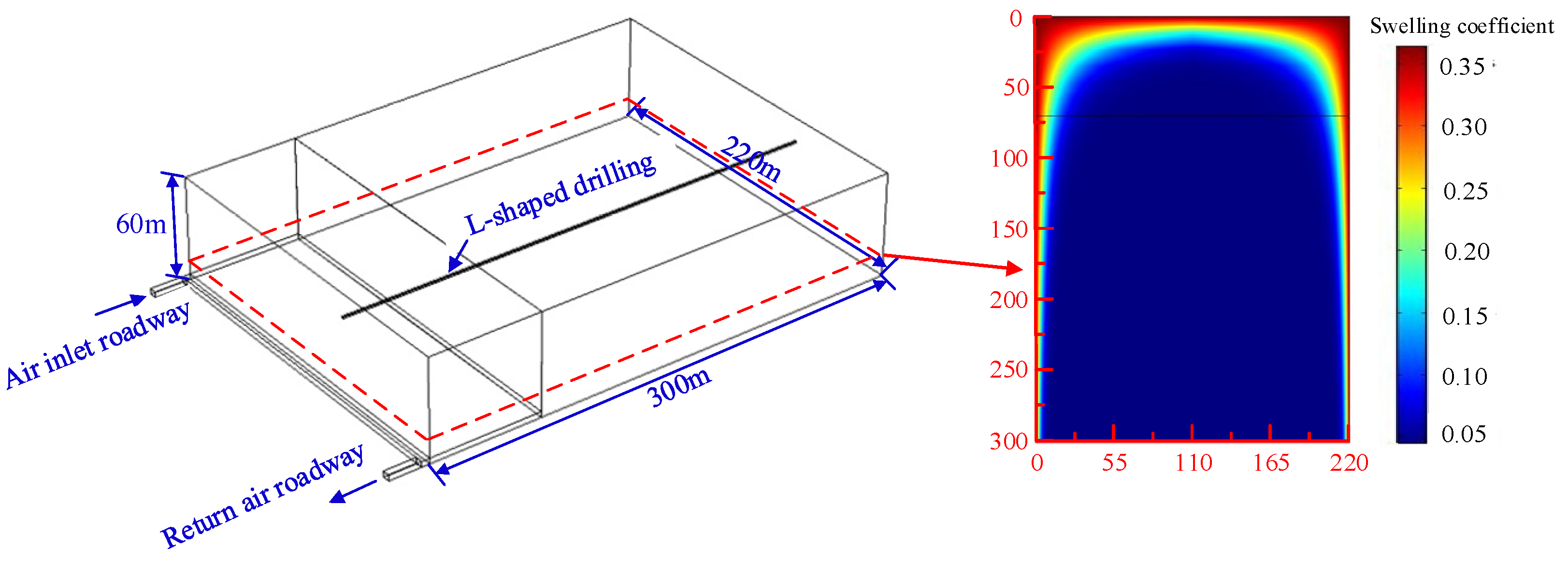

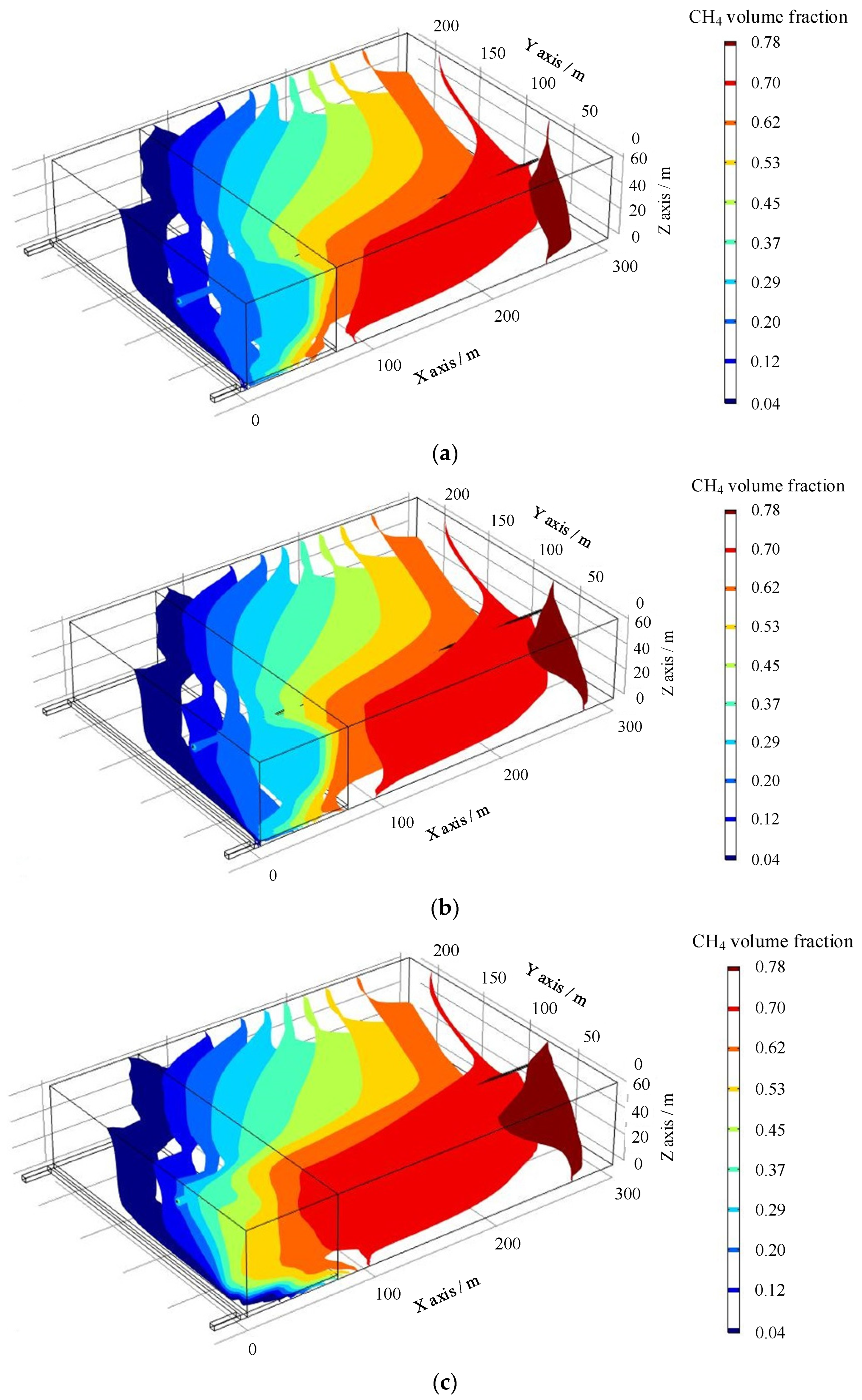

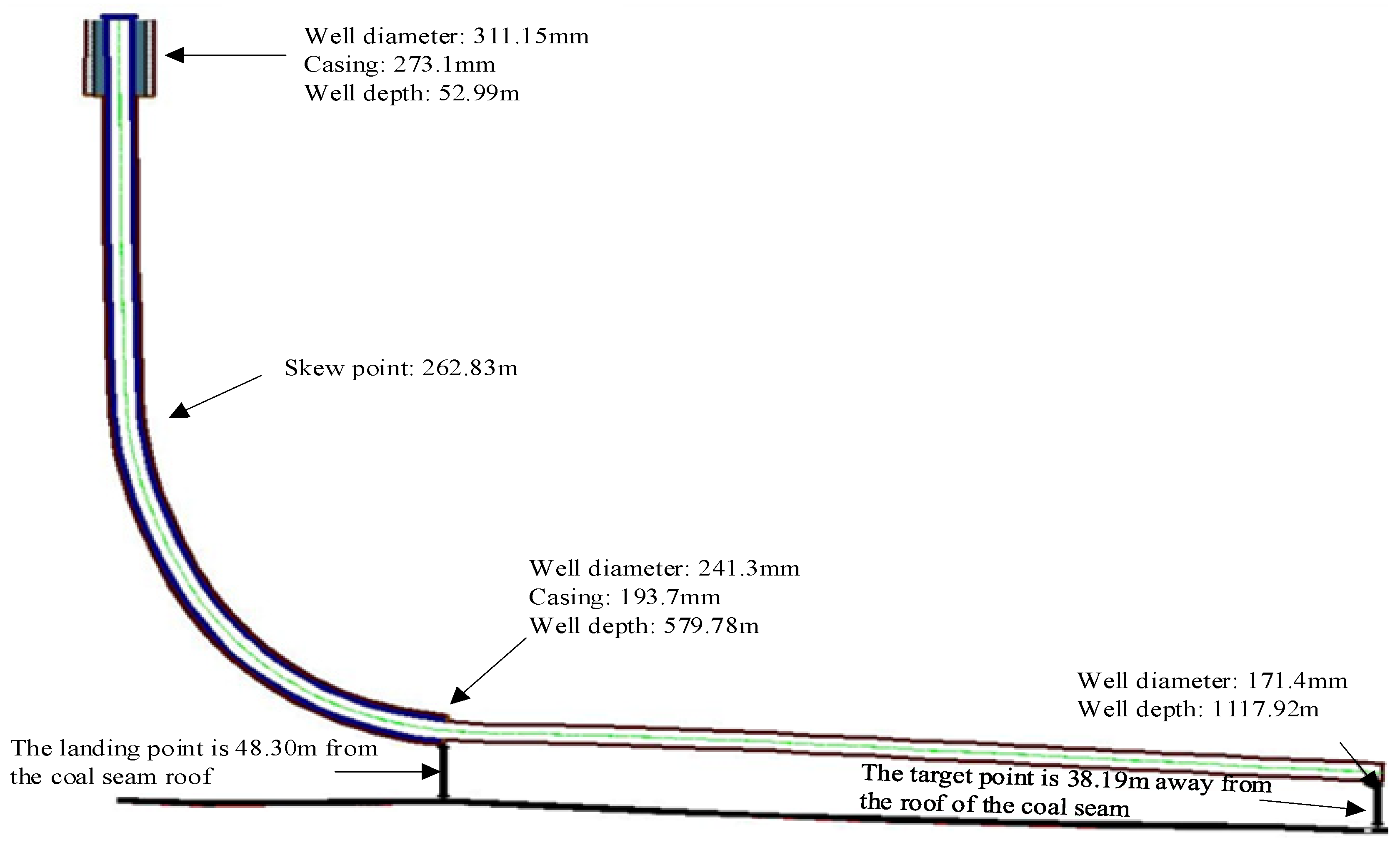

4. Numerical Simulation Study on Gas Extraction of L-Shaped Borehole in Mining Fissure Zone

4.1. Mathematical Model of Gas Migration in Mining Overburden

4.1.1. Gas Transport Equation

4.1.2. Gas Flow Equation in the Goaf

4.1.3. Gas Diffusion Equation

4.2. Physical Model Building

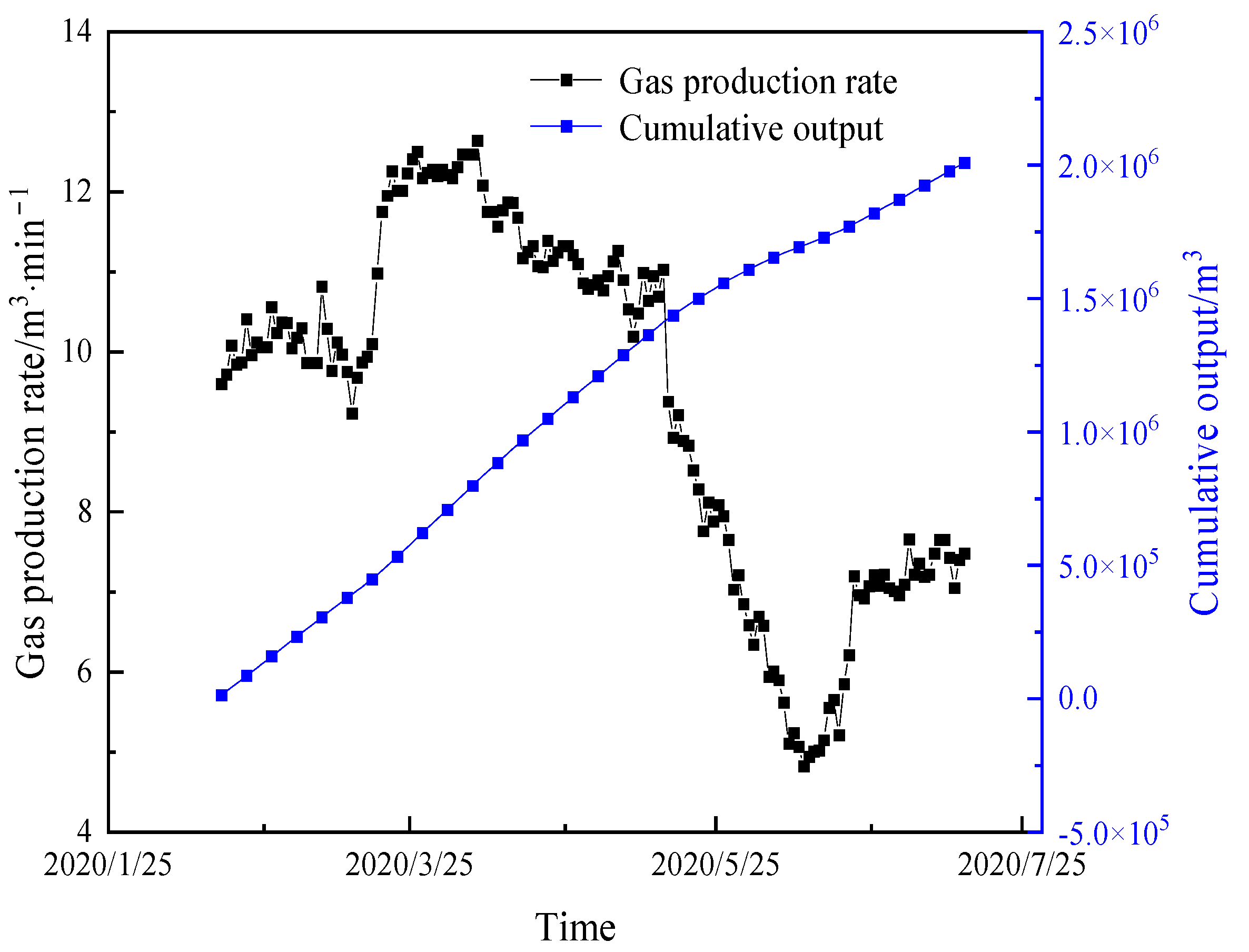

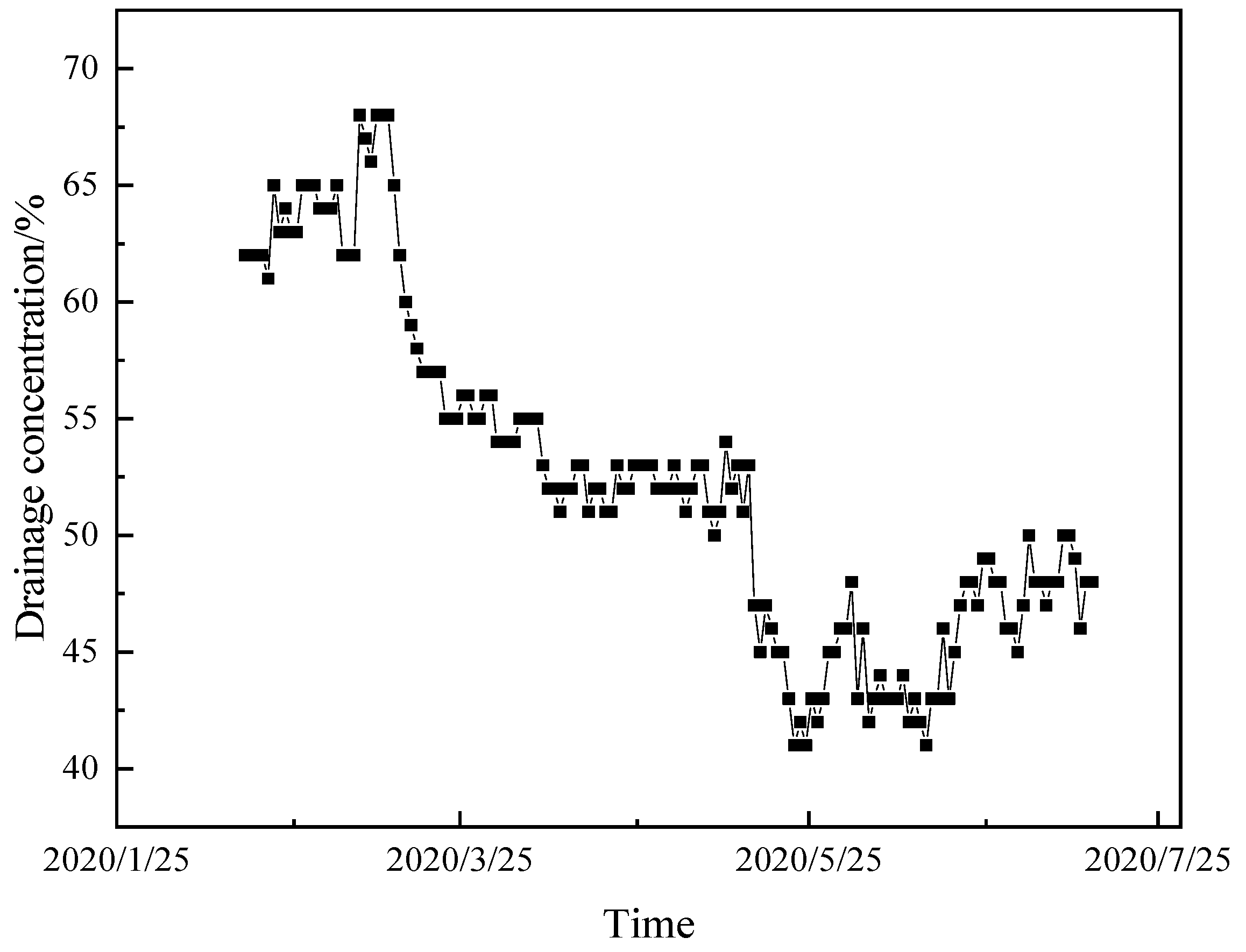

5. Analysis of Gas Extraction Effect in Goaf of L-Shaped Borehole in Mining Fissure Zone

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kao, X.; Wang, W.; Zhu, X.; Zhang, J. Spatial and Temporal Characteristics of Coal Consumption and Carbon Emissions in China. Environ. Sci. Pollut. Res. 2023, 30, 105770–105780. [Google Scholar] [CrossRef]

- Fan, Y.; Deng, C.; Zhang, X.; Li, F.; Wang, X.; Qiao, L. Numerical Study of CO2-Enhanced Coalbed Methane Recovery. Int. J. Greenh. Gas Control 2018, 76, 12–23. [Google Scholar] [CrossRef]

- Shu, L.; Wang, K.; Liu, Z.; Zhao, W.; Zhu, N.; Lei, Y. A Novel Physical Model of Coal and Gas Outbursts Mechanism: Insights into the Process and Initiation Criterion of Outbursts. Fuel 2022, 323, 124305. [Google Scholar] [CrossRef]

- Gao, A.; Qin, B.; Zhang, L.; Ma, D.; Li, L. Experimental Study on Gas Migration Laws at Return Air Side of Goaf under High-Temperature Conditions. Combust. Sci. Technol. 2023, 195, 1930–1944. [Google Scholar] [CrossRef]

- Ren, T.X.; Balusu, R. Proactive Goaf Inertisation for Controlling Longwall Goaf Heatings. Procedia Earth Planet. Sci. 2009, 1, 309–315. [Google Scholar] [CrossRef]

- Wang, Y.; Si, G.; Oh, J.; Belle, B. CFD Modelling of Longwall Goaf Atmosphere under Vertical Boreholes Gas Drainage. Int. J. Coal Geol. 2023, 280, 104400. [Google Scholar] [CrossRef]

- Si, G.; Belle, B. Performance Analysis of Vertical Goaf Gas Drainage Holes Using Gas Indicators in Australian Coal Mines. Int. J. Coal Geol. 2019, 216, 103301. [Google Scholar] [CrossRef]

- Ma, Q.; Xue, J.; Shi, Y.; Zeng, X. Characteristics of Porosity Distribution and Gas Migration in Different Layers of Comprehensive Working Face Goaf. Energies 2023, 16, 2325. [Google Scholar] [CrossRef]

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.; Sun, Y.; Liu, J. Recent Developments in Coal Mine Methane Extraction and Utilization in China: A Review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Xu, C.; Wang, K.; Li, X.; Yuan, L.; Zhao, C.; Guo, H. Collaborative Gas Drainage Technology of High and Low Level Roadways in Highly-Gassy Coal Seam Mining. Fuel 2022, 323, 124325. [Google Scholar] [CrossRef]

- Chai, J. Study on Gas Control in Goaf of High Gas Coal Seam: A Case Study of Tingnan Coal Mine, China. Geofluids 2022, 2022, 5262173. [Google Scholar] [CrossRef]

- Lei, Y. Movement Law of Methane Drained by Large-Diameter Borehole Drilling Machine in the Goaf. Processes 2022, 10, 1669. [Google Scholar] [CrossRef]

- Wang, Y.; Si, G.; Xiang, Z.; Oh, J.; Belle, B.; Webb, D. A Theoretical Goaf Resistance Model Based on Gas Production Analysis in Goaf Gas Drainage. Int. J. Coal Geol. 2022, 264, 104140. [Google Scholar] [CrossRef]

- Qu, Q.; Guo, H.; Loney, M. Analysis of Longwall Goaf Gas Drainage Trials with Surface Directional Boreholes. Int. J. Coal Geol. 2016, 156, 59–73. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, S.; Wang, Y. Research and Application of Drainage Parameters for Gas Accumulation Zone in Overlying Strata of Goaf Area. Saf. Sci. 2012, 50, 778–782. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, S.; Qin, Y.; Hu, X.; Cheng, J. Experimental Study on the Goaf Flow Field of the “U + I” Type Ventilation System for a Comprehensive Mechanized Mining Face. Int. J. Min. Sci. Technol. 2015, 25, 1003–1010. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, Y. A Mathematical Model to Study the Coupling Effect of Deformation-Seepage-Heat Transfer on Coalbed Methane Transport and Its Simulative Application. Math. Probl. Eng. 2020, 2020, 1247240. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Z.; Zhu, D.; Yang, W.; Zhao, D.; Wang, W. Study on the Fractal Characteristics of Coal Body Fissure Development and the Law of Coalbed Methane Migration of around the Stope. Geofluids 2020, 2020, 9856904. [Google Scholar] [CrossRef]

- Liu, Q.; Lin, B.; Zhou, Y.; Li, Y. Porosity Model of the Goaf Based on Overlying Strata Movement and Deformation. Environ. Earth Sci. 2022, 81, 214. [Google Scholar] [CrossRef]

- Dou, L.; Yang, K.; Liu, W.; Chi, X. Mining-Induced Stress-Fissure Field Evolution and the Disaster-Causing Mechanism in the High Gas Working Face of the Deep Hard Strata. Geofluids 2020, 2020, 8849666. [Google Scholar] [CrossRef]

- Wang, G.; Xu, H.; Wu, M.; Wang, Y.; Wang, R.; Zhang, X. Porosity Model and Air Leakage Flow Field Simulation of Goaf Based on DEM-CFD. Arab. J. Geosci. 2018, 11, 148. [Google Scholar] [CrossRef]

- Tian, S.; Mao, J.; Li, H. Porosity Distribution Law of Overlying Strata in the Goaf of the Adjacent Working Face: From the Perspective of Section Coal Pillar Types. Minerals 2022, 12, 782. [Google Scholar] [CrossRef]

- Qin, Z.; Yuan, L.; Guo, H.; Qu, Q. Investigation of Longwall Goaf Gas Flows and Borehole Drainage Performance by CFD Simulation. Int. J. Coal Geol. 2015, 150–151, 51–63. [Google Scholar] [CrossRef]

- Balusu, R.; Belle, B.; Tanguturi, K. Development of Goaf Gas Drainage and Inertisation Strategies in 1.0-Km- and 3.0-Km-Long Panels. Min. Metall. Explor. 2019, 36, 1127–1136. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, H.; Qin, Y.; Guo, M.; He, S.; Wang, K.; Shi, Y.; Xiang, Z. Numerical Simulation and Investigation of Methane Gas Distribution and Extraction in Goaf with U-Type Ventilation of Working Face. Environ. Sci. Pollut. Res. 2023, 30, 59510–59527. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Shang, Y.; Kong, D.; Zhang, G.; Wang, Y.; Wang, Y.; Zhang, Z. Gas Migration Law and Precision Extraction in Close Distance Coal Seam Goaf: A Case Study. Geotech. Geol. Eng. 2023, 41, 3781–3801. [Google Scholar] [CrossRef]

- Zhou, A.; Xu, Z.; Wang, K.; Wang, Y.; An, J.; Shi, Z. Coal Mine Gas Migration Model Establishment and Gas Extraction Technology Field Application Research. Fuel 2023, 349, 128650. [Google Scholar] [CrossRef]

- Li, Z.-X.; Wang, J.-R.; Zhou, X. Numerical Simulation of Gas Drainage during Open Region Movement in Goaf. J. China Univ. Min. Technol. 2004, 33, 74–78. [Google Scholar]

| No. | Lithology | Thickness (m) | Bulk Modulus (MPa) | Poisson’s Ratio | Elastic Modulus (MPa) | Density (kg/m3) | Uniaxial Tensile Strength | Internal Friction Angle | Cohesion (MPa) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Limestone | 12.39 | 4523 | 0.19 | 8412.78 | 2700 | 4.03 | 42 | 4.8 |

| 2 | Medium-grained sandstone | 3.34 | 3240 | 0.17 | 6415.2 | 2510 | 2.35 | 38 | 4.07 |

| 3 | No. 7 coal seam | 4.57 | 1580 | 0.28 | 2085.6 | 1380 | 0.52 | 30 | 1.42 |

| 3 | Fine-grained sandstone | 4.57 | 4176 | 0.18 | 8017.92 | 2680 | 2.62 | 40 | 4.53 |

| 4 | Sandy mudstone | 1.35 | 2800 | 0.24 | 4368 | 2450 | 1.55 | 35 | 3.61 |

| 5 | No. 2 + 3 coal seam | 4.57 | 1580 | 0.28 | 2085.6 | 1380 | 0.52 | 30 | 1.42 |

| 6 | Fine-grained sandstone | 2.75 | 4176 | 0.18 | 8017.92 | 2680 | 2.62 | 40 | 4.53 |

| 7 | Sandy mudstone | 0.78 | 2800 | 0.24 | 4368 | 2450 | 1.55 | 35 | 3.61 |

| 8 | Siltstone | 5.13 | 2530 | 0.25 | 3795 | 2550 | 1.66 | 36 | 3.3 |

| 9 | No. 4 coal seam | 1.12 | 1580 | 0.28 | 2085.6 | 1380 | 0.52 | 30 | 1.42 |

| 10 | Medium-grained sandstone | 6.46 | 3240 | 0.17 | 6415.2 | 2510 | 2.35 | 38 | 4.07 |

| 11 | Sandy mudstone | 6.27 | 2800 | 0.24 | 4368 | 2450 | 1.55 | 35 | 3.61 |

| 12 | Fine-grained sandstone | 6.75 | 4176 | 0.18 | 8017.92 | 2680 | 2.62 | 40 | 4.53 |

| 13 | Medium-grained sandstone | 4.57 | 3240 | 0.17 | 6415.2 | 2510 | 2.35 | 38 | 4.07 |

| 14 | Fine-grained sandstone | 19.92 | 4176 | 0.18 | 8017.92 | 2680 | 2.62 | 40 | 4.53 |

| 15 | Mudstone | 20 | 2230 | 0.26 | 3211.2 | 2230 | 0.89 | 32 | 2.98 |

| 16 | Fine sandstone | 4.97 | 4176 | 0.18 | 8017.92 | 2680 | 2.62 | 40 | 4.53 |

| 17 | Medium-grained sandstone | 45.06 | 3240 | 0.17 | 6415.2 | 2510 | 2.35 | 38 | 4.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, L. Study on Gas Extraction Technology for Goaf Using L-Shaped Borehole on the Ground. Appl. Sci. 2024, 14, 1594. https://doi.org/10.3390/app14041594

Shu L. Study on Gas Extraction Technology for Goaf Using L-Shaped Borehole on the Ground. Applied Sciences. 2024; 14(4):1594. https://doi.org/10.3390/app14041594

Chicago/Turabian StyleShu, Longyong. 2024. "Study on Gas Extraction Technology for Goaf Using L-Shaped Borehole on the Ground" Applied Sciences 14, no. 4: 1594. https://doi.org/10.3390/app14041594

APA StyleShu, L. (2024). Study on Gas Extraction Technology for Goaf Using L-Shaped Borehole on the Ground. Applied Sciences, 14(4), 1594. https://doi.org/10.3390/app14041594