Utilizing Differences in Mercury Injection Capillary Pressure and Nuclear Magnetic Resonance Pore Size Distributions for Enhanced Rock Quality Evaluation: A Winland-Style Approach with Physical Meaning

Abstract

1. Introduction

2. Materials and Techniques

2.1. Rock Samples

2.2. Experimental Setups

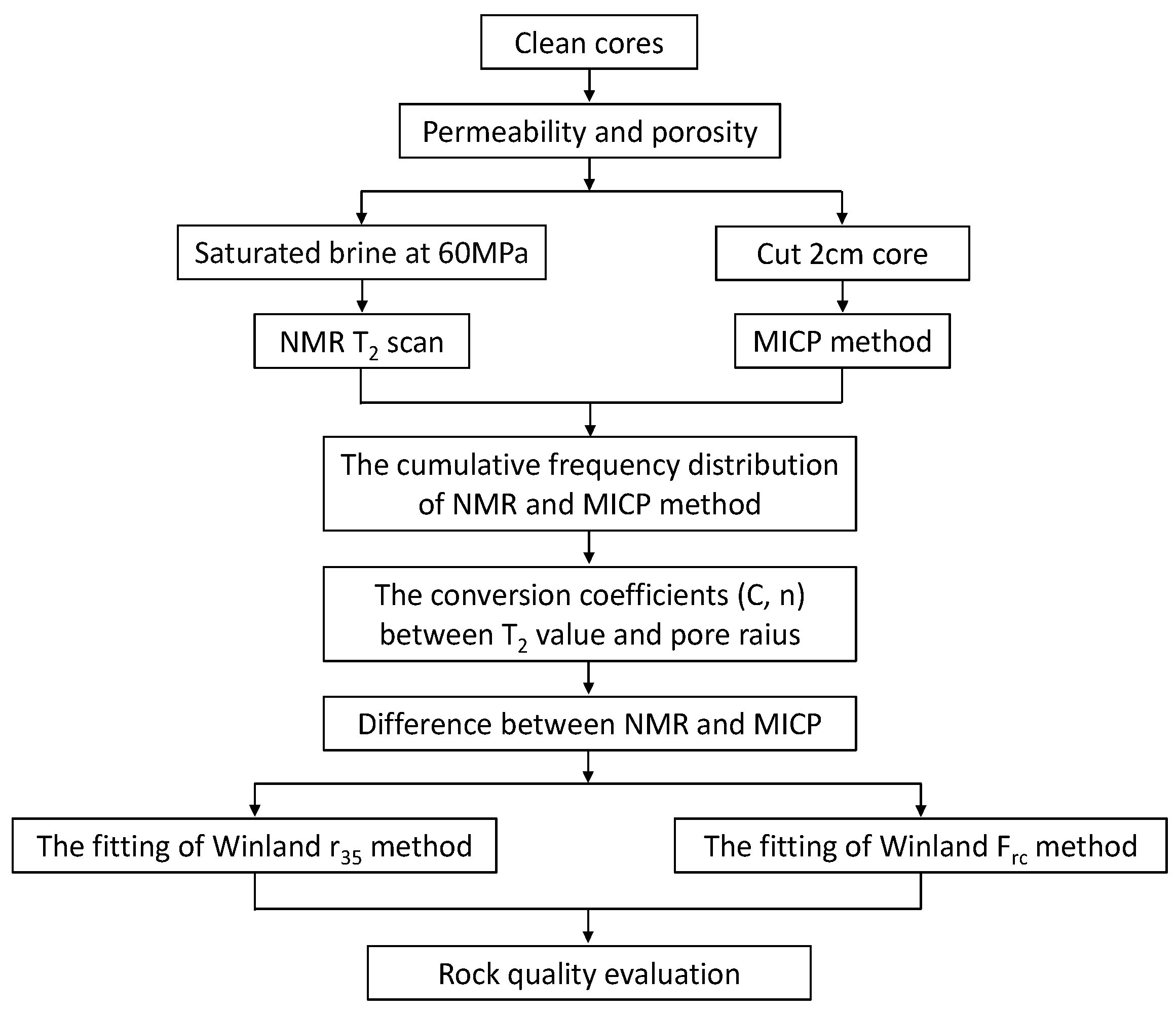

2.3. Experimental Procedures

2.3.1. Permeability and Porosity Measurements

2.3.2. NMR and MICP Measurements

- (1)

- All samples underwent an extensive cleaning process using Dean–Stark apparatus. After cleaning, the core samples were dried at 80 °C for 72 h. The status of the heated samples was ascertained using the T2 relaxation time distribution spectrum. If the T2 signal intensity is high, an additional 72 h of vacuum heating is required until the T2 signal intensity becomes constant.

- (2)

- After confirming that the rock core is thoroughly cleaned, a piece is cut for the MICP experiment with a thickness of 2 cm. The experimental maximum injection pressure is selected based on the lithology. The compressive strength of tight sandstone is usually higher than that of shale. Therefore, we have set the maximum injection pressure for tight sandstone and shale at 200 MPa and 100 MPa, respectively.

- (3)

- The clean rock core is placed in a container and subjected to evacuation treatment for 24 h. Subsequently, simulated formation brine is injected into the container, and the pressure is gradually increased to 60 MPa using the step-wise pressure build-up method [48] at a rate of 5 MPa/h. Water porosity is compared with helium porosity to confirm full saturation of the rock core (with an error of less than 2% [49]). The T2 relaxation time distribution spectrum of the rock sample is then measured.

- (4)

- Based on the cumulative frequency distribution from both MICP and the NMR T2 relaxation time distribution spectrum, translate the T2 relaxation times into a pore size distribution.

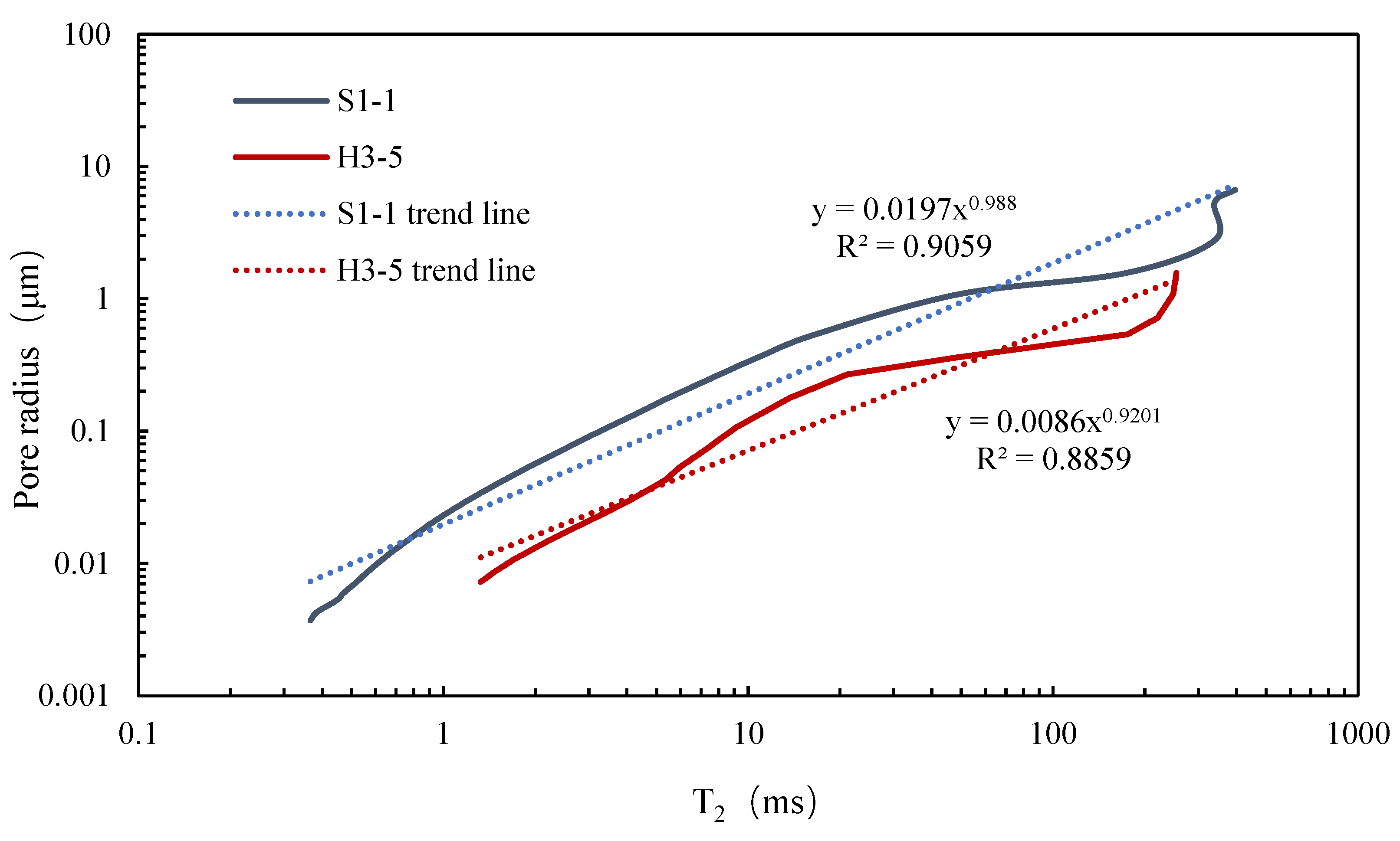

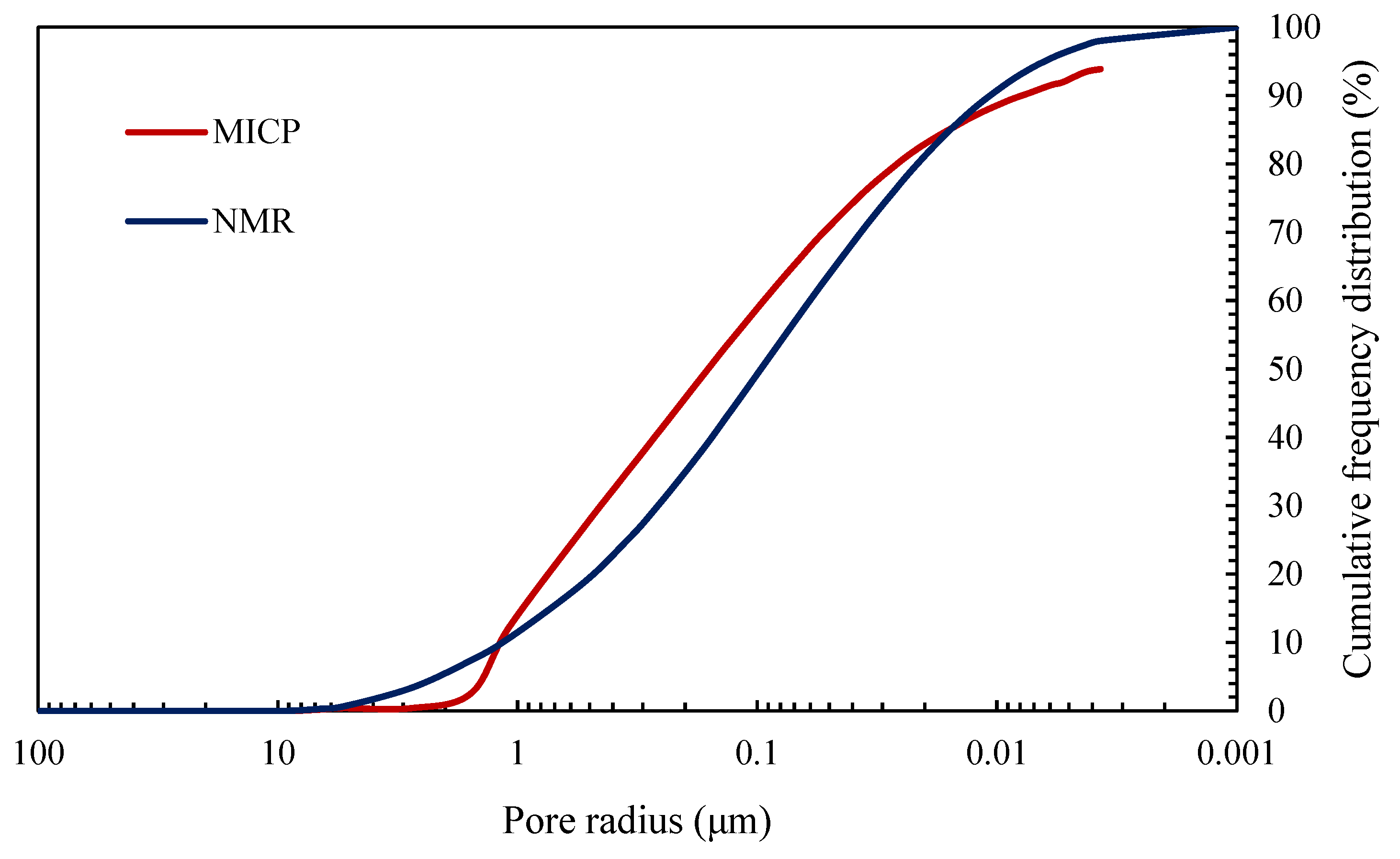

2.3.3. NMR Pore Size Distribution Calibration

3. Result and Discussion

3.1. T2 Relaxation Time Distribution Spectrum

3.2. NMR Pore Size Distribution

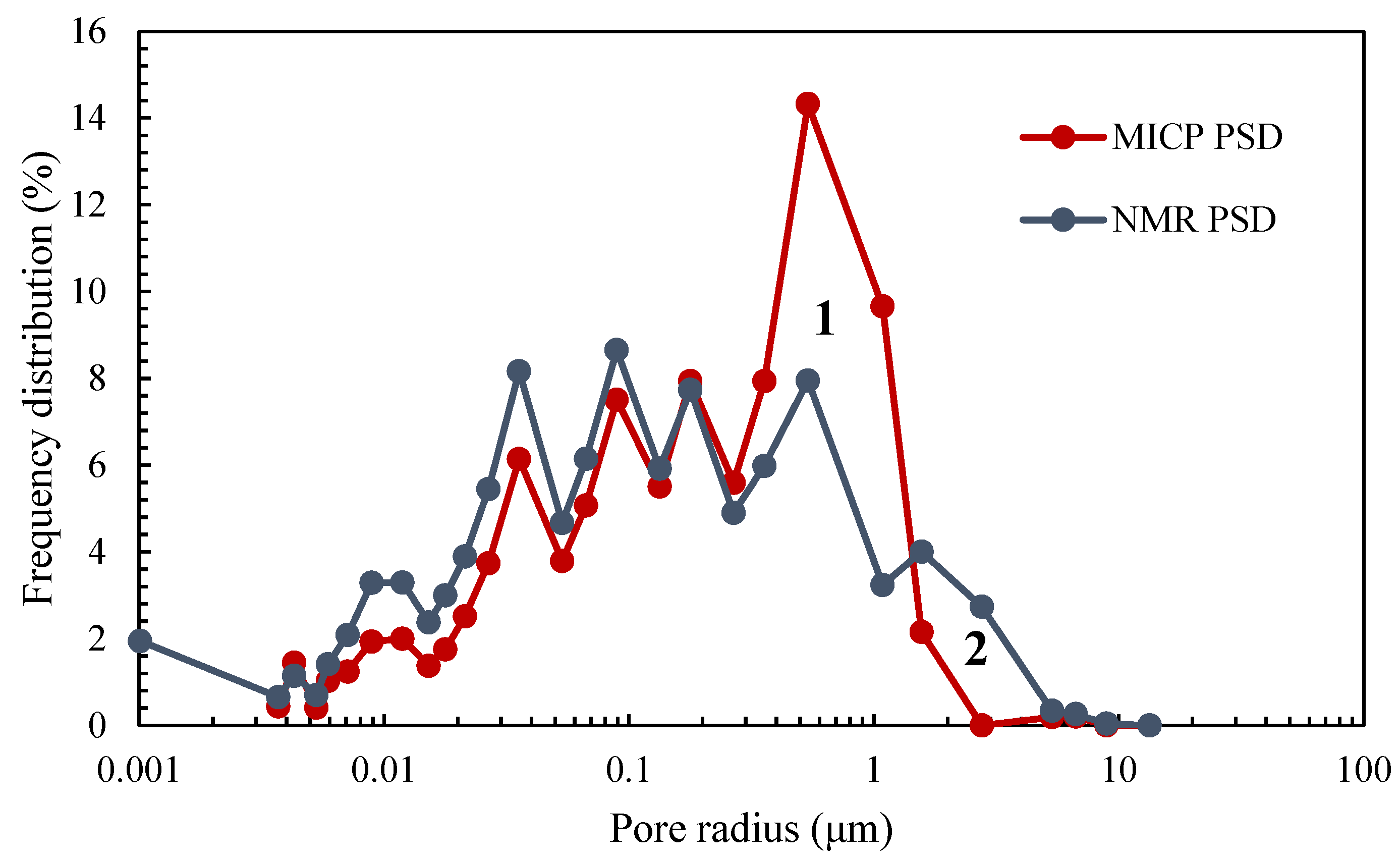

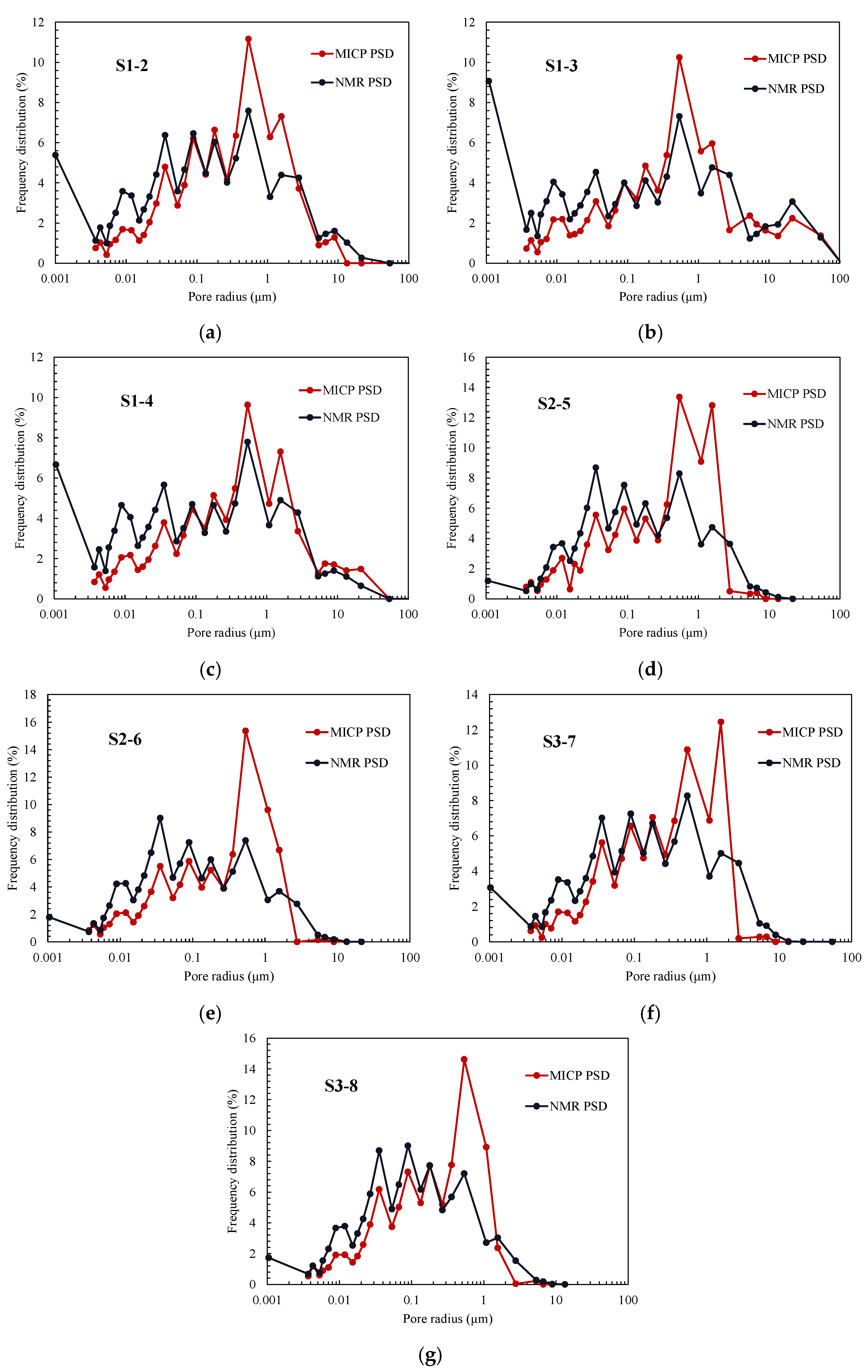

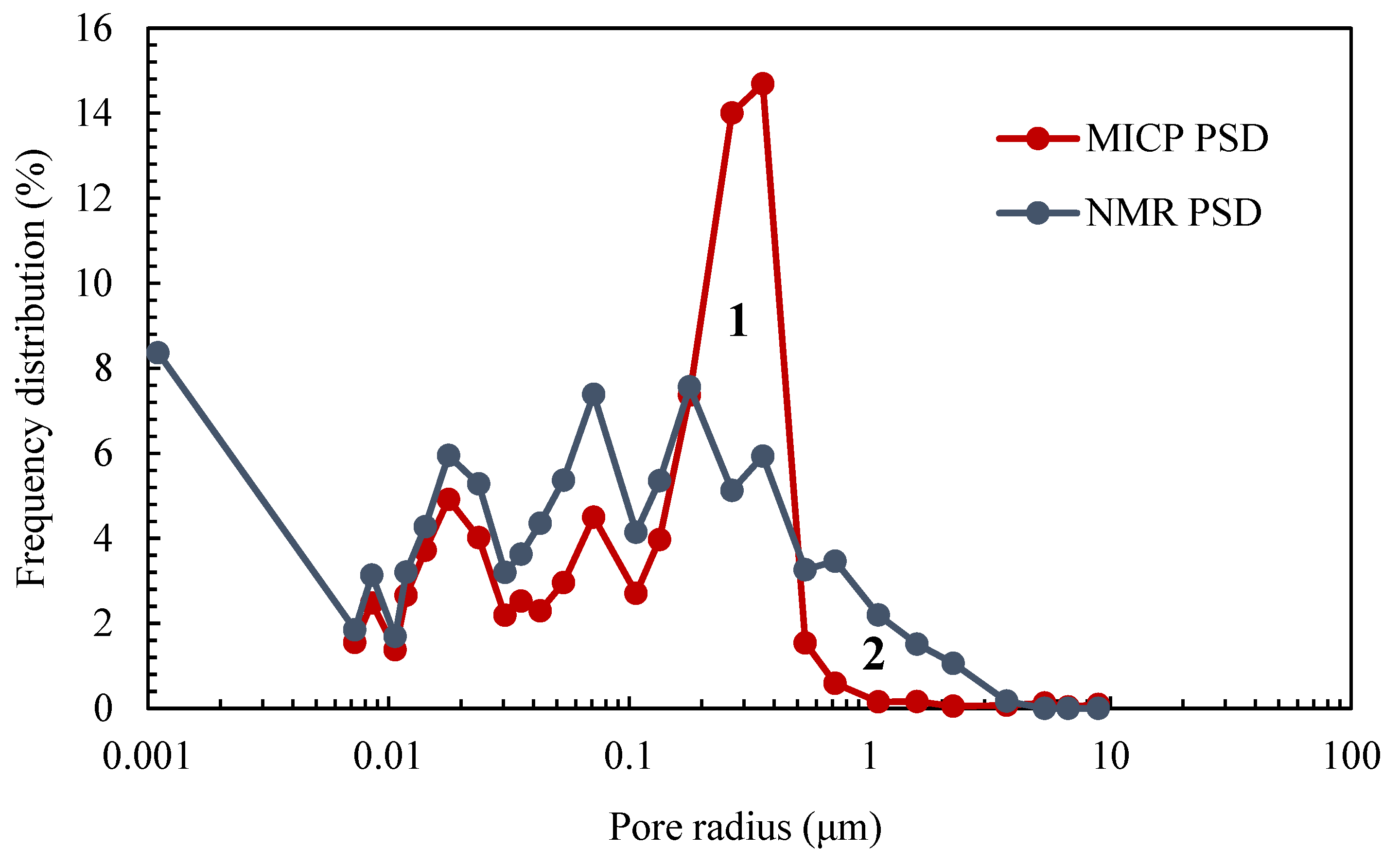

3.3. Comparative Analysis of Sandstone Pore Throat Distributions

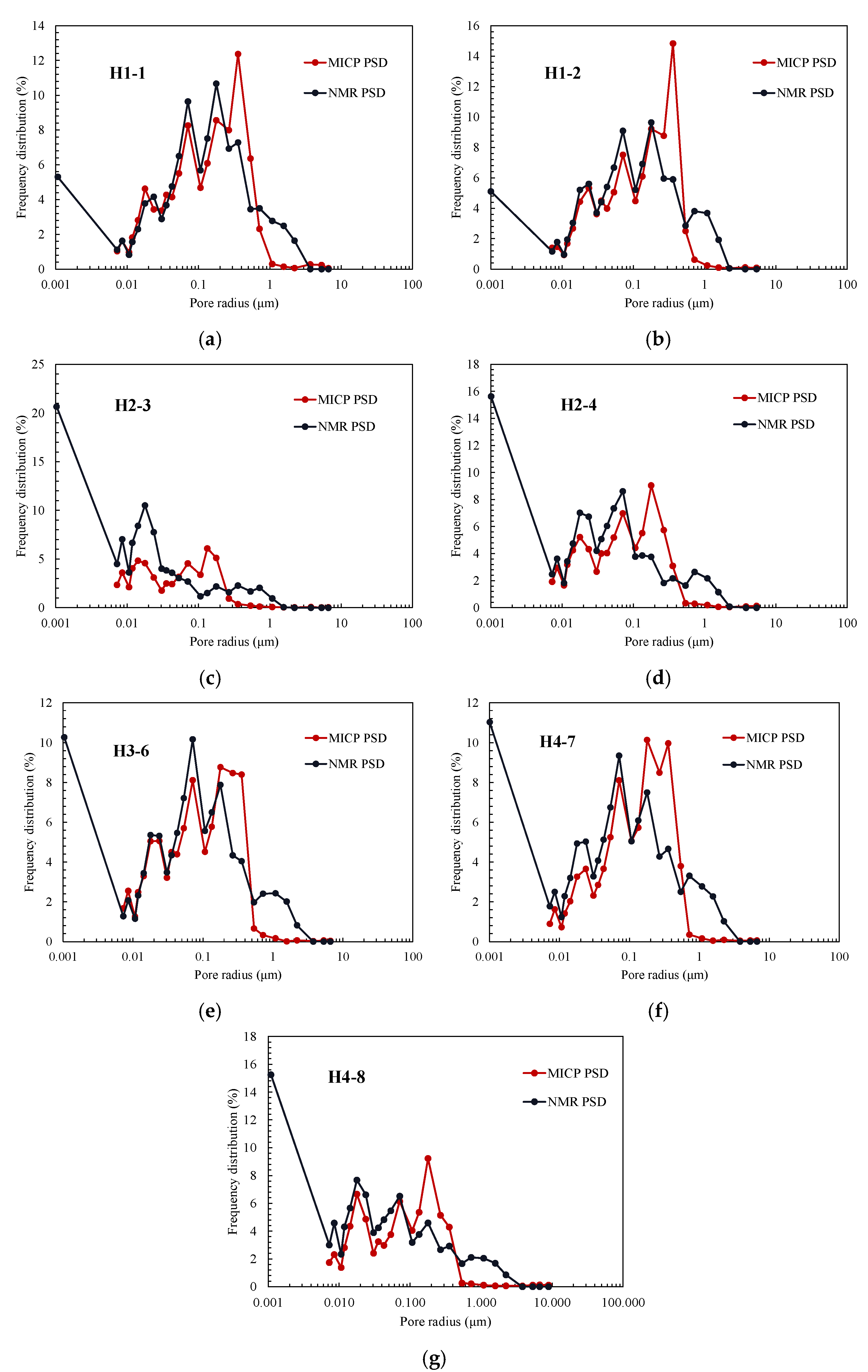

3.4. Comparative Analysis of Shale Pore Throat Distributions

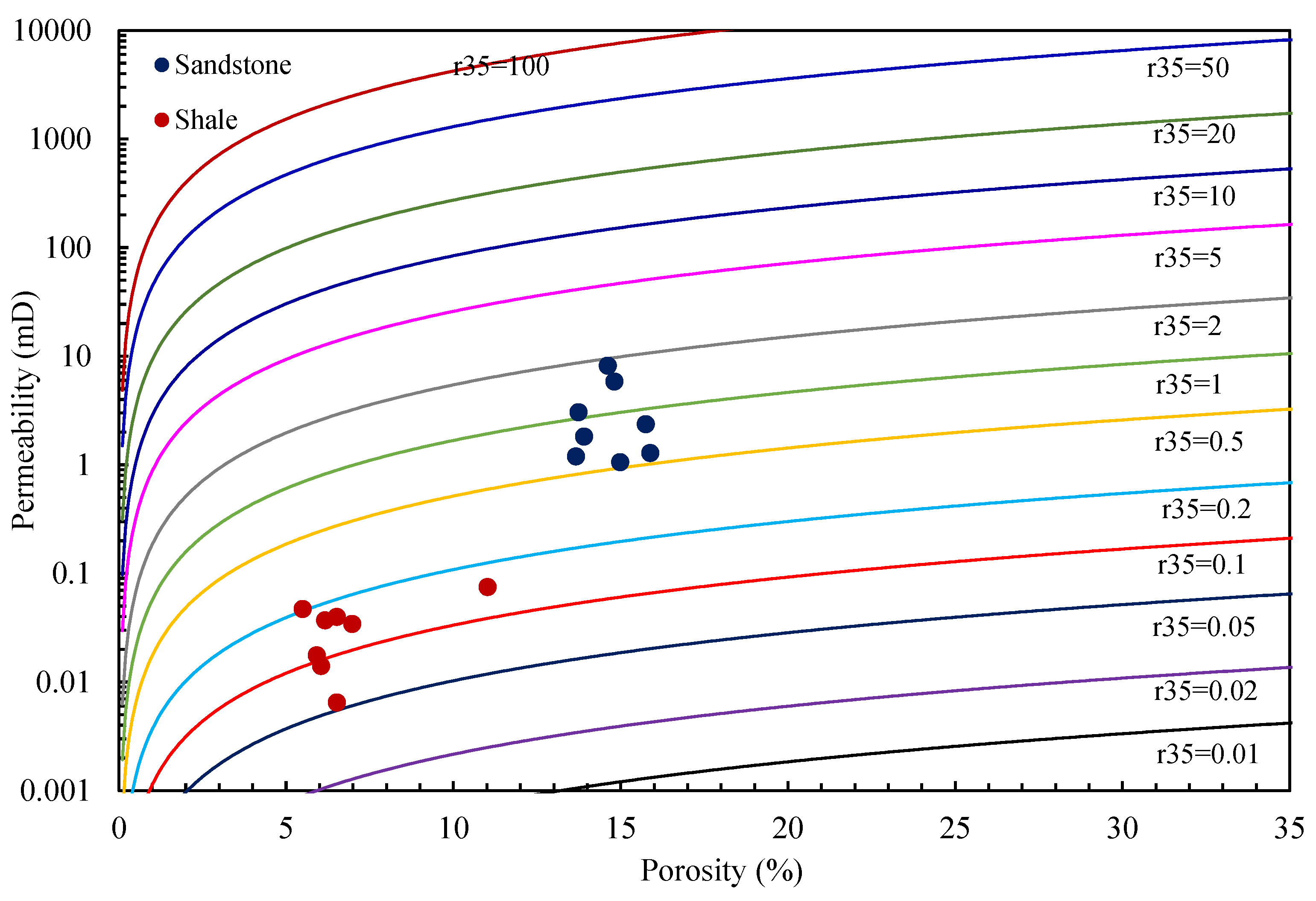

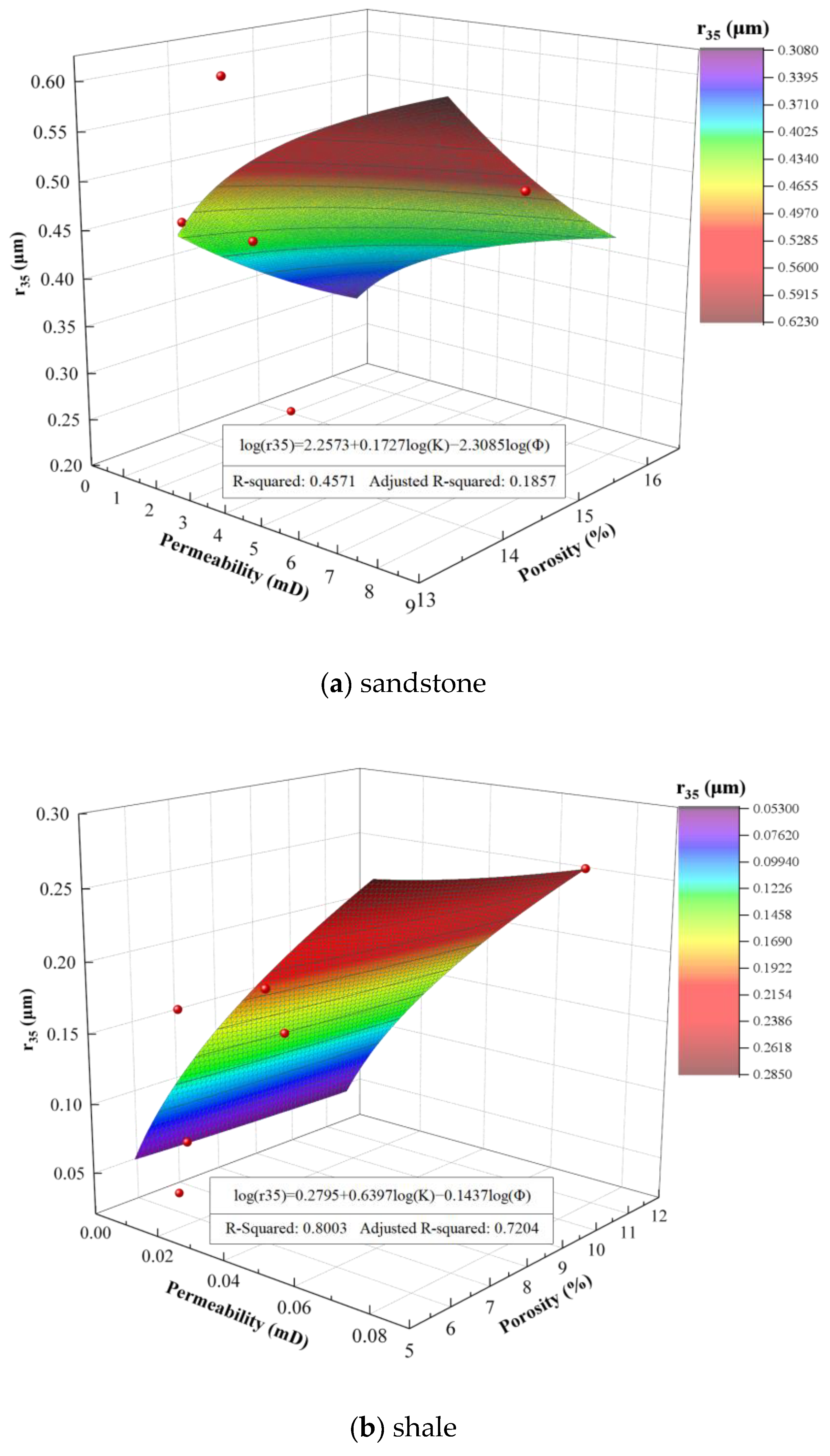

3.5. Correlation of Rock Core Physical Properties

4. Conclusions

- (1)

- In MICP experiments, excessive mercury injection pressures might damage the integrity of the rock’s pore structure, particularly affecting smaller pore sizes and thereby constraining its applicability in micro-pore analysis. Conversely, NMR offers a non-destructive approach to pore structure detection, presenting a distinct advantage in the identification and characterization of micro-pores;

- (2)

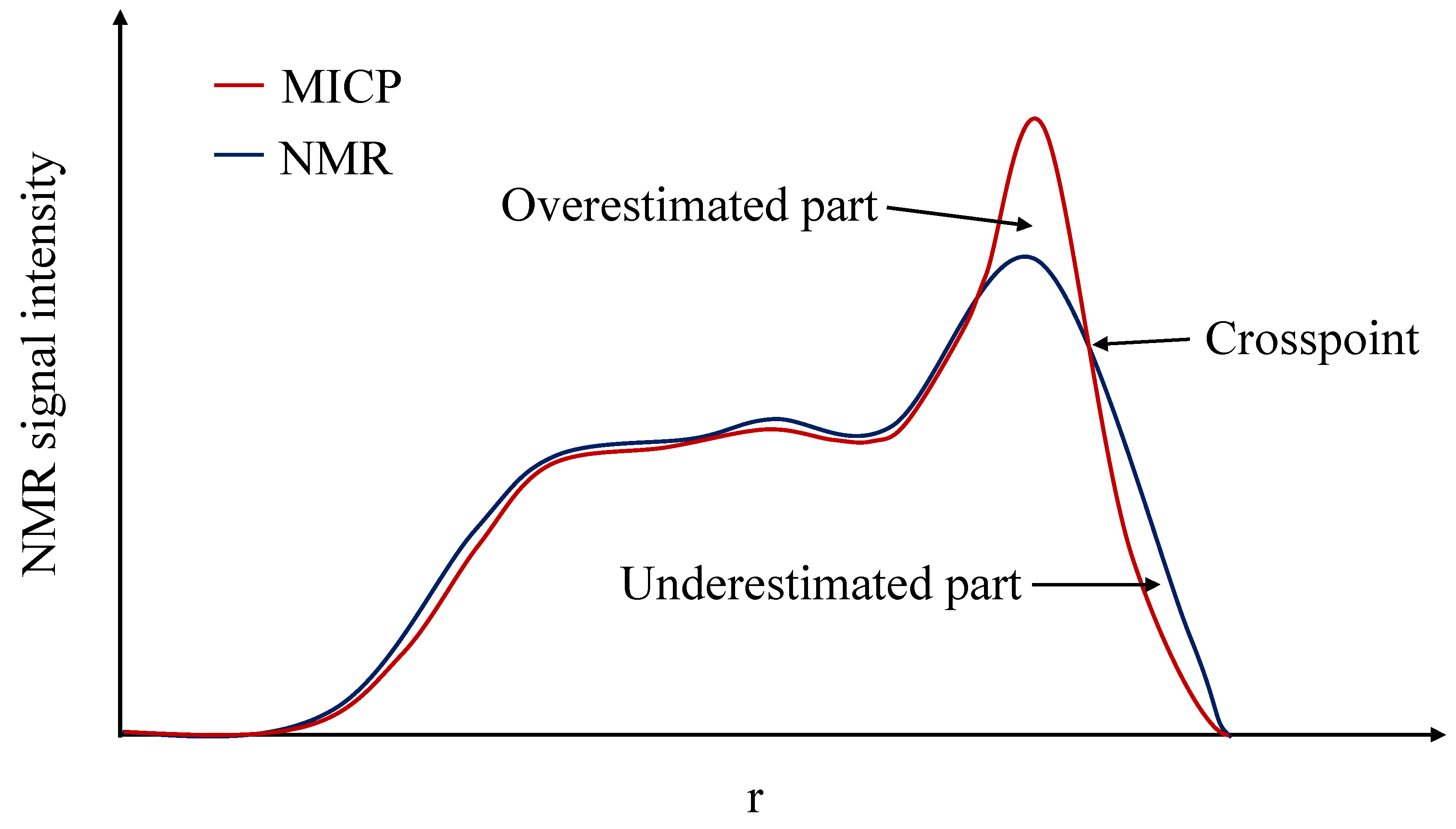

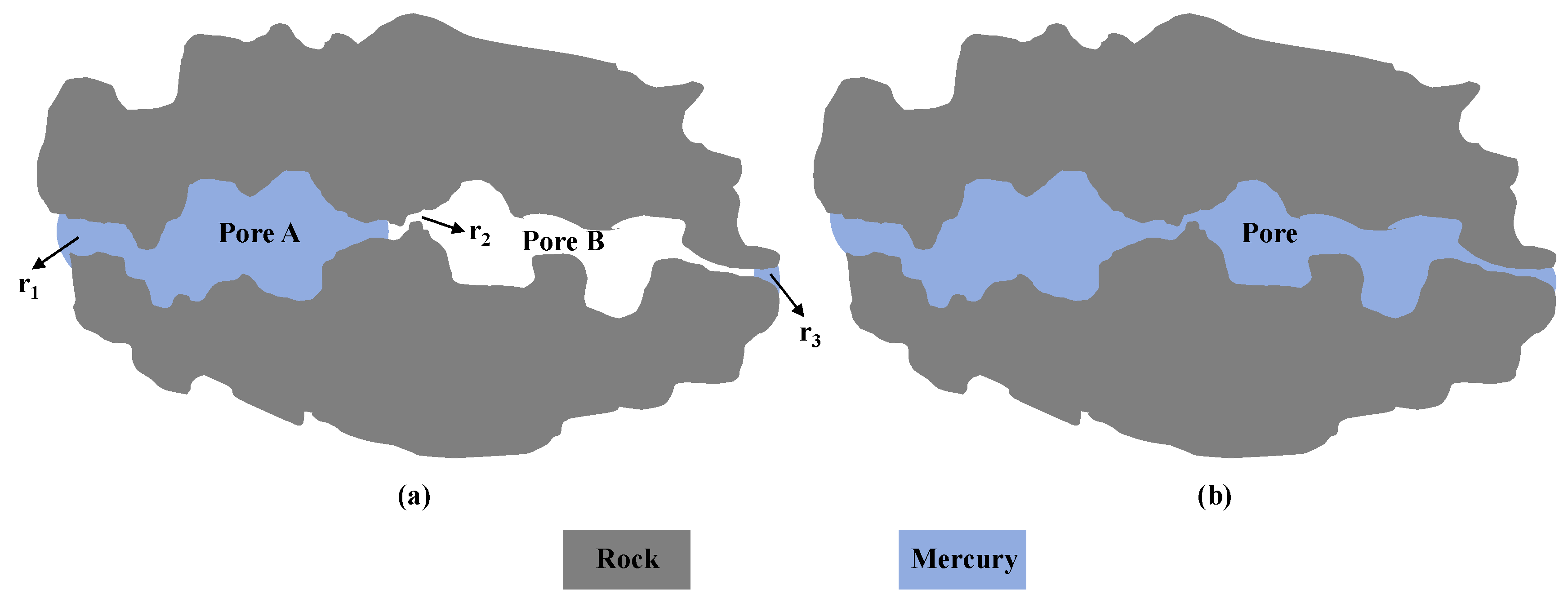

- The heterogeneity of shale and tight sandstone has a noticeable impact on the results obtained from the MICP method. In heterogeneous rocks where large pores are connected to small throats, MICP might overestimate the proportion of small throats and underestimate that of large throats. Due to NMR’s ability to detect all pores containing hydrogen-bearing fluids, it more accurately reflects the rock’s pore distribution;

- (3)

- In shale, specific signals in NMR are provided by kerogen, asphaltene, and bound water. These signals predominantly appear in the region of smaller pore sizes, potentially causing NMR to overestimate the proportion of these small pores;

- (4)

- Based on the Winland r35 method, by integrating information from both NMR and MICP measurements, we established the Winland Frc method. This approach surpasses the fitting accuracy of the traditional Winland method. It represents a potential high-precision, comprehensive tool for rock quality analysis, enhancing the precision of analysis and offering a novel perspective for an in-depth understanding of rock properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| T2S | The surface relaxation time, ms |

| T2D | The diffusion relaxation time, ms |

| T2B | The bulk relaxation time, ms |

| ρ2 | The transverse relaxation rate, μm/ms |

| S/V | The specific surface area of a single pore, μm2/μm3 |

| FS | The pore shape factor, dimensionless |

| R | The pore radius, μm |

| C | The conversion coefficient, dimensionless |

| rc | Controlled throat radius, μm |

| Frc | The volume controlled by pore throat rc, % |

| r35 | The radius corresponding to the point at which mercury intrusion volume reaches 35% of the total pore volume, μm |

| Ka | The absolute permeability, mD |

| Φ | The porosity of the core, % |

References

- Caineng, Z.; Zhi, Y.; Shizhen, T.; Wei, L.; Songtao, W.; Lianhua, H.; Rukai, Z.; Xuanjun, Y.; Lan, W.; Xiaohui, G. Nano-hydrocarbon and the accumulation in coexisting source and reservoir. Pet. Explor. Dev. 2012, 39, 15–32. [Google Scholar]

- Deng, X.; Fu, J.; Yao, J.; Pang, J.; Sun, B. Sedimentary facies of the Middle-Upper Triassic Yanchang Formation in Ordos Basin and breakthrough in petroleum exploration. J. Palaeogeogr. 2011, 13, 443–455. [Google Scholar]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A review on pore structure characterization in tight sandstones. Earth-Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Kale, S.V.; Rai, C.S.; Sondergeld, C.H. Petrophysical characterization of Barnett shale. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, Pittsburgh, PA, USA, 23–25 February 2010; SPE, 2010; p. SPE-131770-MS. [Google Scholar]

- Katsube, T. Shale permeability and pore-structure evolution characteristics. In Natural Resources Canada; Geological Survey of Canada: Ottawa, ON, Canada, 2000. [Google Scholar]

- Yao, Y.; Liu, D. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel 2012, 95, 152–158. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Tiab, D.; Donaldson, E.C. Petrophysics: Theory and Practice of Measuring Reservoir Rock and Fluid Transport Properties; Gulf Professional Publishing: Houston, TX, USA, 2015. [Google Scholar]

- Pittman, E.D. Relationship of porosity and permeability to various parameters derived from mercury injection-capillary pressure curves for sandstone. AAPG Bull. 1992, 76, 191–198. [Google Scholar]

- Iraji, S.; Soltanmohammadi, R.; Munoz, E.R.; Basso, M.; Vidal, A.C. Core scale investigation of fluid flow in the heterogeneous porous media based on X-ray computed tomography images: Upscaling and history matching approaches. Geoenergy Sci. Eng. 2023, 225, 211716. [Google Scholar] [CrossRef]

- Iraji, S.; De Almeida, T.R.; Munoz, E.R.; Basso, M.; Vidal, A.C. The impact of heterogeneity and pore network characteristics on single and multi-phase fluid propagation in complex porous media: An X-ray computed tomography study. Pet. Sci. 2024; in press. [Google Scholar]

- Soltanmohammadi, R.; Iraji, S.; de Almeida, T.R.; Basso, M.; Munoz, E.R.; Vidal, A.C. Investigation of pore geometry influence on fluid flow in heterogeneous porous media: A pore-scale study. Energy Geosci. 2024, 5, 100222. [Google Scholar] [CrossRef]

- Yu, Y.; Luo, X.; Wang, Z.; Cheng, M.; Lei, Y.; Zhang, L.; Yin, J. A new correction method for mercury injection capillary pressure (MICP) to characterize the pore structure of shale. J. Nat. Gas Sci. Eng. 2019, 68, 102896. [Google Scholar] [CrossRef]

- Mastalerz, M.; Drobniak, A.; Hower, J.C. Controls on reservoir properties in organic-matter-rich shales: Insights from MICP analysis. J. Pet. Sci. Eng. 2021, 196, 107775. [Google Scholar] [CrossRef]

- Olson, R.K.; Grigg, M.W. Mercury Injection Capillary Pressure (MICP) a Useful Tool for Improved Understanding of Porosity and Matrix Permeability Distributions in Shale Reservoirs; American Association of Petroleum Geologists: Tulsa, OK, USA, 2008. [Google Scholar]

- Gallegos, D.P.; Smith, D.M. A NMR technique for the analysis of pore structure: Determination of continuous pore size distributions. J. Colloid Interface Sci. 1988, 122, 143–153. [Google Scholar] [CrossRef]

- Benavides, F.; Leiderman, R.; Souza, A.; Carneiro, G.; de Vasconcellos Azeredo, R.B. Pore size distribution from NMR and image based methods: A comparative study. J. Pet. Sci. Eng. 2020, 184, 106321. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, D.; Cai, Y.; Yao, Y.; Pan, Z.; Zhou, Y. Application of nuclear magnetic resonance (NMR) in coalbed methane and shale reservoirs: A review. Int. J. Coal Geol. 2020, 218, 103261. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, B.; Liu, T.; Zheng, Y.; Sun, Y.; Zhang, G.; Li, Q. Multifractal analysis of coal pore structure based on NMR experiment: A new method for predicting T2 cutoff value. Fuel 2021, 283, 119338. [Google Scholar] [CrossRef]

- Rashid, F.; Glover, P.; Lorinczi, P.; Hussein, D.; Collier, R.; Lawrence, J. Permeability prediction in tight carbonate rocks using capillary pressure measurements. Mar. Pet. Geol. 2015, 68, 536–550. [Google Scholar] [CrossRef]

- Yishan, L.; Xiaohu, D.; Lin, Y.; Fuli, C.; Yanling, G.; Zhangxing, C. Quantitative character—ization of pore structure of Lucaogou formation in Jimsar sag. Xinjiang Pet. Geol. 2019, 40, 284–289. [Google Scholar]

- Tangyan, L.; Zaitian, M.; Rongshan, F. Analysis of rock pore structure with NMR spectra. Prog. Geophys. 2003, 18, 737–742. [Google Scholar]

- Yao, Y.; Liu, D.; Cai, Y.; Li, J. Advanced characterization of pores and fractures in coals by nuclear magnetic resonance and X-ray computed tomography. Sci. China Earth Sci. 2010, 53, 854–862. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Che, Y.; Tang, D.; Tang, S.; Huang, W. Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Xu, H.; Yang, Z. Advanced characterization of physical properties of coals with different coal structures by nuclear magnetic resonance and X-ray computed tomography. Comput. Geosci. 2012, 48, 220–227. [Google Scholar] [CrossRef]

- Wang, F.; Yang, K.; Cai, J. Fractal characterization of tight oil reservoir pore structure using nuclear magnetic resonance and mercury intrusion porosimetry. Fractals 2018, 26, 1840017. [Google Scholar] [CrossRef]

- Daigle, H.; Johnson, A. Combining mercury intrusion and nuclear magnetic resonance measurements using percolation theory. Transp. Porous Media 2016, 111, 669–679. [Google Scholar] [CrossRef]

- Lyu, C.; Ning, Z.; Wang, Q.; Chen, M. Application of NMR T 2 to pore size distribution and movable fluid distribution in tight sandstones. Energy Fuels 2018, 32, 1395–1405. [Google Scholar] [CrossRef]

- Marschall, D.; Gardner, J.; Mardon, D.; Coates, G. Method for Correlating NMR Relaxometry and Mercury Injection Data. In 1995 SCA Conference; 1995; p. 40. Available online: https://www.jgmaas.com/SCA/1995/SCA1995-11.pdf (accessed on 24 February 2024).

- Ausbrooks, R.; Hurley, N.F.; May, A.; Neese, D.G. Pore-Size Distributions in Vuggy Carbonates from Core Images, NMR, and Capillary Pressure. In Proceedings of the SPE Annual Technical Conference and Exhibition? Houston, TX, USA, 3–6 October 1999; SPE, 1999; p. SPE-56506-MS. [Google Scholar]

- Daigle, H.; Thomas, B.; Rowe, H.; Nieto, M. Nuclear magnetic resonance characterization of shallow marine sediments from the Nankai Trough, Integrated Ocean Drilling Program Expedition 333. J. Geophys. Res. Solid Earth 2014, 119, 2631–2650. [Google Scholar] [CrossRef]

- Diamond, S. Mercury porosimetry: An inappropriate method for the measurement of pore size distributions in cement-based materials. Cem. Concr. Res. 2000, 30, 1517–1525. [Google Scholar] [CrossRef]

- Xu, H.; Fan, Y.; Hu, F.; Li, C.; Yu, J.; Liu, Z.; Wang, F. Characterization of pore throat size distribution in tight sandstones with nuclear magnetic resonance and high-pressure mercury intrusion. Energies 2019, 12, 1528. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.; You, F.; Wang, P.; Feng, X.; Hu, Z. Pore Size Distribution Characterization by Joint Interpretation of MICP and NMR: A Case Study of Chang 7 Tight Sandstone in the Ordos Basin. Processes 2022, 10, 1941. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R. Impact of paramagnetic minerals on NMR-converted pore size distributions in Permian Carynginia shales. Energy Fuels 2019, 33, 2880–2887. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R. Comparative porosity and pore structure assessment in shales: Measurement techniques, influencing factors and implications for reservoir characterization. Energies 2019, 12, 2094. [Google Scholar] [CrossRef]

- Moro, F.; Böhni, H. Ink-bottle effect in mercury intrusion porosimetry of cement-based materials. J. Colloid Interface Sci. 2002, 246, 135–149. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, B.; Yang, Z.; Ye, G. Ink-bottle effect and pore size distribution of cementitious materials identified by pressurization–depressurization cycling mercury intrusion porosimetry. Materials 2019, 12, 1454. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, S.; Li, J.; Zhang, J.; Xue, H.; Chen, C. Comparisons of SEM, low-field NMR, and mercury intrusion capillary pressure in characterization of the pore size distribution of lacustrine shale: A case study on the Dongying Depression, Bohai Bay Basin, China. Energy Fuels 2017, 31, 9232–9239. [Google Scholar] [CrossRef]

- Gunter, G.; Spain, D.; Viro, E.; Thomas, J.; Potter, G.; Williams, J. Winland Pore Throat Prediction Method-A Proper Retrospect: New Examples from Carbonates and Complex Systems. In Proceedings of the SPWLA Annual Logging Symposium, Abu Dhabi, United Arab Emirates, 18–22 May 2014; SPWLA: Houston, TX, USA, 2014; p. SPWLA-2014-KKK. [Google Scholar]

- Youxin, Z.; Xinning, L.; Zhenshan, P.; Hao, Z.; Qiang, M.; Xueliang, S. The Qiketai tight oil reservoir characteristics of Jurassic in Tuha Basin. Xinjiang Pet. Geol. 2014, 35, 1. [Google Scholar]

- Gang, G.; Hua-ming, L.; Chuan, L.; Zhi-yong, W.; Qing-chun, J. The geologic feature and hydrocarbon accumulation of Niujuanhu oilfield in Santanghu Basin. Xinjiang Pet. Geol. 2006, 27, 535. [Google Scholar]

- Dong, Z.-L. Natural Gas Characteristics and Gas Sources of the Lower Permian in Hechuan-Tongnan Area, Sichuan Basin. In International Field Exploration and Development Conference, 2022; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1074–1082. [Google Scholar]

- Guo, Q.; Li, J.; Chen, N.; Hu, J.; Xie, H.; Gao, X. Modeling of the tight sandstone gas accumulation for the Xujiahe Formation, Hechuan-Tongnan Area, Sichuan Basin. Pet. Explor. Dev. 2011, 38, 409–418. [Google Scholar] [CrossRef]

- GB/T34533-2023; Determination of Porosity, Permeability, and Saturation of Shale. Standard Press of China: Beijing, China, 2023. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT34533-2023 (accessed on 24 February 2024).

- SY/T6490-2023. Specifications for Laboratory Measurement of NMR Parameters of Rock Samples. Available online: https://www.chinesestandard.net/PDF/English.aspx/SYT6490-2023 (accessed on 24 February 2024).

- GB/T29171-2023; Rock capillary Pressure Measurement. Standard Press of China: Beijing, China, 2023. Available online: https://www.chinesestandard.net/PDF/BOOK.aspx/GBT29171-2023 (accessed on 24 February 2024).

- Al Ismail, M.I.; Hol, S.; Reece, J.S.; Zoback, M.D. In The Effect of CO2 Adsorption on Permeability Anisotropy in the Eagle Ford Shale. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014; URTEC, 2014; p. URTEC-1921520-MS. [Google Scholar]

- GB/T29172-2012; Practices for core analysis. National Petroleum Standardization. Standard press of China: Beijing China, 2012. Available online: https://www.chinesestandard.net/Default.aspx?StdID=GB/T29172-2012 (accessed on 24 February 2024).

- Dunn, K.-J.; Bergman, D.J.; LaTorraca, G.A. Nuclear Magnetic Resonance: Petrophysical and Logging Applications; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Coates, G.R.; Xiao, L.; Prammer, M.G. NMR logging. In Principles and Interpretation; Halliburton Energy Service: Huston, TX, USA, 1999. [Google Scholar]

- Kleinberg, R.L.; Horsfield, M.A. Transverse relaxation processes in porous sedimentary rock. J. Magn. Reson. 1990, 88, 9–19. [Google Scholar] [CrossRef]

- Lowden, B.D.; Porter, M.J.; Powrie, L.S. T2 Relaxation Time Versus Mercury Injection Capillary Pressure: Implications for NMR Logging and Reservoir Characterisation. In Proceedings of the SPE Europec Featured at EAGE Conference and Exhibition? The Hague, The Netherlands, 20–22 October 1998; SPE, 1998; p. SPE-50607-MS. [Google Scholar]

- Rosenbrand, E.; Fabricius, I.L.; Fisher, Q.; Grattoni, C. Permeability in Rotliegend gas sandstones to gas and brine as predicted from NMR, mercury injection and image analysis. Mar. Pet. Geol. 2015, 64, 189–202. [Google Scholar] [CrossRef]

- Xiao, L.; Mao, Z.-q.; Zou, C.-c.; Jin, Y.; Zhu, J.-C. A new methodology of constructing pseudo capillary pressure (Pc) curves from nuclear magnetic resonance (NMR) logs. J. Pet. Sci. Eng. 2016, 147, 154–167. [Google Scholar] [CrossRef]

- Lei, Z.; Xiangyang, Q.; Liang, Z.; Keliu, W.; Wei, Z.; Huifang, B.; Cuiping, X.; Tao, W. Reservoir characteristics and development performance of Yanchang Formation in Xunyi exploration area, Ordos Basin. Acta Pet. Sin. 2020, 41, 88. [Google Scholar]

- Yadav, D.; Nair, S.B.; Awasthi, M.K.; Ragoju, R.; Bhattacharyya, K. Linear and nonlinear investigations of the impact of chemical reaction on the thermohaline convection in a permeable layer saturated with Casson fluid. Phys. Fluids 2024, 36, 014106. [Google Scholar] [CrossRef]

- Yadav, D.; Kim, M. Theoretical and numerical analyses on the onset and growth of convective instabilities in a horizontal anisotropic porous medium. J. Porous Media 2014, 17, 1061–1074. [Google Scholar] [CrossRef]

- Li, A.; Ren, X.; Wang, G.; Wang, Y.-Z.; Jiang, K.-L. Characterization of pore structure of low permeability reservoirs using a nuclear magnetic resonance method. J. China Univ. Pet. 2015, 39, 92–98. [Google Scholar]

- Wang, H.; Rezaee, R.; Saeedi, A. Evaporation process and pore size distribution in tight sandstones: A study using NMR and MICP. Procedia Earth Planet. Sci. 2015, 15, 767–773. [Google Scholar] [CrossRef][Green Version]

- Wu, Y.; Tahmasebi, P.; Lin, C.; Zahid, M.A.; Dong, C.; Golab, A.N.; Ren, L. A comprehensive study on geometric, topological and fractal characterizations of pore systems in low-permeability reservoirs based on SEM, MICP, NMR, and X-ray CT experiments. Mar. Pet. Geol. 2019, 103, 12–28. [Google Scholar] [CrossRef]

- Willis, K.L.; Abell, A.B.; Lange, D.A. Image-based characterization of cement pore structure using wood’s metal intrusion. Cem. Concr. Res. 1998, 28, 1695–1705. [Google Scholar] [CrossRef]

- Crawford, B.; Gaillot, P.; Alramahi, B. Petrophysical Methodology for Predicting Compressive Strength in Siliciclastic “Sandstone-to-Shale” Rocks. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Salt Lake City, UT, USA, 27–30 June 2010; ARMA, 2010; p. ARMA-10-196. [Google Scholar]

- Kolodzie Jr, S. Analysis of Pore Throat Size and use of the Waxman-Smits Equation to Determine OOIP in Spindle Field, Colorado. In Proceedings of the SPE Annual Technical Conference and Exhibition? Dallas, TX, USA, 21–24 September 1980; SPE, 1980; p. SPE-9382-MS. [Google Scholar]

- Iraji, S.; Soltanmohammadi, R.; Matheus, G.F.; Basso, M.; Vidal, A.C. Application of unsupervised learning and deep learning for rock type prediction and petrophysical characterization using multi-scale data. Geoenergy Sci. Eng. 2023, 230, 212241. [Google Scholar] [CrossRef]

- Lafage, S.I. An Alternative to the Winland R35 Method for Determining Carbonate Reservoir Quality; Texas A&M University: College Station, TX, USA, 2008. [Google Scholar]

- Rivas, J.; Busnego, H.; Bejarano, C.; Meza, R. Modeling of Pore Throat Radio using Pittman Modified Equation for Carabobo Area in the Faja Petrolífera del Orinoco. 2014. Available online: https://www.researchgate.net/publication/272351788_Modeling_of_Pore_Throat_Radio_using_Pittman_Modified_Equation_for_Carabobo_Area_in_the_Faja_Petrolifera_del_Orinoco (accessed on 24 February 2024).

| Author | Porous Media Type | Crosspoint | Overestimated Part |

|---|---|---|---|

| Marschal et al. [29] | Shaly sandstone | 170 ms | 100~170 ms |

| Robin et al. [30] | Carbonate | 1300 ms | 700~1300 ms |

| Hugh and Andrew [31] | Sandstone | 0.25 μm | 0.11~0.25 μm |

| Sidney [32] | Wood’s metal | 9 μm | 0.05~9 μm |

| Hongjun et al. [33] | Tight sandstone | 0.4 μm | 0.1~0.4 μm |

| Well Number | Samples | Length (mm) | Diameter (mm) | Volume (mL) | Helium Porosity (%) | Permeability (mD) | Lithology |

|---|---|---|---|---|---|---|---|

| S1 | 1 | 87.01 | 24.40 | 40.69 | 14.98 | 1.06 | Sandstone |

| 2 | 71.52 | 24.50 | 33.72 | 13.74 | 3.06 | Conglomerate sandstones | |

| 3 | 57.78 | 24.55 | 27.35 | 14.61 | 8.20 | ||

| 4 | 53.14 | 24.45 | 24.95 | 14.81 | 5.86 | ||

| S2 | 5 | 72.10 | 24.55 | 34.13 | 13.90 | 1.83 | Sandstone |

| 6 | 72.10 | 24.50 | 33.99 | 13.66 | 1.20 | ||

| S3 | 7 | 72.53 | 24.52 | 34.25 | 15.75 | 2.37 | |

| 8 | 67.10 | 24.45 | 31.50 | 15.88 | 1.29 | ||

| H1 | 1 | 56.30 | 25.11 | 27.88 | 5.49 | 0.0471 | Shale |

| 2 | 53.31 | 25.11 | 26.40 | 6.16 | 0.0371 | ||

| H2 | 3 | 40.49 | 25.40 | 20.52 | 6.51 | 0.0065 | |

| 4 | 39.94 | 25.47 | 20.35 | 6.04 | 0.0141 | ||

| H3 | 5 | 40.49 | 25.43 | 20.57 | 11.02 | 0.0753 | |

| 6 | 41.83 | 25.37 | 21.15 | 6.97 | 0.0344 | ||

| H4 | 7 | 32.50 | 25.40 | 16.47 | 6.51 | 0.0399 | |

| 8 | 32.80 | 25.40 | 16.62 | 5.91 | 0.0177 |

| Well Number | Samples | Saturation of MICP (%) | C | n | R2 |

|---|---|---|---|---|---|

| S1 | 1 | 93.194 | 0.0197 | 1.0121 | 0.9059 |

| 2 | 85.503 | 0.0112 | 0.8718 | 0.9951 | |

| 3 | 78.665 | 0.0129 | 0.7945 | 0.9950 | |

| 4 | 81.174 | 0.0179 | 0.8916 | 0.9878 | |

| S2 | 5 | 92.531 | 0.0261 | 1.0490 | 0.9475 |

| 6 | 88..878 | 0.0231 | 1.0635 | 0.9498 | |

| S3 | 7 | 89.929 | 0.0179 | 0.9565 | 0.9157 |

| 8 | 92.171 | 0.0213 | 1.0685 | 0.9447 | |

| H1 | 1 | 94.802 | 0.0281 | 1.3238 | 0.8993 |

| 2 | 93.544 | 0.0245 | 1.4426 | 0.8858 | |

| H2 | 3 | 59.246 | 0.0192 | 1.3348 | 0.8872 |

| 4 | 79.073 | 0.0204 | 1.3472 | 0.9088 | |

| H3 | 5 | 83.450 | 0.0086 | 1.0868 | 0.8859 |

| 6 | 89.400 | 0.0173 | 1.2396 | 0.8662 | |

| H4 | 7 | 83.649 | 0.0227 | 1.3416 | 0.8995 |

| 8 | 75.774 | 0.0207 | 1.2822 | 0.8448 |

| Well Number | Samples | Helium Porosity (%) | Permeability (mD) | rc (μm) | r35 (μm) | Frc (%) |

|---|---|---|---|---|---|---|

| S1 | 1 | 14.98 | 1.06 | 1.2048 | 0.2035 | 4.9107 |

| 2 | 13.74 | 3.06 | 1.5758 | 0.4464 | 7.1410 | |

| 3 | 14.61 | 8.20 | 1.2340 | 0.5160 | 11.2015 | |

| 4 | 14.81 | 5.86 | / | / | / | |

| S2 | 5 | 13.90 | 1.83 | 2.0965 | 0.6010 | 4.1977 |

| 6 | 13.66 | 1.20 | 1.5316 | 0.4525 | 3.8504 | |

| S3 | 7 | 15.75 | 2.37 | 1.7845 | 0.4321 | 5.4742 |

| 8 | 15.88 | 1.29 | 1.3765 | 0.3388 | 3.0388 | |

| H1 | 1 | 5.49 | 0.0471 | 0.3938 | 0.2034 | 9.8615 |

| 2 | 6.16 | 0.0371 | 0.3662 | 0.1830 | 8.9962 | |

| H2 | 3 | 6.51 | 0.0065 | 0.1417 | 0.0226 | 6.0439 |

| 4 | 6.04 | 0.0141 | 0.2388 | 0.2581 | 6.4697 | |

| H3 | 5 | 11.02 | 0.0753 | 0.3586 | 0.1970 | 8.8264 |

| 6 | 6.97 | 0.0344 | 0.2707 | 0.0758 | 8.9040 | |

| H4 | 7 | 6.51 | 0.0399 | 0.3161 | 0.1665 | 9.2728 |

| 8 | 5.91 | 0.0177 | 0.2028 | 0.1535 | 8.6696 |

| Lithology | Tuha Sandstone | Hechuan Shale |

|---|---|---|

| A1 | 2.2573 | 0.2795 |

| B1 | 0.1727 | 0.6397 |

| C1 | −2.3085 | −0.1437 |

| R2 (r35) | 0.4571 | 0.8003 |

| (r35) | 0.1857 | 0.7204 |

| A2 | 1.2527 | 1.5502 |

| B2 | 0.5548 | 0.2316 |

| C2 | −0.6095 | −0.327 |

| R2 (Frc) | 0.9267 | 0.8711 |

| (Frc) | 0.8900 | 0.8195 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Z.; Wang, S.; Guo, P.; Zhao, W. Utilizing Differences in Mercury Injection Capillary Pressure and Nuclear Magnetic Resonance Pore Size Distributions for Enhanced Rock Quality Evaluation: A Winland-Style Approach with Physical Meaning. Appl. Sci. 2024, 14, 1881. https://doi.org/10.3390/app14051881

Gu Z, Wang S, Guo P, Zhao W. Utilizing Differences in Mercury Injection Capillary Pressure and Nuclear Magnetic Resonance Pore Size Distributions for Enhanced Rock Quality Evaluation: A Winland-Style Approach with Physical Meaning. Applied Sciences. 2024; 14(5):1881. https://doi.org/10.3390/app14051881

Chicago/Turabian StyleGu, Zheng, Shuoshi Wang, Ping Guo, and Wenhua Zhao. 2024. "Utilizing Differences in Mercury Injection Capillary Pressure and Nuclear Magnetic Resonance Pore Size Distributions for Enhanced Rock Quality Evaluation: A Winland-Style Approach with Physical Meaning" Applied Sciences 14, no. 5: 1881. https://doi.org/10.3390/app14051881

APA StyleGu, Z., Wang, S., Guo, P., & Zhao, W. (2024). Utilizing Differences in Mercury Injection Capillary Pressure and Nuclear Magnetic Resonance Pore Size Distributions for Enhanced Rock Quality Evaluation: A Winland-Style Approach with Physical Meaning. Applied Sciences, 14(5), 1881. https://doi.org/10.3390/app14051881