Abstract

Expansive soil exhibits significant swellings and shrinkages, which may result in severe damage or the collapse of structures built upon it. Calcium-based admixtures, such as lime, are commonly used to improve this problematic soil. However, traditional chemical additions can increase significant environmental stress. This paper proposes a sustainable solution, namely, the use of lignin fiber (LF) from the paper industry to partially replace lime as an amendment for expansive soils. Both the macroscopic and microscopic characteristics of the lignin fiber-treated expansive soil are extensively studied. The results show that the mechanical properties of expansive soil are improved by using lignin fiber alone. Under the condition of an optimal dosage of 8%, the compressive strength of lignin fiber-modified soil can reach 193 kPa, the shear strength is increased by 40% compared with the untreated soil, and the water conductivity is also improved with the increase in dosage. In addition, compared with 2% lime-modified soil, the compressive strength of 8% lignin fiber- and 2% lime composite-treated expansive soil increased by 50%, the cohesion increased by 12%, and the water conductivity decreased significantly. The microstructure analysis shows that at an 8% lignin fiber content, lignin fibers interweave into a network in the soil, which effectively enhances the strength and stability of the improved soil. Simultaneously, the fibers can form bridges across the adjacent micropores, leading to the merging of pores and transforming fine, dispersed micropores into larger, connected macropores. Lime promotes the flocculation of soil particles, forming larger aggregates and thus resulting in larger pores. The addition of fibers exerts an inhibitory effect on the flocculation reaction in the composite-improved soil. In conclusion, lignin fibers are an effective addition used to partially replace calcium admixture for the treatment of expansive soil, which provides a sustainable and environmentally friendly treatment scheme for reducing industrial waste.

1. Introduction

Expansive soil is widespread in the world, especially in China; one-third of the country’s land area is occupied by expansive soil [1]. These soils are considered problematic soils due to their volume change behavior caused by their water-sensitive properties. This behavior is mainly induced by the clay minerals of the montmorillonite family. These typical clay minerals have a strong binding capacity with water, showing swelling and softening under water absorption and shrinkage and hardening under water loss [2,3]. Globally, expansive soils impact over 8 million square kilometers, affecting countries including the United States, India, and Australia. In these regions, the associated economic losses to infrastructure are estimated to run into billions of USD annually. Considering the extensive impacts of expansive soils, it is crucial to conduct research and implement sustainable mitigation strategies within civil engineering projects. This ensures compliance with engineering standards and minimizes potential adverse effects. [4].

Soil improvement is usually used to improve the engineering properties of expansive soils. Soil improvement methods are mainly divided into two categories: physical and chemical improvement. The physical improvement method usually includes the addition of fibers [5,6,7], geotextiles [8], etc., to the soil or changes to the particle gradation by adding coarse particles such as steel slag [9], sand [10,11], rubber particles [12], gravel [13], and construction waste [14], thereby enhancing the physical and strength characteristics of the soil. In addition to these materials, bentonite has been successfully used to improve soil compactness, reduce permeability, and enhance mechanical stability [15]. At present, the chemical modification method mainly involves adding lime [16,17], cement [18], or chemical slurry [19] to the soil and aims to achieve soil improvement by adjusting the mineral composition or structure inside the soil. However, the production and use of alkaline chemical materials such as lime and cement will produce a large amount of carbon dioxide [20].

Nowadays, more and more attention has been paid to green and economically improved materials in the field of soil treatment. Lignin fiber, as an economical byproduct of the paper industry with a wide range of sources, has a high level of toughness and is insoluble in water. It is non-toxic, tasteless, and environmentally friendly [21]. In particular, lignin fibers have been treated at high temperatures and chemically modified to provide excellent resistance to degradation. This resistance allows lignin fibers to maintain their structural stability in alkaline or other harsh environments, which is not the case with many other natural fibers. Currently, lignin fiber has been relatively widely used in improving the performance of asphalt pavement [22,23,24], but its application in the geotechnical field is still rare. Moslemi et al. [25] treated soil with lignin fibers and found that the shear strength of the improved soil was significantly improved by longer fibers. Dong et al. [26,27] added lignin fibers into loess, and their results showed that the lignin fibers significantly improved the strength, thermal conductivity, thermal diffusivity, and specific heat of the loess. Dong et al. [28] also studied the improvement effect of lignin fibers on the strength and deformation characteristics of red clay through a series of experimental tests and a scanning electron microscope test. The results showed that lignin fibers can improve the strength of red clay to a certain extent. Chen et al. [29] showed that lignin fiber–fly ash-treated expansive soils had greater strength and water stability. Fan et al. [30] studied the effects of freeze–thawing on lignin fiber-treated expansive soils, and the results showed that lignin fibers can effectively improve the freeze–thaw resistance of expansive soils. Previous studies have focused on the general effect of lignin fiber on different kinds of soils. The effectiveness of lignin fiber improvement has been confirmed, but a certain gap in strength compared to traditional lime-modified soil has also been observed. According to existing studies, the optimal dosage of traditional amendments such as lime for expansive soils is generally 4–6% [31,32]. Although the strength of this amendment method has improved, the carbon emissions and environmental pollution to the surrounding soil caused by high dosages should not be underestimated. Considering both environmental friendliness and improvement effects, the lignin fiber and lime composite improvement method could be a potential approach. However, there is limited study in this area. Furthermore, the microscopic mechanism of lignin fiber treatment is still not clear.

This study aims to explore a novel method for soil improvement which involves the use of lignin fiber (LF) from the paper industry combined with lime to enhance the properties of expansive soils. Lime is currently a common material for improving expansive soils, but its environmental impact has prompted a search for more sustainable alternatives. This paper proposes the partial replacement of lime with lignin fibers to reduce the environmental load and investigates the potential effects of this composite material on the mechanical properties and microstructure of the soil. The uniqueness of this method lies in its use of industrial byproducts for soil stabilization, which not only lowers treatment costs but also enhances environmental sustainability. By optimizing the ratio of lignin fibers to lime, this study provides an effective approach to the sustainable improvement of expansive soils, utilizing industrial waste and enhancing the eco-friendliness and economic benefits of soil improvement materials.

2. Materials and Methods

2.1. Test Materials

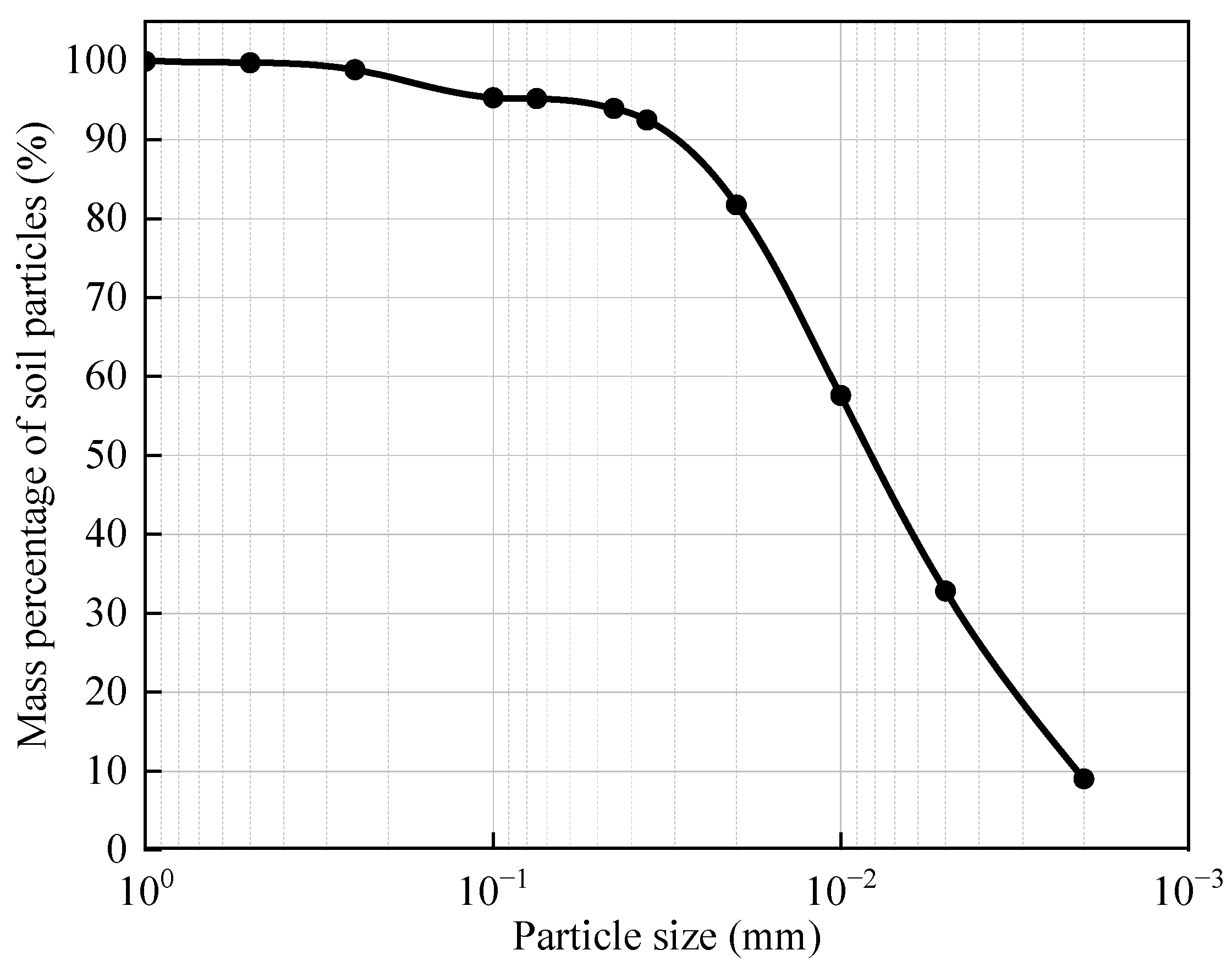

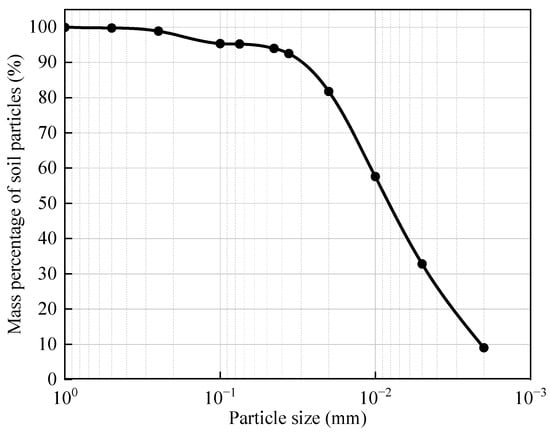

The soil used in this experiment was collected from a construction site in Ankang City, Shanxi Province. The sampling depth was 2 m. Expansive soil from Ankang City, located in a renowned expansive soil region south of the Qinling Mountains, was chosen for its high expansiveness and plasticity, making it an ideal subject for studying the properties and engineering challenges of such soils. The particle size distribution of the soil was obtained using the BT-9300ST from Liaoning Dandong Baxter Instrument Co. (Dandong, China) laser, as shown in Figure 1. Within the framework of the Unified Soil Classification System (USCS) [33], the expansive soil, characterized by a liquid limit of 58.41%, a plastic limit of 33.73%, and a plasticity index of 24.68%, was classified as a high-plasticity clay (CH). Furthermore, this soil exhibited a free swell ratio of 77%, categorizing it as a soil of medium expansiveness. The basic physical properties of the soil were measured in accordance with the “Standard for Test Methods of Soil Engineering” (GB/T 50123-2019) [34]. More detailed basic physical properties of the soil are shown in Table 1. The mineral composition of the test soil was determined by an X-ray diffraction (XRD) semi-quantitative analysis, in which the content of montmorillonite was 24% and the content of illite was 20%, as shown in Table 2.

Figure 1.

Particle gradation curve of Ankang expansive soil.

Table 1.

Basic physical indexes of Ankang expansive soil.

Table 2.

XRD mineral composition of Ankang expansive soil.

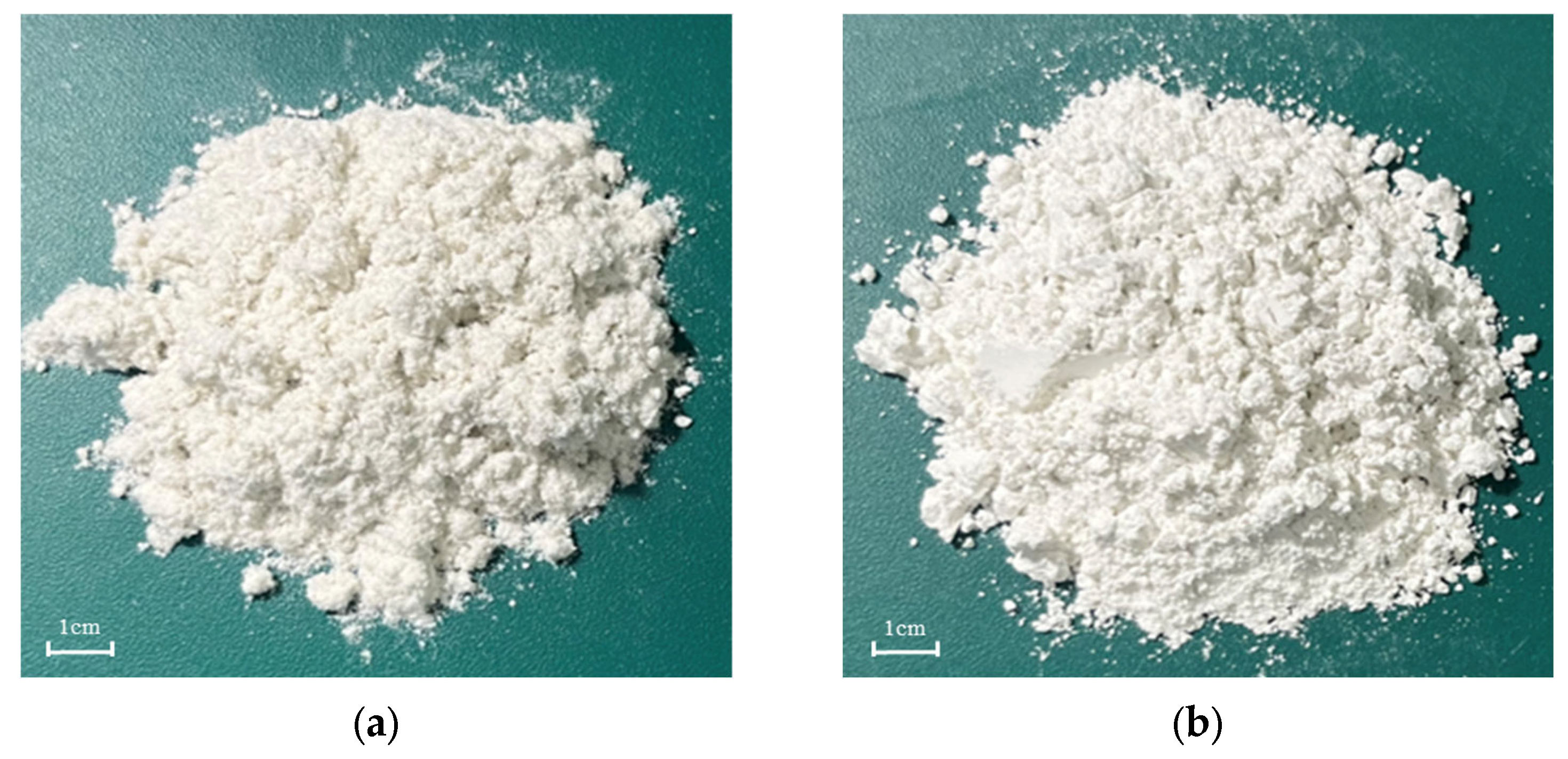

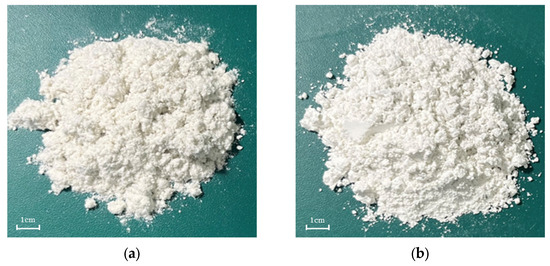

The lignin fibers are grayish-white, neutral in pH, insoluble in water, and environmentally friendly. They have good hydrophilic properties. These fibers are organic fibers extracted from chemically treated natural wood, which have good chemical stability and corrosion resistance, as illustrated in Figure 2a. The lime used in the test contains calcium oxide at a concentration of ≥98%, as depicted in Figure 2b.

Figure 2.

Tested materials: (a) lignin fiber and (b) lime.

2.2. Sample Preparation

First, the undisturbed soil was air-dried, crushed, and sifted through a 2 mm sieve to prepare soil samples. The lignin fibers were filtered through a 1 mm sieve and mixed with the dry, expansive soils [35]. Subsequently, pure water was gradually sprayed into the mixture until it reached the optimum moisture content. The mixed soil samples were sealed in a fresh-keeping bag and stored for 12 h to ensure uniform water distribution within the samples.

In this test, the diameter of the unconfined compressive specimen was 38 mm, and the height was 80 mm. The direct shear specimen was a round cake-shaped sample with a diameter of 50 mm and a height of 20 mm. The infiltrated sample was a cylindrical sample with a diameter of 38.1 mm and a height of 20 mm. The specific sample production process was as follows: The sample was compacted into three layers. After compaction, the prepared samples were wrapped in cling film and placed in a constant temperature and humidity box for standard curing. The curing conditions were 20 °C and a humidity of 92% ± 2%. The test parameters and sample preparations followed the “Standard for Test Methods of Soil Engineering” (GB/T 50123-2019) [34].

3. Test Scheme

In this study, the mechanical behavior of the treated expansive soils was measured. The test program included the unconfined compressive strength test, the direct shear test, and the hydraulic conductivity test. Moreover, the microstructure of the improved soil was analyzed using scanning electron microscopy and mercury intrusion porosimetry. Aiming to reduce the amount of lime, this experiment sought to determine the optimal dosage of lignin fibers for composite improvement. By comparing the expansive soil improved with only lignin fiber, only lime, and the composite improvement, the study discusses the advantages of the various improvement methods. The specific test dosage ratio information is presented in Table 3.

Table 3.

Basic information on soil samples.

In the unconfined compressive strength test, the axial loading rate was set as 1 mm/min. The instrument used in the direct shear test was a pneumatic direct shear instrument with a strain rate of 0.8 mm/min, and the vertical pressures were 50 kPa, 100 kPa, 200 kPa, and 400 kPa, respectively. In the hydraulic conductivity test, the saturated hydraulic conductivity of the improved soil was measured using a rigid wall permeameter, with the water injection pressure set to 1 MPa (equivalent to a water head difference of 1 m). The instrument used for the scanning electron microscopy analysis was a Hitachi S4800 from Qingdao Jiading Analytical Instrument Co. (Qingdao, China), with magnifications of 500× and 1000×. The equipment used for the mercury intrusion porosimetry was an Auto-pore IV 9510 from Micromeritics Instrument Corp. (Norcross, GA, USA), capable of measuring pore sizes ranging from 5 nm to 360 μm.

4. Test Results Analysis

4.1. Analysis of the Results of Lignin Fiber-Improved Soil

4.1.1. Unconfined Compressive Strength Test

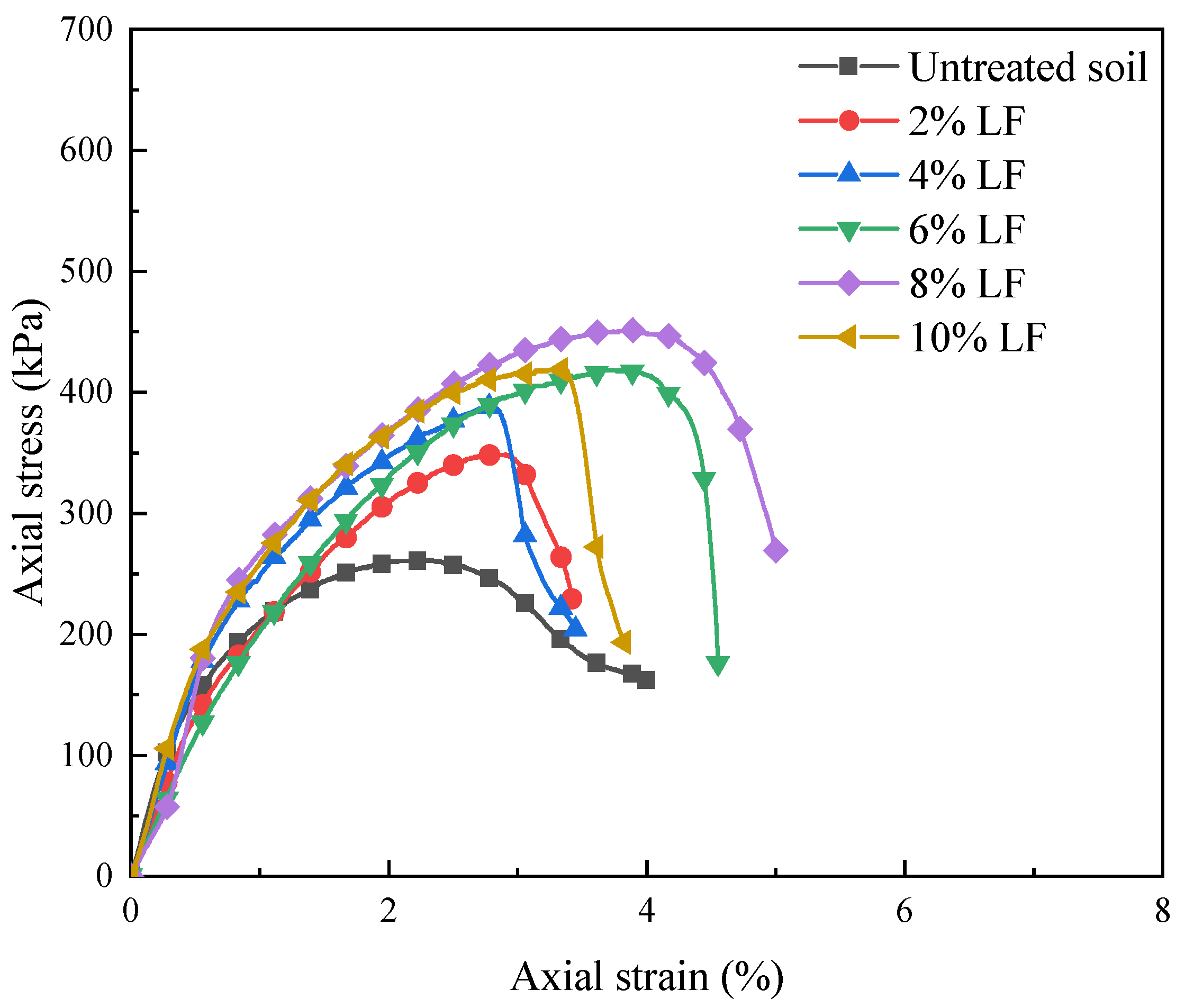

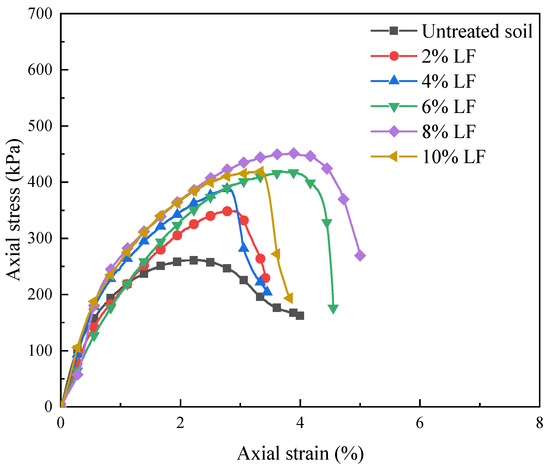

Figure 3 demonstrates that the addition of an appropriate amount of lignin fibers can increase the compressive strength of expansive soil. The unconfined compressive strength of the improved soil initially increases with the increasing lignin fiber content, reaching a maximum at 8%. The addition of 2% to 10% lignin fibers increased the unconfined compressive strength by 87 kPa, 127 kPa, 157 kPa, 191 kPa, and 163 kPa, respectively. As the lignin fiber content increases, the slope of the stress–strain curve also gradually increases, indicating that lignin fibers contribute to the improvement of the elastic modulus of expansive soil. After the addition of lignin fibers, the stress–strain curve of the improved soil exhibits stress softening, indicating that it does not alter the stress–strain characteristics of the expansive soil. At 2% lignin fiber content, lignin fibers are mainly present in the soil alone, and the effect on compressive strength is limited. As the lignin fiber content increases, the lignin fibers not only weave together to form a network structure but also effectively fill the pores between the soil particles. When the lignin fiber content reaches 10%, there are too many lignin fibers that cannot be evenly distributed in the soil and tend to agglomerate. As a result, a significant reduction was observed in soil strength and stability. This behavior is aligned with findings by Marcuello et al. (2020), who reported that relative humidity impacts the Young’s modulus of lignocellulosic polymers and their adhesion with cellulose nanocrystals at the nanoscale, providing a microstructural explanation for the variance in performance observed at different lignin fiber concentrations [36].

Figure 3.

The relationship curves between the axial stress and axial strain of the expansive soil improved by different contents of lignin fibers.

As shown in Figure 3, the strain at the maximum stress initially increases and then decreases with the increase in lignin fiber content, peaking at 8%. The strain at the maximum stress for the other doped soil samples exceeds that of the untreated soil, indicating that lignin fibers enhance the ductility of expansive soils. A moderate fiber content improves the toughness and strength of the soil by providing a physical bridging effect, which increases soil cohesion and crack resistance. Aslan and Zülfü [37] also observed that the enhancement of unconfined compressive strength in clay soils through basalt fiber (BF) additions is effective only to a certain limit. Specifically, a 4% BF reinforcement raised the qu value by 29.35% compared to unreinforced clay, but a further increase to 5% BF resulted in a slight reduction of 2.02%. This indicates that more fibers can lead to a greater fiber concentration, which results in the formation of aggregates, as also observed by Dong Fanchao et al. in their study on the shear strength of loess improved with lignin fibers, where a high fiber content led to fiber agglomeration [38]. Similarly, this decline is attributed to fiber aggregation caused by electrostatic interactions at higher fiber concentrations, which prevents even dispersion and diminishes the interface effectiveness between the fibers and the soil [39].

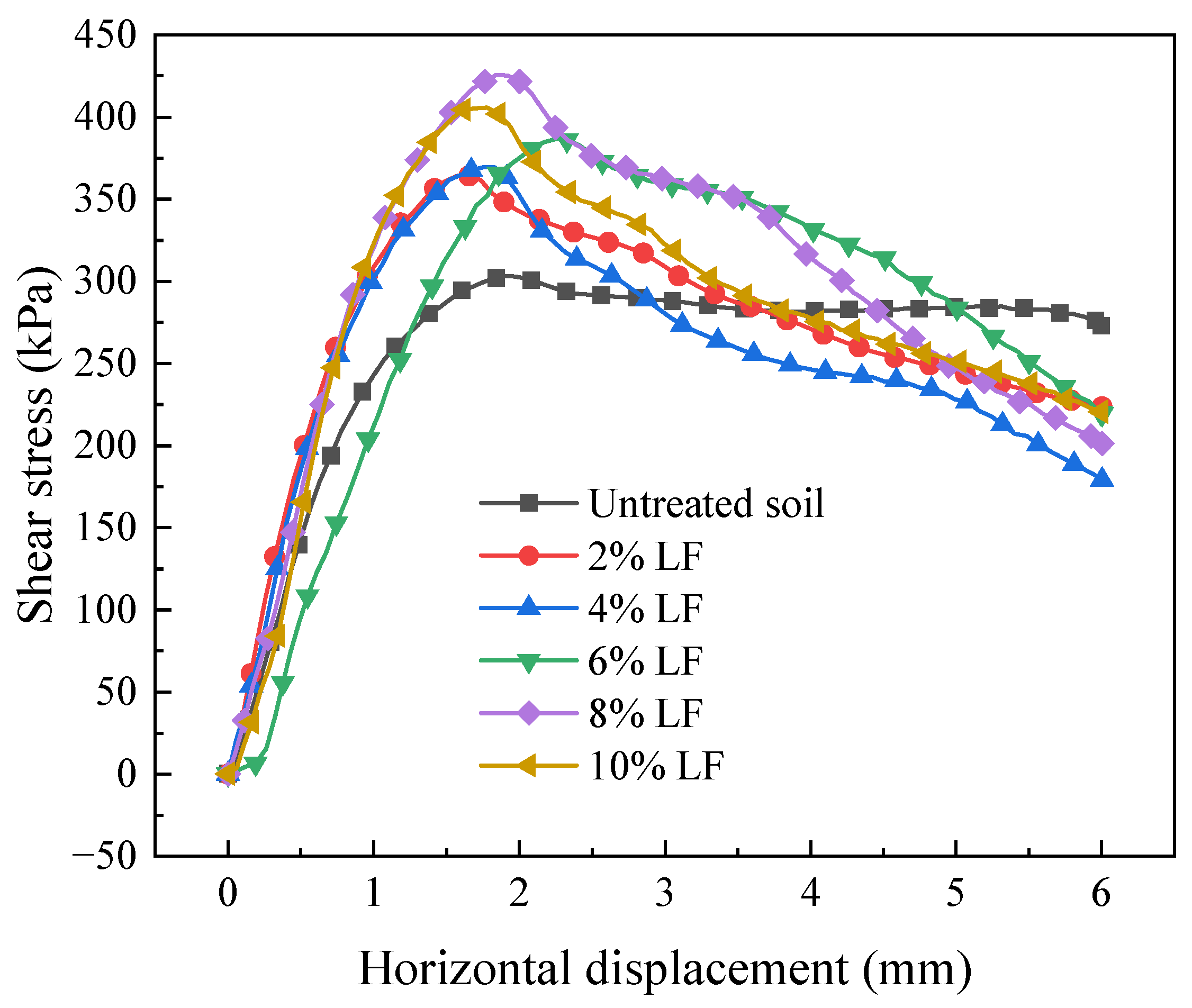

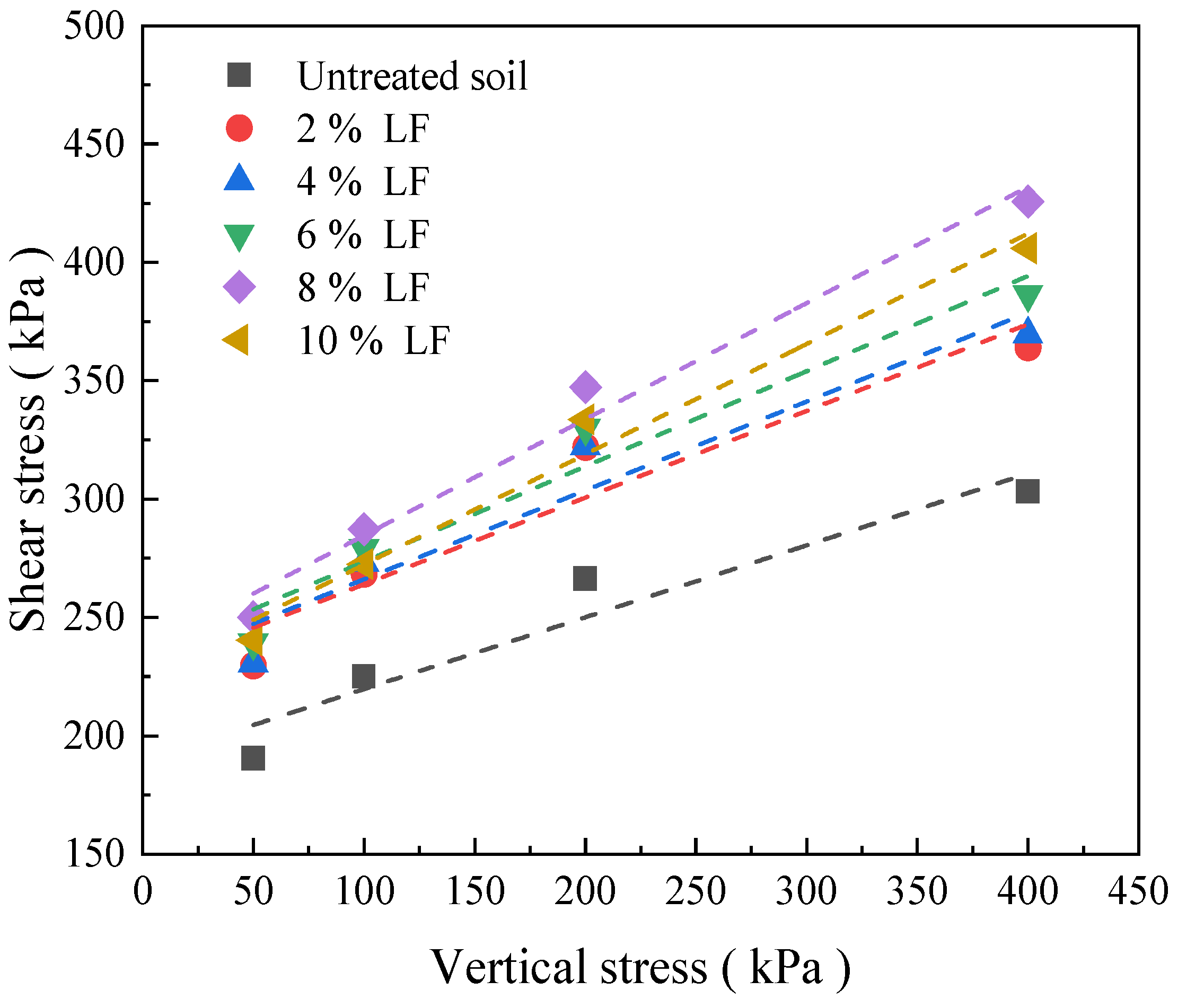

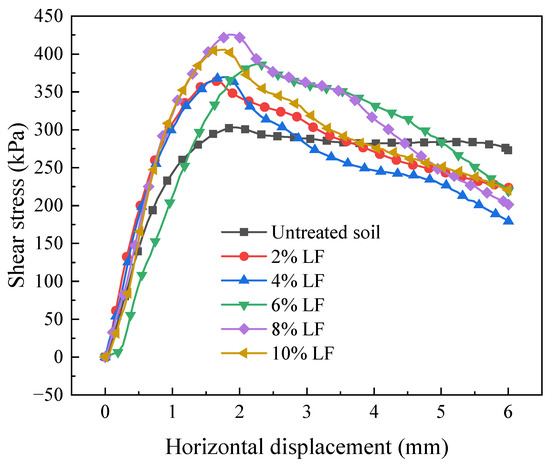

4.1.2. Direct Shear Test

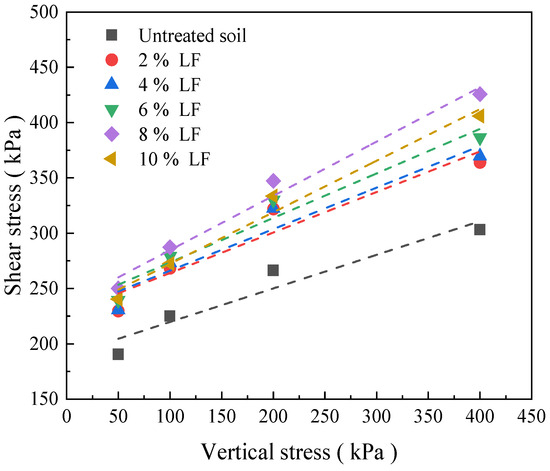

Figure 4 shows the stress–strain relationship curves of the improved soil with different lignin fiber contents under a 400 kPa vertical pressure. As shown in Figure 4, after fibers are added to the soil sample, the shear stress increases with the shear displacement and gradually decreases after reaching its peak. The shear strength of the improved soil for five different dosages is 364.15, 369.75, 386.56, 425.77, and 405.91 kPa, respectively, and the shear strength increase rates range from 20.12% to 40.57%, indicating a significant improvement in shear resistance. Figure 5 presents the fitting curve of the direct shear test for the improved soil with different lignin fiber contents. Under each vertical stress, the shear strength of the fiber-improved soil is greater than that of the untreated soil. The results indicated that the treated sample with a fiber content of 8% had the highest shear strength. This can be attributed to the optimal balance between fiber volume and dispersion within the soil matrix. At this concentration, the fibers are sufficiently abundant to significantly enhance the soil structure by bridging soil particles and providing additional resistance against shear forces. However, they are not so concentrated as to cause significant fiber agglomeration, which can weaken the soil by reducing effective stress transfer and soil particle contact, as previously discussed with reference to the findings from Dong Fanchao et al. [38] and Aslan and Zülfü [37]. This optimal fiber content thus maximizes the reinforcement benefits while minimizing the negative effects of over-concentration, leading to the highest shear strength observed in the samples.

Figure 4.

The relationship curves of the shear stress and horizontal displacement of the expansive soil improved by different contents of lignin fibers.

Figure 5.

The fitting curves of the shear strength and vertical stress of the expansive soil improved by different contents of lignin fibers.

Table 4 demonstrates that the cohesion (c) and internal friction angle (φ) of the soil improved with lignin fiber initially increase and then decrease as the lignin fiber content increases. At 8% lignin fiber content, the cohesion rose from 166.83 kPa to a maximum value of 210.53 kPa. At 10% lignin fiber content, the cohesion slightly decreased to 204.16 kPa. Similarly, the internal friction angle (φ) increased from 16.12° to a maximum of 26.00° at 8% fiber content before decreasing to 24.44° at 10% fiber content. This phenomenon is attributed to the toughness of the fibers and their ability to absorb stress and energy during shearing. The distribution of fibers in the soil forms an effective network that prevents excessive movement and the failure of soil particles under stress, enhancing the overall shear resistance and improving the cohesive strength of the soil [6,40]. However, when the fiber content is very high, the fibers cannot be evenly distributed in the soil, leading to the formation of fiber aggregates. This decreases the strength of the soil. The trend in the internal friction angle is similar to that of cohesion. The addition of fibers significantly changed the frictional properties of the fracture surface of the expansive soil. This is mainly due to most fibers on the shear plane not being arranged parallel to the shear direction. This enhances the interlocking between soil particles and fibers, thereby increasing the internal friction angle.

Table 4.

Fitting parameters of the cohesion and internal friction angle of the expansive soil improved by different contents of lignin fibers.

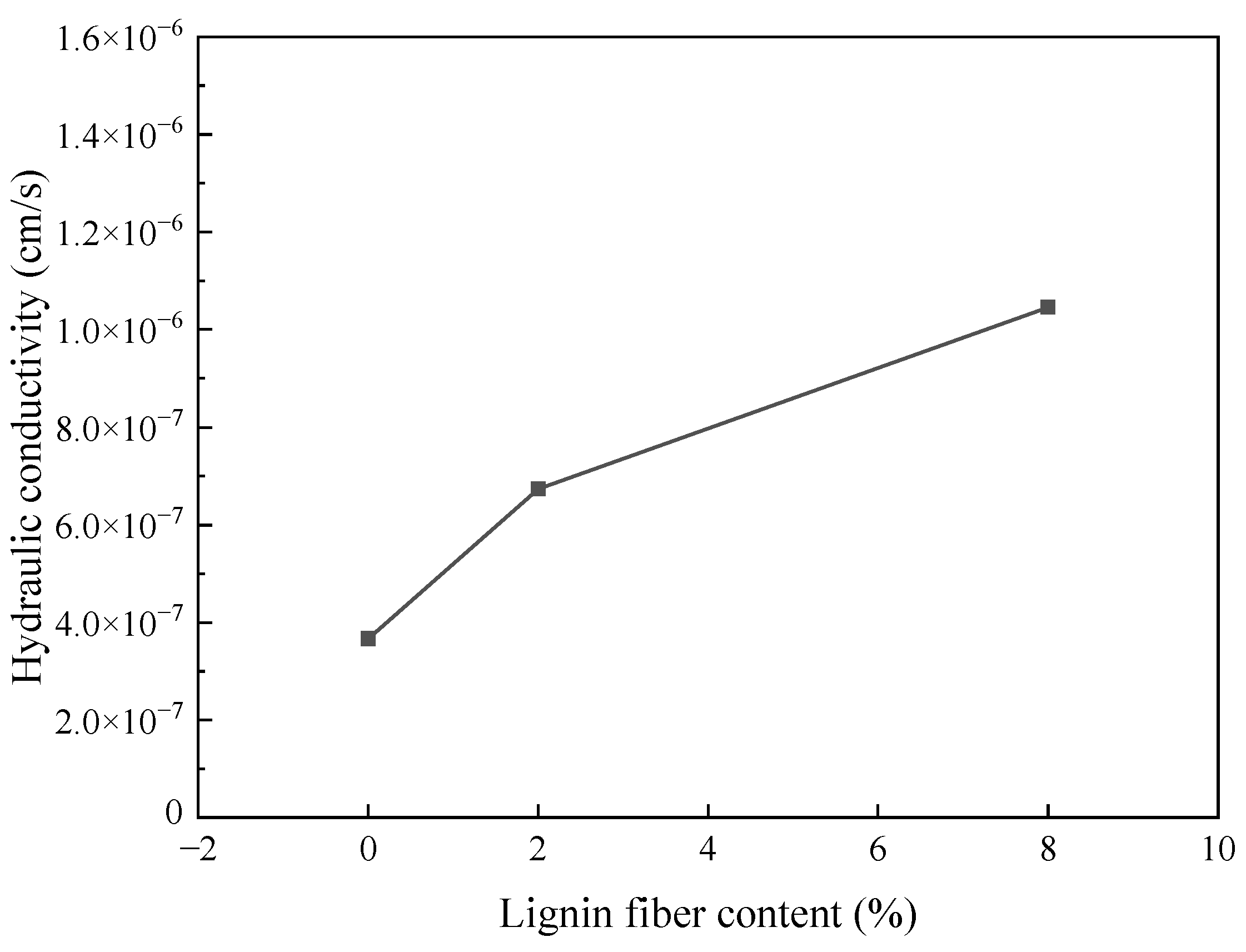

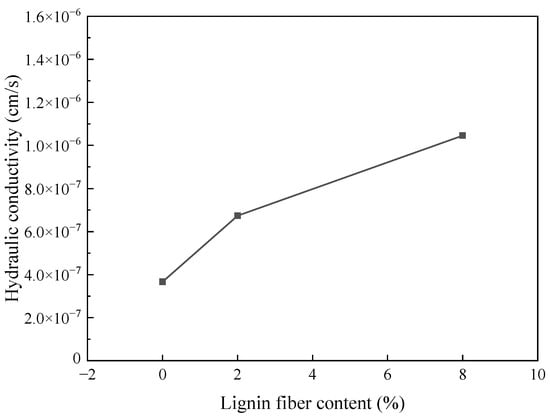

4.1.3. Hydraulic Conductivity Test

Based on the results of the unconfined compressive strength and direct shear tests, the optimum content of lignin fibers was determined to be 8%. Consequently, a rigid wall permeameter was utilized to conduct the hydraulic conductivity test on soil improved with 8% lignin fiber. Untreated soil and soil improved with 2% lignin fiber served as the control group.

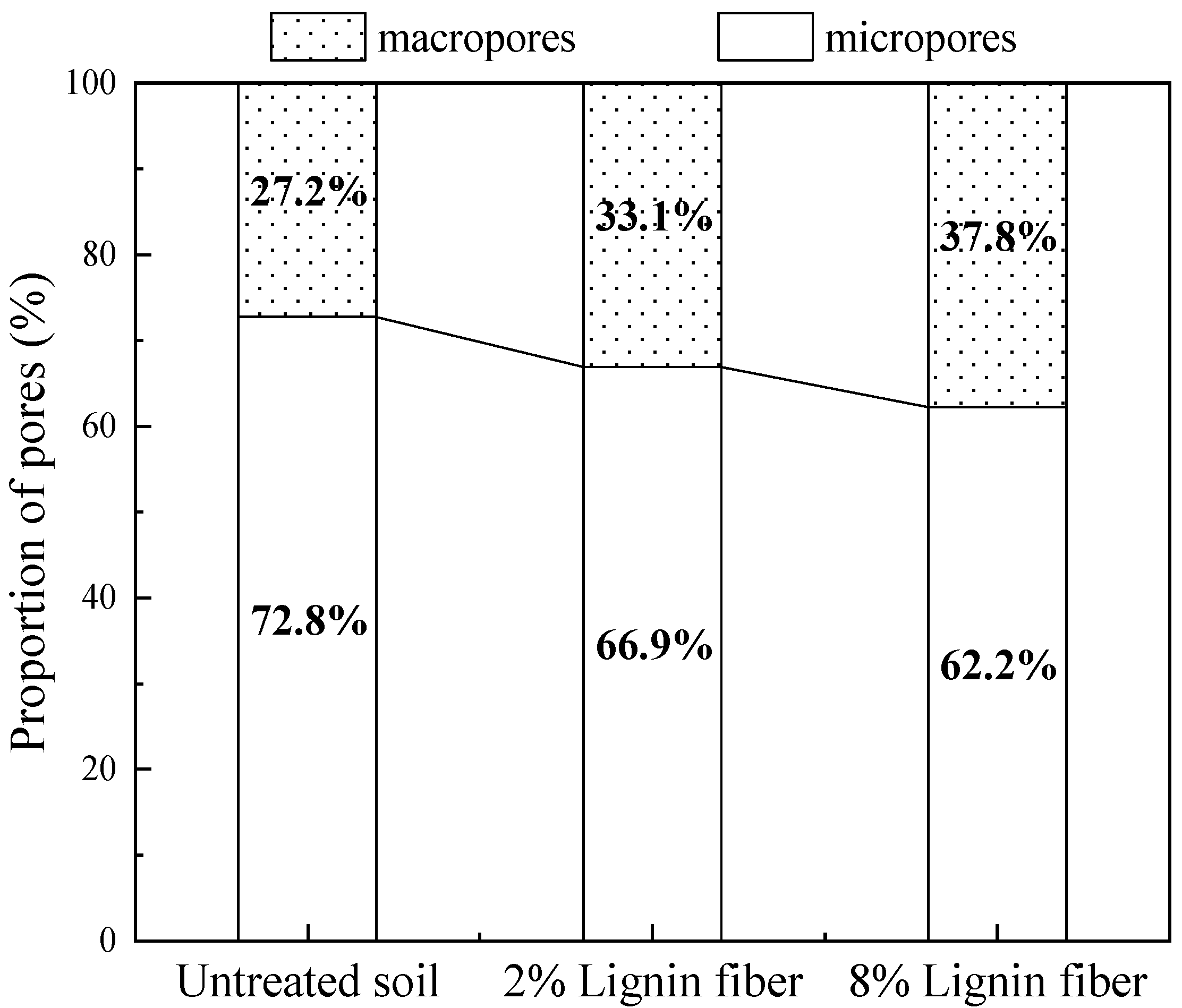

As shown in Figure 6, the hydraulic conductivity of the untreated soil, 2% fiber-improved soil, and 8% fiber-improved soil is 3.67 × 10−7 cm/s, 6.74 × 10−7 cm/s, and 1.05 × 10−6 cm/s, respectively. It is observed that after the addition of lignin fibers, the hydraulic conductivity of the sample slightly increases, with the growth rate ranging from 45% to 65% as the content increases. This demonstrates that lignin fibers significantly influence the hydraulic conductivity of expansive soil. When lignin fibers are mixed with soil, larger macropores will be formed, which increase the permeability of the treated soils. These findings are corroborated by the detailed pore structure analysis presented in Figure 9, where the proportion of macropores in the soil significantly increases from 27.2% in the untreated soil to 33.1% and 37.8% in the 2% and 8% fiber-improved soil, respectively. This is consistent with the results of the hydraulic conductivity tests and supports the conclusion that lignin fibers enhance soil permeability by forming larger macropores. This aligns with the findings from Maher and Ho [41], who reported that the inclusion of fibers in kaolinite clay significantly increased its hydraulic conductivity, especially at higher fiber contents. Similarly, Miller and Rifai [42] observed that within certain limits, the fiber content helped maintain the hydraulic conductivity at acceptable levels for waste containment applications, although higher contents significantly increased the conductivity.

Figure 6.

The relationship curve of the hydraulic conductivity and lignin fiber contents of the expansive soil improved by lignin fibers.

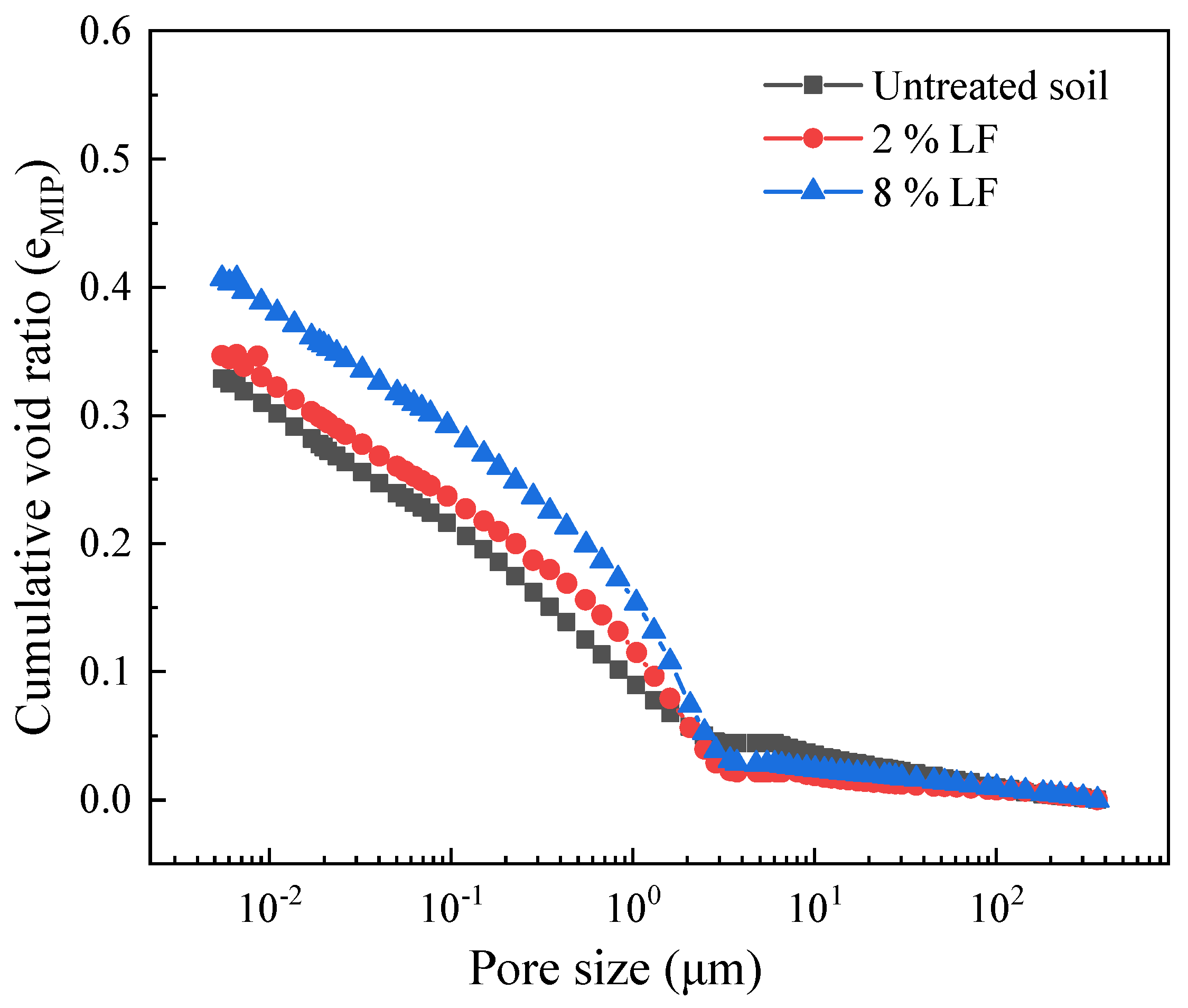

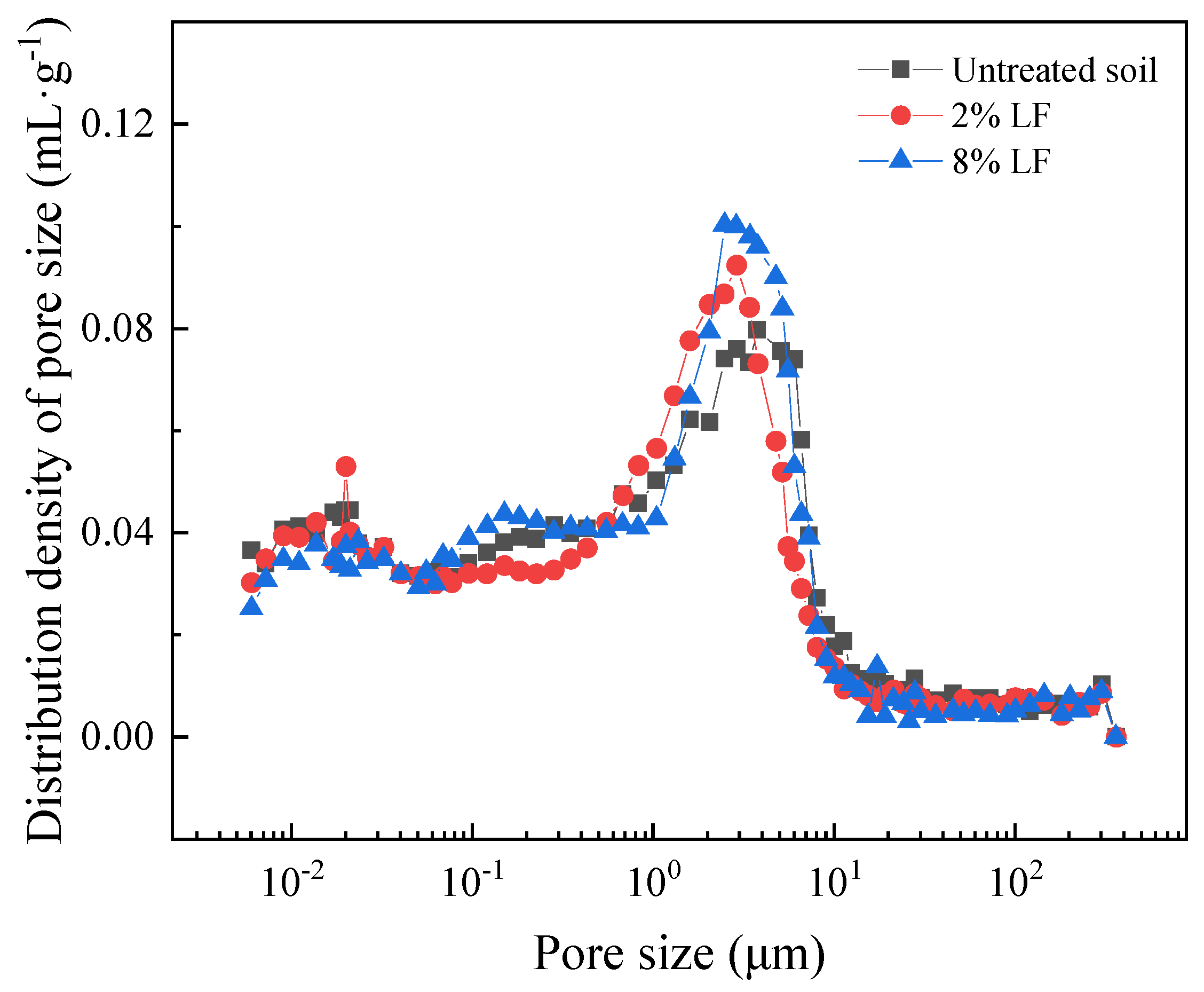

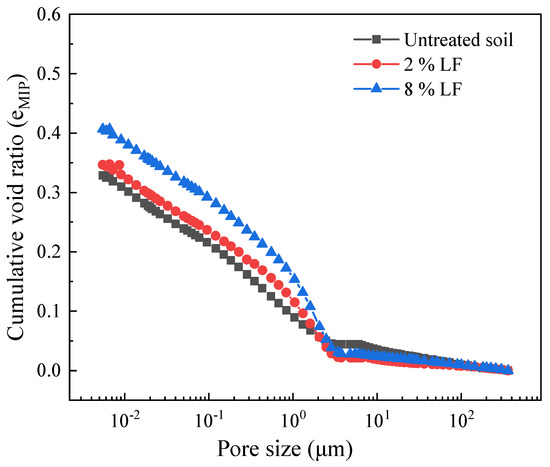

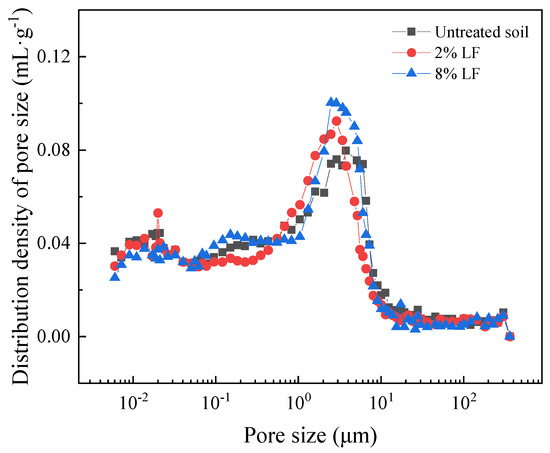

4.1.4. Microstructure Investigations

As shown in Figure 7, treatment with lignin fibers significantly increases the total mercury intrusion porosity. As the lignin fiber content increases, the cumulative void ratio of the fiber-improved soil continues to increase. Figure 8 presents the pore size distribution curve of the expansive soil and the lignin fiber-improved soil. As shown in Figure 8, the pore size distribution of the fiber-improved soil exhibits a unimodal structure. After the addition of fibers, the peak value of the modal size shifts to the left, from 3.76 to 2.48 μm, gradually. However, the quantities of these pore families with peak values increased due to the lignin fiber treatment.

Figure 7.

Cumulative pore distribution curves of expansive soil improved by different contents of lignin fibers.

Figure 8.

The pore density distribution curves of expansive soil improved by different contents of lignin fibers.

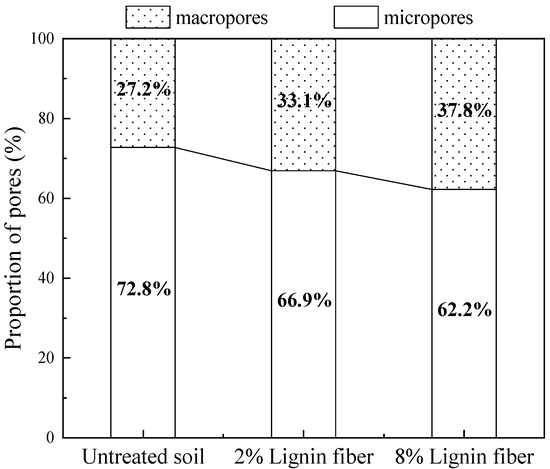

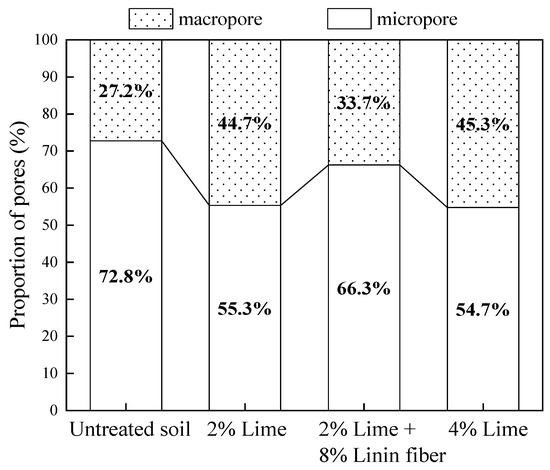

To further analyze the effect of the lignin fiber content on the pore distribution of the amended expansive soils, these pores were classified into two categories: micropores (<1 µm) and macropores (>1 µm).

Figure 9 demonstrates that the proportions of macropores and micropores in the untreated soil were 27.2% and 72.8%, respectively. With the increase in fiber content, the proportion of macropores in the 2% lignin fiber-improved soil increased to 33.1%, while the proportion of micropores decreased to 66.9%. The proportions of macropores and micropores in the 8% lignin fiber-improved soil stood at 37.8% and 62.2%, respectively. The proportion of macropores in the improved soil significantly increased by 5.9% to 10.6% compared with the untreated soil. This increase in macropores is primarily attributed to the physical filling of lignin fibers in the micropores of the samples. In addition, lignin fibers can form aggregates, creating more macropores. As a result, the increasing macropores can increase the permeability of the treated soil. This is consistent with the results of the hydraulic conductivity tests above.

Figure 9.

The percentage change in various types of pores in expansive soil improved by different contents of lignin fibers.

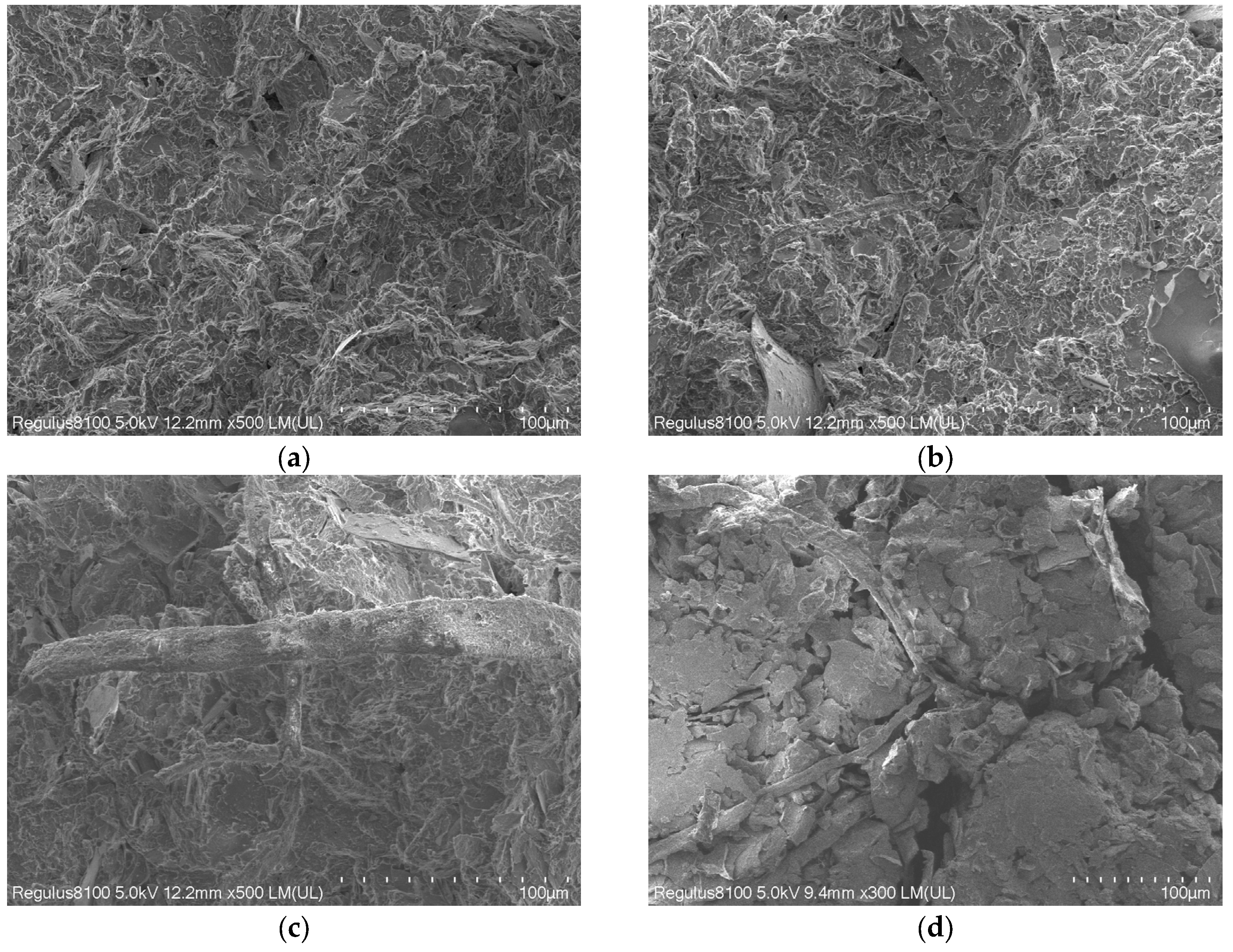

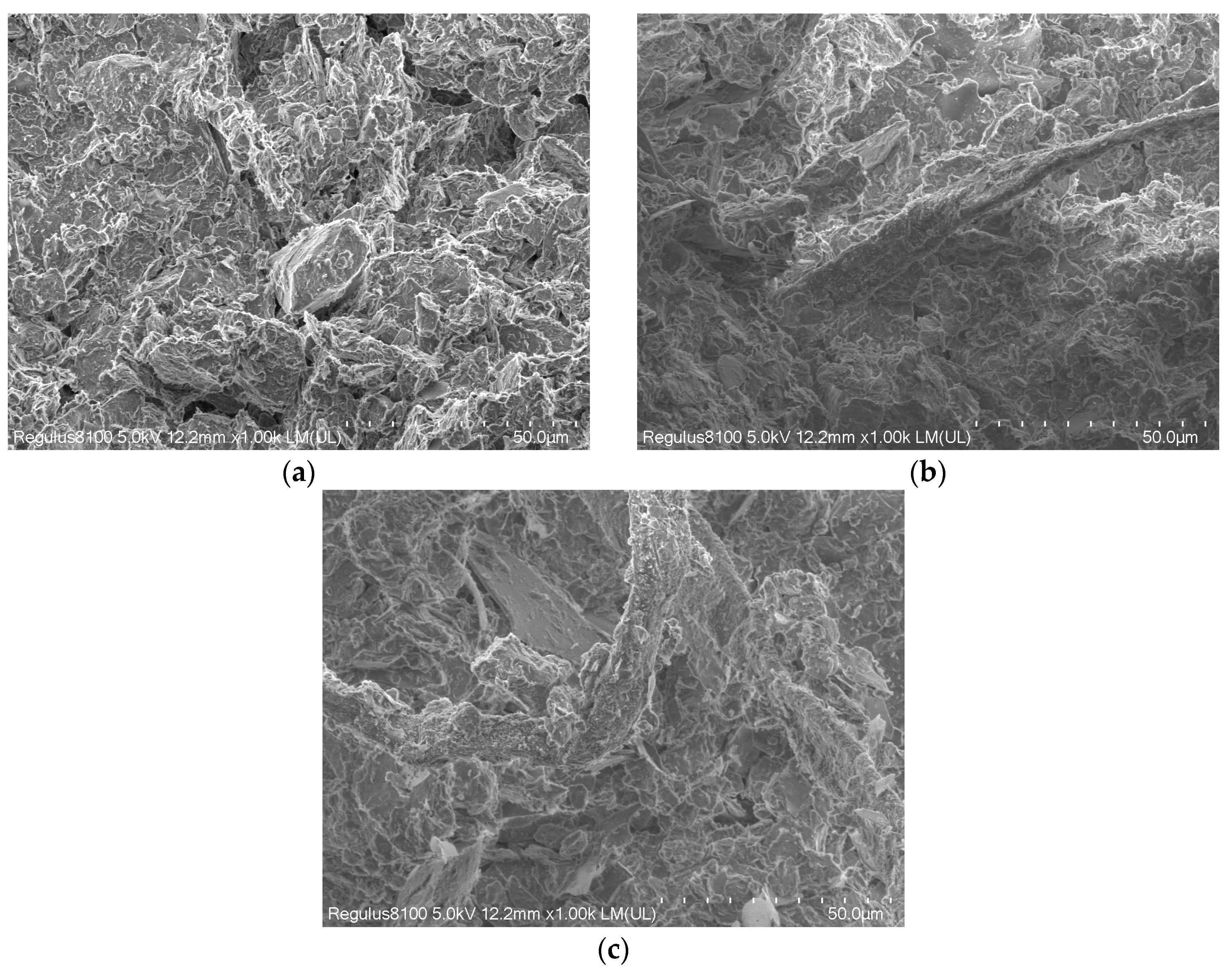

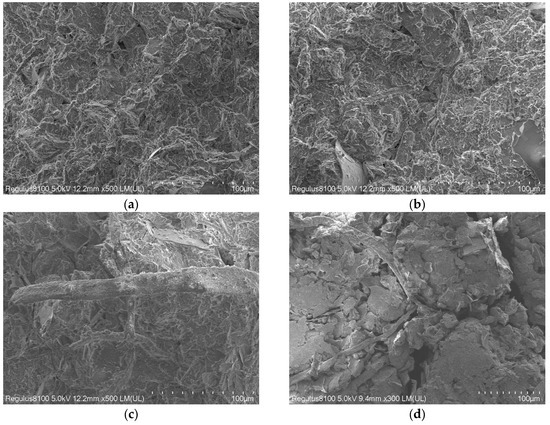

Figure 10 presents a scanning electron microscope image of lignin fiber-improved soil at various dosages. As shown in Figure 10b, with a lignin fiber content of 2%, the fibers predominantly exist in the soil individually and connect with the soil particles. In this case, the tensile stress of individual fibers contributes to the increasing strength of the treated soil. As shown in Figure 10c, at a fiber content of 8%, the fibers intertwine in the soil, forming a grid structure and exhibiting a bridging effect. As shown in Figure 10d, the fibers effectively fill the pores. Consequently, besides the effect of the tensile strength of the fibers, a three-dimensional enhancement effect is also superimposed. That is, lignin fibers not only fill the pores but also make the soil denser, thereby enhancing its strength and stability, leading to a largely improved shear strength in the case of the samples treated with a higher content of fibers. Note that, when an excessive amount of fibers is added, agglomeration among the fibers may occur, altering the particle connection structure and reducing the soil strength.

Figure 10.

Scanning electron microscopy of lignin fiber-improved soil: (a) lignin fiber content of 0% (500 times), (b) lignin fiber content of 2% (500 times), (c) lignin fiber content of 8% (500 times), and (d) lignin fiber content of 8% (300 times) (different magnifications for subfigure (d)).

4.2. Analysis of Test Results of Lignin Fiber–Lime Composite-Improved Soil

4.2.1. Unconfined Compressive Strength Test

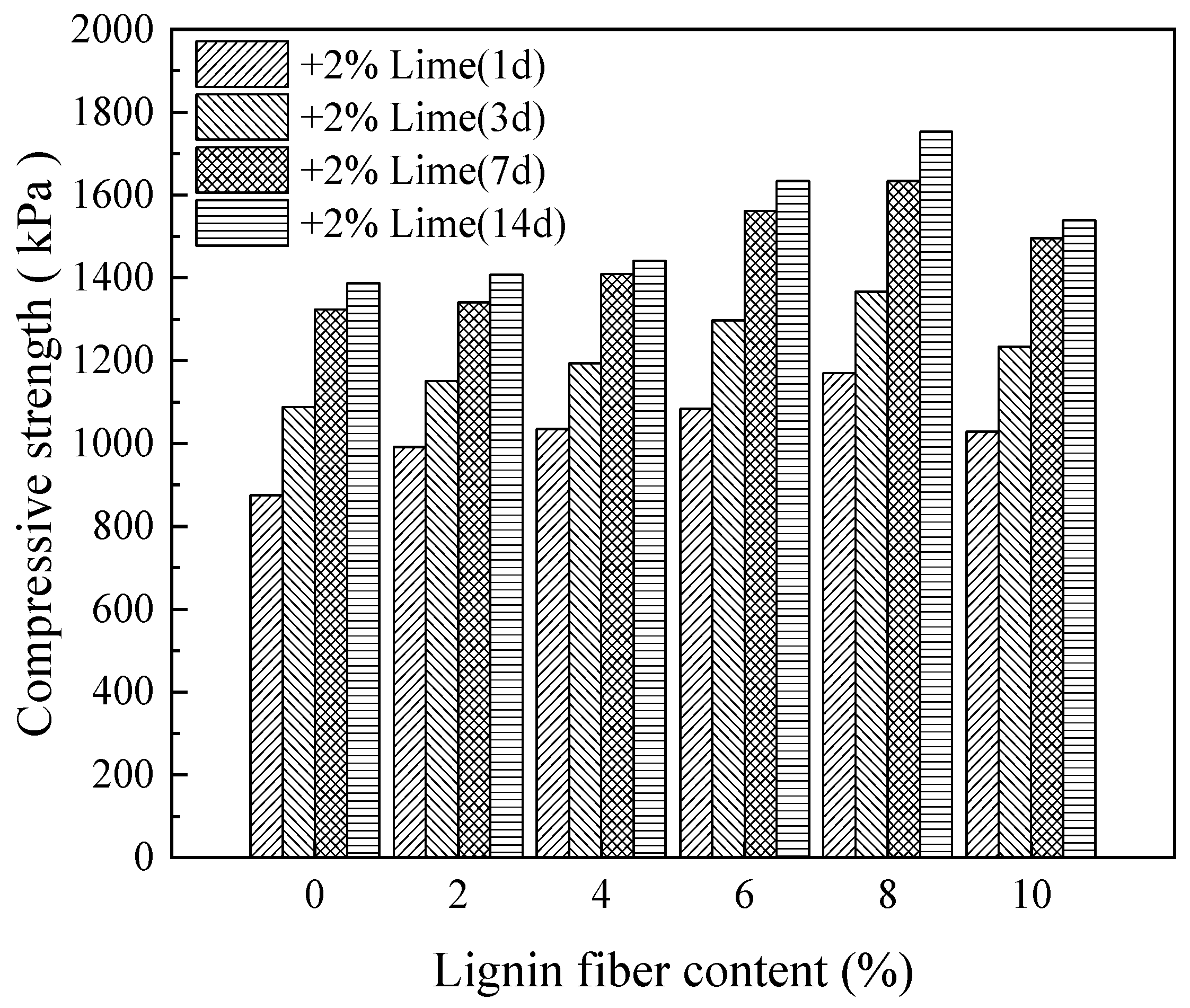

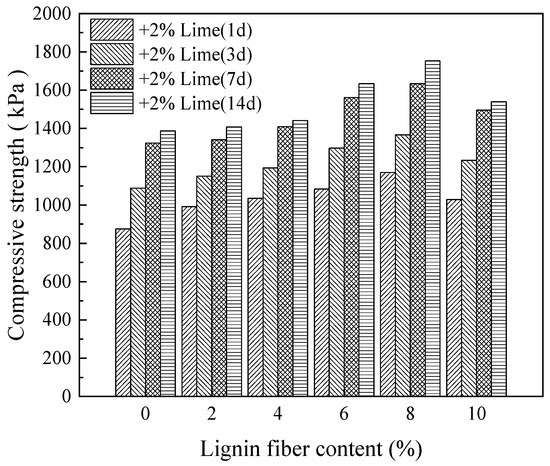

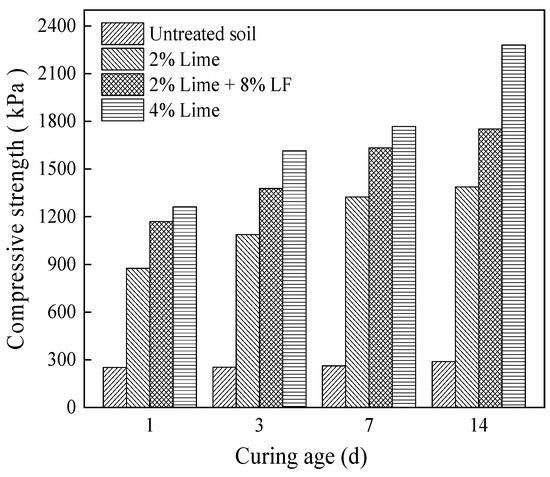

Based on the test results for the solely lignin fiber treatment, an optimum content of 8% was identified. In order to reduce lime addition, a series of experimental tests were performed to study the effectiveness of lime and lignin fiber treatment. In the unconfined compressive strength test, four groups of soil samples were prepared for comparative analysis: untreated soil, soil improved with (0% to 10%) lignin fibers and 2% lime composite, and soil improved with 4% lime. To study the curing time’s effect, the soil samples were tested after 1, 3, 7, and 14 days of curing.

Figure 11 illustrates the relationship between the compressive strength of the composite-improved soils. As shown in Figure 11, the compressive strength of the improved soil significantly increased with the 2% lime treatment. Furthermore, as the lignin fiber content increased, the compressive strength of the composite-improved soil initially increased, peaked at 8%, and then declined. In comparison to the soil improved with 2% lime, the strength of the soil improved with a mixture of 8% lignin fiber and 2% lime showed a 39.32% and 49.66% increase after 7 days and 14 days, respectively. Therefore, the optimum lignin fiber content in composite-improved soil is determined to be 8%.

Figure 11.

The relationship between the lignin fiber contents and the compressive strength of the composite-improved soil.

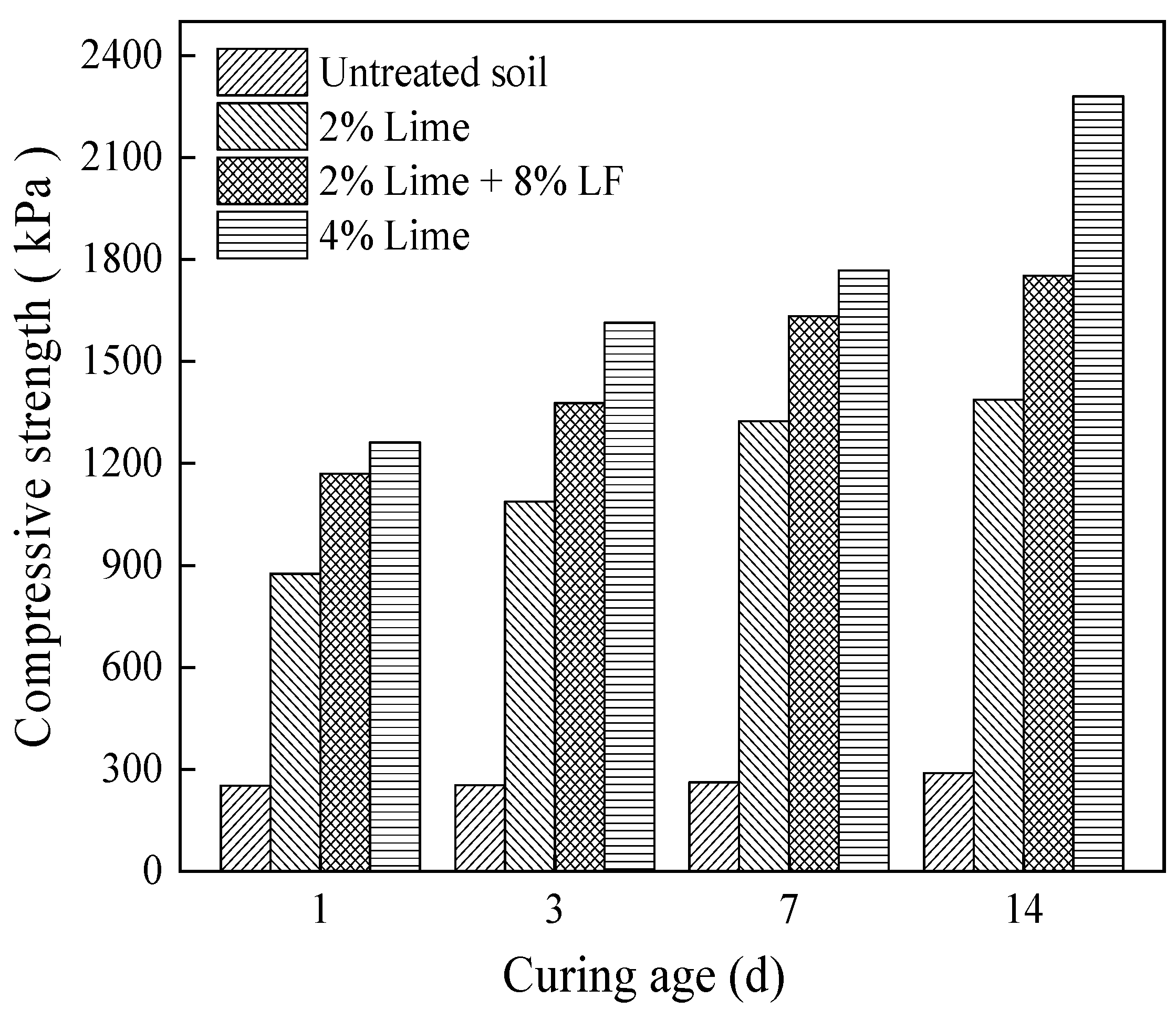

In Figure 12, the compressive strength of the soil improved with the 8% lignin fibers and 2% lime mixture is depicted at different curing ages, in contrast to the soils improved with 2% and 4% lime. As shown in Figure 12, the compressive strength of the composite-improved soil at various curing ages surpasses that of the soil improved with 2% lime but falls short of the strength of the soil improved with 4% lime. After 7 and 14 days of curing, the compressive strength of the composite-improved soil reaches 92.40% and 76.84% of the strength of the soil improved with 4% lime alone.

Figure 12.

The relationship between the compressive strength and the curing days of the improved soils with different treatments.

4.2.2. Direct Shear Test

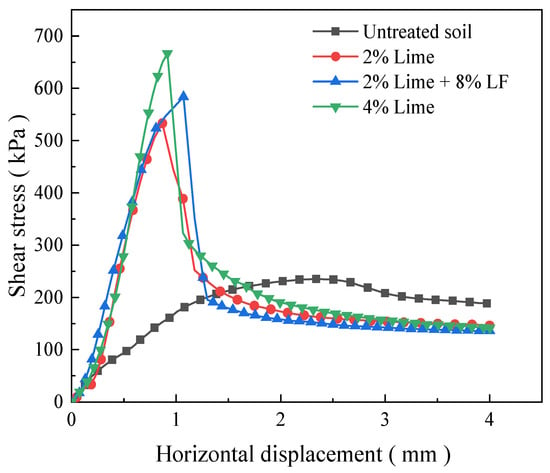

Based on the results of the unconfined compressive strength test for the composite-improved soils, it was determined that the optimum content of lignin fibers mixed into 2% lime-improved soil is 8%. Therefore, a direct shear test was conducted with four groups of soil samples for a comparative analysis: untreated soil, soil improved with 2% lime, soil improved with 4% lime, and soil improved with 8% lignin fibers and 2% lime. After sample preparation, tests were performed after 1, 3, 7, and 14 days of curing.

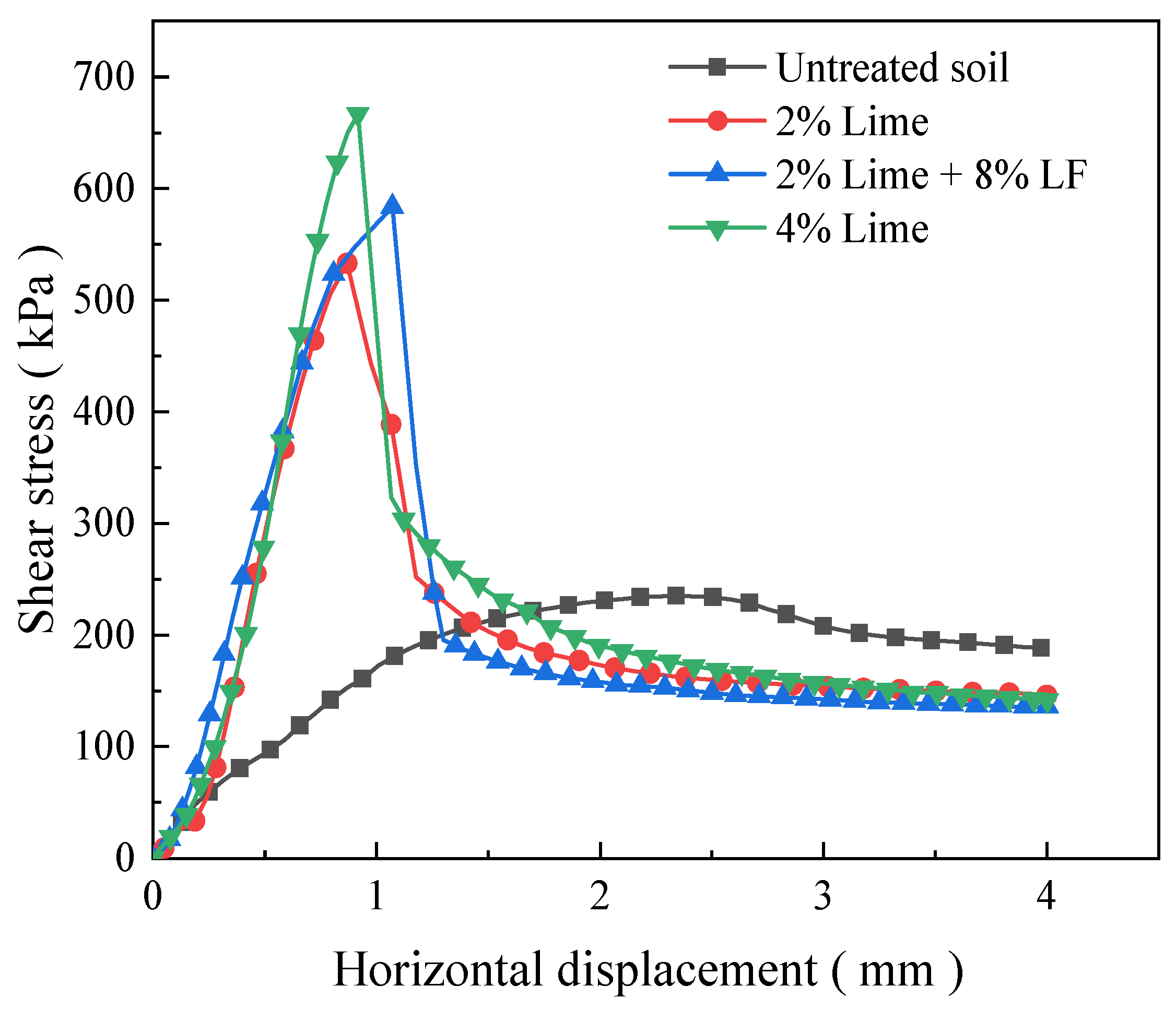

As shown in Figure 13, the results reveal that the addition of lime significantly increases the shear stress of the improved soil, which then experiences a rapid reduction after reaching its peak value. This shift leads to a change in the failure mode from plastic to brittle failure. This phenomenon can be attributed to the reactions between the lime and clay minerals, leading to the creation of cementation that fills the pores between soil particles and enhances their bonding force. Moreover, after the addition of 8% lignin fibers, an improvement in the ultimate strain corresponding to the peak strength was observed.

Figure 13.

The relationship between the shear stress and the horizontal displacement of the improved soils with different treatments (200 kPa).

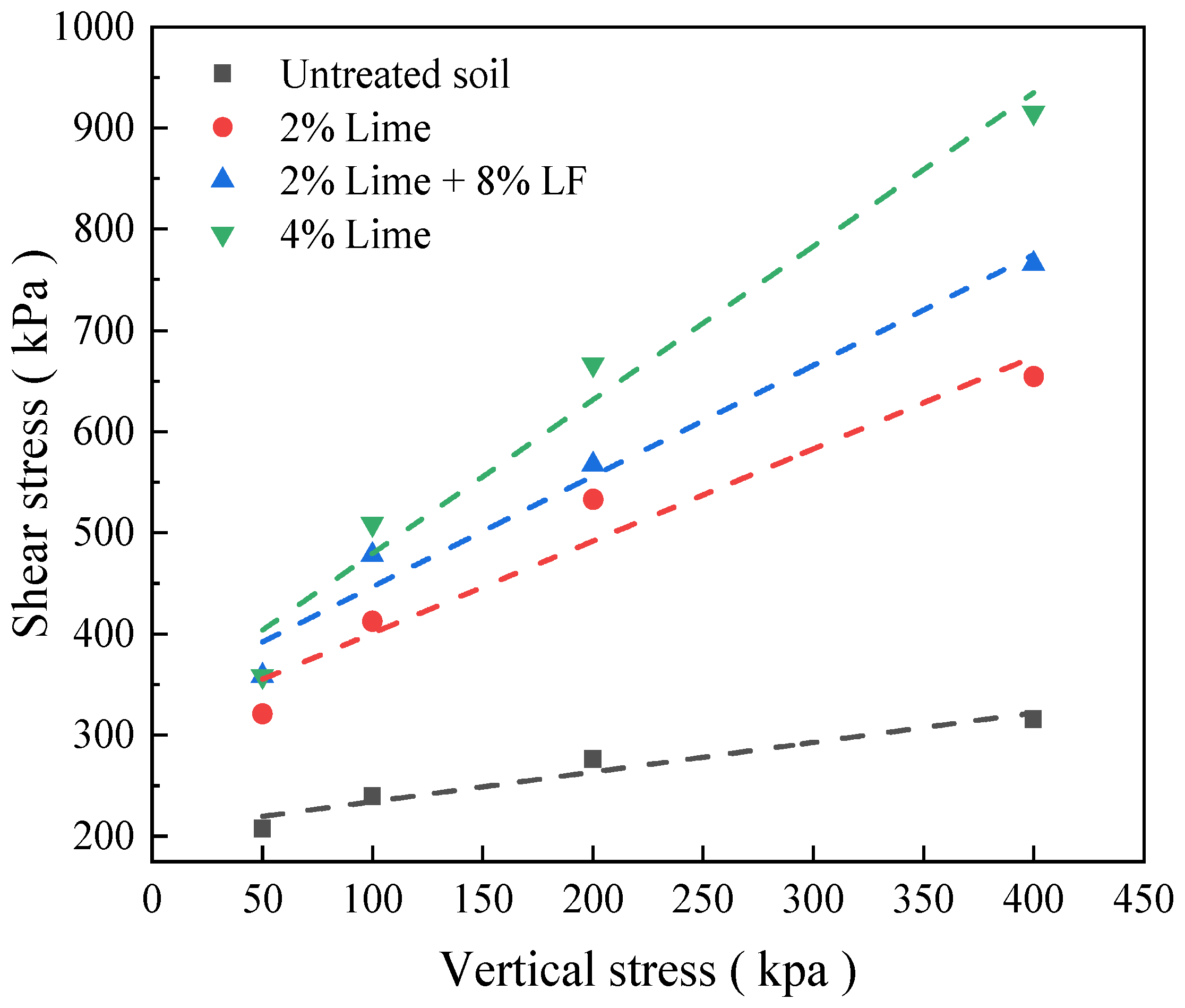

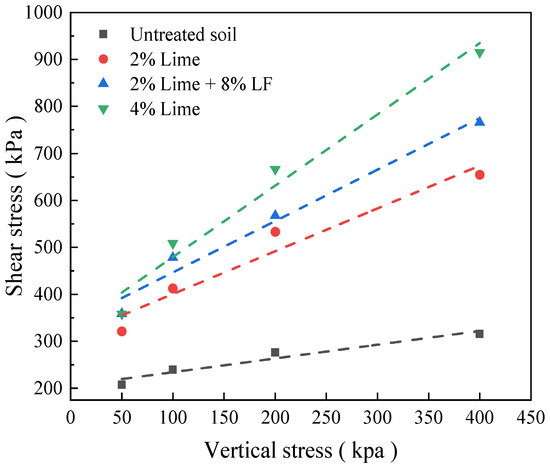

As illustrated in Figure 14, the shear stress shows a linear increase with vertical stress, with the fitting line for the improved soils significantly surpassing that of the untreated soil. This indicates a substantial improvement in the shear strength of the soil. Simultaneously, the inclination angle of the fitting line increases, indicating a gradual increase in the internal friction angle of the improved soil.

Figure 14.

The fitting curves of the shear stress and vertical stress of the improved soils with different treatments.

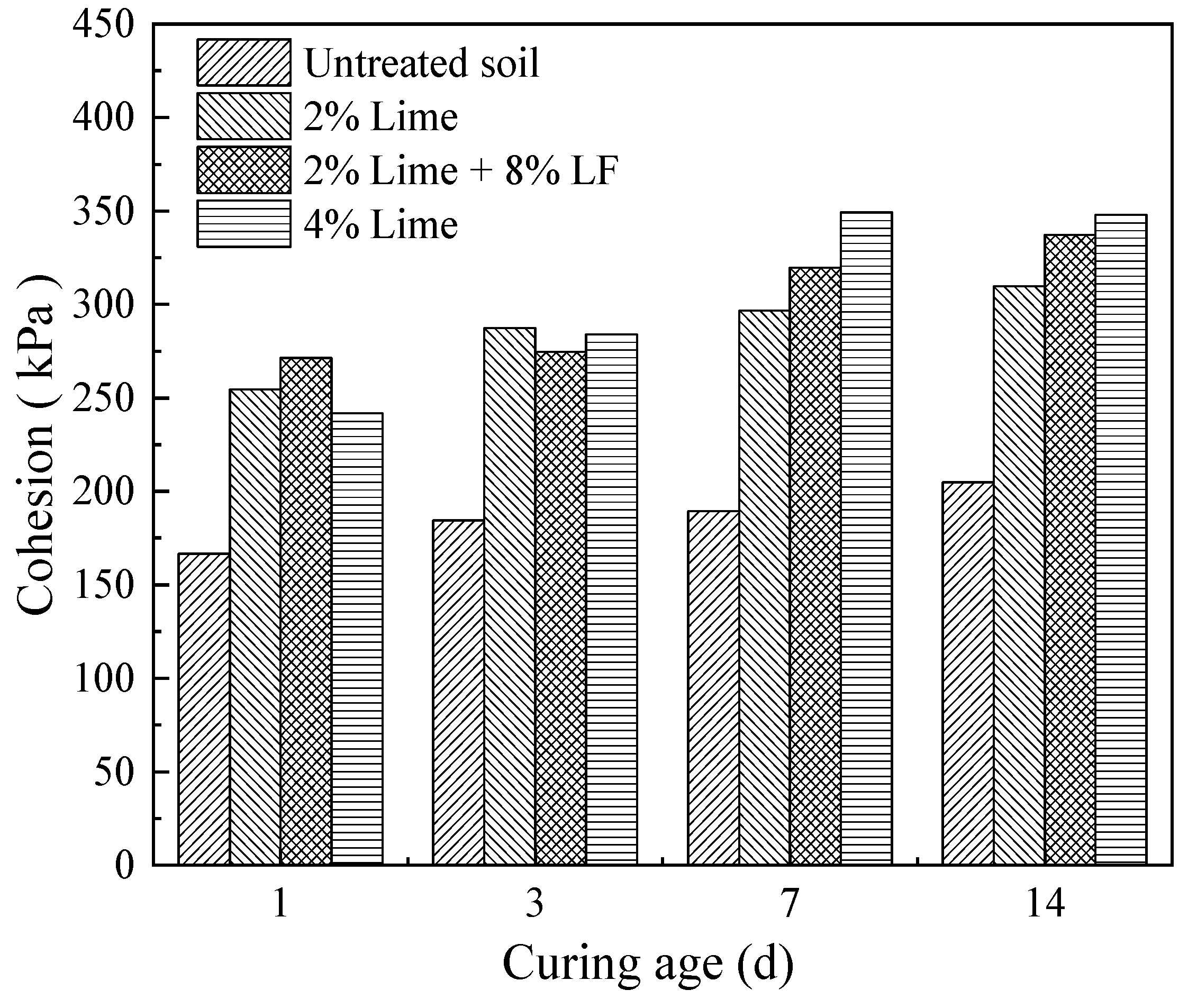

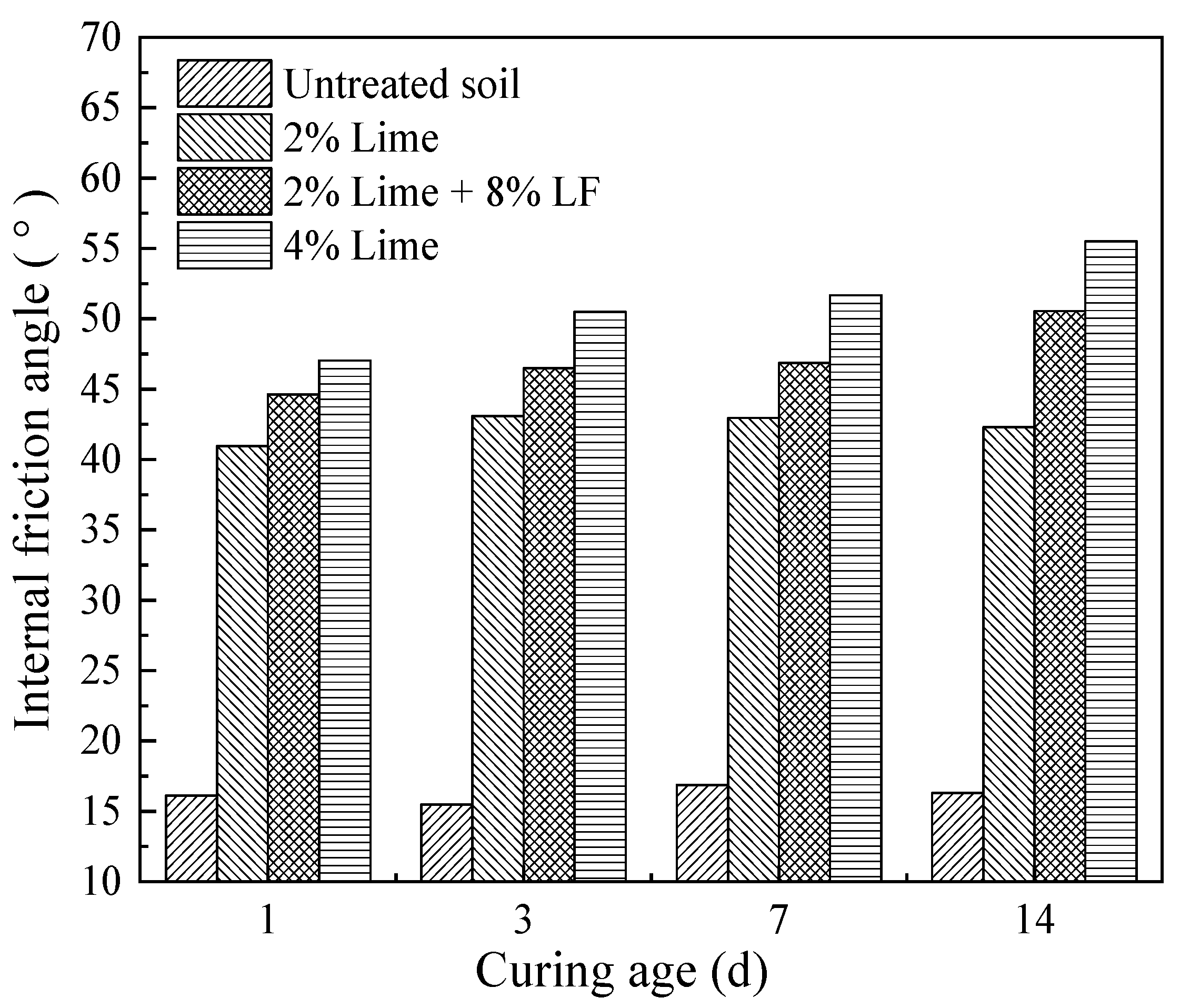

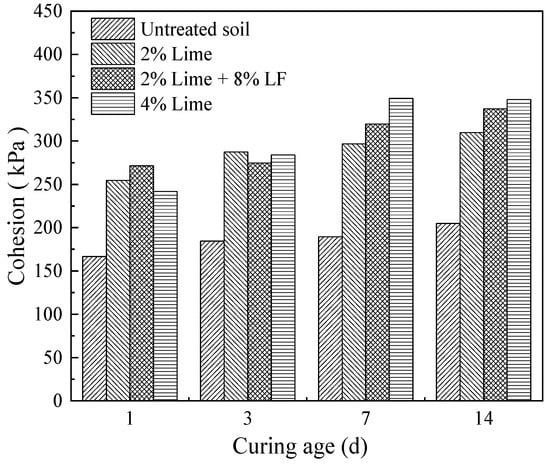

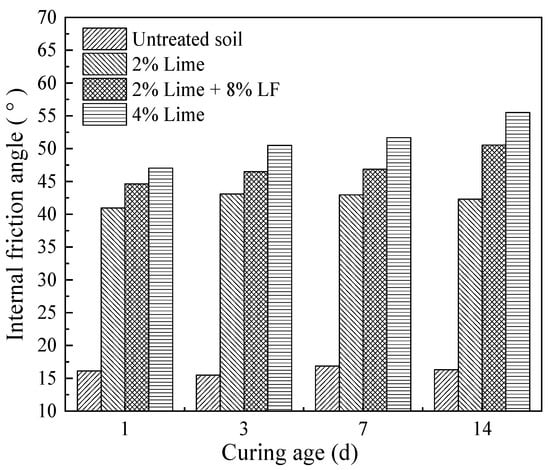

The relationship between the cohesion and internal friction angle of the improved soils with different treatments at different curing ages is depicted in Figure 15 and Figure 16. The cohesion of the improved soil with different treatments increases with the curing age. After 1 day of curing, the cohesion of the composite-improved soil reaches its peak. After 7 and 14 days of aging, the cohesion of the composite-amended soil reached 91.59% and 96.95% of the cohesion of the 4% lime-improved soil, respectively, and increased by 7.76% ~ 12.17% for the 2% lime-improved soil. This indicates that with smaller curing ages, the reaction between the lime and soil particles is insufficient. At this stage, the bridging and filling effects of the fibers in the soil are more pronounced, consequently increasing cohesion in the composite-improved soil. As the curing age increases, the cohesion of the lime-improved soil with a higher dosage gradually exceeds that of the composite-improved soil.

Figure 15.

The relationship between the cohesions and the curing days of the improved soils with different treatments.

Figure 16.

The relationship between the internal friction angle and the curing days of the improved soils with different treatments.

Figure 16 shows the changes in the internal friction angle over time for the different soil treatments. The internal friction angle of the composite-improved soil increased from 44.63° to 50.56°. For the improved soil with 4% lime, the internal friction angle increased from 47.03° to 55.56°. In contrast, the internal friction angle of the improved soil with 2% lime remained around 42°, showing minimal variation but still higher than that of untreated soil. In the case of lime treatment, cementitious materials gradually fill the pores and bind the soil particles together, consequently increasing the soil strength. During curing, a continuous increase in strength can be observed because of the increasing quantity of cementitious compounds generated. Therefore, the higher strength gain is also consistent with more cementitious materials, as for the improved soil with a larger content of lime. Conversely, lignin fibers create a three-dimensional network structure, increasing porosity and enhancing strength. As for mixture improvement, both the effect of the lignin fibers and that of the lime contribute to strength enhancement. However, lime treatment plays a major role in the mixture treatment. As a result, the 4% lime-improved soil presents a higher strength than the mixture-improved soil.

4.2.3. Hydraulic Conductivity Test

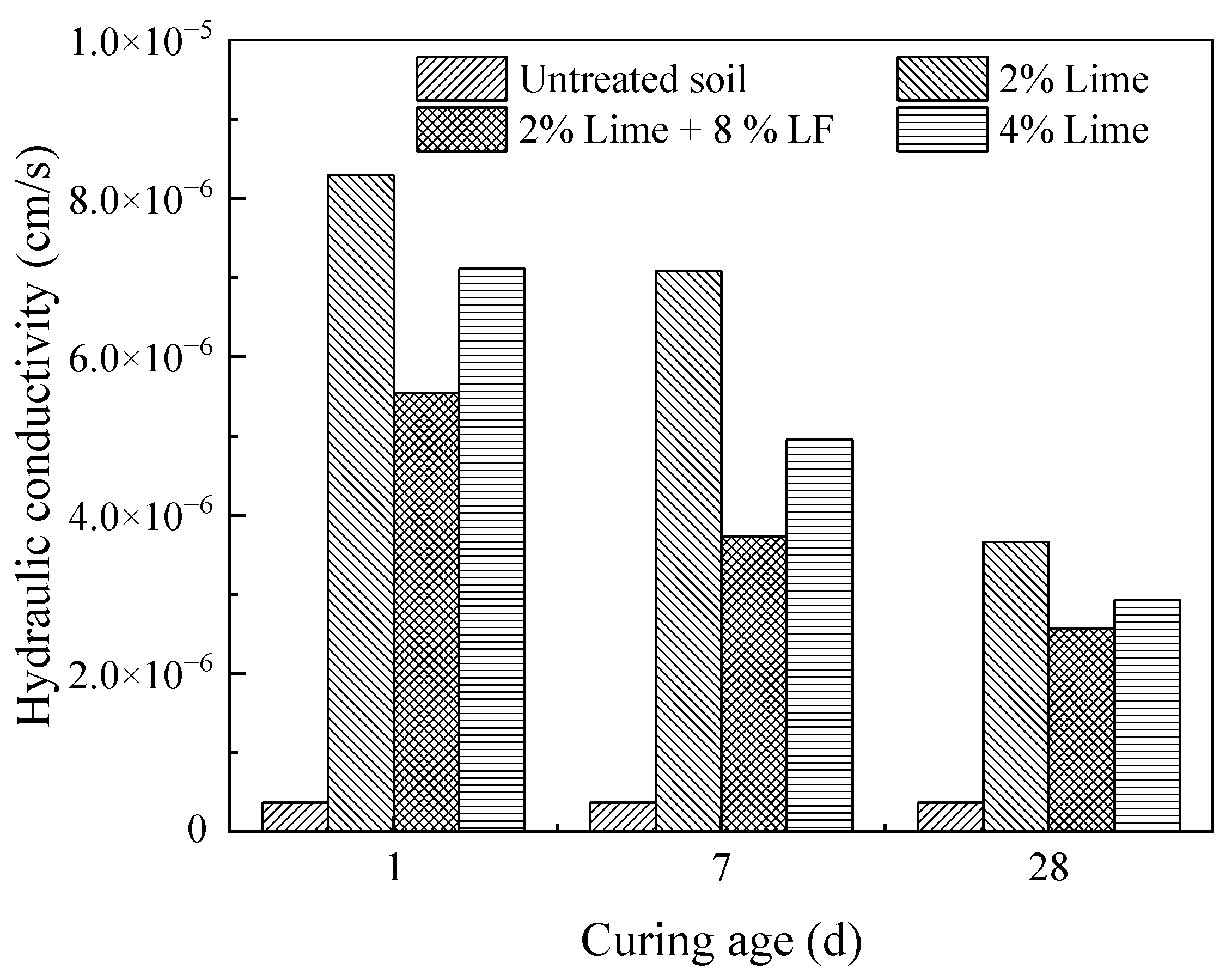

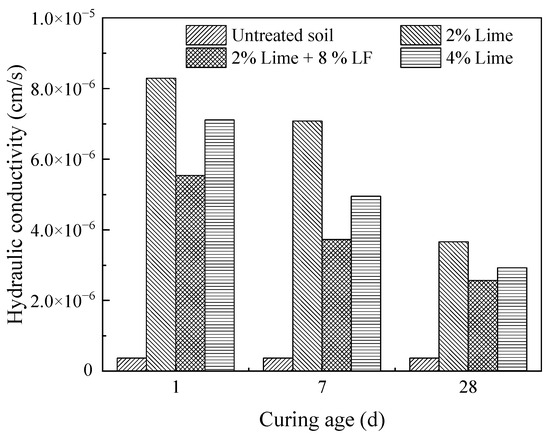

In this experiment, a rigid wall permeameter was used to conduct saturated hydraulic conductivity tests on four groups of soil samples: untreated soil, 2% lime-improved soil, 4% lime-improved soil, and soil improved with an 8% fiber and 2% lime composite. Tests were conducted after 1, 7, and 14 days of curing, respectively.

As shown in Figure 17, the hydraulic conductivity of the improved soil decreases with increasing curing days. With the increasing curing time, the chemical reactions between the lime and the soil, as well as the connections between the lignin fibers, cementing materials, and soil particles, become more stable. These cementing material products enhance the strength and stability of the soil, filling some pores and thereby reducing the hydraulic conductivity. Additionally, as shown in Figure 17, the hydraulic conductivity of the composite-improved soil is lower than that of the solely lime-improved soil at each curing age. This indicates that the addition of lignin fibers significantly reduces the hydraulic conductivity of the sample.

Figure 17.

The relationship between the hydraulic conductivity and the curing days of the improved soils with different treatments.

4.2.4. Microstructure Investigations

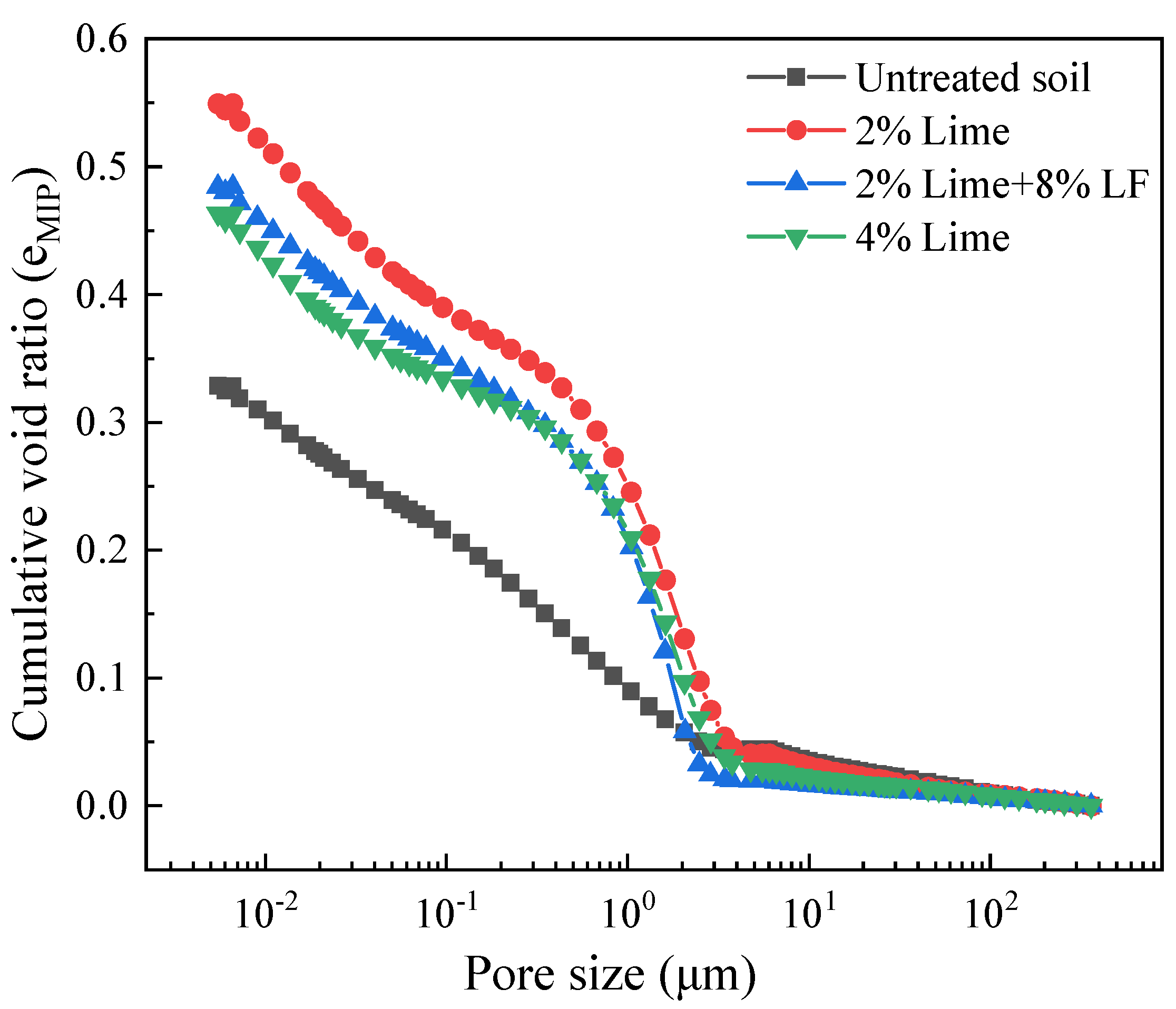

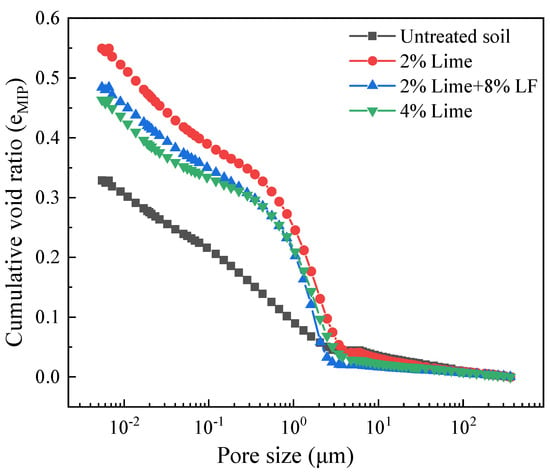

Figure 18 presents the cumulative pore distribution curves of the improved soil with various treatments. It is evident that within the pore size range of 0.1 to 2 μm, as the pore size decreases, the total mercury intrusion porosity significantly increases. This indicates that a large population of pores primarily concentrated in this range occurs in the improved soils. The total intruded void ratio of the 2% lime-improved soil is the largest, followed by the composite-improved soil, with the 4% lime-improved soil having the smallest value. This indicates that the composite treatment of 8% lignin fibers and 2% lime actually reduces the porosity compared to the soil solely improved with 2% lime. A decrease in porosity also leads to reduced hydraulic conductivity, thereby impacting the permeability of the improved soil. This outcome is consistent with the observed reduction in hydraulic conductivity in the composite-improved soils, as presented in Figure 17. This interpretation is corroborated by the findings of Li and Chai [43], who reported that under various freeze–thaw cycles, the porosity volume of fiber–lime composite-improved soils significantly diminishes relative to that of soils treated with lime alone across different dry densities.

Figure 18.

Cumulative pore distribution curves of the improved soils with different treatments.

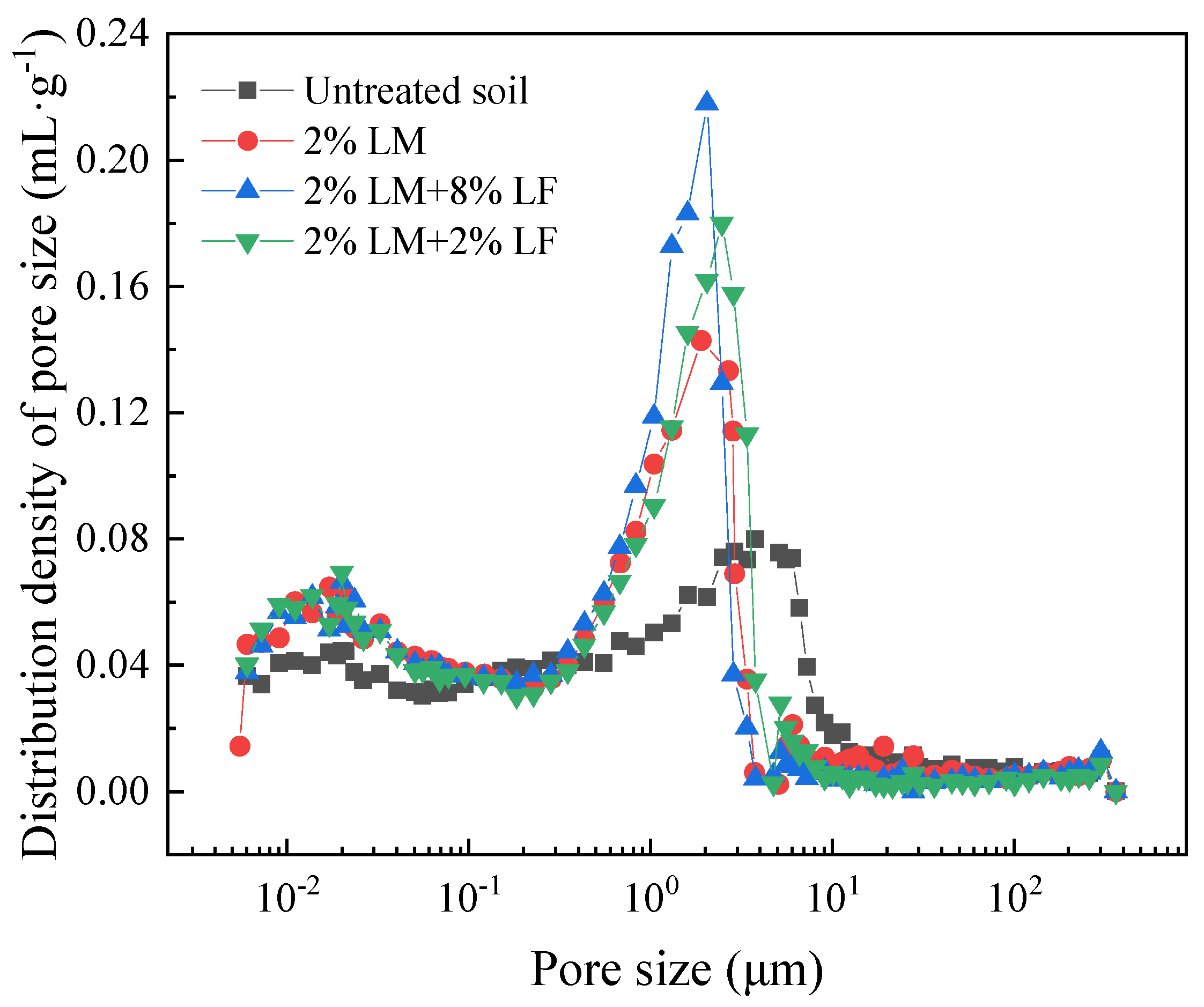

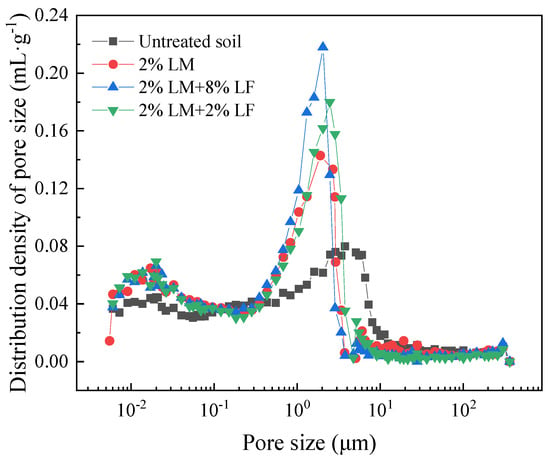

As illustrated in Figure 19, the average pore diameters of the improved soils are much smaller than that of the untreated soil. The peak values of the pore distribution curves shift to the left, with corresponding pore sizes of 2.49, 2.46, and 2.04 μm, respectively. The pore size distribution densities at these peaks are 0.142, 0.179, and 0.218 mL/g, respectively.

Figure 19.

The pore density distribution curves of the improved soils with different treatments.

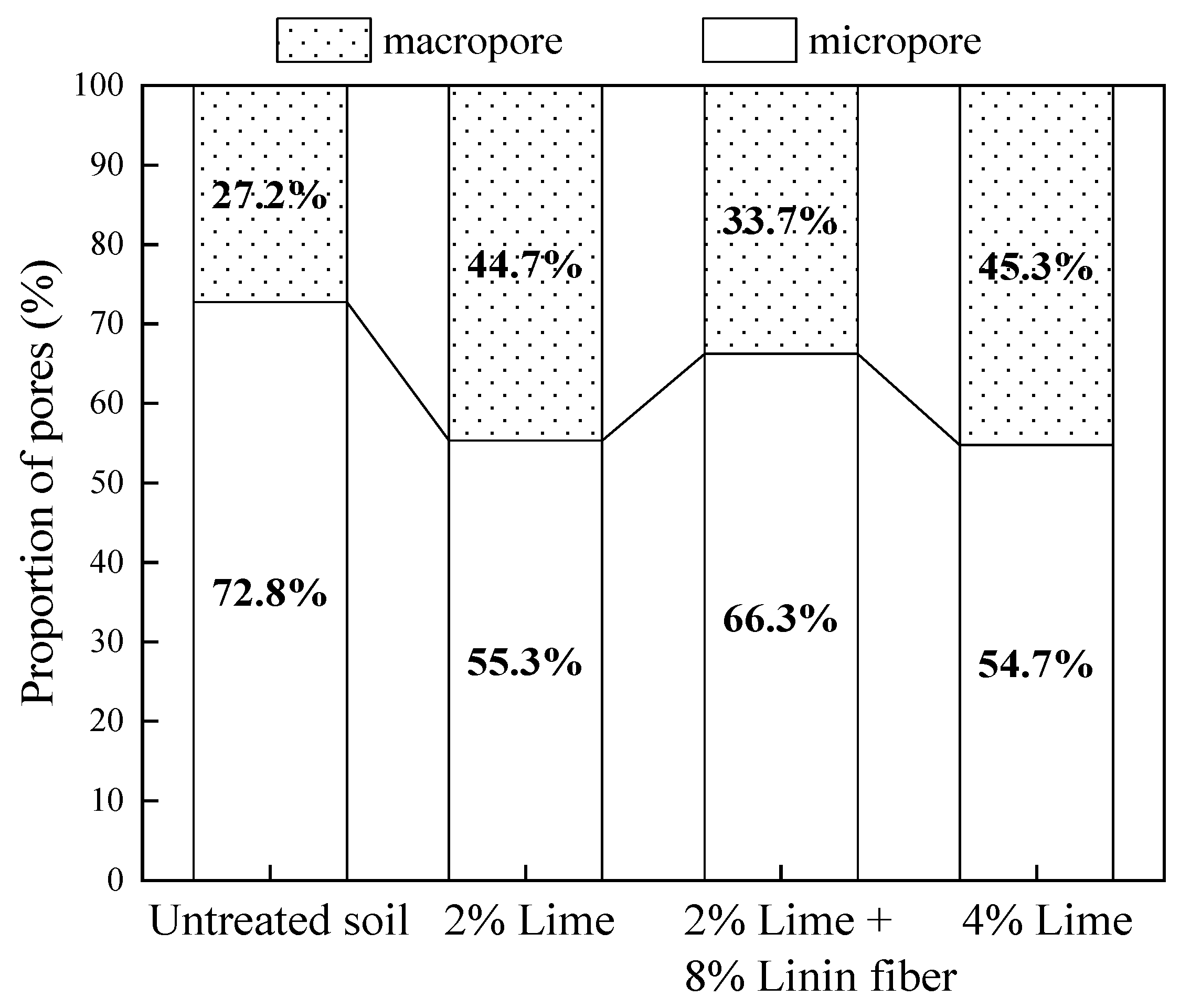

Figure 20 shows the proportions of various pores in the soils improved with the different treatments. In comparison with the untreated soil, the macropores in the 2% lime-improved soil and the 4% lime-improved soil increased by 17.5% and 18.1%, respectively, whereas those in the composite-improved soil improved soil increased by only 6.5%. In the case of the lime-treated expansive soils, the ion exchange reaction and flocculation process of the soil particles take place, leading to the generation of aggregates and large pores. As for the lignin fiber- and lime-improved expansive soils, the lignin fibers fill the pores, leading to a reduction in the quantity of macropores. This result is also consistent with the lower permeability observed in the composite-improved soil compared with that of the lime-improved soil.

Figure 20.

Changes in the percentage of various pore types in the expansive soil improved by different treatments.

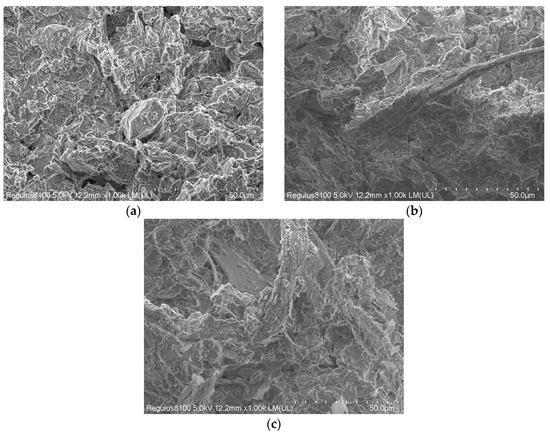

As illustrated in Figure 21, the SEM observations reveal that the content of lignin fibers has an essential role in the microstructure of the treated samples. As for the soil treated with 2% lime and 2% lignin fibers, a more compact microstructure can be observed (as shown in Figure 21a), in comparison with the soil only treated with 2% lime (as shown in Figure 21a). That is, the appearance of lignin fibers provides more junctures but less porosity between particles. In the case of the sample treated with 2% lime and 8% lignin fibers, as illustrated in Figure 21c, more lignin fibers form a much denser microstructure.

Figure 21.

Scanning electron microscopy of composite-improved soils with different contents of lignin fibers and 2% lime: (a) lignin fiber content of 0% (1000 times), (b) lignin fiber content of 2% (1000 times), and (c) lignin fiber content of 8% (1000 times).

5. Conclusions

This study focuses on the mechanical properties and microstructure of the expansive soils improved with lignin fibers and lime composites. The following conclusions can be made:

- The addition of lignin fibers significantly increases the compressive strength of the expansive soils, with an optimum fiber content of 8%. In contrast, the mixture treatment of 8% lignin fibers and 2% lime further elevates the compressive strength of the soil by approximately 50% compared to the soil treated with 2% lime alone.

- Similarly, the 8% lignin fiber-treated sample presents a maximum soil cohesion of 210 kPa. As for the mixture treatment, the soil treated with a composite of 2% lime and 8% lignin fibers has a cohesion increase of 12% compared to the soil treated with 2% lime alone.

- The treatment with lignin fibers increased the hydraulic conductivity of the soils by increasing the porosity of the soil. However, the lignin fiber- and lime composite-treated soil shows a relatively lower hydraulic conductivity than the soil only treated with lime, which can be attributed to the denser microstructure after the composite treatment.

- The microstructure investigations indicated that the treatment of lignin fibers can enhance the soil microstructure by creating a strong network that fills the pores between soil particles. Furthermore, the addition of lime will improve the microstructure through cementitious materials, which adhere to the surfaces of the fibers and form bonds between the fibers and the soil particles. These mechanisms contribute to a significant increase in the soil strength.

- The use of lignin fibers and lime, either alone or in combination, can significantly improve the hydro-mechanical properties of expansive soils. It provides an ecological and sustainable potential method of reusing industrial byproducts in the field of soil stabilization.

- Future research should include further tests such as bearing ratio and water stability tests to enhance our understanding of soil performance under different conditions. Additionally, exploring the variability in soil properties like water content and dry density across different environmental settings will be crucial for applying these findings to real-world scenarios.

Author Contributions

Writing—original draft, T.W.; writing—review and editing, Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jones, L. Expansive Soils. In Selective Neck Dissection for Oral Cancer; Techniques in Dentistry and Oral & Maxillofacial Surgery; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–7. [Google Scholar]

- Sun, D.A.; Zhang, J.R.; Lv, H.B. Soil-water characteristic curve of Nanyang expansive soil in full suction range. Geotech. Mech. 2013, 34, 1839–1846. [Google Scholar]

- Wei, J.; Wei, J.; Huang, Q.; Zainal Abidin, S.M.I.B.S.; Zou, Z. Mechanism and Engineering Characteristics of Expansive Soil Reinforced by Industrial Solid Waste: A Review. Buildings 2023, 13, 1001. [Google Scholar] [CrossRef]

- Wang, C.H.; Cha, W.H.; Wang, J.J. Summarization of swelling and shrinkage mechanism and new treatment methods of expansive soil. Subgrade Eng. 2020, 6–11. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A. Swell–Compression Characteristics of a Fiber–Reinforced Expansive Soil. Geotext. Geomembr. 2018, 46, 183–189. [Google Scholar] [CrossRef]

- Gao, L.; Hu, G.H.; Yang, C.; Xiang, C. Shear strength characteristics of basalt fiber reinforced clay. Chin. J. Geotech. Eng. 2016, 38, 231–237. [Google Scholar]

- Zhao, J.Y.; Kong, Y.P.; Gao, X.H. Study on Shear Strength and Interface Quantity Characteristics of Coir Fiber Reinforced Soil. J. Highw. Transp. Res. Dev. 2023, 40, 36–44. [Google Scholar]

- Tiwari, N.; Satyam, N.; Puppala, A.J. Effect of Synthetic Geotextile on Stabilization of Expansive Subgrades: Experimental Study. J. Mater. Civ. Eng. 2021, 33, 04021273. [Google Scholar] [CrossRef]

- Zumrawi, M.; Babikir, A. Laboratory Study of Steel Slag Used in Stabilizing Expansive Soil. Asian Eng. Rev. 2017, 4, 1–6. [Google Scholar] [CrossRef]

- Alnmr, A.; Ray, R.P.; Alsirawan, R. A State-of-the-Art Review and Numerical Study of Reinforced Expansive Soil with Granular Anchor Piles and Helical Piles. Sustainability 2023, 15, 2802. [Google Scholar] [CrossRef]

- Yang, J.; Li, X.C.; Zhang, G.D.; Tang, Y.W. Experimental study on expansion characteristics of expansive soil improved by weathered sand. J. Yangtze River Sci. Res. Inst. 2013, 30, 67–72. [Google Scholar]

- Lv, J.H.; Yang, Z.N.; Shi, W. Study on the Influence of Soil Sample Thickness on the Crack Evolution Law of Rubber Reinforced Expansive Soil. J. Eng. Geol. 2022, 30, 1140–1147. [Google Scholar]

- Dong, B.L.; Huang, H.H.; Pei, S.W.; Xu, Y.Z. Experimental Study on Expansion Characteristics of Gravel-Improved Expansive Soil. J. Undergr. Space Eng. 2018, 14, 1213–1217. [Google Scholar]

- Zhao, H.; Chu, F.C.; Ye, H.; Guo, K.L. Experimental study on basic physical properties of expansive soil improved by industrial waste. Sci. Technol. Eng. 2017, 17, 230–235. [Google Scholar]

- Eyo, E.; Abbey, S.; Oti, J.; Ng’ambi, S.; Ganjian, E.; Coakley, E. Microstructure and Physical-Mechanical Characteristics of Treated Kaolin-Bentonite Mixture for Application in Compacted Liner Systems. Sustainability 2021, 13, 1617. [Google Scholar] [CrossRef]

- Baglari, D.; Dash, S. Improvement of expansive soil by lime and reinforcement. In Proceedings of the Indian Geotechnical Conference, Roorkee, India, 24 December 2013. [Google Scholar]

- Chen, L.; Zhang, F.H.; Fan, Y.Z.; Li, J.N. Experimental study on expansion characteristics and mechanical properties of lime-improved expansive soil compacted samples. Sci. Technol. Eng. 2014, 14, 269–272. [Google Scholar]

- Zhan, Y.L.; Huang, Z.; Liu, S.Y. Experimental Study on Cement Modified Expansive Soil in Anyang. Sci. Technol. Eng. 2013, 13, 7418–7421. [Google Scholar]

- Estabragh, A.R.; Rafatjo, H.; Javadi, A.A. Treatment of an Expansive Soil by Mechanical and Chemical Techniques. Geosynth. Int. 2014, 21, 233–243. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting Future Carbon Emissions from Cement Production in Developing Countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Guo, W.; Ren, Y.X. Study on the properties and microscopic analysis of lignin fiber modified soil under freeze-thaw cycle conditions. Geotech. Eng. 2020, 42, 135–140. [Google Scholar]

- Xie, T.; Zhao, K.; Wang, L. Reinforcement Effect of Different Fibers on Asphalt Mastic. Mater. Basel Switz. 2022, 15, 8304. [Google Scholar] [CrossRef]

- Peng, B. Application of methyl cellulose in bituminous mixtures. J. Xi Univ. Archit. Technol. Nat. Sci. Ed. 2005, 37, 104–107. [Google Scholar]

- Xie, M.J.; Wen, Y.T.; Xu, L.L.; Wu, K. Composite Modification with Cellulose Fiber/Glass Fiber to Enhance the Pavement Performance ofAsphalt Concrete. J. Build. Mater. 2023, 26, 1200–1206. [Google Scholar]

- Moslemi, A.; Tabarsa, A.; Mousavi, S.Y.; Monfared, M.H.A. Shear Strength and Microstructure Characteristics of Soil Reinforced with Lignocellulosic Fibers-Sustainable Materials for Construction. Constr. Build. Mater. 2022, 356, 129246. [Google Scholar] [CrossRef]

- Dong, C.F.; Lin, C.; Zhang, W.Y.; Sun, X.L.; Huang, Y.L. Study on thermal and mechanical properties of lignin fiber modified loess in cold and arid regions. Resour. Environ. Arid Reg. 2022, 36, 119–126. [Google Scholar]

- Dong, C.F.; Zhang, W.Y.; Zhang, R.X.; Huang, Y.L. Experimental study on mechanical and thermal properties of lignin fiber modified loess under freeze-thaw action. Permafr. Glacier 2022, 44, 612–622. [Google Scholar]

- Dong, J.; Chen, Y.; Wu, Z.H.; Yang, H. Experimental study on the shear strength and deformation characteristics of ligninfiberred clay. J. Geomech. 2019, 25, 421–427. [Google Scholar]

- Chen, Y.H.; Cai, W.; Ou, M.X. Experimental study on expansive soil improved by lignin fiber-high calcium fly ash composite. J. Saf. Environ. 2023, 1–11. [Google Scholar] [CrossRef]

- Fan, K.W.; Yan, J. Study on strength characteristics and microstructure of lignin fiber modified expansive soil in seasonal frozen area. J. Cent. South Univ. Nat. Sci. Ed. 2022, 53, 326–334. [Google Scholar]

- Jha, A.K.; Sivapullaiah, P.V. Lime Stabilization of Soil: A Physico-Chemical and Micro-Mechanistic Perspective. Indian Geotech. J. 2020, 50, 339–347. [Google Scholar] [CrossRef]

- Gong, J.L.; Liu, H.X.; Wang, Z. Study on the Compressive and Mechanical Properties of Expansive Soil Improved by Lime. J. Transp. Sci. Eng. 2022, 38, 35–40. [Google Scholar]

- Howard, A.K. Soil Classification Handbook: Unified Soil Classification System; Geotechnical Branch, Division of Research and Laboratory Services, Engineering and Research Center, Bureau of Reclamation: Denver, CO, USA, 1986.

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Ministry of Water Resources of the People’s Republic of China. China Planning Press: Beijing, China, 2019.

- Gao, Z.N.; Wang, Q.; Zheng, L. Effect of sample preparation and mixing method on strength of lignin fiber modified loess. J. Earthq. Eng. 2021, 43, 930–934. [Google Scholar]

- Marcuello, C.; Foulon, L.; Chabbert, B.; Aguié-Béghin, V.; Molinari, M. Atomic Force Microscopy Reveals How Relative Humidity Impacts the Young’s Modulus of Lignocellulosic Polymers and Their Adhesion with Cellulose Nanocrystals at the Nanoscale. Int. J. Biol. Macromol. 2020, 147, 1064–1075. [Google Scholar] [CrossRef] [PubMed]

- Topçuoğlu, Y.A.; Gürocak, Z. Increasing Strength of Clay Soils with the Use of Basalt Fiber: An Experimental Study. Turk. J. Sci. Technol. 2024, 19, 87–96. [Google Scholar] [CrossRef]

- Dong, C.F.; Zhang, W.Y.; Sun, X.L. Experimental Study on the Shear Strength of Lignin Fiber Improved Loess. Saf. Environ. Eng. 2022, 29, 102–110. [Google Scholar]

- Song, Y.; Geng, Y.; Dong, S.; Ding, S.; Xu, K.; Yan, R.; Liu, F. Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay. Sustainability 2023, 15, 4411. [Google Scholar] [CrossRef]

- Wang, D.Y.; Tang, C.S.; Li, J. Shear strength characteristics of fiber-reinforced unsaturated cohesive soils. Chin. J. Geotech. Eng. 2013, 35, 1933–1940. [Google Scholar]

- Maher, M.H.; Ho, Y.C. Mechanical Properties of Kaolinite/Fiber Soil Composite. J. Geotech. Eng. 1994, 120, 1381–1393. [Google Scholar] [CrossRef]

- Miller, C.J.; Rifai, S. Fiber Reinforcement for Waste Containment Soil Liners. J. Environ. Eng. 2004, 130, 891–895. [Google Scholar] [CrossRef]

- Wei, L.; Chai, S.; Xue, M.; Wang, P.; Li, F. Structural Damage and Shear Performance Degradation of Fiber–Lime–Soil under Freeze–Thaw Cycling. Geotext. Geomembr. 2022, 50, 845–857. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).