Abstract

This study investigates data-driven business model innovation (DDBMI) for incumbent manufacturers, underscoring its importance in various strategic and managerial contexts. Employing topic modeling, the study identifies nine key topics of DDBMI. Through qualitative thematic synthesis, these topics are further refined, interpreted, and categorized into three levels: Enablers, value creators, and outcomes. This categorization aims to assess incumbent manufacturers’ preparedness for DDBMI. Additionally, a knowledge framework is developed based on the identified nine key topics of DDBMI to aid incumbent manufacturers in enhancing their understanding of DDBMI, thereby facilitating the practical application and interpretation of data-driven approaches to business model innovation.

1. Introduction

In the age of digitalization, businesses are witnessing a wide range of phenomena driven by advanced technologies such as information and communication technology (ICT), big data, cloud computing, artificial intelligence (AI), the Internet of Things (IoT), robotics and automation, 5G, and blockchain. These technology-driven phenomena are not acting in isolation: Interconnectedness and the potential for synergy lead to many possibilities for smart products, services, market accessibility, and business expansion. For example, the integration of servitization [1] and Industry 4.0 (I4.0) leads to the digital transformation of manufacturing companies. The current developments promise a future for business that is unprecedented in history, presenting challenges and opportunities for companies [2,3].

Significant transitions are expected in how businesses operate, manage, and run their operations. Effective addressing of challenges and opportunities is necessary to support a transition that adapts to technological changes and promotes innovation for both customers and businesses. Technological progress leads to a rapid increase in data and the use of data-driven methods, making them valuable for decision-making, predictive/prescriptive analysis, optimization, risk management, and business model innovation (BMI) [4]. Thus, business models (BMs) incorporating data-driven approaches have become a significant research subject relevant to various types of businesses, including small- and medium-sized enterprises (SMEs), large companies, startups, and incumbents.

Emerging data-driven technologies and approaches can contribute to data-driven business model innovation (DDBMI) by enabling the development of novel services, products, revenue models, and shifts in business strategies [5,6,7,8,9]. Innovation strategies face challenges from a big data perspective, including data-related issues such as deciding which data to use, handling analytics, and applying insights for operational changes [10]. The process of DDBMI is complex, as it involves data selling, data platforms, business improvements, and data products, each with its challenges [11]. For instance, a data-selling model presents numerous ethical and privacy concerns.

The challenges incumbent manufacturers encounter in DDBMI stem from several factors, including the requirement for diverse resources and capabilities and the complexity within and between organizations [12,13]. DDBMI challenges incumbent manufacturers because existing systems encompass outdated technology and infrastructure, and past process stability creates irreversible lock-in [14,15]. Due to these challenges, incumbents are likelier to fail in their endeavors for DDBMI [16]. To address these challenges, incumbent manufacturers need to acknowledge the complexities within their organizations, strategize the essential activities, and foresee the preparedness needed for DDBMI.

Preparedness involves management and staff readiness to implement performance improvements, recognize organizational benefits, enact process and behavioral changes, and monitor progress [17]. It encompasses technology exploration, resource assessment, leveraging partnerships, adaptability, reinvention, and strategic change. Such preparations represent a pre-stage of potential DDBMI. They can be described as a process of experimentation and learning that enhances the understanding of change initiatives and guides managers to take proactive steps [18]. Organizational preparedness helps incumbent manufacturers navigate DDBMI.

Despite the importance of BMI preparedness, current research predominantly concentrates on preparedness in crises or BMI as a response to crises [19,20]. The lack of clarity extends to understanding the relevant topics essential for incumbent manufacturers to prepare for DDBMI and the interconnectedness of these topics. Existing studies emphasize the critical role of strategy, leadership, and company culture in SMEs’ preparedness for AI and big data-related transformations [21]. To better prepare for disruptions, managers must identify internal and external factors that enable BMI, such as digitalization, customer needs, and future trends [22]. Hence, there is a need for further research on how researchers and practitioners can understand these enablers and assess preparedness for DDBMI. Three research questions are raised:

- What are the key topics of DDBMI for incumbent manufacturers that have the potential to support the DDBMI process?

- What are the key aspects of each topic required to understand their impact on DDBMI?

- What comprises a knowledge framework that integrates the key topics and their aspects, enabling incumbent manufacturers to enhance their preparedness for DDBMI?

We answer these research questions by identifying and integrating nine topics categorized into five aspects relevant to the DDBMI of incumbent manufacturers. These nine topics were identified through topic modeling and subsequently refined, interpreted, and categorized through thematic synthesis. Building on these findings, we developed a topic classification across three levels to evaluate incumbent manufacturers’ preparedness for DDBMI. In the final step, we identified key aspects (i.e., infrastructure and technology, capabilities, theory and framework, strategies and solutions, and evaluation criteria) of the nine topics and compiled this information into a knowledge framework. A knowledge framework is a structured representation of knowledge that typically includes key concepts, principles, theories, and relationships among them.

The paper is structured as follows: First, we provide an overview of the theoretical background of BMs, BMI, and organizational preparedness. Second, we outline our methodology for identifying and integrating nine key topics for DDBMI. Next, in the results section, we propose a knowledge framework to support DDBMI. Finally, we conclude the paper by discussing its contributions to research, managerial insights, limitations, and potential avenues for future research.

2. Conceptual Background

2.1. Business Model and Business Model Innovation

BMs emphasize a system-level, holistic approach to explaining how firms “do business”. Firm activities play a significant role in various proposed conceptualizations of BMs. One approach involves describing the BM in detail using nine elements, including, among others, the value proposition, customer segments, key activities, and revenue streams [23]. Another approach distinguishes a BM by describing the target customer, the value proposition to meet the customer’s needs, the value architecture to deliver value to the customer, and the value capture to describe the cost structure and revenue streams [24]. However, as opinions converge over time, researchers now have a common understanding regarding how to describe a BM [25]. A BM comprises four dimensions: Value proposition, value delivery, value creation, and value capture. These dimensions explain how a company operates, creates customer value, and ensures financial success [26,27]. The value proposition is intended to deliver value to customers through products, services, and the job-to-be-done, designed to address their core needs [12,28]. Value delivery ensures efficiency, personalized channels, and robust customer service and supports target customer segments, channels, and relationships. Value creation aims to maximize customer perceived value by addressing needs and minimizing risks through technologies, resources and capabilities, processes, key activities, partners, and ecosystems. The fourth dimension, value capture, optimizes revenues and minimizes costs through well-defined revenue models and cost structures [29].

Innovation is introducing something new and creating value for stakeholders [30], typically by addressing a recognized problem. BMI involves devising and implementing a new BM to generate value for the target customers and the company. According to Amit and Zott [31], BMI can manifest in various ways, such as by adding new key activities or linking activities in novel ways, by changing one or more parties that perform the activities or by altering any of the BM dimensions [23,24,32,33,34]. The rise of new technologies (e.g., digitalization, cloud computing, big data, and IoT) has led to disruptive innovations and many opportunities for BMI [35]. The BMI process is commonly divided into the phases of initiation, ideation, integration, and implementation [36] but sometimes extended to six iterative and incremental phases [34,37]. When incumbents are concerned, BMI is called BM reconfiguration [38]. BM reconfiguration entails structurally changing the BM’s dimensions or architecture [39] and involves establishing a new business logic and new methods for revenue generation [40,41]. Adopting a new architectural design necessary for utilizing new technologies enables value proposition, value delivery, value creation, and value capture [42].

One core dimension of a BM is the value proposition, which describes an exchange between a supplier and a buyer. However, the value proposed does not necessarily need to be tied to a physical product; it can also be a data-driven service. Data and analytics are essential in business operations, decision-making, and development [43]. Data can be a source of competitive advantage and a driver for successful BMs [44]. DDBMs propose value by applying data, delivering and creating data-driven value for the customers, and capturing data-driven value for the company [44,45]. DDBMs, enabled by digital technologies, utilize data as a key resource and data processing as a key activity, especially for collecting and aggregating data, and perform business analytics to deliver, create, and capture value [46]. AI-driven BMs are a subset of DDBMs leveraging AI technologies that learn and improve their performance without humans having to explicitly program them, contributing to AI-driven value propositions, key resources, key processes, and revenue models [47].

The Industrial Internet of Things (IIoT) affects manufacturing companies’ value proposition, internal infrastructure, and customer relations [48]. Digitalization provides new building blocks for DDBMI, such as digital value propositions, digital services, or digital channels. Incumbent manufacturers face many challenges regarding BMI, including recognizing the necessity and urgency to reconfigure the BM [49], organizing the transition phase from the old (possibly very successful) BM to the new intended one [50], and ensuring sustainability [51]. Challenges specific to DDBMI are acquiring and exploiting relevant data [44], transforming physical products into smart products and smart services [52], and transitioning product sales to pay-per-use, pay-per-outcome or performance-based contracting systems [53]. Despite the digital transformation of BMs being a well-known concept, a structured approach with phases, activities, and outcomes is not well defined [54].

2.2. Organizational Preparedness

Organizational preparedness is a state in which management and staff are ready to execute performance improvements, identify opportunities for organizational benefits, make changes to processes and behaviors, and monitor improvement concerning these changes [17]. Organizational preparedness is categorized into management readiness, organizational readiness, operational readiness, and preparation for changes [17]. Based on the work by Loshin [17], we are applying organizational preparedness to DDBMI: In the context of DDBMI, managerial readiness involves awareness of the technological, organizational, and operational requirements necessary to recognize the need for and importance of reconfiguring the BM. Challenges and the necessary steps to prepare for the BMI process can be identified.

Organizational preparedness ensures that people, processes, and tools are well coordinated when incumbent manufacturers initiate DDBMI. Preparedness for change encompasses fulfilling various technological and infrastructural requirements, processes, and capabilities, as well as the strategic and managerial acumen necessary for initiating changes while considering various interdependent key aspects [55,56]. Organizational preparedness relies heavily on capabilities, given that companies require appropriate capabilities to address changes, challenges, and opportunities effectively. As per Teece [57], capabilities encompass ordinary and dynamic capabilities. Ordinary capabilities are essential for routine operational and administrative functions. Dynamic capabilities, on the other hand, are further divided into second- and first-order categories. Second-order dynamic capabilities involve adjusting and recombining ordinary capabilities while developing new ones. First-order dynamic capabilities, which hold particular significance for BMI, focus on upgrading, renewing, and reconfiguring second-order dynamic capabilities alongside ordinary capabilities.

Preparedness for innovation can be chaotic, insufficient, acceptable, high, or excellent [58]. The key steps for evaluating the preparedness of companies for I4.0 include the following: (1) Awareness of I4.0 requirements, (2) assessment of the level of activities, key resources, and key advantages, (3) evaluation of preparedness for gaining competitive advantage in the context of I4.0, and (4) assessment of readiness to compete in the era of I4.0 [59]. SMEs can be categorized into craft manufacturers, preliminary stage planners, I4.0 users, and full-scale adopters based on their preparedness for I4.0 concerning BMI [5]. Significant differences exist in organizational and managerial practices among companies categorized as adopters, beginners, and non-adopters regarding implementing I4.0 technologies [60]. Therefore, the managerial challenges and the necessity for tools and guidelines to effectively prepare for adopting changes, as well as understanding the level of preparedness of companies to transform and adopt BMs for I4.0, are significant. BMI carries the risk of failure, and the negative social perceptions attached to business failure might hinder companies from undertaking such innovations [61]. Technological, organizational, and environmental readiness necessitate a framework integrating technology, organization, and environment to successfully implement an enterprise’s green (product and process) innovations [62].

Pigosso and McAloone [63] introduced an online tool called MATChE, designed for manufacturing companies to evaluate their readiness to transition to a circular economy. This tool assesses readiness across eight dimensions: (1) Organization, (2) strategy and BMI, (3) product and service innovation, (4) manufacturing and value chain, (5) technology and data, (6) use, support, and maintenance, (7) takeback and end-of-life strategies, and (8) policy and market. Antony et al. [64] identified a preparedness model with ten dimensions through qualitative analysis and developed a quantitative model to rank these ten dimensions based on their importance for preparedness.

3. Methods

This section provides an overview of data acquisition methods, identifying topics relevant to incumbent manufacturers’ DDBMI and the thematic synthesis of the identified topics. First, relevant literature is searched from the Scopus database, and their titles, keywords, and abstracts are used for topic modeling using the Latent Dirichlet Allocation (LDA) methodology. LDA is an unsupervised, probabilistic modeling technique employed to extract topics from a corpus of documents. It is applied for exploratory analysis of large text data. Our implementation of LDA is based on the framework by Asmussen and Møller [65]. Several studies [66,67,68] have utilized LDA-based models to explore and compare topics from text data in business and innovation research.

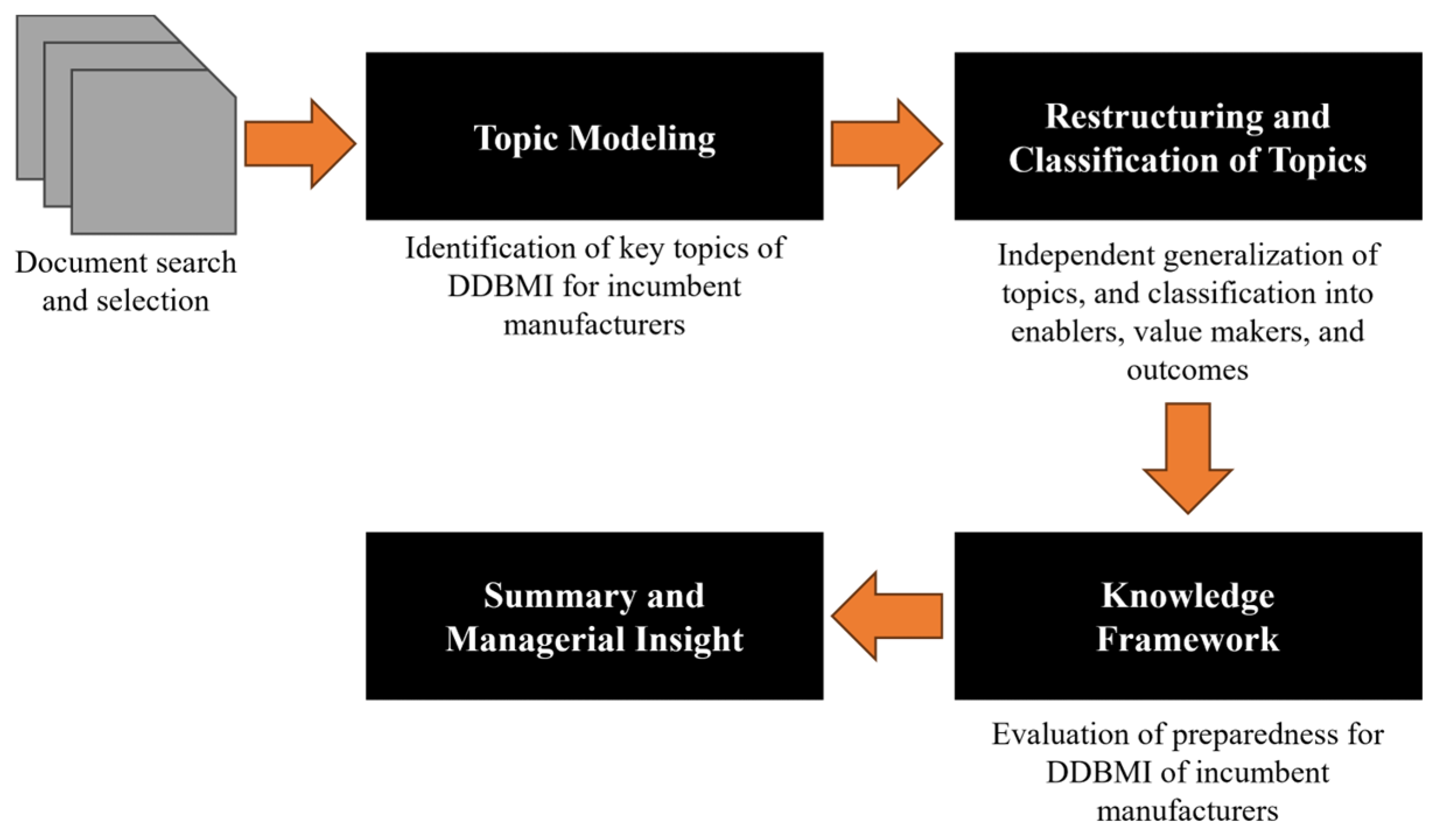

The identified topics must be understood and interpreted for the underlying analytical themes and thematic categorization needed for generalization. Therefore, we followed a thematic synthesis analysis approach [69] to synthesize themes and provide a generalized category of topics for DDBMI from the multiple topics identified by topic modeling. Thematic categorization of topics is a qualitative approach involving four team members restructuring topics into independent and generalized definitions, partitioning the restructured topics into different classes, and further developing a knowledge framework considering five different aspects of these topics. The workflow illustration is shown in Figure 1.

Figure 1.

Schematic diagram of the workflow.

In the following sections, we elaborate on the steps for topic identification, starting from data acquisition, preprocessing, and topic modeling to topic selection.

3.1. Data Extraction

To categorize the topics related to DDBMs and incumbent manufacturers, we constructed the search terms and :

- = “business model” AND (incumbent OR established OR mature) AND (“data driven” OR “big data” OR “artificial intelligence” OR “machine learning” OR IoT OR IIoT OR digitalization OR “machine learning” OR “deep learning” OR “process mining”).

- = AND (manufacturing OR production OR “industry 4.0”)

The search term includes manufacturing and production-related terms and refines the search criteria for incumbent manufacturers. Data extraction involves retrieving title, keywords, and abstract information from 410 papers, comprising 137 documents from and 273 documents from , obtained from Scopus. These papers were selected from 260 journals and conference proceedings from 1998 to 2021.

3.2. Data Preprocessing

For topic modeling, we preprocessed the data for each document. First, we combined the title, keywords, and abstract into a single text content and formed two corpora from searches and , respectively. Next, we changed all the text into lowercase characters, removing all punctuation, including non-alphanumeric characters such as commas, periods, parentheses, and other non-English characters. Subsequently, we removed stopwords (e.g., the, and, so, or) and performed stemming of words. We constructed a document-term matrix for topic modeling by breaking down texts into tokens, considering unigram and bi-gram terms.

3.3. Topic Modeling (LDA)

We employ the LDA approach for topic modeling. LDA is a generative model applied to identify latent topics in a collection of documents [70,71]. The underlying assumption is that a probability distribution of latent topics represents each document. Additionally, each topic is assumed to be a probability distribution of words, with both the topic distributions across all documents and the word distributions of topics sharing a common Dirichlet prior. The objective of LDA is to uncover the latent topics and their corresponding probabilities within the collection, along with the distribution of topics across each document. This is achieved by maximizing the likelihood of the observed data, given the topic assignments for each word in each document and the topic distributions across the entire matrix of documents (rows) and words (columns). The likelihood function is described as follows:

is the total number of documents in the corpus. is a document topic distribution, and is the topic distribution for document of topics and . is the predefined value for several topics. is the total words in document . is a topic-word distribution, where . is the topic assignment and a multinomial distribution with parameter .

We utilized a collapsed Gibbs sampling technique implemented in the STM package [72] for parameter estimation. The number of topics is optimized using semantic coherence [73] and exclusivity [74,75] metrics for adaptive LDA model selection. Semantic coherence is maximized when the most probable words in each topic frequently co-occur, and exclusivity maximizes the criterion measuring the exclusive co-occurring keywords between topics. The selected number of topics based on semantic coherence and exclusivity from LDA analysis provide topic-word and document-topic distribution.

3.4. Manual Topic Selection (Thematic Synthesis)

The identified topics from topic modeling for searches and are a combination of mixed and overlapping topics and are discussed in industry-specific contexts. To generalize topics, our four-member team selected topics that can be independently described and generalized for incumbent manufacturers. For the generalization of topics, first, each keyword under each topic is selected from the topic model results of and . The search is specifically employed to harness relevant topics adaptable to incumbent manufacturers’ contexts; however, the search specifies a broader category of incumbents for the DDBMI search.

The topics are obtained from topic modeling, where keywords are common recurring words within the text data and are considered topic keywords; however, they lack deeper meaning and a general context, requiring appropriate interpretations based on these keywords. In our case, for thematic analysis, instead of selecting top topic keywords for relevant interpretations, which may overlap and lack generalization for DDBMI, we obtained generalized topics for DDBMI for incumbents through thematic analysis. In this process, we first selected the top 30 keywords (from a topic word distribution matrix showing high probability representing a topic) and FREX words from each topic of the topic model, constructing descriptive themes presented in the Table A1 and Table A2 in Appendix A, showing patterns that emerged from topic modeling.

Our goal is to achieve a generalized thematic categorization based on the thematic description of the keywords and the generation of analytical themes from the topic modeling results. To achieve this, we filtered the keywords in the topics and assigned a value of 0 or 1 independently by four members. If the subtopic is relevant to the BM based on descriptive theme analysis, we assign 1; otherwise, 0. We enter the next level for topic interpretation for all the subtopics coded 1 at least once. Next, we performed analytical theme generation on selected subtopics, discussing each subtopic based on a description of conceptual relevance in DDBMI for incumbents (generation of analytical themes) within the context of BMI by examining associated documents. Subsequently, each subtopic is coded as 1 or 0.

The subtopics are considered relevant when at least three team members agree (overall score three or greater) that they apply to incumbent manufacturers, have sufficient presence in the literature, and have conceptual relevance for DDBMI. For thematic categorization, each member independently checked the similarity of each selected subtopic based on the analytical themes. Then, we conducted a joint discussion to categorize each similar subtopic and assigned a generalized description to highly relevant categories significant for DDBMI. Additionally, we examined the description of each category pertinent to the group of subtopics within the literature and if they are discussed in the context of the assigned description. These rearranged selected subtopics are grouped based on their descriptive themes, analytical description, and thematic similarity, as shown in Table 1, with relevant descriptions significant for DDBMI.

Table 1.

Nine topics relevant for incumbent manufacturers’ DDBMI.

4. Results

4.1. Key Topics for Data-Driven Business Models

Table A1 and Table A2 (see Appendix A) display the topics obtained from two different topic models for and . These topic models show the recurring keywords under each topic, which help define and characterize the topic. However, the overlapping and industry-specific presence of topics does not fully describe the general idea of DDBMI. For example, Topic 4 in Table A1 (with the highest topic mean proportion) is a mixture of keywords with mixed themes related to BMs, digital economy, circular economy, sustainability, logistics and supply chain management, integration, and transformation. These co-occurring keywords emphasize the importance of adapting BMs to align with digital, circular, and sustainable principles to drive success and innovation in manufacturing. Thematic synthesis is necessary to separate and categorize these co-occurring keywords in different topics (Table A1 and Table A2) for an analysis of topics common to incumbent manufacturers.

Through manual selection (thematic synthesis) from the topic modeling outcomes, we identified nine non-overlapping topics relevant to incumbent manufacturers’ DDBMI. These selected topics are outlined in Table 1. The “Refined keywords” column includes words extracted from the topic modeling outcomes, specifically the top main and FREX keywords highlighted in Table A1 and Table A2. We regrouped these keywords based on their similarity and relation to one another to create a generalized and non-overlapping overview of topics. Additionally, we provided a topic description based on the keywords in each group and arranged them according to sample size.

First, we will briefly define the selected topics and explain their relevance for DDBMI. Topic 1, digitalization, is defined in the BMI context as leveraging digital technologies to transform BMs, create new value [76], and enhance existing capabilities, thereby creating a “visionary digital value proposition” [77]. Incumbents must prioritize digitalization in DDBMI to influence value creation, value capture, value delivery, and sustainability [78].

Topic 2, sustainability, is defined along the lines of the triple bottom line, i.e., social, environmental, and economic value creation [79,80]. Appropriate initiatives include training and competence development supported by ICT technologies [81], reducing energy consumption through efficient optimization of big data, AI, and sensors [82], and creating financial gains by retrofitting production into an interconnected cyber-physical system as a low-cost alternative [83,84,85,86].

Topic 3, platformization, refers to digital platforms that feature modular technological architectures with core-periphery structures [87] and utilize technologies to connect users, resources, and tools through streamlined interactions and transactions. Digital platforms organize customers and companies, gather knowledge, facilitate value interactions between market actors (e.g., producers and consumers), and create ecosystems [88,89]. Platform ecosystems leverage production, innovation, and transaction logic based on an open system to create value [90]. Digital platforms positively affect BMI by facilitating capability reconfiguration [91] and driving companies’ sustainability-oriented innovation through open innovation [9]. Incumbents adopting digital platforms face challenges in developing internal readiness and necessary capabilities for platform ecosystems and managing hybridity as platforms extend existing BMs without replacing them [92,93].

Topic 4, the IoT, is defined as a group of infrastructures interconnecting connected objects and allowing their management, data mining, and access to the data they generate [94]. IoT aids incumbent manufacturers by generating real-time data for improved energy efficiency, resource and workflow optimization, predictive maintenance, targeted marketing, and new product and service creation. The manufacturing sector sees potential for BMI through IoT-based virtual/digital applications and IoT-based automation [95].

Topic 5, servitization, integrates services into traditional product-centric BMs, enabling a shift towards service-oriented BMs offering services or integrated product-service systems instead of physical products [96,97]. Servitization is an archetype of I4.0 BMs that exploits digital technologies [98], creates value through digital service innovations (i.e., business enablers, service enhancement, and digital service offerings) [99], and makes reorganizing production and management practices necessary [100]. In manufacturing, there are three types of service-based BMs: Product-oriented, process-oriented, and outcome-oriented digital servitization [101].

Topic 6, AI, is defined as intelligent computer systems with cognitive capabilities similar to humans, employed to sense the environment, comprehend information, learn from data, and act autonomously [102,103]. AI capabilities positively impact servitization, moderated by absorptive capacity [104]. AI develops systems that mimic and extend human cognitive capabilities, improving efficiency, reducing costs, and saving time [105]. Challenges during the application of AI in BMI are developing technological capabilities, upskilling employees, matching AI with existing resources and infrastructures, transforming AI functionalities, value processes, and ecosystems in parallel, and integrating AI-driven transformations with established ecosystem actors [106,107].

Topic 7, big data, refers to large, complex datasets that demand specialized decision-making and insight discovery methods to facilitate efficient extraction, analysis, and visualization [108]. Big data includes heterogeneous, unstructured, and trans-semiotic formats beyond alphanumeric systems and real-time characteristics [109]. Either internally generated from routine operations or external sources, big data can be analyzed through automated techniques such as clustering, aggregation, and data mining to reveal patterns and trends in organizational environments [109]. Integrating big data with servitization can extract valuable insights from products and services utilizing customer data [110]. Big data empowers firms to create value by augmenting their capabilities [111], notably by integrating non-technical resources alongside data and technology to cultivate robust big data analytics capability [112]. The higher failure rate of big data-driven solutions underscores several challenges, encompassing the prevalent utilization of AI-driven models characterized by difficulties in explanation and user acceptance, alongside concerns related to project selection, process redesign, and the need for continual relearning [113].

Topic 8, the sharing economy, is defined as an IT-facilitated peer-to-peer model enabling the commercial or non-commercial sharing of underutilized goods or services via an intermediary without transferring ownership [114]. The sharing economy is a new approach to value creation, capture, and delivery with innovative value architecture [115], which results in new BMs prioritizing collaborative consumption and resource sharing [116]. Manufacturers are encouraged to adopt the sharing economy BM in markets of comparable size or with diverse product usage needs [117].

Topic 9, mobile networks, facilitate the integration of technologies such as cloud computing, the IoT, the IIoT, machine-to-machine edge computing, cyber-physical systems (CPS), and intelligent logistics. Advanced mobile technologies, like 5G, are anticipated to meet the future demands of the industrial internet, offering higher data rates, increased capacity, reduced latency, and enhanced reliability [118]. This development is expected to facilitate industrial communications and enable alternative configurations of value networks. Integrating 5G with smart manufacturing will establish intelligent networks [119].

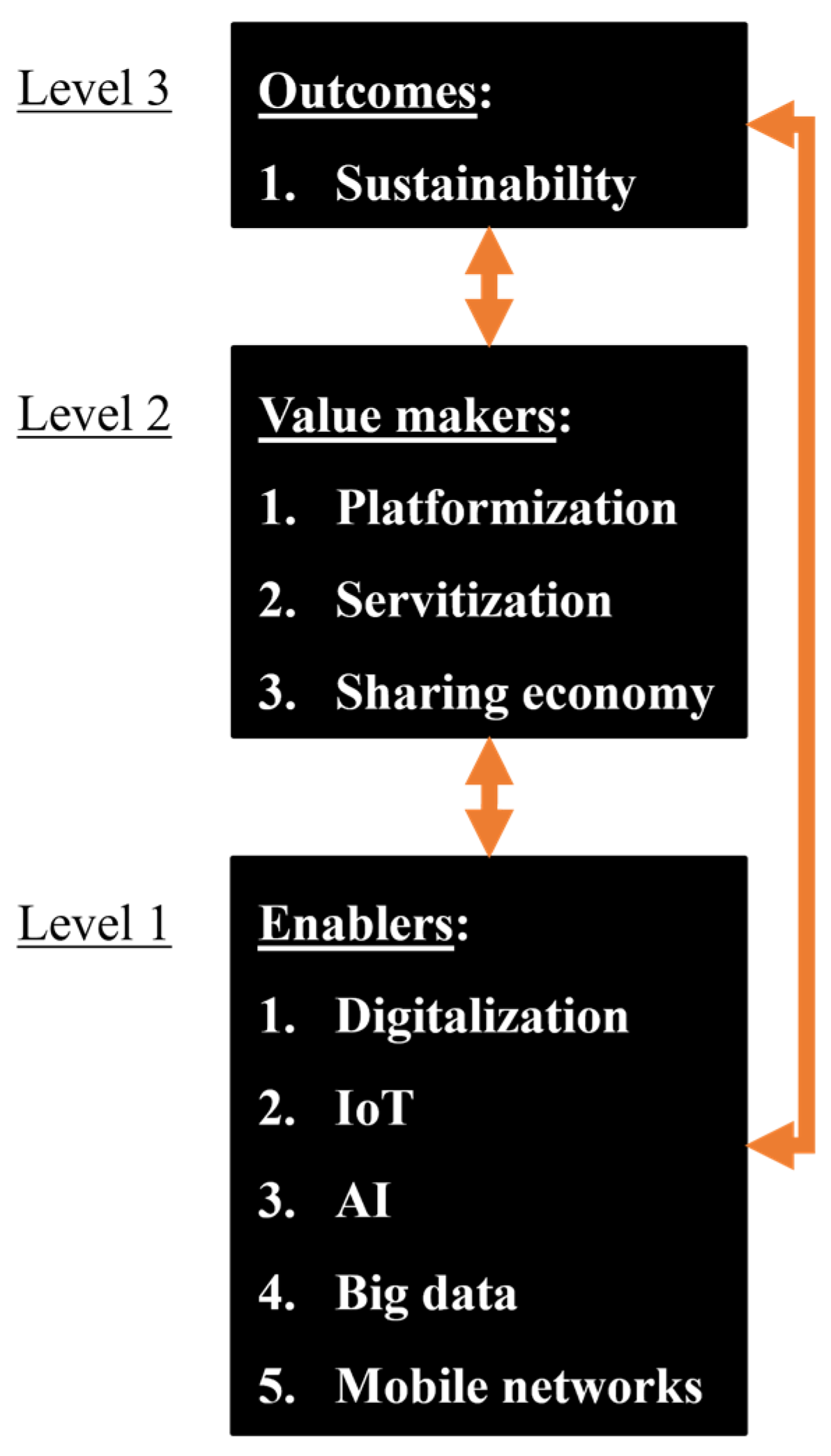

4.2. Three Levels for the Preparedness of Data-Driven Business Models

Next, we categorize the topics into three levels: Enablers, value makers, and outcomes (see Figure 2). At the first level, enablers such as digitalization, IoT, AI, big data, and mobile networks are the foundation of DDBMs, facilitating data collection, acquisition, and analysis [42,120]. This categorization is based on several studies discussing the role of digitalization [121,122], the IoT [101,123,124,125], AI [107,126], big data [125,127], and mobile networks [128] as enablers of DDBMI.

Figure 2.

Classification of topics into three levels for the preparedness of DDBMs.

On the second level, value makers (platformization, the sharing economy, and servitization) utilize data to add sustainable value for the company and its stakeholders, including customers, suppliers, or others, contributing to company growth, profitability, resource utilization, and innovation [89,129,130]. Studies discuss the importance of platformization [131,132,133], servitization [134,135,136], and the sharing economy [129,137] as value makers during DDBMI, which benefit from the enablers. Value makers and enablers share a reciprocal relationship: Enablers empower value makers technologically to add value by providing tools and capabilities to exploit new opportunities, enhance efficiency, improve productivity, and foster innovation [138,139]. Similarly, value makers prompt enablers to add value for stakeholders by shaping companies through defining business strategies and utilizing technology and data-driven approaches.

At the third level, outcomes (sustainability) represent the focal points for sustainable and data-driven manufacturing in incumbents, relying on support from enablers (first level) and value makers (second level). Outcomes, as sustainability objectives, encompass social, environmental, and economic dimensions for long-term added value and innovation [140]. The most crucial connection exists between enablers and value makers, while all other connections can be described as feedback loops. The three levels elucidate how a DDBM forms an interconnected construct characterized by complexities arising from the interdependencies within and between levels. Successfully handling these interdependencies can contribute to the preparedness of DDBMs.

Enablers, value makers, and outcomes are interdependent. Numerous studies highlight the interdependence among individual BMI topics and emphasize their conceptual and strategic interconnectedness [141,142,143,144]. Incumbent manufacturers must understand the interplay and alignment of enablers, value makers, and outcomes with business objectives. A simultaneous understanding of the variables influenced by the three levels is necessary, ranging from innovation potential, capabilities, and customer expectations to market trends, organizational processes, and operational efficiency.

Successful strategies require understanding challenges and identifying the business’ key variables, which are influenced by the interconnected topics. Key variables are crucial for developing, implementing, and succeeding with a BM, as they influence each other and impact the BMI process. At the intersection of technological shifts and BMs lies the strategic dilemma of choosing between technological innovation and servitization, with the optimal solution being a combination of technological and service innovation [145]. Only “prepared” companies can meet the challenges and leverage the opportunities posed by IoT technologies to utilize them for service-oriented innovation and digital servitization [101].

Therefore, incumbent manufacturers need a knowledge framework to understand the impact of enablers, value makers, and outcomes on driving DDBMI, to evaluate their (organizational, managerial, technical, and operational) preparedness for DDBMI, and to assess preparatory steps. The preparatory steps require utilizing the nine topics to understand their interdependence and impact, recognizing DDBMI opportunities, and acquiring insights for each topic. Such insights are gained by classifying the nine topics into three levels and help develop an evidence-based approach [146] to assess incumbent manufacturers’ preparedness for DDBMI. Such an evidence-based approach can draw insights from evidence-based healthcare.

Key characteristics of evidence-based healthcare include risk management, robust decision-making, contextual adaptation, and patient safety. Furthermore, a strong theoretical model in intervention planning and a methodology for integrating strategies and tools are important [147]. Without such a foundation, the desired outcomes may not be achieved. The principles of evidence-based healthcare can be applied to evidence-based entrepreneurship: Baba and HakemZadeh [148] present a theoretical model for evidence-based managerial decision-making, which encompasses the generation and evaluation of evidence and a decision-making process influenced by individual, organizational, and institutional levels. In evidence-based entrepreneurship, meta-analyses, which involve calibrating relationships between variables, offer theoretical and methodological advantages. They can accumulate knowledge, stimulate theory development, provide evidence-based practices, and formulate recommendations for researchers and practitioners [149].

An evidence-based approach to assess the preparedness of incumbent manufacturers for DDBMI requires them to systematically generate and evaluate available evidence. Evidence can be generated by synthesizing information from various sources with sufficient detail and scientific knowledge, which aids in informed decision-making by ensuring theoretical understanding and rational interpretation. In practice, incumbent manufacturers will need domain experts to develop an approach at the organizational level to assess their preparedness for DDBMI. Although our knowledge framework cannot directly test the preparedness hypothesis, it can establish the groundwork for gathering evidence by assessing the crucial aspects of various topics for the DDBMI process. The knowledge framework will be presented in the following subsection.

4.3. Knowledge Framework for Data-Driven Business Model Innovation

To address a wide range of DDBMI challenges, we present a knowledge framework (see Table 2) that integrates the nine identified topics across five aspects: (1) Infrastructure and technology, (2) capabilities, (3) theories and frameworks, (4) strategies and solutions, and (5) evaluation. The five aspects represent the technological or strategic requirements of the DDBMI process, and their implementation can serve as preparatory steps for DDBMI. The knowledge framework is built upon existing research literature, merging the nine topics (see Section 4.1) with five aspects, whose derivation is clarified in the subsequent section. Table 2 offers an overview of the combination of topics and aspects. The references have been integrated under the corresponding aspect headings to enhance presentation clarity, as including references for each bullet point in every cell would be overly extensive.

Before delving into the specifics of the five aspects, we briefly acknowledge studies examining these aspects within specific topics, such as infrastructure and technology [150,151,152], infrastructure and capabilities [119,153,154], theories [155,156], strategies and solutions [125,157,158], and evaluation [159,160]. Furthermore, we consulted other literature to investigate and comprehend the significance of these aspects for the knowledge framework. Based on the consensus expressed in these sources, five aspects are selected to support the development of a robust, evidence-based knowledge framework for DDBMI: Infrastructure and technology (first aspect) play a crucial role in innovation, as the simultaneous execution of digital innovation strategies and IT infrastructure is required. Capabilities (second aspect) serve as the foundation for the value proposition. Theory and framework (third aspect), strategies and solutions (fourth aspect), and evaluation (fifth aspect) are adopted from the cyclical framework for evidence-based healthcare implementation planning [147].

These five aspects require interactions and overlap with strategy, business processes, and information systems to transform BMs into DDBMs [161]. The subcategories of each topic under each aspect are derived from the current literature on incumbent manufacturers’ DDBMI and may be incomplete, given the limitations of the conducted literature search. The five aspects are recognized as foundational features of DDBMI and incorporated into a knowledge framework comprising relevant DDBMI topics across the levels of enablers, value makers, and outcomes (see Figure 2). The aspects divide each topic into manageable levels, enabling incumbent manufacturers to understand the connections between topics, address complexities and challenges, and gain strategic insights essential for the preparatory steps of DDBMI using an evidence-based approach.

Infrastructure and technology (first aspect) are essential for DDBMI, as it relies on robust infrastructures such as technology, sensors, software, hardware, and communication networks. Incumbent manufacturers must develop or retrofit infrastructure that supports DDBMI, aligns with strategic goals, and provides value to customers and partners [150]. Infrastructure and digital technology are important for collaboration, scaling up implementation plans, facilitating innovation management, enabling new product ideas, and complementing the external knowledge search for process innovation [162].

Incumbent manufacturers need to possess certain capabilities (second aspect) to implement the nine topics, such as being agile and adaptable to market changes, managing internal and external operations, data, and customers, investing in infrastructure and talent, focusing on developing strategies and methods, and possessing technical and business expertise [154,163]. Business and technical expertise includes comprehending competitiveness, market dynamics, and the ability to evaluate potential avenues of innovation. Management, infrastructure, and talent requirements impact DDBMI capabilities, new data product categories, and new data product performance. While small and young companies focus on a specific technological area and seek external partnerships, large incumbents with existing technological capabilities strengthen their internal capabilities, such as intra-group synergies and complementarities [151].

The nine topics require the creation of theories and frameworks (third aspect) to effectively carry out DDBMI processes, along with problem solving and pattern recognition. Theories explain phenomena, while frameworks provide a structure for organizing and implementing practical solutions. The evaluation framework for theories in the information systems domain describes theories as tools for explanation and prediction. Theories can make novel contributions by addressing focal phenomena not previously discussed, modifying existing theories to explain new phenomena, or providing new perspectives on existing focal phenomena [164]. General and industry-specific theories and frameworks are essential for explaining and predicting the course of DDBMI. Theoretical understanding in technology forecasting for future use is crucial, as BM theory has a high predictive ability for future digital technology use in businesses [155].

Theories and frameworks are utilized to understand problems, recognize patterns, guide future research with critical insight, and, most importantly, facilitate strategies and solutions development (fourth aspect) for DDBMI. A deeper understanding of underlying principles leads to the development of more strategic and intentional decision-making. Business model patterns (BMPs) are innovative tools that identify recurring patterns in BMs, simplifying the characterization of BMs within BM frameworks [165]. BMPs facilitate problem solving, help identify key BM attributes, and enable knowledge transfer from past experiences to the current context [8,166,167]. One example is the work by Curtis [158], who utilized unsupervised ML (k-medoids) to analyze 63 sharing-economy BMs, considering 17 attributes and 93 configuration options, and identified six solution patterns for sharing-economy BMI.

Different qualitative and quantitative evaluation (fifth aspect) measures and metrics are necessary to assess the effectiveness of implemented strategies and solutions. Examples include outcome-based evaluation, process evaluation, data-driven business analytics, Key Performance Indicators (KPIs), and expert insights. Several studies discuss the essential metrics and KPIs for different aspects of DDBMI [159].

Table 2.

Knowledge Framework of Three Levels, Nine Topics, and Five Aspects Related to DDBMI.

Table 2.

Knowledge Framework of Three Levels, Nine Topics, and Five Aspects Related to DDBMI.

| Infrastructure and Technology [48,107,150,151,152,162] | Capabilities [91,93,107,153,168,169] | Theory and Framework [8,96,106,130,155,170,171,172,173] | Strategies and Solutions [125,150,174,175,176,177,178,179] | Evaluation [58,159,160,180,181,182] | ||

|---|---|---|---|---|---|---|

| Enablers | Digitalization | -Digital devices and software -High-speed internet -Cyber security -Cloud services | -Business strategy -Process optimization -Digital tools and technologies -Data management | -Digital maturity -Digital transformation -Digital reorientation -Digital manufacturing | -Data management systems -Business process and workflow -Digital strategy | -Digitalization KPIs |

| Internet of Things | -Sensors and connectors -Connectivity and coordination across devices and networks -Cloud computing | -IoT-appropriate adaption of skills, knowledge, and experience -Problem-solving skills instead of an operator role -IT system management | -Collaboration and integration (shop floor and equipment) -Customer integration into product and service engineering -Product and service innovation | -System and operational efficiency -Process and resource optimization -Automation and smart factory -Quality control and monitoring -Predictive maintenance and demand | -Product and service robustness measures and evaluation -Customer experience, KPIs | |

| AI | -AI, ML, technology stack -Data analytics tools/frameworks -Computing resources -Computational performance | -Data science, ML, modeling -Data processing and analytics -Teamwork of data engineers, data scientists, and business experts | -AI-enabled BMs -AI-driven strategic implications -Smart manufacturing -Trust-commitment theory -Human-AI collaboration theory | -Product design and planning -Material and inventory management -Forecasting, optimization, simulation, and predictive analytics -AI-enabled services | -Model accuracy, reusability, cost-effectiveness, and longevity -Interpretability and explainability -Performance evaluation of AI-enabled services | |

| Big Data | -Data storage and sharing -Data security and access control -Data architecture -Data management tools -Computational resources | -Design, develop, and maintain cloud computing and warehousing -Process and analyze data -Teamwork of data engineers, data scientists, and business experts | -Data mining -Data-driven innovation -Data-driven transformation -Data-driven automation | -Data as a service -Data monetization -Real-time analytics and monitoring -Data integration -Data quality and accessibility | -Data quality and access KPIs | |

| Mobile Network | -Mobile value network -Mobile technologies -Online omnichannel -Integrated data analytics systems | -Align value creation and capture with transition type -Seamless customer experiences | -App-driven freemium BM design -Online omnichannel BM design | -Integrated data analytics systems -Effective supply chains and logistics -Decision-making supported by mobile technology | -Use of mobile technologies -Factors impacting omnichannel management | |

| Value makers | Platformization | -IT resources, hardware, software -Cloud computing -Scalable and interoperable technology infrastructure | -Data analytics -Platform-based solutions -Digital marketing -Customer relationship management -Data monetization | -Platform-enabled marketplaces -Platform-based servitization -Platform as a service -Multisided platforms -Platform ecosystems | -Industry-specific service platforms -Online on-demand solutions -Customer segmentation -Improved customer channels -Third-party system integration | -Business experts’ evaluation -Customer response -User activity analytics and KPIs -Social network analytics -Platform KPIs |

| Servitization | -Product-service systems -Digital servitized ecosystems -Smart, connected products -Technology transfer (platform and multi-stage model) | -Align product-service systems with value proposition -Increase maturity of digital servitized ecosystems -Reorganize production practices | -Service-centric BM design -Integrated service systems -Designing novel services -Digital servitized ecosystems -Network orchestration | -Service delivery platform -Service network design -Smart product development -Supply chain management -Big data analytics for servitization | -Current service offer measures -Organizational predisposition -Intention for future service offers -Service revenue -Servitization KPIs | |

| Sharing Economy | -Digital platform -Connectivity -Mobile payment systems -Maintenance infrastructure | -Application development -Legal requirements -Franchising -User data analytics -Blockchain technology | -Platform ecosystems -Pay-per-use BM -Customer behavior | -Demand planning -Platformization -Customer behavior analytics -Multi-stakeholder management -Multi-user environment | -Utilization measuring -Booking frequency -KPI visualization -Time-in-use monitoring | |

| Outcomes | Sustainability | -Energy infrastructure -Sustainability measurement -Monitoring and visualization | -Energy monitoring -Scope 1,2,3 knowledge -CO2 emission calculation -Greenhouse gas protocol -Cause and effect relationship | -Sustainable business value -Circular strategies supporting innovation -Circular economy BM design -Infrastructure sharing | -Digital transformation -Sustainable practices and production -Energy-efficient products/services -Optimization (e.g., energy consumption, cost, processing time) | -Sustainability KPIs -Product life cycle -Environmental impact -Evaluations of product design, production alternatives |

The knowledge framework categorizes nine topics and five aspects, resulting in 45 cells. Each cell corresponds to a specific topic and aspect, capturing variability across topics, aspects, and within individual cells. A framework proposed by Mariani et al. (2023) [126] for AI acceptance, adoption, and innovation includes technological antecedents (e.g., digitalization, IoT, and big data) and consequences involving BM, process, and product innovation. This can be applied to DDBMI by interpreting the identified topics as antecedents or consequences. Incumbents wishing to implement a DDBMI must assess their preparedness across such topics, embodying antecedents or consequences while considering their various aspects. When utilizing the table, readers can examine a topic across the five aspects, an aspect across the nine topics, or delve into a specific cell (i.e., one topic and one aspect). Instead of elaborating on all 45 cells, we provide three examples illustrating these various approaches to interpreting the table.

Firstly, examining a single topic alongside its five aspects can shed light on conceptual nuances within the topic. Due to its significance across various industries, we have chosen digitalization as an example. Digitalization can be explored through the following aspects: (1) Infrastructure: Specific components and systems are necessary to integrate digital technologies, facilitating digital transformation and enabling technology-driven value creation for companies. (2) Capabilities: Digitalization capabilities are crucial for companies effectively utilizing the infrastructure. (3) Theory and Frameworks: Capabilities support developing and comprehending theories and frameworks. (4) Strategy: Digitalization strategies benefiting DDBMI can be derived from existing theories and frameworks. (5) Evaluation: Corresponding evaluation criteria are vital for assessing the impacts of digitalization strategies and ensuring their alignment with the company’s BM.

Secondly, we explore a single aspect—capabilities—across all nine topics: Companies must cultivate complementary capabilities across enablers, value makers, and outcomes. Capabilities related to enablers (such as digitalization, IoT, AI, big data, and mobile networks) must align to support DDBMI. These capabilities vary among companies [112] and cannot be substituted. Enabler capabilities are crucial for developing capabilities related to value makers (including platformization, servitization, and the sharing economy) [183]. Finally, outcomes (in this case, sustainability) are built upon the capabilities developed at previous levels and rely on them for their development.

Thirdly, we delve into a specific cell, focusing on the combination of a particular topic and aspect. We chose digitalization and theory and framework for this example. Various theories and frameworks in digitalization, such as digital transformation [172] and digital maturity [184], offer unique perspectives. Digital transformation emphasizes strategic adoption to reconfigure BMs and reshape a company’s value architecture to support a sustainable long-term turnaround strategy [185]. Digital maturity assesses a company’s readiness and progression through digital transformation stages, exploring digital technologies’ impact and identifying new sales outlets through service-oriented manufacturing, networked collaborative manufacturing, and enhanced value-added space [186].

In summary, the knowledge framework provides an overview of nine topics and their corresponding five aspects concerning incumbent manufacturers’ DDBMI. The framework is adaptable to various contexts and is intended to aid in preparing for DDBMI. In practice, it will be necessary for companies to expand upon each topic and aspect as needed to assess their preparedness for DDBMI. This approach may assist companies in aligning enablers, value makers, and outcomes with DDBMI objectives, customer needs, and new market requirements.

5. Discussion

In our study, we aimed to address three research questions. The first question was tackled using topic modeling and thematic synthesis, revealing nine key topics crucial for incumbent manufacturers in DDBMI. These topics include the following: (1) Digitalization, (2) IoT, (3) AI, (4) big data, (5) mobile networks, (6) platformization, (7) servitization, (8) the sharing economy, and (9) sustainability.

The second question was approached through thematic categorization, wherein the nine topics were classified into essential aspects for comprehending their impact on DDBMI. These aspects encompass (1) infrastructure and technology, (2) capabilities, (3) theory and framework, (4) strategies and solutions, and (5) evaluation.

Finally, the third question was addressed by combining the previous findings—the nine topics and associated aspects—into a knowledge framework. This framework is designed to support incumbent manufacturers to enhance their preparedness for DDBMI.

5.1. Theoretical Contribution

The theoretical contribution of our work is twofold: First, we present a knowledge framework (see Table 2) that outlines three levels, nine topics, and five aspects. This framework categorizes these topics into enablers, value creators, and outcomes, and examines each topic through five aspects. It consolidates the existing infrastructure, technology, capabilities, theoretical foundations, strategies, solutions, and evaluation criteria incumbent manufacturers encounter when implementing digital technologies for DDBMI. Incumbent manufacturers face significant challenges in adopting DDBMs, especially due to the intricate interplay and interconnectedness of these various topics. Therefore, their considerations must include a conceptual understanding of these interrelated topics. By defining these topics and aspects and identifying their relationships, our framework facilitates knowledge transfer and supports future decision-making processes. It illustrates the impact of these nine topics on DDBMI and is instrumental in developing integrated solutions tailored to incumbent manufacturers’ needs. Additionally, it is a valuable resource for future research in that it provides an overview of the connections between enablers, value makers, and outcomes, thereby stimulating further and deeper analyses of these topics.

Second, our paper contributes to a better understanding of the theory of organizational preparedness by categorizing the nine topics across five aspects. The knowledge framework can be utilized to evaluate incumbent manufacturers’ preparedness for DDBMI by clarifying the topics’ interdependence as enablers, value makers, and outcomes. The knowledge framework prompts incumbent manufacturers to assess their preparedness regarding each aspect of the topics by addressing the following questions: (1) What level of preparedness is necessary to achieve our desired business outcomes and implement the planned DDBMI? (2) What level of preparedness do we currently possess for each topic and aspect concerning DDBMI by identifying strengths and weaknesses? (3) What are the key positive and negative interactions among different topics and aspects that could influence our overall business objectives? Each point within the knowledge framework, associated with a different topic and its related aspect, must undergo empirical testing, meta-analysis, and scrutiny by internal and external experts to assess preparedness for DDBMI.

5.2. Managerial Insights

The knowledge framework offers a solution to organizational challenges and fosters preparedness by clarifying the identified topics. By breaking down the topics in a structured and detailed manner, the framework provides managers with guidelines for analyzing how their companies score along the different aspects of the respective topics, offering a means to assess their preparedness for DDBMI. By identifying shortcomings, the framework can set the direction for strategy development, such as building necessary capabilities. To apply the knowledge framework in practice, managers must identify the interdependent topics and their roles as enablers, value makers, and outcomes.

Collaboration within and outside the company is encouraged to develop expertise in the knowledge framework’s topics. Managers must foster an environment that encourages collaboration by accessing diverse channels that help develop organizational, managerial, and operational preparedness for DDBMI. The knowledge framework can help managers make informed decisions regarding DDBMI by aiding them in identifying opportunities, understanding barriers, and exploring technologies. For instance, an incumbent manufacturer pursuing a sustainable DDBM must consider technological infrastructures, capabilities, frameworks, proposed solutions, and methods for evaluating sustainability-related outcomes and challenges. Other necessary enablers in the form of technologies, such as the IoT, and the sharing economy for added value must be incorporated. Therefore, expertise in data-driven technologies, sharing, and sustainability is essential.

5.3. Limitations and Future Research

Limitations of our work stem from the fact that we did not conduct empirical research, such as case studies, to validate, expand, refine, discuss, and evaluate our knowledge framework. Designing business case studies that identify key variables for each level, topic, and aspect to understand their interconnection could be a starting point for further research. Furthermore, our study focused on incumbent manufacturers, so we cannot make any statements regarding the transferability of our results to other types of companies and industries. As differences exist among industries, other levels, topics, and aspects may be important in industries other than manufacturing. Therefore, the required knowledge would vary, and adjustments to the knowledge framework would be necessary. The interconnection of various levels, topics, and aspects necessitates further research to optimize DDBMI strategies based on industry-specific innovation potential. Lastly, our work focuses on DDBMI; therefore, no general statements can be inferred for BMI. The relationships among the topics and their impact on key BMI variables could be studied in the context of BMI.

More research is needed on incumbent manufacturers’ BMI through the adoption of new technologies and data-driven approaches, given their increasing significance in current business practices. Our analysis lays the groundwork for future research that could focus on three key points: Future research could enhance the knowledge framework by conducting empirical studies to explore technologies and business strategies and providing practical details for each level, topic, and aspect. An expanded framework could assist in identifying requirements of additional topics and aspects across the different levels. By improving their understanding, incumbent manufacturers would be better equipped to utilize technologies and data effectively to transform their existing BMs into DDBMs.

Future research could also implement industry-specific case studies to pinpoint the key variables influenced by these topics and aspects and devise methods for analyzing their interrelationships. Such analyses should focus on topics in their various roles (e.g., enablers, value creators, and outcomes), as in fields such as digital manufacturing, where measures aimed at digital transformation, innovation, and the circular economy are interconnected.

Author Contributions

Conceptualization, S.T. and H.J.; methodology, S.T.; validation, S.T., N.B., M.B. and H.J.; formal analysis, S.T., N.B., M.B. and H.J.; investigation, S.T.; resources, H.J.; data curation, S.T.; writing—original draft preparation, S.T., N.B. and M.B.; writing—review and editing, N.B. and H.J.; visualization, S.T. and N.B.; supervision, H.J.; project administration, S.T. and H.J.; funding acquisition, H.J. All authors have read and agreed to the published version of the manuscript.

Funding

The financial support by the Austrian Federal Ministry for Digital and Economic Affairs, the National Foundation for Research, Technology and Development, and the Christian Doppler Research Association is gratefully acknowledged.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Appendix A

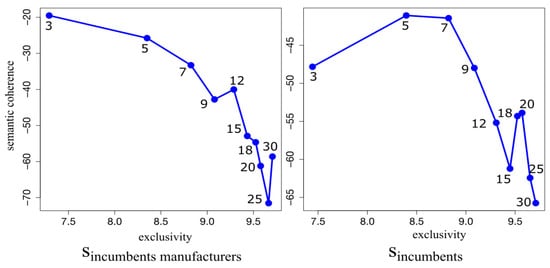

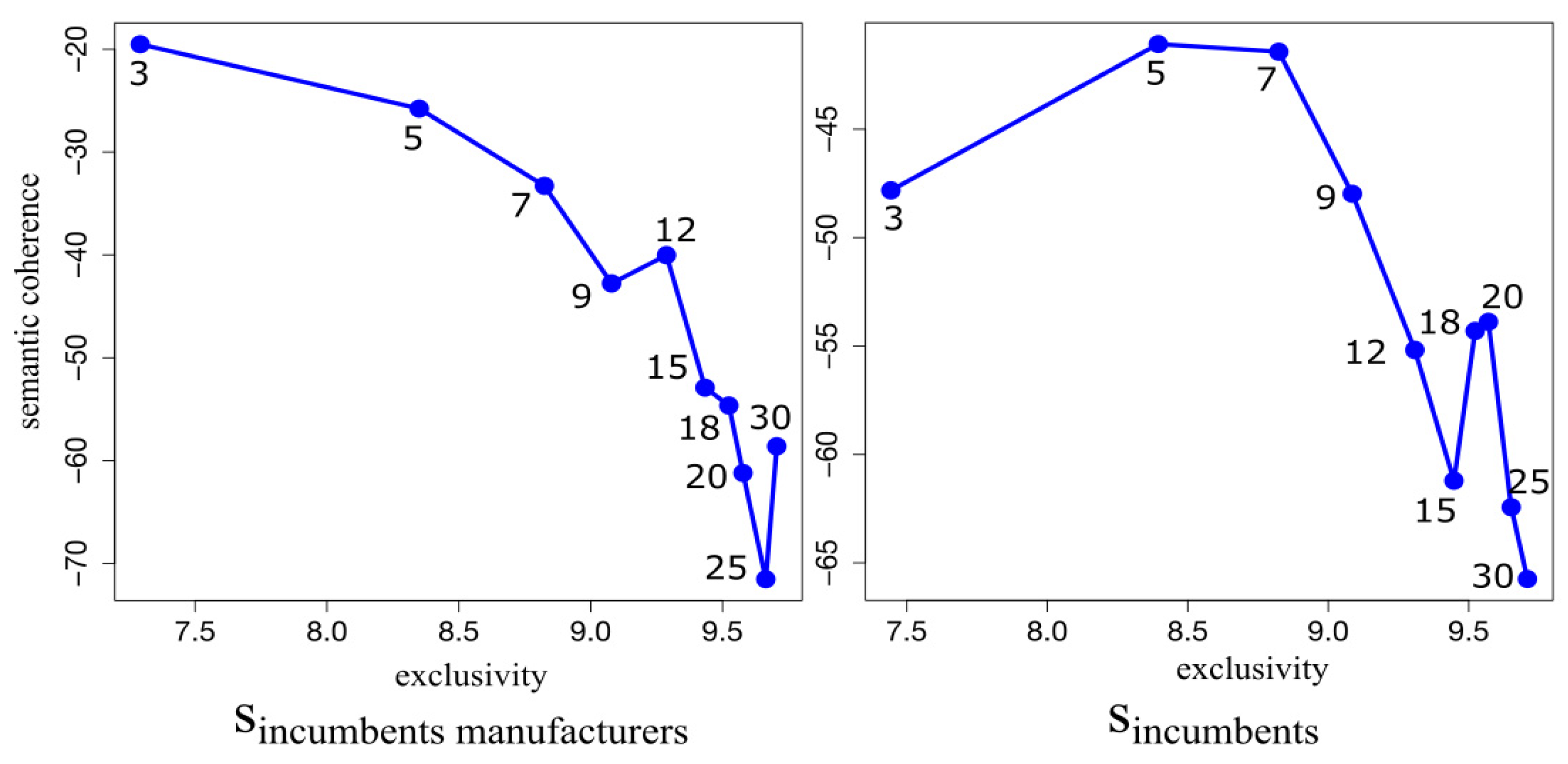

The LDA approach and the number of topic optimization approach based on semantic coherence and exclusivity from LDA analysis provide topic-word and document-topic distribution. Using the topic-word distribution, we performed separate topic analyses for and and conducted semantic content analysis separately for papers in both categories. To optimize the number of topics for LDA, we evaluated semantic coherence and exclusivity metrics for different values of for and searches (see Figure A1). Table A1 visualizes the results.

Figure A1.

Mean semantic coherence and exclusivity measures for and searches.

Figure A1.

Mean semantic coherence and exclusivity measures for and searches.

The elbow approach [187] was used for selecting an optimal , and was chosen for and searches, so that seven topics each were established. This was done because the relative distance for semantic coherence and exclusivity was optimal compared to their minimum values. Next, the top keywords from the topic-word distribution and the mean topic proportion from the document-topic distribution were obtained. The results are shown in Table A1 and Table A2: In the left column, the top keywords show the co-occurrence of keywords describing the topics, and the mean topic proportion indicates the prevalence of the seven topics in the selected documents. The right column shows exclusive keywords based on FREX metrics [75].

Table A1.

Topics of the papers selected for corpus from search.

Table A1.

Topics of the papers selected for corpus from search.

| Topic | Mean Topic Proportion | Top Keywords (Document-Word Distribution) | FREX |

|---|---|---|---|

| 1 | 0.136 | manufacture, technological, service, business, energy, model, digital, industrial, business model, product, transition, smart, research, innovate, develop, economic, 3D print, economy, global, company, change, firm, platform, cloud, manage, transform, roadmap | retrofit, world energy, kibs, service composition, smart retrofit, energy, connotation, prosumer, d print, print, energy transition, carbon, service business, carbon neutral, cloud manufacture, drive force, ecologic, ir technology, manufacture innovation, neutral, politic, specific roadmap, technological convergence, roadmap, cloud, digital economy, composite, digital manufacture, service |

| 2 | 0.107 | system, industrial, research, base, technological, datum, manage, engine, design, business, mobile, digital, model, analysis, study, material, product, smart, process, develop, truck, manufacture, method, require, service, transition, engineer material, integrate, chain, safety | truck, engineer material, dl truck, occupational, health safety, intercommunicating, material datum, occupational health, business intercommunicating, india, road, wave, mobile, decouple, intercommunicating system, engine, transport, safety, city, system base, reliability, material, format, standard, document, control, digitalisation, smart city |

| 3 | 0.124 | industrial, model, business, digital, business model, technological, iiot, process, machine, manufacture, product, datum, design, research, service, study, innovate, transition, system, internet, change, require, support, world, smes, paper, base, enterprise, learn, analysis | mot, post, digital world, post digital, iiot, machine, grind machine, lean, learn, support vector, vector, vector machine, grind, robot, smes, software, simulate, choice behavior, megatrends, train, innovation strategy, choice, experience, bmc, iiot business, thing iiot, medium, industrial internet, personal, support |

| 4 | 0.21 | business, model, industrial, business model, digital, circular, economy, technological, sustain, circular economy, study, company, logistic, product, develop, transition, transform, manufacture, process, research, innovate, circular business, system, case, digital technology, manage, construct, digital transformation, practical, integrate, success | local energy, integrate system, ceramic, holonic, logistic player, sustainable construction, circular economy, circular, circular business, logistic, share economy, economy, construction business, eco design, environmental social, gig, gig economy, intelligent asset, logistic infrastructure, talent, fashion, construct, sustain, share, asset, sustain business, recycle, principle, ceramic tile, digitisation |

| 5 | 0.145 | innovate, industrial, business, model, business model, digital, value, study, capability, develop, model innovation, ecosystem, platform, technological, manufacture, sustain, transform, research, transition, strategy, incumbent, firm, creation, base, implicate, paper, market, provide, company, system | reputation, corporate reputation, value innovation, capability provide, creation strategy, sustainability, model innovation, capability, corporate, incumbent, conflict, digital leadership, experience orientation, innovation value, longitudinal study, taiwan, wine, wine industry, innovate, logic, platform, digital platform, ecosystem, develop business, bmi, distinct, longitudinal, i environment, singapore |

| 6 | 0.146 | business, model, business model, industrial, technological, manufacture, digital, innovate, service, research, develop, product, process, disrupt, servitization, paper, company, internet, transition, challenge, base, value, transform, impact, revolution, industrial internet, firm, industrial revolution, competition, framework | model disrupt, technology roadmap, servitization, pattern, mine, start, disrupt, bm innovation, i bms, model pattern, niche innovation, taxonomy, redistribute, model business, redistribute manufacture, industrial internet, bms, transition technology, big datum, technological business, legal, drive business, african, emphasize, internet business, laser technology, legal tech, mine automation, network organisation, process innovation |

| 7 | 0.128 | product, technological, industrial, model, business, value, process, business model, service, system, digital, laser, develop, network, sensor, manage, collaborate, innovate, base, transition, manufacture, creation, approach, high, enable, intelligence, design, study, interact, fabricate | nano, micro nano, nano fabrication, laser micro, laser process, upgradability product, sensor, laser, library, fabricate, library service, process technological, artificial intelligence, interact, micro, artificial, collaborate, upgradability, caevs, interdependence, journalist, plm, wearable, technological gap, cycle, preparation, perform, network, device, life cycle |

Table A2.

Topics of the papers selected for corpus from sincumbent search.

Table A2.

Topics of the papers selected for corpus from sincumbent search.

| Topic | Mean Topic Proportion | Top Keywords (Document-Word Distribution) | FREX |

|---|---|---|---|

| 1 | 0.094 | inform, model, business, service, system, social, design, develop, technological, information system, digit, innovate, base, manage, process, business model, network, effect, analysis, medium, customer, decision, software, user, impact, approach, online, fintech, strategy, project | information security, software developer, agent base, healthcare organization, shenzhen, behavior information, cohesion, disease, health information, improve medical, information disclosure, outsource, sentiment, sentiment analysis, service failure, software project, interface design, collective intelligence, design principle, dominant logic, fintech bank, local newspaper, model fintech, visualisation, collective awareness, infrastructure transformation, mental model, route optimization, asymmetric, communication decision |

| 2 | 0.149 | business, model, digit, business model, industrial, technological, market, innovate, value, study, research, approach, develop, service, product, transit, sustain, smes, operate, firm, base, system, transform, paper, datum, design, strategic, publish, organizational, mobile, mobile network | knowledge complexity, organizational collaboration, physical system, spanish publish, cooperate, inter, inter organizational, medicine, music, datum share, resilience, rural, music industry, transfer, blend, standard, supplier, base medicine, cooperation behavior, drug, kibs, mscd, strategic alliance, translation precision, supply chain, electronic |

| 3 | 0.178 | digit, business, platform, model, business model, innovate, disrupt, technological, study, transform, strategy, develop, value, research, energy, market, incumbent, digital platform, organic, company, process, service, industrial, case, enable, product, transit, manage, publish, firm | side platform, platform company, luxury, platform strategy, multisided, multisided platform, publish process, market entry, multi side, platform, digital platform, disrupt, digital disruption, disruption innovation, agricultural, side, access economy, acquisition, agribusiness, cba, commercial property, consumer robot, dsi, embed system, entrepreneurial ecosystem, farm, firm growth, flip |

| 4 | 0.13 | energy, model, business, house, business model, digit, transit, develop, technological, policy, provide, system, afford, innovate, governance, market, affordable house, profit, sector, service, study, economy, sustain, datum, industrial, build, operate, base, energy transition, work | affordable house, procure, tax, urban energy, solar, energy model, house developer, profit house, tenant, blue, blue ocean, house industry, ocean, house, afford, parental labour, profit provider, sbm, energy, energy system, fund, energy transition, australia, governance, australian government, build environment, civil, economic analysis, economy profile, energy performance |

| 5 | 0.142 | business, model, datum, digit, business model, value, manage, innovate, economy, process, share, operate, firm, creation, role, transit, value creation, market, study, technological, paper, develop, approach, design, drive, industrial, organic, company, base, hybrid | incubation, vessel, pathologist, reference model, refer, application orient, datum science, diy, diy lab, epc, turnaround, vessel design, hybrid, share economy, omni, omni channel, tourism, antagonistic, antagonistic asset, net neutrality, resource orchestration, sap, sap reference, talent, datum drive, datum, datum analytics, schedule, distribution system, healthcare |

| 6 | 0.234 | business, digit, model, business model, innovate, transform, digital transformation, technological, incumbent, company, value, industrial, model innovation, digital technological, research, study, service, digital business, firm, energy, digital innovation, datum, manage, understand, case, disrupt, change, develop, strategic, base | model transform, urban datum, discontinuous innovation, digital opportunity, effectual, innovation adoption, digital business, complementary asset, energy company, hesitant fuzzy, print house, digital innovation, digital transformation, iot, path dependence, innovation digital, model innovation, csps, dffs, fuzzy, transform digital, path, digital technological, incumbent, impact digital, transform, professional service, establish company, model digital, business model |

| 7 | 0.074 | digit, model, innovate, develop, business, business model, system, technological, manage, capability, city, risk, process, datum, inform, economy, entrepreneurship, ecosystem, economic, communicate, dynamic, study, industrial, company, market, project, smart, transit, leadership, dynamic capability | digital leadership, privacy economics, heuristic, develop dynamic, digital entrepreneurship, leadership, entrepreneurship, dynamic capability, datum protection, guardian, innovation capability, parent guardian, personal datum, risk analysis, socialist, innovation system, smart city, risk, city, protect, creative, innovation ecosystem, universal, cognition, art, entrepreneurial, capability, communicate, market orient, expect |

References

- Frank, A.G.; Mendes, G.H.S.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Sahoo, S.; Lo, C.-Y. Smart manufacturing powered by recent technological advancements: A review. J. Manuf. Syst. 2022, 64, 236–250. [Google Scholar] [CrossRef]

- Jodlbauer, H.; Brunner, M.; Bachmann, N.; Tripathi, S.; Thürer, M. Supply Chain Management: A Structured Narrative Review of Current Challenges and Recommendations for Action. Logistics 2023, 7, 70. [Google Scholar] [CrossRef]

- Dragos, T.; Buzatu, A.I.; Baba, C.-A.; Georgescu, B. Business Model Innovation Through the Use of Digital Technologies: Managing Risks and Creating Sustainability. Amfiteatru Econ. 2020, 22, 758–774. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Lee, J.; Suh, T.; Roy, D.; Baucus, M. Emerging Technology and Business Model Innovation: The Case of Artificial Intelligence. J. Open Innov. Technol. Mark. Complex. 2019, 5, 44. [Google Scholar] [CrossRef]

- Zaki, M. Digital transformation: Harnessing digital technologies for the next generation of services. J. Serv. Mark. 2019, 33, 429–435. [Google Scholar] [CrossRef]

- Weking, J.; Stöcker, M.; Kowalkiewicz, M.; Böhm, M.; Krcmar, H. Leveraging industry 4.0-A business model pattern framework. Int. J. Prod. Econ. 2020, 225, 107588. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, S.; Chen, Y.; Lyulyov, O.; Pimonenko, T. Digitalization Effect on Business Performance: Role of Business Model Innovation. Sustainability 2023, 15, 9020. [Google Scholar] [CrossRef]

- Del Vecchio, P.; Di Minin, A.; Petruzzelli, A.M.; Panniello, U.; Pirri, S. Big data for open innovation in SMEs and large corporations: Trends, opportunities, and challenges. Creat. Innov. Manag. 2018, 27, 6–22. [Google Scholar] [CrossRef]

- Lange, H.E.; Höft, M.; Drews, P. “Ideation is Fine, but Execution is Key”: How Incumbent Companies Realize Data-Driven Business Models. In Proceedings of the 2021 IEEE 23rd Conference on Business Informatics (CBI), Bolzano, Italy, 1–3 September 2021; pp. 191–200. [Google Scholar]

- Massa, L.; Tucci, C.L. Business model innovation. In The Oxford Handbook of Innovation Management; Dodgson, M., Gann, D.M., Phillips, N., Eds.; Oxford University Press: Oxford, UK, 2013; pp. 420–441. [Google Scholar]

- Foss, N.J.; Saebi, T. Fifteen Years of Research on Business Model Innovation. J. Manag. 2017, 43, 200–227. [Google Scholar] [CrossRef]

- Laudien, S.M.; Daxböck, B. Path dependence as a barrier to business model change in manufacturing firms: Insights from a multiple-case study. J. Bus. Econ. 2016, 86, 611–645. [Google Scholar] [CrossRef]

- Ivanov, M.; Bernroider, E. Digital Innovation Management and Path Dependence: An Integrated Perspective of Manufacturing Incumbents. In Proceedings of the 56th Hawaii International Conference on System Sciences, Maui, HI, USA, 3–6 January 2023; pp. 4274–4283. [Google Scholar]

- Haftor, D.M.; Climent Costa, R. Five dimensions of business model innovation: A multi-case exploration of industrial incumbent firm’s business model transformations. J. Bus. Res. 2023, 154, 113352. [Google Scholar] [CrossRef]

- Loshin, D. Business Intelligence: The Savvy Manager’s Guide, 2nd ed.; Elsevier Science: Waltham, MA, USA, 2012. [Google Scholar]