Loss Research and Thermal Analysis of BLDC Hollow-Cup Motor Under Reactor Suppression

Abstract

1. Introduction

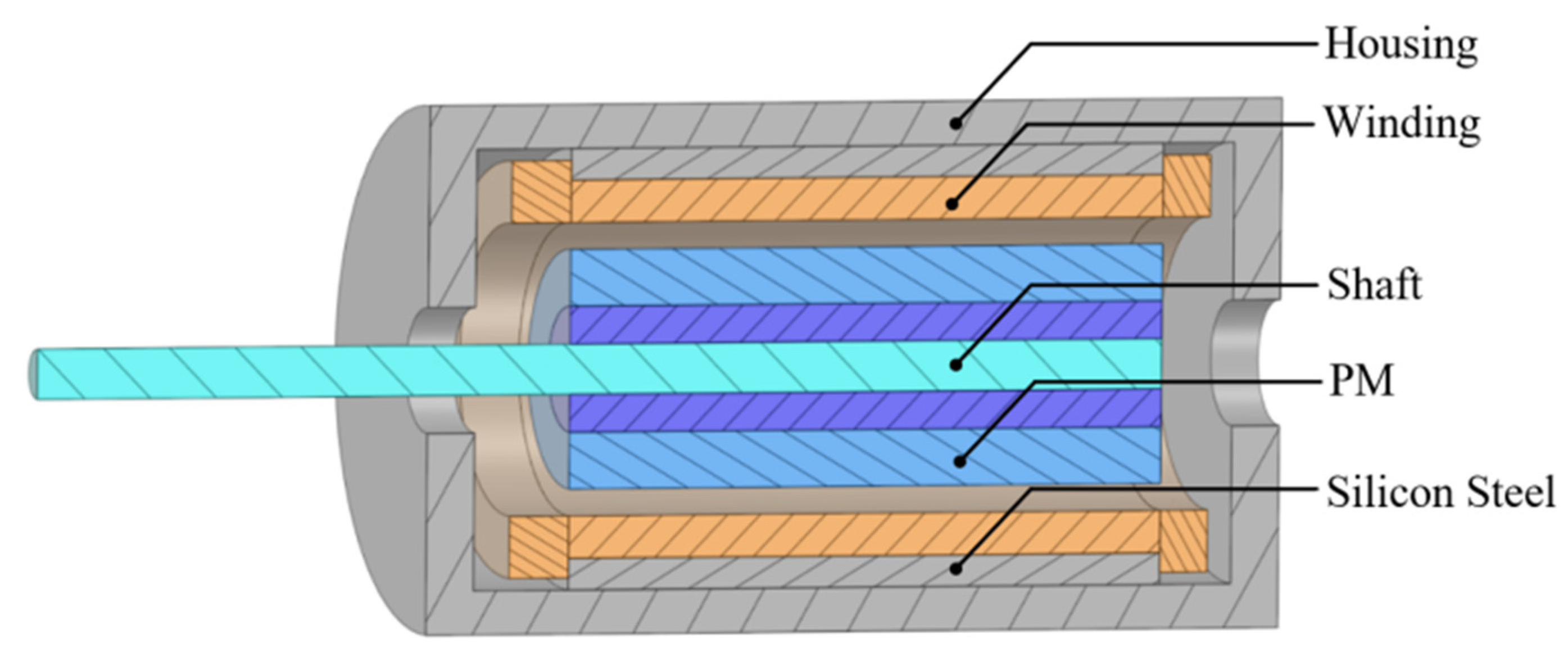

2. BLDC Hollow-Cup Motor Structure

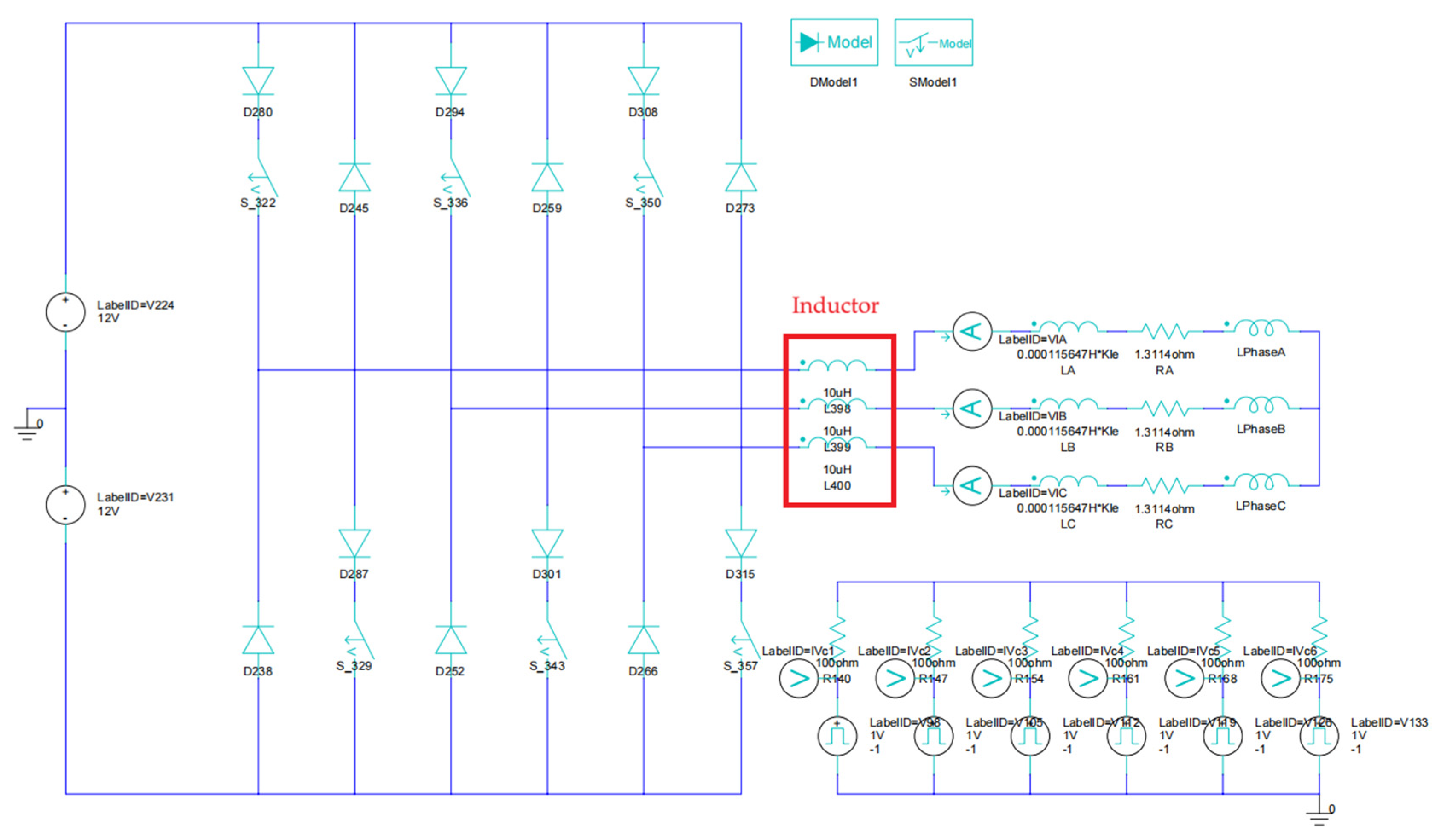

3. Improvement Design Study

3.1. Theoretical Foundation

3.2. Optimization Method

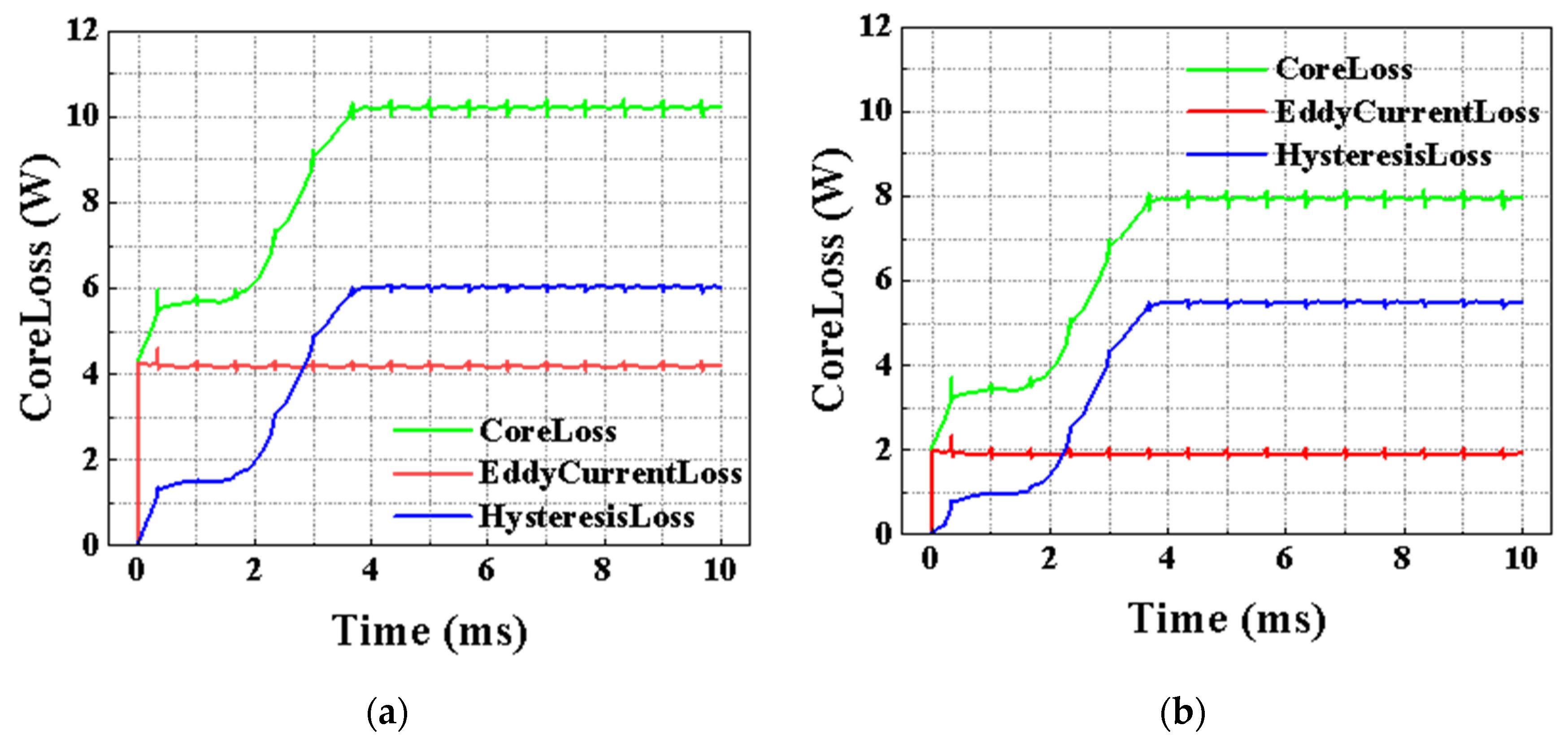

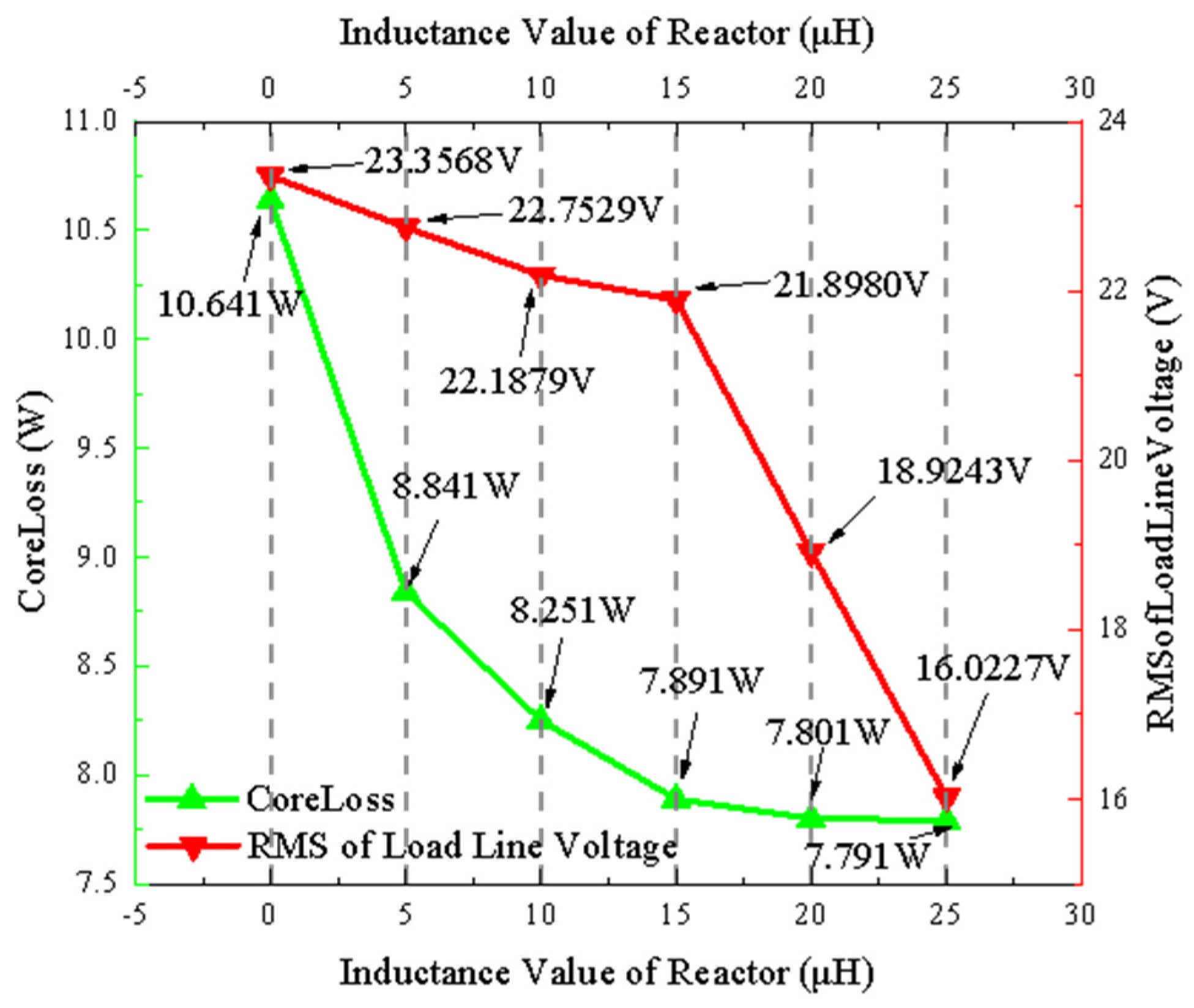

3.3. Core Loss Analysis Considering Inductance Value

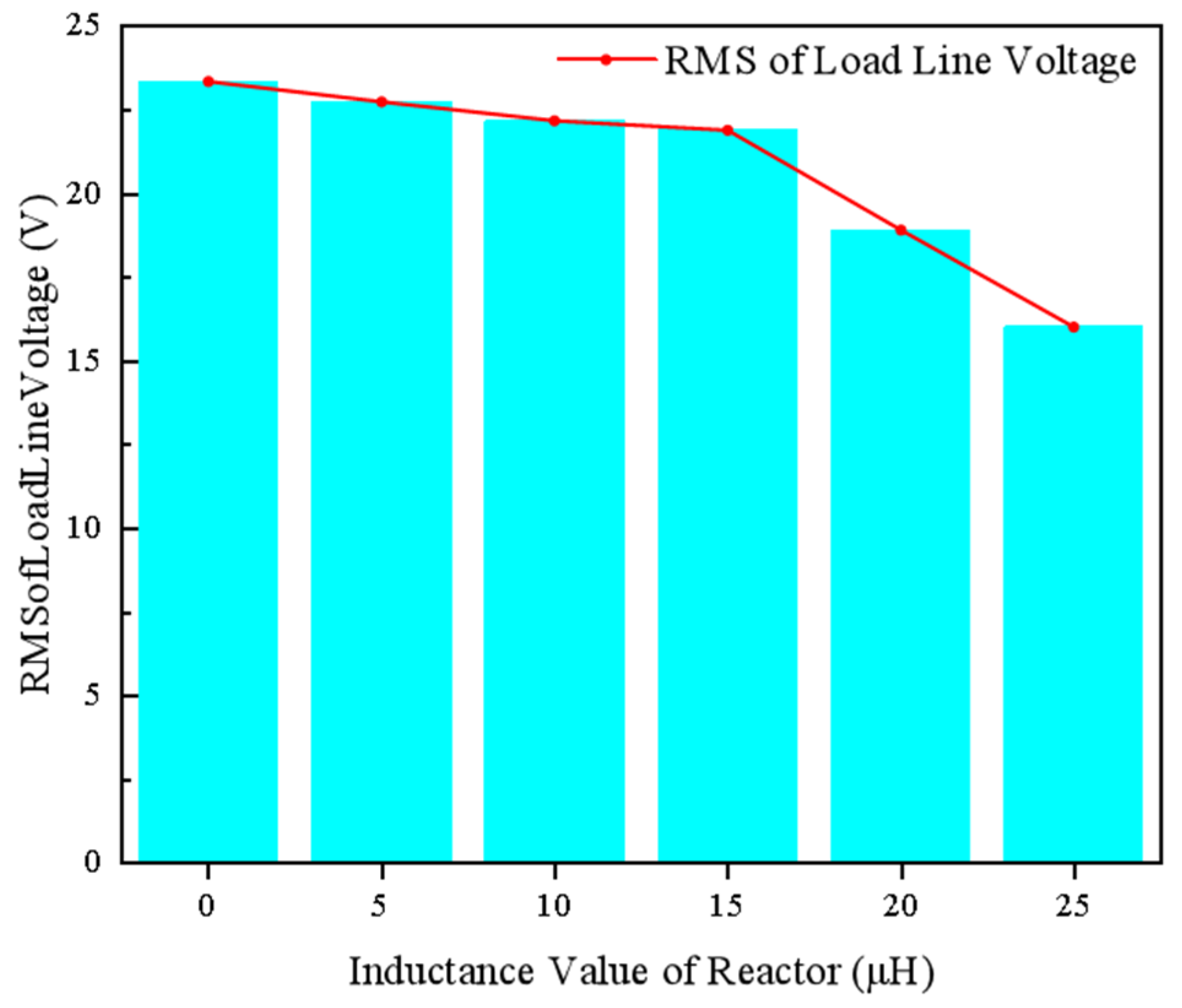

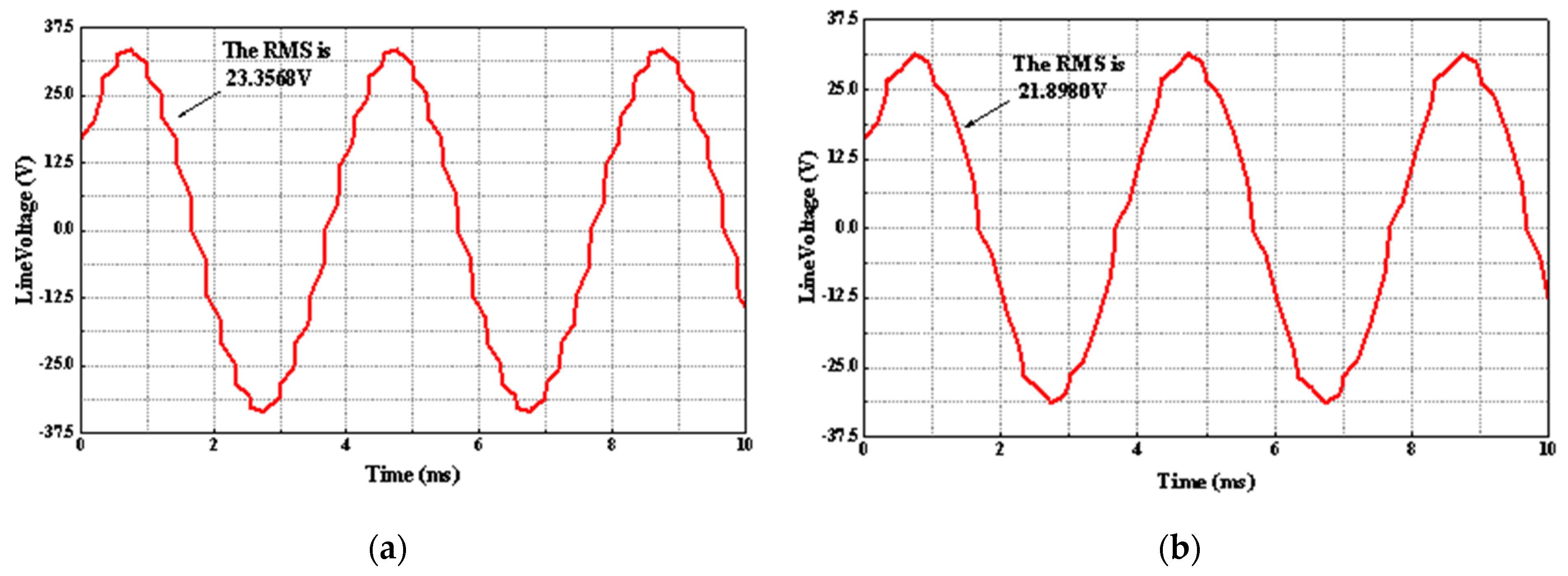

3.4. RMS of Load Line Voltage Analysis Considering Inductance Value

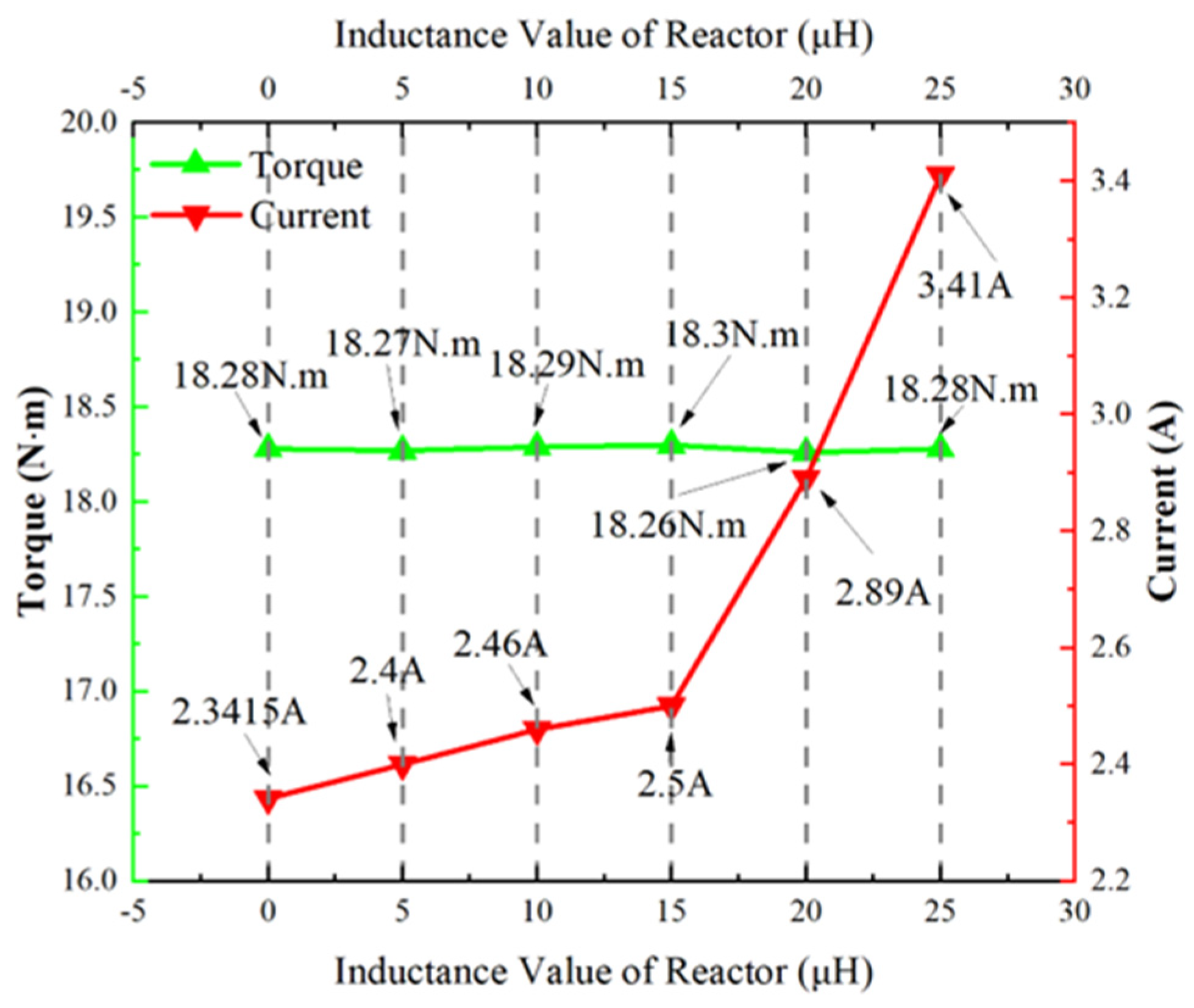

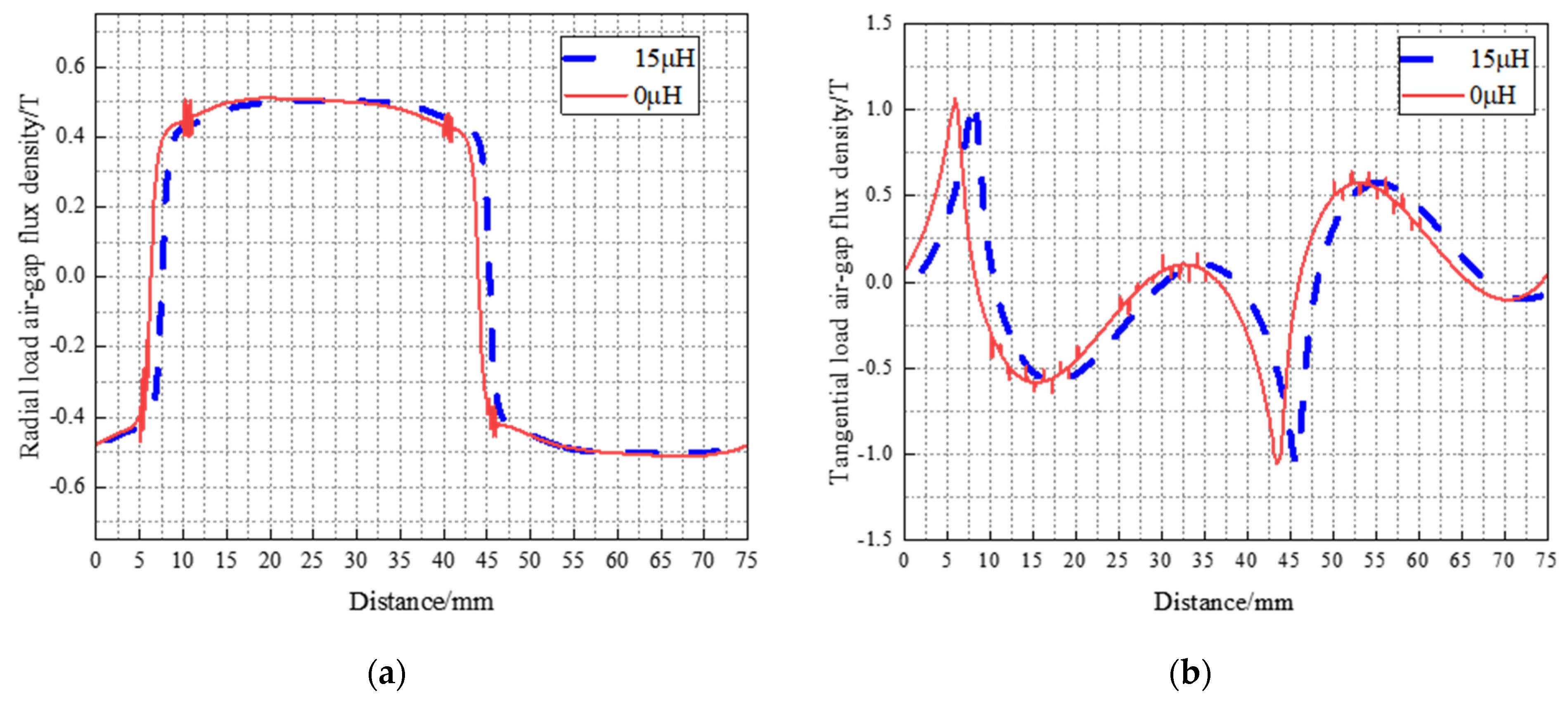

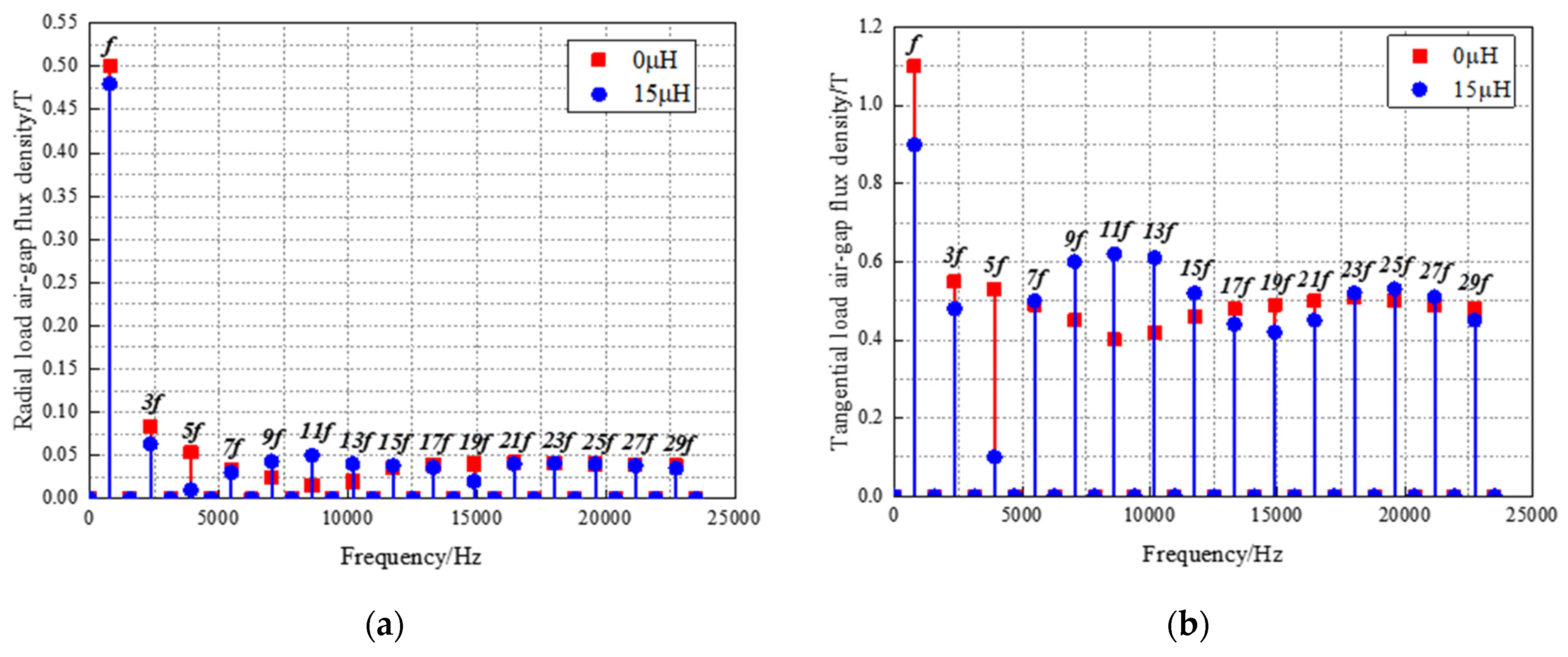

3.5. Air-Gap Density Distribution and Current Time-Harmonics Analysis

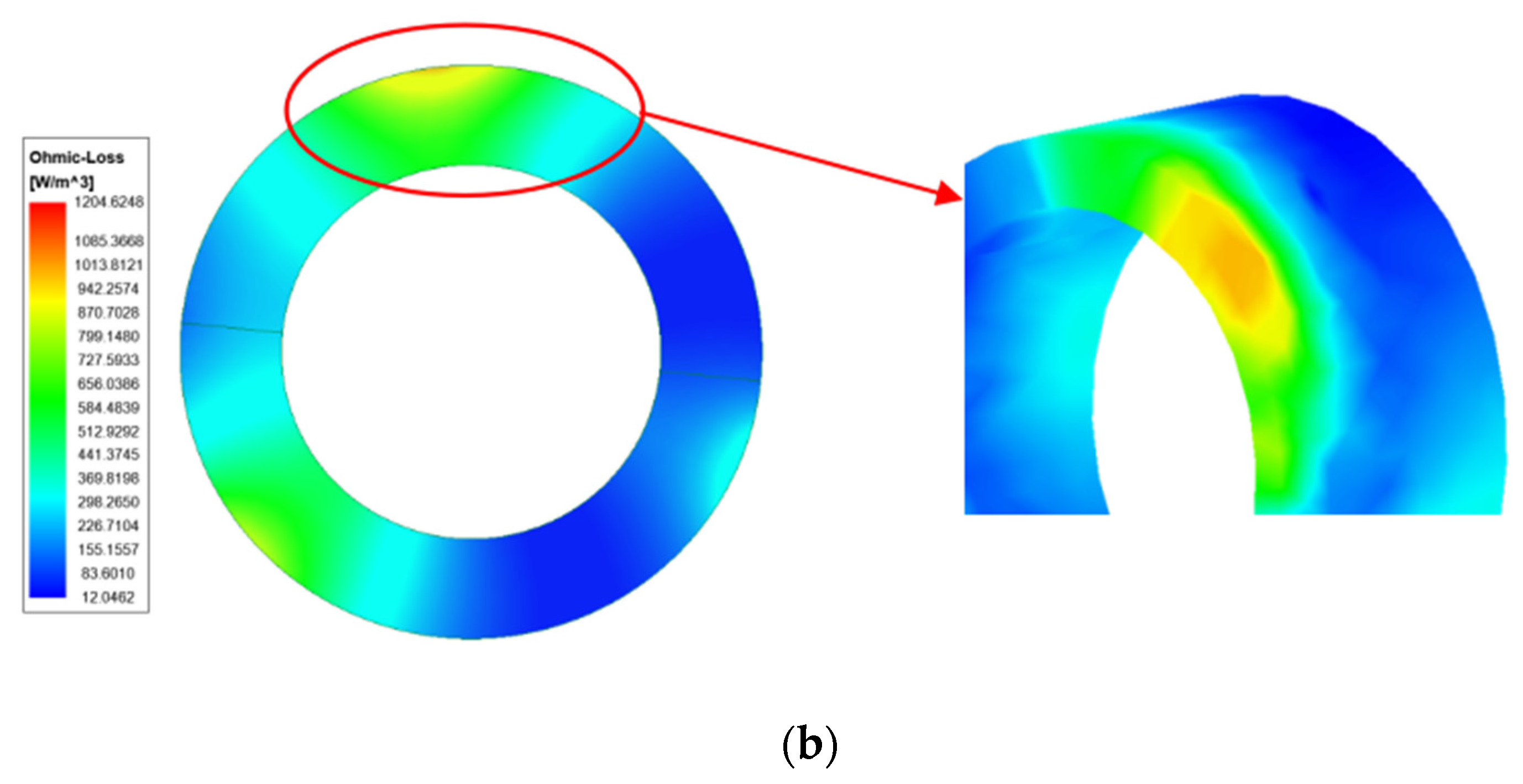

3.6. Rotor Eddy Current Loss Analysis

4. Electromagnetic–Temperature Field Coupling Analysis

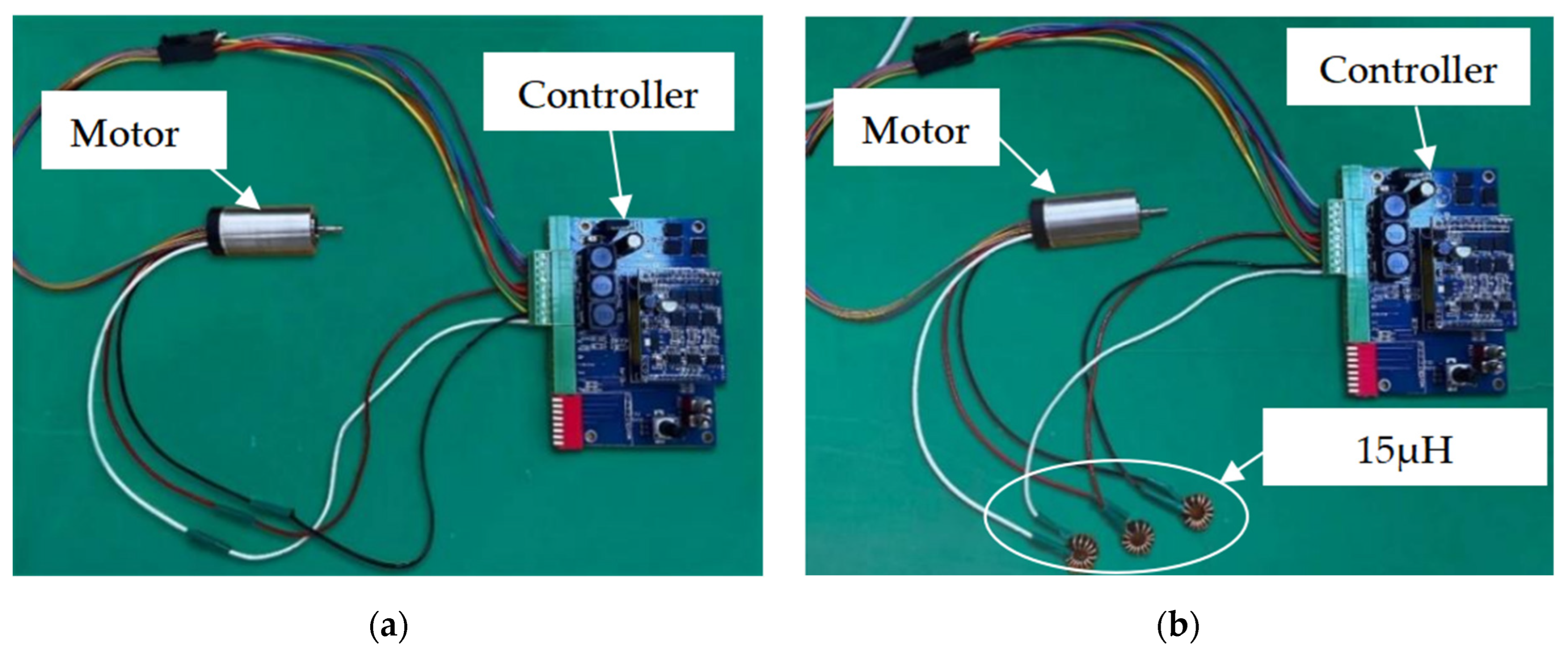

- (1)

- The reactor is not connected in series between the motor and the controller.

- (2)

- The reactor includes the inductance of 15 μH in series between the motor and the controller.

4.1. Setup Heat Source

4.2. Thermal Conductivity and Convection Heat Dissipation Factor

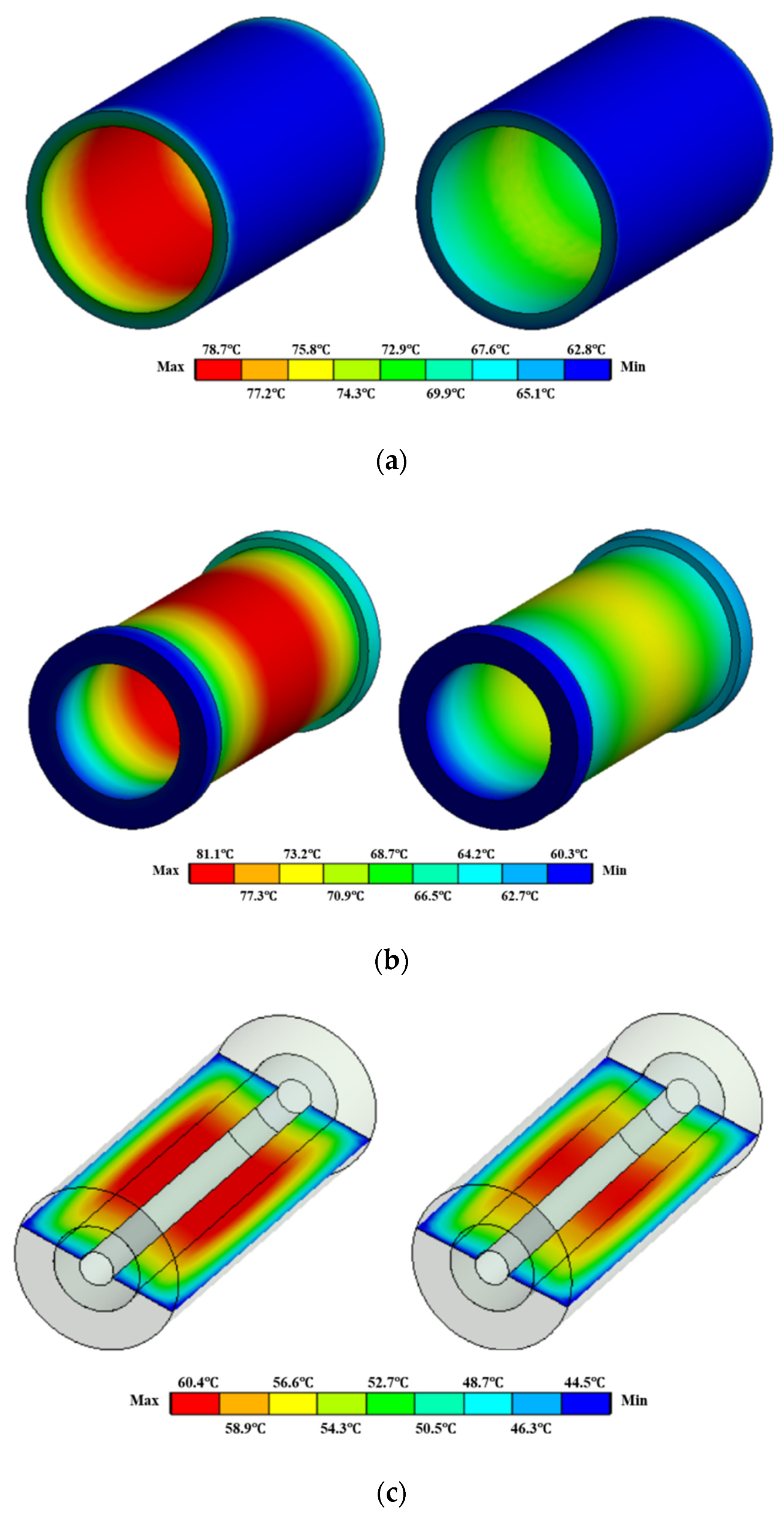

4.3. Temperature Field Simulation Results

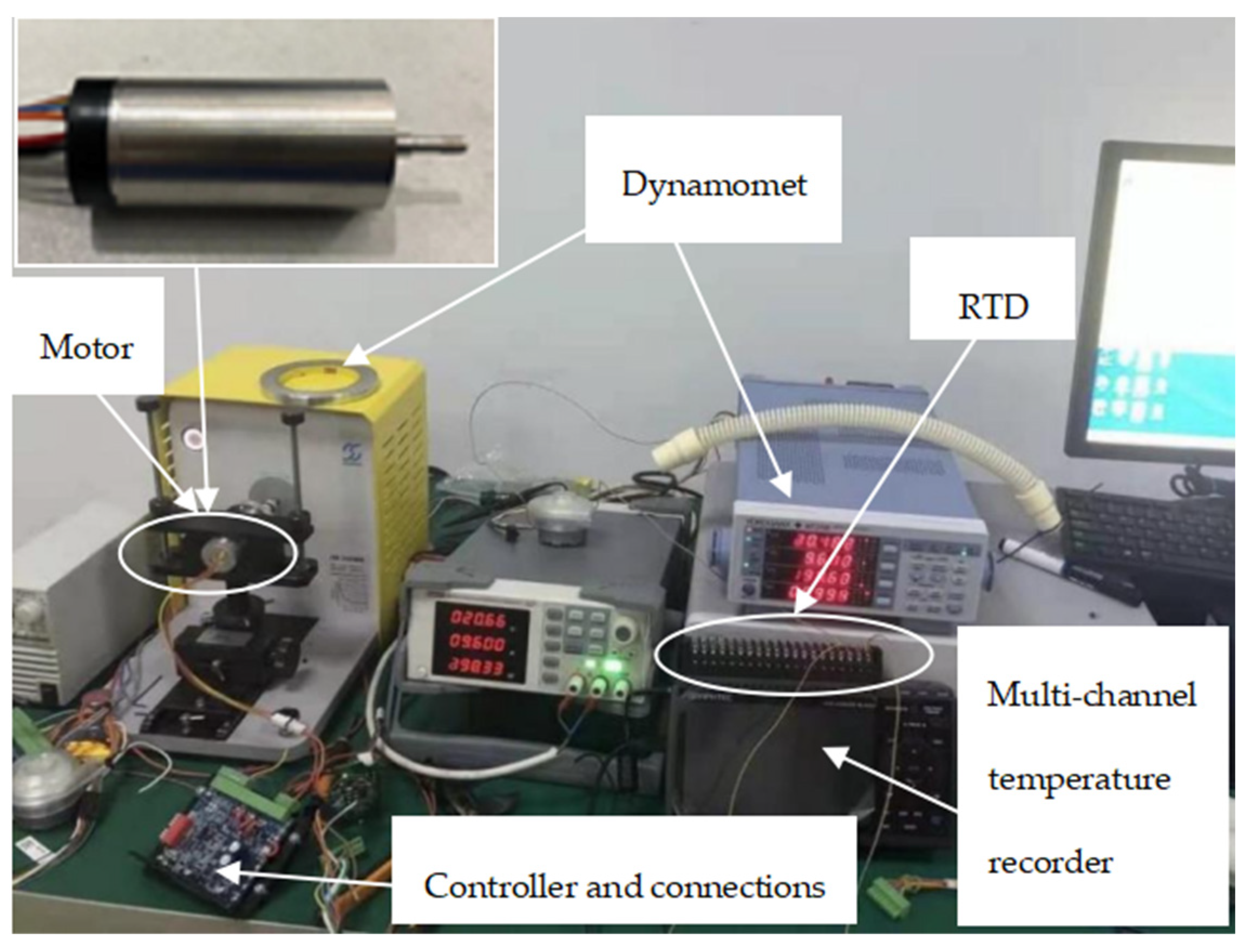

5. Experiments and Comparative Analysis

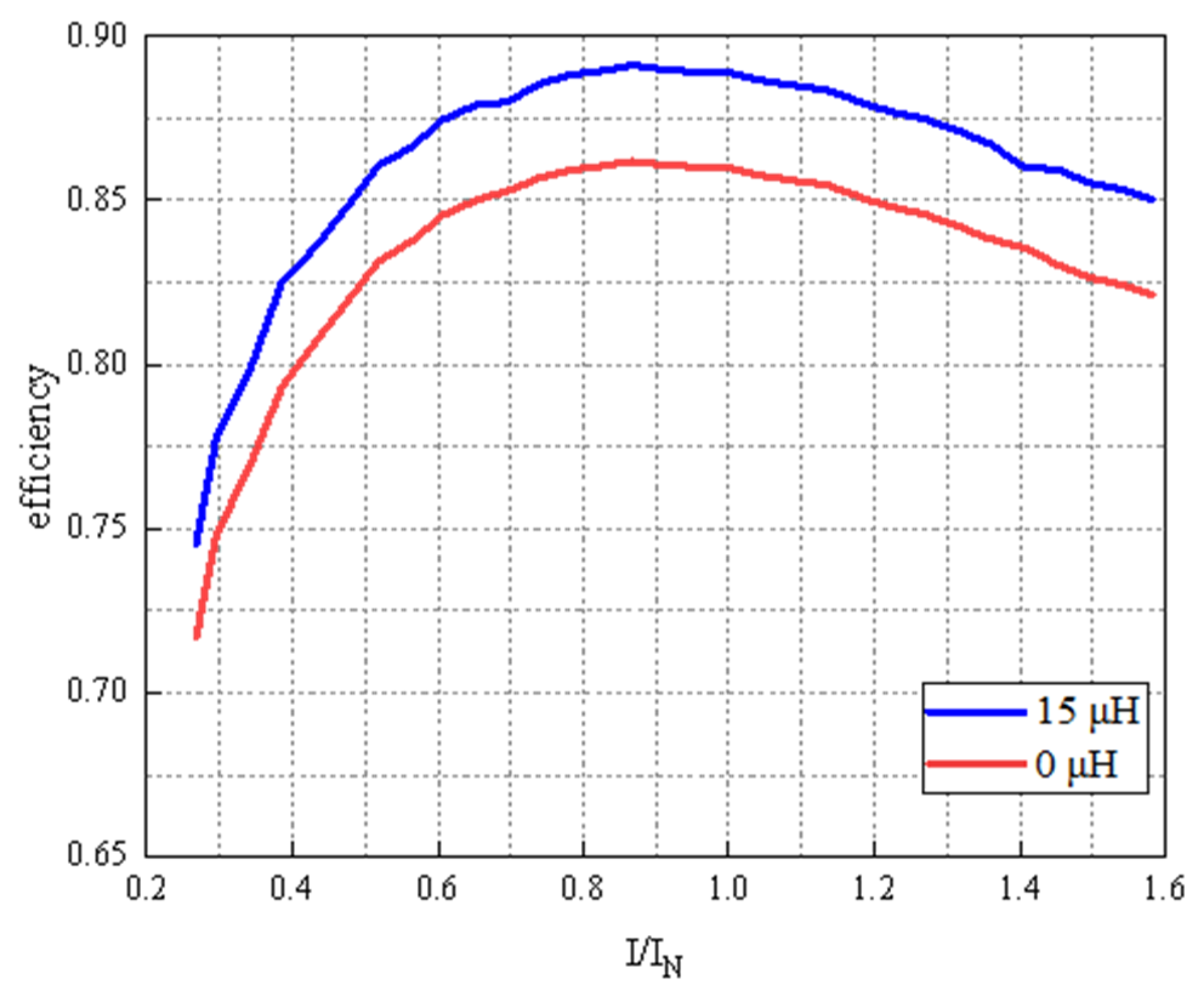

5.1. Efficiency Test Experiment

5.2. Temperature Rise Experiment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| I1/In | DC Current I1/A | DC Voltage U1/V | Input P1/W | Speed n/r/min | Torque T/N·m | Output P2/W | Effi. ƞ/% |

|---|---|---|---|---|---|---|---|

| 0.30 | 1.8 | 23.673 | 30.89 | 50,489 | 0.004012 | 21.69 | 74.69 |

| 0.39 | 1.59 | 23.567 | 40.12 | 49,833 | 0.006389 | 29.89 | 79.66 |

| 0.52 | 2.18 | 23.712 | 53.41 | 49,003 | 0.007689 | 43.57 | 83.14 |

| 0.61 | 2.549 | 23.489 | 62.33 | 48,713 | 0.010059 | 51.84 | 84.67 |

| 0.70 | 3.106 | 23.901 | 71.89 | 48,398 | 0.013008 | 59.19 | 85.13 |

| 0.85 | 3.698 | 23.478 | 89.71 | 47,280 | 0.014999 | 76.67 | 86.33 |

| 0.91 | 3.745 | 23.633 | 93.67 | 47,113 | 0.015976 | 79.46 | 85.79 |

| 1.00 | 4.283 | 23.678 | 103.45 | 46,398 | 0.018630 | 88.15 | 85.67 |

| 1.09 | 4.396 | 23.789 | 111.03 | 46,289 | 0.021113 | 94.37 | 85.43 |

| 1.22 | 5.199 | 23.569 | 124.84 | 45,031 | 0.021986 | 105.89 | 84.8 |

| 1.31 | 5.713 | 23.496 | 132.78 | 44,811 | 0.024663 | 111.46 | 83.09 |

| 1.41 | 5.998 | 23.465 | 143.59 | 44,702 | 0.026789 | 119.03 | 82.99 |

| 1.50 | 6.66 | 23.39 | 151.72 | 43,695 | 0.027133 | 124.82 | 82.17 |

| 1.58 | 6.91 | 23.296 | 160.13 | 43,338 | 0.029386 | 131.74 | 81.99 |

| I1/In | DC Current I1/A | DC Voltage U1/V | Input P1/W | Speed n/r/min | Torque T/N·m | Output P2/W | Effi. ƞ/% |

|---|---|---|---|---|---|---|---|

| 0.30 | 1.27 | 22.866 | 30.30 | 50,407 | 0.004463 | 23.56 | 77.75 |

| 0.39 | 1.66 | 22.823 | 39.48 | 49,907 | 0.006232 | 32.57 | 82.50 |

| 0.52 | 2.23 | 22.759 | 52.99 | 49,161 | 0.008859 | 45.61 | 86.07 |

| 0.61 | 2.61 | 22.717 | 61.88 | 48,696 | 0.010614 | 54.13 | 87.47 |

| 0.70 | 3.00 | 22.673 | 70.93 | 48,228 | 0.012359 | 62.42 | 88.00 |

| 0.85 | 3.735 | 22.59 | 88.09 | 47,300 | 0.015849 | 78.51 | 89.12 |

| 0.91 | 3.93 | 22.568 | 92.55 | 47,088 | 0.016701 | 82.35 | 88.98 |

| 1.00 | 4.30 | 22.527 | 101.12 | 46,594 | 0.018424 | 89.89 | 88.90 |

| 1.09 | 4.68 | 22.483 | 109.96 | 46,124 | 0.02015 | 97.33 | 88.51 |

| 1.22 | 5.26 | 22.418 | 123.14 | 45,381 | 0.022727 | 108.01 | 87.71 |

| 1.31 | 5.64 | 22.375 | 131.83 | 44,924 | 0.024424 | 114.90 | 87.16 |

| 1.41 | 6.06 | 22.327 | 141.33 | 44,419 | 0.026124 | 121.52 | 85.98 |

| 1.50 | 6.43 | 22.284 | 149.70 | 43,959 | 0.027821 | 128.07 | 85.55 |

| 1.58 | 6.80 | 22.240 | 158.06 | 43,504 | 0.029504 | 134.41 | 85.04 |

References

- Mousavi aghdam, S.R. Design and analysis of a novel topology for slotless brushless DC (BLDC) motors with en-hanced torque and efficiency. IET Electr. Power Appl. 2021, 15, 284–298. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, T.; Zhao, H.; Wu, T. An Analytical Iron Loss Calculation Model of Inverter-Fed Induction Motors Considering Supply and Slot Harmonics. IEEE Trans. Ind. Electron. 2019, 66, 9194–9204. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, R.; Wei, Y.; Yu, D.; Xie, S.; Fang, S. Optimization and Experimental Validation of Amorphous Alloy High-Speed Asynchronous Motor for Simultaneous Reduction on Core and Copper Losses. IEEE Access 2023, 11, 101112–101122. [Google Scholar] [CrossRef]

- Yoshida, R.; Tanaka, M.; Masuda, R.; Horiuchi, M.; Takazawa, K.; Sato, M.; Mizuno, T.; Nirei, M. Reduction of Iron Loss in Ultrahigh-Speed Interior Winding Synchronous Motor Using Magnetic Composite Material. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021. [Google Scholar]

- Hu, Y.; Zhu, S.; Xu, L.; Jiang, B. Reduction of Torque Ripple and Rotor Eddy Current Losses by Closed Slots Design in a High-Speed PMSM for EHA Applications. IEEE Trans. Magn. 2021, 58, 8102206. [Google Scholar] [CrossRef]

- Ishikawa, T.; Takahashi, K.; Ho, Q.V.; Matsunami, M.; Kurita, N. Analysis of Novel Brushless DC Motors Made of Soft Magnetic Composite Core. IEEE Trans. Magn. 2012, 48, 971–974. [Google Scholar] [CrossRef]

- Soda, N.; Hayashi, N.; Enokizono, M. Analytical Study on Core Loss Reduction of Segmented Stator Core Motor in Con-sideration of Rolling Direction of Nonoriented Electrical Steel Sheet. IEEE Trans. Ind. Appl. 2021, 57, 4745–4753. [Google Scholar] [CrossRef]

- Yamazaki, K.; Utsunomiya, K.; Tanaka, A.; Nakada, T. Rotor Surface Optimization of Interior Permanent Magnet Synchronous Motors to Reduce Both Rotor Core Loss and Torque Ripples. IEEE Trans. Ind. Appl. 2022, 58, 4488–4497. [Google Scholar] [CrossRef]

- Ma, J.; Zhu, Z.Q. Magnet Eddy Current Loss Reduction in Permanent Magnet Machines. IEEE Trans. Ind. Appl. 2019, 55, 1309–1320. [Google Scholar] [CrossRef]

- Zhang, Z.; Deng, Z.; Gu, C.; Sun, Q.; Peng, C.; Pang, G. Reduction of Rotor Harmonic Eddy-Current Loss of High-Speed PM BLDC Motors by Using a Split-Phase Winding Method. IEEE Trans. Energy Convers. 2019, 34, 1593–1602. [Google Scholar] [CrossRef]

- Liang, Y.; Zhao, F.; Xu, K.; Wang, W.; Liu, J.; Yang, P. Analysis of Copper Loss of Permanent Magnet Synchronous Motor With Formed Transposition Winding. IEEE Access 2021, 9, 101105–101114. [Google Scholar] [CrossRef]

- Niu, L.; Zhang, M. The Loss and Efficiency Analysis and Research of Interior Permanent Magnet Synchronous Motors for Traction Applications. IEEE Access 2023, 11, 5538–5557. [Google Scholar] [CrossRef]

- Bhattacharya, K.; Santra, S.B.; Chatterjee, D.; Padmanaban, S. Torque Ripple and Loss Minimization of Trapezoidal Brushless DC Motor Drive by Harmonics Current Excitation Switching Technique. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Smart Grid and Renewable Energy (PESGRE), Cochin, India, 2–4 January 2020; pp. 1–6. [Google Scholar]

- Minh, D.B.; Quoc, V.D.; Huy, P.N. Efficiency Improvement of Permanent Magnet BLDC Motors for Electric Vehicles. Engi-Neering. Technol. Appl. Sci. Res. 2021, 11, 7615–7618. [Google Scholar] [CrossRef]

- Im, S.H.; Gu, B.G. Interturn fault tolerant drive method by limiting copper loss of interior permanent magnet synchronous motor. IEEE Trans. Ind. Electron. 2019, 67, 7973–7981. [Google Scholar] [CrossRef]

- Vafaie, M.H.; Mirzaeian Dehkordi, B. Minimising power losses and torque ripples of permanent-magnet synchronous motor by parallel execution of a two-stage predictive control system. IET Power Electron. 2020, 13, 3590–3600. [Google Scholar] [CrossRef]

- Karnavar, P.H.; Jisha, V. Harmonic Reduction and Power Factor Improvement of BLDC Motor Drive System Using a Selective Harmonic Elimination PWM Based Controller. In Proceedings of the 2020 International Conference on Power, Instrumentation, Control and Computing (PICC), Thrissur, India, 17–19 December 2020; pp. 1–5. [Google Scholar]

- Khazaee, A.; Zarchi, H.A.; Markadeh, G.A. Loss model based efficiency optimized control of brushless DC motor drive. ISA Trans. 2018, 86, 238–248. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Chai, F.; Pei, Y.; Doppelbauer, M. Investigation of PM Loss in Spoke-Type Permanent Magnet Vernier Motors With Different Stator Topologies for In-Wheel Direct Drive. IEEE Trans. Ind. Appl. 2022, 58, 4562–4574. [Google Scholar] [CrossRef]

- Liu, K.; Chen, J.; Wang, Y.; Qiu, S.; Lin, J.; Zhang, C. Temperature Analysis of the Surface-mounted Permanent Magnet Synchronous Motor. In Proceedings of the 2023 IEEE 18th Conference on Industrial Electronics and Applications (ICIEA), Ningbo, China, 18–22 August 2023; pp. 315–319. [Google Scholar]

- Li, Z.; Wang, P.; Liu, L.; Xu, Q.; Che, S.; Zhang, L.; Du, S.; Zhang, H.; Sun, H. Loss calculation and thermal analysis of ultra-high speed permanent magnet motor. Heliyon 2022, 8, e11350. [Google Scholar] [CrossRef] [PubMed]

- Ou, J.; Liu, Y.; Liang, D.; Doppelbauer, M. Investigation of PM Eddy Current Losses in Surface-Mounted PM Motors Caused by PWM. IEEE Trans. Power Electron. 2019, 34, 11253–11263. [Google Scholar] [CrossRef]

| Motor Parameters | Numerical Value |

|---|---|

| Rated power | 90 W |

| Rated voltage (DCV) | 24 V |

| Rated speed | 47,000 r/min |

| Rated efficiency | 85% |

| Frequency | 783 Hz |

| Number of poles | 2 |

| Air-gap length | 0.5 mm |

| Stator inner diameter | 20 mm |

| Stator outer diameter | 27 mm |

| Stator length | 50 mm |

| PM length | 50 mm |

| Inductance of Reactor/μH | Core Loss /W | Winding Loss /W | Rotor Eddy Current Loss/W |

|---|---|---|---|

| 0 (without reactor) | 10.64 | 8.64 | 1.49 |

| 15 | 8.03 | 4.99 | 0.98 |

| Component (Material) | Density /(kg/m3) | Constant-Pressure Specific Heat Capacity/(j/(kg.k)) | Thermal Conductivity /(W/(m.k)) |

|---|---|---|---|

| Stator (Silicon Steel) | 7650 | 502 | 40 |

| Winding (Copper) | 8987 | 381 | 387.6 |

| Winding (Copper) | 8400 | 504 | 12 |

| Component | Convection Heat Dissipation Factor/(W/(m2·°C)) |

|---|---|

| Stator end face | 44.1 |

| Rotor end face | 121.2 |

| Rotor surface and stator inner circle | 126.2 |

| Component (Material) | Tmax/°C (Reactor Inductance = 0) | Tmax/°C (Reactor Inductance = 15 µH) | Temperature Difference/°C |

|---|---|---|---|

| Stator (Silicon Steel) | 78.7 | 72.9 | −5.8 |

| Winding (Copper) | 81.1 | 73.2 | −7.9 |

| Rotor | 60.4 | 54.3 | −6.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Sun, Y.; Zhao, J.; Liu, B.; Mi, Y. Loss Research and Thermal Analysis of BLDC Hollow-Cup Motor Under Reactor Suppression. Appl. Sci. 2025, 15, 1523. https://doi.org/10.3390/app15031523

Du J, Sun Y, Zhao J, Liu B, Mi Y. Loss Research and Thermal Analysis of BLDC Hollow-Cup Motor Under Reactor Suppression. Applied Sciences. 2025; 15(3):1523. https://doi.org/10.3390/app15031523

Chicago/Turabian StyleDu, Jingjuan, Yumeng Sun, Jian Zhao, Boran Liu, and Yanqing Mi. 2025. "Loss Research and Thermal Analysis of BLDC Hollow-Cup Motor Under Reactor Suppression" Applied Sciences 15, no. 3: 1523. https://doi.org/10.3390/app15031523

APA StyleDu, J., Sun, Y., Zhao, J., Liu, B., & Mi, Y. (2025). Loss Research and Thermal Analysis of BLDC Hollow-Cup Motor Under Reactor Suppression. Applied Sciences, 15(3), 1523. https://doi.org/10.3390/app15031523