Water Consumption, Quantity and Quality of Wastewater and Sewage Sludge from Polish Dairies

Abstract

1. Introduction

2. Materials and Methods

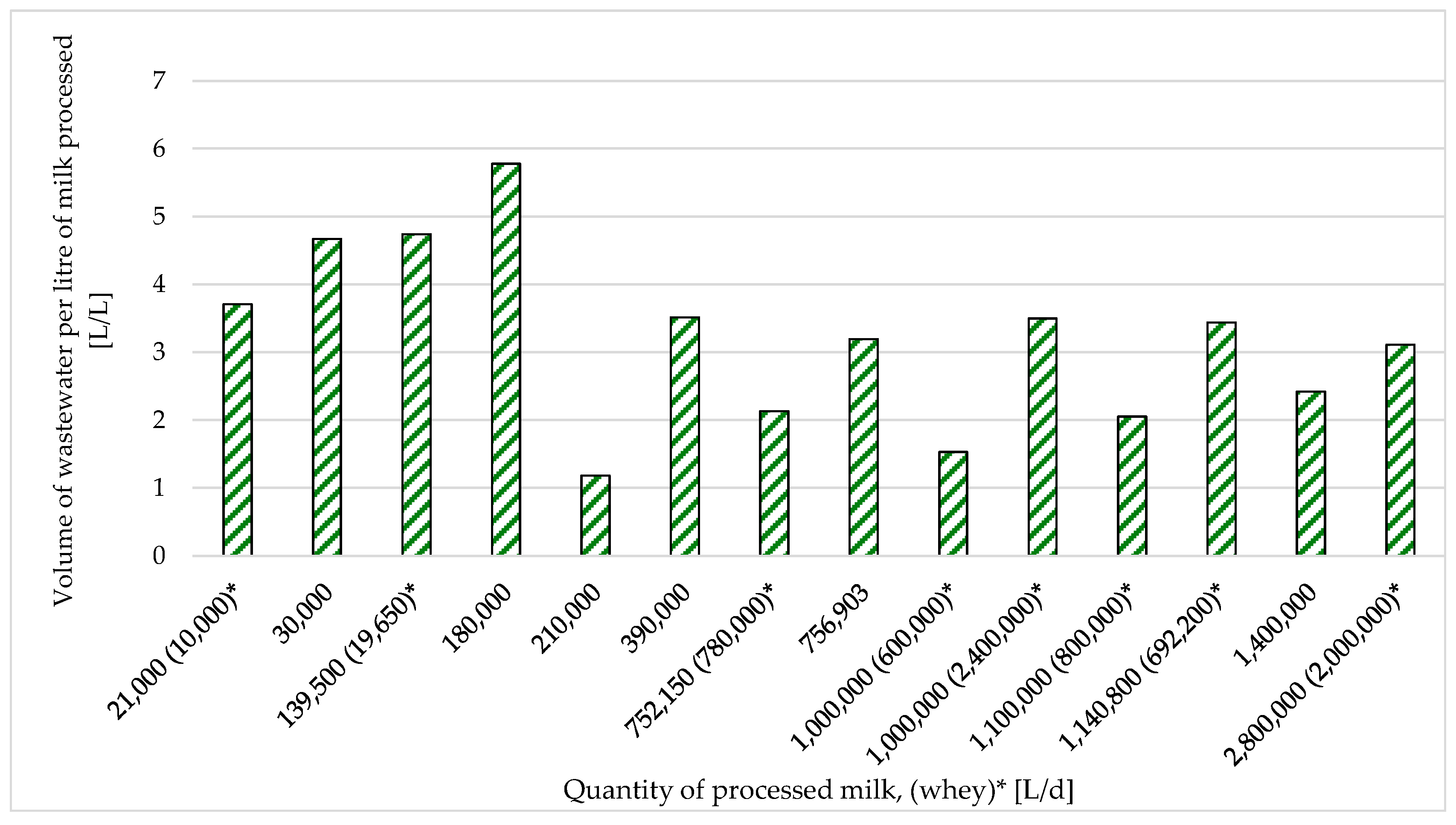

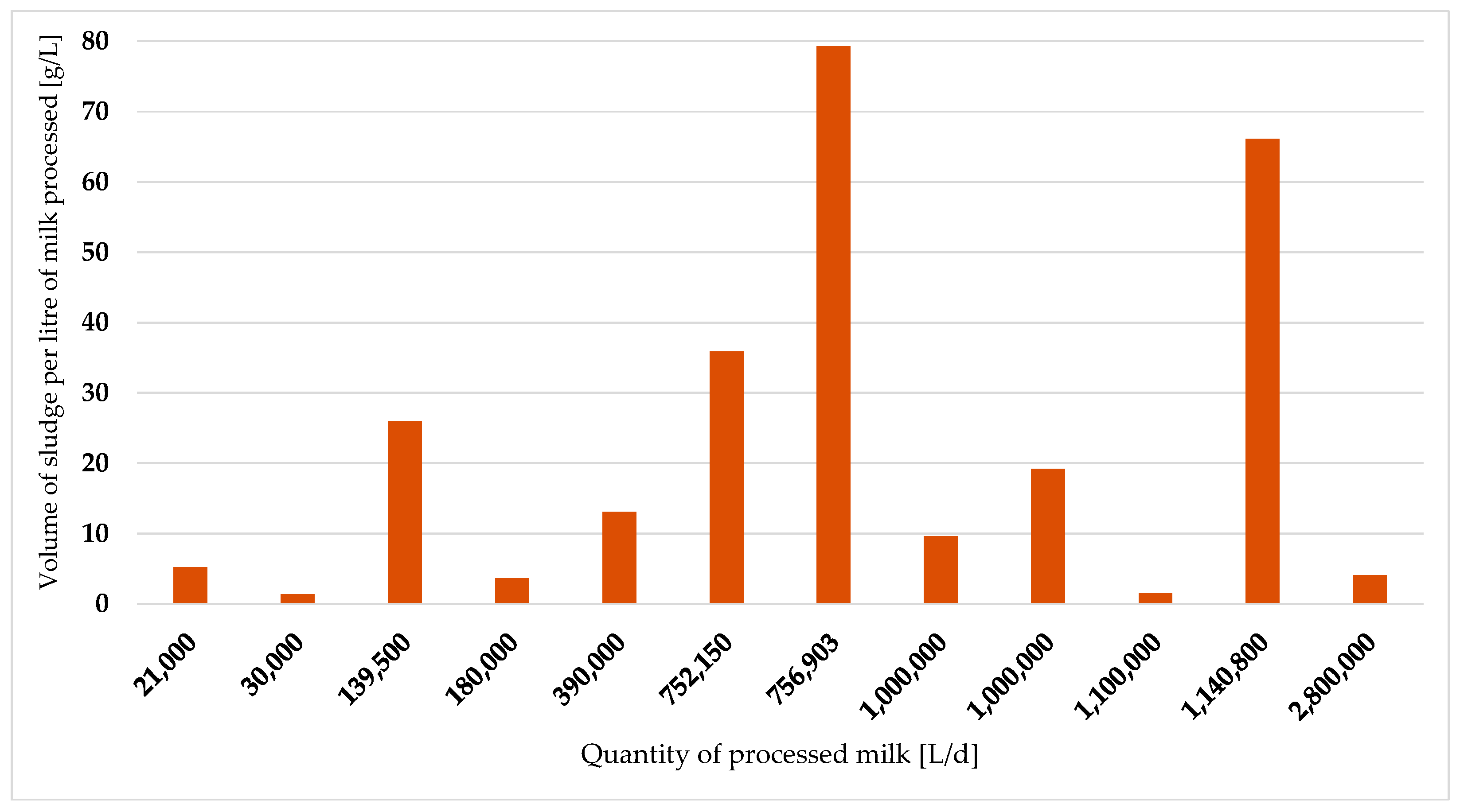

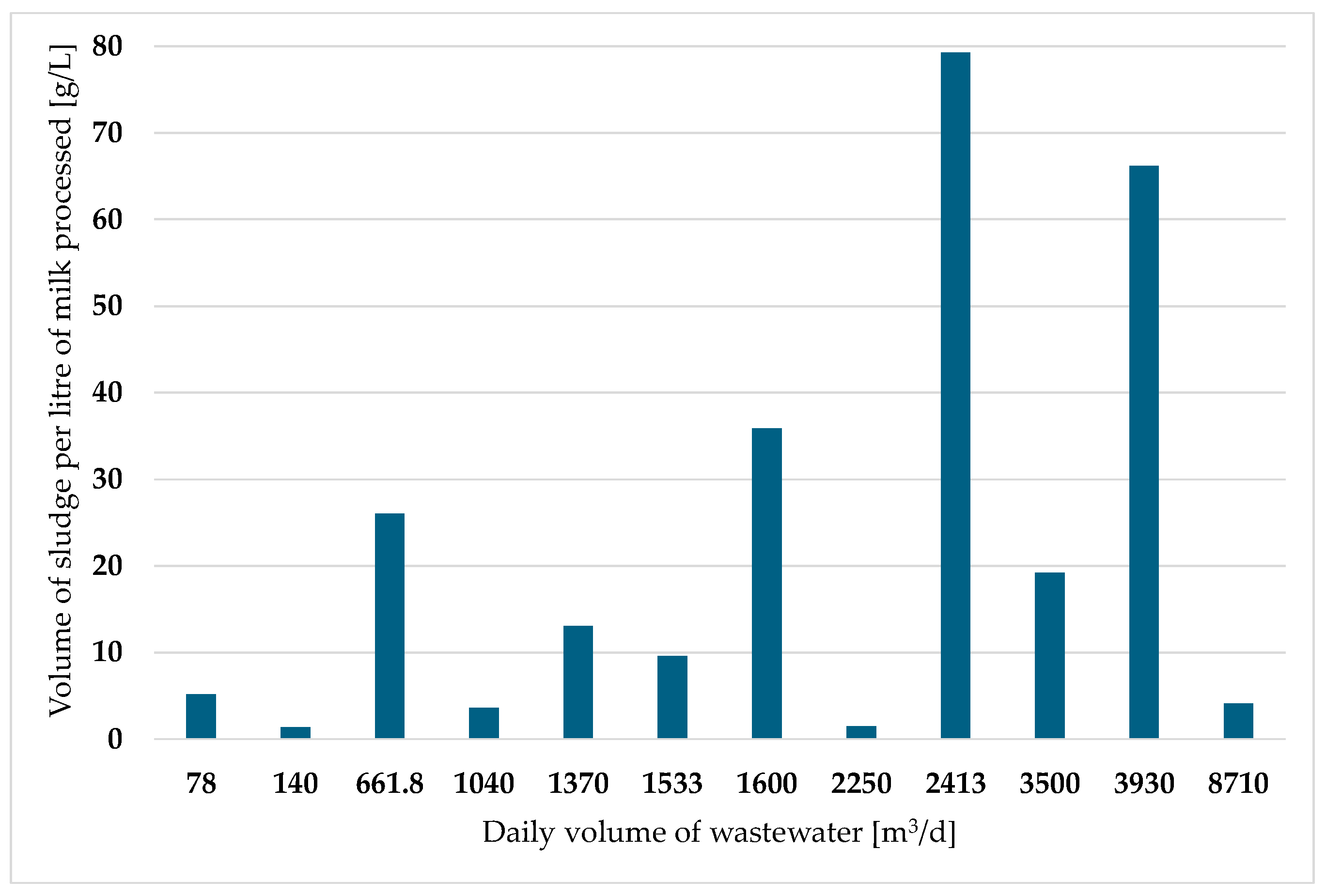

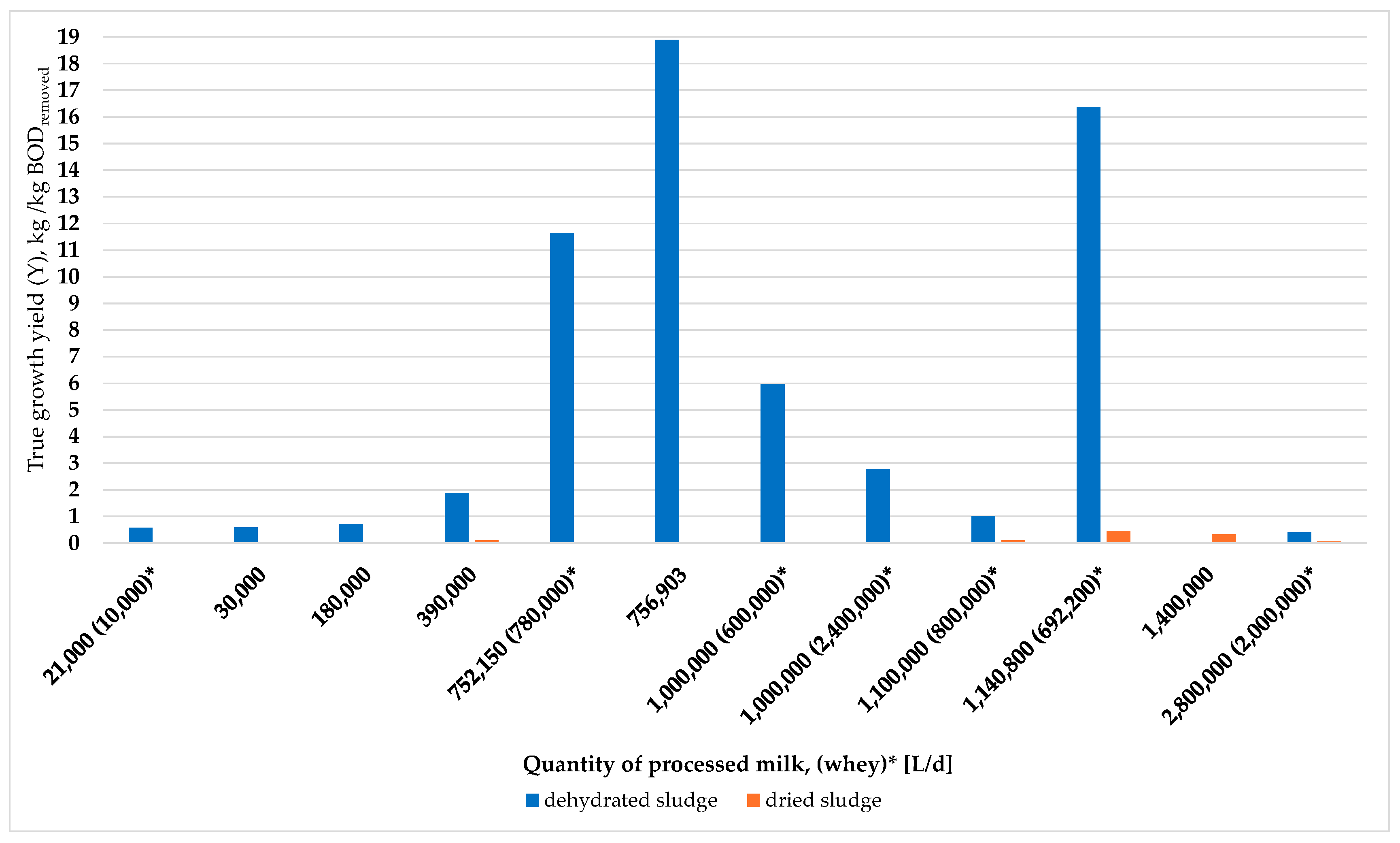

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eurostat. Milk and Milk Product Statistics. 2024. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Milk_and_milk_product_statistics (accessed on 2 October 2024).

- Stasinakis, A.S.; Charalambous, P.; Vyrides, I. Dairy wastewater management in EU: Produced amounts, existing legislation, applied treatment processes and future challenges. J. Environ. Manag. 2022, 303, 114152. [Google Scholar] [CrossRef]

- Eurostat. Milk and Milk Product Statistics. 2021. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Milk_and_milk_product_statistics#Milk_production (accessed on 2 October 2024).

- EDA. Product Environmental Footprint Category Rules for Dairy Products. The European Dairy Association. 2018. Available online: https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR-DairyProducts_2018-04-25_V1.pdf (accessed on 22 October 2024).

- JRC. Best Available Techniques (BAT) Reference Document for the Food, Drink and Milk Industries. Industrial Emissions Directive 2010/75/EU Integrated Pollution Prevention and Control. 2019. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC118627 (accessed on 15 October 2024).

- Danalewich, J.R.; Papagiannis, T.G.; Belyea, R.L.; Tumbleson, M.E.; Raskin, L. Characterization of dairy waste streams, current treatment practices, and potential for biological nutrient removal. Water Res. 1998, 32, 3555–3568. [Google Scholar] [CrossRef]

- Boguniewicz-Zablocka, J.; Klosok-Bazan, I.; Naddeo, V. Water quality and resource management in the dairy industry. Environ. Sci. Pollut. Res. 2019, 26, 1208–1216. [Google Scholar] [CrossRef]

- Bella, K.; Venkateswara Rao, P. Anaerobic digestion of dairy wastewater: Effect of different parameters and co-digestion options—A review. Biomass Convers. Bioref. 2023, 13, 2527–2552. [Google Scholar] [CrossRef]

- Available online: https://www.portalspozywczy.pl/mleko/wiadomosci/ile-gatunkow-sera-produkuje-sie-w-polsce-ten-segment-rosnie-w-sile,255276.html (accessed on 10 December 2024).

- Janczukowicz, W.; Zieliński, M.; Dębowski, M. Biodegradability evaluation effluents originated in selected sections of dairy production. Bioresour. Technol. 2008, 99, 4199–4205. [Google Scholar] [CrossRef] [PubMed]

- Janczukowicz, W. Phosphorus removal from process dairy wastewater in a sequencing biological reactor in the presence of selected volatile fatty acids (VFA) application. In Dissertations and Monographs; Publishing House of the University of Warmia and Mazury: Olsztyn, Poland, 2005. (In Polish) [Google Scholar]

- Ashekuzzaman, S.M.; Forrestal, P.; Richards, K.; Fenton, O. Dairy industry derived wastewater treatment sludge: Generation, type and characterization of nutrients and metals for agricultural reuse. J. Clean. Prod. 2019, 230, 1266–1275. [Google Scholar] [CrossRef]

- Rodziewicz, J.; Janczukowicz, W.; Jóźwiakowski, K.; Mielcarek, A. A review on generation, composition, and valorization of dairy processing sludge: A circular economy-based sustainable approach. Dairy Rev. 2024, 11, 2–9. (In Polish) [Google Scholar]

- Ashekuzzaman, S.M.; Kwapinska, M.; Leahy, J.J.; Richards, K.; Fenton, O. Novel use of dairy processing sludge derived pyrogenic char (DPS-PC) to remove phosphorus in discharge effluents. Waste Biomass Valoriz. 2020, 11, 1453–1465. [Google Scholar] [CrossRef]

- Ciećko, Z.; Wyszkowski, M.; Rolka, E. Chemical characteristics of sewage sludge from dairy treatment plants. Probl. Noteb. Adv. Agric. Sci. 2001, 477, 313–318. (In Polish) [Google Scholar]

- Lopez-Mosquera, M.E.; Cascallana, V.; Seoane, S. Comparison of the effects of dairy sludge and a mineral NPK fertilizer on an acid soil. Investig. Agrar. Prod. Prot. Veg. 2002, 17, 87–99. [Google Scholar]

- Filipek, T.; Fidecki, M.; Harasim, P. The influence of sewage sludge from dairy on yielding and some quality indices on grain of winter wheat. Ann. UMCS Sect. E 2004, 59, 1925–1931. (In Polish) [Google Scholar]

- Ashekuzzaman, S.M.; Fenton, O.; Meers, E.; Forrestal, P.J. Differing phosphorus crop availability of aluminium and calcium precipitated dairy processing sludge potential recycled alternatives to mineral phosphorus fertilizer. Agronomy 2021, 11, 427. [Google Scholar] [CrossRef]

- Ministry of Climate and Environment (Warsaw, Poland). Data (Database of Products and Packaging and Waste Management) from the Ministry of Climate and Environment Received in the Response on the Letter. 16 February 2024. [Google Scholar]

- Statistical Yearbook of the Republic of Poland 2024; Statistics Poland: Warsaw, Poland, 2024.

- PN-EN ISO 5815-1:2019-12; Water Quality—Determination of Biochemical Oxygen Demand After n Days (BODn)—Part 1: Dilution Method with Seeded Inoculum and Allylthiourea. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN ISO 15705:2005; Water Quality—Determination of the Chemical Oxygen Demand Index (ST-COD)—Small-Scale Sealed-Tube Method. Polish Committee for Standardization: Warsaw, Poland, 2005.

- PN-EN 872:2007+Ap1:2007; Water Quality—Determination of Suspended Solids—Method by Filtration Through Glass Fibre Filters. Polish Committee for Standardization: Warsaw, Poland, 2007.

- PN-EN 12260: 2004 (A),(W),(NR); Water Quality—Determination of Total Nitrogen—Method by Oxidation with Peroxodisulfate. Polish Committee for Standardization: Warsaw, Poland, 2004.

- PN-EN ISO 11885:2009; Water Quality—Determination of Selected Elements by Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES). Polish Committee for Standardization: Warsaw, Poland, 2009.

- PN-EN ISO 10523:2012 (A); Water Quality—Determination of pH. Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN 15934:2013-02; Sludge, Treated Biowaste, Soil and Waste—Determination of Dry Matter Content by Drying at 105 °C. Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-EN 15935:2022-01; Soil, Waste, Treated Bio-Waste and Sewage Sludge—Determination of Losses on Ignition. Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-75/C-04576/15(W); Determination of Ammonium Nitrogen in Sewage Sludge—Distillation Method. Polish Committee for Standardization: Warsaw, Poland, 1975.

- PN-EN 13342:2002; Characterization of Sewage Sludge—Determination of Kjeldahl Nitrogen. Polish Committee for Standardization: Warsaw, Poland, 2002.

- PN-EN 16173:2012; Sludge, Treated Biowaste and Soil—Digestion of Nitric Acid Soluble Fractions. Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN 15933:2013-02; Sludge, Treated Biowaste and Soil—Determination of pH. Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-Z-19000-4:2001; Soil Quality—Assessment of Soil Sanitary Condition—Detection of Eggs of Intestinal Parasites Ascaris Lumbricoides and Trichuris Trichiura. Polish Committee for Standardization: Warsaw, Poland, 2001.

- PN-EN ISO 6579-1:2017-04/A1:2020-09; Microbiology of the Food Chain—Horizontal Method for the Detection, Enumeration and Serotyping of Salmonella—Part 1: Detection of Salmonella spp. Polish Committee for Standardization: Warsaw, Poland, 2020.

- Kim, W.-J.; Park, H.W.; Heldman, D.R. Clean-In-Place (CIP) wastewater management using nanofiltration (NF)-forward osmosis (FO)-direct contact membrane distillation (DCMD): Effects of draw salt Food Research International. Food Res. Int. 2024, 178, 113939. [Google Scholar] [CrossRef] [PubMed]

- Prasad, P.; Pagan, R.; Kauter, M.; Price, N. Eco-Efficiency for the Dairy Processing Industry. UNEP Working Group for Cleaner Production in the Food Industry, Victoria, Australia. 2004. Available online: https://espace.library.uq.edu.au/data/UQ_40900/Eco-efficiency_manual_201_Pagan.pdf?Expires=1738412586&Key-Pair-Id=APKAJKNBJ4MJBJNC6NLQ&Signature=cpDzKlQIdBNXAz08uJagO3kTLdDN8lIoN7t6o8Y1K9KkE-PvCZhbLRg1dg78bixFWu04jhsEmo~iV3xiShttUEuUkCRp8d-ViMgCt0AG-NDD7yeUGTjv4hG79pCfP08WBl2Tf5sbAZmq8jQbEsTpS761-~ET~sfyUVLkV9W9rgg1omvsNnx7amkPX3d2zE5N8pcpa6Dv0giT8QwETUBJSTf4GJJ4HEAch1ZVK7dKyJr3ul8hbfSfRmEImiRzSb0OxTUnUkAPfsa2Gq8hQzC6eeq3QAfvnobU92eTVjNCI3ZhPpNnk0DwaVaC16j0aifnyPPgE3lzekeE4qwubGyzaA__ (accessed on 2 December 2024).

- Prazeres, A.R.; Carvalho, F.; Rivas, J. Cheese whey management: A review. J. Environ. Manag. 2012, 110, 48–68. [Google Scholar] [CrossRef]

- Carvalho, F.; Prazeres, A.R.; Rivas, J. Cheese whey wastewater: Characterization and treatment. Sci. Total Environ. 2013, 445–446, 385–396. [Google Scholar] [CrossRef]

- Giner-Santonja, G.; Karlis, P. Developing EU environmental standards for the food, drink and milk industries: Key environmental issues and data collection. Environ. Sci. Eur. 2020, 32, 152. [Google Scholar] [CrossRef]

- Harper, W.J.; Blaisdell, J.L.; Grosshopf, J. Dairy Food Plant Wastes and Waste Treatment Practices; U.S. Environmental Protection Agency: Washington, DC, USA, 1971.

- Nazos, T.T.; Stratigakis, N.C.; Spantidaki, M.; Lagouvardou-Spantidaki, A.; Ghanotakis, D.F. Characterization of Cheese whey Effluents and Investigation of Their Potential to be used as a Nutrient Substrate for Chlorella Biomass Production. Waste Biomass Valoriz. 2023, 14, 3643–3655. [Google Scholar] [CrossRef]

- Zkeri, E.; Iliopoulou, A.; Katsara, A.; Korda, A.; Aloupi, M.; Gatidou, G.; Fountoulakis, M.S.; Stasinakis, A.S. Comparing the use of a two-stage MBBR system with a methanogenic MBBR coupled with a microalgae reactor for medium-strength dairy wastewater treatment. Bioresour. Technol. 2021, 323, 124629. [Google Scholar] [CrossRef] [PubMed]

- Ji, S.; Ma, W.; Wei, Q.; Zhang, W.; Jiang, F.; Chen, J. Integrated ABR and UASB system for dairy wastewater treatment: Engineering design and practice. Sci. Total Environ. 2020, 749, 142267. [Google Scholar] [CrossRef]

- Al-Tayawi, A.N.; Sisay, E.J.; Beszédes, S.; Kertész, S. Wastewater Treatment in the Dairy Industry from Classical Treatment to Promising Technologies: An Overview. Processes 2023, 11, 2133. [Google Scholar] [CrossRef]

- Finnegan, W.; Clifford, E.; Goggins, J.; O’Leary, N.; Dobson, A.; Rowan, N.; Xiao, L.; Miao, S.; Fitzhenry, K.; Leonard, P.; et al. Dairy Water: Striving for sustainability within the dairy processing industry in the Republic of Ireland. J. Dairy Res. 2018, 85, 366–374. [Google Scholar] [CrossRef] [PubMed]

- Arunadevi, P.S.; Saravanaraja, M. Two phase upflow anaerobic sludge blanket (UASB) reactor on the reduction of chemical oxygen demand in dairy effluent. Asian J. Adv. Agric. Res. 2020, 3, 15–23. [Google Scholar]

- Ribeiro, T.S.; Aguiar, A. Performance evaluation of a wastewater treatment plant from a dairy in the state of Minas Gerais, Brazil: A case study. Environ. Monit. Assess. 2024, 196, 956. [Google Scholar] [CrossRef] [PubMed]

- Janczukowicz, W.; Rodziewicz, J.; Czaplicka, K.; Kłodowska, I.; Mielcarek, A. The effect of volatile fatty acids (VFAs) on nutrient removal in SBR with biomass adapted to dairy wastewater. J. Environ. Sci. Health A 2013, 48, 809–816. [Google Scholar] [CrossRef]

- Skrydstrup, J.; Larsen, S.L.; Rygaard, M. Eco-efficiency of water and wastewater management in food production: A case study from a large dairy in Denmark. J. Ind. Ecol. 2020, 24, 1101–1112. [Google Scholar] [CrossRef]

- Martín-Rilo, S.; Coimbra, R.N.; Martín-Villacorta, J.; Otero, M. Treatment of dairy industry wastewater by oxygen injection: Performance and outlay parameters from the full scale implementation. J. Clean. Prod. 2015, 86, 15–23. [Google Scholar] [CrossRef]

- Available online: https://clearfox.com/dairy-industry-wastewater/ (accessed on 9 October 2024).

- Regulation (EU) 2020/741 of the European Parliament and of the Council on minimum requirements for water reuse. Off. J. Eur. Union 2020, L 177, 32–55.

- Tabelini, D.B.; Lima, J.P.P.; Borges, A.C.; Aguiar, A. A review on the characteristics and methods of dairy industry wastewater treatment in the state of Minas Gerais, Brazil. J. Water Process Eng. 2023, 53, 103779. [Google Scholar] [CrossRef]

- Metcalf & Eddy, Inc. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; McGraw Hill: New York, NY, USA, 2014. [Google Scholar]

- Shi, W.; Healy, M.G.; Ashekuzzaman, S.M.; Daly, K.; Leahy, J.J.; Fenton, O. Dairy processing sludge and co-products: A review of present and future re-use pathways in agriculture. J. Clean. Prod. 2021, 314, 128035. [Google Scholar] [CrossRef]

- Hu, Y.; Khomenko, O.; Shi, W.; Velasco-Sánchez, Á.; Ashekuzzaman, S.M.; Bennegadi-Laurent, N.; Daly, K.; Fenton, O.; Healy, M.G.; Leahy, J.J.; et al. Systematic review of dairy processing sludge and secondary STRUBIAS products used in agriculture. Front. Sustain. Food Syst. 2021, 5, 763020. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Gaffey, J.; Sharma, M.; Dewhurst, R.J.; Moreau, B.; Newbold, J.; Clark, W.; Thakur, V.K.; Gupta, V.K. Valorization of dairy waste and by-products through microbial bioprocesses. Bioresour. Technol. 2022, 346, 126444. [Google Scholar] [CrossRef]

- Mohapatra, J.; Kumar, R.; Basak, B.; Ganesh Saratale, R.; Dattatraya Saratale, G.; Mishra, A.; Tripathy, S.K.; Jeon, B.-H.; Chakrabortty, S. A review on generation, composition, and valorization of dairy processing sludge: A circular economy-based sustainable approach. J. Ind. Eng. Chem. 2024, 143, 45–64. [Google Scholar] [CrossRef]

- CEC; European Commission. Council Directive 86/278/EEC of 12 June 1986 on the Protection of the Environment, and in Particular of the Soil, When Sewage Sludge is Used in Agriculture; CEC: Luxembourg, 1986. [Google Scholar]

- Boruszko, D.; Dąbrowski, W. Research on the Effectiveness of the Flotation Process and Properties of Flotation Sludge from Dairy Wastewater Pretreatment. Eng. Environ. Prot. 2014, 17, 269–280. (In Polish) [Google Scholar]

| Plant Number | Production Profile | Quantity of Processed Milk, (Whey) * [L/d] | Volume of Water Used [m3/d] | Is There a Closed Water Circuit in the Plant? | Does the Facility Have a WWTP? | Does the Treatment Plant Treat Industrial and Domestic Wastewater? |

|---|---|---|---|---|---|---|

| 1 | no data | 2,800,000 (2,000,000) * | 6500 | Yes | Yes | Yes |

| 2 | UHT products, milk powder, cottage cheese, butter, granular cheese, whey concentrate, cheese packaging | 1,400,000 | 3171 | no data | Yes | Yes |

| 3 | milk processing, cottage cheese, cream, yoghurt, | 1,140,800 (692,200) * | 2750 | no data | Yes | No |

| 4 | no data | 1,100,000 (800,000) * | 1650 | No | Yes | Yes |

| 5 | matured cheese, mozzarella cheese, cheese packaging, processed cheese, whey powder (WPC, lactose, permeate) | 1,000,000 (2,400,000)* | 3000 | no data | Yes | Yes |

| 6 | no data | 1,000,000 (600,000) * | 1875 | no data | Yes | Yes |

| 7 | cheeses, butter, whey powder | 930,000 | 1637 | no data | No | No |

| 8 | no data | 756,903 | 2334 | no data | Yes | Yes |

| 9 | matured cheese, cottage cheese, fermented drinks, butter, powder (milk + whey), whey concentrate | 752,150 (780,000) * | 1648 | no data | Yes | Yes |

| 10 | cheese (cheddar, mozzarella and Dutch cheese) | 395,381 (355,000) * | 690 | no data | No | No |

| 11 | dairy products, hard cheese, cottage cheese, whey powder and milk | 390,000 | 1120 | no data | No | No |

| 12 | blue cheese | 252,690 (98,480) * | 504 | no data | No | No |

| 13 | matured cheese | 210,000 | 497 | Yes | No | No |

| 14 | no data | 180,000 | no data | no data | Yes | Yes |

| 15 | cottage cheese, quark, fermented drinks, sweetcream, sour cream, milk powder | 139,500 (19,650) * | 451.1 | no data | Yes | Yes |

| 16 | no data | 30,000 | 60 | no data | Yes | Yes |

| 17 | cottage cheese, cheese, drinking milk (pasteurized), butter, yoghurts, buttermilk, cream | 21,000 (10,000) * | 78 | no data | Yes | Yes |

| 18 | processed cheese, matured cheese | no data | 150 | no data | Yes | Yes |

| Plant Number | Quantity of Processed Milk, (Whey) * [Ll/d] | Daily Volume of Sewage [m3/d] | Wastewater Treatment Technology | Wastewater Treatment and Sludge Processing Equipment | Pollution Indicator [mg/L] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| BOD | COD | Suspended Solids | Ntot | Ptot | pH | Fats | |||||

| 1 | 2,800,000 (2,000,000) * | 8710 | Aerobic | screening grit chamber, equalization tank, emergency tank, dissolved air floatation (DAF), multiphase activated sludge chamber, secondary sedimentation tank, wastewater and sludge pumping stations | 3275 | 5032 | 1109 | 168 | 52.5 | 6.7–9.3 | n.d./n.d. |

| 2 | 1,400,000 | 3393 | Aerobic and anaerobic | screenings, grit trap, dissolved air floatation (DAF), sludge thickener | 1008 | 2002 | 426.6 | 61.0 | 44.9 | 7.2 | n.d. |

| 3 | 1,140,800 (692,200) * | 3930 | Aerobic | horizontal grit chamber, pumping station, equalization tank, oxygen purification block, radial and horizontal sedimentation tank | 1200 | 1932 | 678 | 44.6 | 25.1 | 6.5–9.5 | 250–400 |

| 4 | 1,100,000 (800,000) * | 2250 | Aerobic | pumping station, screenings, degreaser, biological chamber, aeration tank, secondary sedimentation tank | 750 | 1800 | 180 | 52.8 | 13 | 7.2 | 70 |

| 5 | 1,000,000 (2,400,000) * | 3500 | Aerobic and anaerobic | screenings, grit trap, dissolved air floatation (DAF), UASB bioreactor, hydrolyser, two oxygen reactors, secondary sedimentation tank, combined heat and power plant, biogas plant | 2000 | 4200 | 580 | 100 | 25 | 8.3 | 75 |

| 6 | 1,000,000 (600 000) * | 1533 | Aerobic and anaerobic | equalization tank, dissolved air floatation (DAF), activated sludge chambers, secondary sedimentation tank | 1076 | 2311 | 518 | 72 | 15.5 | 7.1 | 102 |

| 7 | 930,000 | no data | not applicable | not applicable | 465 | 1133 | 185 | 44 | 9 | 8 | 22 |

| 8 | 756,903 | 2413 | Aerobic and anaerobic | screenings, grit trap, dissolved air floatation (DAF), MBBR, anoxic chamber, IFAS chamber, secondary sedimentation tank | 1341 | 2426 | 751 | 106 | 28.5 | 8.9 | 56.33 |

| 9 | 752,150 (780,000) * | 1600 | Aerobic | pumping stations, screenings, equalization tank, circulation trenches, MBR reactors, dissolved air floatation (DAF) | 1474 | 2644 | 437 | 113 | 22.2 | 6.6 | 46.7 |

| 10 | 395,381 (355,000)* | no data | not applicable | not applicable | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

| 11 | 390,000 | 1370 | Mechanical treatment | pump station, fine screens, buffer tank, dissolved air floatation (DAF) | 2000 | 3000 | 800 | n.d. | 40 | n.d. | n.d. |

| 12 | 256,200 (98,480) * | no data | not applicable | not applicable | 890 | 1765 | 390 | 16.2 | 50 | 7.25 | 63.5 |

| 13 | 210,000 | 247 | not applicable | not applicable | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

| 14 | 180,000 | 1040 | Aerobic | Kessener brushes, aerators, jet pumps | 900 | 1440 | 424 | 84.6 | 16.45 | n.d. | n.d. |

| 15 | 139,500 (19,650) * | 661.8 | Aerobic | screenings, horizontal grit chamber, aeration chamber, secondary sedimentation tank | n.d. | 2,736 | 765 | 98 | 20.1 | 7.95 | n.d. |

| 16 | 30,000 | 140 | Aerobic | activated sludge chambers | 520 | 850 | 75 | 65 | 14 | 7.7 | n.d. |

| 17 | 21,000 (10,000) * | 78 | Aerobic | activated sludge chambers | 2453 | 3790 | 670 | 152 | 28 | 8 | 71.6 |

| 18 | no data | 90 | Aerobic and anaerobic | gravity grease separator, pumping station, equalization tank, dissolved air floatation (DAF), activated sludge chambers | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

| No. | Production Profile | Quantity of Processed Milk [L/d] | Does the WWTP Treat Production and Domestic Wastewater? | Daily Amount of Sewage [m3/d] | Sewage Sludge Processing Technology | Annual Amount of Sludge [mg/year] | Are the Sludge Used for Agriculture? |

|---|---|---|---|---|---|---|---|

| 1 | Production of cottage cheese, cheese, drinking milk (pasteurized), butter, yoghurt, buttermilk, kefir, cream | 21,000 | YES | 78 | Aerobic | 40 | YES |

| 2 | no data | 30,000 | YES | 140 | Aerobic | 15 | NO |

| 3 | Production of cottage cheese, fermented drinks, creams, milk powder | 139,500 | YES | 661.8 | Aerobic | 1324 | YES |

| 4 | no data | 180,000 | YES | 1040 | Aerobic | 237.6 | YES |

| 5 | Production of dairy products, hard cheese, cottage cheese, whey and milk powder | 390,000 | NO | 1370 | no data | 1860 | YES |

| 6 | Production of matured cheese, cottage cheese, fermented drinks, butter, powders (milk + whey), whey concentrate | 752,150 | YES | 1600 | The thickened excess sludge is channelled to an external biogas plant together with the post-flotation sludge | 9843.58 | no data |

| 7 | no data | 756,903 | YES | 2413 | Aerobic and anaerobic | 21,900 | YES |

| 8 | Production of hard cheese, mozzarella cheese, cheese packaging, production of processed cheese, production of whey powders (WPC, lactose, permeate) | 1,000,000 | YES | 3500 | Aerobic and anaerobic | 7000 | no data |

| 9 | no data | 1,000,000 | YES | 1533 | Aerobic | 3508 | YES |

| 10 | no data | 1,100,000 | YES | 2250 | Aerobic | 600 | YES |

| 11 | Milk processing, production of cottage cheese, cream, yoghurt | 1,140,800 | YES | 3930 | Part of excess sewage sludge is channelled into agricultural biogas plants | 27,553 (dewatered) 779 DM | YES |

| 12 | Production of UHT products, milk powder, cottage cheese, butter, granulated cheese, whey concentrate, cheese packaging | 1,400,000 | YES | 3393 | Aerobic and anaerobic cogeneration, drying of secondary fermentation sludge with a belt dryer | 414 DM | YES |

| 13 | no data | 2,800,000 | YES | 8710 | Aerobic and anaerobic | 4181 (646 DM) | YES |

| 14 | Production of processed cheese and ripened cheese | no data | YES | 90 | Sludge screw press–sludge dewatering line | 200 | no data |

| No. | Quantity of Processed Milk [L/d] | Does the WWTP Treat Production and Domestic Wastewater? | Sewage Sludge Processing Technology | Physicochemical and Sanitary Indicators of Sludge | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Live Egg Larvae Ascaris sp., Trichuris sp., Toxocara sp. Salmonella bacteria in 100 g | Dry Matter | Organic Compounds | N-NH4 | TKN | Mg | Ca | TP | Cr | Zn | Cd | Cu | Ni | Pb | Hg | pH | ||||

| [%] | [% DM] | [mg/kg DM] | - | ||||||||||||||||

| 1 | 21,000 | YES | Aerobic | Not detected | 9.52 | 73.15 | 0.17 | 6.18 | 0.31 | 6.14 | 2.74 | 8.98 | 723 | 0.27 | 18 | 6.47 | 8.47 | 0.28 | 7.45 |

| 2 | 139,500 | YES | Aerobic | Not detected | 12.37 | 72.8 | 1.93 | 8.29 | 0.31 | 4.21 | 2.79 | 15.4 | 1138 | 0.77 | 133.4 | 14.97 | 15.93 | 0.08 | 7.57 |

| 3 | 756,903 | YES | Aerobic and anaerobic | Not detected | 16.65 | 46.15 | 1.19 | 5.65 | 0.38 | 10.5 | 8.13 | 20.65 | 298 | 0.83 | 27.45 | 8.05 | 3.84 | 0.02 | 7.9 |

| 4 | 1,000,000 | YES | Aerobic and anaerobic | Not detected | 10.81 | 80.2 | 0.14 | 6.68 | 0.27 | 1.93 | 2.63 | 10.39 | 597 | 0.25 | 15.96 | 5.01 | 16.52 | 0.01 | 6.05 |

| 5 | 1,000,000 | YES | Aerobic | Not detected | 12.1 | 76.7 | 1.00 | 5.2 | 0.36 | 1.13 | 1.03 | 11.57 | 314 | 0.09 | 18.1 | 10.37 | 4.9 | 0.1 | 12.1 |

| 6 | 1,140,800 | NO | Part of excess sludge is transferred to agricultural biogas plants | Not detected | 6.14 | 70.33 | 0.23 | 6.36 | 0.56 | 4.52 | 4.36 | 6.5 | 87.3 | 0.25 | 8.19 | 3.51 | 2.5 | 0.01 | 7.4 |

| 7 | 1,400,000 | YES | Aerobic and anaerobic | Not detected | 15.6 | 59.2 | 1.42 | 7.37 | 0.66 | 6.59 | 6.23 | 20.7 | 278 | 1.18 | 37.5 | 16.7 | 2.49 | 0.04 | 8.1 |

| 8 | 2,800,000 | YES | Aerobic and anaerobic | Not detected | 20.53 | 40.15 | 0.6 | 3.86 | 0.66 | 19.6 | 2.67 | 8.36 | 143.5 | 0.3 | 8.43 | 12.25 | 2.51 | 0.02 | 10.0 |

| 9 | NO DATA | YES | Sludge screw press–sludge dewatering line | Not detected | 23.65 | 62 | 1.06 | 4.35 | 0.63 | 7.85 | 3.9 | 10.3 | 145 | 0.5 | 49 | 11.55 | 7.05 | 0.01 | 7.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodziewicz, J.; Mielcarek, A.; Kłobukowska, K.; Jóźwiakowski, K.; Siwiec, T.; Bugajski, P.; Janczukowicz, W. Water Consumption, Quantity and Quality of Wastewater and Sewage Sludge from Polish Dairies. Appl. Sci. 2025, 15, 1525. https://doi.org/10.3390/app15031525

Rodziewicz J, Mielcarek A, Kłobukowska K, Jóźwiakowski K, Siwiec T, Bugajski P, Janczukowicz W. Water Consumption, Quantity and Quality of Wastewater and Sewage Sludge from Polish Dairies. Applied Sciences. 2025; 15(3):1525. https://doi.org/10.3390/app15031525

Chicago/Turabian StyleRodziewicz, Joanna, Artur Mielcarek, Karolina Kłobukowska, Krzysztof Jóźwiakowski, Tadeusz Siwiec, Piotr Bugajski, and Wojciech Janczukowicz. 2025. "Water Consumption, Quantity and Quality of Wastewater and Sewage Sludge from Polish Dairies" Applied Sciences 15, no. 3: 1525. https://doi.org/10.3390/app15031525

APA StyleRodziewicz, J., Mielcarek, A., Kłobukowska, K., Jóźwiakowski, K., Siwiec, T., Bugajski, P., & Janczukowicz, W. (2025). Water Consumption, Quantity and Quality of Wastewater and Sewage Sludge from Polish Dairies. Applied Sciences, 15(3), 1525. https://doi.org/10.3390/app15031525