Decision-Making Framework for Aviation Safety in Predictive Maintenance Strategies

Abstract

:1. Introduction

1.1. Background and Motivation

1.2. Related Works

1.3. Research Gap, Contributions and Paper Structure

- A comprehensive decision-making framework that prioritizes aviation safety by incorporating key criteria such as flight safety impact, regulatory compliance, and reliability predictability, alongside economic and operational considerations.

- The application of the analytic hierarchy process (AHP) for criteria weighting, ensuring transparency and alignment with the aviation sector’s safety and regulatory imperatives.

- Validation of the framework through expert surveys, historical maintenance data, and real-world case studies, highlighting its ability to enhance decision-making and reduce safety risks.

- Practical recommendations for integrating PM strategies into existing aviation maintenance operations, ensuring both enhanced safety and cost efficiency while aligning with global aviation standards.

2. Materials and Methods

2.1. Predictive Maintenance in Aviation

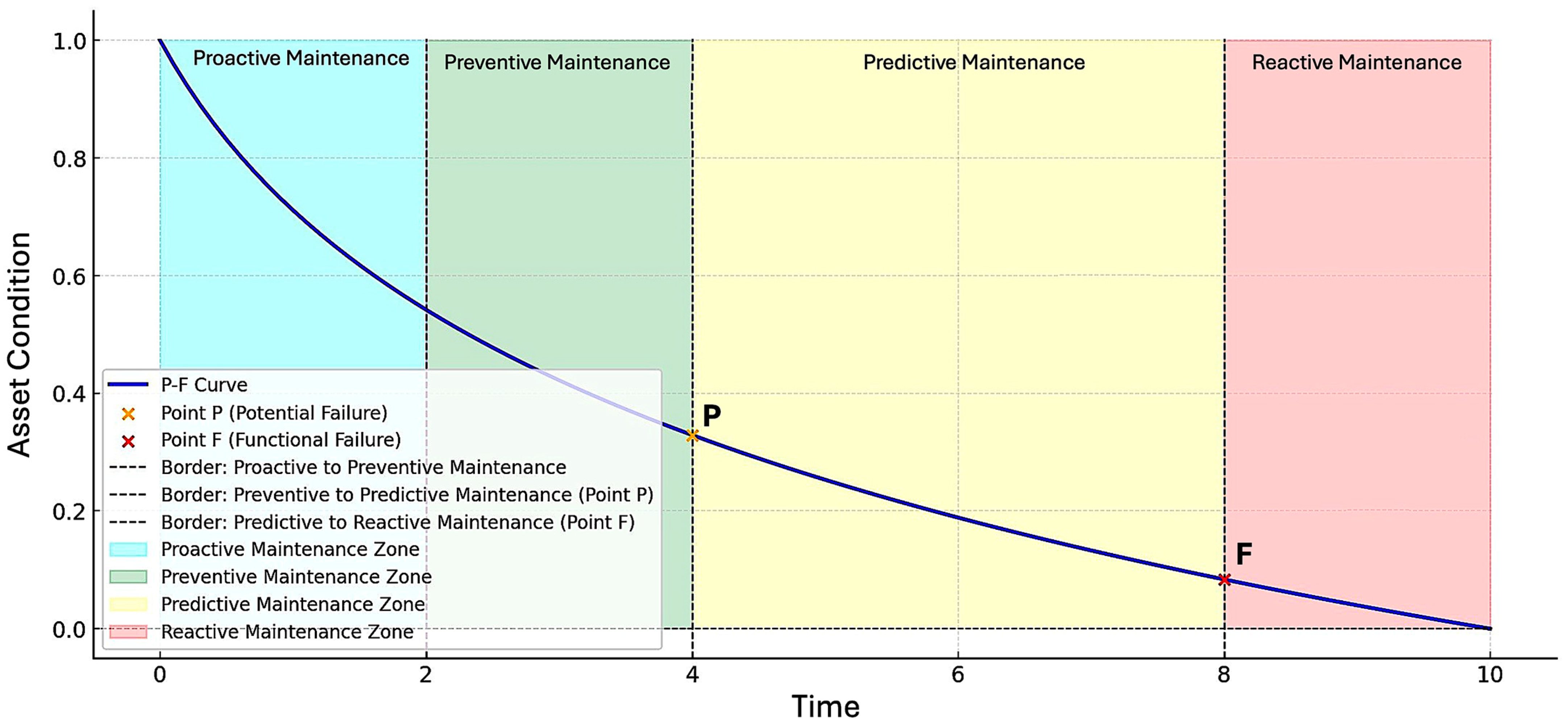

- Proactive maintenance zone occurs before any detectable degradation, focusing on eliminating root causes through design improvements and best practices.

- Preventive maintenance zone refers to scheduled interventions based on estimated component lifespans, often occurring near point P.

- Predictive maintenance zone is the critical window between point P and point F, where condition-monitoring tools detect issues and trigger timely interventions.

- Reactive maintenance zone refers to post-failure interventions when the system has already ceased to function.

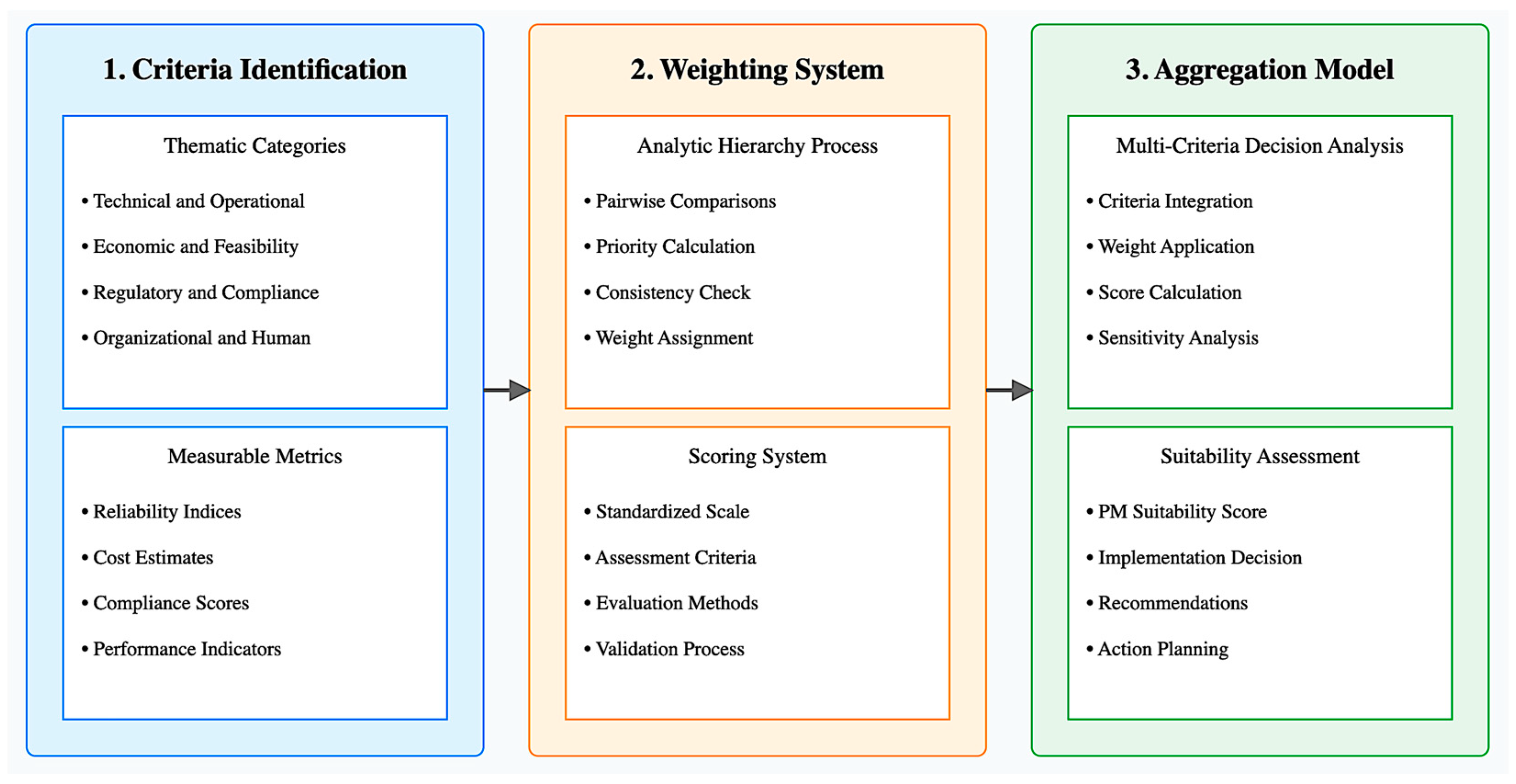

2.2. Conceptual Framework for Study

3. Results

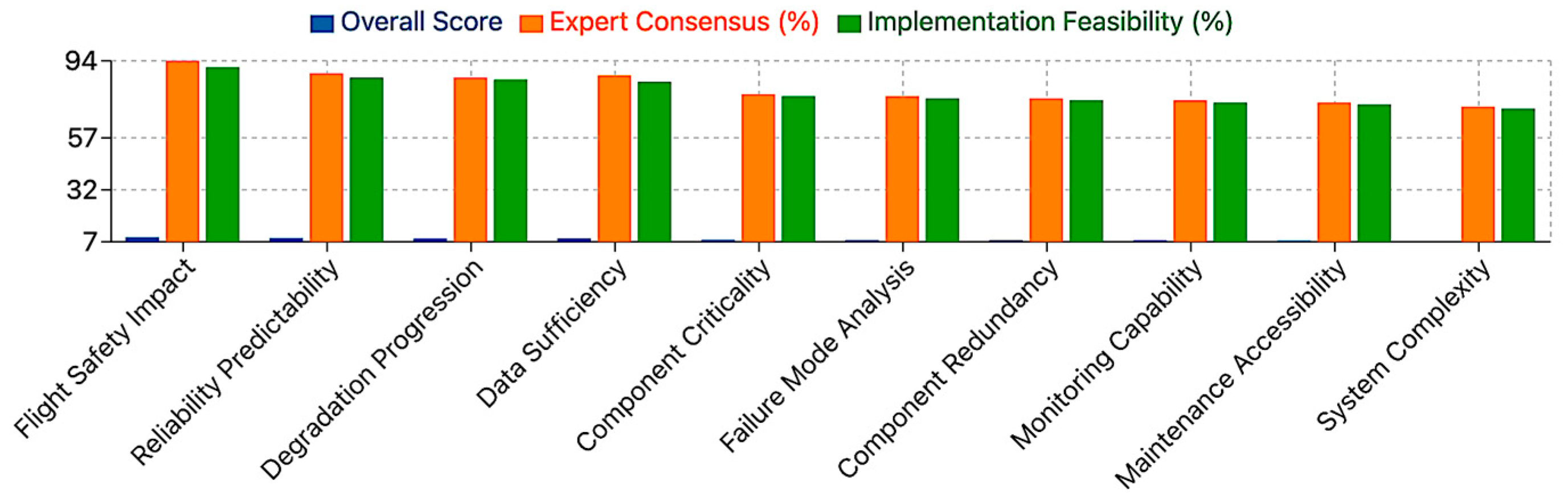

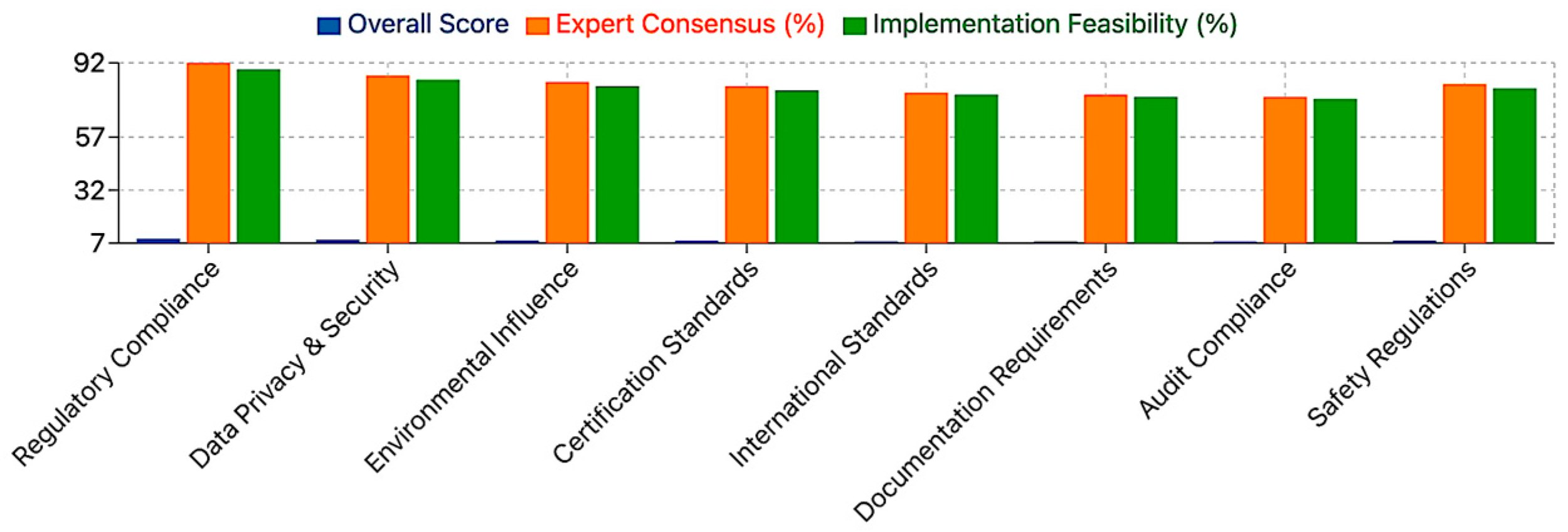

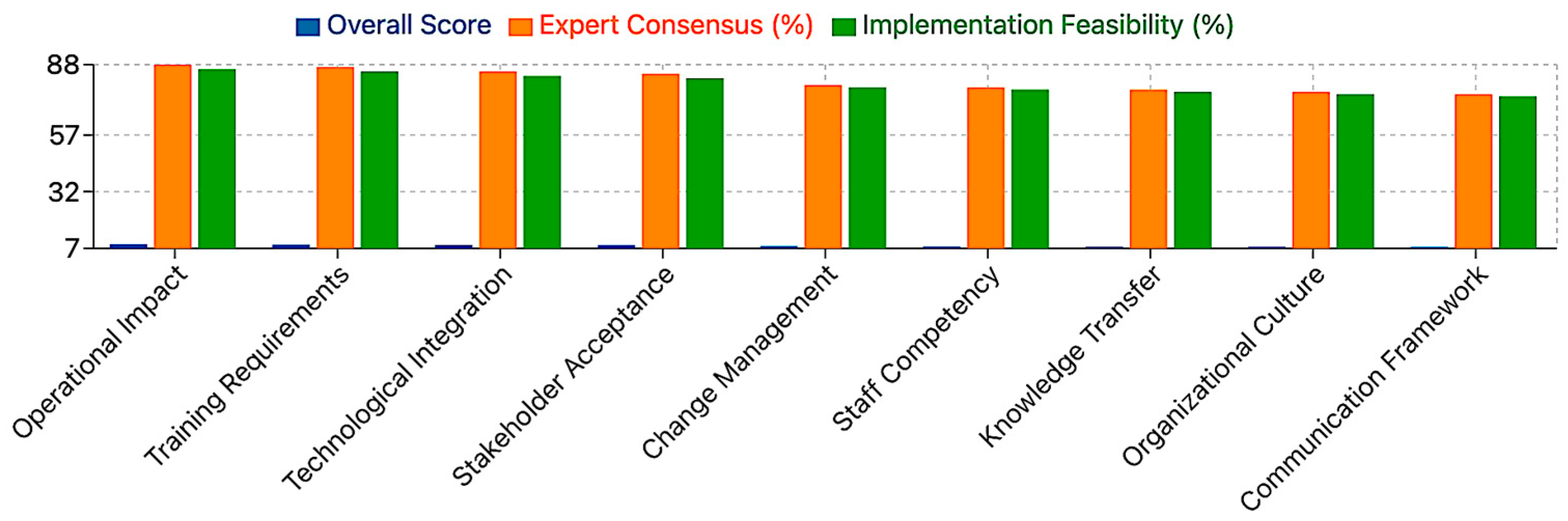

3.1. Methodology of Selecting Categories and Factors for PM in Aviation

3.2. Criteria Influencing the Feasibility of Predictive Maintenance for Aircraft

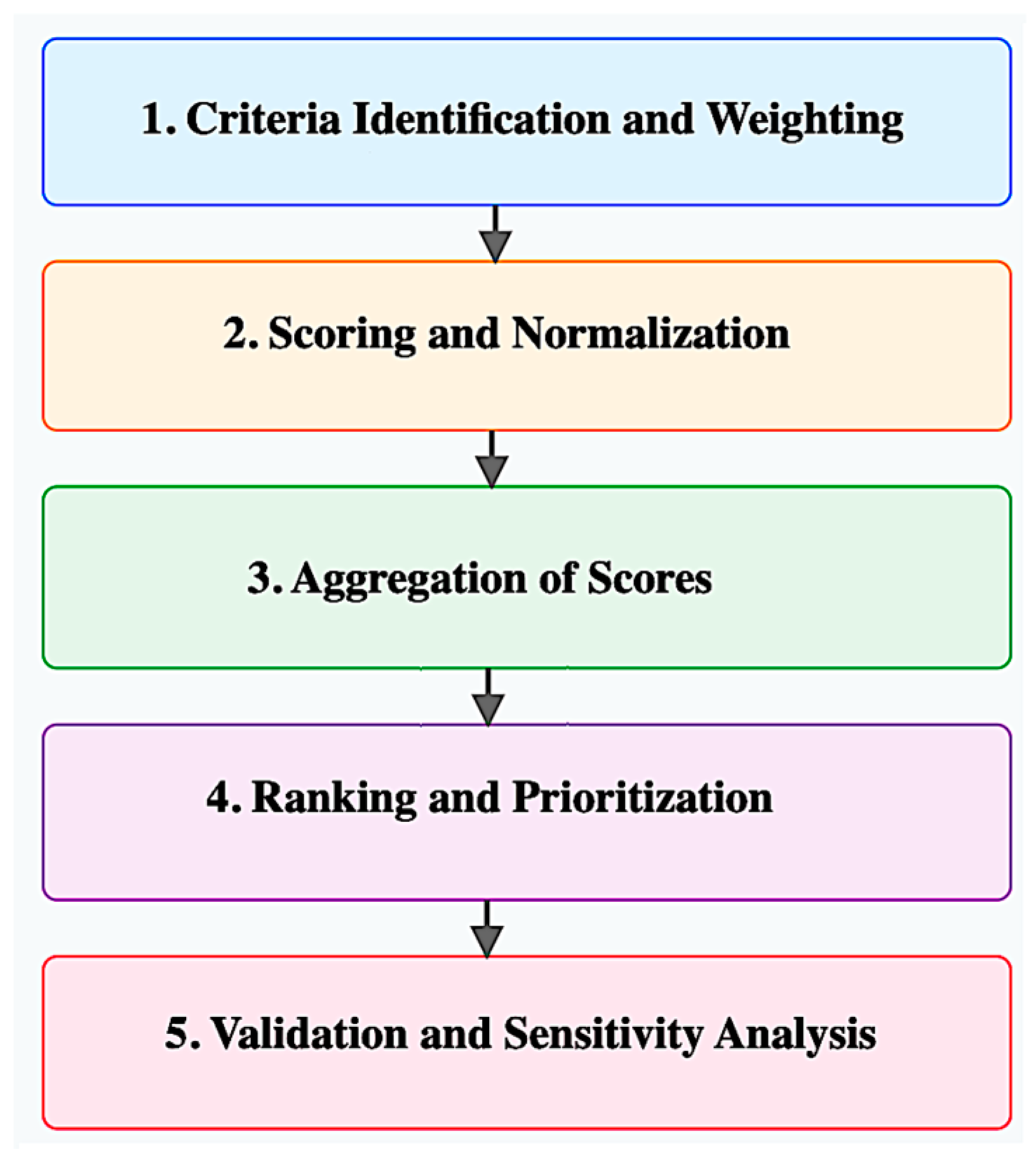

3.3. MCDA-Based Decision-Making Framework for PM Implementation

3.3.1. General Approach for Decision-Making Framework Development

- Criterion-level aggregation: Normalized scores within each thematic category are weighted and summed to produce a category score.

- Category-level aggregation: Category scores are weighted and combined to calculate an overall PM suitability score for each component.

3.3.2. Define Decision Variables and Criteria

- If , then PM is recommended for component .

- If , then PM may not be beneficial or feasible for component .

- The criteria that most influence the final decision.

- How robust the PM decision is to variations in scoring and weighting.

- Potential adjustments to the model to reflect changing operational needs or new information.

3.3.3. Case Studies

3.3.4. Methodology for Defining Weighting of Criteria and Scoring Components

- Darker blue indicates a stronger relative importance (higher ratio).

- Lighter blue indicates weaker relative importance (lower ratio).

- White cells (no blue) indicate either equal importance (1.0) or where the row criterion is less important than the column criterion (values < 1).

3.3.5. Validation and Comparative Analysis

4. Discussion

4.1. Expected Outcomes of PM Implementation

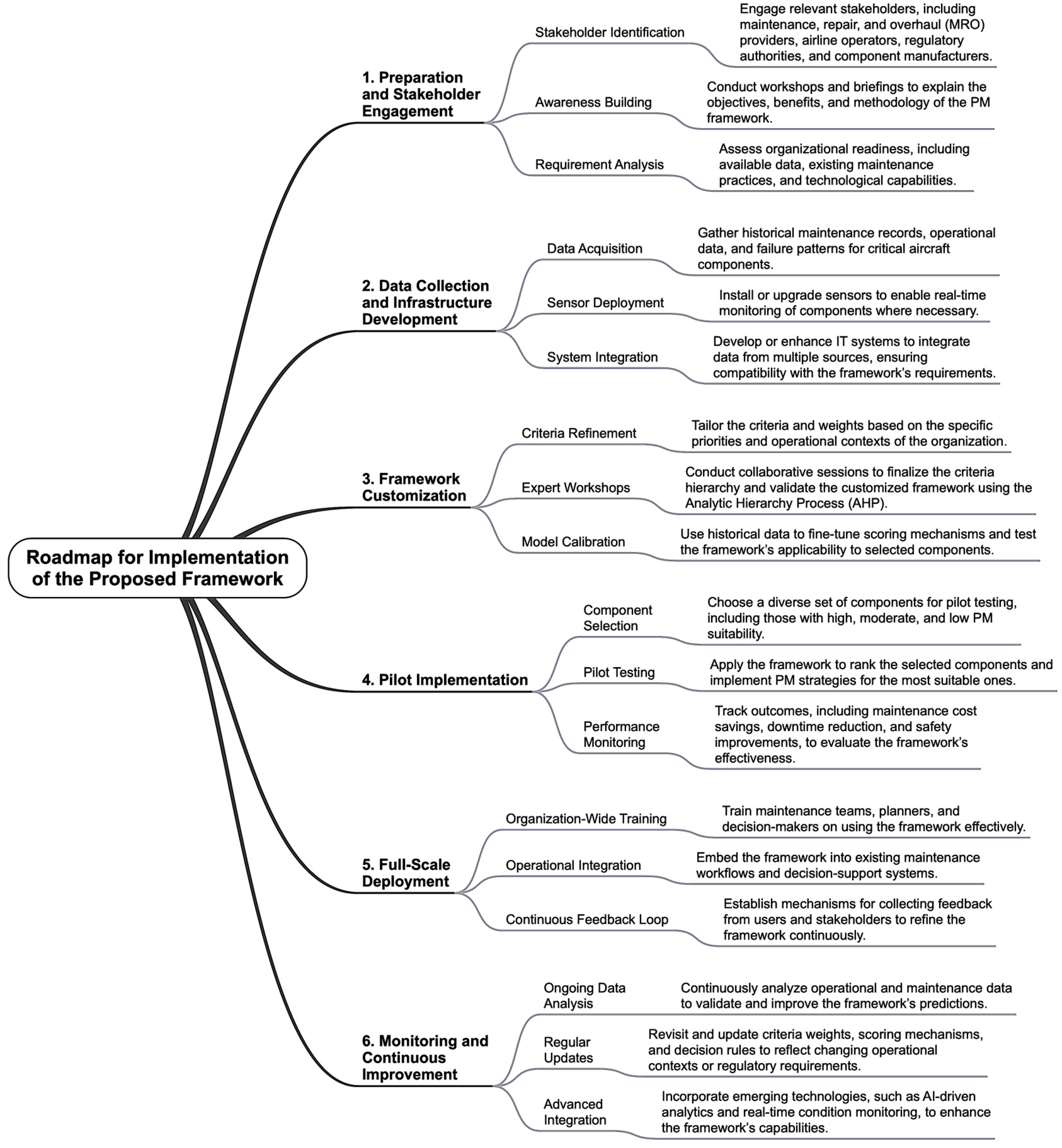

4.2. Roadmap for Implementation of the Proposed PM Framework

4.3. Challenges and Limitations of the Study

4.4. Future Research Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Verhagen, W.J.C.; Santos, B.F.; Freeman, F.; van Kessel, P.; Zarouchas, D.; Loutas, T.; Yeun, R.C.K.; Heiets, I. Condition-Based Maintenance in Aviation: Challenges and Opportunities. Aerospace 2023, 10, 762. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Khan, N.; Abdi, S.A.A.; Khan, T.A.; Rizvi, S.S.A. Minimization of High Maintenance Cost and Hazard Emissions Related to Aviation Engines: An Implementation of Functions Optimizations by Using Genetic Algorithm for Better Performance. Eng. Proc. 2023, 46, 11. [Google Scholar] [CrossRef]

- IATA. Airline Maintenance Cost Executive Commentary (FY2020 Data). Available online: https://www.iata.org/contentassets/8437020db31a4717b70677d9b06b1a45/fy2022-mcx-report_public.pdf (accessed on 30 December 2024).

- BS EN 13306:2017; Maintenance—Maintenance Terminology. British Standards Institution: London, UK, 2017. Available online: https://knowledge.bsigroup.com/products/maintenance-maintenance-terminology?version=tracked (accessed on 30 December 2024).

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Feng, Q.; Bi, X.; Zhao, X.; Chen, Y.; Sun, B. Heuristic hybrid game approach for fleet condition-based maintenance planning. Reliab. Eng. Syst. Saf. 2017, 157, 166–176. [Google Scholar] [CrossRef]

- Li, Z.; Guo, J.; Zhou, R. Maintenance scheduling optimization based on reliability and prognostics information. In Proceedings of the Annual Reliability and Maintainability Symposium (RAMS), Tucson, AZ, USA, 25–28 January 2016; pp. 1–5. [Google Scholar] [CrossRef]

- European Commission. Directorate-General for Mobility and Transport; Directorate-General for Research and Innovation. Flightpath 2050: Europe’s Vision for Aviation: Maintaining Global Leadership and Serving Society’s Needs; Publications Office: Brussels, Belgium, 2011; Available online: https://data.europa.eu/doi/10.2777/50266 (accessed on 30 December 2024).

- Lin, L.; Luo, B.; Zhong, S. Multi-objective decision-making model based on CBM for an aircraft fleet with reliability constraint. Int. J. Prod. Res. 2018, 56, 4831–4848. [Google Scholar] [CrossRef]

- Florian, E.; Sgarbossa, F.; Zennaro, I. Machine learning-based predictive maintenance: A cost-oriented model for implementation. Int. J. Prod. Econ. 2021, 236, 108114. [Google Scholar] [CrossRef]

- Krishnamurthy, L.; Adler, R.; Buonadonna, P.; Chhabra, J.; Flanigan, M.; Kushalnagar, N.; Nachman, L.; Yarvis, M. Design and deployment of industrial sensor networks: Experiences from a semiconductor plant and the North Sea. In Proceedings of the 3rd International Conference on Embedded Networked Sensor Systems, San Diego, CA, USA, 2–4 November 2005; pp. 64–75. [Google Scholar] [CrossRef]

- Mobley, R.K. Maintenance Fundamentals, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Carnero, M.C. An evaluation system of the setting up of predictive maintenance programmes. Reliab. Eng. Syst. Saf. 2006, 91, 945–963. [Google Scholar] [CrossRef]

- Hanchinal, A.R.; Shanbhog, N.R.; Totad, K.S.; Patgar, T.V.; Dhulavvagol, P.M. Deep Learning Approach for Predictive Maintenance of an Aircraft Engine. In ICT for Intelligent Systems. ICTIS 2024; Lecture Notes in Networks and Systems; Choudrie, J., Mahalle, P.N., Perumal, T., Joshi, A., Eds.; Springer: Singapore, 2024; Volume 1112. [Google Scholar] [CrossRef]

- Hermawan, A.P.; Kim, D.-S.; Lee, J.-M. Predictive Maintenance of Aircraft Engine using Deep Learning Technique. In Proceedings of the 2020 International Conference on Information and Communication Technology Convergence (ICTC), Jeju, Republic of Korea, 21–23 October 2020; pp. 1296–1298. [Google Scholar] [CrossRef]

- Pebrianti, D.; Khalani, Z.; Rusdah; Bayuaji, L. Predictive Maintenance in Aerospace Industry Using Convolutional Neural Network. In Proceedings of the 2024 9th International Conference on Mechatronics Engineering (ICOM), Kuala Lumpur, Malaysia, 15–17 January 2024; pp. 157–162. [Google Scholar] [CrossRef]

- Ingole, O.; Pande, A.; Dongre, A.; Jadhav, D.; Dhamecha, D.; Daspute, H.; Komble, S.; Bhosale, T. Investigation of Different Regression Models For The Predictive Maintenance of Aircraft’s Engine. In Proceedings of the 2022 Fourth International Conference on Emerging Research in Electronics, Computer Science and Technology (ICERECT), Mandya, India, 12–14 August 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Heim, S.; Clemens, J.; Steck, J.E.; Basic, C.; Timmons, D.; Zwiener, K. Predictive Maintenance on Aircraft and Applications with Digital Twin. In Proceedings of the 2020 IEEE International Conference on Big Data (Big Data), Atlanta, GA, USA, 10–13 December 2020; pp. 4122–4127. [Google Scholar] [CrossRef]

- Stanton, I.; Munir, K.; Ikram, A.; El-Bakry, M. Predictive maintenance analytics and implementation for aircraft: Challenges and opportunities. Syst. Eng. 2023, 26, 216–237. [Google Scholar] [CrossRef]

- Myo, T.; Ahmed, M.R.; Al Hadidi, H.; Al Baroomi, B. Trends and Challenges of Machine Learning-Based Predictive Maintenance in Aviation Industry. In Proceedings of the First International Conference on Aeronautical Sciences, Engineering and Technology (ICASET 2023); Khan, A.A., Hossain, M.S., Fotouhi, M., Steuwer, A., Khan, A., Kurtulus, D.F., Eds.; Springer: Singapore, 2024. [Google Scholar] [CrossRef]

- Scott, M.J.; Verhagen, W.J.C.; Bieber, M.T.; Marzocca, P. A Systematic Literature Review of Predictive Maintenance for Defence Fixed-Wing Aircraft Sustainment and Operations. Sensors 2022, 22, 7070. [Google Scholar] [CrossRef] [PubMed]

- Kabashkin, I.; Susanin, V. Unified Ecosystem for Data Sharing and AI-Driven Predictive Maintenance in Aviation. Computers 2024, 13, 318. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Kabashkin, I.; Perekrestov, V. Ecosystem of Aviation Maintenance: Transition from Aircraft Health Monitoring to Health Management Based on IoT and AI Synergy. Appl. Sci. 2024, 14, 4394. [Google Scholar] [CrossRef]

- Lee, J.; Mitici, M.; Blom, H.A.P.; Bieber, P.; Freeman, F. Analyzing Emerging Challenges for Data-Driven Predictive Aircraft Maintenance Using Agent-Based Modeling and Hazard Identification. Aerospace 2023, 10, 186. [Google Scholar] [CrossRef]

- Fu, S.; Avdelidis, N.P. Prognostic and Health Management of Critical Aircraft Systems and Components: An Overview. Sensors 2023, 23, 8124. [Google Scholar] [CrossRef] [PubMed]

- Kabashkin, I.; Susanin, V. Decision-Making Model for Life Cycle Management of Aircraft Components. Mathematics 2024, 12, 3549. [Google Scholar] [CrossRef]

- Louhichi, R.; Sallak, M.; Pelletan, J. A Study of the Impact of Predictive Maintenance Parameters on the Improvment of System Monitoring. Mathematics 2022, 10, 2153. [Google Scholar] [CrossRef]

- Cavalieri, S.; Salafia, M.G. A Model for Predictive Maintenance Based on Asset Administration Shell. Sensors 2020, 20, 6028. [Google Scholar] [CrossRef] [PubMed]

- Tiddens, W.; Braaksma, J.; Tinga, T. Decision Framework for Predictive Maintenance Method Selection. Appl. Sci. 2023, 13, 2021. [Google Scholar] [CrossRef]

- Kabashkin, I. Unified Aviation Maintenance Ecosystem on the Basis of 6G Technology. Electronics 2024, 13, 3824. [Google Scholar] [CrossRef]

- Timjerdine, M.; Taibi, S.; Moubachir, Y. Leveraging AI and Industry 4.0 in Aircraft Maintenance: Addressing Challenges and Improving Efficiency. In Proceedings of the 2024 International Conference on Global Aeronautical Engineering and Satellite Technology (GAST), Marrakesh, Morocco, 15–17 January 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Kabashkin, I. The Iceberg Model for Integrated Aircraft Health Monitoring Based on AI, Blockchain, and Data Analytics. Electronics 2024, 13, 3822. [Google Scholar] [CrossRef]

- Assis, R.; Marques, P.C. A Dynamic Methodology for Setting Up Inspection Time Intervals in Conditional Preventive Maintenance. Appl. Sci. 2021, 11, 8715. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Fishburn, P.C. Additive Utilities with Incomplete Product Set: Applications to Priorities and Assignments. Oper. Res. 1967, 15, 537–542. [Google Scholar] [CrossRef]

- Linstone, H.A.; Turoff, M. The Delphi Method: Techniques and Applications; Addison-Wesley Publishing Company: Reading, MA, USA, 1975. [Google Scholar]

- Mastering Multi-Criteria Decision Analysis: A Practical Guide to Enhancing Decision-Making in AI and Machine Learning; TailoredRead AI: New York, NY, USA, 2024; Available online: https://tailoredread.com/book/mastering-multi-criteria-decision-analysis-practical-guide-8ac655c5584b (accessed on 30 December 2024).

- Gavião, L.O.; Sant’Anna, A.P.; Lima, G.B.A.; Garcia, P.A.d.A. Composition of Probabilistic Preferences in Multicriteria Problems with Variables Measured in Likert Scales and Fitted by Empirical Distributions. Standards 2023, 3, 268–282. [Google Scholar] [CrossRef]

| Technique | Applications | Tools |

|---|---|---|

| Vibration Analysis | Rotating equipment, motors | Accelerometers, vibration sensors, data collectors |

| Infrared Thermography | Electrical panels, heat exchangers | Infrared cameras, thermal imaging systems |

| Ultrasound Testing | Compressed air systems, valves | Ultrasonic detectors, acoustic cameras |

| Oil Analysis | Hydraulic systems, engines | Spectrometers, particle counters |

| Machine Learning Algorithms | Predictive analytics | IoT sensors, AI-driven maintenance platforms |

| SCADA Systems | Centralized monitoring | Distributed sensors with real-time data dashboards |

| Component | Applicability of P-F Curve | Reason |

|---|---|---|

| Engines (Turbines) | High | Condition monitoring (e.g., vibration, thermography) detects degradation over time. |

| Landing Gear | High | Wear and fatigue can be monitored with condition-based tools (e.g., crack detection). |

| Hydraulic Systems | Medium | Degradation (e.g., fluid contamination) is gradual and measurable, but sudden failures can occur. |

| Avionics (Electronics) | Low | Failures are often sudden and not preceded by detectable degradation. |

| Structural Components | High (for fatigue-related failures) | Cracks and corrosion follow predictable degradation patterns, detectable through inspections. |

| Fuel Systems | Medium | Degradation (e.g., clogging, leaks) can sometimes be gradual, but unexpected events also occur. |

| i | Score for Engine | Score for FMC | ||

|---|---|---|---|---|

| 1. | Flight Safety Impact | 0.15 | 0.95 | 0.95 |

| 2. | Reliability Predictability | 0.1 | 0.9 | 0.4 |

| 3. | Degradation Progression | 0.1 | 0.85 | 0.3 |

| 4. | Data Sufficiency | 0.1 | 0.9 | 0.6 |

| 5. | Economic Feasibility | 0.1 | 0.8 | 0.5 |

| 6. | Regulatory Compliance | 0.05 | 0.9 | 0.8 |

| 7. | Technological Integration | 0.05 | 0.85 | 0.6 |

| 8. | Environmental Influence | 0.05 | 0.8 | 0.6 |

| 9. | Operational Impact | 0.1 | 0.9 | 0.7 |

| 10. | Scalability | 0.05 | 0.9 | 0.6 |

| 11. | Workforce Training | 0.05 | 0.8 | 0.7 |

| 12. | Data Privacy and Security | 0.05 | 0.9 | 0.5 |

| 13. | End-of-Life Management | 0.05 | 0.85 | 0.6 |

| 14. | Stakeholder Acceptance | 0.05 | 0.9 | 0.6 |

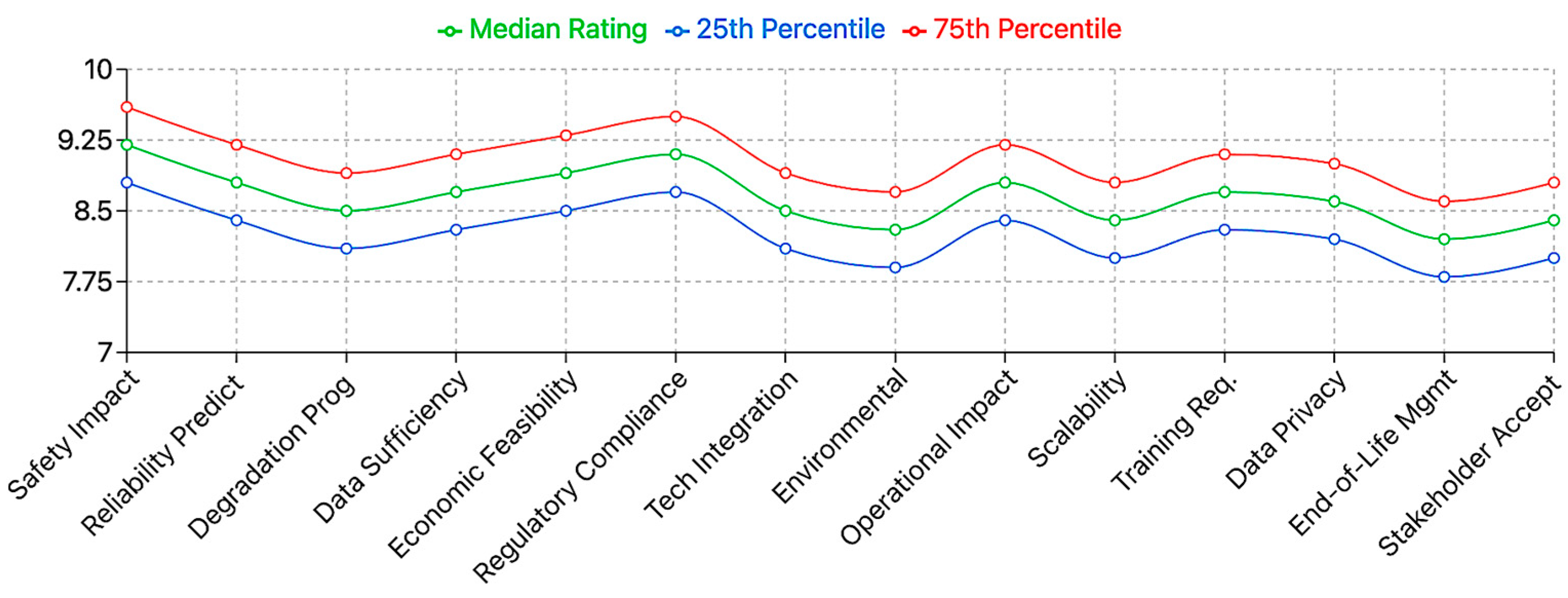

| Criterion | Median | Std Dev | Weight |

|---|---|---|---|

| Flight Safety Impact | 9.20 | 0.38 | 0.15 |

| Reliability Predictability | 8.80 | 0.42 | 0.10 |

| Degradation Progression | 8.50 | 0.45 | 0.10 |

| Data Sufficiency | 8.70 | 0.43 | 0.10 |

| Economic Feasibility | 8.90 | 0.41 | 0.10 |

| Regulatory Compliance | 9.10 | 0.39 | 0.05 |

| Technological Integration | 8.50 | 0.45 | 0.05 |

| Environmental Influence | 8.30 | 0.47 | 0.05 |

| Operational Impact | 8.80 | 0.42 | 0.10 |

| Scalability | 8.40 | 0.46 | 0.05 |

| Workforce Training | 8.70 | 0.43 | 0.05 |

| Data Privacy | 8.60 | 0.44 | 0.05 |

| End-of-Life Management | 8.20 | 0.48 | 0.05 |

| Stakeholder Acceptance | 8.40 | 0.46 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabashkin, I.; Fedorov, R.; Perekrestov, V. Decision-Making Framework for Aviation Safety in Predictive Maintenance Strategies. Appl. Sci. 2025, 15, 1626. https://doi.org/10.3390/app15031626

Kabashkin I, Fedorov R, Perekrestov V. Decision-Making Framework for Aviation Safety in Predictive Maintenance Strategies. Applied Sciences. 2025; 15(3):1626. https://doi.org/10.3390/app15031626

Chicago/Turabian StyleKabashkin, Igor, Roman Fedorov, and Vladimir Perekrestov. 2025. "Decision-Making Framework for Aviation Safety in Predictive Maintenance Strategies" Applied Sciences 15, no. 3: 1626. https://doi.org/10.3390/app15031626

APA StyleKabashkin, I., Fedorov, R., & Perekrestov, V. (2025). Decision-Making Framework for Aviation Safety in Predictive Maintenance Strategies. Applied Sciences, 15(3), 1626. https://doi.org/10.3390/app15031626