Abstract

In recent decades, adopting alternative resources in infrastructure applications has garnered global attention to address environmental concerns. Olive waste ash (OWA), a locally available byproduct obtained from the olive oil production process, is a promising green material that plays a vital role as a partial cement substitute. This paper evaluates the mechanical and durability properties of cement paste—a key component of paving blocks—incorporating OWA at replacement levels of 0, 5, 10, 15, and 20%, with a constant water-to-cementitious ratio of 0.45. Density, compressive strength, and flexural strength are assessed at 1, 7, 28, and 90 days, while total water absorption (TWA) and capillary water absorption (CWA) are measured at 28 days. The results reveal that OWA slightly reduces density, compressive strength, and flexural strength, with the optimal results observed at a substitution level of 10%. At 90 days, the compressive strength of the control cement paste is 50 MPa, whereas the 10% OWA mixture exhibits a value of 46 MPa, corresponding to only an 8% reduction. Additionally, two predictive models are proposed: the hyperbolic model for compressive strength variation with curing time and the capillary-diffusive model for capillary water absorption as a function of time. Both models demonstrate a strong fit with experimental data. Correlations between different properties indicate a strong correlation between compressive strength, density, and flexural strength, while a negative linear relationship exists between compressive strength and water absorption. This study underscores OWA’s potential to improve sustainable paving blocks by providing suitable mechanical and durability characteristics, offering both environmental and economic benefits.

1. Introduction

Recently, researchers have been increasingly concentrating on utilizing paving blocks in infrastructure applications, thanks to their substantial benefits. Paving blocks are structural materials applied on hard surfaces, including driveways, pedestrian sidewalks, garden patios, and pool terraces [1,2]. These blocks are formulated to withstand severe environmental conditions, including temperature variations, heavy rainfall, and freeze–thaw cycles, which can drastically shorten their lifespan or that of the concrete [3]. However, the large-scale use of cement in the production of paving blocks contributes to CO2 emissions, as cement is recognized as the second largest industrial emitter and is projected to account for up to 23% of total emissions by 2050 [4]. This ecological impact has motivated researchers to find suitable solutions by appropriately opting for sustainable alternatives to traditional cement [5]. Among these alternatives, a broad range of ashes such as municipal solid waste incineration bottom ash (MSWI-BA) [6,7], corncob ash [8], bamboo leaf ash [9,10], date palm ash [11], and rice husk ash [12] have been explored thanks to their pozzolanic features and environmental effectiveness. Previous attempts to integrate rice straw ash into pavement systems—specifically paver blocks—have convincingly demonstrated the potential of agricultural ashes in such applications [3]. Rice straw ash’s capacity to preserve structural integrity and stability reinforces its suitability for these purposes [3].

Olive waste ash (OWA), produced from the combustion of olive pomace, has attracted interest as a locally available agricultural byproduct in Mediterranean areas [13,14,15,16]. The annual quantity of waste generated from olive crops is estimated at approximately three tons per hectare of olive orchards, resulting in biomass production of about 3.3 × 107 tons [17]. Compared to cement production, the combustion of pomace used as a biofuel for energy purposes results in lower CO2 emissions [18]. According to a study conducted in an olive pomace plant in Greece, the combustion of pomace used as biofuel instead of traditional fossil fuels can save about 9100 tons of carbon emissions [19]. Additionally, there are a variety of types of olive waste, including olive stones used for thermal insulation in a mortar [20], olive kernel shells implemented for self-compacted lightweight mortar [21], and olive wood waste applied in masonry blocks [22]. Similarly, OWA has been potentially applied in several sectors, including concrete, geopolymers, soil stabilization, embankments, and brick manufacturing, to limit the detrimental effects of cement and dispose of unused residues. The results of a prior study highlight that employing OWA reduces the compressive and flexural strength of cement paste [23]. For instance, the addition of OWA tends to decrease the 28-day compressive strength from 27.44 to 16.41 MPa and the 28-day flexural strength from 8.89 to 4.81 MPa, with varying OWA content from 0% to 15%, respectively [23]. On the other hand, replacing cement with 10% OWA substantially boosts the durability of the cement paste [24]. This improvement is associated with a reduction in all length change parameters—whether shrinkage or expansion—thereby strengthening its resistance to cracking [24].

The widespread accumulation of waste has brought massive pressure on the ecosystem. Nonetheless, a significant portion of the unused waste is considered pozzolanic resources, which are frequently applied in construction activities. Partially replacing traditional cement with pozzolanic materials helps to reduce the tremendous amount of residue and its ecological impact. As known, pozzolanic materials are natural or industrial resources essentially consisting of high amounts of silicon dioxide or silica (SiO2) and aluminum oxide or alumina (Al2O3) [23]. When mixed with water, these materials chemically react with hydration products (calcium hydroxide) to form additional calcium–silicate–hydroxide (C-S-H) gel, responsible for the strength development of ash-infused composites. In particular, the oxide composition of OWA indicates that this ash is predominantly composed of highly reactive SiO2, rendering it an appealing precursor for pozzolan, as reported in the literature [23,24]. This characteristic guarantees the potential OWA in light of its efficient properties and environmental friendliness, which are defined by its pozzolanic reaction, filler effect, and low-cost effectiveness [24].

It seeks to evaluate the features of cementitious systems employed in the construction of paving blocks. Given that concrete is one of the key components of these blocks, a wide range of green concrete that incorporates OWA is being explored, such as conventional concrete [2,17], non-structural recycled concrete [25], concrete pavement [21,26], and high-performance concrete [27]. Previous research pointed out that the utilization of 5% OWA in the concrete results in a compressive strength comparable to the reference mixture [28,29]. Similarly, the beneficial impact of olive seed ash on the mechanical performance of concrete is also observed, demonstrating that OWA is a promising resource for producing concrete without compromising its structural integrity [30]. Furthermore, incorporating treated olive biomass bottom ash into concrete pavement improves its mechanical strength [31]. Moreover, olive waste biomass ash can act as a filler in self-compacting concrete with compressive strength similar to that of mixtures made with conventional fillers [32].

In brick manufacturing, olive pomace ash, which partly replaces clay, adversely affects both compressive strength and bulk density [33]. In addition, the inclusion of 30 to 40% olive biomass ash causes a drop in compressive strength, which is possibly attributed to an excess of waste content [19]. However, a previous investigation highlights the potential of using olive pomace ash as an effective method for boosting the strength of bricks [34].

In the construction of road embankments, OWA can be used as an economic agent for expansive soil stabilization. Hence, OWA is a pozzolanic material due to its high content of calcium, which improves the bearing capacity, unconfined compressive strength, and the dry density of the soil [35,36]. Another study has been carried out on the implementation of OWA to produce rammed earth blocks [13]. The test results prove that OWA meets the pozzolanic properties due to its ability to enhance mechanical features [13]. In the case of rigid pavement, OWA enhances the durability and strength of concrete material at 7.5% of replacement for cement [37]. In addition, an investigation confirmed that olive pomace ash and olive stone biomass ash are two effective waste materials that serve as alkaline source activators to fabricate geopolymers with good bulk density [38,39].

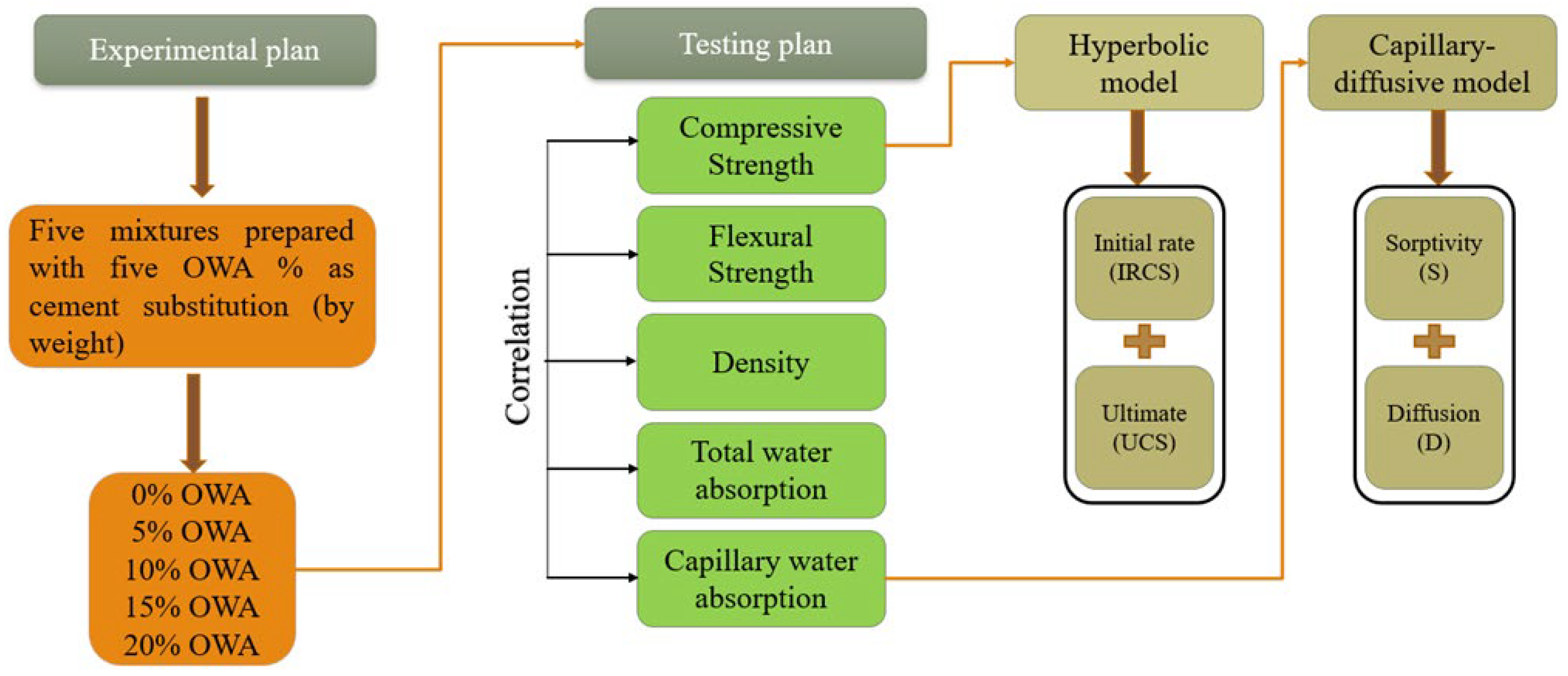

This study explores the impact of OWA as a partial cement substitute on the physical and mechanical properties of cement paste for paving block applications. Five partial substitution levels (0, 5, 10, 15, and 20%) are examined to determine their impact on density, compressive strength, flexural strength, and water absorption behavior, highlighting the correlations between diverse parameters. Furthermore, two predictive models—the hyperbolic model for compressive strength and the capillary-diffusive model for sorptivity and diffusion—are suggested to validate experimental data. The integration of these two models represents a significant contribution to this study by better understanding the interaction between mechanical and durability characteristics in the presence of OWA.

In summary, this study underscores that OWA can be an ideal candidate to improve durability, promote sustainability, and reduce the carbon footprint of cementitious systems used in paving block applications, offering an eco-friendly solution.

2. Experimental Test

2.1. Materials

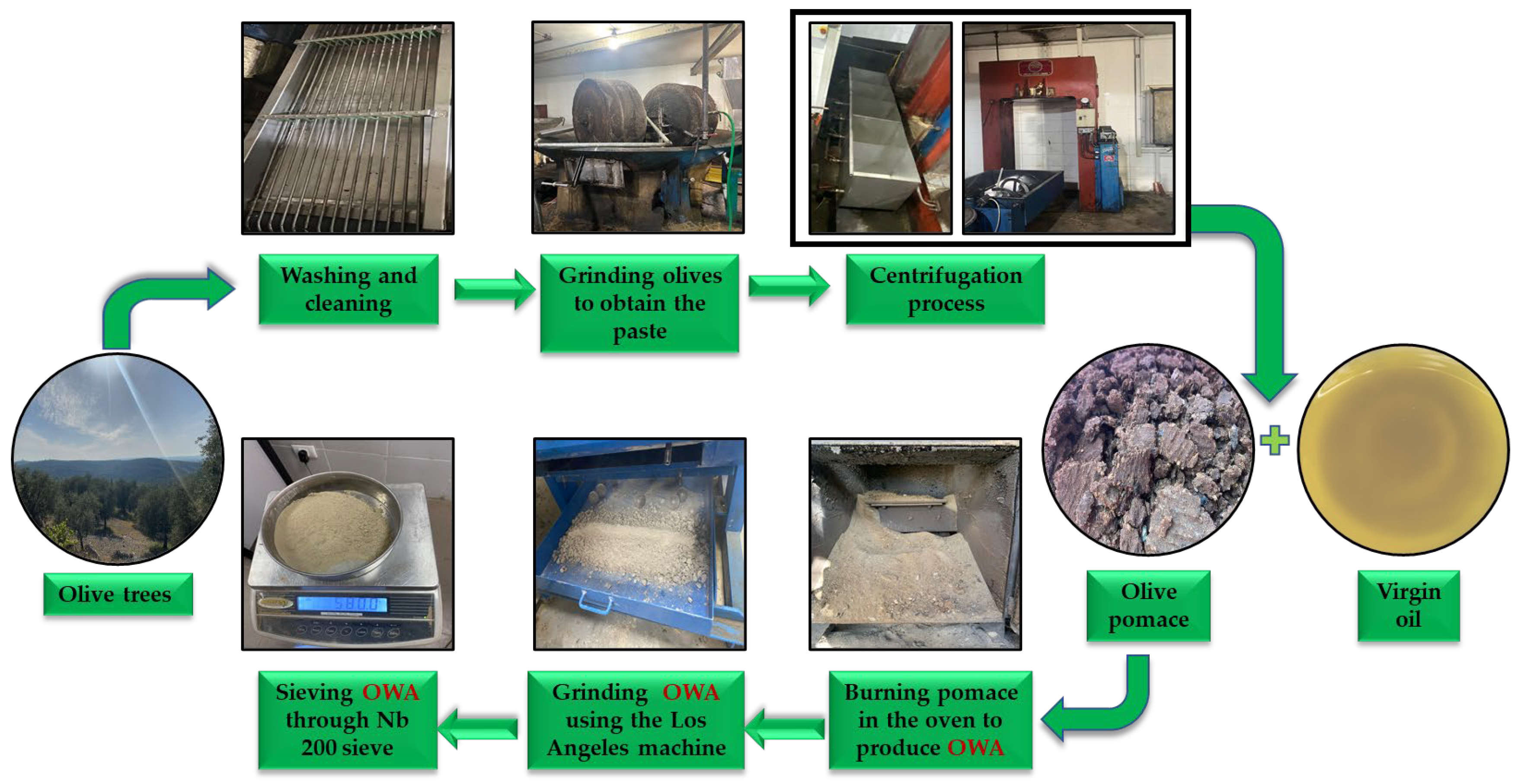

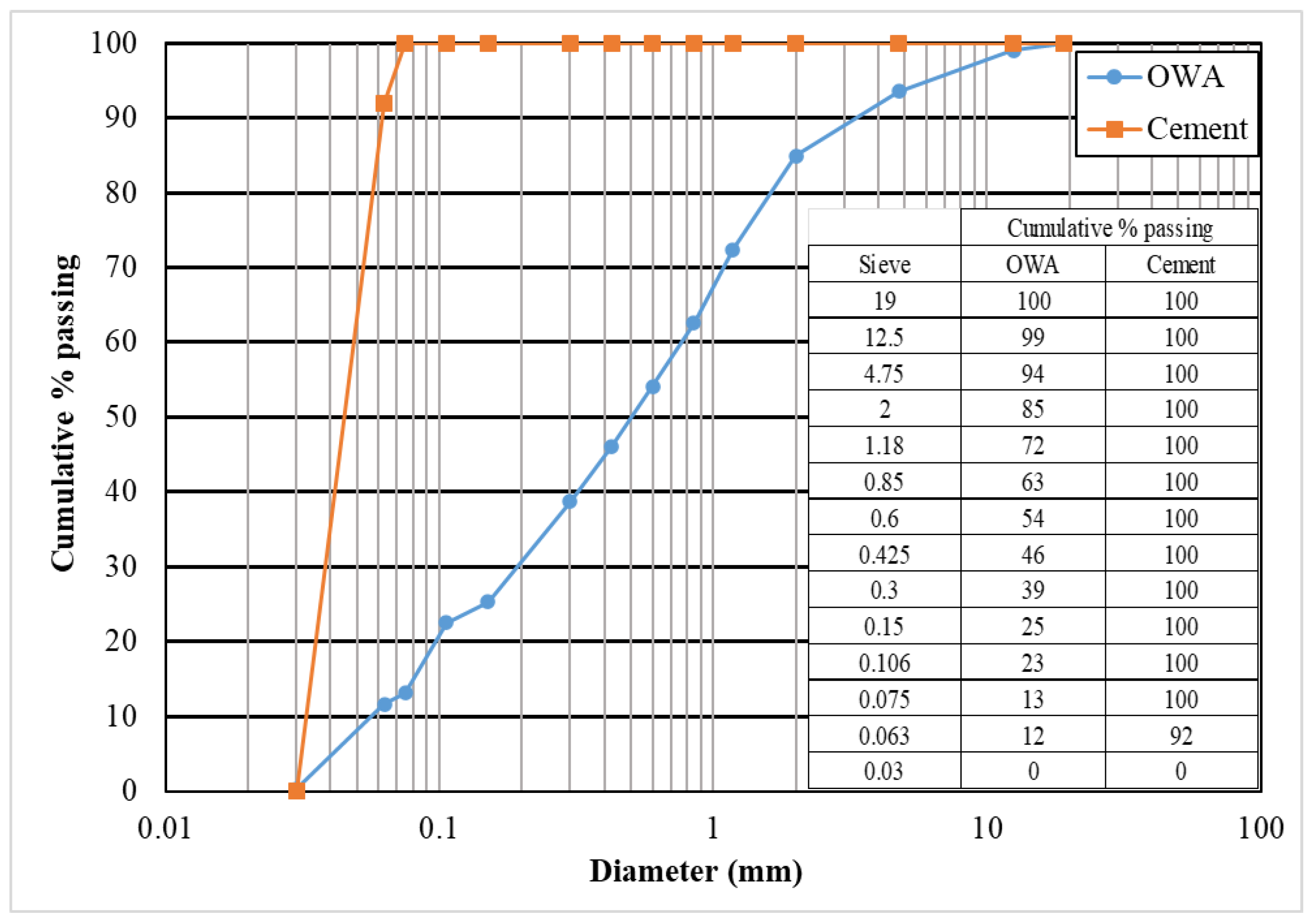

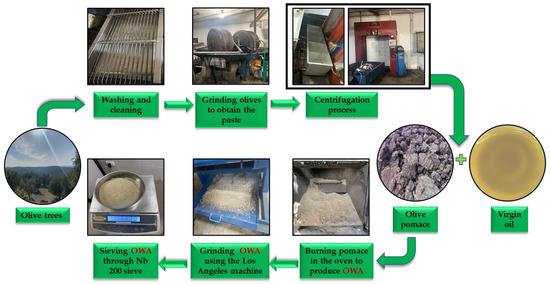

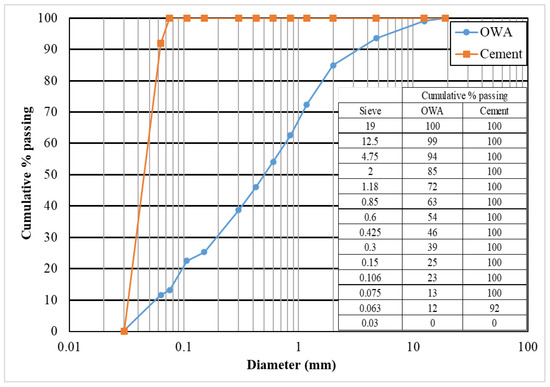

The experimental work implemented two main materials, Ordinary Portland cement (OPC) CN PA-L 42.5 type 1 and OWA. The OPC, which was obtained from the Sabaa plant in Tripoli, Lebanon, presented a particle size distribution adequate for proper cement hydration. The OWA obtained from Zgharta, North Lebanon, had a density of 950 kg/m3 and a water absorption rate of 28%. Additionally, the morphology of OWA particles was characterized by a rough texture and angular, irregular, or partially rounded shapes. Upon the cultivation of olive trees, stems, leaves, and any fragments not used in the oil extraction mechanism were removed. The traditional oil extraction method started with washing the harvested olives with water. These cleaned olives were milled between two mats to produce a fine paste, facilitating the release of oil. After extraction, the paste underwent a centrifugation technique to separate the solid particles suspended in the olive oil, resulting in virgin olive oil and olive pomace as the solid residue. The olive pomace, which was collected from an olive press, was then burnt in a closed-system boiler at a high temperature of 500 °C for approximately 8 h until it was transformed into ashes. Once cooled, the resulting ashes were subjected to grinding using a Los Angeles machine to break down larger particles. The final step involved sieving the ashes through a Nb 200 sieve to obtain fine OWA particles. A brief description of the process of olive waste ash (OWA) production is clarified in Figure 1. The OWA’s particle size distribution is shown in Figure 2, and its chemical composition is depicted in Table 1. The analysis indicated that the OWA was primarily composed of silicon (Si) and calcium (Ca), rendering it a highly appealing precursor for pozzolanic materials [24].

Figure 1.

Process of OWA preparation.

Figure 2.

Particle size distribution of OWA and cement.

Table 1.

Chemical composition of OWA and cement.

2.2. Mixture Proportions

Five cement paste mixtures were prepared with OWA replacement levels of 0, 5, 10, 15, and 20% by mass, maintaining a constant water-to-cementitious ratio of 0.45. Table 2 presents the proportions of all mixtures. These substitution levels were selected based on main considerations, including laboratory trial tests and several prior studies reported in the literature review. The assessment of concrete containing 10, 20, 30, and 40% OWA proved that replacement levels should be limited to 20% because of the detrimental mechanical performance observed beyond this threshold [29].

Table 2.

Mix proportions of paste.

2.3. Specimen Preparation

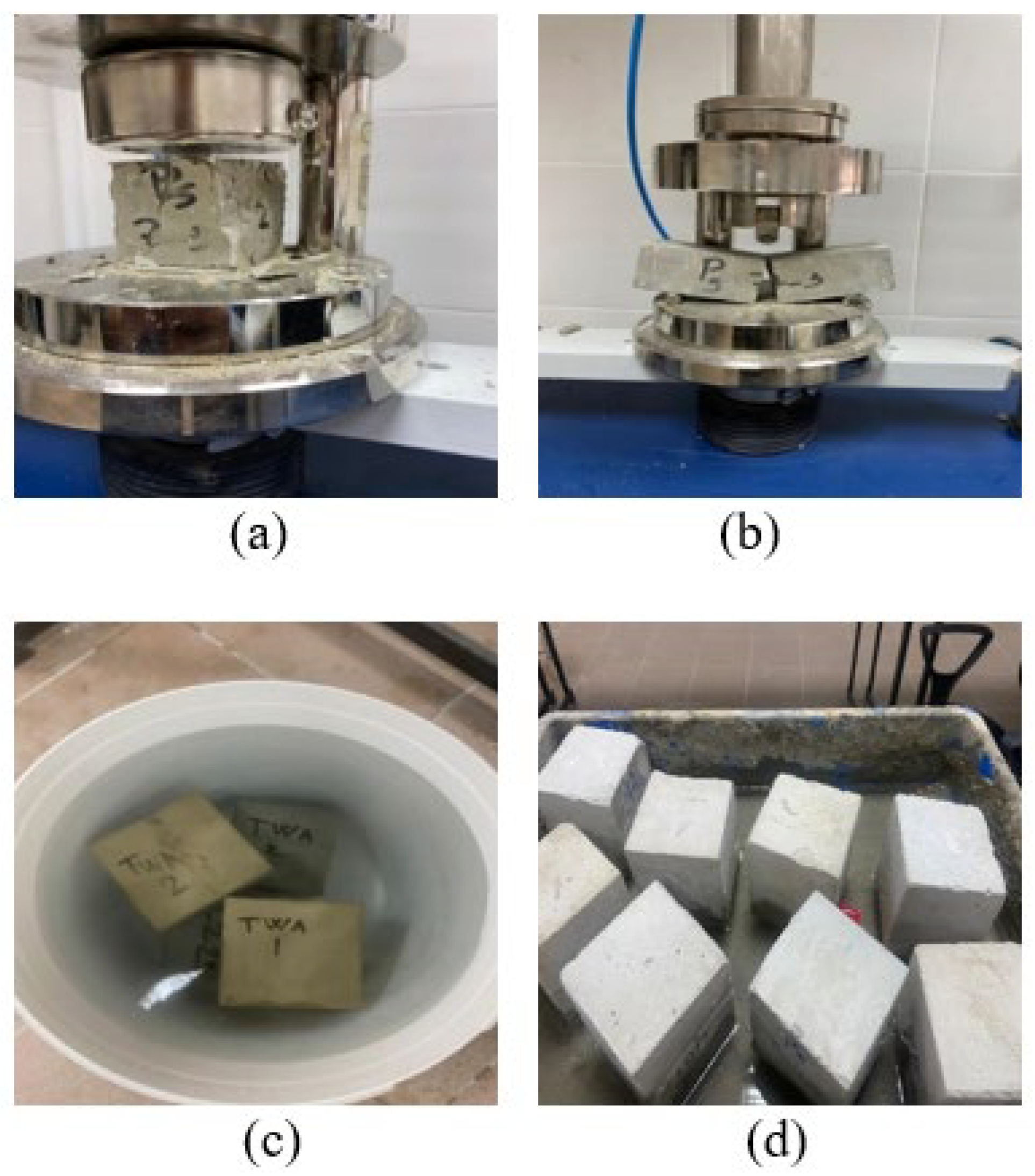

To prepare the different mixtures, cement, OWA, and water were mixed for 5 min until homogeneity was achieved. Then, the pastes were cast into pre-oiled cubes covered with a plastic sheet and stored in the room for 24 h. After demolding, the test specimens were cured in water until reaching the ages of 1, 7, 28, and 90 days.

2.4. Test Method

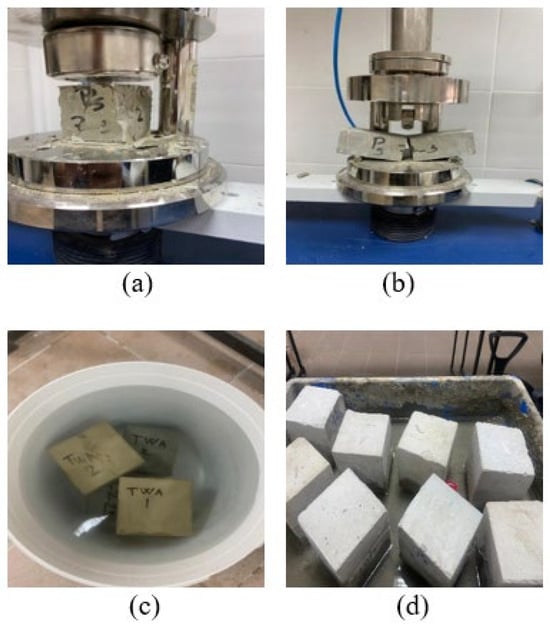

The density and compressive strength of pastes were measured using 50 × 50 × 50 mm3 cubes according to ASTM C138 [40] and ASTM C109 [41], respectively. The flexural strength test was conducted on 40 × 40 × 160 mm3 beams following ASTM C348 guidelines [42]. To predict the compressive strength over time, the hyperbolic model was used [43,44,45,46,47]. This model was effective in determining the initial rate (IRCS) and ultimate value (UCS) of the compressive strength. The hyperbolic function, which was solved using MATLAB software R2024, is represented as follows:

where

| Cs | = | compressive strength value (MPa) |

| t | = | curing age (days) |

| A | = | initial rate of compressive strength (IRCS) (MPa/day) |

| B | = | ultimate compressive strength (UCS) values (MPa) |

For the TWA test, 100 × 100 × 100 mm3 cubes were used following ASTM C1585 specifications [48]. The process included several steps. First, the specimens were cast, demolded, and then cured in the water at a controlled temperature of 24 °C until the testing date. During testing, the specimens were removed from the water and dried in an oven at 80 °C for 48 h until a constant weight was achieved, denoted as the dry weight (A). The specimens were then immersed in water for five minutes, removed, and their weight was recorded as the initial weight (B). This process was repeated at intervals of 10, 20, 60, 120, and 450 min. The percentage of total water absorption was calculated as per the following formula:

Regarding the CWA evaluation, 100 × 100 × 100 mm3 cubes were tested adhering to ASTM C1585 guidelines [48]. These cubes underwent the same curing process as previously performed and were subsequently dried. Upon removal from the oven, the cubes were sealed on four sides at a distance of 3 to 5 mm from the bottom surface, as depicted in Figure 3. The weight of the specimens was reported as W1, representing the dry weight. After one min of submersion, the cubes were taken out, wiped, and weighed as W2. This procedure was repeated at 3, 5, 10, 30, 60, 120, and 140 min and one, two, and three days. Using the obtained results, the CWA at each reading was determined as follows:

where

| W2 − W1 | = | Cumulative water absorption (kg) |

| A | = | Surface area of the cube through which water penetrates (m2) |

| d | = | Density of water (kg/m3) |

Figure 3.

All experimental tests: (a) compressive strength test; (b) flexural strength test; (c) TWA test; (d) CWA test.

2.5. Capillary-Diffusive Model (Cuba Model)

It is worth noting that sorptivity is the key parameter of water transport in concrete, representing the water uptake via capillary pores at early ages. Despite the ability of this main characteristic to evaluate the near-surface properties, it is crucial to study the water flow through very small pores at larger times for durability purposes, referred to as the diffusion mechanism [49,50]. The diffusion process fundamentally reflects the movement of water inside the matrix and can be measured over a couple of years, as asserted in a previous study that applied a three-year program to monitor the pore diffusion coefficients for concrete, cement paste, and mortar [50]. As reported in the literature review, a wide range of factors control the evolution of the flow of water through small or large pores, including the pore structure, the curing regime, and the preconditioning temperature [51,52,53]. More accurately, the curing in water promotes the refinement of the pores, thus resulting in a high level of impermeability, but this result is not found in the samples cured in open air [51,52]. Also, the sorptivity is improved with the elevation in the preconditioning temperature. This means that a dry specimen exposed to a temperature of 100 °C experiences greater capillary forces applied on its pores to allow the water to flow and that these are greater than a partially dried specimen at 50 °C. However, the variation in temperature does not affect the diffusion coefficients [52]. The capillary-diffusive model, also known as Cuba’s model, is used to predict both the sorptivity and diffusion processes [48], which can be used in various fields such as material science, environmental engineering, and soil science. The equation of the model is the summation of the mass per unit of area of water absorbed by capillarity and diffusion, which can be represented as

where

| M | = | mass of water absorbed (kg) |

| A | = | surface area of the cube through which water penetrates (m2) |

| C | = | constant linked to the distance from the concrete surface where the pores control the initial sorption (m) |

| ρ | = | density of the water (kg/m3) |

| S | = | sorptivity coefficient (kg/m2·s½) |

| t | = | time for recording the sorptivity (s) |

| C0 | = | invariance of water concentration (kg/m3) |

| L | = | sample depth (m) |

| D | = | diffusion coefficient (m2/s) |

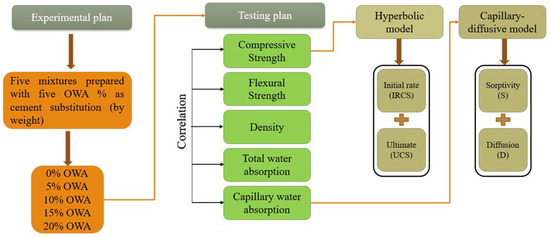

The flowchart of the experimental work is illustrated in Figure 4, noting that three replicates are prepared for each test.

Figure 4.

Flowchart of the experimental work.

3. Experimental Test Results and Analysis

3.1. Density

The density of the pastes containing various replacement percentages is depicted in Table 3. It is apparent that the presence of OWA slightly reduces the density of all samples, but these reductions are not significant (around 2.5%). For instance, the control mix records the highest density of 1938 kg/m3 at 90 days of curing. Over the same period, the density slightly decreases, reaching 1920, 1916, 1908, and 1892 kg/m3 for 5, 10, 15, and 20% OWA, respectively. Such behavior may be attributed to the lower density of OWA relative to ordinary cement, suggesting its suitability to produce lighter paving blocks, making them more efficient for handling and transportation, thereby speeding up project completion.

Table 3.

Density for all pastes.

3.2. Compressive Strength (CS)

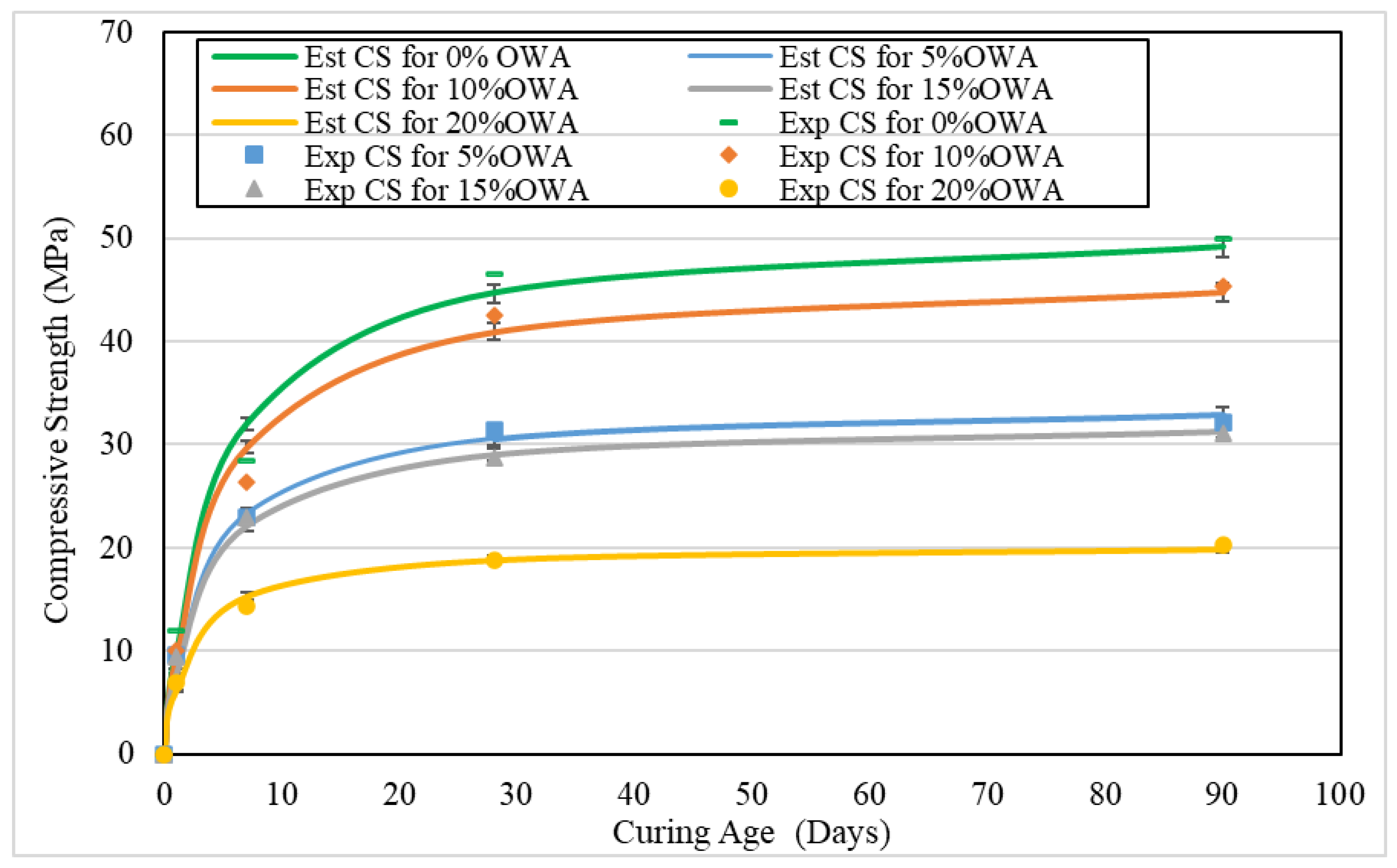

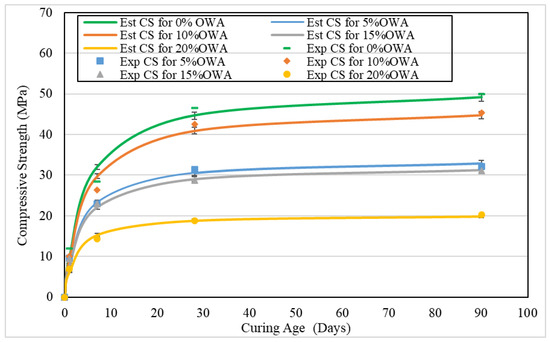

Figure 5 provides valuable insights into how the incorporation of OWA affects the compressive strength of the cement paste. As illustrated, the compressive strength increases with time in all samples. For instance, the compressive strength values for cement paste without OWA rise from 28 to 47 MPa between 7 and 28 days, followed by a further increase, reaching a measurement of 50 MPa at 90 days. Furthermore, the samples containing OWA show values lower than those for the reference cement paste. In the case of the addition of 5% OWA, the compressive strength value is 32 MPa at 90 days of curing, which is 36% lower than the control mixture. However, the rate of the drop is significantly reduced for the inclusion of 10% OWA, reaching about an 8% decline, corresponding to a compressive strength magnitude of 46 MPa. It appears from the chemical composition that OWA possesses two important properties: First, OWA exhibits some cementitious characteristics due to the presence of good amounts of CaO (36.13%) [13]. Second, OWA can be regarded as a pozzolanic material in light of the presence of SiO2 (24.7%) [36]. When OWA reacts with water, there is a formation of additional C-S-H gel, which is the main contributor to strength development [13,36]. Therefore, the incorporation of 10% OWA could be appropriate to generate the optimal compressive strength. On the other side, as the OWA substitution level exceeds 10%, especially at 15 and 20%, a significant reduction in compressive strength is noted. For instance, the 90-day compressive strength is recorded at 31 and 20 MPa, corresponding to a reduction of 38% and 60%, respectively, in comparison to the reference mixture. Generally, this decline is mostly due to two reasons. Firstly, the loss of the amount of cement contributes to a decrease in the amount of hydration products, such as dicalcium silicate (C2S) and tricalcium silicate (C3S), which are primarily responsible for strengthening the matrix [20]. Another possible reason is that as the proportions of OWA go up, the porosity of the body structure becomes greater, which is evidenced by the decrease in the density as witnessed earlier [20,28].

Figure 5.

Compressive strength of pastes (experimental and estimated).

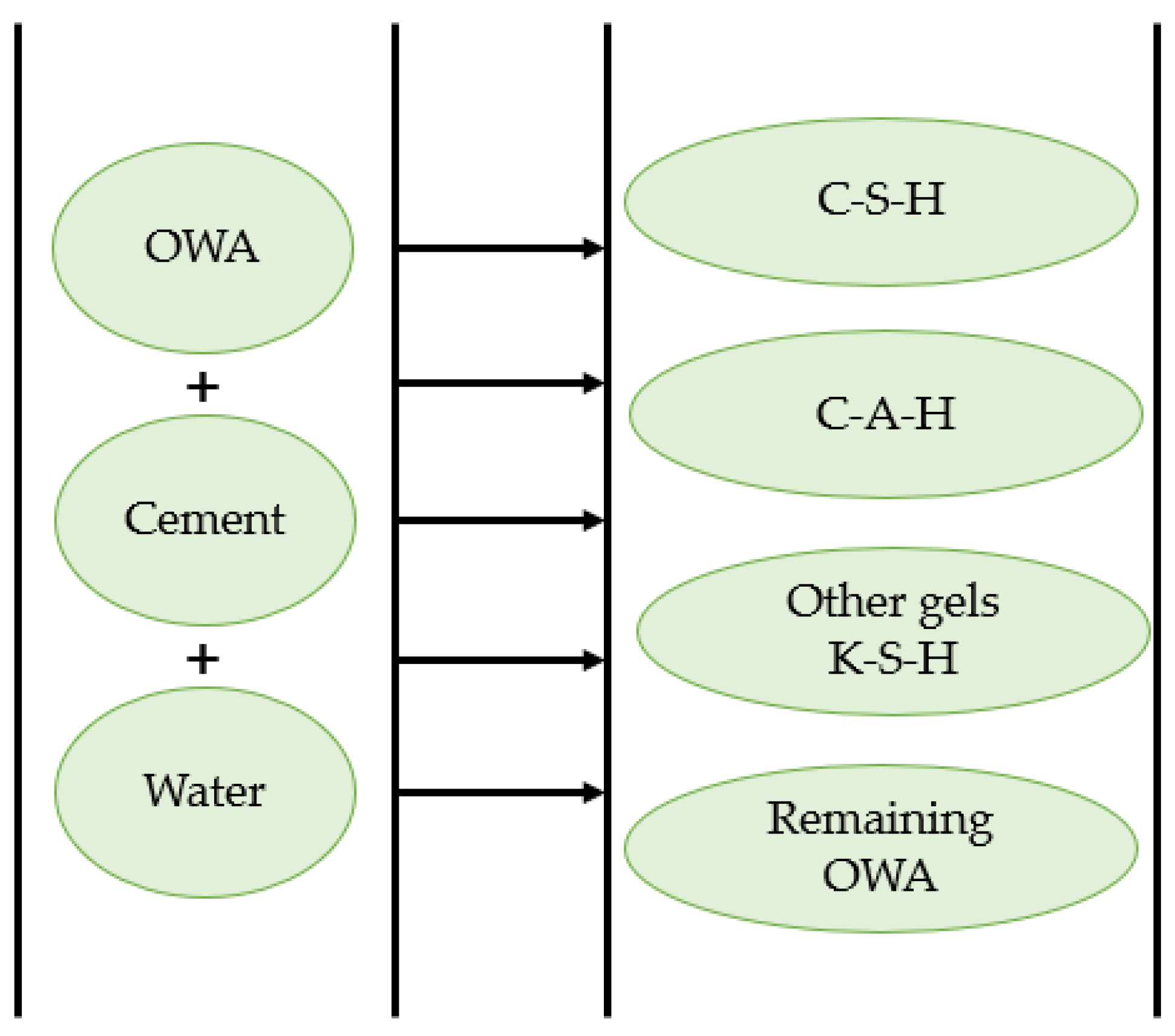

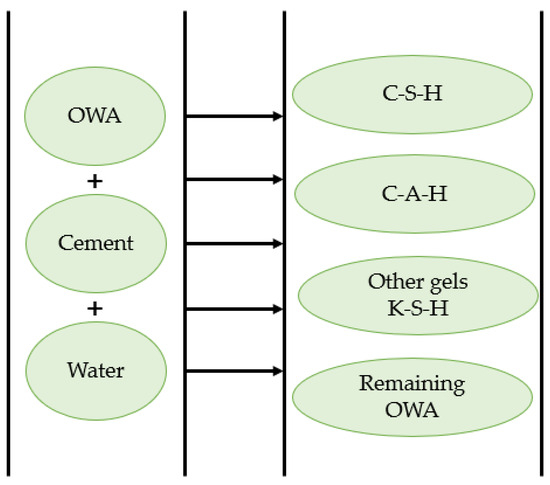

Determining the pozzolanic activity index (PAI) is imperative to emphasize that OWA undergoes pozzolanic reactivity. The PAI represents the ratio of compressive strength between OWA-based paste at diverse levels and the reference paste measured after 28 days of curing. At a substitution level of 10%, the PAI stands at 90%, satisfying the ASTM C618-00 guidelines [53]. This demonstrates that 10% OWA can achieve 90% of the compressive strength of the control mixture, validating that OWA is a pozzolanic material that generates additional hydration products responsible for strength gain. The set of chemical reactions between various mixture components is detailed in Figure 6.

Figure 6.

Set for chemical reactions between various mixture components.

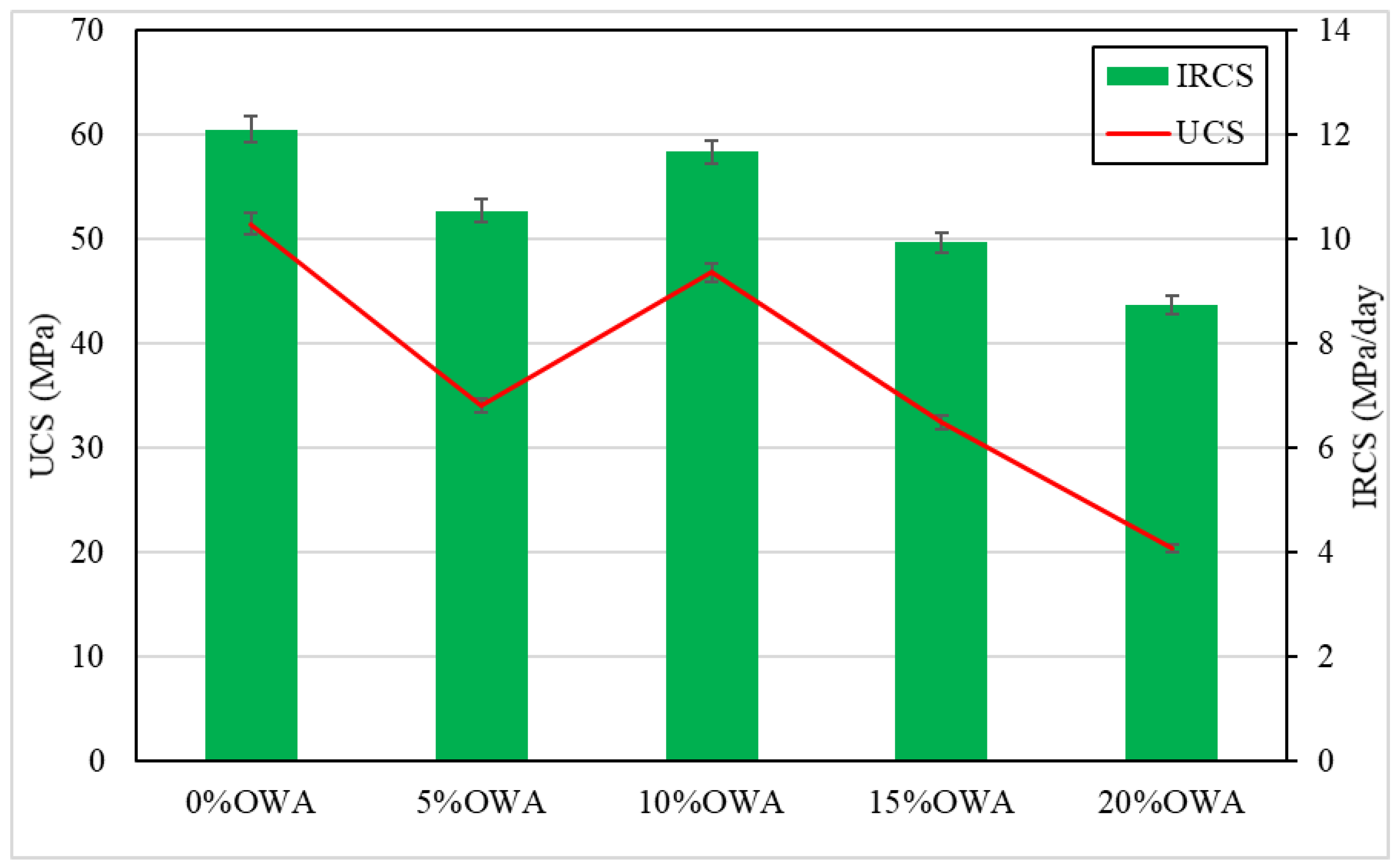

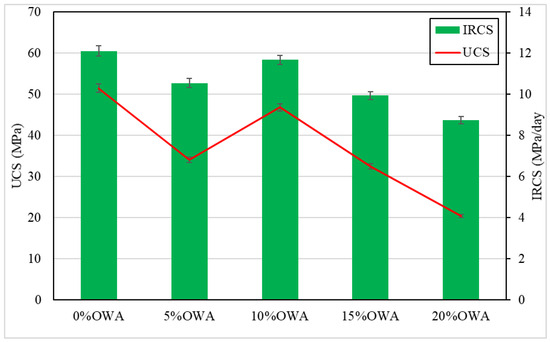

The hyperbolic model yields satisfactory results, demonstrating a strong agreement with the experimental data. The coefficient of determination (R2) is high, with values of 0.97, 0.99, 0.99, 0.99, and 0.98 for cement replacement of 0, 5, 10, 15, and 20% OWA, respectively. This mathematical model confirms its viability for practical applications in OWA-based matrices. Figure 7 displays the results of the IRCS and UCS values for each mixture. As seen, the IRCS values witness a consistent trend with that of the compressive strength analysis. For instance, relative to the control paste, there is a little decrease of 10% for the addition of 10% OWA. After this level, the samples containing 15% and 20% OWA show a more noticeable drop in IRCS, with declines of 23% and 33%, respectively. These fluctuations highlight OWA’s impact on the IRCS measurements. More precisely, as IRCS describes the strength gain at an early age, it can be deduced that OWA delays the hydration process and, thus, leads to a drop in IRCS values [20]. Similarly, the UCS characteristics followed a clear trend similar to the pattern for compressive strength. For instance, the control paste showed the highest UCS of 51 MPa among all mixtures. This value sharply drops for the inclusion of 5% OWA, reaching a magnitude of 34 MPa, which is equivalent to 33% relative to the reference paste. However, this reduction is followed by a significant growth in the compressive strength in the long-term period in the samples containing 10% of OWA. For example, the UCS value is 47 MPa, which corresponds to a slight loss of 8%. The UCS values drop again with the excessive addition of this ash. Particularly, the samples incorporating 15% and 20% of OWA show UCS values of 32 and 20 MPa, indicating average rates of 41% and 62% decline. This negative behavior in mechanical performance pertains to the excessive amount of OWA, which provides the matrix with a significant number of voids, weakening the long-term strength development [28]. All in all, it can be considered that 10% is the optimal level of cement substitution in terms of improving gains of compressive strength at an early age (IRCS) and in the long-term period (UCS) where the pozzolanic activity is effective for strength development. Therefore, this level is well-suited for several paving applications, including pedestrian sidewalks and light traffic zones.

Figure 7.

Evolution of compressive strength parameters (IRCS and UCS).

3.3. Flexural Strength

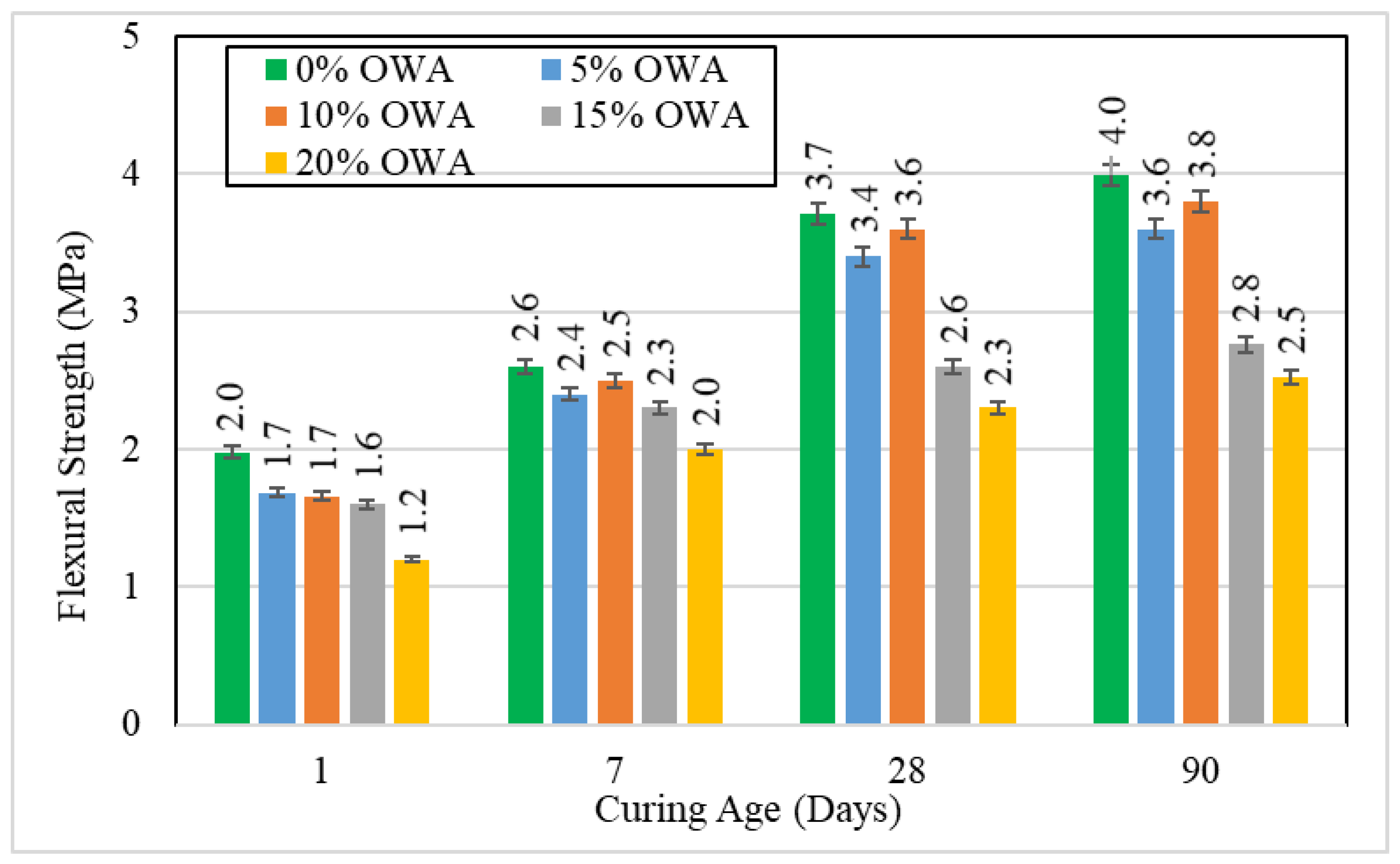

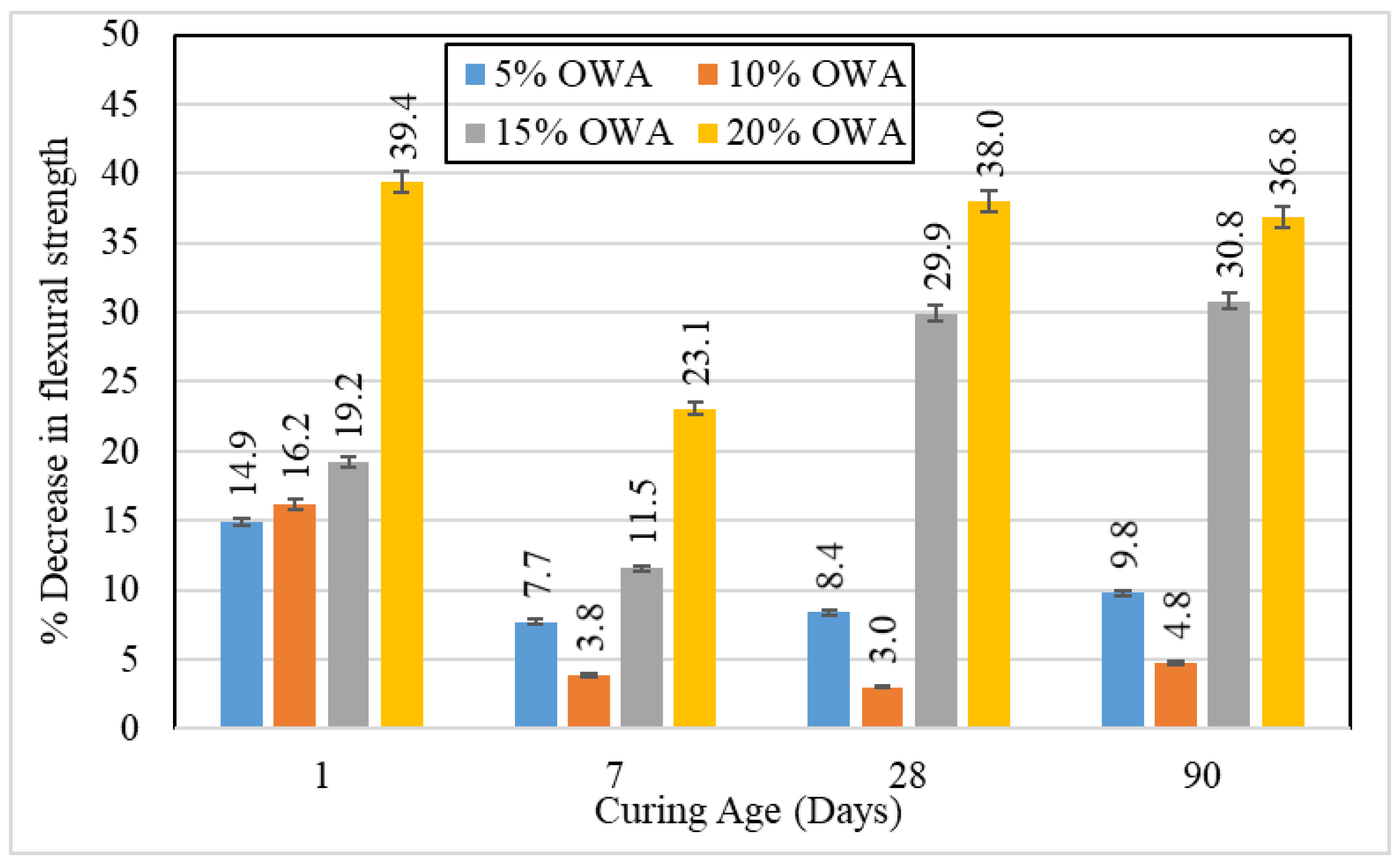

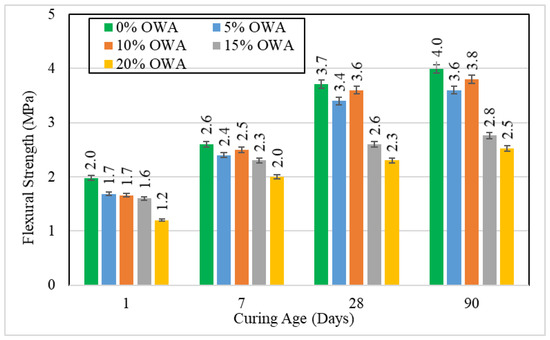

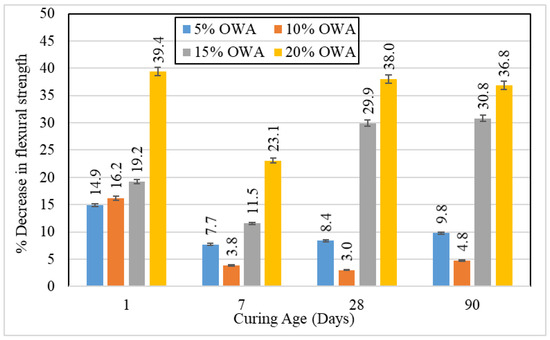

Figure 8 depicts the effect of OWA on the flexural strength of cement pastes for all partial replacement levels after 1, 7, 28, and 90 days. To further assess the evolution of the flexural strength in dependence on the control paste, the rates of variation in the strength are monitored in Figure 9. The trend in flexural strength aligns closely with the observed pattern of compressive strength. For instance, the 90-day flexural strength varies between 4 and 2.5 MPa for pastes regardless of OWA levels. The drop reaches its peak rate for the addition of 20%, having a rate of 37%. However, among all OWA mixtures, it is noticed that the paste containing 10% of OWA exhibits the highest value, showing the lowest decline rates of 3% and 5% after 28 and 90 days, respectively. The loss of flexural strength can be related to the reduced cement content in the mixture, which is required for reinforcing the material [28,29]. Another explanation for this decline is that this ash diminishes or weakens the bonding between OWA and the cement particles, which is accompanied by an increase in the number of voids in the paste [29].

Figure 8.

Evolution of flexural strength.

Figure 9.

Percentage decrease in flexural strength.

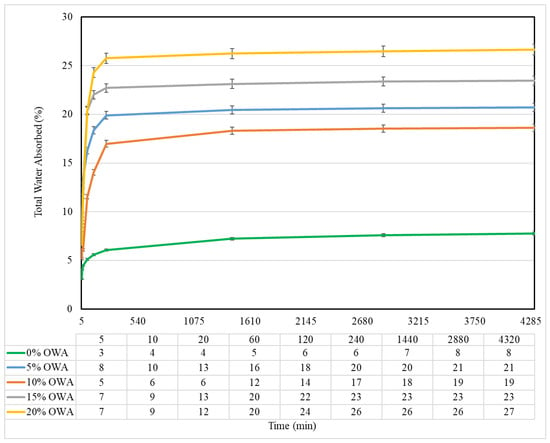

3.4. Total Water Absorption (TWA)

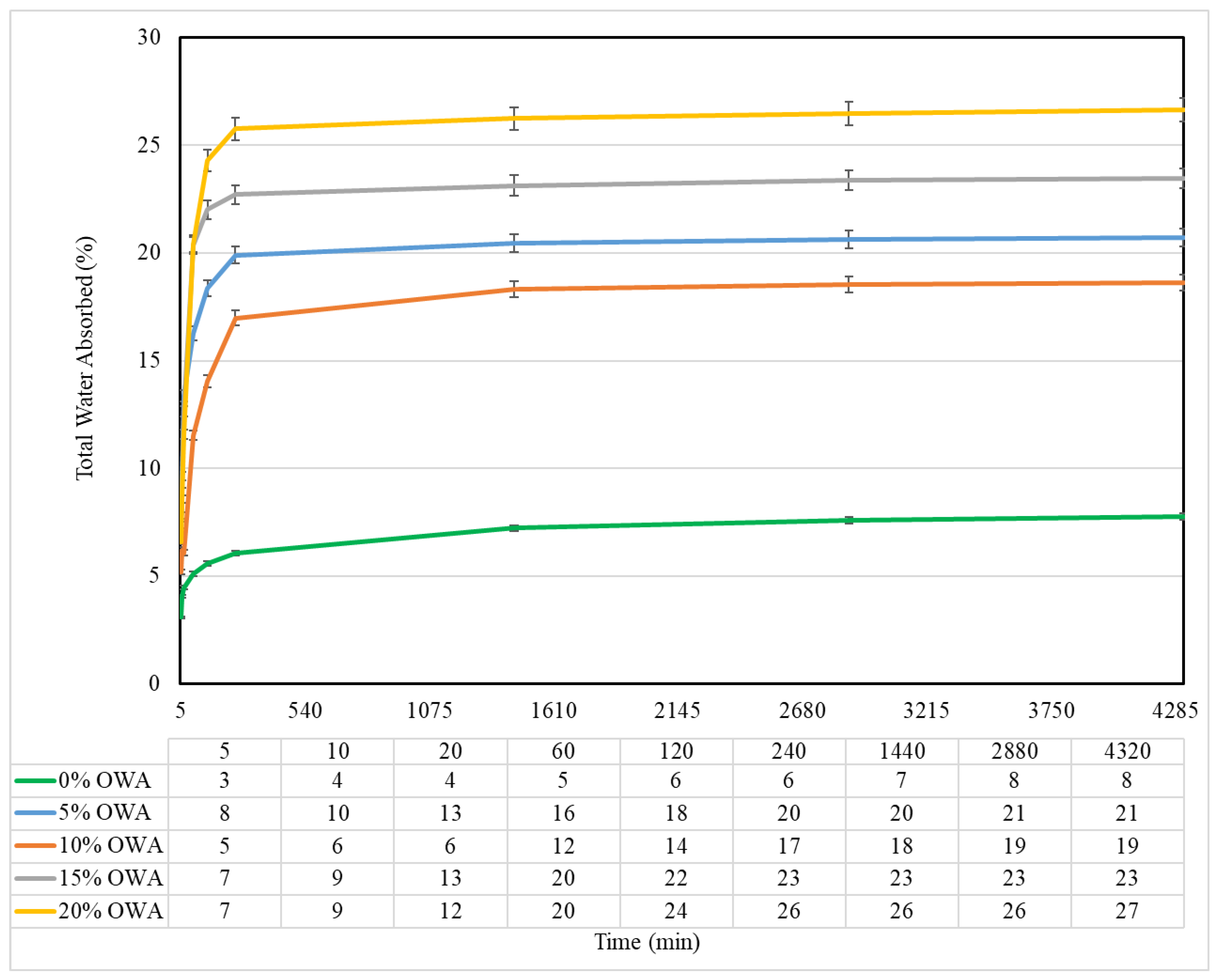

As illustrated in Figure 10, the control mixture shows the lowest TWA of 7.7% at 28 days. Subsequently, this value sharply rises at early ages as the OWA percentage changes. After 72 h of water immersion, the TWAs are 21%, 19%, 23%, and 27% for 5%, 10%, 15%, and 20% of OWA content, respectively. Compared to the reference paste, these numerical values correspond to growth rates of 169, 141, 205, and 246%, with 10% OWA demonstrating the lowest rate among the OWA-based pastes. It is worth noting that all specimens exhibit constant TWA measurements throughout the next three days. This signifies that the pores are filled with water, meaning that they are saturated, and no additional water can be absorbed [20]. It can be deduced that OWA has a detrimental influence on the water absorption of cement-based materials, as reported in the literature [20]. This high ability of OWA to absorb water can be attributed to two factors, including the porous structure and the lower specific gravity of OWA compared to ordinary cement. In detail, the incorporation of OWA in the cement paste increases the voids that are occupied by water, leading to greater total water absorption [13]. Moreover, the lower specific gravity of OWA entails a less dense matrix, and thereby, the interaction between water and lighter particles existent in OWA becomes more noticeable [13].

Figure 10.

Effect of OWA on TWA after 28 days.

3.5. Capillary Water Absorption (CWA)

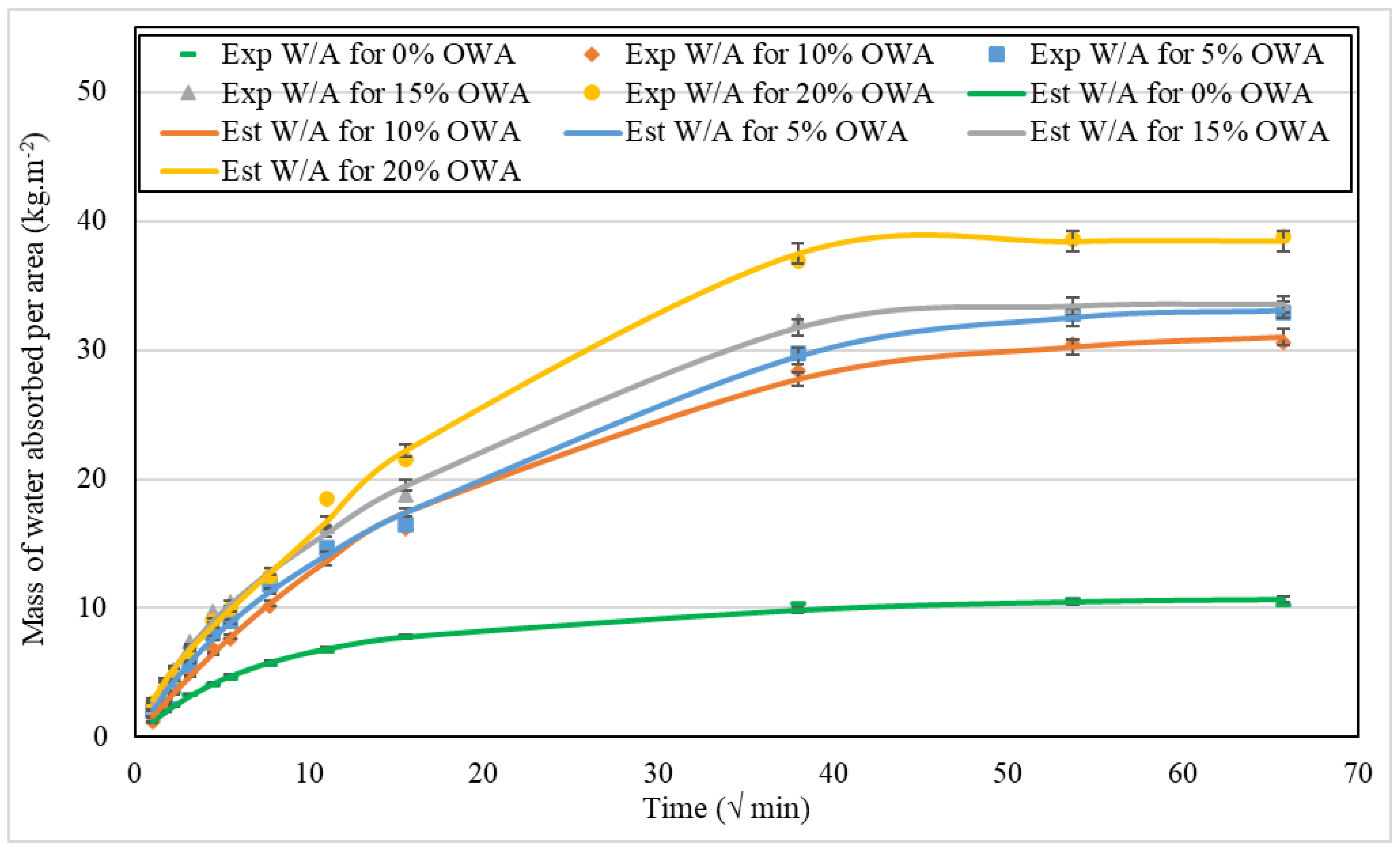

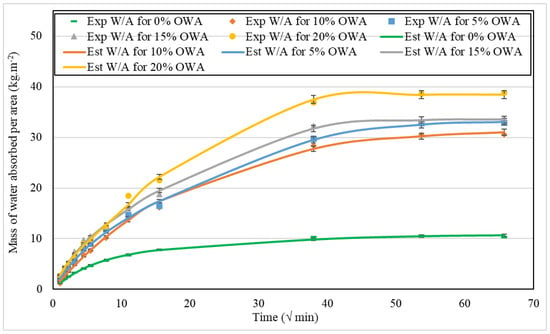

Figure 11 represents the measured and calculated mass of water absorbed per unit of area over 72 h versus the square root of time (t½) at 28 days. As elucidated in the curve, the control mixture exhibits the lowest mass of water-absorbed magnitude, standing at 10.3 kg/m2. With increasing OWA levels, the water absorption shows fluctuations. In the first 24 h, pastes with 5 and 10% OWA exhibit similar values for S and D. Nonetheless, after this period, a slight difference appears, with the lowest measurements noted in the 10% OWA paste. Beyond this level, the mass of water absorbed increases again to reach 38.8 kg/m2 for the samples of 20% OWA substitution, displaying the biggest rise of 270% compared to the reference specimen. Including excessive amounts of OWA accelerates water uptake by capillarity, with the best performance observed in 10% OWA pastes. This may be interpreted by the increased porosity observed in the paste, as shown in the density tests (decrease in the density). This explanation is proved by previous works indicating OWA’s impact on material porosity [13,51].

Figure 11.

Mass of water absorbed per unit of area after 28 days (Experimental and Estimated).

Furthermore, the proposed capillary-diffusive model accurately predicts the mass of absorbed water per unit of area, yielding a high degree of correlation between the estimated and the experimental data. In particular, the coefficient of determination (R2) is approximately 0.99 for all replacement levels after 28 days of curing.

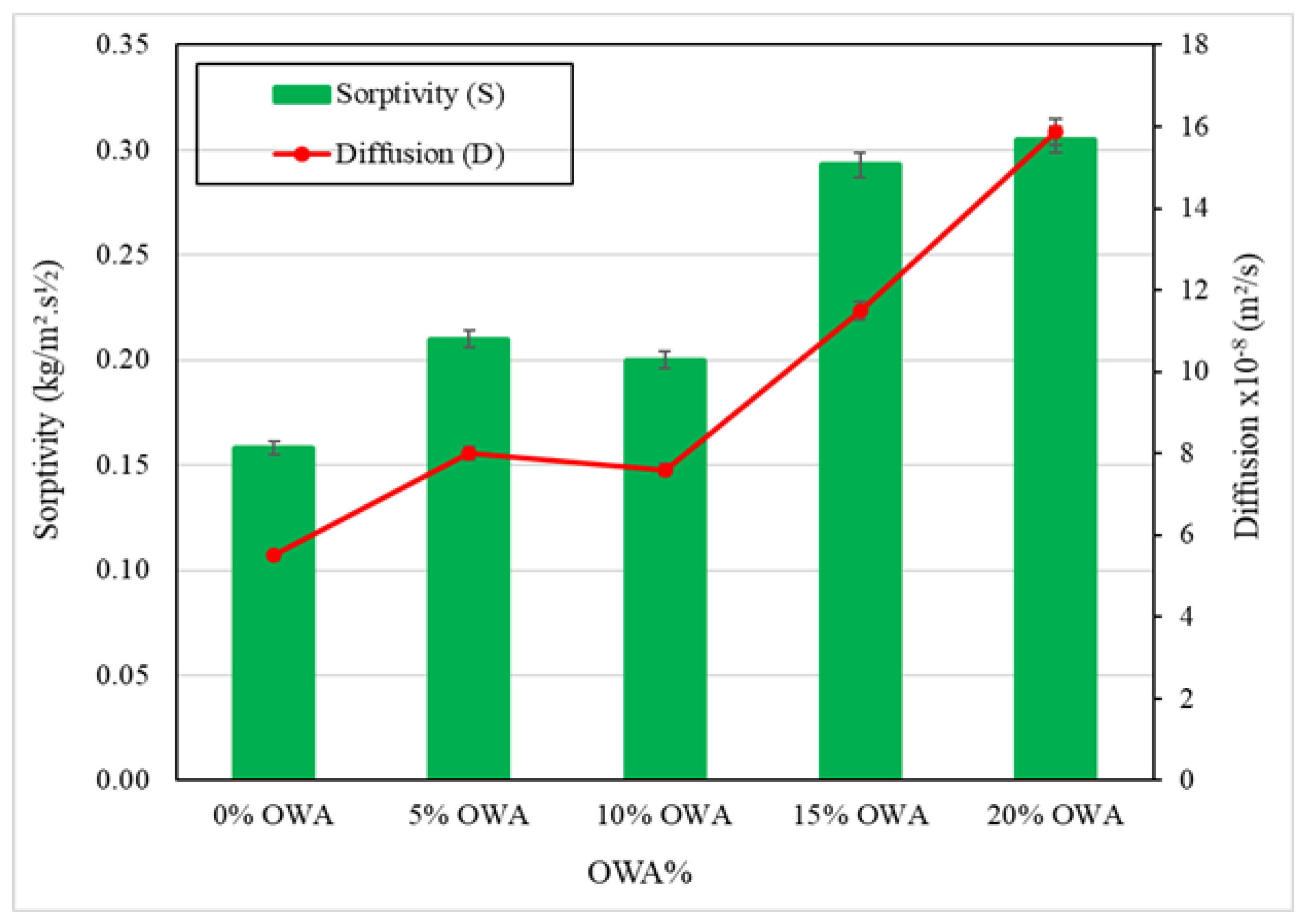

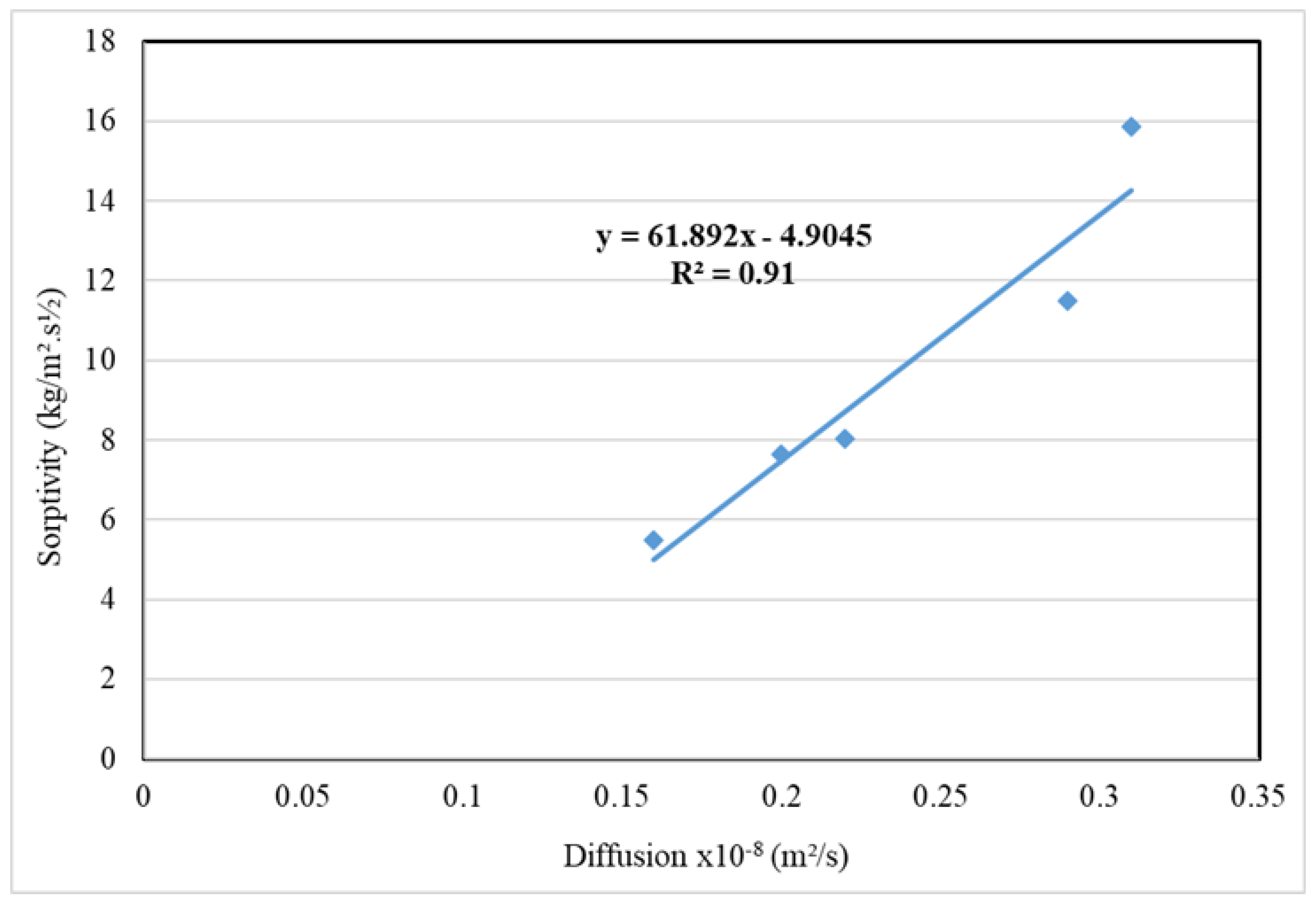

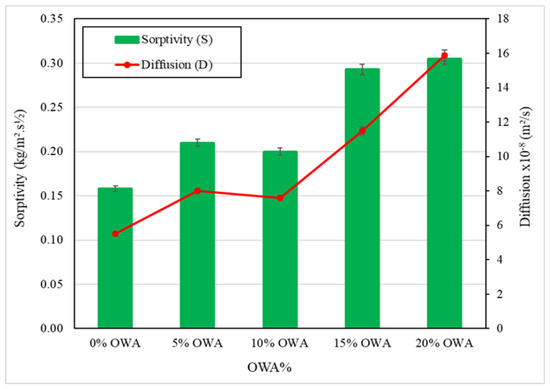

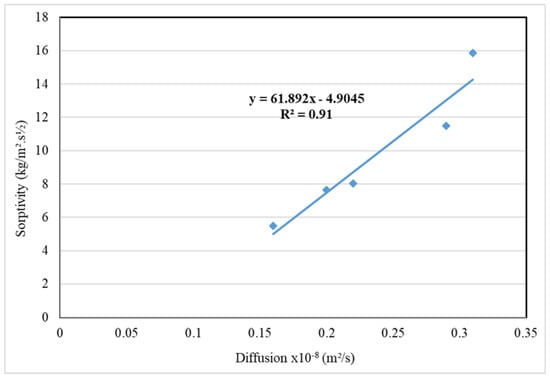

The results of the capillary-diffusive model are presented in Table 4. The evolution of both sorptivity (S) and diffusion (D) on day 28 is illustrated in Figure 12. All samples follow the same trend as for CWA analysis, meaning that S and D behave identically to CWA. Due to the diffusion mechanism, the water continues to flow through the capillary pores after it has been absorbed, hence justifying the strong relationship between those two characteristics (S and D) [54]. To further visualize the link between S and D, a regression equation is calculated, indicating a high coefficient of determination R2 = 0.91, as inferred in Figure 13.

Table 4.

Parameters for all mixes after 28 days.

Figure 12.

Evolution of sorptivity and diffusion at 28 days.

Figure 13.

Correlation between diffusion and sorptivity at 28 days.

As observed from the curve, the reference sample records the lowest sorptivity and diffusion across all mixtures. More precisely, the S and D values recorded for the reference specimen are 0.158 kg/m2·s½ and 5.5 × 10−8 m2/s after 72 h. As the percentage of OWA rises, these two variables fluctuate, achieving optimal performance for 10% OWA pastes. Beyond this threshold, S and D increase again with the highest magnitudes of 0.305 kg/m2·s½ and 1.59 × 10−8 m2/s for the sample made with 20% OWA. This is equivalent to growth rates of 92% and 180%, respectively, relative to the control paste.

Such increase is primarily due to the porous nature of OWA, which makes the paste become more integrated with pores (increased porosity), thus leading to a greater water uptake [13]. In addition, the rise in D values suggests that OWA may accelerate the diffusion of water, promoting the ease with which water can pass through the paste. This water absorption behavior is identical to that observed when using banana leaf ash. However, rice husk ash contributes to the reduction in permeability. All in all, OWA can be a major contributor to facilitating the passage of water through capillary action and diffusion, thus leading to the formation of a paste that absorbs water quickly near the surface and promotes water penetration in the deeper layers [49,50,51]. In such scenarios, OWA-based paving blocks with high water absorption capabilities can be ideal in permeable pavement systems, limiting surface runoff and refilling groundwater. However, these blocks can be applied in water-intensive infrastructure projects such as rain gardens and pooling areas. This positions OWA-based paving blocks as a challenging solution for tackling water management practices, particularly at 10% OWA.

3.6. Comparison with Other Agricultural Ashes

The results of this investigation demonstrate significant pozzolanic activity, particularly at a 10% replacement level, showing slight reductions of 8% and 5% in compressive and flexural strength, respectively. The density values exhibit a marginal decrease, reaching an ultimate decline of 2.5% at higher OWA content. Nevertheless, OWA contributes to an augmentation in the porosity of the mixture, leading to increased water absorption.

A comparative analysis was conducted between OWA and other agricultural ashes, chosen for their comparable impact on the mechanical and durability performance of paving blocks, to contextualize these findings. Bamboo leaf ash exhibits comparable water absorption characteristics to OWA-based matrices [9,10]. This mechanism is mostly attributed to the introduction of more pores into the matrices [9,10]. Conversely, date palm ash shows stronger adverse impacts, reducing mechanical properties by 20% at a 20% cement replacement level, which is more pronounced than the decreases noted with OWA [11]. Nonetheless, date palm ash exhibits a high resistance against elevated temperatures, providing a stable cementitious composite and diminishing the vulnerability to thermal cracking [11]. Similarly to OWA, rice husk ash produces a cement paste with reduced density [12]. Corn cob ash exhibits fluctuations in strength findings depending on the substitution percentages [8]. More precisely, this byproduct improves the compressive strength by 25% at a substitution level of up to 10%, while beyond this threshold, the trend reverses, showcasing a drop in this property [8]. Furthermore, corn cob ash facilitates water transport by 20% at higher replacement levels, accompanied by a 15% decline in density compared to the control mixture [8]. Similarly, the inclusion of OWA is vital in enhancing moisture transport, making it an essential element for maintaining the moisture levels required for proper cement hydration.

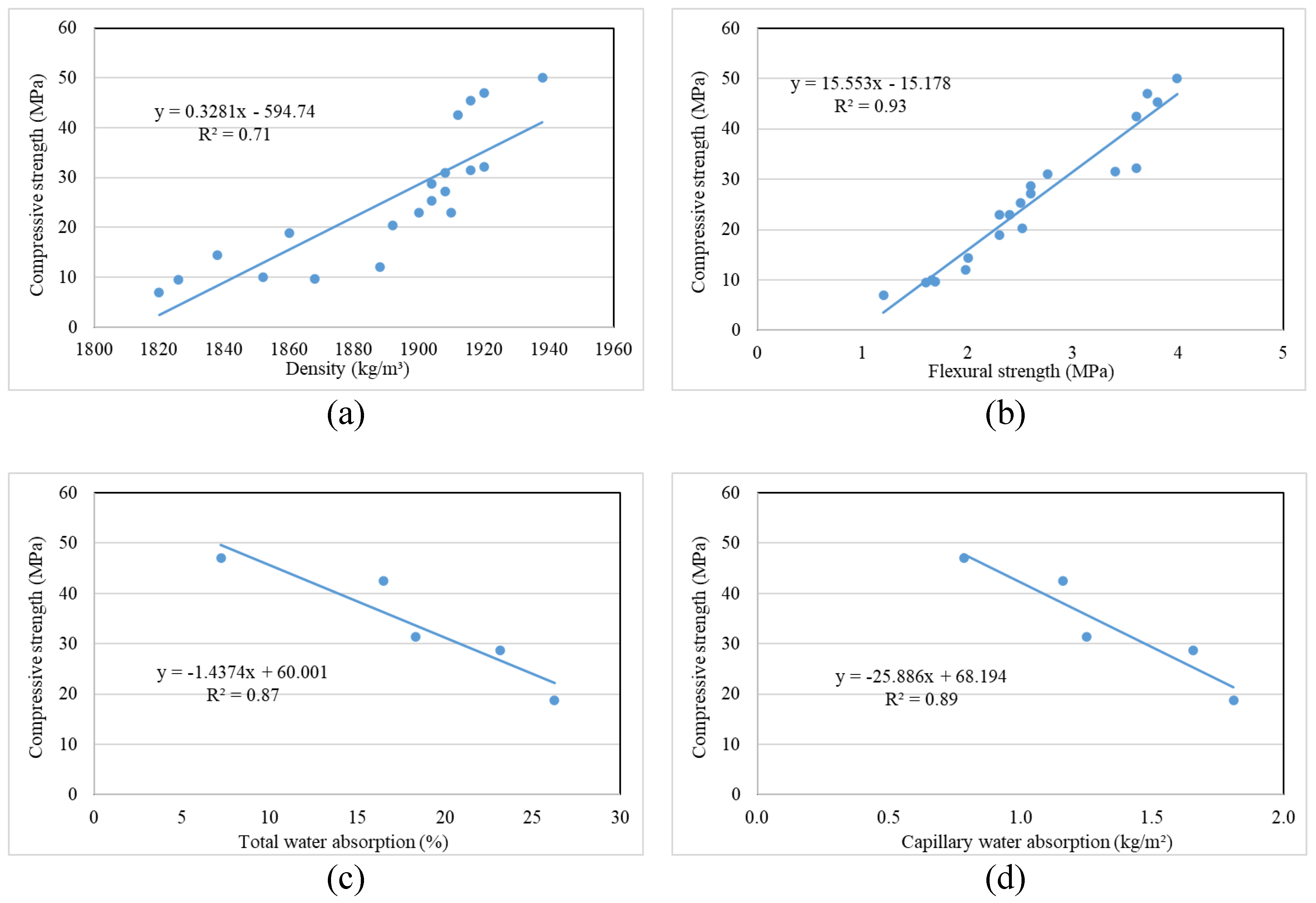

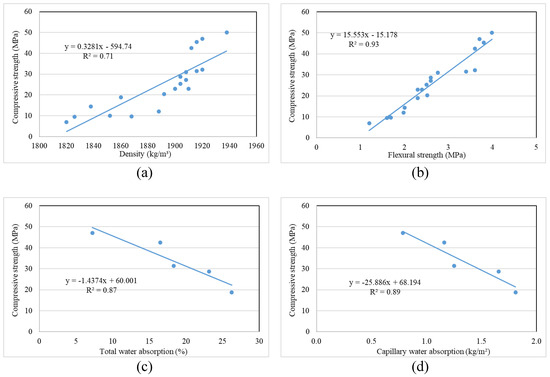

4. Correlations Between Different Properties

Figure 14 shows the correlations between compressive strength and different properties for all samples at all curing days. As seen, there is a positive linear relation between the compressive strength and the density, with high coefficient of determination values ranging from 0.85 to 0.92. This strong correlation is probably related to the fact that a reduction in density leads to a loss in compressive strength [2]. Similarly, the compressive strength has high agreement with the flexural strength, indicated by high R2 values exceeding 90%. This is consistent with the findings of a prior study [55]. This excellent agreement refers to the fact that both compressive and flexural strength work together to effectively resist the different stresses in materials, such as compressive and tensile stresses [55,56]. In other words, the enhancement of the material’s ability to endure compressive stresses means there is also an improvement in its capability to handle bending or tensile stresses [55,56]. Conversely, a negative linear correlation is noticed between compressive strength and TWA, with a higher TWA leading to lower compressive strength due to the introduction of more voids and a delayed hydration process [27,57,58]. Similarly, an adverse correlation exists between compressive strength and CWA, proving that the absorption of water by capillarity weakens the strength of the matrix [28]. All in all, the porosity, the density of the matrix, the absorption of water, and the pozzolanic activity of OWA can identify a good combination that describes the evolution of the compressive strength.

Figure 14.

Correlation between compressive strength and: (a) flexural strength; (b) density; (c) TWA; (d) CWA.

5. Discussion

This study underscores the effect of OWA used as an alternative to cement on the physical, mechanical, and water absorption properties of cement paste for paving block applications. The findings indicate that although OWA reduces compressive strength and increases water absorption, incorporating 10% OWA provides an optimal balance between strength and durability.

In terms of strength, the drop in compressive strength is primarily attributed to the loss of hydration products such as C-S-H gel, which plays a vital role in strength gain. Nevertheless, incorporating 10% as cement replacement exhibits a minimal reduction in compressive strength due to the achievement of sufficient pozzolanic activity that compensates for the removal of cement. This demonstrates that 10% is the optimal replacement level, maintaining the mechanical performance. Similarly, replacing cement with rice husk ash and bamboo leaf ash slightly reduces compressive strength at lower percentages [59,60].

In terms of durability, OWA contributes to a progressive increase in water absorption measurements. This growth is likely related to the fact that OWA is a porous body that leads to the introduction of more voids in the mixture. Among all OWA-based cement pastes, 10% OWA presents the lowest increase percentage in water absorption, ensuring tolerable durability performance in paving blocks.

In terms of practical implications, integrating OWA into paving blocks seems beneficial in limiting cement consumption and valorizing agricultural-based wastes. Furthermore, the lower density of OWA-based cement pastes leads to the production of lighter paving blocks, facilitating transportation and accelerating construction. Nonetheless, the augmentation in water absorption can be treated by providing additional sealant and coatings, especially in regions highly vulnerable to moisture.

Even though the results are promising, this study presents certain limitations in distinct fields. The current investigation concentrates on the short-term strength and durability characteristics of cement paste containing OWA. Future studies must be conducted on the long-term behavior of OWA-incorporated paving blocks under severe environmental conditions, including freeze–thaw cycles and sulfate attacks. Moreover, it is essential to evaluate the effect of OWA on the volume stability characteristics of paving systems alongside microstructural analysis to deeply comprehend the modified hydration process and porosity caused by OWA.

6. Conclusions

The current research investigates the application of olive waste ash (OWA), produced from burning pomace—a byproduct generated during olive oil extraction—as a partial cement substitute in pavement systems. For this issue, physical properties such as density, total water absorption (TWA), and capillary water absorption (CWA) coefficient, along with mechanical properties such as the compressive strength and flexural strength of the cement paste, are evaluated. In light of the findings, the following conclusions can be made:

- The inclusion of OWA slightly reduces the compressive strength, with optimal performance at 10% OWA, exhibiting only an 8% decrease compared to the control mixture. This suggests that paving blocks made with 10% OWA can perform well in infrastructure practices, including pedestrian sidewalks and low-traffic volume paved surfaces, attributed to their sufficient compressive strength.

- The density of all specimens marginally drops with increasing OWA content, achieving a reduction of about 2.5% at 20% OWA relative to the reference paste. This results in lighter paving blocks, which are more efficient in terms of transportation and handling.

- The addition of OWA results in a decrease in flexural strength regardless of the amount induced. However, the incorporation of 10% OWA leads to a flexural strength magnitude comparable to the control mixture, with only a 3% reduction, rendering it a perfect choice for sidewalks and pedestrian areas.

- After 28 days of curing, OWA significantly increases water absorption, with the lowest growth observed at 10% OWA. This increase highlights the appropriateness of OWA-based paving blocks for use in permeable pavement systems, water pooling, and rain gardens.

- Both hyperbolic and capillary-diffusive models accurately validate compressive strength and water absorption characteristics, reinforcing their utility in optimizing the material properties of paving blocks.

- There are strong correlations between compressive strength, density, and flexural strength, while a negative linear relationship exists between compressive strength and water absorption.

Replacing 10% of traditional cement with OWA demonstrates satisfactory mechanical and durability performance in cement paste, positioning it as a promising green material for further exploration in paving block applications. Although this work concentrates on cement paste, which serves as the binding component in mortar and concrete, expanding the scope to assess the effect of OWA on the mechanical and durability of these cement-based systems in practical applications could be valuable. This approach reduces environmental impact and contributes to cost efficiency through waste valorization; nevertheless, further investigation should examine the life-cycle assessment or cost–benefit analysis to quantify these benefits. Moreover, the results highlight that OWA could also offer new possibilities for broader infrastructure applications, including pedestrian sidewalks, garden pathways, light-traffic zones, and landscaping projects, where its sustainable characteristics can be leveraged to develop resilient, low-carbon construction solutions. To confirm its feasibility in paving blocks, future studies should assess actual paving block mixtures, considering the effect of aggregates and manufacturing techniques such as vibro-compaction. Furthermore, future research should evaluate the long-term durability of extensive infrastructure projects, especially in regions vulnerable to freeze–thaw cycles.

Author Contributions

Conceptualization, J.K. and H.G.; methodology, S.G. and H.G.; formal analysis, S.G. and H.G.; writing—original draft preparation, S.G., A.E. and H.G.; writing—review and editing, H.G. and S.C.; supervision, J.K. and A.E.; project administration, H.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are included in this paper.

Acknowledgments

The authors express their gratitude for the assistance provided by the staff and technicians at BAU Laboratories.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bilir, T.; Aygun, B.F.; Shi, J.; Gencel, O.; Ozbakkaloglu, T. Influence of different types of wastes on mechanical and durability properties of interlocking concrete block paving (ICBP): A review. Sustainability 2022, 14, 3733. [Google Scholar] [CrossRef]

- Busari, A.A.; Loto, R.T.; Ajayi, S.; Oluwajana, S.D.; Eletu, A. Development of sustainable interlocking concrete paving blocks using bamboo leaf ash and metakaolin. Heliyon 2024, 10, e31845. [Google Scholar] [CrossRef] [PubMed]

- Duppati, S.; Gopi, R. Strength and durability studies on paver blocks with rice straw ash as partial replacement of cement. Mater. Today Proc. 2022, 52, 710–715. [Google Scholar] [CrossRef]

- Wang, X.; Chin, C.S.; Xia, J. Material characterization for sustainable concrete paving blocks. Appl. Sci. 2019, 9, 1197. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Adak, D. Roadmap to a net-zero carbon cement sector: Strategies, innovations and policy imperatives. J. Environ. Manag. 2024, 359, 121052. [Google Scholar] [CrossRef]

- Bello, A.S.; Al-Ghouti, M.A.; Abu-Dieyeh, M.H. Sustainable and long-term management of municipal solid waste: A review. Bioresour. Technol. Rep. 2022, 18, 101067. [Google Scholar] [CrossRef]

- Ferreira, C.; Ribeiro, A.; Ottosen, L. Possible applications for municipal solid waste fly ash. J. Hazard. Mater. 2003, 96, 201–216. [Google Scholar] [CrossRef]

- Fava, G.; Naik, T.R.; Pierpaoli, M. Compressive strength and leaching behavior of mortars with biomass ash. Recycling 2018, 3, 46. [Google Scholar] [CrossRef]

- Frías, M.; Savastano, H.; Villar, E.; de Rojas, M.I.S.; Santos, S. Characterization and properties of blended cement matrices containing activated bamboo leaf wastes. Cem. Concr. Compos. 2012, 34, 1019–1023. [Google Scholar] [CrossRef]

- Umoh, A.A.; Odesola, I.A. Characteristics of Bamboo Leaf Ash Blended Cement Paste and Mortar. Civ. Eng. Dimens. 2015, 17, 22–28. [Google Scholar] [CrossRef][Green Version]

- Blaisi, N.I. Environmental assessment of utilizing date palm ash as partial replacement of cement in mortar. J. Hazard. Mater. 2018, 357, 175–179. [Google Scholar] [CrossRef] [PubMed]

- Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Alaskar, A. Recycling of rice husk waste for a sustainable concrete: A critical review. J. Clean. Prod. 2021, 312, 127734. [Google Scholar] [CrossRef]

- Ghanem, H.; Bouz, C.E.; Ramadan, R.; Trad, A.; Khatib, J.; Elkordi, A. Effect of Incorporating Cement and Olive Waste Ash on the Mechanical Properties of Rammed Earth Block. Infrastructures 2024, 9, 122. [Google Scholar] [CrossRef]

- Maddalena, R.; Roberts, J.J.; Hamilton, A. Can Portland cement be replaced by low-carbon alternative materials? A study on the thermal properties and carbon emissions of innovative cements. J. Clean. Prod. 2018, 186, 933–942. [Google Scholar] [CrossRef]

- Chalikias, M.S.; Kyriakopoulos, G.; Kolovos, K.G. Environmental sustainability and financial feasibility evaluation of woodfuel biomass used for a potential replacement of conventional space heating sources. Part I: A Greek case study. Oper. Res. 2010, 10, 43–56. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Rosales, J.; Beltrán, M.G.; Cabrera, M.; Velasco, A.; Agrela, F. Feasible use of biomass bottom ash as addition in the manufacture of lightweight recycled concrete. Waste Biomass Valorization 2016, 7, 953–963. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Tayeh, B.A.; Aisheh, Y.I.A.; Salih, M.N.A. Utilising olive-stone biomass ash and examining its effect on green concrete: A review paper. J. Mater. Res. Technol. 2023, 24, 7091–7107. [Google Scholar] [CrossRef]

- Vourdoubas, J. Possibilities of creating zero CO2 emissions olive pomace plants due to energy use in Crete, Greece. Open J. Energy Effic. 2016, 5, 78–87. [Google Scholar] [CrossRef][Green Version]

- Barreca, F.; Fichera, C.R. Use of olive stone as an additive in cement lime mortar to improve thermal insulation. Energy Build. 2013, 62, 507–513. [Google Scholar] [CrossRef]

- Cheboub, T.; Senhadji, Y.; Khelafi, H.; Escadeillas, G. Investigation of the engineering properties of environmentally-friendly self-compacting lightweight mortar containing olive kernel shells as aggregate. J. Clean. Prod. 2020, 249, 119406. [Google Scholar] [CrossRef]

- Antoun, M.; Issa, C.A.; Aouad, G.; Gerges, N. Sustainable masonry blocks: Olive wood waste as substitute for fine aggregates. Case Stud. Constr. Mater. 2021, 15, e00590. [Google Scholar] [CrossRef]

- Alkheder, S.; Obaidat, Y.T.; Taamneh, M. Effect of olive waste (Husk) on behavior of cement paste. Case Stud. Constr. Mater. 2016, 5, 19–25. [Google Scholar] [CrossRef]

- Ghazzawi, S.; Ghanem, H.; El-Zahab, S.; Khatib, J.; Elkordi, A. Effect of Olive Waste Ash as a partial replacement of cement on volume stability of cement paste. Infrastructures 2024, 9, 193. [Google Scholar] [CrossRef]

- Di Giacomo, G.; Romano, P. Evolution of the olive oil industry along the entire production chain and related waste management. Energies 2022, 15, 465. [Google Scholar] [CrossRef]

- de Moraes Pinheiro, S.M.; Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Olive-stone biomass ash (OBA): An alternative alkaline source for the blast furnace slag activation. Constr. Build. Mater. 2018, 178, 327–338. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Al-Akhras, K.M.; Attom, M.F. Performance of olive waste ash concrete exposed to elevated temperatures. Fire Saf. J. 2009, 44, 370–375. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hadzima-Nyarko, M.; Zeyad, A.M.; Al-Harazin, S.Z. Properties and durability of concrete with olive waste ash as a partial cement replacement. Adv. Concr. Constr. 2021, 11, 59–71. [Google Scholar] [CrossRef]

- Adwan, O.K.; Maraqa, F.R. Utilisation of olive mill waste and coal ashes in normal concrete mixes. Asian J. Sci. Technol. 2019, 10, 9348–9352. [Google Scholar] [CrossRef]

- Eisa, A. Properties of concrete incorporating recycled post-consumer environmental wastes. Int. J. Concr. Struct. Mater. 2014, 8, 251–258. [Google Scholar] [CrossRef]

- Rosales, M.; Rosales, J.; Agrela, F.; de Rojas, M.S.; Cabrera, M. Design of a new eco-hybrid cement for concrete pavement, made with processed mixed recycled aggregates and olive biomass bottom ash as supplementary cement materials. Constr. Build. Mater. 2022, 358, 129417. [Google Scholar] [CrossRef]

- Cuenca, J.; Rodríguez, J.; Martín-Morales, M.; Sánchez-Roldán, Z.; Zamorano, M. Effects of olive residue biomass fly ash as filler in self-compacting concrete. Constr. Build. Mater. 2013, 40, 702–709. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Leite-Costa, J. Use of bottom ash from olive pomace combustion in the production of eco-friendly fired clay bricks. Waste Manag. 2016, 48, 323–333. [Google Scholar] [CrossRef]

- Pérez-Villarejo, L.; Eliche-Quesada, D.; Carrasco-Hurtado, B.; Sánchez-Soto, P.J. Valorization of olive biomass fly ash for production eco friendly ceramic bricks. Encycl. Renew. Sustain. Mater. 2020, 5, 285–294. [Google Scholar] [CrossRef]

- Arabani, M.; Hassanjani, M.H.; Farkhondeh, J.; Taleghani, M.Y. Enhancing mechanical properties of hot mix asphalt with olive kernel ash: A sustainable modifier. Constr. Build. Mater. 2024, 451, 138740. [Google Scholar] [CrossRef]

- Cabrera, M.; Rosales, J.; Ayuso, J.; Estaire, J.; Agrela, F. Feasibility of using olive biomass bottom ash in the sub-bases of roads and rural paths. Constr. Build. Mater. 2018, 181, 266–275. [Google Scholar]

- Dahim, M.A.; Abuaddous, M.; Al-Mattarneh, H.; Alluqmani, A.E.; Ismail, R. The use of olive waste for development sustainable rigid pavement concrete material. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2022; Volume 1212, p. 012032. [Google Scholar] [CrossRef]

- Camilo, E.P.; Beltrán, R.C.; Expósito, J.J.V.; Toledo, G.E.P.; Iglesias, F.A.C. Study of olive pomace bottom ashes as a sustainable alkaline activator in the syntesis of geopolymers. J. Build. Eng. 2025, 104, 112383. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Bayagoob, K.H.; Amin, M.; Tayeh, B.A.; Mostafa, S.A.; Agwa, I.S. Effect of olive waste ash on the properties of high-strength geopolymer concrete. Struct. Concr. 2024. [Google Scholar] [CrossRef]

- ASTM, C.138; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM, C109/C109M-16a; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM, C348-02; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2002.

- Ghanem, H.; Ramadan, R.; Khatib, J.; Elkordi, A. Volume Stability and Mechanical Properties of Cement Paste Containing Natural Fibers from Phragmites-Australis Plant at Elevated Temperature. Buildings 2024, 14, 1170. [Google Scholar] [CrossRef]

- Ramadan, R.; Ghanem, H.; Khatib, J.M.; ElKordi, A.M. Effect of Plant-based natural fibers on the mechanical properties and volume change of cement paste. Int. J. Build. Pathol. Adapt. 2024. [Google Scholar] [CrossRef]

- Khatib, J.; Ramadan, R.; Ghanem, H.; Elkordi, A. Effect of adding Phragmites-Australis Fiber on the mechanical properties and volume stability of mortar. Fibers 2024, 12, 14. [Google Scholar] [CrossRef]

- Ghanem, H.; Ramadan, R.; Khatib, J.; Elkordi, A. A review on chemical and autogenous shrinkage of cementitious systems. Materials 2024, 17, 283. [Google Scholar] [CrossRef]

- Khatib, J.M.; Ramadan, R.; Ghanem, H.; Elkordi, A.; Sonebi, M. Effect of limestone fines as a partial replacement of cement on the chemical, autogenous, drying shrinkage and expansion of mortars. Mater. Today Proc. 2022, 58, 1199–1204. [Google Scholar] [CrossRef]

- ASTM, C1585; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013.

- Neithalath, N. Evaluating the short-and long-term moisture transport phenomena in lightweight aggregate concretes. Mag. Concr. Res. 2007, 59, 435–445. [Google Scholar] [CrossRef]

- Fleury, M.; Chevalier, T.; Berthe, G.; Dridi, W.; Adadji, M. Water diffusion measurements in cement paste, mortar and concrete using a fast NMR based technique. Constr. Build. Mater. 2020, 259, 119843. [Google Scholar] [CrossRef]

- Villar-Cocina, E.; Valencia-Morales, E.; Vega-Leyva, J.; Munoz, J.A. Kinetics of the water absorption in GGBS-concretes: A capillary-diffusive model. Comput. Concr. Int. J. 2005, 2, 19–30. [Google Scholar] [CrossRef]

- Martys, N.S.; Ferraris, C.F. Capillary transport in mortars and concrete. Cem. Concr. Res. 1997, 27, 747–760. [Google Scholar] [CrossRef]

- ASTM Standard C618-08a; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2008.

- Yang, L.; Gao, D.; Zhang, Y.; Tang, J.; Li, Y. Relationship between sorptivity and capillary coefficient for water absorption of cement-based materials: Theory analysis and experiment. R. Soc. Open Sci. 2019, 6, 190112. [Google Scholar] [CrossRef]

- Beltrán, M.G.; Agrela, F.; Barbudo, A.; Ayuso, J.; Ramirez, A. Mechanical and durability properties of concretes manufactured with biomass bottom ash and recycled coarse aggregates. Constr. Build. Mater. 2014, 72, 231–238. [Google Scholar] [CrossRef]

- Beltrán, M.G.; Barbudo, A.; Agrela, F.; Jiménez, J.R.; de Brito, J. Mechanical performance of bedding mortars made with olive biomass bottom ash. Constr. Build. Mater. 2016, 112, 699–707. [Google Scholar] [CrossRef]

- Ghanem, H.; Machaka, M.; Khatib, J.; Elkordi, A.; Baalbaki, O. Effect of partial replacement of cement by MSWIBA on the properties of mortar. Acad. J. Civ. Eng. 2019, 37, 82–89. [Google Scholar] [CrossRef]

- Al-Massri, G.; Ghanem, H.; Khatib, J.; Kırgız, M.S.; Elkordi, A. Chemical shrinkage, autogenous shrinkage, drying shrinkage, and expansion stability of interfacial transition zone material using alkali-treated banana fiber for concrete. J. Struct. Integr. Maint. 2024, 9, 2390650. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Agwa, I.S.; Tayeh, B.A.; Abd-Elrahman, M.H. Effect of using a combination of rice husk and olive waste ashes on high-strength concrete properties. Case Stud. Constr. Mater. 2022, 17, e01486. [Google Scholar] [CrossRef]

- Alyami, M.; Hakeem, I.Y.; Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of agricultural olive, rice husk and sugarcane leaf waste ashes on sustainable ultra-high-performance concrete. J. Build. Eng. 2023, 72, 106689. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).