Prediction Model for Compaction Quality of Earth-Rock Dams Based on IFA-RF Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Method for Collecting Compaction Quality Influence Parameters

2.2. Uncertainty Analysis of Parameters

2.3. Traditional Evaluation Methods for Compaction Quality

2.3.1. Evaluation of Rolling Quality Based on BP Neural Network

2.3.2. Evaluation of Rolling Quality Based on Regression Analysis

2.4. Improving Firefly Optimization Algorithm

2.4.1. Firefly Algorithm

2.4.2. Dynamic Inertia Weight

2.4.3. Adaptive Factor

2.4.4. Differential Evolution Strategy

2.4.5. Improved Firefly Algorithm

2.4.6. Algorithm Performance Comparison

2.5. Compression Quality Evaluation Model Based on an Improved Firefly Algorithm Optimizing Random Forest

2.5.1. Random Forest

2.5.2. Improved Firefly Optimized Random Forest Algorithm

| Algorithm 1: The pseudo-code of the IFA-RF algorithm |

| Input: Rolling parameters, material characteristic parameters, meteorological factors 1: Initialize IFA-RF parameters, such as the number of fireflies, maximum iteration count (max_gen), Mtry, Ntree, lower bounds for parameters, upper bounds for parameters, and dim. 2: Initialize the firefly population and fitness values. 3: Compute the initial fitness of each firefly’s position in the random forest model and identify the initial optimal solution. 4: For gen = 1:max_gen % Loop through the number of iterations 5: Dynamically adjust the differential evolution parameter (F) using a sine-function-based adaptive factor. 6: For i = 1:n % Iterate over each firefly 7: For j = 1:n % Compare each firefly 8: If Check each firefly’s fitness and compute the distance between two fireflies, then update the position using the dynamically adjusted inertia weight. 9: Verify if the search position exceeds the search space. If so, reposition the firefly within the bounds; otherwise, leave the position unchanged. 10: End if 11: End For 12: Randomly select two fireflies and perform differential mutation to generate a new solution, ensuring that the mutated solution stays within the search space. 13: Perform crossover based on a defined crossover probability to randomly select genes and generate a trial solution. 14: Calculate the fitness of the new solution using random forest. 15: If 16: the fitness of the trial solution is better than the current one, update the firefly’s position and fitness. 17: End If 18: If 19: the fitness of the current optimal solution is better, update the optimal solution and its fitness. 20: End If 21: End For 22: End For 23: Output the optimal random forest parameters. 24: Use the optimized parameters to train the random forest model and predict dry density. Output: Prediction results of dry density |

3. Results

3.1. Data Acquisition and Preprocessing

3.2. Construction of the Driving Model and Correlation Analysis

3.3. Quantitative Results of Uncertainty in Parameters

3.4. IFA-RF Algorithm Model Optimization and Learning

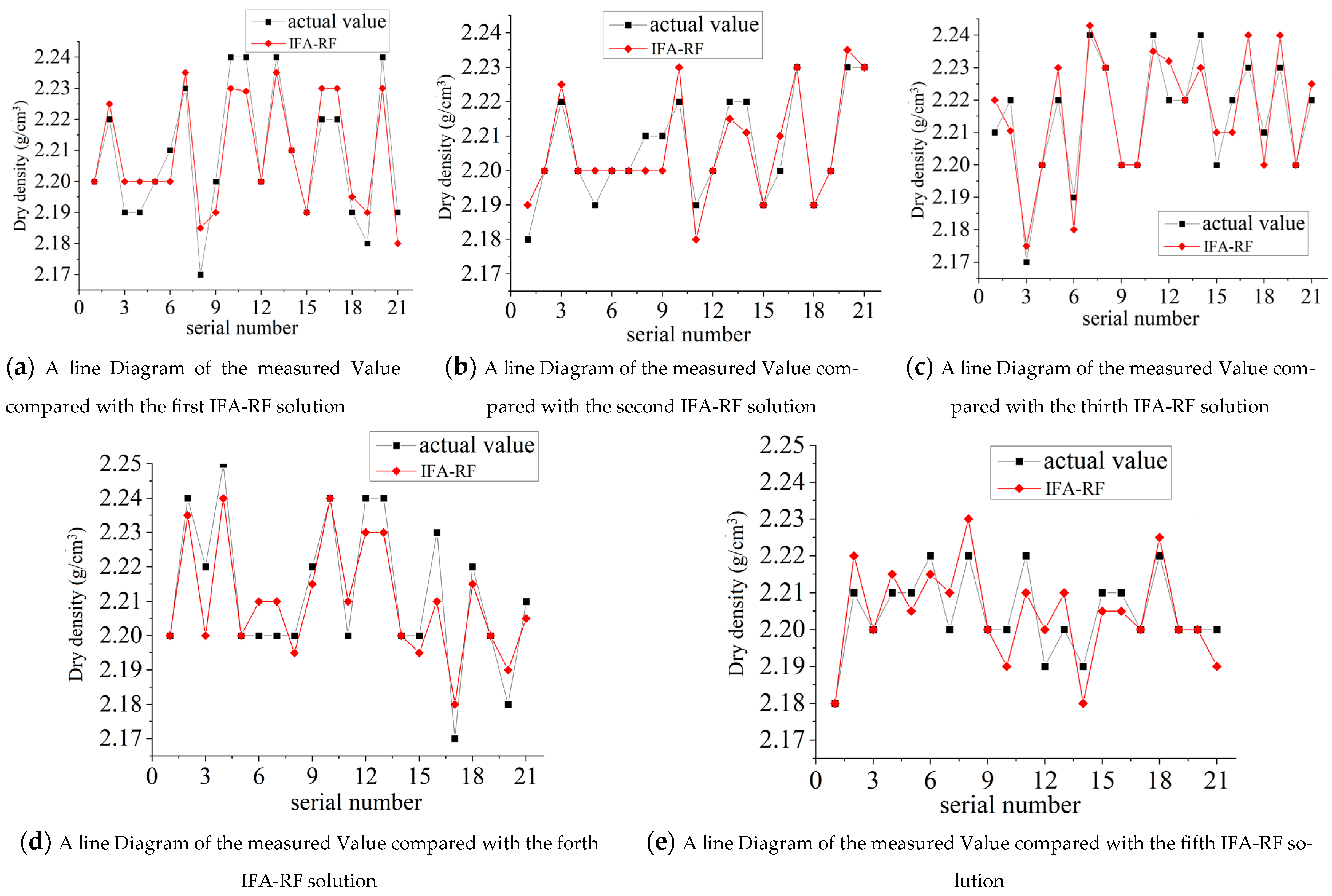

3.5. Prediction Results Analysis

3.6. Comparison and Discussion of Compaction Quality Prediction Models

4. Conclusions

- (1)

- Uncertainty Analysis: An uncertainty analysis method was applied to scientifically and rationally analyze the influencing parameters of compaction quality. The uncertainty was quantified, and by considering the parameter uncertainty, the evaluation results for the earth-rock dam compaction quality were made more comprehensive and precise.

- (2)

- IFA: An improved firefly algorithm, coupled with DIW, adaptive factors, and DES, was proposed. DIW allowed the search process to gradually shift from broad exploration to local optimization. A sine function was used to adjust the F parameter in the differential evolution strategy, enhancing the algorithm’s adaptability. Additionally, differential mutation and crossover strategies were introduced in each iteration to improve the population diversity and enhance the global search capability. Compared to the traditional FA, the proposed IFA demonstrated superior accuracy, effectiveness, and robustness when optimizing four benchmark functions.

- (3)

- Compaction Quality Prediction Model: A compaction quality prediction model based on the IFA-RF was developed. The algorithm adaptively optimized the Ntree and Mtry parameters of the RF, creating a model that revealed the complex nonlinear relationships between input factors, such as compaction parameters, material source parameters, and meteorological parameters, and the compaction quality. The model’s predictive performance was further improved. Verification through an engineering case study showed that, compared to prediction models based on traditional RF, BPNNs, and MLR, the proposed model exhibited superior accuracy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, P.; Wang, X.; Liu, Z.; Yu, J.; Liu, M. Porosity- and Reliability-Based Evaluation of Concrete-Face Rock Dam Compaction Quality. Autom. Constr. 2017, 81, 196–209. [Google Scholar] [CrossRef]

- Zhong, D.; Liu, D.; Cui, B. Real-Time Compaction Quality Monitoring of High Core Rockfill Dam. Sci. China Technol. Sci. 2011, 54, 1906–1913. [Google Scholar] [CrossRef]

- Cui, B.; Zhong, D. Theory and Application of System Integration for Real-Time Monitoring of Core Rock-Fill Dam Filling Construction Quality. Trans. Tianjin Univ. 2012, 18, 173–179. [Google Scholar] [CrossRef]

- Liu, D.H.; Wang, A.G.; Liu, Y.G.; Li, B.Y. Real-Time Monitoring and Assessment of Compaction Quality for Earth-Rock Dam Basing on Roller Vibration Behavior Analysis. J. Hydraul. Eng. 2014, 45, 163–170. [Google Scholar] [CrossRef]

- Ran, C.Y. Study About the Method of Construction Quality Control and Evaluation of Rock-Fill Dams; Sichuan University: Chengdu, China, 2005. [Google Scholar]

- Wang, R.; Zhong, D.; Wu, B.; Yue, P. Compaction Quality Evaluation of Rockfill Dam Based on Compaction and Material Parameters. J. Hydroelectr. Eng. 2015, 34, 146–152. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, D.; Wu, B.; Shi, M. Evaluation of Compaction Quality Based on SVR with CFA: Case Study on Compaction Quality of Earth-Rock Dam. J. Comput. Civil Eng. 2018, 32, 05018001. [Google Scholar] [CrossRef]

- Liu, S.; Yang, Y.; Su, H.; Zhao, Y.; Yang, T. A Compaction Quality Evaluation Model for Gravel-Faced Rockfill Dams Based on Hybrid Optimization Algorithm and Its Engineering Application. Water Resour. Hydropower Eng. 2023, 54, 141–149. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, D.; Guan, T.; Tong, D.; Deng, S. Real-Time Evaluation of Compaction Quality of Earth-Rock Dams Using Fuzzy Logic Based on KM and AC-BFA. J. Hydroelectr. Eng. 2019, 38, 165–178. [Google Scholar] [CrossRef]

- Hao, Z.; Chen, X.; Xiao, X.; Yan, H.; Li, T.; Yao, J.; Xie, K. A Full-Section Compaction Quality Evaluation Method for Subgrade Based on ML-Uncertainty Theory. J. Railw. Sci. Eng. 2025, 22, 649–663. [Google Scholar]

- Anderegg, R.; Kaufmann, K. Intelligent Compaction with Vibratory Rollers: Feedback Control Systems in Automatic Compaction and Compaction Control. Transp. Res. Rec. 2004, 1868, 124–134. [Google Scholar] [CrossRef]

- Rinehart, R.V.; Mooney, M.A. Instrumentation of a Roller Compactor to Monitor Vibration Behavior During Earthwork Compaction. Autom. Constr. 2008, 17, 144–150. [Google Scholar] [CrossRef]

- Kassem, E.; Liu, W.; Scullion, T.; Masad, E.; Chowdhury, A. Development of Compaction Monitoring System for Asphalt Pavements. Constr. Build. Mater. 2015, 96, 334–345. [Google Scholar] [CrossRef]

- Sivagnanasuntharam, S.; Sounthararajah, A.; Kodikara, J. A New Approach to Maximising the Benefits of Current Intelligent Compaction Technology for Asphalt Materials. Constr. Build. Mater. 2023, 393, 132031. [Google Scholar] [CrossRef]

- Jain, V.; Chouhan, R.; Dhamaniya, A. Exploring the Efficacy of Artificial Intelligence in Speed Prediction: Explainable Machine-Learning Approach. J. Comput. Civil Eng. 2025, 39, 04025004. [Google Scholar] [CrossRef]

- Lin, W.; Zhong, D.; Hu, W.; Lü, P.; Yan, Y.; Ren, B. Study on Dynamic Evaluation of Compaction Quality of Earth Rock Dam Based on Random Forest. J. Hydraul. Eng. 2018, 49, 945–955. [Google Scholar] [CrossRef]

- Hu, Y.; Castro-Lacouture, D.; Asce, A.M. Clash Relevance Prediction Based on Machine Learning. J. Comput. Civ. Eng. 2018, 33, 04018060. [Google Scholar] [CrossRef]

- Liu, D.; Dai, Q.; Tang, X.; Zhang, R.; Lu, T.; Chen, J. An Improved Random Forest–Based Operation Duration Prediction of Long-Distance Tunnel Construction Considering Geological Uncertainty. J. Comput. Civil Eng. 2025, 39, 04024060. [Google Scholar] [CrossRef]

- Cui, B.; Yan, C.; Wang, J. Research on Compaction Quality Prediction Model of Core Wall Gravel Soil Based on FOA-RF Algorithm. Adv. Sci. Technol. Water Resour. 2023, 43, 42–48. [Google Scholar]

- Zhu, Y.; Wang, X.; Cui, B.; Chen, W.; Xuan, X.; Yu, H. Research on an ISSA-Stacking Ensemble Learning Surrogate Model of Dam Foundation Grouting Volume Prediction. J. Tianjin Univ. Sci. Technol. 2024, 57, 174–185. [Google Scholar]

- Zhang, S.; Zheng, D.; Chen, Z. Dam Deformation Prediction Model Based on Improved PSO-RF Algorithm. Adv. Sci. Technol. Water Resour. 2022, 42, 39–44. [Google Scholar]

- Jaynes, E.T. Information theory and statistical mechanics. Phys. Rev. 1957, 106, 620. [Google Scholar] [CrossRef]

- Aggarwal, M.; Hanmandlu, M. Representing Uncertainty with Information Sets. IEEE Trans. Fuzzy Syst. 2016, 24, 1–15. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Chen, N.L.; Wang, J. Small-sample yarn quality prediction using random forest algorithm. J. Donghua Univ. (Nat. Sci. Ed.) 2023, 49, 80–86. [Google Scholar] [CrossRef]

- Ge, P.S.; Wang, C.Y.; Wang, Y.; Zhang, T.; Xue, H.T.; Xia, C.D. Fault diagnosis of hub motor bearings under small-sample conditions via SMOTE-IGWO-RF. J. Ordnance Equip. Eng. 2024, 45, 1–9. [Google Scholar]

| Functions | Optimal Solution | FA | IFA | ||

|---|---|---|---|---|---|

| Optimal Solution | Execution Time (s) | Optimal Solution | Execution Time (s) | ||

| f1 | f(0,0,0,0,0) = 0 | 0.005622466 | 1.47 | 2.04 × 10−15 | 1.52 |

| f2 | f(0,0,0,0,0) = 0 | 4.093030513 | 2.03 | 0.996754151 | 2.11 |

| f3 | f(0,0,0,0,0) = 0 | 0.167418872 | 2.51 | 4.23 × 10−8 | 2.58 |

| f4 | f(0,0,0,0,0) = 0 | 0.001441134 | 2.08 | 0.001130785 | 2.15 |

| Moisture Content (%) | P5 Content (%) | Rolling Thickness | Humidity | Total Passes | Dry Density | |

|---|---|---|---|---|---|---|

| Number of cases | 106 | 106 | 106 | 106 | 106 | 106 |

| average | 8.526 | 42.38486 | 0.2556 | 44.75280 | 19.7 | 2.2104 |

| median | 8.5 | 42.75 | 0.26 | 49.66935 | 19 | 2.21 |

| standard deviation | 0.2756 | 4.54036 | 0.03186 | 17.28726 | 5.667 | 0.01702 |

| minimum value | 8 | 2.35559 | 0.16 | 11.058 | 9 | 2.17 |

| Maximum value | 9.4 | 48.2 | 0.31 | 72.42679 | 36 | 2.25 |

| Group (%) | 38.2–40.2 | 40.2–42.2 | 42.2–44.2 | 43.42–46.2 | 46.2–48.2 |

|---|---|---|---|---|---|

| Count (n) | 9 | 34 | 37 | 11 | 9 |

| Frequency | 0.09 | 0.34 | 0.37 | 0.11 | 0.09 |

| Parameter | Material Source Parameters | Compaction Parameters | Meteorological Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| P5 Content | Moisture Content | Curvature Coefficient | Uniformity Coefficient | Compaction Thickness | Static Compaction Cycles | Total Compaction Cycles | Total Compaction Cycles | Temperature | Humidity | |

| Entropy value | 0.8766 | 0.7760 | 0.7109 | 0.6755 | 0.5082 | 0.5915 | 0.3093 | 0.6409 | 0.8569 | 0.9093 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, W.; Yan, Y.; Xu, P.; Zhang, X.; Zhong, Y. Prediction Model for Compaction Quality of Earth-Rock Dams Based on IFA-RF Model. Appl. Sci. 2025, 15, 4024. https://doi.org/10.3390/app15074024

Lin W, Yan Y, Xu P, Zhang X, Zhong Y. Prediction Model for Compaction Quality of Earth-Rock Dams Based on IFA-RF Model. Applied Sciences. 2025; 15(7):4024. https://doi.org/10.3390/app15074024

Chicago/Turabian StyleLin, Weiwei, Yuling Yan, Pu Xu, Xiao Zhang, and Yichuan Zhong. 2025. "Prediction Model for Compaction Quality of Earth-Rock Dams Based on IFA-RF Model" Applied Sciences 15, no. 7: 4024. https://doi.org/10.3390/app15074024

APA StyleLin, W., Yan, Y., Xu, P., Zhang, X., & Zhong, Y. (2025). Prediction Model for Compaction Quality of Earth-Rock Dams Based on IFA-RF Model. Applied Sciences, 15(7), 4024. https://doi.org/10.3390/app15074024