A Comparative Study of the Structural, Morphological, and Functional Properties of Native Potato Starch and Spray-Dried Potato Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Spray-Dried Starch Powders

2.3. X-Ray Diffraction (XRD) and Differential Scanning Calorimetry (DSC)

2.4. Fourier-Transform Infrared Spectroscopy (FTIR)

2.5. Optical Microscopy

2.6. Physical Properties

2.6.1. Moisture Content

2.6.2. Particle Size Distribution

2.6.3. Color Analysis

2.6.4. Bulk and Tapped Density

2.6.5. Flowability and Cohesiveness

2.6.6. Water Holding Capacity

2.6.7. Hygroscopicity

2.7. Statistical Analysis

3. Results

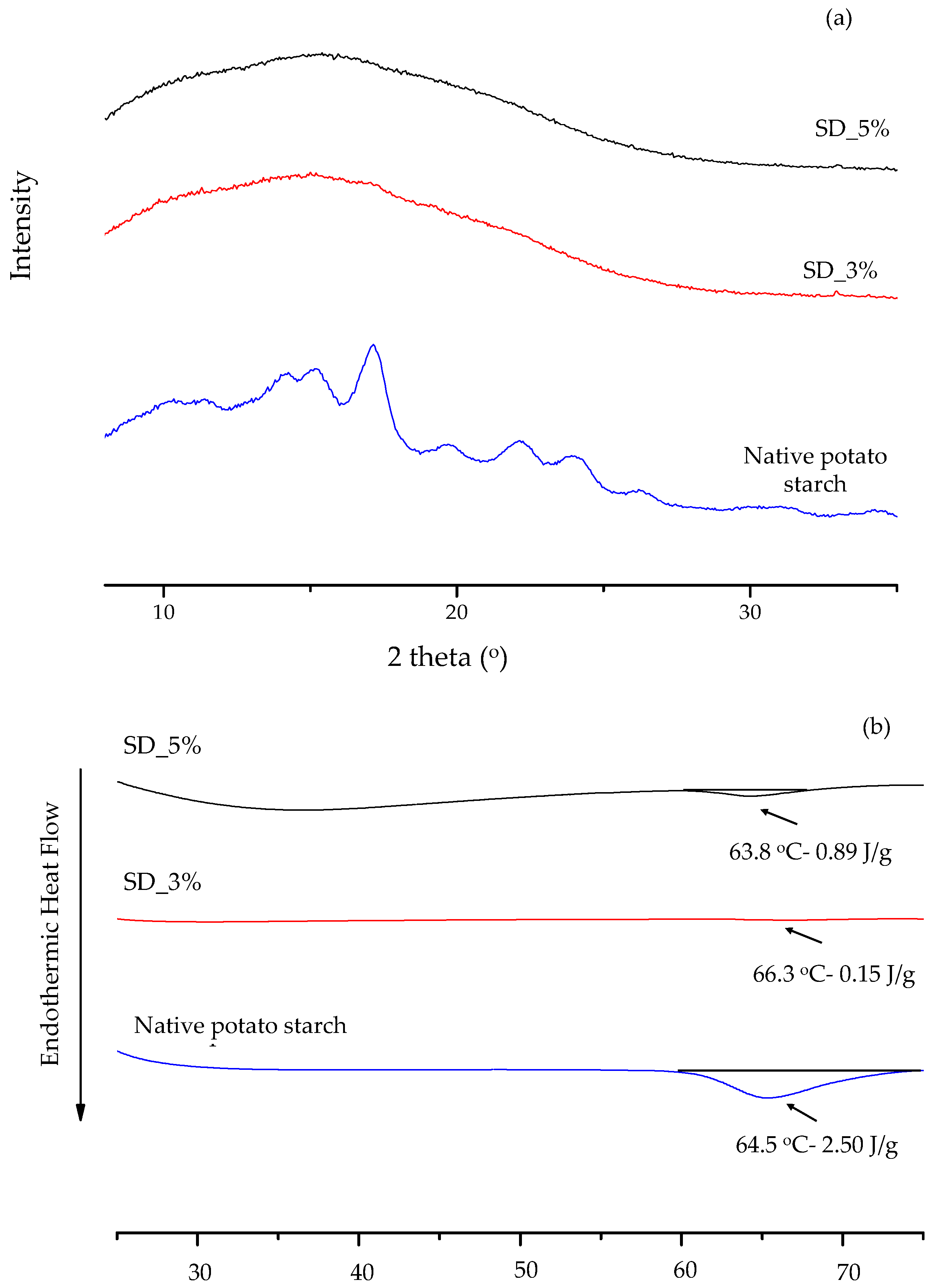

3.1. X-Ray Diffraction Analysis (XRD) and Differential Scanning Calorimetry (DSC)

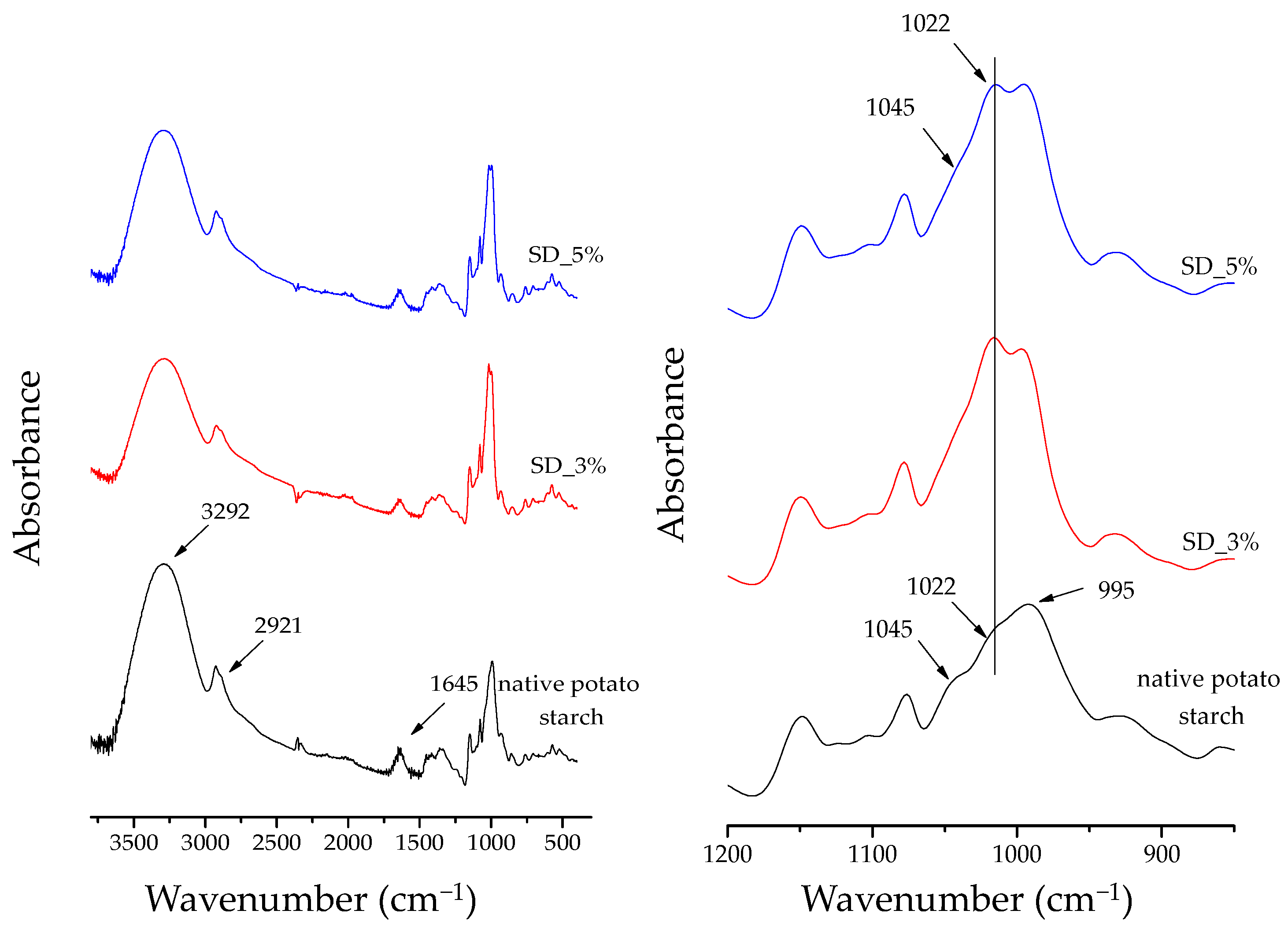

3.2. Fourier Transform Infrared Spectroscopy (FTIR)

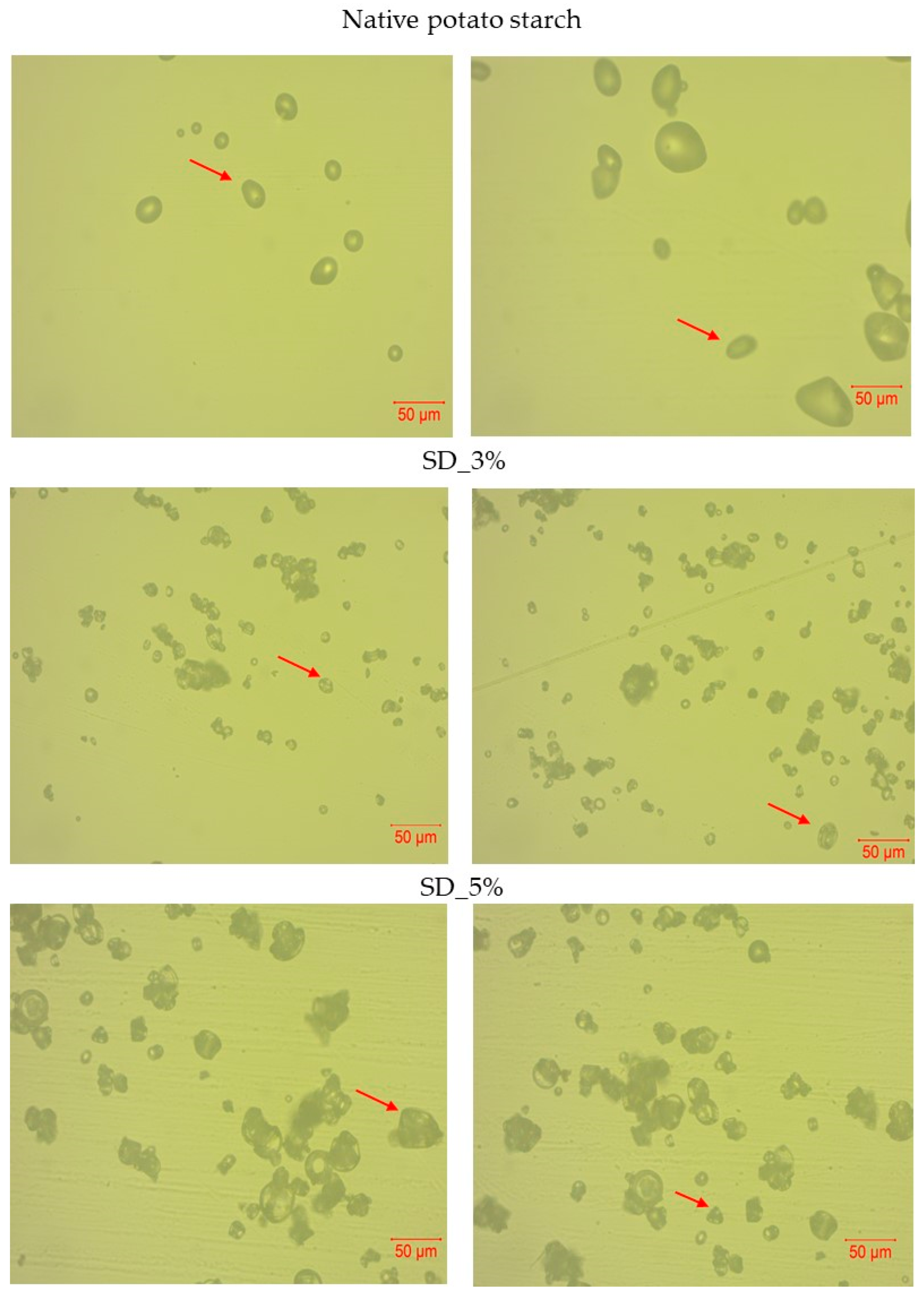

3.3. Optical Microscopy

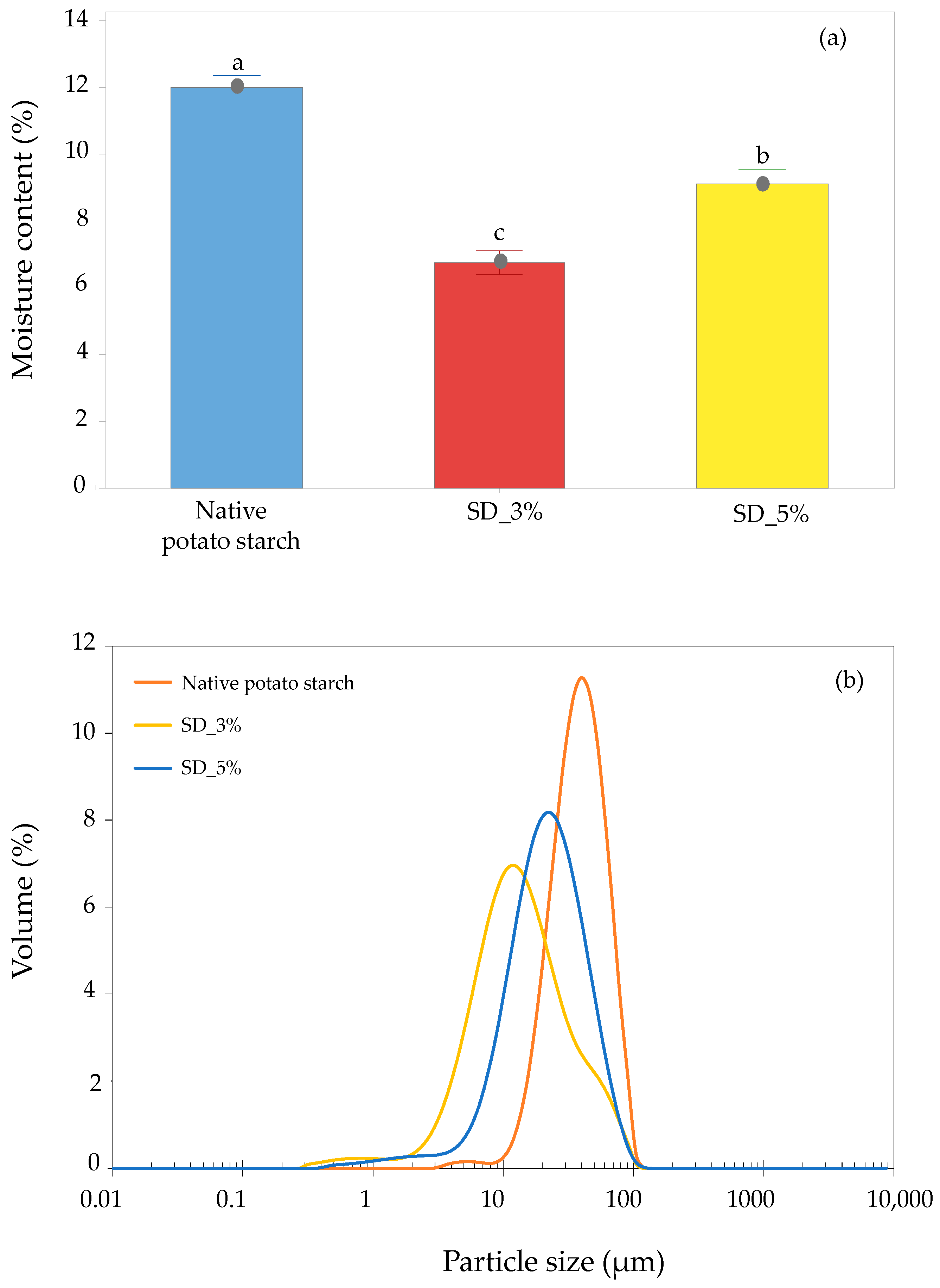

3.4. Moisture and Particle Size Analysis

3.5. Color Analysis

3.6. Bulk and Particle Properties

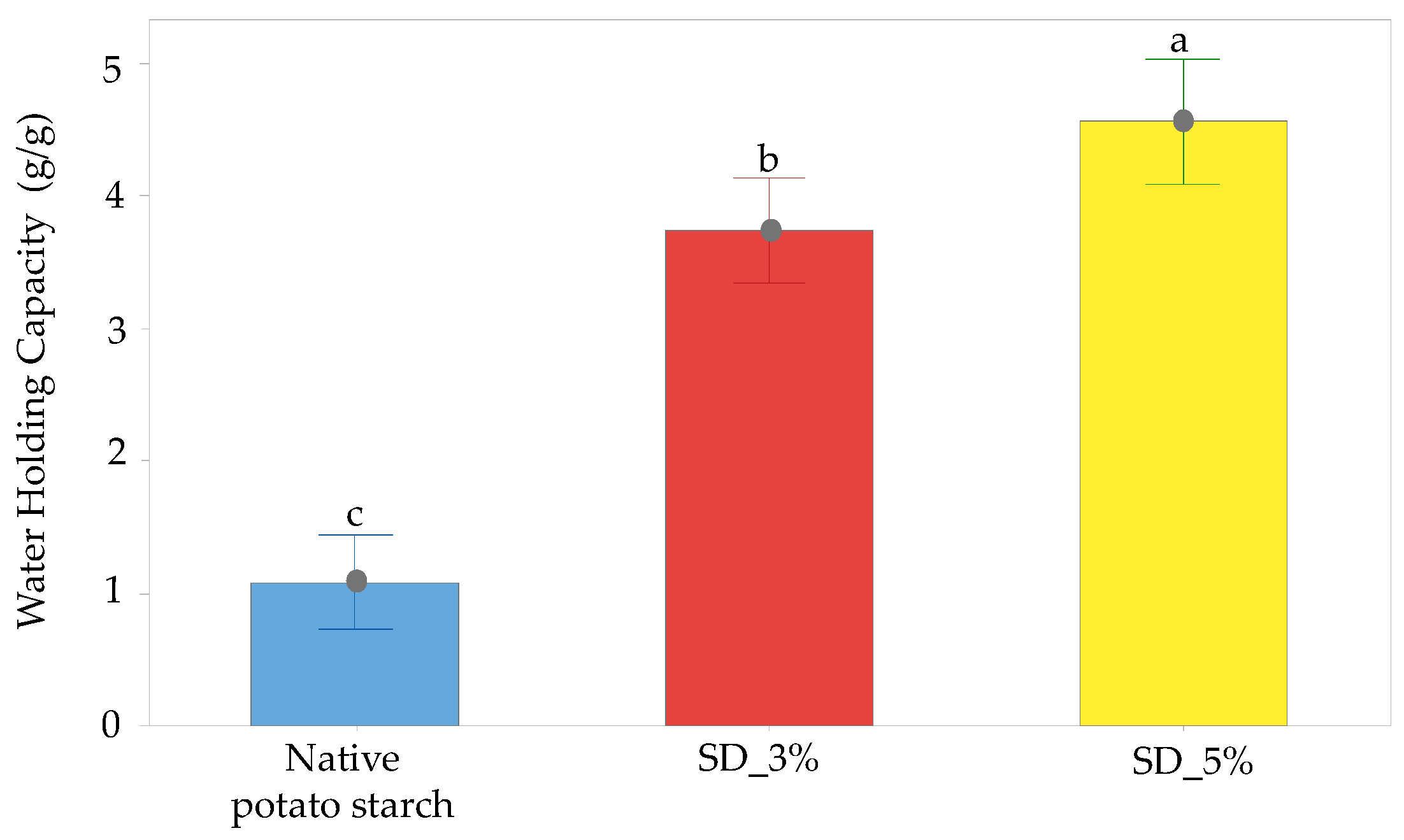

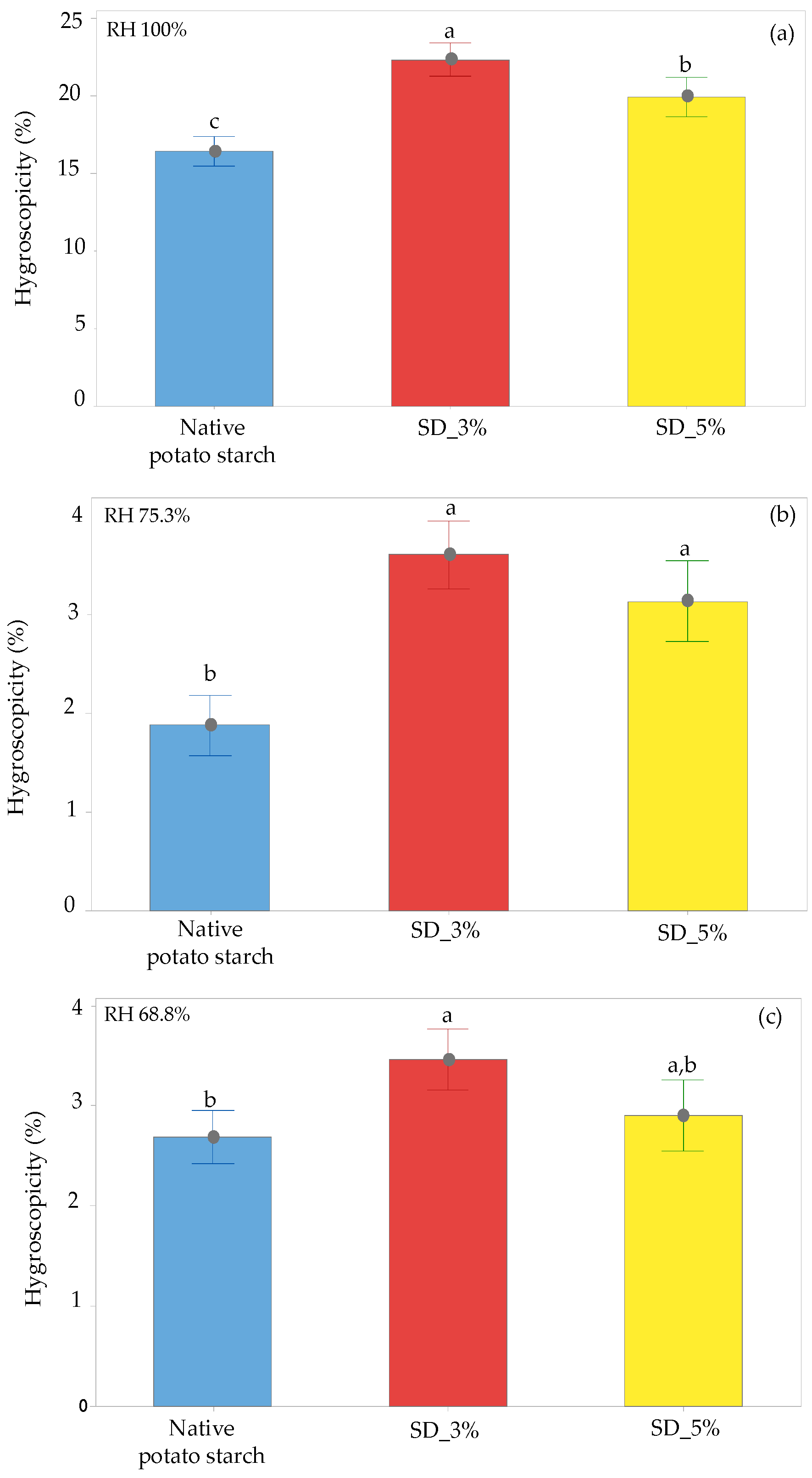

3.7. Water Holding Capacity (WHC) and Hygroscopicity

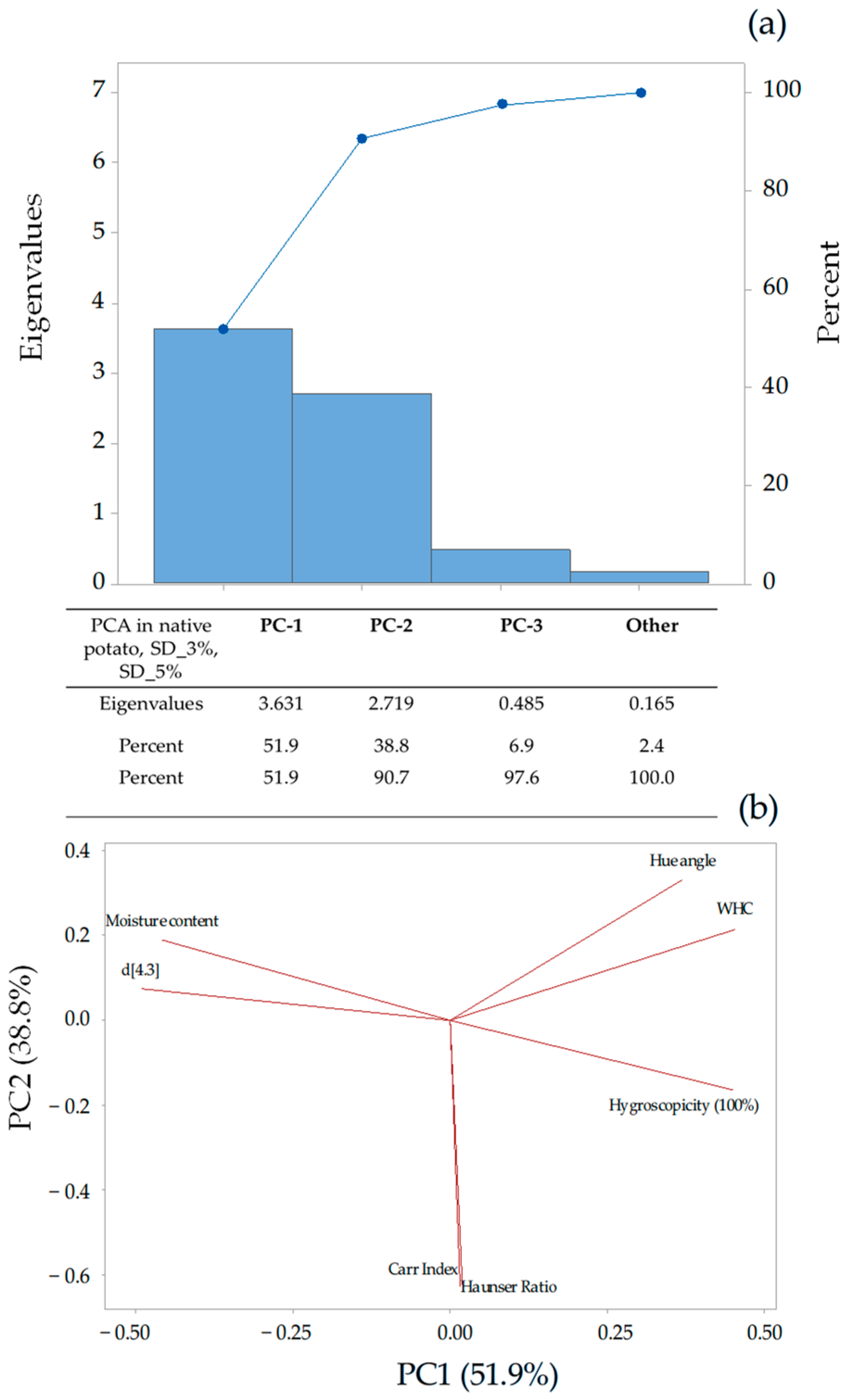

3.8. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| XRD | X-ray diffraction |

| DSC | Differential scanning calorimetry |

| FTIR | Fourier transform infrared spectroscopy |

References

- Robertson, T.M.; Alzaabi, A.Z.; Robertson, M.D.; Fielding, B.A. Starchy Carbohydrates in a Healthy Diet: The Role of the Humble Potato. Nutrients 2018, 10, 1764. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.J.; Liu, H.; Zeng, F.K.; Yang, Y.C.; Xu, D.; Zhao, Y.C.; Liu, X.F.; Kaur, L.; Liu, G.; Singh, J. Potato Processing Industry in China: Current Scenario, Future Trends and Global Impact. Potato Res. 2023, 66, 543–562. [Google Scholar] [CrossRef] [PubMed]

- Woolfe, J. Sweet Potato: An Untapped Food Resource; Cambridge University Press: Cambridge, UK, 1992. [Google Scholar]

- Tan, Y.; Zhao, Y.; Hu, H.; Fu, N.; Zhang, C.; Zhang, H.; Dai, X. Drying kinetics and particle formation of potato powder during spray drying probed by microrheology and single droplet drying. Food Res. Int. 2019, 116, 483–491. [Google Scholar] [CrossRef]

- Zeeman, S.C.; Kossmann, J.; Smith, A.M. Starch: Its Metabolism, Evolution, and Biotechnological Modification in Plants. Annu. Rev. Plant Biol. 2010, 61, 209–234. [Google Scholar] [CrossRef] [PubMed]

- Kaur, M.; Sandhu, K.S.; Singh, N.; Lim, S.T. Amylose Content, Molecular Structure, Physicochemical Properties and In Vitro Digestibility of Starches from Different Mungbean (Vigna radiate L.) Cultivars. Starch-Stärke 2011, 63, 709–716. [Google Scholar] [CrossRef]

- Fuentes, C.; Kang, I.; Lee, J.; Song, D.; Sjöö, M.; Choi, J.; Lee, S.; Nilsson, L. Fractionation and characterization of starch granules using field-flow fractionation (FFF) and differential scanning calorimetry (DSC). Anal Bioanal. Chem. 2019, 411, 3665–3674. [Google Scholar] [CrossRef]

- Awolu, O.O.; Olofinlae, S.J. Physico-Chemical, Functional and Pasting Properties of Native and Chemically Modified Water Yam (Dioscorea alata) Starch and Production of Water Yam Starch-Based Yoghurt. Starch-Stärke 2016, 68, 719–726. [Google Scholar] [CrossRef]

- Shen, H.; Yu, J.; Bai, J.; Liu, Y.; Ge, X.; Li, W.; Zheng, J. A New Pre-Gelatinized Starch Preparing by Spray Drying and Electron Beam Irradiation of Oat Starch. Food Chem. 2023, 398, 133938. [Google Scholar] [CrossRef]

- dos Santos, T.P.R.; Franco, C.M.L.; Leonel, M. Gelatinized Sweet Potato Starches Obtained at Different Preheating Temperatures in a Spray Dryer. Int. J. Biol. Macromol. 2020, 149, 1339–1346. [Google Scholar] [CrossRef]

- Chiu, W.; Solarek, D. Starch Chemistry and Technology; Bemiller, J., Whistler, R., Eds.; Academic Press: Burlington, VT, USA, 2009; pp. 629–655. [Google Scholar]

- Sarifudin, A.; Sholichah, E.; Setiaboma, W.; Tongta, S. Cold Water Swelling Starch: Methods to Prepare and Recent Applications. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1011, 012025. [Google Scholar] [CrossRef]

- Din, Z.U.; Xiong, H.G.; Fei, P. Physical and Chemical Modification of Starches: A Review. Crit. Rev. Food Sci. Nutr. 2015, 57, 2691–2705. [Google Scholar]

- dos Santos, T.P.R.; Franco, C.M.L.; Mischan, M.M.; Leonel, M. Behavior of Sweet Potato Starch After Spray-Drying Under Different Pretreatment Conditions. Starch-Stärke 2019, 71, 1800245. [Google Scholar] [CrossRef]

- Fu, Z.; Wang, L.; Li, D.; Adhikari, B. Effects of Partial Gelatinization on Structure and Thermal Properties of Corn Starch after Spray Drying. Carbohydr. Polym. 2012, 88, 1319–1325. [Google Scholar] [CrossRef]

- Marinopoulou, A.; Karageorgiou, V.; Papastergiadis, E.; Iordanidis, C.; Dagklis, A.; Raphaelides, S.N. Production of Spray-Dried Starch Molecular Inclusion Complexes on an Industrial Scale. Food Bioprod. Process. 2019, 116, 186–195. [Google Scholar] [CrossRef]

- Marinopoulou, A.; Karageorgiou, V.; Petridis, D.; Raphaelides, S.N. Physical Properties of Starch-Paracetamol Molecular Inclusion Complexes Produced by the Spray Drying Process on an Industrial Scale. Dry Technol. 2020, 39, 1950–1967. [Google Scholar] [CrossRef]

- Marinopoulou, A.; Zoumaki, M.; Raphaelides, S.; Karageorgiou, V.; Goulas, A. Characterization of Spray-Dried Starch Systems of Natural Antioxidant Compounds. Starch-Stärke 2024, 76, 2300069. [Google Scholar] [CrossRef]

- Marinopoulou, A.; Zoumaki, M.; Goulas, A.; Petridis, D.; Raphaelides, S.; Aslampaloglou, A.; Tzikas, A.; Karageorgiou, V. Functional Characteristics and Physical Properties of Spray Dried Starch Inclusion Complexes with Drugs. Starch-Stärke 2021, 74, 2100176. [Google Scholar] [CrossRef]

- He, X.H.; Xia, W.; Chen, R.; Dai, T.; Luo, S.; Chen, J.; Liu, C. A New Pre-Gelatinized Starch Preparing by Gelatinization and Spray Drying of Rice Starch with Hydrocolloids. Carbohydr. Polym. 2020, 229, 115485. [Google Scholar] [CrossRef]

- Fadimu, G.J.; Adenekan, M.K.; Akinlua, O.; Al Juhaimi, F.; Ghafoor, K.; Babiker, E.E. Effect of Heat Moisture Treatment and Partial Acid Hydrolysis on the Morphological, Functional and Pasting Properties of Sweet Potato Starch. Qual. Assur. Saf. Crops Foods 2018, 10, 423–430. [Google Scholar] [CrossRef]

- dos Santos, T.P.R.; Franco, C.M.L.; Mischan, M.M.; Leonel, M. Improvement in Spray-Drying Technology for Preparation of Pregelatinized Cassava Starch. Food Sci. Technol. 2019, 39, 939–946. [Google Scholar] [CrossRef]

- Mauro, R.R.; Vela, A.J.; Ronda, F. Impact of Starch Concentration on the Pasting and Rheological Properties of Gluten-Free Gels. Effects of Amylose Content and Thermal and Hydration Properties. Foods 2023, 12, 2281. [Google Scholar] [CrossRef] [PubMed]

- Odigboh, E.U.; Mohsenin, N.N. Effects of concentration on the viscosity profile of cassava starch pastes during the cooking-cooling process. J. Texture Stud. 1975, 5, 441–457. [Google Scholar] [CrossRef]

- Lee, S.W.; Rhee, C. Effect of heating condition and starch concentration on the structure and properties of freeze-dried rice starch paste. Food Res. Int. 2007, 40, 215–223. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Malvern. Getting Started-Manual Mastersizer 1.3; Malvern Instruments Ltd.: Malvern, UK, 1997. [Google Scholar]

- Stojanovic, Z.; Markovic, S. Determination of Particle Size Distribution by Laser Diffraction. Technics-New Mater. 2012, 21, 11–20. [Google Scholar]

- Milovanovic, B.; Djekic, I.; Miocinovic, J.; Djordjevic, V.; Lorenzo, J.M.; Barba, F.J.; Mörlein, D.; Tomasevic, I. What Is the Color of Milk and Dairy Products and How Is It Measured? Foods 2020, 9, 1629. [Google Scholar] [CrossRef] [PubMed]

- de Lima, P.M.; Dacanal, G.C.; Pinho, L.S.; de Sá, S.H.G.; Thomazini, M.; Favaro-Trindade, C.S. Combination of Spray-Chilling and Spray-Drying Techniques to Protect Carotenoid-Rich Extracts from Pumpkin (Cucurbita moschata) Byproducts, Aiming at the Production of a Powdered Natural Food Dye. Molecules 2022, 27, 7530. [Google Scholar] [CrossRef]

- Nishad, J.; Selvan, C.J.; Mir, S.A.; Bosco, S.J.D. Effect of Spray Drying on Physical Properties of Sugarcane Juice Powder (Saccharum officinarum L.). J. Food Sci. Technol. 2017, 54, 687–697. [Google Scholar] [CrossRef] [PubMed]

- Carr, R.L. Evaluating Flow Properties of Solids. Chem. Eng. J. 1965, 72, 163–168. [Google Scholar]

- Hausner, H.H. Friction Conditions in a Mass of Metal Powder. J. Powder Metall. 1967, 3, 7–13. [Google Scholar]

- Fitzpatrick, J.J. Food powder flowability. In Encapsulated and Powdered Foods; Onwulata, C., Ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 247–260. [Google Scholar]

- Rana, S.; Gupta, S.; Rana, A.; Bhushan, S. Functional properties, phenolic constituents, and antioxidant potential of industrial apple pomace for utilization as active food ingredient. Food Sci. Hum. Wellness 2015, 4, 180–187. [Google Scholar] [CrossRef]

- Ladjevardi, Z.; Mousavi, M.; Askari, G.; Dolati, Μ.; Kahn, C.; Arab-Tehrany, E. Structural, functional and emulsifying properties of wheat corn, chickpea and OSA-modified chickpea starches, a comparative study. J. Food Meas. Charact. 2024, 18, 4496–4513. [Google Scholar] [CrossRef]

- Cai, Y.Z.; Corke, H. Production and Properties of Spray-Dried Amaranthus Betacyanin Pigments. J. Food Sci. 2000, 65, 1248–1252. [Google Scholar] [CrossRef]

- Taguchi, T.; Onishi, M.; Katsuno, N.; Miwa, N.; Oomoto, C.; Sato, M.; Sekita, M.; Yamaguchi, H.; Imaizumi, T.; Nishizu, T. Evaluation of Starch Retrogradation by X-Ray Diffraction Using a Water-Addition Method. LWT-Food Sci. Technol. 2023, 173, 114341. [Google Scholar] [CrossRef]

- Rocha, T.S.; Carneiro, A.P.A.; Franco, C.M.L. Effect of Enzymatic Hydrolysis on Some Physicochemical Properties of Root and Tuber Granular Starches. Ciênc. Tec. Aliment. 2010, 30, 544–551. [Google Scholar] [CrossRef]

- Wu, W.; Jiao, A.; Xu, E.; Chen, Y.; Jin, Z. Effects of Extrusion Technology Combined with Enzymatic Hydrolysis on the Structural and Physicochemical Properties of Porous Corn Starch. Food Bioprocess Technol. 2020, 13, 442–451. [Google Scholar] [CrossRef]

- Su, Q.; Sun, L.; Chen, L.; Wang, X.; Liu, K.; Gong, K. The Influence of Different Drying Methods on the Molecular Structure and Digestive Resistance of Type 3 Resistant Starch (RS3). Food Chem. 2025, 474, 142971. [Google Scholar] [CrossRef]

- Pozo, C.; Rodríguez-Llamazares, S.; Bouza, R.; Barral, L.; Castaño, J.; Müller, N.; Restrepo, I. Study of the Structural Order of Native Starch Granules Using Combined FTIR and XRD Analysis. J. Polym. Res. 2018, 25, 266. [Google Scholar] [CrossRef]

- Cyras, V.P.; Tolosa Zenklusen, M.C.; Vazquez, A. Relationship between Structure and Properties of Modified Potato Starch Biodegradable Films. J. Appl. Polym. Sci. 2006, 101, 4313–4319. [Google Scholar] [CrossRef]

- Likhitkar, S.; Bajpai, A.K. Magnetically Controlled Release of Cisplatin from Superparamagnetic Starch Nanoparticles. Carbohydr. Polym. 2012, 87, 300–308. [Google Scholar] [CrossRef]

- Lourdin, D.; Putaux, J.-L.; Potocki-Véronèse, G.; Chevigny, C.; Rolland-Sabaté, A.; Buléon, A. Crystalline Structure in Starch. In Starch: Metabolism and Structure; Nakamura, Y., Ed.; Springer: Tokyo, Japan, 2015; pp. 61–90. [Google Scholar]

- Tiozon, R.N., Jr.; Bonto, A.P.; Padua, J.A.H.; Elbo, E.G.A.; Sampang, J.R.; Kamka Jon, K.; Camacho, D.H.; Thumanu, K. Investigating the Effect of Ultrasonication on the Molecular Structure of Potato Starch Using Synchrotron-Based Infrared Spectroscopy. Biointerf. Res. Appl. Chem. 2022, 12, 6686–6698. [Google Scholar]

- Chakraborty, I.; Pallen, S.; Shetty, Y.; Roy, N.; Mazumder, N. Advanced Microscopy Techniques for Revealing Molecular Structure of Starch Granules. Biophys. Rev. 2020, 12, 105–122. [Google Scholar] [CrossRef] [PubMed]

- Tonon, R.V.; Grosso, C.R.F.; Hubinger, M.D. Influence of Emulsion Composition and Inlet Air Temperature on the Microencapsulation of Flaxseed Oil by Spray Drying. Food Res. Int. 2011, 44, 282–289. [Google Scholar] [CrossRef]

- Both, E.M.; Siemons, I.; Boom, R.M.; Schutyser, M.A.I. The Role of Viscosity in Morphology Development During Single Droplet Drying. Food Hydrocoll. 2019, 94, 510–518. [Google Scholar] [CrossRef]

- dos Santos, T.P.R.; Franco, C.M.L.; do Carmo, E.L.; Jane, J.L.; Leonel, M. Effect of Spray-Drying and Extrusion on Physicochemical Characteristics of Sweet Potato Starch. J. Food Sci. Technol. 2019, 56, 376–383. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, C.C.; Germer, S.P.M.; de Aguirre, J.M. Effects of Spray-Drying Conditions on the Physicochemical Properties of Blackberry Powder. Dry Technol. 2011, 30, 154–163. [Google Scholar] [CrossRef]

- Tonon, R.V.; Brabet, C.; Hubinger, M.D. Influence of Process Conditions on the Physicochemical Properties of Açaí (Euterpe oleraceae Mart.) Powder Produced by Spray-Drying. J. Food Eng. 2008, 88, 411–418. [Google Scholar] [CrossRef]

- Koç, B.; Koç, M.; Baysan, U. Food Powders Bulk Properties. In Food Powders: Properties and Characterization; Ermiş, E., Ed.; Springer: Cham, Switzerland, 2021; pp. 1–36. [Google Scholar]

- Masters, K. Spray-air Contact (Mixing and Flow). In Spray Drying Handbook, 3rd ed.; Masters, K., Ed.; Halsted Press: New York, NY, USA, 1979; pp. 286–290. [Google Scholar]

- Krishnaiah, D.; Bono, A.; Nandam, R.J.; Zahari, F.W. Effect of Potato Starch on the Antioxidant Properties of Morinda citrifolia Spray-Dried Microparticles. MOJ Food Process. Technol. 2015, 1, 1–4. [Google Scholar]

- Jinapong, N.; Suphantharika, M.; Jamnong, P. Production of Instant Soymilk Powders by Ultrafiltration, Spray Drying, and Fluidized Bed Agglomeration. J. Food Eng. 2008, 84, 194–205. [Google Scholar] [CrossRef]

- Marinopoulou, A.; Karageorgiou, V.; Iordanidis, C.; Dagklis, A.; Zoumakis, N.; Raphaelides, S.N. Parametric analysis of the spray drying process for the production of starch molecular inclusion complexes with fatty acids. Dry Technol. 2019, 39, 580–595. [Google Scholar] [CrossRef]

- Dini, M.; Raseira, M.D.C.B.; Scariotto, S.; Carra, B.; Abreu, E.D.; Mello-Farias, P.; Cantillano, R.F. Color Shade Heritability of Peach Flesh. J. Agric.Sci. 2019, 11, 236. [Google Scholar] [CrossRef]

- Aryaee, H.; Ariaii, P.; Zare, D.; Mirdamadi, S.; Naghizadeh Raeisi, S. Evaluation of the Physicochemical Characteristics of a Blend Fruit Juice Powder Mixed with Lactiplantibacillus plantarum: A Comparison of Spray Drying and Freeze Drying. J. Food Process. Preserv. 2023, 2023, 5597647. [Google Scholar] [CrossRef]

- Samborska, K.; Gajek, P.; Kamińska-Dwórznicka, A. Spray Drying of Honey: The Effect of Drying Agents on Powder Properties. Pol. J. Food Nutr. Sci. 2015, 65, 109–118. [Google Scholar] [CrossRef]

- Rayo, L.M.; Carvalho, L.C.; Sardá, F.A.; Dacanal, G.C.; Menezes, E.W.; Tadini, C.C. Production of instant green banana flour (Musa cavendischii, var. Nanicão) by a pulsed-fluidized bed agglomeration. LWT Food Sci. Technol. 2015, 63, 461–469. [Google Scholar] [CrossRef]

- Jiang, G.; Wu, Z.; Ameer, K.; Li, S.; Ramachandraiah, K. Particle size of ginseng (Panax ginseng Meyer) insoluble dietary fiber and its effect on physicochemical properties and antioxidant activities. Appl. Biol. Chem. 2020, 63, 70. [Google Scholar] [CrossRef]

- Nguyen, D.Q.; Nguyen, T.H.; Mounir, S.; Allaf, K. Effect of Feed Concentration and Inlet Air Temperature on the Properties of Soymilk Powder Obtained by Spray Drying. Dry Technol. 2018, 36, 817–829. [Google Scholar] [CrossRef]

- Koç, B.; Sakin-Yılmazer, M.; Kaymak-Ertekin, F.; Balkır, P. Physical Properties of Yoghurt Powder Produced by Spray Drying. J. Food Sci. Technol. 2012, 51, 1377–1383. [Google Scholar] [CrossRef]

- Sheng, Y.H.; Lu, Q.Y.; Zhang, K. Effect of Different Potato Powder on the Quality of Potato Noodles. J. Henan Univ. Technol. (Nat. Sci. Ed.) 2017, 38, 38–44. [Google Scholar]

- Ng, L.H.; Ling, J.K.U.; Hadinoto, K. Formulation Strategies to Improve the Stability and Handling of Oral Solid Dosage Forms of Highly Hygroscopic Pharmaceuticals and Nutraceuticals. Pharmaceutics 2022, 14, 2015. [Google Scholar] [CrossRef]

- Carpin, M.; Bertelsen, H.; Dalberg, A.; Bech, J.K.; Risbo, J.; Schuck, P.; Jeantet, R. How Does Particle Size Influence Caking in Lactose Powder? J. Food Eng. 2017, 209, 61–67. [Google Scholar] [CrossRef]

- Kaiser, H.F. The application of electronic computers to factor analysis. Educ. Psychol. Meas. 1960, 20, 141–151. [Google Scholar] [CrossRef]

| Coding | Air Tinlet (°C) 1 | Air Toutlet (°C) 2 | RH (%) Ambient Air 3 | Dry Bulb T (°C)- Ambient Air 4 | Wet Bulb T (°C)- Ambient Air 5 | Absolute Humidity (Kg H2O/Kg Dry Air) Ambient Air | Dry Bulb T (°C) -Outlet Air 6 | Wet Bulb T (°C)-Outlet Air 7 | Absolute Humidity (Kg H2O/Kg Dry Air) Outlet Air |

|---|---|---|---|---|---|---|---|---|---|

| SD_3% | 220 | 105 | 76 | 9 | 7 | 0.0054 | 100 | 85 | 0.956 |

| SD_5% | 220 | 90 | 79 | 27.5 | 24.5 | 0.0182 | 85 | 70 | 0.306 |

| Samples | Span | Uniformity | Specific Surface (m2/g) | D(4.3) (μm) | D(3.2) (μm) | D(0.1) (μm) | D(0.5) (μm) | D(0.9) (μm) |

|---|---|---|---|---|---|---|---|---|

| Native potato starch | 1.31 (±0.09) c | 0.40 (±0.03) c | 0.18 (±0.00) c | 45.25 (±1.32) a | 34.18 (±0.42) a | 20.56 (±1.31) a | 41.87 (±1.12) a | 75.42 (±4.12) a |

| SD_3% | 2.85 (±0.45) a | 0.85 (±0.09) a | 0.73 (±0.03) a | 20.98 (±0.97) c | 8.22 (±0.25) c | 4.97 (±0.04) c | 13.82 (±0.61) c | 44.43 (±7.79) b |

| SD_5% | 1.87 (±0.08) b | 0.58 (±0.03) b | 0.43 (±0.00) b | 26.41 (±0.23) b | 13.88 (±0.06) b | 9.05 (±0.04) b | 23.02 (±0.24) b | 52.06 (±2.42) b |

| Samples | L* | a* | b* | Whiteness Index [WI] | Yellowness Index [YI] | Chroma [C*] | Hue Angle [H°] |

|---|---|---|---|---|---|---|---|

| Native potato starch | 99.76 (±0.30) a | 0.38 (±0.05) a | 3.57 (±0.11) b | 74.15 (±0.44) a | 7.01 (±0.16) a | 3.59 (±0.10) b | 83.86 (±0.90) c |

| SD_3% | 96.07 (±1.74) a | 0.16 (±0.04) b | 3.83 (±0.26) a | 69.37 (±2.71) b | 7.30 (±0.53) a | 3.83 (±0.26) a | 86.91 (±1.41) b |

| SD_5% | 96.01 (±0.53) a | −0.15 (±0.04) c | 3.77 (±0.15) ab | 73.60 (±1.49) a | 6.95 (±0.25) a | 3.77 (±0.15) ab | 92.24 (±0.73) a |

| Samples | Bulk Density (g/mL) | Tapped Density (g/mL) | Carr Index [CI] (%) | Hausner Ratio [HR] |

|---|---|---|---|---|

| Native potato starch | 0.51 (±0.08) a | 0.59 (±0.10) a | 13.18 (±7.26) ab | 1.16 (±0.10) ab |

| SD_3% | 0.14 (±0.01) b | 0.16 (±0.01) b | 17.52 (±5.43) a | 1.22 (±0.08) a |

| SD_5% | 0.15 (±0.01) b | 0.15 (±0.01) b | 5.49 (±3.49) b | 1.06 (±0.04) b |

| Variables | Moisture Content | Hue Angle | Carr Index | Hausner Ratio | WHC | Hygroscopicity (100%) |

|---|---|---|---|---|---|---|

| Hue angle | −0.223 | |||||

| p-value | 0.212 | |||||

| Carr index | −0.355 | −0.473 | ||||

| p-value | 0.042 | 0.005 | ||||

| Hausner ratio | −0.353 | −0.455 | 0.996 | |||

| p-value | 0.044 | 0.008 | 0.000 | |||

| WHC | −0.527 | 0.903 | −0.308 | −0.295 | ||

| p-value | 0.002 | 0.000 | 0.081 | 0.096 | ||

| Hygroscopicity (100%) | −0.914 | 0.234 | 0.330 | 0.335 | 0.523 | |

| p-value | 0.000 | 0.190 | 0.061 | 0.056 | 0.002 | |

| D(4.3) | 0.924 | −0.489 | −0.197 | −0.202 | −0.742 | −0.896 |

| p-value | 0.000 | 0.004 | 0.271 | 0.260 | 0.000 | 0.000 |

| Variables | PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | PC7 |

|---|---|---|---|---|---|---|---|

| Moisture content | 0.067 | 0.663 | −0.062 | −0.078 | 0.365 | −0.639 | 0.066 |

| Hue angle | −0.161 | −0.386 | −0.392 | −0.256 | 0.773 | 0.091 | −0.022 |

| Carr index | 0.622 | −0.206 | −0.185 | −0.070 | −0.082 | −0.240 | −0.684 |

| Hausner ratio | 0.623 | −0.195 | −0.219 | −0.028 | −0.060 | −0.071 | 0.719 |

| WHC | −0.075 | −0.500 | 0.487 | 0.452 | 0.194 | −0.512 | 0.061 |

| Hygroscopicity (100%) | −0.431 | −0.263 | −0.442 | −0.263 | −0.471 | −0.504 | 0.068 |

| D(4.3) | 0.068 | −0.111 | 0.572 | −0.806 | −0.009 | −0.066 | 0.046 |

| Hue angle | 0.067 | 0.663 | −0.062 | −0.078 | 0.365 | −0.639 | 0.066 |

| Variables | PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | PC7 |

|---|---|---|---|---|---|---|---|

| Moisture content | −0.460 | −0.114 | 0.102 | −0.165 | 0.457 | 0.727 | −0.030 |

| Hue angle | −0.081 | −0.730 | −0.441 | −0.480 | −0.144 | −0.122 | −0.003 |

| Carr index | 0.418 | −0.387 | 0.329 | 0.134 | 0.159 | 0.118 | 0.714 |

| Hausner ratio | 0.409 | −0.388 | 0.392 | 0.106 | 0.182 | 0.024 | −0.695 |

| WHC | −0.404 | −0.010 | 0.616 | −0.395 | 0.149 | −0.524 | 0.075 |

| Hygroscopicity (100%) | 0.371 | 0.270 | −0.325 | −0.339 | 0.725 | −0.209 | 0.015 |

| D(4.3) | 0.372 | 0.283 | 0.222 | −0.665 | −0.406 | 0.353 | −0.010 |

| Variables | PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | PC7 |

|---|---|---|---|---|---|---|---|

| Moisture content | 0.307 | 0.349 | 0.626 | 0.388 | 0.032 | 0.072 | −0.485 |

| Hue angle | 0.468 | −0.153 | −0.199 | −0.038 | 0.026 | −0.817 | −0.221 |

| Carr index | −0.442 | 0.292 | −0.174 | −0.088 | 0.739 | −0.147 | −0.337 |

| Hausner ratio | −0.439 | 0.295 | −0.201 | −0.071 | −0.671 | −0.154 | −0.449 |

| WHC | 0.429 | −0.125 | −0.445 | −0.247 | 0.044 | 0.529 | −0.510 |

| Hygroscopicity (100%) | −0.214 | −0.545 | 0.526 | −0.543 | 0.005 | −0.045 | −0.289 |

| D(4.3) | 0.262 | 0.609 | 0.151 | −0.692 | −0.028 | −0.034 | 0.238 |

| Variables | PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | PC7 |

|---|---|---|---|---|---|---|---|

| Moisture content | −0.483 | 0.148 | 0.334 | −0.559 | −0.246 | 0.510 | −0.029 |

| Hue angle | 0.281 | 0.446 | 0.565 | −0.136 | 0.613 | −0.086 | −0.021 |

| Carr index | 0.108 | −0.569 | 0.393 | 0.017 | −0.022 | −0.022 | −0.713 |

| Hausner ratio | 0.112 | −0.565 | 0.420 | −0.049 | −0.018 | −0.028 | 0.699 |

| WHC | 0.409 | 0.343 | 0.320 | 0.057 | −0.749 | −0.220 | −0.005 |

| Hygroscopicity (100%) | 0.478 | −0.137 | −0.359 | −0.780 | 0.021 | −0.119 | −0.031 |

| D(4.3) | −0.517 | 0.008 | 0.089 | −0.235 | −0.019 | −0.818 | −0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marinopoulou, A.; Zoumaki, M.; Sampanis, D.; Karageorgiou, V.; Raphaelides, S.; Goulas, A. A Comparative Study of the Structural, Morphological, and Functional Properties of Native Potato Starch and Spray-Dried Potato Starch. Appl. Sci. 2025, 15, 4566. https://doi.org/10.3390/app15084566

Marinopoulou A, Zoumaki M, Sampanis D, Karageorgiou V, Raphaelides S, Goulas A. A Comparative Study of the Structural, Morphological, and Functional Properties of Native Potato Starch and Spray-Dried Potato Starch. Applied Sciences. 2025; 15(8):4566. https://doi.org/10.3390/app15084566

Chicago/Turabian StyleMarinopoulou, Anna, Maria Zoumaki, Dimitrios Sampanis, Vassilis Karageorgiou, Stylianos Raphaelides, and Athanasios Goulas. 2025. "A Comparative Study of the Structural, Morphological, and Functional Properties of Native Potato Starch and Spray-Dried Potato Starch" Applied Sciences 15, no. 8: 4566. https://doi.org/10.3390/app15084566

APA StyleMarinopoulou, A., Zoumaki, M., Sampanis, D., Karageorgiou, V., Raphaelides, S., & Goulas, A. (2025). A Comparative Study of the Structural, Morphological, and Functional Properties of Native Potato Starch and Spray-Dried Potato Starch. Applied Sciences, 15(8), 4566. https://doi.org/10.3390/app15084566