Shear Properties of the Interface Between Polyurethane Concrete and Normal Concrete

Abstract

:1. Introduction

- Research Significance

- Novelty of This Research

- A comprehensive evaluation of the influence of various factors, including interface treatment protocols, adhesive formulations, and steel fiber incorporation, on the interfacial bond strength has been carried out.

- A generalized predictive model for the shear strength of the PUC–NC interface, applicable to a variety of concrete substrate surface treatment techniques, has been established.

- The failure mechanisms of the PUC–NC interface under different surface treatment conditions have been systematically investigated through room-temperature oblique shear testing.

2. Materials and Methods

2.1. Raw Materials

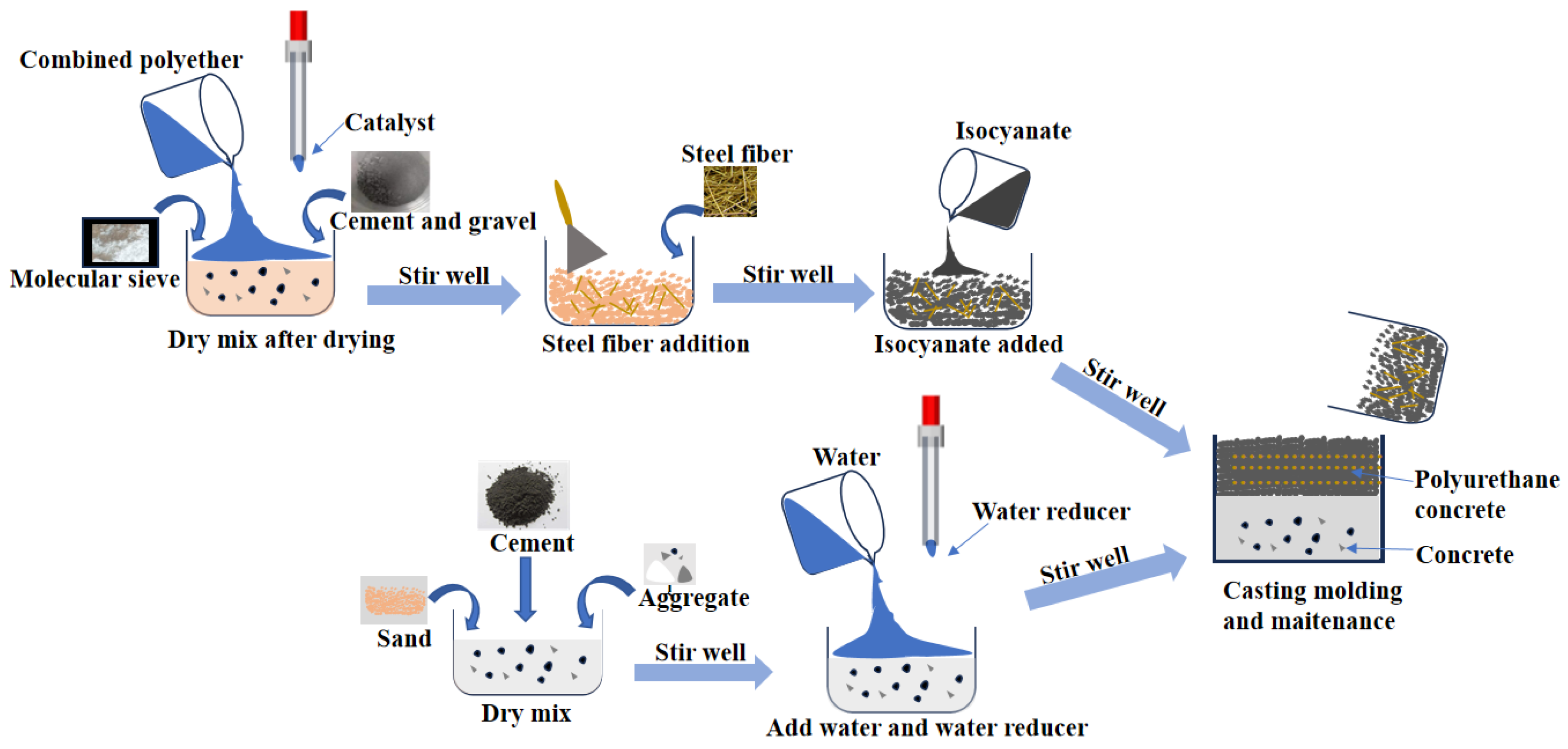

2.1.1. Polyurethane Concrete (PUC)

2.1.2. Normal Concrete (NC)

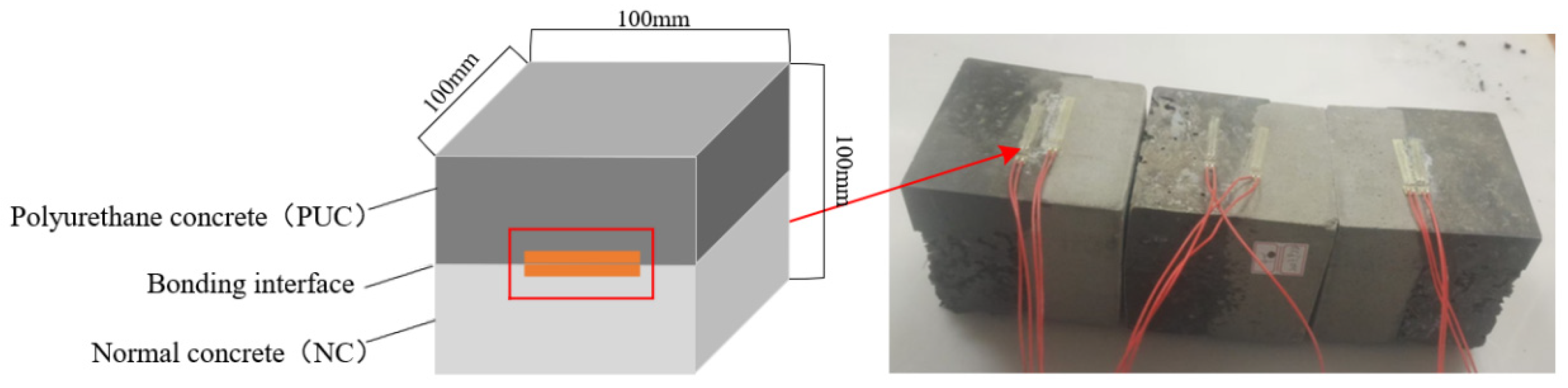

2.2. Preparation of Specimens

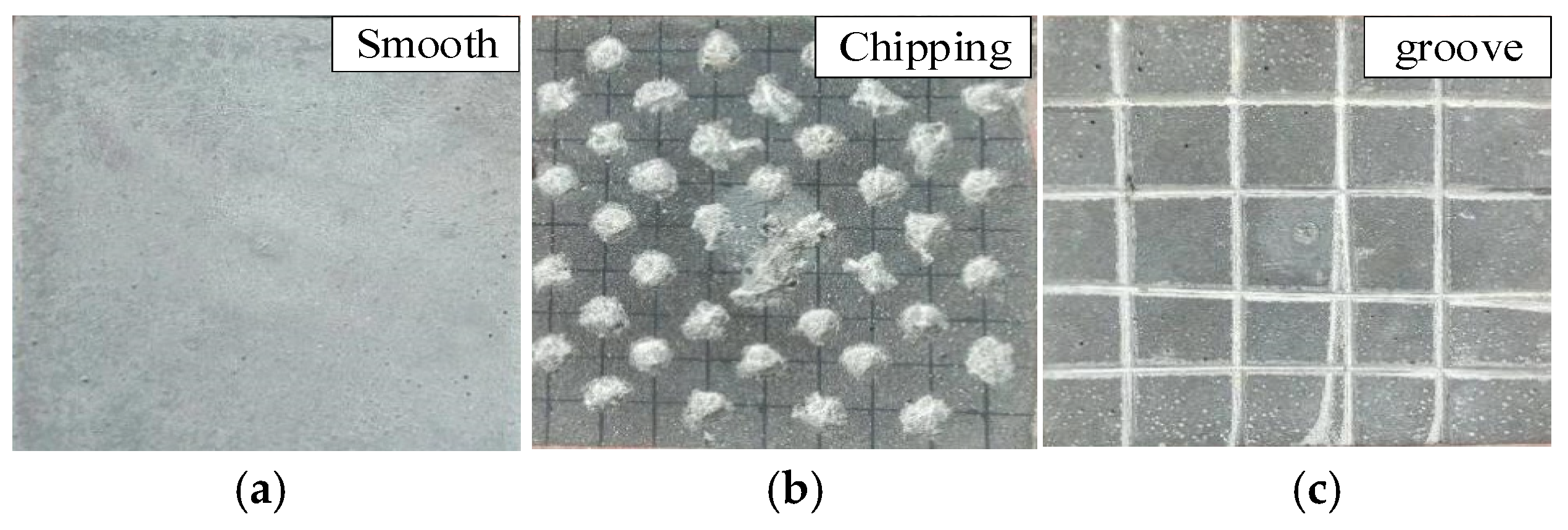

2.2.1. Treatment of Concrete Roughness

2.2.2. Preparation of Polyurethane Mortar

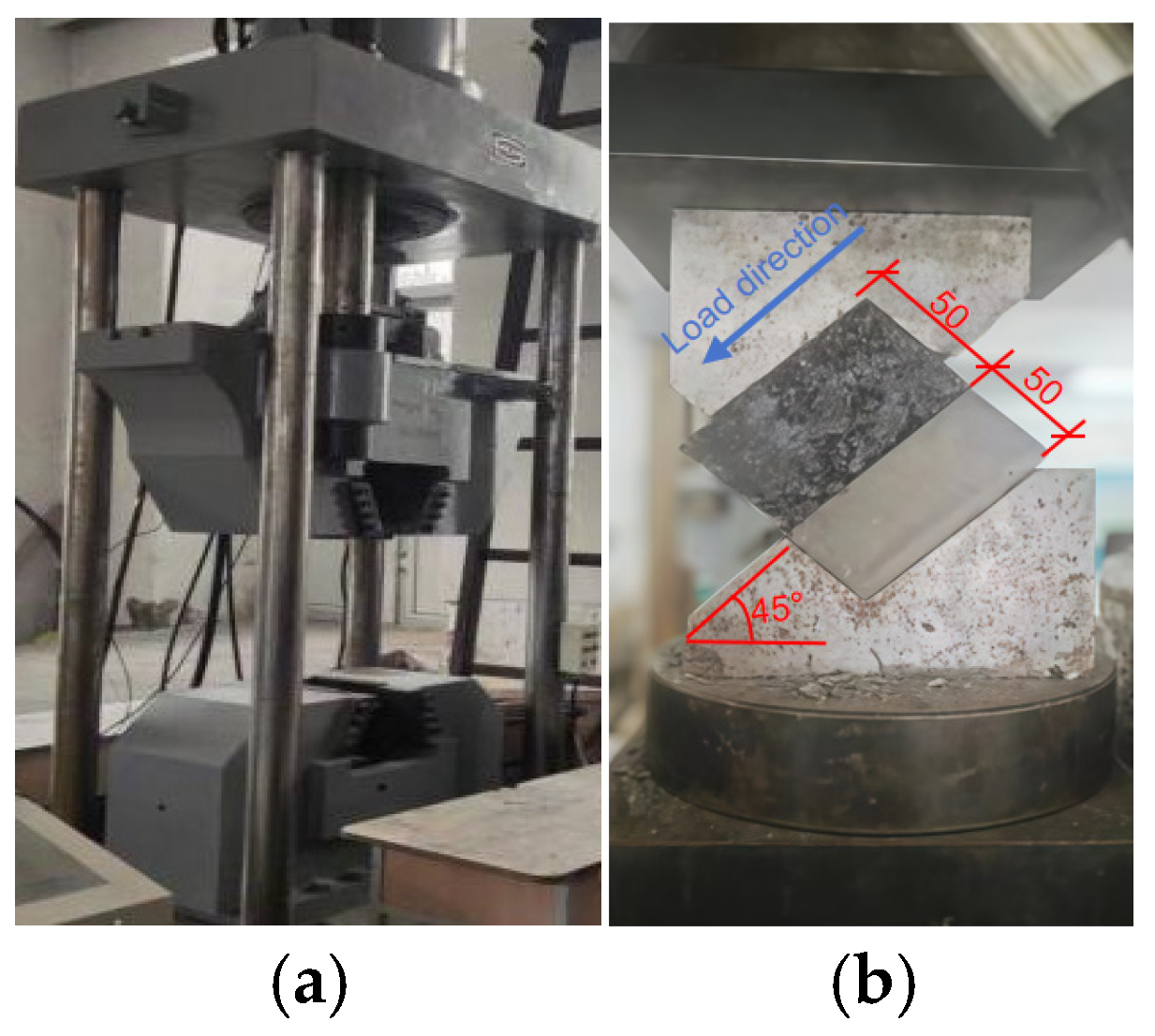

2.3. Test Loading and Measurements

3. Results

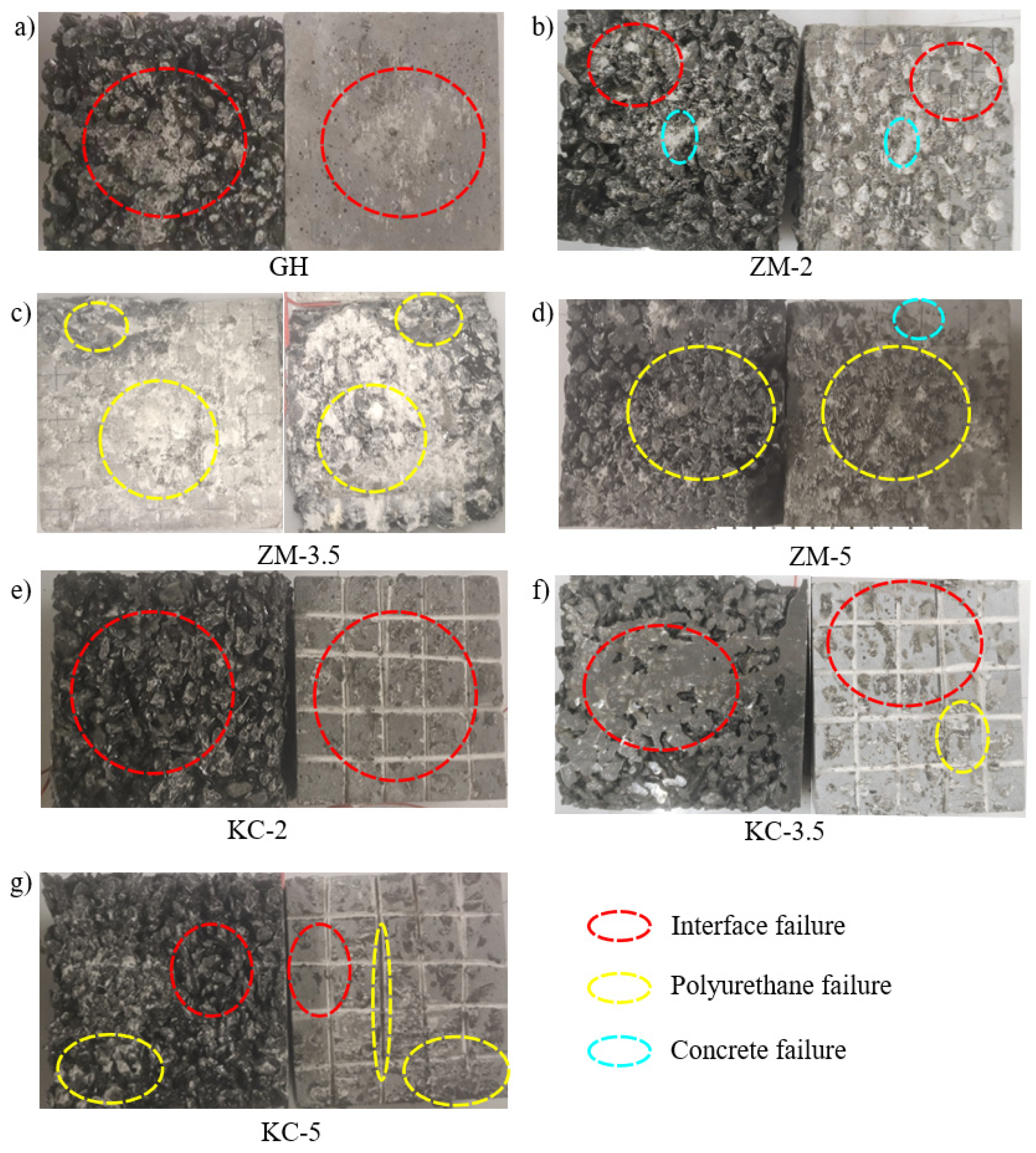

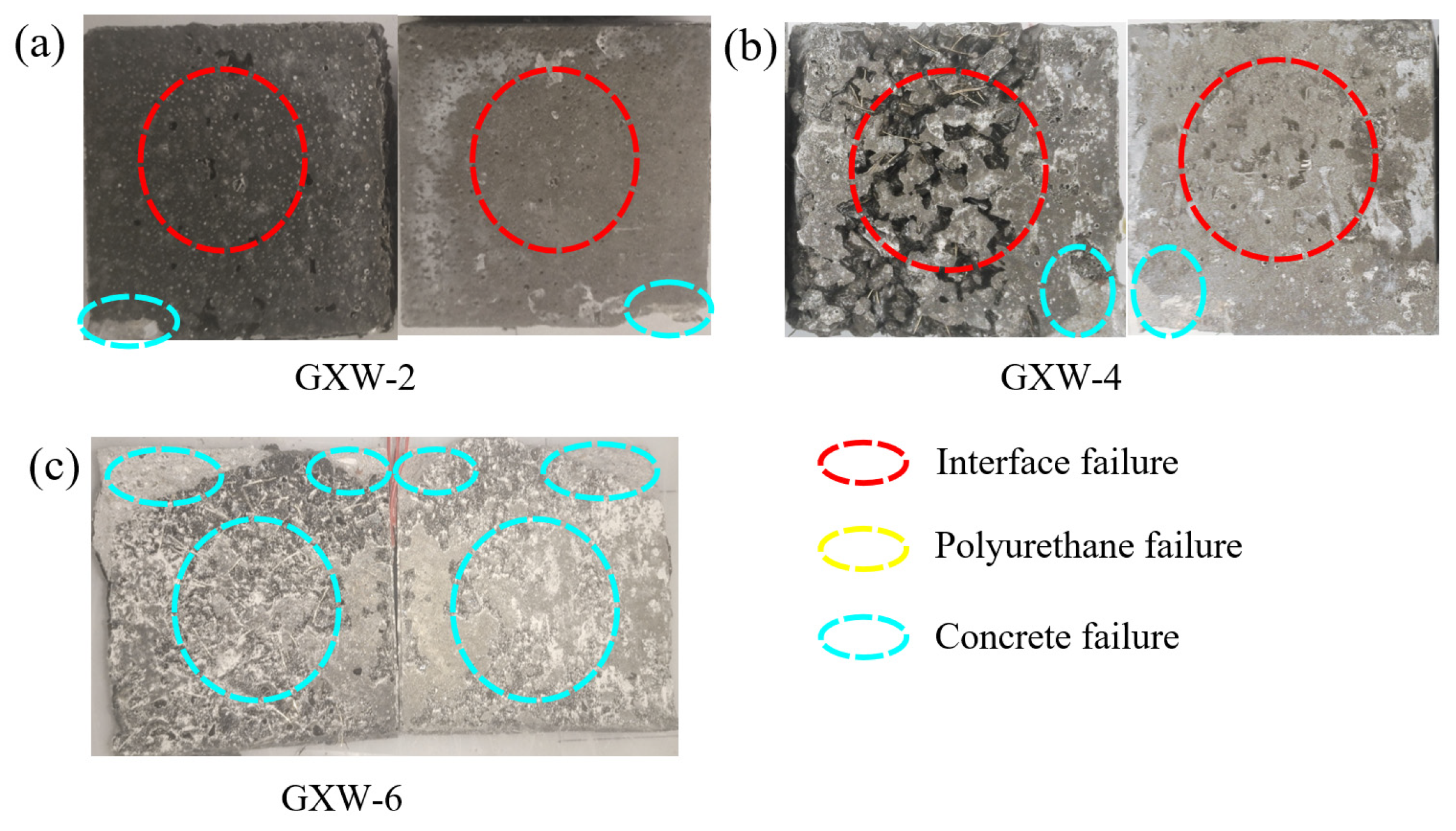

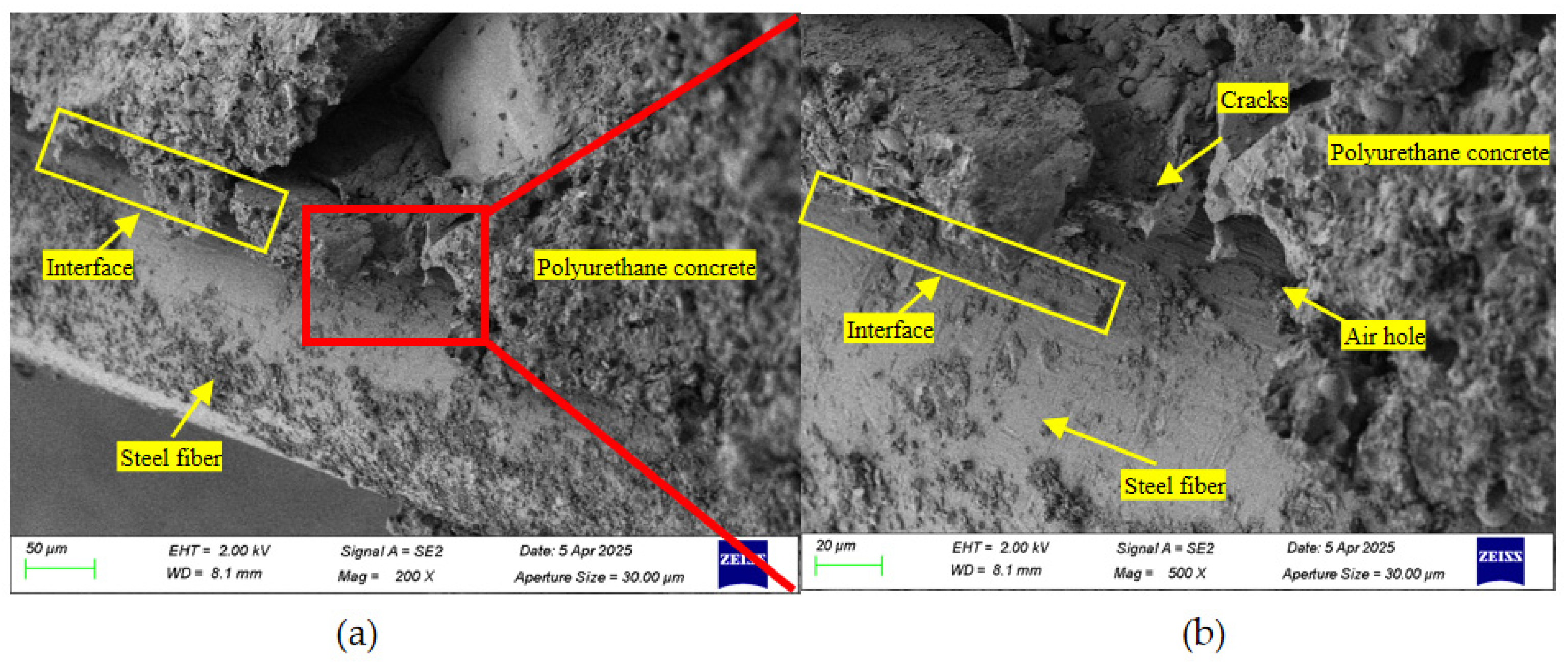

3.1. Failure Modes and Characteristic Values

- (1)

- Interface Failure (Type A): Shear failure occurs along the interface, with no damage or detachment of the NC. The surfaces of the two materials remain smooth or exhibit minimal bonding with NC (bonding area ratio less than 10%), indicating a low bond strength at the interface, leading to direct splitting of the composite specimen from the interface.

- (2)

- PUC Failure (Type B): The cohesive strength of the NC and the bond strength at the interface are higher than the cohesive strength of the PUC. The composite specimen fails on the PUC side.

- (3)

- NC Shear Failure (Type C): The NC matrix near the interface experiences shear damage. When failure occurs, a significant amount of NC remains adhered to the PUC surface. The PUC–NC interface remains largely intact, indicating that the cohesive strength of the PUC and the bond strength at the interface are greater than the cohesive strength of the NC, resulting in failure on the concrete side of the specimen.

- (4)

- Mixed Failure (Type D): This failure mode suggests that a combination of the PUC’s cohesive strength, the concrete’s cohesive strength and the adhesion between the PUC and NC contributes to the bond strength at the interface, leading to damage in both the PUC and NC.

- (5)

- Partial Interface Failure with Partial NC Failure (Type A/C): This mode involves partial failure of the NC substrate, with shear failure occurring in the transitional zone of the interface and the NC side. A thin layer of NC substrate remains adhered to the surface of the PUC.

3.2. Shear Failure Modes

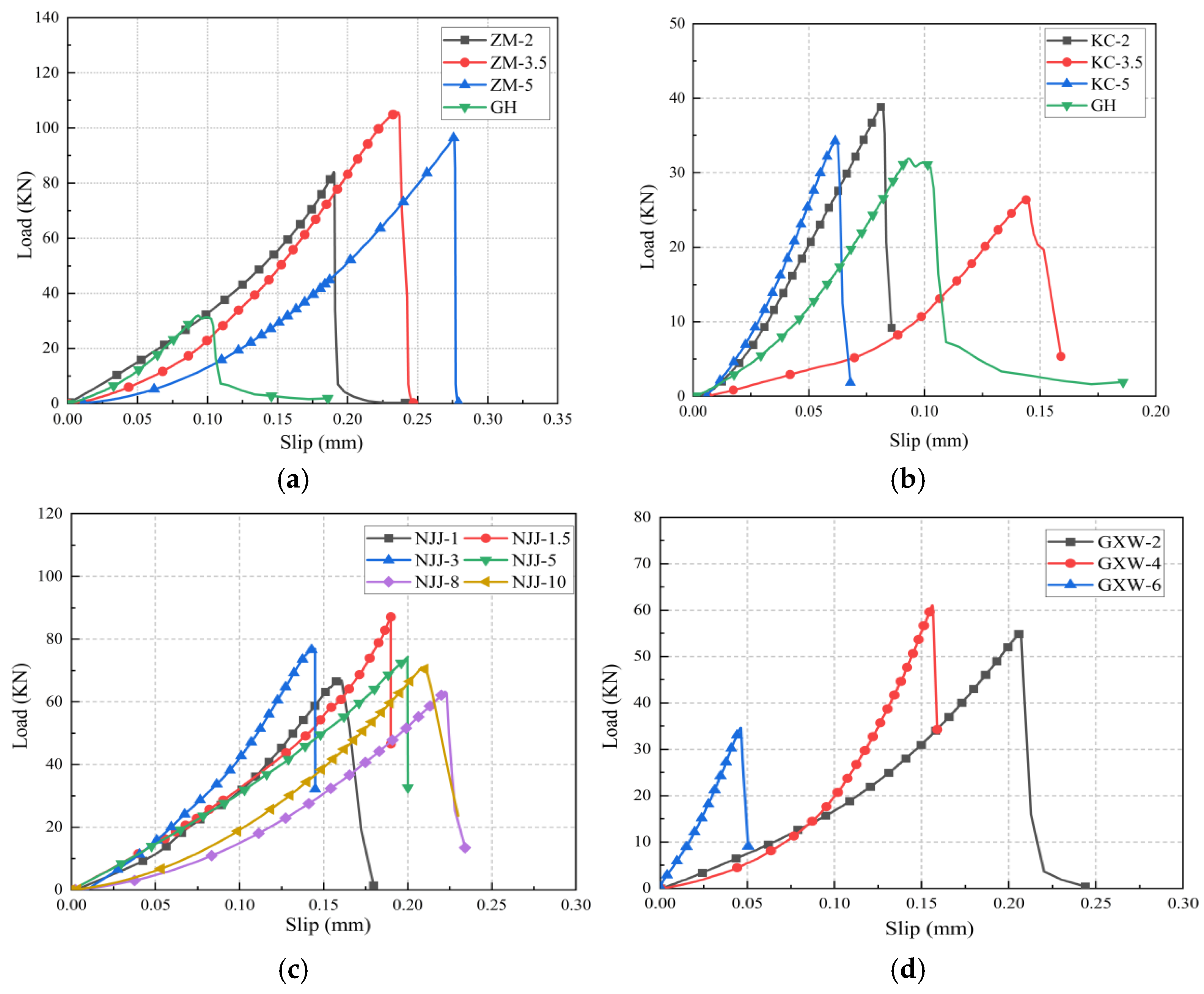

3.3. Load–Displacement Curve

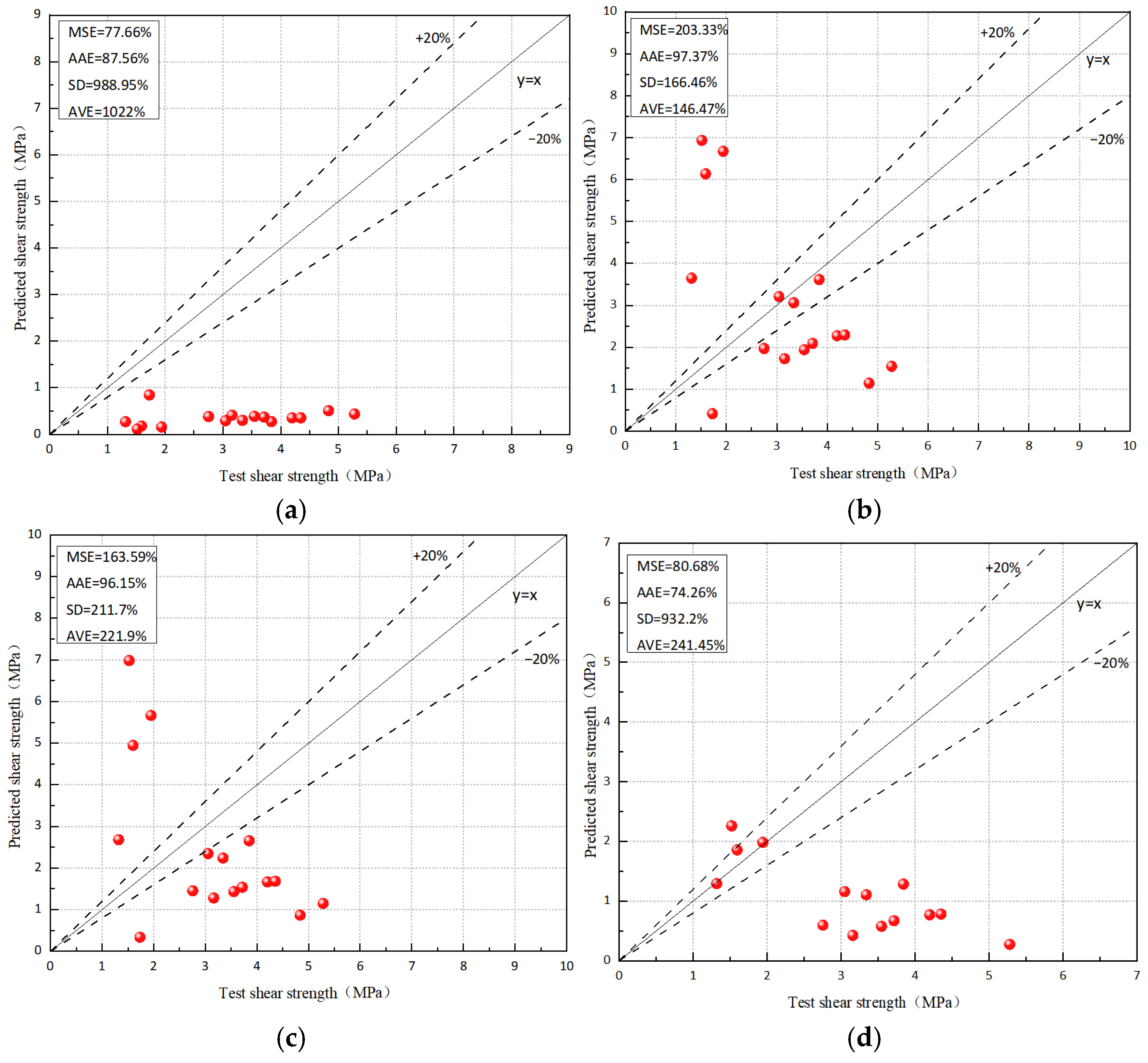

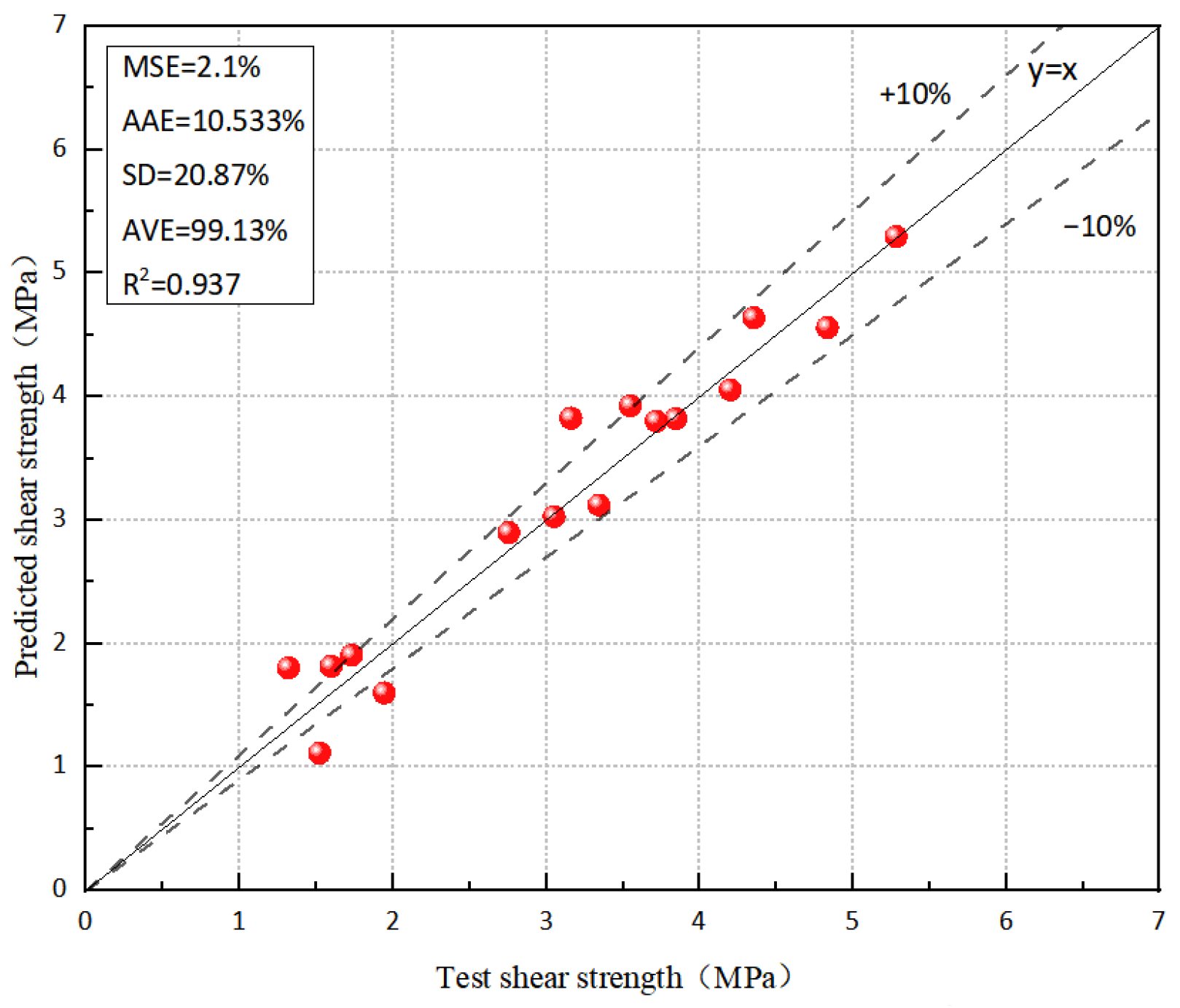

4. Constitutive Model for PUC–NC Interface Bonding Performance

5. Conclusions

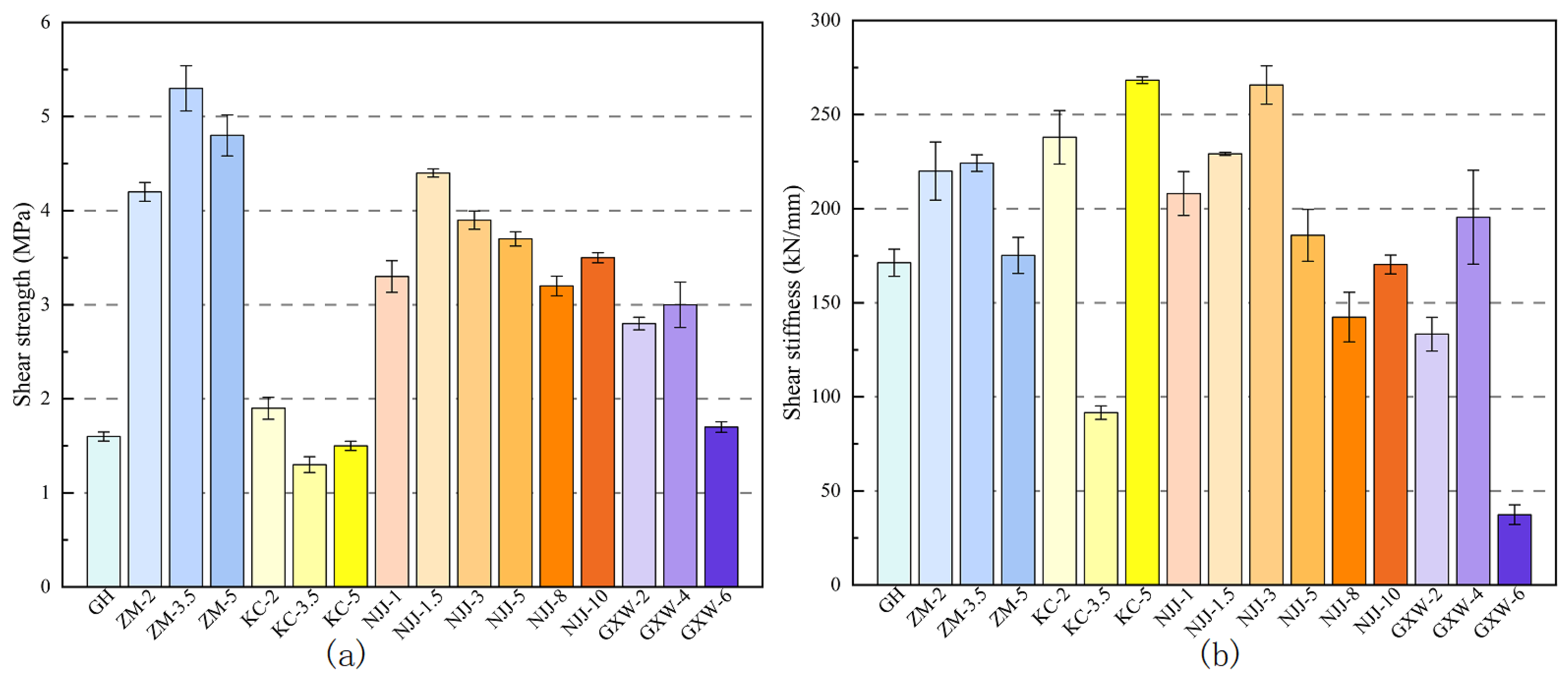

- Effect of Surface Roughness on Shear Performance: The surface roughness of the interface has a significant impact on the shear strength of the PUC–NC interface. The roughened interface exhibited the highest shear strength, approximately 32% higher than the smooth interface and 15% higher than the grooved interface. Roughening significantly increased the surface roughness, enhancing the bonding strength between polyurethane and concrete, thus improving the shear performance. In contrast, the smooth interface showed the lowest shear strength (3.5 MPa), indicating insufficient mechanical bonding.

- Effect of Adhesive Application Rate: The application rate of the adhesive had a notable effect on enhancing shear strength. An appropriate adhesive application rate (approximately 0.2 kg/m2) resulted in an 18% increase in shear strength, reaching 4.6 MPa, compared to the interface without adhesive. Excessive adhesive (application rate greater than 0.3 kg/m2) did not further improve the shear strength. The brittle layered structure formed by excess adhesive could even reduce the interface toughness.

- Effect of Steel Fiber Content: The addition of steel fibers had a complex impact on the shear performance of the interface. At low fiber contents (e.g., 0.5% and 1%), steel fibers effectively improved the shear strength, with the highest shear strength of 5.3 MPa observed at 1% steel fiber content, which was a 22% increase compared to the interface without steel fibers.

- Load–Displacement Behavior: The load–displacement curves of all specimens exhibited typical brittle failure characteristics, with the curves approximately linear up to the ultimate load. The interface treatment group (ZM) and adhesive application group (NJJ) showed a superior bonding performance, with significantly higher maximum displacement and shear strength compared to the other treatments. This confirms the importance of interface design in enhancing structural repair effectiveness.

- Prediction Model for Shear Strength: Based on the adhesive test data, a predictive model for the shear strength of the PUC–NC interface is proposed. Through nonlinear regression analysis, the model can accurately predict shear strength under various interface treatment conditions, providing a theoretical basis for future interface design in engineering applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hooton, R.D. Future directions for design, specification, testing, and construction of durable concrete structures. Cem. Concr. Res. 2019, 124, 105827. [Google Scholar] [CrossRef]

- Tian, X.; Zhu, N. Durability prediction method of concrete soil based on deep belief network. Adv. Civ. Eng. 2022, 2022, 4338306. [Google Scholar] [CrossRef]

- Yi, Y.; Zhu, D.; Guo, S.; Zhang, Z.; Shi, C. A review on the deterioration and approaches to enhance the durability of concrete in the marine environment. Cem. Concr. Compos. 2020, 113, 103695. [Google Scholar] [CrossRef]

- Hu, D.; Sun, Q.; Yan, B. Experimental study on the interface shear performance of elastic polyurethane concrete–steel plate. Structures 2022, 45, 2306–2317. [Google Scholar] [CrossRef]

- Jiang, Z.; Tang, C.; Yang, J.; You, Y.; Lv, Z. A lab study to develop polyurethane concrete for bridge deck pavement. Int. J. Pavement Eng. 2022, 23, 1404–1412. [Google Scholar] [CrossRef]

- Zhang, K.; Sun, Q. The use of Wire Mesh-Polyurethane Cement (WM-PUC) composite to strengthen RC T-beams under flexure. J. Build. Eng. 2018, 15, 122–136. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Kouchaki, H.G.; Mohammadi, M.H.; Haghighatpour, P.J.; Choupani, N.; Asadi, P.; Akbari, M.; Darvish, M.G.; Sadowski, T. Fracture toughness determination for epoxy-based polymer concrete mixtures: Applicability of different rectangular beam and circular disc specimens. Compos. Part C Open Access 2024, 14, 100446. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Wong, H.S.; Abousnina, R.; AlAjarmeh, O.S.; Zhuge, Y.; Schubel, P. Optimal design for epoxy polymer concrete based on mechanical properties and durability aspects. Constr. Build. Mater. 2020, 232, 117229. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, Y.; Li, C.; Hu, Z.; Lv, H.; Zhang, J.; Meng, X. Preparation and application research of hybrid alkali-resistant glass fiber reinforced cement grout. Case Stud. Constr. Mater. 2023, 19, e02674. [Google Scholar] [CrossRef]

- Al-kahtani, M.S.M.; Zhu, H.; Ibrahim, Y.E.; Haruna, S.I.; Al-qahtani, S.S.M. Study on the Mechanical Properties of Polyurethane-Cement Mortar Containing Nanosilica: RSM and Machine Learning Approach. Appl. Sci. 2023, 13, 13348. [Google Scholar] [CrossRef]

- Haruna, S.I.; Ibrahim, Y.E.; Al-shawafi, A. Evaluation of Bond Strength of Concrete Repaired Using Polyurethane Grout Material under Static and Impact Loads Coupled with Statistical Analysis. Polymers 2024, 16, 2729. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chai, J.; Li, Y.; Wang, R.; Qin, Y.; Cao, Z. Experimental investigation of the interfacial bonding properties between polyurethane mortar and concrete under different influencing factors. Constr. Build. Mater. 2023, 408, 133800. [Google Scholar] [CrossRef]

- Niu, S.; Wang, Z.; Wang, J.; Wang, D.; Sun, X. Experimental investigation on flexural performance of polyester polyurethane concrete steel bridge deck composite structure. Case Stud. Constr. Mater. 2023, 18, e01915. [Google Scholar] [CrossRef]

- Zhai, D.; Sun, Q. Molecular dynamics and experimental study of the interfacial adhesion mechanism of polyurethane-based repair materials. Constr. Build. Mater. 2025, 459, 139796. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Q.; Ding, H.; Leng, S.; Cui, H.; Xu, B.; Cui, H. Investigation of interfacial bonding properties of polyurethane concrete and cement concrete/steel reinforcement. Adv. Mater. Sci. Eng. 2022, 2022, 5644468. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Q.; Liu, Y.; Rim, C.; Kim, C. Preparation of polyurethane concrete and its novel application in bridge expansion joint anchorage zone. J. Reinf. Plast. Compos. 2024, 43, 1356–1374. [Google Scholar] [CrossRef]

- Li, L.; Yu, T.; Wu, Y.; Wang, Y.; Guo, C.; Li, J. Research on the Properties of a New Type of Polyurethane Concrete for Steel Bridge Deck in Seasonally Frozen Areas. Coatings 2022, 12, 1732. [Google Scholar] [CrossRef]

- Han, Y.; Meng, X.; Feng, F.; Song, X.; Huang, F.; Wen, W. Study on Temperature-Dependent Uniaxial Tensile Tests and Constitutive Relationship of Modified Polyurethane Concrete. Materials 2023, 16, 2653. [Google Scholar] [CrossRef]

- Chen, J.; Ma, X.; Wang, H.; Xie, P.; Huang, W. Experimental study on anti-icing and deicing performance of polyurethane concrete as road surface layer. Constr. Build. Mater. 2018, 161, 598–605. [Google Scholar] [CrossRef]

- Hassani Niaki, M. Fracture mechanics of polymer concretes: A review. Theor. Appl. Fract. Mech. 2023, 125, 103922. [Google Scholar] [CrossRef]

- Ibrahim Haruna, S.; Zhu, H.; Jiang, W.; Shao, J. Evaluation of impact resistance properties of polyurethane-based polymer concrete for the repair of runway subjected to repeated drop-weight impact test. Constr. Build. Mater. 2021, 309, 125152. [Google Scholar] [CrossRef]

- Karimi, H.R.; Khedri, E.; Aliha, M.R.M.; Shaker, H.; Jafari Haghighatpour, P. Repair efficiency evaluation for cracked asphalt mixture pavement in different ambient temperatures using bitumen and polymer concrete as repair materials. Constr. Build. Mater. 2023, 369, 130556. [Google Scholar] [CrossRef]

- Guo, C.; Pei, L.; Guan, H.; Chu, X.; Wang, H.; Shi, F.; An, Z.; Qin, L. Experimental study on interfacial damage mechanisms of polymer-concrete composite structure. J. Build. Eng. 2023, 75, 106968. [Google Scholar] [CrossRef]

- Qin, L.; Guo, C.; Sun, W.; Guan, H.; Yan, W.; Wang, F. Experimental investigation on the interfacial shear bond performance of non-water reacting polymer and concrete. Constr. Build. Mater. 2022, 331, 127351. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, Y.; Yang, Y.; Sun, Q.; Luo, T.; Zhang, H. Influence of surface roughness and hydrophilicity on bonding strength of concrete-rock interface. Constr. Build. Mater. 2019, 213, 156–166. [Google Scholar] [CrossRef]

- Ummin, O.; Li, Y.; Li, K.; Chen, Y.; Jia, H.; Zuo, J. Influence of surface roughness and interfacial agent on the interface bonding characteristics of polyurethane concrete and cement concrete. J. Build. Eng. 2024, 91, 109596. [Google Scholar] [CrossRef]

- Zhong, Y.; Xu, S.; Chi, J.; Zhang, B.; Shen, G.; Yang, Z.; Cheng, H.; Wang, B. Experimental study on the interface bonding characteristic of polyurethane and pavement materials. Constr. Build. Mater. 2023, 397, 132390. [Google Scholar] [CrossRef]

- Li, X.; Wang, F.; Fang, H.; Zheng, D.; Fu, Y. Bond Behavior between Concrete and Self-Expansion Polymer Material under Normal Pressures. Adv. Civ. Eng. 2021, 2021, 6675102. [Google Scholar] [CrossRef]

- Zhang, P.; Wu, G.; Zhu, H.; Meng, S.P.; Wu, Z.S. Mechanical performance of the wet-bond interface between FRP plates and cast-in-place concrete. J. Compos. Constr. 2014, 18, 04014016. [Google Scholar] [CrossRef]

- Neubauer, U.; Rostasy, F. Bond failure of concrete fiber reinforced polymer plates at inclined cracks—Experiments and fracture mechanics model. Spec. Publ. 1999, 188, 369–382. [Google Scholar]

- Nakaba, K.; Kanakubo, T.; Furuta, T.; Yoshizawa, H. Bond behavior between fiber-reinforced polymer laminates and concrete. Struct. J. 2001, 98, 359–367. [Google Scholar]

- Savoia, M.; Ferracuti, B.; Mazzotti, C. Non linear bond-slip law for FRP-concrete interface. In Fibre-Reinforced Polymer Reinforcement for Concrete Structures: (In 2 Volumes); World Scientific: Singapore, 2003; pp. 163–172. [Google Scholar]

- Lu, X.Z.; Teng, J.G.; Ye, L.P.; Jiang, J.J. Bond-slip models for FRP sheets/plates bonded to concrete. Eng. Struct. 2005, 27, 920–937. [Google Scholar] [CrossRef]

| Component | Main Chemical Compositions | Mixing Mass Ratio/(kg) |

|---|---|---|

| Part 1 | 90% polyether polyols and 10% chain extender crosslinkers | 1 |

| Part 2 | MDI-based isocyanate group | 1 |

| Part 3 | Stone and cement | 5:1 |

| Part 4 | Molecular sieve activated powder | 0.3 |

| Name | Particle Size (μm) | Bulk Density (g/mL) | Static Water Adsorption (%) | PH Value |

|---|---|---|---|---|

| Molecular sieve activated powder | 2−4 | ≥0.45 | ≥25.0 | 9−11 |

| Density (g/m3) | Initial Setting Time (min) | Final Setting Time (min) | Compressive Strength at 3 Days (MPa) | Compressive Strength at 28 Days (MPa) |

|---|---|---|---|---|

| 3.28 | 200 | 240 | 18.3 | 42.6 |

| Water–Cement Ratio | Water (kg/m3) | Cement (kg/m3) | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Superplasticizer (%) |

|---|---|---|---|---|---|

| 0.38 | 175 | 420 | 1083 | 722 | 0.27 |

| Steel Fiber Type | Length (mm) | Length-Diameter Ratio | Density (t/m3) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| End hooked steel fiber | 30 | 40 | 7.8 | 210 |

| Sample Number | Pu (kN) | S0.7Pu (mm) | Failure Mode |

|---|---|---|---|

| GH | 31.92 | 0.093 | A |

| ZM-2 | 84.03 | 0.191 | A |

| ZM-3.5 | 105.64 | 0.236 | A/B |

| ZM-5 | 96.68 | 0.276 | A/B |

| KC-2 | 38.90 | 0.082 | A |

| KC-3.5 | 26.38 | 0.144 | A |

| KC-5 | 30.44 | 0.057 | B |

| NJJ-1 | 66.85 | 0.161 | A/C |

| NJJ-1.5 | 87.08 | 0.190 | A/C |

| NJJ-3 | 76.92 | 0.145 | D |

| NJJ-5 | 74.34 | 0.200 | D |

| NJJ-8 | 63.22 | 0.222 | D |

| NJJ-10 | 70.98 | 0.208 | D |

| GXW-2 | 55.11 | 0.207 | A/C |

| GXW-4 | 61.01 | 0.156 | A/C |

| GXW-6 | 34.61 | 0.463 | C |

| Specimen | Pu (KN) | S0.7Pu (mm) | Shear Strength (MPa) | Shear Stiffness (kN/mm) | Average Shear Strength (MPa) | Average Shear Stiffness (kN/mm) |

|---|---|---|---|---|---|---|

| GH | 31.44 | 0.0630 | 1.6 | 174.1 | 1.6 | 171.3 |

| 33.25 | 0.0720 | 1.7 | 161.4 | |||

| 31.09 | 0.0610 | 1.6 | 178.4 | |||

| ZM-2 | 83.22 | 0.1265 | 4.1 | 231.1 | 4.2 | 220.0 |

| 86.00 | 0.1509 | 4.3 | 198.0 | |||

| 82.85 | 0.1259 | 4.1 | 230.3 | |||

| ZM-3.5 | 98.26 | 0.1493 | 4.9 | 230.3 | 5.3 | 224.2 |

| 109.52 | 0.1740 | 5.4 | 220.3 | |||

| 109.15 | 0.1721 | 5.4 | 221.9 | |||

| ZM-5 | 99.93 | 0.1865 | 4.9 | 187.5 | 4.8 | 175.3 |

| 100.59 | 0.2146 | 5.0 | 164.1 | |||

| 89.36 | 0.1795 | 4.5 | 174.2 | |||

| KC-2 | 36.50 | 0.0512 | 1.8 | 249.5 | 1.9 | 237.9 |

| 38.30 | 0.0615 | 1.9 | 217.9 | |||

| 41.95 | 0.0596 | 2.1 | 246.3 | |||

| KC-3.5 | 26.01 | 0.1001 | 1.3 | 90.9 | 1.3 | 91.7 |

| 24.93 | 0.0905 | 1.2 | 96.4 | |||

| 28.08 | 0.1119 | 1.4 | 87.8 | |||

| KC-5 | 31.24 | 0.0409 | 1.6 | 267.3 | 1.5 | 268.3 |

| 30.08 | 0.0395 | 1.5 | 266.5 | |||

| 30.00 | 0.0388 | 1.5 | 270.6 | |||

| NJJ-1 | 67.91 | 0.1215 | 3.3 | 195.6 | 3.3 | 208.0 |

| 61.86 | 0.0968 | 3.1 | 223.6 | |||

| 70.84 | 0.1211 | 3.5 | 204.7 | |||

| NJJ-1.5 | 88.44 | 0.1346 | 4.4 | 230.0 | 4.4 | 229.2 |

| 87.09 | 0.1336 | 4.4 | 228.1 | |||

| 86.6 | 0.1320 | 4.3 | 229.6 | |||

| NJJ-3 | 75.5 | 0.0985 | 3.8 | 268.2 | 3.9 | 265.7 |

| 75.98 | 0.0961 | 3.8 | 276.7 | |||

| 79.82 | 0.1108 | 4.0 | 252.1 | |||

| NJJ-5 | 75.42 | 0.1501 | 3.8 | 175.9 | 3.7 | 185.9 |

| 75.39 | 0.1496 | 3.8 | 176.4 | |||

| 72.22 | 0.1231 | 3.6 | 205.3 | |||

| NJJ-8 | 66.10 | 0.1842 | 3.3 | 125.6 | 3.2 | 142.4 |

| 61.14 | 0.1356 | 3.1 | 157.8 | |||

| 62.56 | 0.1523 | 3.1 | 143.8 | |||

| NJJ-10 | 71.33 | 0.1515 | 3.6 | 164.8 | 3.5 | 170.4 |

| 70.25 | 0.145 | 3.5 | 169.6 | |||

| 71.24 | 0.1409 | 3.6 | 177.0 | |||

| GXW-2 | 54.12 | 0.1365 | 2.7 | 138.8 | 2.8 | 133.3 |

| 57.01 | 0.1654 | 2.9 | 120.6 | |||

| 54.22 | 0.1351 | 2.7 | 140.5 | |||

| GXW-4 | 60.25 | 0.0987 | 3.0 | 213.7 | 3.0 | 195.5 |

| 66.14 | 0.1445 | 3.3 | 160.2 | |||

| 54.36 | 0.0895 | 2.7 | 212.6 | |||

| GXW-6 | 36.05 | 0.415 | 1.8 | 30.4 | 1.7 | 37.4 |

| 33.3 | 0.3001 | 1.7 | 38.8 | |||

| 34.48 | 0.2804 | 1.7 | 43.0 |

| Model | ||

|---|---|---|

| Neubauer et al. [30] | ||

| Nakaba et al. [31] | ||

| Savoia et al. [32] | ||

| Bilinear constitutive model [33] | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yue, X.; Liu, Z.; Mi, B.; Wang, L.; Sun, Q.; Wang, X.; Dai, Z. Shear Properties of the Interface Between Polyurethane Concrete and Normal Concrete. Appl. Sci. 2025, 15, 4580. https://doi.org/10.3390/app15084580

Zhang Y, Yue X, Liu Z, Mi B, Wang L, Sun Q, Wang X, Dai Z. Shear Properties of the Interface Between Polyurethane Concrete and Normal Concrete. Applied Sciences. 2025; 15(8):4580. https://doi.org/10.3390/app15084580

Chicago/Turabian StyleZhang, Yuhan, Xinlong Yue, Zhengyi Liu, Boyang Mi, Lu Wang, Quansheng Sun, Xu Wang, and Zhongnan Dai. 2025. "Shear Properties of the Interface Between Polyurethane Concrete and Normal Concrete" Applied Sciences 15, no. 8: 4580. https://doi.org/10.3390/app15084580

APA StyleZhang, Y., Yue, X., Liu, Z., Mi, B., Wang, L., Sun, Q., Wang, X., & Dai, Z. (2025). Shear Properties of the Interface Between Polyurethane Concrete and Normal Concrete. Applied Sciences, 15(8), 4580. https://doi.org/10.3390/app15084580