Comprehensive Analysis of Scheduling Processes in Road Intersections: Associating Deficiencies and Their Consequences in Colombian Projects

Abstract

:1. Introduction

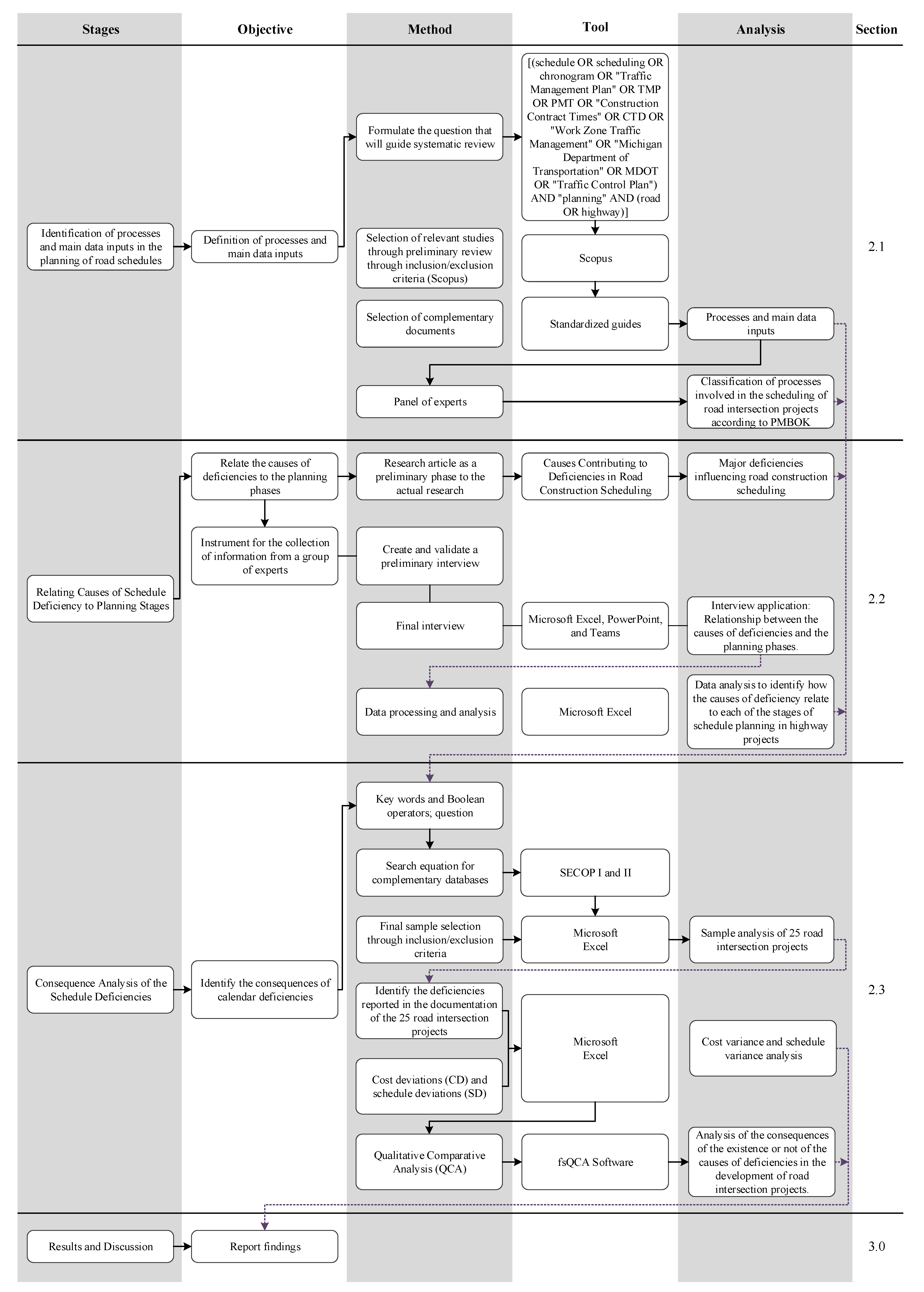

2. Research Method

2.1. Identification of Processes and Data Inputs in the Planning of Road Schedules

2.2. Relating Causes of Schedule Deficiency to Planning Stages

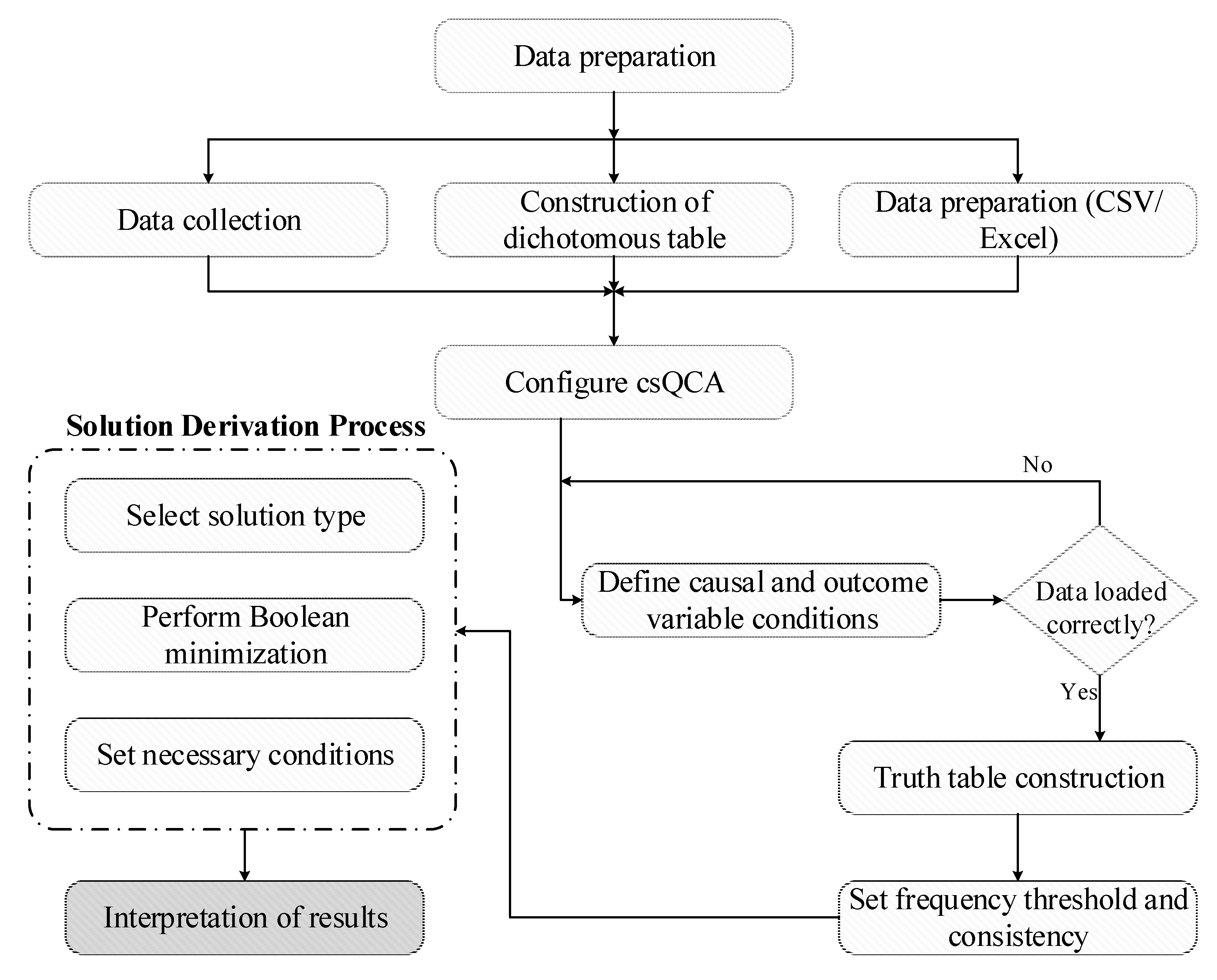

2.3. Consequence Analysis of the Schedule Deficiencies

3. Results and Analysis

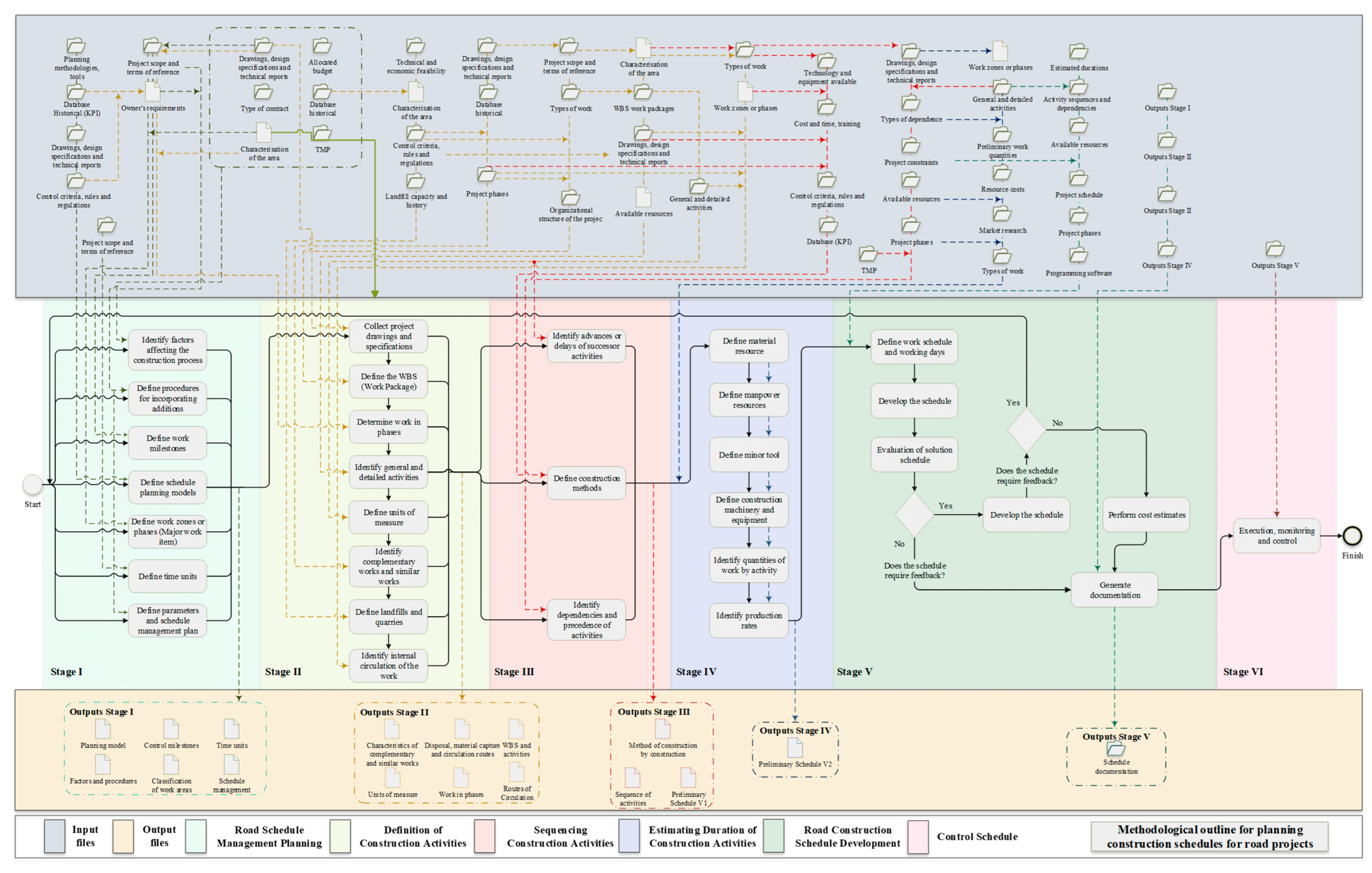

3.1. Processes and Data Inputs in the Planning of Road Schedules

3.1.1. Road Schedule Management Planning

3.1.2. Definition of Construction Activities

3.1.3. Sequencing Construction Activities

3.1.4. Estimating Duration of Construction Activities

3.1.5. Road Construction Schedule Development

3.2. Causes of Schedule Deficiencies Related to Planning Stages

3.3. Deviation Magnitudes by Causes of Deficiency

3.4. Qualitative Comparative Analysis

4. Discussion

4.1. Impact of the Causes of Deficiency on Deviations

4.2. Causes Identified in Road Intersection Projects and Relationship with Previous Studies

4.3. Practical Benefits of the Research Method

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| BIM | Building Information Modeling |

| CD | Cost Deviation |

| CPM | Critical Path Method |

| CS | Consistency |

| fsQCA | Fuzzy-set Qualitative Comparative Analysis |

| KPI | Key Performance Indicator |

| PC | Planned Cost |

| PMBOK | Project Management Body of Knowledge |

| PS | Planned Schedule |

| QCA | Qualitative Comparative Analysis |

| SD | Schedule Deviation |

| SECOP I | Colombian Public Procurement Platform (version I) |

| SECOP II | Colombian Public Procurement Platform (version II) |

| TMP | Traffic Management Plan |

| WBS | Work Breakdown Structure |

Appendix A. Technical Information About Road Projects Analyzed

| # | ID | Year | Website SECOP | Type | Entity | Planned Cost (COP) | Planned Cost USD | Real Cost (COP) | Cost Variation | Planned Duration (Months) | Real Duration (Months) | Time Variation |

| 1 | LP-DO-067-2015 | 2015 | I | Public bidding | INVIAS | 30,933,112,654.00 | 12,208,238.51 | 39,933,112,654.00 | 29.1% | 31 | 46 | 48.4% |

| 2 | LP-DO-SRN-038-2016 | 2016 | I | Public bidding | INVIAS | 9,075,396,655.00 | 2,937,354.28 | 14,211,314,737.00 | 56.6% | 18 | 35 | 94.4% |

| 3 | LP-SGT-SRN-020-2013 | 2013 | I | Public bidding | INVIAS | 1,734,744,480.00 | 909,309.60 | 1,668,882,757.00 | −3.8% | 5 | 5.53 | 10.6% |

| 4 | 2021-001 | 2021 | I | Public bidding | INVIAS | 20,368,828,636.00 | 5,482,447.79 | 29,997,366,624.00 | 47.3% | 6 | 20.4 | 240.0% |

| 5 | LP-SV-01450-2021 | 2020 | II | Public bidding | NdeS Government | 8,370,000,000.00 | 2,250,713.94 | 10,946,725,153.00 | 30.8% | 10 | 19.8 | 98.0% |

| 6 | 2609-2012 | 2012 | I | Direct Adjudication | Jardin Municipality/Antioquia | 758,900,000.00 | 413,840.11 | 1,670,036,551.00 | 120.1% | 11 | 77 | 600.0% |

| 7 | LP-DT-CAQ-018-2016 | 2016 | I | Public bidding | INVIAS | 7,028,052,185.00 | 2,274,708.20 | 7,028,052,185.00 | 0.0% | 20 | 25.2 | 26.0% |

| 8 | LP-DT-SPA-078-2014 | 2014 | I | Public bidding | INVIAS | 967,619,398.00 | 509,101.88 | 1,451,429,097.00 | 50.0% | 4 | 16.7 | 317.5% |

| 9 | SA-MC-DT-ANT-007-2017 | 2017 | I | Minor Cost Selection | INVIAS | 726,649,729.00 | 248,767.45 | 726,649,729.00 | 0.0% | 2 | 3 | 50.0% |

| 10 | OB-120-2023 | 2023 | I | Special Contract | Antioquia Government | 4,155,658,089.20 | 937,206.53 | 4,155,658,089.20 | 0.0% | 7 | 9.5 | 35.7% |

| 11 | 019-2021-IP | 2021 | I | Special Contract | Chocó Government | 4,947,763,837.00 | 1,331,733.77 | 5,795,477,344.00 | 17.1% | 4.6 | 9.9 | 116.8% |

| 12 | LP-DO-075-2015 | 2015 | I | Public bidding | INVIAS | 191,855,672,734.00 | 75,718,853.08 | 273,435,860,825.00 | 42.5% | 48 | 107.7 | 124.4% |

| 13 | CDI-089-2021 | 2021 | II | Special Contract | DNP | 8,792,315,443.00 | 2,366,528.35 | 8,792,315,443.00 | 0.0% | 18 | 32.7 | 81.7% |

| 14 | DAJ-LP-005-2020 | 2021 | II | Public bidding | Armenia Municipality | 906,012,558.00 | 243,861.18 | 613,694,375.00 | −32.3% | 4 | 18.2 | 355.0% |

| 15 | 002-L.P.2021 | 2021 | II | Public bidding | Pasto Municipality | 5,682,838,571.00 | 1,529,585.54 | 6,244,101,410.00 | 9.9% | 7 | 11.5 | 64.3% |

| 16 | LP-013-2021 | 2021 | II | Public bidding | Manizales Municipality | 25,324,780,604.00 | 6,816,385.47 | 40,765,706,827.00 | 61.0% | 24 | 36.5 | 52.1% |

| 17 | LP-019-2021 | 2021 | II | Public bidding | Zipaquira Municipality | 3,371,434,797.00 | 907,451.07 | 3,489,501,704.00 | 3.5% | 6 | 17.2 | 186.7% |

| 18 | LP-007-2022 | 2022 | II | Public bidding | Manizales Municipality | 1,412,177,608.00 | 373,936.22 | 1,411,532,841.00 | 0.0% | 5 | 2.8 | −44.0% |

| 19 | LP-013-2022 | 2022 | II | Public bidding | Vilavicencio Municipality | 2,639,145,442.00 | 698,829.99 | 3,775,562,959.00 | 43.1% | 6 | 10.5 | 75.0% |

| 20 | IA-001-2023 | 2023 | II | Special Contract | Soacha Municipality | 12,379,038,691.00 | 2,791,787.87 | 12,478,870,093.00 | 0.8% | 23 | 23 | 0.0% |

| 21 | DAJ-SAMC-008-2024 | 2024 | II | Minor Cost Selection | Armenia Municipality | 470,094,127.00 | 121,757.02 | 488,457,749.15 | 3.9% | 1.5 | 1.5 | 0.0% |

| 22 | 20001188 H4 DE 2020 | 2020 | II | Public bidding | AEROCIVIL | 60,425,858,014.00 | 16,248,664.37 | 60,425,858,014.00 | 0.0% | 16 | 24 | 50.0% |

| 23 | IDU-LP-SGI-017-2022 | 2022 | II | Public bidding | IDU | 477,834,784,322.00 | 126,527,804.52 | 493,099,593,582.00 | 3.2% | 36 | 36 | 0.0% |

| 24 | IDU-LP-SGI-038-2021 | 2021 | II | Public bidding | IDU | 181,740,991,864.00 | 48,917,172.29 | 181,740,991,864.00 | 0.0% | 41 | 41 | 0.0% |

| 25 | IDU-LP-SGI-012-2018 | 2018 | II | Public bidding | IDU | 79,198,370,092.00 | 27,410,729.89 | 86,236,640,112.00 | 8.9% | 21 | 32.4 | 54.3% |

Appendix B. Relationship Between Causes Identified and Road Intersection Projects

| # | ID | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | C16 | C17 | C18 | C19 | C20 | C21 | C22 |

| 1 | LP-DO-067-2015 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |||||||||||||

| 2 | LP-DO-SRN-038-2016 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||||

| 3 | LP-SGT-SRN-020-2013 | Yes | Yes | Yes | |||||||||||||||||||

| 4 | 2021-001 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |||||||||||||

| 5 | LP-SV-01450-2021 | Yes | Yes | Yes | Yes | ||||||||||||||||||

| 6 | 2609-2012 | Yes | Yes | Yes | Yes | ||||||||||||||||||

| 7 | LP-DT-CAQ-018-2016 | Yes | Yes | Yes | |||||||||||||||||||

| 8 | LP-DT-SPA-078-2014 | Yes | |||||||||||||||||||||

| 9 | SA-MC-DT-ANT-007-2017 | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||||||

| 10 | OB-120-2023 | ||||||||||||||||||||||

| 11 | 019-2021-IP | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||

| 12 | LP-DO-075-2015 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||

| 13 | CDI-089-2021 | Yes | Yes | ||||||||||||||||||||

| 14 | DAJ-LP-005-2020 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | |||||||||||||||

| 15 | 002-L.P.2021 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||||

| 16 | LP-013-2021 | Yes | Yes | Yes | Yes | Yes | |||||||||||||||||

| 17 | LP-019-2021 | Yes | Yes | Yes | Yes | Yes | |||||||||||||||||

| 18 | LP-007-2022 | Yes | Yes | Yes | |||||||||||||||||||

| 19 | LP-013-2022 | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||||||||||||||

| 20 | IA-001-2023 | ||||||||||||||||||||||

| 21 | DAJ-SAMC-008-2024 | Yes | |||||||||||||||||||||

| 22 | 20001188 H4 DE 2020 | Yes | Yes | Yes | Yes | ||||||||||||||||||

| 23 | IDU-LP-SGI-017-2022 | Yes | Yes | Yes | Yes | Yes | |||||||||||||||||

| 24 | IDU-LP-SGI-038-2021 | Yes | Yes | Yes | |||||||||||||||||||

| 25 | IDU-LP-SGI-012-2018 | Yes | Yes | Yes | Yes | Yes | Yes |

References

- Karimi, S.; Piroozfar, P. Exploring Causes of Delays in National Road and Highway Projects in Developing Construction Economy. J. Eng. Proj. Prod. Manag. 2022, 12, 137–148. [Google Scholar] [CrossRef]

- Koike, A.; Tavasszy, L.; Sato, K.; Monma, T. Spatial Incidence of Economic Benefit of Road-Network Investments: Case Studies under the Usual and Disaster Scenarios. J. Infrastruct. Syst. 2012, 18, 252–260. [Google Scholar] [CrossRef]

- Tan, F.; Tsolakis, D. Economy-Wide and Employment Impacts of Road Construction and Maintenance Investment. Road Transp. Res. 2013, 22, 56–69. [Google Scholar]

- Global Infrastructure Outlook. Forecasting Infrastructure Investment Needs and Gaps. Available online: https://outlook.gihub.org/ (accessed on 3 April 2025).

- Sa’dl Issa Alkhawaja, A.; Varouqa, I.F. Risks Management of Infrastructure Line Services and Their Impact on the Financial Costs of Road Projects in Jordan. Meas. Sens. 2023, 25, 100647. [Google Scholar] [CrossRef]

- Castañeda, K.; Sánchez, O.; Herrera, R.F.; Mejía, G. Highway Planning Trends: A Bibliometric Analysis. Sustainability 2022, 14, 5544. [Google Scholar] [CrossRef]

- Nguyen, T.A.; Nguyen, T.A.; Tran, T. Van Building Information Modeling (BIM) for Construction Project Schedule Management: A Review. Eng. Technol. Appl. Sci. Res. 2024, 14, 13133–13142. [Google Scholar] [CrossRef]

- Kaliba, C.; Muya, M.; Mumba, K. Cost Escalation and Schedule Delays in Road Construction Projects in Zambia. Int. J. Proj. Manag. 2009, 27, 522–531. [Google Scholar] [CrossRef]

- Mohammadi, A.; Igwe, C.; Amador-Jimenez, L.; Nasiri, F. Applying Lean Construction Principles in Road Maintenance Planning and Scheduling. Int. J. Constr. Manag. 2020, 22, 2364–2374. [Google Scholar] [CrossRef]

- Zaalouk, A.; Moon, S.; Han, S.H. Operations Planning and Scheduling in Off-Site Construction Supply Chain Management: Scope Definition and Future Directions. Autom. Constr. 2023, 153, 104952. [Google Scholar] [CrossRef]

- Ahiwako, O.; Oloke, D.; Suresh, S.; Khatib, J. Implementing The Last Planner System in a Road Construction Project in Nigeria. Built Environ. J. 2015, 12, 32–49. [Google Scholar]

- Elghaish, F.; Abrishami, S.; Hosseini, M.R.; Abu-Samra, S.; Gaterell, M. Integrated Project Delivery with BIM: An Automated EVM-Based Approach. Autom. Constr. 2019, 106, 102907. [Google Scholar] [CrossRef]

- Ballesteros-Pérez, P.; Sanz-Ablanedo, E.; Mora-Melià, D.; González-Cruz, M.C.; Fuentes-Bargues, J.; Pellicer, E. Earned Schedule Min-Max: Two New EVM Metrics for Monitoring and Controlling Projects. Autom. Constr. 2019, 103, 279–290. [Google Scholar] [CrossRef]

- Saki, R.; Yeom, C. Causes of Variation Orders in Road Construction Projects in Tanzania. Open Transp. J. 2022, 16, e187444782208182. [Google Scholar] [CrossRef]

- Shayanfar, E.; Schonfeld, P. Selecting and Scheduling Interrelated Road Projects with Uncertain Demand. Transp. A Transp. Sci. 2019, 15, 1712–1733. [Google Scholar] [CrossRef]

- Brutovský, M.; Prievozník, P.; Sventeková, E. Risk Assessment of Key Elements in Road Transport Infrastructure. Transp. Res. Procedia 2023, 74, 1352–1359. [Google Scholar] [CrossRef]

- Limenih, Z.M.; Demisse, B.A.; Haile, A.T. The Usefulness of Adopting the Last Planner System in the Construction Process of Addis Ababa Road Projects. Adv. Civ. Eng. 2022, 2022, 7846593. [Google Scholar] [CrossRef]

- Chen, L.; Lu, Q.; Han, D. A Bayesian-Driven Monte Carlo Approach for Managing Construction Schedule Risks of Infrastructures under Uncertainty. Expert. Syst. Appl. 2023, 212, 118810. [Google Scholar] [CrossRef]

- Hosseininasab, S.M.; Shetab-Boushehri, S.N.; Hejazi, S.R.; Karimi, H. A Multi-Objective Integrated Model for Selecting, Scheduling, and Budgeting Road Construction Projects. Eur. J. Oper. Res. 2018, 271, 262–277. [Google Scholar] [CrossRef]

- Miralinaghi, M.; Woldemariam, W.; Abraham, D.M.; Chen, S.; Labi, S.; Chen, Z. Network-Level Scheduling of Road Construction Projects Considering User and Business Impacts. Comput. Aided Civ. Infrastruct. Eng. 2020, 35, 650–667. [Google Scholar] [CrossRef]

- Mahmoudi, R.; Shetab-Boushehri, S.N.; Hejazi, S.R.; Emrouznejad, A.; Rajabi, P. A Hybrid Egalitarian Bargaining Game-DEA and Sustainable Network Design Approach for Evaluating, Selecting and Scheduling Urban Road Construction Projects. Transp. Res. E Logist. Transp. Rev. 2019, 130, 161–183. [Google Scholar] [CrossRef]

- Bagloee, S.A.; Sarvi, M.; Patriksson, M.; Asadi, M. Optimization for Roads’ Construction: Selection, Prioritization, and Scheduling. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 833–848. [Google Scholar] [CrossRef]

- Hosseininasab, S.M.; Shetab-Boushehri, S.N. Integration of Selecting and Scheduling Urban Road Construction Projects as a Time-Dependent Discrete Network Design Problem. Eur. J. Oper. Res. 2015, 246, 762–771. [Google Scholar] [CrossRef]

- Sharma, H.; Asce, A.; Mcintyre, C.; Gao, Z.; Asce, M.; Nguyen, T.-H. Developing a Traffic Closure Integrated Linear Schedule for Highway Rehabilitation Projects. J. Constr. Eng. Manag. 2009, 135, 146–155. [Google Scholar] [CrossRef]

- Lucko, G. Optimizing Cash Flows for Linear Schedules Modeled with Singularity Functions by Simulated Annealing. J. Constr. Eng. Manag. 2011, 137, 523–535. [Google Scholar] [CrossRef]

- Yogesh, G.; Hanumanth Rao, C. A Study on Linear Scheduling Methods in Road Construction Projects. Mater. Today Proc. 2021, 47, 5475–5478. [Google Scholar] [CrossRef]

- Abbondati, F.; Lamberti, R.; Capaldo, F.S. Linear Scheduling Analysis Toolkit for Road and Airports Construction Projects. ARPN J. Eng. Appl. Sci. 2016, 11, 6863–6874. [Google Scholar]

- Kannan, S.R.; Senthil, R. Production Based Scheduling Method for Linear Construction in Road Projects. KSCE J. Civ. Eng. 2014, 18, 1292–1301. [Google Scholar] [CrossRef]

- Chong, H.Y.; Lopez, R.; Wang, J.; Wang, X.; Zhao, Z. Comparative Analysis on the Adoption and Use of BIM in Road Infrastructure Projects. J. Manag. Eng. 2016, 32, 05016021. [Google Scholar] [CrossRef]

- Shah, R.K. A New Approach for Automation of Location-Based Earthwork Scheduling in Road Construction Projects. Autom. Constr. 2014, 43, 156–169. [Google Scholar] [CrossRef]

- Saneii, M.; Kazemeini, A.; Seilabi, S.E.; Miralinaghi, M.; Labi, S. A Methodology for Scheduling Within-Day Roadway Work Zones Using Deep Neural Networks and Active Learning. Comput. Aided Civ. Infrastruct. Eng. 2023, 38, 1101–1126. [Google Scholar] [CrossRef]

- Briner, R.; Denyer, D. Systematic Review and Evidence Synthesis as a Practice and Scholarship Tool. In The Oxford Handbook of Evidence-Based Management; Oxford Academic: Oxford, UK, 2012; pp. 112–129. ISBN 9780199763986. [Google Scholar]

- Lockwood, C.; Porritt, K.; Munn, Z.; Rittenmeyer, L.; Salmond, S.; Bjerrum, M.; Loveday, H.; Carrier, J.; Stannard, D. Systematic Reviews of Qualitative Evidence. In JBI Manual for Evidence Synthesis; JBI: North Adelaide, Australia, 2020. [Google Scholar]

- Herrera, R.F.; Sánchez, O.; Castañeda, K.; Porras, H. Cost Overrun Causative Factors in Road Infrastructure Projects: A Frequency and Importance Analysis. Appl. Sci. 2020, 10, 5506. [Google Scholar] [CrossRef]

- Castañeda, K.; Sánchez, O.; Herrera, R.F.; Gómez-Cabrera, A.; Mejía, G. Building Information Modeling Uses and Complementary Technologies in Road Projects: A Systematic Review. Buildings 2024, 14, 563. [Google Scholar] [CrossRef]

- Saieg, P.; Dominguez, E.; Nascimento, D.; Goyannes, R. Interactions of Building Information Modeling, Lean and Sustainability on the Architectural, Engineering and Construction Industry: A Systematic Review. J. Clean. Prod. 2018, 174, 788–806. [Google Scholar] [CrossRef]

- Federal Highway Administration. Michigan Department of Transportation (MDOT) Guide for Contract Time Determination (CTD) Procedures Purpose; Federal Highway Administration: Washington, DC, USA, 2002. [Google Scholar]

- Hildreth, J.; Tech, V. Contract Time Determination Guidelines Contract Time Determination Guidelines Background; Virginia Tech. College of Engineering: Blacksburg, VA, USA, 2007. Available online: https://www.vdot.virginia.gov/media/vdotvirginiagov/doing-business/technical-guidance-and-support/construction/construction-scheduling/0708_ContractTimeDeterminationGuidelines_acc070822.pdf (accessed on 15 April 2025).

- Gondy, C.; Hildreth, J. Contract Time Determination Guidelines; Virginia Tech: Blacksburg, VA, USA, 2007. [Google Scholar]

- PMI. Guía de Los Fundamentos Para La Dirección de Proyectos (Guía Del PMBOK®); PMI: Hong Kong, China, 2021; ISBN 9781628250091. [Google Scholar]

- Castañeda, K.; Sánchez, O.; Herrera, R.F.; Mejía, G. Deficiencies Causes in Road Construction Scheduling: Perspectives from Construction Professionals. Heliyon 2025, 11, e41514. [Google Scholar] [CrossRef]

- Colombia Compra Eficiente. SECOP I. Available online: https://www.colombiacompra.gov.co/secop/secop-i (accessed on 11 June 2024).

- Colombia Compra Eficiente. SECOP II. Available online: https://www.colombiacompra.gov.co/secop/secop-ii (accessed on 11 June 2024).

- FsQCA, version 4.1; University of California: Los Angeles, CA, USA, 2023.

- Medina, I.; Álamos-Concha, P.; Castillo Ortiz, P.J.; Rihoux, B. Análisis Cualitativo Comparado, 1st ed.; Centro de Investigaciones Sociológicas, Ed.; Centro de Investigaciones Sociológicas: Madrid, Spain, 2017; Volume 1. [Google Scholar]

- Bol, D.; Luppi, F. Confronting Theories Based in Necessary Relations: Making the Best of QCA Possibilities. Polit. Res. Q. 2013, 66, 205–210. [Google Scholar] [CrossRef]

- Campbell, B.; Humphrey, T.F. Procedures Used in Development of Unified Transportation Work Programs for the Massachusetts Planning Process. In Proceedings of the 52nd Annual Meeting of the Highway Research Board, Washington, DC, USA, 22–26 January 1973; pp. 1–22. [Google Scholar]

- Lee, C.; Cha, M.; Kim, H.; Cho, H. Detailed Activity-Based Earthwork Scheduling Model to Aid during the Planning Stage of Road Construction. Appl. Sci. 2023, 13, 12902. [Google Scholar] [CrossRef]

- Fernandez, I.S.; Castillo, D.; Jaime, I.; Magaña, V. Conceptos de La Gerencia de Proyectos Aplicados a Carreteras; AMIVTAC Asociación Mexicana de Ingeniería de Vías Terrestre A.C.: Mexico City, Mexico, 2019. [Google Scholar]

- Texas Department of Transportation. Contract Time Determination; Texas Department of Transportation: Austin, TX, USA, 2018. [Google Scholar]

- Florida Department of Transportation. Guidance for Establishing Construction Contract Duration; Florida Department of Transportation: Tallahassee, FL, USA, 2021. [Google Scholar]

- Hassanein, A.; Moselhi, O. Planning and Scheduling Highway Construction. J. Constr. Eng. Manag. 2004, 130, 638–646. [Google Scholar] [CrossRef]

- Samaca Cabra, Y.M.; Lucia Vanegas, O.; Quintero Prieto, W.C.; Nancy Diaz-Piraquive, F. Evaluation of the Management of the Scope, Schedule and Cost in the Stage of Studies and Designs of Road Mesh Works, for a Consulting Contract in the City of Bogotá. In Proceedings of the 2020 Congreso Internacional de Innovacion y Tendencias en Ingenieria, CONIITI 2020, Bogota, Colombia, 30 September–2 October 2020; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2020. [Google Scholar]

- Paz, J.C.; Rozenboim, D.; Cuadros, Á.; Cano, S.; Escobar, J.W. A Simulation-Based Scheduling Methodology for Construction Projects Considering the Potential Impacts of Delay Risks. Constr. Econ. Build. 2018, 18, 41–69. [Google Scholar] [CrossRef]

- IDAHO Transportation Department. Contract Time Determination in Project Development; IDAHO Transportation Department: Boise, ID, USA, 2011. [Google Scholar]

- Valdes, D.; Puerto, C.; Figueroa, A.; Colucci, B.; Sotomayor, R. Developing an Educational Module to Increase Engineering Students’ Knowledge of Highway Work Zones and Temporary Traffic Control Plans. In Proceedings of the American Society for Engineering Education, Online, 22–26 June 2020; pp. 1–14. [Google Scholar]

- Le, C.; Jeong, H.D. Determining Highway Project Contract Time from Project Duration Estimates. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2023, 15, 04523019. [Google Scholar] [CrossRef]

- Kiran Kumar, J.; Victor, K.; Naomi Nischala, K. Planning, Scheduling and Resource Optimization for Road Construction. Int. J. Recent. Technol. Eng. 2019, 8, 2625–2629. [Google Scholar] [CrossRef]

- Sun, H.; Jiao, R.; Xie, M. Scheduling Asphalt Highway Construction Operations Using the Combination of Line-of-Balance and Discrete Event Simulation Techniques. In Proceedings of the International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; IEEE Technology Management Council: New York, NY, USA, 2009. [Google Scholar]

- Yin, Y.; Choi, K.; Asce, M.; Jeong, H.D.; Asce, A.M.; Touran, A.; Asce, F. Integration of Schedule, Cost, Traffic, and Risk into the Determination of Construction Contract Times. J. Manag. Eng. 2022, 38, 04022061. [Google Scholar] [CrossRef]

- Zhai, D.; Shan, Y.; Sturgill, R.E.; Taylor, T.R.B.; Goodrum, P.M. Using Parametric Modeling to Estimate Highway Construction Contract Time. Transp. Res. Rec. 2016, 2573, 1–9. [Google Scholar] [CrossRef]

- Castañeda, K.; Sánchez, O.; Herrera, R.F.; Pellicer, E.; Porras, H. BIM-Based Traffic Analysis and Simulation at Road Intersection Design. Autom. Constr. 2021, 131, 103911. [Google Scholar] [CrossRef]

- Rashidi, A.; Yong, W.Y.; Maxwell, D.; Fang, Y. Construction Planning through 4D BIM-Based Virtual Reality for Light Steel Framing Building Projects. Smart Sustain. Built Environ. 2023, 12, 1153–1173. [Google Scholar] [CrossRef]

- Xinting, G.; Weimin, Z. Apply Digital-Twin Model to Optimize the Planning of Equipment Pipeline System in the Laboratory Campus. In Computational Design and Robotic Fabrication; Springer: Singapore, 2024; Part F2072; pp. 260–272. [Google Scholar] [CrossRef]

- Schlosser, T.; Schlosser, P.; Zuzulová, A.; Cápayová, S.; Bálint, G. Traffic Planning as a Preliminary Tool in Project Documentation for BIM. Buildings 2022, 12, 381. [Google Scholar] [CrossRef]

- Hui, S.; Jing, K.T.; Yee, H.C.; Siyao, C.; Zihao, D.; Yangle, S. The Impacts of 5D Building Information Modelling towards Cost Management in the Construction Industry. J. Adv. Res. Appl. Sci. Eng. Technol. 2023, 32, 471–487. [Google Scholar] [CrossRef]

- Baldrich Aragó, A.; Roig Hernando, J.; Llovera Saez, F.J.; Coll Bertran, J. Quantity Surveying and BIM 5D. Its Implementation and Analysis Based on a Case Study Approach in Spain. J. Build. Eng. 2021, 44, 103234. [Google Scholar] [CrossRef]

- Trochymiak, W.; Krygier, A.; Stachura, M.; Jaworski, J. The BIM 5D Model of the Bridge Built Using the Incremental Launching Method. Arch. Civ. Eng. 2023, 69, 157–172. [Google Scholar] [CrossRef]

- Caldart, C.W.; Scheer, S. Construction Site Design Planning Using 4D BIM Modeling. Gest. Prod. 2022, 29, e5312. [Google Scholar] [CrossRef]

- Le, P.L.; Dao, T.M.; Chaabane, A. BIM-Based Framework for Temporary Facility Layout Planning in Construction Site: A Hybrid Approach. Constr. Innov. 2019, 19, 424–464. [Google Scholar] [CrossRef]

- RazaviAlavi, S.R.; AbouRizk, S. Construction Site Layout Planning Using a Simulation-Based Decision Support Tool. Logistics 2021, 5, 65. [Google Scholar] [CrossRef]

- Zavari, M.; Shahhosseini, V.; Ardeshir, A.; Sebt, M.H. Multi-Objective Optimization of Dynamic Construction Site Layout Using BIM and GIS. J. Build. Eng. 2022, 52, 104518. [Google Scholar] [CrossRef]

- Zavari, M.; Shahhosseini, V.; Ardeshir, A.; Sebt, M.H. BIM-Based Estimation of Inputs for Site Layout Planning and Locating Irregularly Shaped Facilities. Autom. Constr. 2022, 141, 104431. [Google Scholar] [CrossRef]

- Choi, K.; Kwak, Y.H.; Pyeon, J.-H.; Son, K. Schedule Effectiveness of Alternative Contracting Strategies for Transportation Infrastructure Improvement Projects. J. Constr. Eng. Manag. 2012, 138, 323–330. [Google Scholar] [CrossRef]

- Esmaeili, B.; Hallowell, M. Integration of Safety Risk Data with Highway Construction Schedules. Constr. Manag. Econ. 2013, 31, 528–541. [Google Scholar] [CrossRef]

- Darsa, M.H.; Negash, B.T. Significant Factors Causing Delay of Ethiopian Road Construction Projects Performing by Foreign General Contactors. Int. J. Sustain. Constr. Eng. Technol. 2023, 14, 103–116. [Google Scholar] [CrossRef]

- Jeong, H.S.; Atreya, S.; Oberlender, G.D.; Chung, B.Y. Automated Contract Time Determination System for Highway Projects. Autom. Constr. 2009, 18, 957–965. [Google Scholar] [CrossRef]

- Lee, E.B.; Thomas, D.K.; Alleman, D. Incorporating Road User Costs into Integrated Life-Cycle Cost Analyses for Infrastructure Sustainability: A Case Study on Sr-91 Corridor Improvement Project (Ca). Sustainability 2018, 10, 179. [Google Scholar] [CrossRef]

- Mohajeri Borje Ghaleh, R.; Pourrostam, T.; Mansour Sharifloo, N.; Majrouhi Sardroud, J.; Safa, E. Delays in the Road Construction Projects from Risk Management Perspective. Infrastructures 2021, 6, 135. [Google Scholar] [CrossRef]

| Id | Profession (Grade) | Country | Rol | Years of Experience |

|---|---|---|---|---|

| 1 | Civil Engineer, M.Sc., Ph.D. | Spain | Academic/Researcher | >15 |

| 2 | Civil Engineer, M.Sc., Ph.D. (c) | Colombia | Academic/Researcher | >15 |

| 3 | Civil Engineer, M.Sc., Ph.D. | Colombia | Academic/Researcher | >10 |

| 4 | Civil Engineer, M.Sc., Ph.D. (c) | Chile | Academic/Researcher | >5 |

| 5 | Civil Engineer, M.Sc. | Colombia | Consultant/Designer | >5 |

| Id | Profession (Grade) | Country | Rol | Years of Experience |

|---|---|---|---|---|

| 1 | Civil Engineer, M.Sc., Ph.D. | Spain | Academic/Researcher | >15 |

| 2 | Civil Engineer, M.Sc., Ph.D. | Chile | Consultant/Designer | >15 |

| 3 | Architect, Ph.D. | Spain | Academic/Researcher | >15 |

| 4 | Civil Engineer, M.Sc., Ph.D. | Spain | Academic/Researcher | >15 |

| 5 | Civil Engineer, M.Sc., Ph.D. | Colombia | Academic/Researcher | >10 |

| 6 | Civil Engineer, M.Sc., Ph.D. | Colombia | Academic/Researcher | >10 |

| 7 | Architect, M.Sc., Ph.D. | Spain | Academic/Designer | >10 |

| 8 | Civil Engineer, M.Sc., Ph.D. | Colombia | Academic/Researcher | >7 |

| 9 | Civil Engineer, M.Sc., | Colombia | Consultant/Designer | >7 |

| 10 | Civil Engineer, Ph.D. | Chile | Researcher/Designer | >5 |

| Id | Process | Input Files | References |

|---|---|---|---|

| P1 | Identify factors affecting the construction process | Drawings, design specifications and technical reports, type of contract, characterization of the area, allocated budget, database historical, Traffic Management Plan (TPM) | [37,39,47,48,49,50,51,52,53] |

| P2 | Define procedures for incorporating additions | Project scope and terms of reference, owner’s requirements | [37,39,53,54] |

| P3 | Define work milestones | Project scope and terms of reference, owner’s requirements, drawings, design specifications, and technical reports | [39,48,49,53,55] |

| P4 | Define work zones or phases (Major work item) | Project scope and terms of reference, owner’s requirements, drawings, design specifications and technical reports, characterization of the area | [37,47,50,51,52,55,56] |

| P5 | Define schedule planning models | Planning methodologies, tools, database historical (KPI), drawings, design specifications and technical reports, control criteria, rules and regulations | [48,49,54] |

| P6 | Define time units | Project scope and terms of reference | [39,51,53] |

| P7 | Define parameters and schedule management plan | Project scope and terms of reference, owner’s requirements | [47,48,49] |

| P8 | Collect project drawings and specifications | Drawings, design specifications, and technical reports | [39,48,49,50,53,55] |

| P9 | Determine work in phases | Project scope and terms of reference, owner’s requirements, drawings, design specifications and technical reports, characterization of the area | [47,49,50,52,55,56] |

| P10 | Define landfills and quarries | Technical and economic feasibility, characterization of the area, control criteria, rules and regulations, landfill capacity and history, database historical | [38,48,51] |

| P11 | Identify complementary works and similar works | Drawings, design specifications, technical reports, database historical, control criteria, rules and regulations, project phases | [37,47,50,53,55,57,58] |

| P12 | Define the WBS (Work Package) | Drawings, design specifications and technical reports, project scope and terms of reference, types of work, control criteria, rules and regulations, project phases | [39,49,50,51,52,53,55,58,59] |

| P13 | Identify general and detailed activities | Project scope and terms of reference, characterization of the area, WBS work packages, drawings, design specifications and technical reports, available resources, control criteria, rules and regulations | [37,39,48,49,50,51,52,53,55,58,59] |

| P14 | Define units of measure | Types of work, WBS work packages, general and detailed activities | [39,50,51] |

| P15 | Identify the internal circulation of the work | Characterization of the area, types of work, work zones or phases, drawings, design specifications and technical reports, project phases, general and detailed activities | [47,48,51,56] |

| P16 | Identify advances or delays of successor activities | Types of work, WBS work packages, general and detailed activities | [39,50,51,58] |

| P17 | Define construction methods | Types of work, technology and equipment available, cost and time, training, drawings, design specifications and technical reports, project phases, control criteria, rules and regulations, database (KPI) | [50,52,53,60] |

| P18 | Identify dependencies and precedence of activities | Types of work, drawings, design specifications and technical reports, types of dependence, project constraints, available resources, project phases, TPM | [39,47,48,49,51,52,53,54,58] |

| P19 | Define material resources | Drawings, design specifications and technical reports, work zones or phases, general and detailed activities, preliminary work quantities, resource costs, market research, types of work | [37,39,48,49,50,51,52,53,55,58] |

| P20 | Define manpower resources | [39,48,49,50,51,52,53,55] | |

| P21 | Define minor tool | [48,49,50,51,53] | |

| P22 | Define construction machinery and equipment | [48,49,50,51,52,53] | |

| P23 | Identify quantities of work by activity | [37,39,48,49,50,51,52,53,58,61] | |

| P24 | Identify production rates | [37,39,48,49,50,51,53] | |

| P25 | Define work schedule and working days | Estimated durations, activity sequences and dependencies, available resources, project schedule, project phases, programming software, general and detailed activities, project constraints | [39,49,50,51,52,53,55,57] |

| P26 | Develop the schedule | [37,39,48,49,51,53] | |

| P27 | Evaluation of solution schedule | [37,39,47,48,51,53,54] | |

| P28 | Perform cost estimates | [48,49,53] | |

| P29 | Generate documentation | Output stages I, II, III, and IV | [62] |

| Id | Deficiencies in Road Project Schedule Planning | Road Schedule Management Planning | Definition of Construction Activities | Sequencing Construction Activities | Estimating Duration of Construction | Road Construction Schedule Development |

|---|---|---|---|---|---|---|

| C1 | Poor estimation of workforce performance | ✔ | ||||

| C2 | Poor estimation of workforce quantity | ✔ | ✔ | |||

| C3 | Deficient coordination with public utilities (water, sanitary, electrical, and other surface or subway networks) | ✔ | ||||

| C4 | Inadequate estimation of permit acquisition durations | ✔ | ||||

| C5 | Inadequate weather forecasting | ✔ | ||||

| C6 | Deficient estimation of material quantities | ✔ | ✔ | ✔ | ||

| C7 | Inadequate estimation of construction document approval times | ✔ | ||||

| C8 | Request for project start time extensions (applies in cases of rescheduling requests) | ✔ | ||||

| C9 | Inadequate exploration of existing site conditions | ✔ | ||||

| C10 | Lack of experience of the planner | ✔ | ✔ | ✔ | ✔ | |

| C11 | Failures in the definition of successor and predecessor relationships between activities | ✔ | ||||

| C12 | Failures in the configuration of the work schedule (working days, holidays, working hours, seasons of the year) | ✔ | ||||

| C13 | Omission or deficiency in the definition of work packages (WBS) | ✔ | ||||

| C14 | Inadequacy of planning software adopted | ✔ | ||||

| C15 | Lack of planning of storage and parking sites | ✔ | ✔ | |||

| C16 | Omission of road markings in planning | ✔ | ✔ | |||

| C17 | Poor zoning of the construction process based on traffic conditions | ✔ | ||||

| C18 | Failures in on-site traffic estimation | ✔ | ✔ | |||

| C19 | Poor planning of machinery routes | ✔ | ||||

| C20 | Lack of verification during the schedule preparation | ✔ | ||||

| C21 | Inadequate estimation and consideration of waiting times (setting time or other waiting times between activities) | ✔ | ||||

| C22 | High complexity of construction work | ✔ | ✔ |

| Causes of Deficiency | Frequency n = 25 | Affected | Unaffected | |||

|---|---|---|---|---|---|---|

| C10 | Lack of experience of the planner | 15 (60.0%) | 128.0% | 26.2% | 47.8% * | 6.5% * |

| C6 | Deficient estimation of material quantities | 14 (56.0%) | 136.0% | 27.9% | 52.4% * | 7.2% * |

| C16 | Omission of road markings in planning | 14 (56.0%) | 151.8% | 23.9% | 36.5% * | 11.3% * |

| C13 | Omission or deficiency in the definition of work packages (WBS) | 12 (48.0%) | 122.4% | 30.1% | 97.4% * | 10.8% * |

| C3 | Deficient coordination with public utilities (water, sanitary, electrical, and other surface or subway networks) | 10 (40.0%) | 79.0% | 15.4% | 184.6% | 33.7% |

| C9 | Inadequate exploration of existing site conditions | 10 (40.0%) | 127.1% | 15.8% | 136.6% | 33.3% |

| C22 | High complexity of construction work | 10 (40.0%) | 73.9% | 29.2% | 189.8% | 20.0% * |

| C4 | Inadequate estimation of permit acquisition durations | 8 (32.0%) | 104.1% | 16.2% | 225.5% | 45.3% |

| Stage | Cost Deviation (CD) | Schedule Deviation (SD) | ||||

|---|---|---|---|---|---|---|

| Combinations | CS | CG | Combinations | CS | CG | |

| Road Schedule Management Planning | C3 | 0.438 | 0.700 | C3 | 0.450 | 0.900 |

| C8 | 0.188 | 1.000 | C8 | 0.150 | 1.000 | |

| C16 | 0.563 | 0.643 | C16 | 0.600 | 0.857 | |

| C18 | 0.125 | 1.000 | C18 | 0.100 | 1.000 | |

| C22 | 0.500 | 0.800 | C22 | 0.400 | 0.800 | |

| C3 + C16 | 0.750 | 0.667 | C3 + C16 | 0.750 | 0.833 | |

| C3 + C22 | 0.625 | 0.667 | C3 + C22 | 0.650 | 0.867 | |

| C16 + C22 | 0.813 | 0.650 | C16 + C22 | 0.800 | 0.800 | |

| C3 + C16 + C22 | 0.900 | 0.818 | ||||

| Definition of Construction Activities | C6 | 0.625 | 0.714 | C6 | 0.200 | 0.071 |

| C9 | 0.438 | 0.700 | C9 | 0.200 | 0.100 | |

| C10 | 0.750 | 0.800 | C10 | 0.400 | 0.133 | |

| C13 | 0.625 | 0.833 | C13 | 0.200 | 0.083 | |

| C15 | 0.063 | 0.333 | C15 | 0.000 | 0.000 | |

| C16 | 0.563 | 0.643 | C16 | 0.400 | 0.143 | |

| C22 | 0.500 | 0.800 | C22 | 0.400 | 0.200 | |

| C6 + C10 | 0.813 | 0.722 | ||||

| C6 + C13 | 0.750 | 0.750 | ||||

| C6 + C16 | 0.813 | 0.684 | ||||

| C6 + C22 | 0.750 | 0.706 | ||||

| C10 + C13 | 0.750 | 0.750 | ||||

| C10 + C16 | 0.938 | 0.682 | ||||

| C10 + C22 | 0.813 | 0.813 | ||||

| C13 + C16 | 0.813 | 0.684 | ||||

| C16 + C22 | 0.813 | 0.650 | ||||

| C22 + C13 | 0.813 | 0.813 | ||||

| Sequencing Construction Activities | C10 | 0.750 | 0.800 | C10 | 0.650 | 0.867 |

| C11 | 0.063 | 1.000 | C11 | 0.050 | 1.000 | |

| C17 | 0.125 | 1.000 | C17 | 0.100 | 1.000 | |

| C18 | 0.125 | 1.000 | C18 | 0.100 | 1.000 | |

| C10 + C17 | 0.813 | 0.813 | ||||

| C10 + C18 | 0.813 | 0.813 | ||||

| Estimating Duration of Construction | C1 | 0.188 | 0.750 | C1 | 0.200 | 1.000 |

| C2 | 0.250 | 0.800 | C2 | 0.250 | 1.000 | |

| C4 | 0.375 | 0.750 | C4 | 0.360 | 0.875 | |

| C6 | 0.625 | 0.714 | C6 | 0.650 | 0.929 | |

| C7 | 0.250 | 1.000 | C7 | 0.150 | 0.750 | |

| C10 | 0.750 | 0.800 | C10 | 0.650 | 0.867 | |

| C15 | 0.063 | 0.333 | C15 | 0.150 | 1.000 | |

| C19 | 0.125 | 1.000 | C19 | 0.100 | 1.000 | |

| C21 | 0.063 | 1.000 | C21 | 0.050 | 1.000 | |

| C6 + C10 | 0.813 | 0.722 | C6 + C10 | 0.750 | 0.833 | |

| C4 + C7 | 0.438 | 0.778 | C6 + C4 | 0.700 | 0.875 | |

| C4 + C6 + C10 + C7 | 0.813 | 0.684 | C4 + C10 | 0.700 | 0.875 | |

| C2 + C4 + C7 | 0.563 | 0.750 | C4 + C6 + C10 | 0.800 | 0.842 | |

| C2 + C4 + C6 + C10 | 0.813 | 0.650 | ||||

| Road Construction Schedule Development | C2 | 0.250 | 0.800 | C2 | 0.250 | 1.000 |

| C5 | 0.188 | 0.600 | C5 | 0.250 | 1.000 | |

| C6 | 0.625 | 0.714 | C6 | 0.650 | 0.929 | |

| C10 | 0.750 | 0.800 | C10 | 0.650 | 0.867 | |

| C12 | 0.000 | 0.000 | C12 | 0.050 | 1.000 | |

| C20 | 0.125 | 1.000 | C20 | 0.100 | 1.000 | |

| C6 + C10 | 0.813 | 0.722 | C6 + C10 | 0.750 | 0.833 | |

| C2 + C5 + C20 | 0.375 | 0.667 | ||||

| Causes of Deficiency | Affected | ||||

|---|---|---|---|---|---|

| C16 | Omission of road markings in planning | 151.80% | 23.90% | 1 | 5 |

| C6 | Deficient estimation of material quantities | 136.00% | 27.90% | 2 | 3 |

| C10 | Lack of experience of the planner | 128.00% | 26.20% | 3 | 4 |

| C9 | Inadequate exploration of existing site conditions | 127.10% | 15.80% | 4 | 7 |

| C13 | Omission or deficiency in the definition of work packages (WBS) | 122.40% | 30.10% | 5 | 1 |

| C4 | Inadequate estimation of permit acquisition durations | 104.10% | 16.20% | 6 | 6 |

| C3 | Deficient coordination with public utilities (water, sanitary, electrical, and other surface or subway networks) | 79.00% | 15.40% | 7 | 8 |

| C22 | High complexity of construction work | 73.90% | 29.20% | 8 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castañeda, K.; Sánchez, O.; Peña, C.A.; Herrera, R.F.; Mejía, G. Comprehensive Analysis of Scheduling Processes in Road Intersections: Associating Deficiencies and Their Consequences in Colombian Projects. Appl. Sci. 2025, 15, 4614. https://doi.org/10.3390/app15094614

Castañeda K, Sánchez O, Peña CA, Herrera RF, Mejía G. Comprehensive Analysis of Scheduling Processes in Road Intersections: Associating Deficiencies and Their Consequences in Colombian Projects. Applied Sciences. 2025; 15(9):4614. https://doi.org/10.3390/app15094614

Chicago/Turabian StyleCastañeda, Karen, Omar Sánchez, Carlos A. Peña, Rodrigo F. Herrera, and Guillermo Mejía. 2025. "Comprehensive Analysis of Scheduling Processes in Road Intersections: Associating Deficiencies and Their Consequences in Colombian Projects" Applied Sciences 15, no. 9: 4614. https://doi.org/10.3390/app15094614

APA StyleCastañeda, K., Sánchez, O., Peña, C. A., Herrera, R. F., & Mejía, G. (2025). Comprehensive Analysis of Scheduling Processes in Road Intersections: Associating Deficiencies and Their Consequences in Colombian Projects. Applied Sciences, 15(9), 4614. https://doi.org/10.3390/app15094614