Mechanical, Electrical and Fractural Characteristics of Carbon Nanomaterial-Added Cement Composites

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Mechanical Properties

3.2. Fractural Characteristics

Fracture Energy and Fracture Toughness

3.3. Electrical Conductivity

3.4. Porosity

4. Conclusions

- Compared to all other CNM-added cement composites, 0.3% CNT-added cement composites showed the maximum increase in compressive strength. For the CNF-added cement composite, the current study concluded that compressive strength increased with an increase in the CNF content ratio. GNP- and graphene-added cement composites demonstrated that adding a small dosage of 0.1% is ideal for improving the compressive strength.

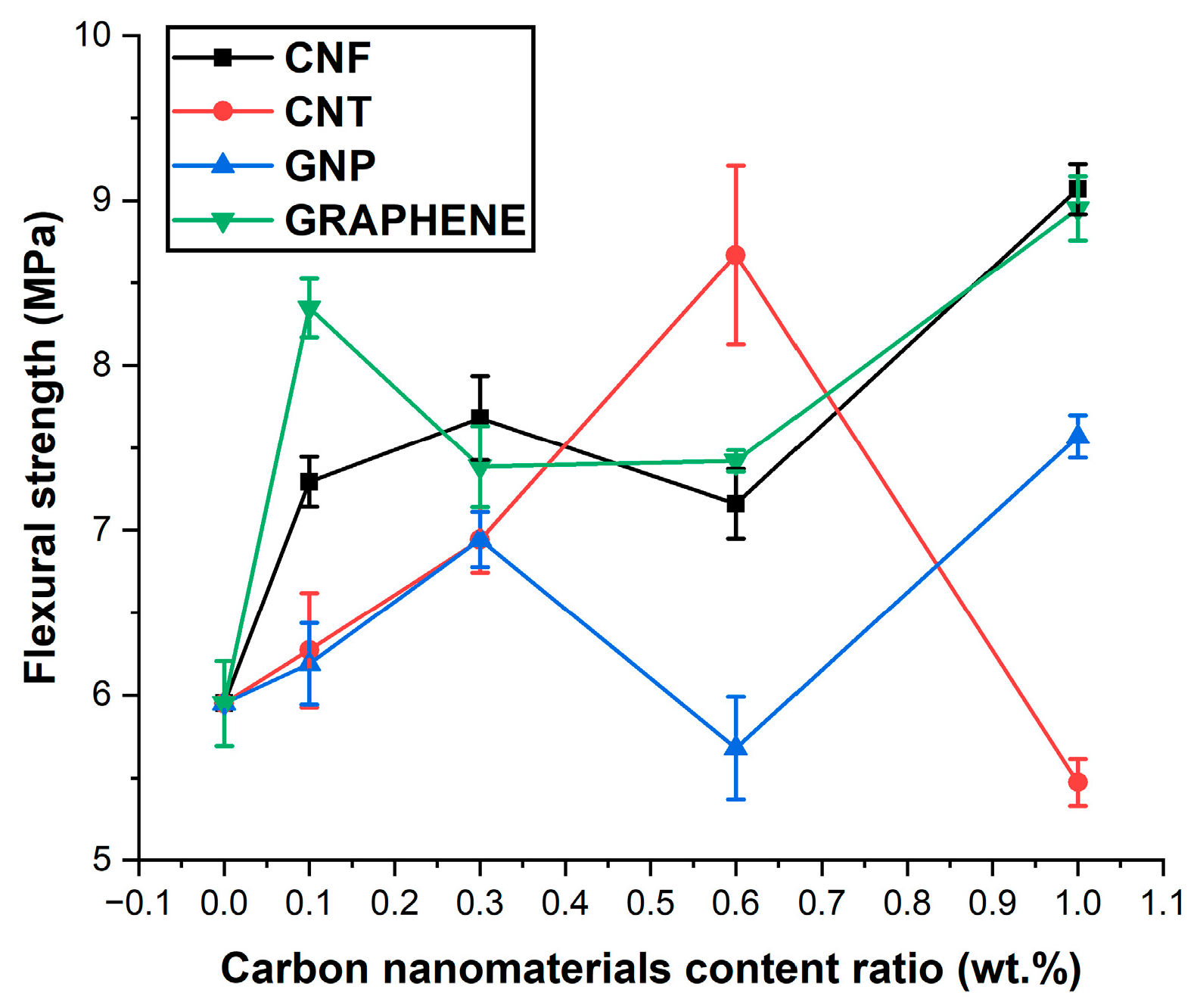

- Similar to compressive strength results, cement composites with 1.0% CNF ratio exhibited the highest flexural strength among all CNM-added cement composites. Regarding GNP or graphene-added cement composites, the maximum flexural strength was achieved with a 1.0% dosage. The flexural strength of cement composites improved as the CNT dosage increases up to 0.6%.

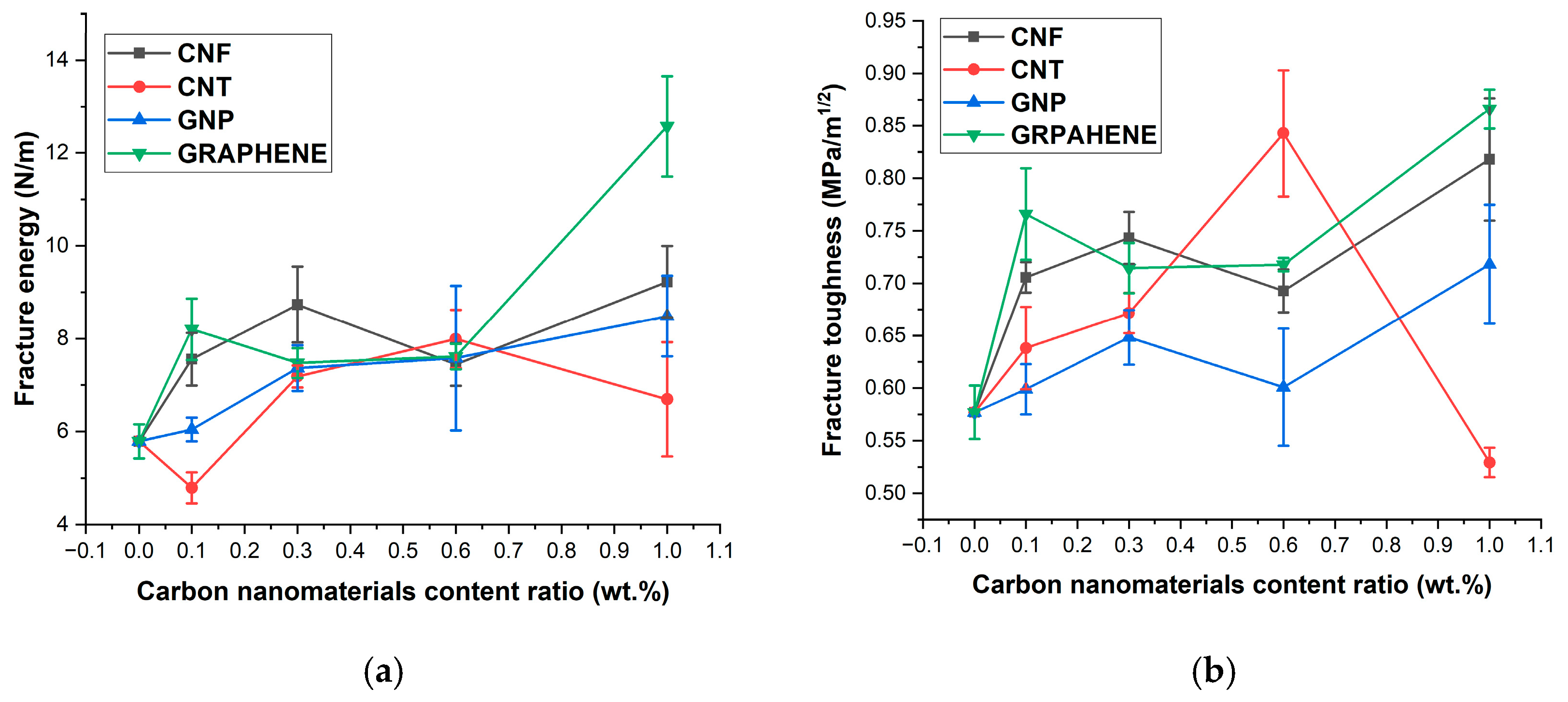

- The fracture characteristics of the CNM/composites underlined that graphene-added cement composites attained the maximum fracture energy. Accordingly, fracture toughness was improved with a 1.0% content ratio compared to that of other CNM-added composites. Similarly, CNF- and GNP-added cement composites showed maximum improvement in fractural characteristics at 1.0% dosage. The CNT-added cement composites exhibited maximum fractural characteristics at a CNT dosage of 0.6%.

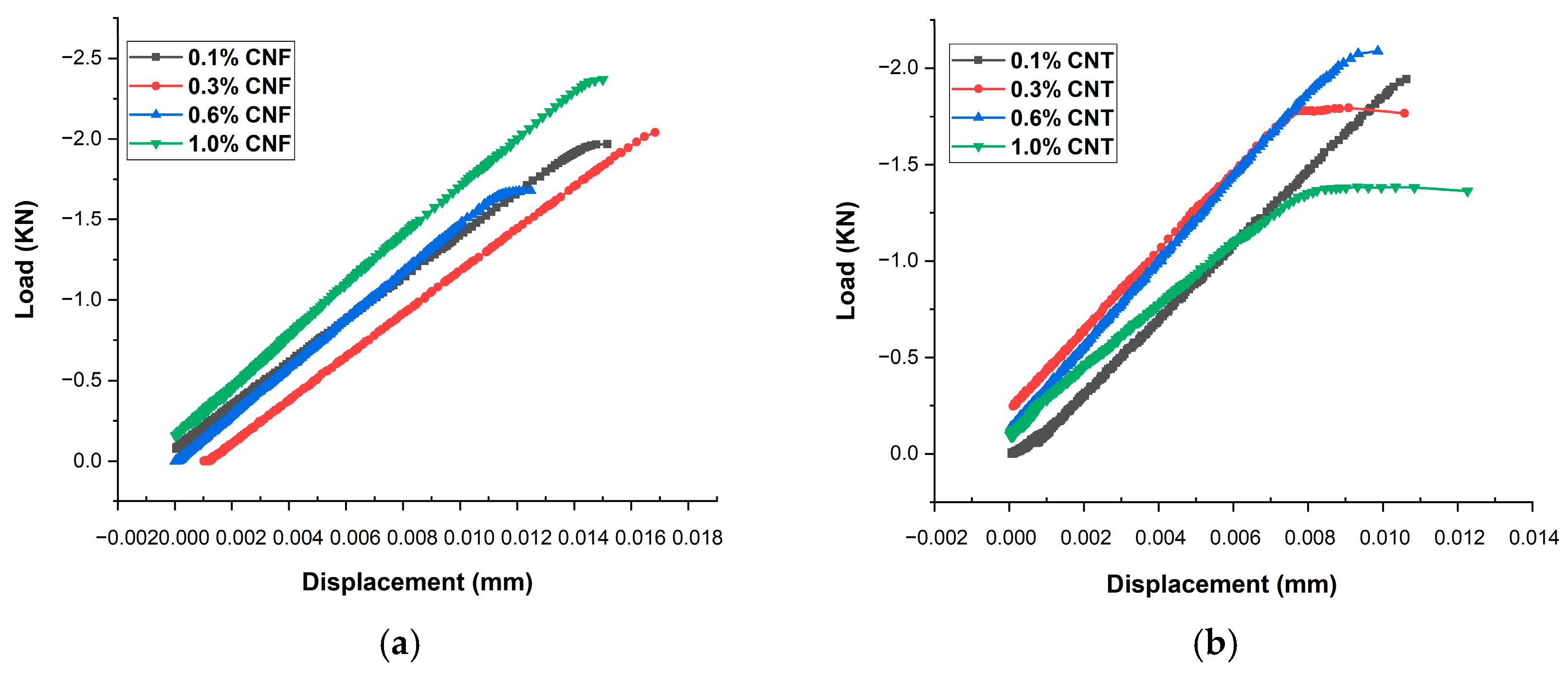

- A CNT content ratio between 0.3% and 0.6% can be the optimal ratio for improving cement composites’ mechanical and fractural characteristics. When CNT content was further increased to 1.0%, a sharp decrease in mechanical properties and fractural characteristics was observed. This phenomenon was due to the non-uniform dispersion of CNT in the cement matrix, which created agglomerations of CNT, thereby decreasing the mechanical properties and flexural characteristics.

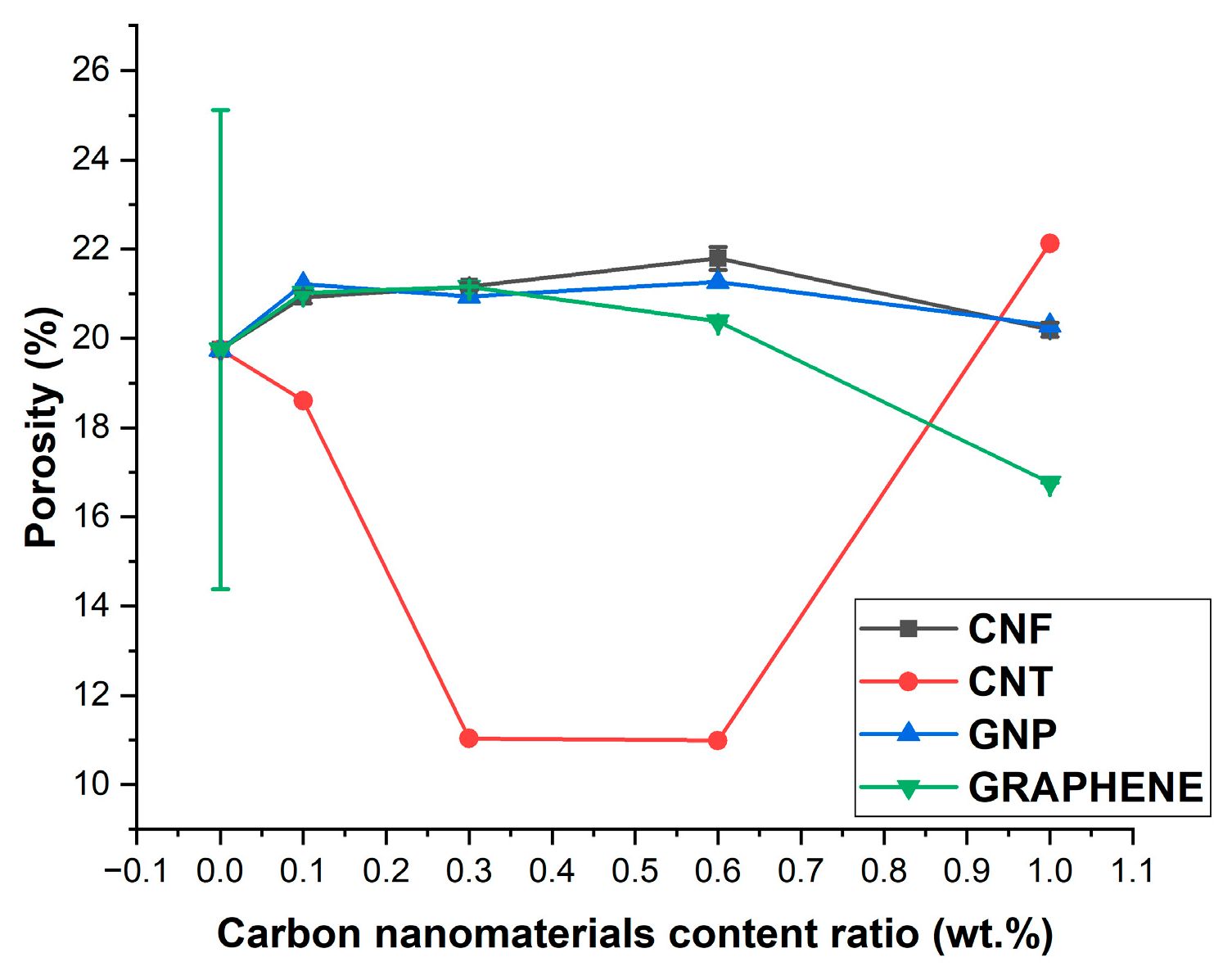

- The porosity results of CNF/cement composites showed an inverse relationship with all mechanical properties and flexural characteristics. In the GNP/cement, CNT/cement, and graphene/cement composites, flexural strength, fracture toughness, and fracture energy improved as porosity decreased. However, an increase in compressive strength did not exhibit a clear relationship with the porosity. Besides porosity, factors such as the aspect ratio of CNMs and the degree of dispersion of CNMs in cement composites require further investigation.

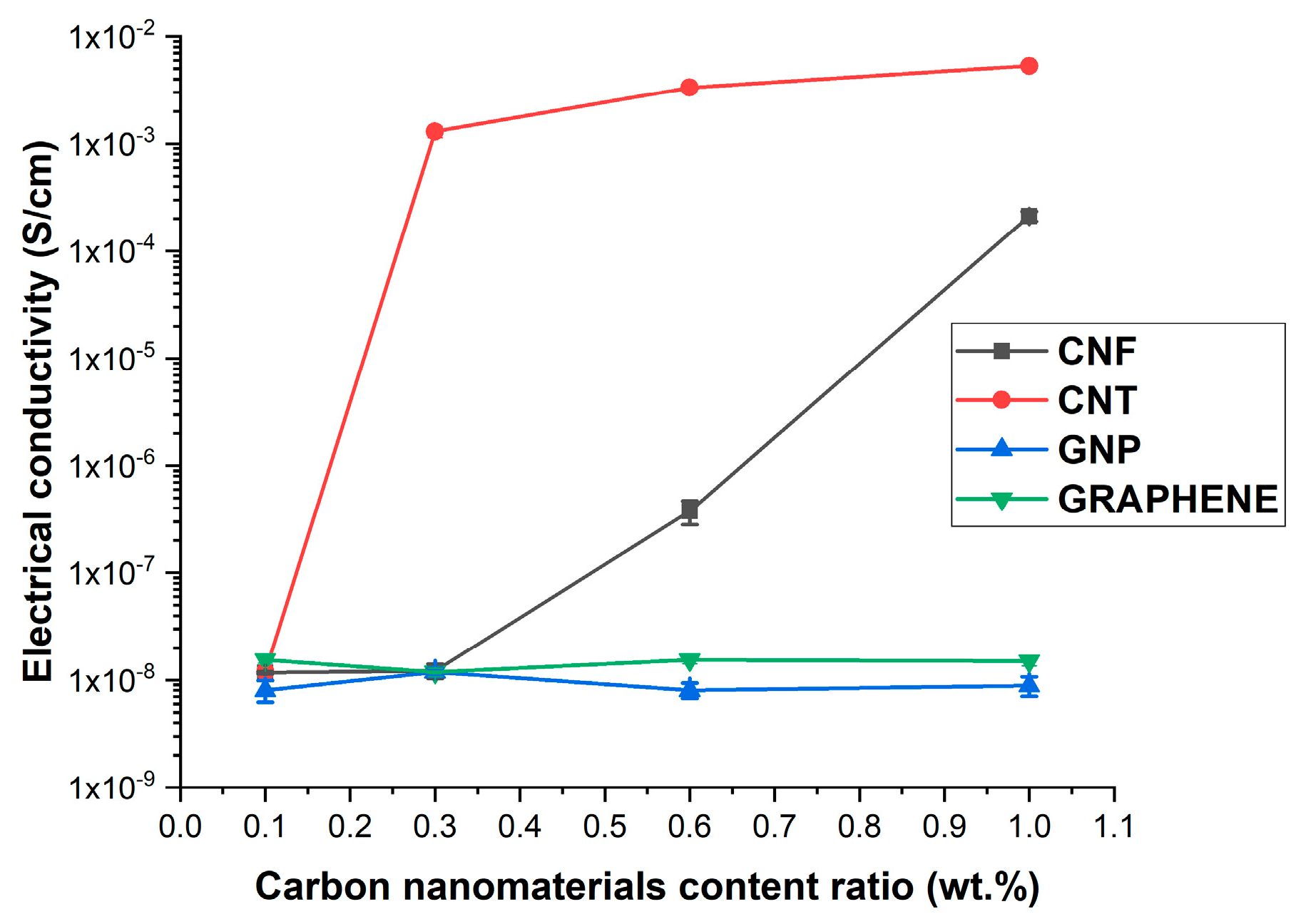

- Based on electrical conductivity test results, the CNF/cement composites showed a percolation threshold ranging from 0.3% to 1.0%, and CNT/cement showed a percolation threshold ranging from 0.1% to 0.3%. Meanwhile, the GNP and graphene showed an insignificant change in electrical conductivity with an increased content ratio, and exhibited no percolation threshold phenomena.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CMOD | Crack mouth opening displacement |

| CNFs | Carbon nanofibers |

| CNMs | Carbon nanomaterials |

| CNTs | Carbon nanotubes |

| COD | Crack opening displacement |

| GNP | Graphite nanoplatelets |

| GOs | Graphene oxides |

| MWCNTs | Multi-walled carbon nanotubes |

| OPC | Ordinary Portland cement |

| SP | Superplasticizer |

| SWCNTs | Single-walled carbon nanotubes |

| UTM | Universal testing machine |

References

- Singh, H. Steel Fiber Reinforced Concrete Behavior, Modelling and Design; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 1152701095966. [Google Scholar]

- Lu, L.; Ouyang, D.; Xu, W. Mechanical Properties and Durability of Ultra High Strength Concrete Incorporating Multi-Walled Carbon Nanotubes. Materials 2016, 9, 419. [Google Scholar] [CrossRef] [PubMed]

- Słowik, M. The Analysis of Failure in Concrete and Reinforced Concrete Beams with Different Reinforcement Ratio. Arch. Appl. Mech. 2019, 89, 885–895. [Google Scholar] [CrossRef]

- Du, M.; Jing, H.; Gao, Y.; Su, H.; Fang, H. Carbon Nanomaterials Enhanced Cement-Based Composites: Advances and Challenges. Nanotechnol. Rev. 2020, 9, 115–135. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on Nanoparticles and Nanostructured Materials: History, Sources, Toxicity and Regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef]

- Power, A.C.; Gorey, B.; Chandra, S.; Chapman, J. Carbon Nanomaterials and Their Application to Electrochemical Sensors. Nanotechnol. Rev. 2018, 7, 19–41. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Biswas, S.; Kim, H.; Nam, I. Characteristics of Epoxy-Based Composites Incorporating Hybridized Networks of Carbon or Graphite Nanoplatelets. Sensors 2020, 20, 2094. [Google Scholar] [CrossRef]

- Rainieri, C.; Pannunzio, C.; Song, Y.; Fabbrocino, G.; Schulz, M.J.; Shanov, V. The Status of Research on Self-Sensing Properties of CNT-Cement Based Composites and Prospective Applications to SHM. Key Eng. Mater. 2013, 569–570, 759–766. [Google Scholar] [CrossRef]

- Saifuddin, N.; Raziah, A.Z.; Junizah, A.R. Carbon Nanotubes: A Review on Structure and Their Interaction with Proteins. J. Chem. 2013, 2013, 676815. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of Nanocarbon-Engineered Multifunctional Cementitious Composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N.; Emon, M.A.B. Potential of Carbon Nanotube Reinforced Cement Composites as Concrete Repair Material. J. Nanomater. 2016, 2016, 1421959. [Google Scholar] [CrossRef]

- Naeem, F.; Lee, H.K.; Kim, H.K.; Nam, I.W. Flexural Stress and Crack Sensing Capabilities of MWNT/Cement Composites. Compos. Struct. 2017, 175, 86–100. [Google Scholar] [CrossRef]

- Evangelista, A.C.J.; de Morais, J.F.; Tam, V.; Soomro, M.; Di Gregorio, L.T.; Haddad, A.N. Evaluation of Carbon Nanotube Incorporation in Cementitious Composite Materials. Materials 2019, 12, 1504. [Google Scholar] [CrossRef] [PubMed]

- Mohsen, M.O.; Al-diseet, M.M.; Aburumman, M.O.; Abdel-jaber, M.; Taha, R.; Al Ansari, M.S.; Taqa, A.A. Hybrid Effect of GNPs, GOs, and CNTs on the Flexural and Compressive Strengths of Cement Paste. J. Build. Eng. 2023, 73, 106679. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Han, B.; Sun, S.; Qin, Y.; Han, X.; Yang, G.; Li, M.; Fan, X.; Peng, W. Advances in Self-Sensing Cement-Based Composites Containing Nano Materials for Smart Civil Infrastructures. Measurement 2024, 230, 114514. [Google Scholar] [CrossRef]

- Yazdani, N.; Mohanam, V. Carbon Nano-Tube and Nano-Fiber in Cement Mortar: Effect of Dosage Rate and Water-Cement Ratio. Int. J. Mater. Sci. 2014, 4, 45. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N. Optimum Mix Ratio for Carbon Nanotubes in Cement Mortar. KSCE J. Civ. Eng. 2015, 19, 1405–1412. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Falara, M.G.; Katotriotou, M.K.; Konsta-Gdoutos, M.S.; Gdoutos, E.E. MWCNT and CNF Cementitious Nanocomposites for Enhanced Strength and Toughness. Conf. Proc. Soc. Exp. Mech. Ser. 2016, 7, 241–246. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Multi-Scale Mechanical and Fracture Characteristics and Early-Age Strain Capacity of High Performance Carbon Nanotube/Cement Nanocomposites. Cem. Concr. Compos. 2010, 32, 110–115. [Google Scholar] [CrossRef]

- Kang, S.T.; Seo, J.Y.; Park, S.H. The Characteristics of CNT/Cement Composites with Acid-Treated MWCNTs. Adv. Mater. Sci. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Lee, H.S.; Balasubramanian, B.; Gopalakrishna, G.V.T.; Kwon, S.J.; Karthick, S.P.; Saraswathy, V. Durability Performance of CNT and Nanosilica Admixed Cement Mortar. Constr. Build. Mater. 2018, 159, 463–472. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.A.; Hawreen, A.; Guedes, M. Durability of Multi-Walled Carbon Nanotube Reinforced Concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Bhatrola, K.; Kothiyal, N.C.; Maurya, S.K. Durability & Mechanical Properties of Functionalized Multiwalled Carbon Nanotube Incorporated Pozzolana Portland Cement Composite. Mater. Today Proc. 2023, 93, 249–256. [Google Scholar] [CrossRef]

- Liu, J.; Fu, J.; Ni, T.; Yang, Y. Fracture Toughness Improvement of Multi-Wall Carbon Nanotubes/Graphene Sheets Reinforced Cement Paste. Constr. Build. Mater. 2019, 200, 530–538. [Google Scholar] [CrossRef]

- Hu, Y.; Luo, D.; Li, P.; Li, Q.; Sun, G. Fracture Toughness Enhancement of Cement Paste with Multi-Walled Carbon Nanotubes. Constr. Build. Mater. 2014, 70, 332–338. [Google Scholar] [CrossRef]

- Singh, R.K.; Danoglidis, P.A.; Shah, S.P.; Konsta, M.S. On the Interactions of Carbon Nanotubes with Metakaolin Cementitious Binders: Effects on ITZ, Modulus and Toughness. Constr. Build. Mater. 2023, 408, 133605. [Google Scholar] [CrossRef]

- Nam, I.W.; Lee, H.K. Image Analysis and DC Conductivity Measurement for the Evaluation of Carbon Nanotube Distribution in Cement Matrix. Int. J. Concr. Struct. Mater. 2015, 9, 427–438. [Google Scholar] [CrossRef]

- Coppola, L.; Buoso, A.; Corazza, F. Electrical Properties of Carbon Nanotubes Cement Composites for Monitoring Stress Conditions in Concrete Structures. Appl. Mech. Mater. 2011, 82, 118–123. [Google Scholar] [CrossRef]

- Pisello, A.L.; D’Alessandro, A.; Sambuco, S.; Rallini, M.; Ubertini, F.; Asdrubali, F.; Materazzi, A.L.; Cotana, F. Multipurpose Experimental Characterization of Smart Nanocomposite Cement-Based Materials for Thermal-Energy Efficiency and Strain-Sensing Capability. Sol. Energy Mater. Sol. Cells 2017, 161, 77–88. [Google Scholar] [CrossRef]

- Onthong, S.; O’Rear, E.A.; Pongprayoon, T. Composite Nanoarchitectonics by Interfacial Bonding for Conductivity and Strength Development of Grafted Multiwall Carbon Nanotube/Cement. Constr. Build. Mater. 2023, 392, 131940. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Xiao, H. Self-Deicing Road System with a CNFP High-Efficiency Thermal Source and MWCNT/Cement-Based High-Thermal Conductive Composites. Cold Reg. Sci. Technol. 2013, 86, 22–35. [Google Scholar] [CrossRef]

- Yazdani, N.; Brown, E. Carbon Nanofibers in Cement Composites: Mechanical Reinforcement; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9781782423447. [Google Scholar]

- Barbhuiya, S.; Chow, P. Nanoscaled Mechanical Properties of Cement Composites Reinforced with Carbon Nanofibers. Materials 2017, 10, 662. [Google Scholar] [CrossRef] [PubMed]

- Galao, O.; Zornoza, E.; Baeza, F.J.; Bernabeu, A.; Garcés, P. Efecto de La Adición de Nanofibras de Carbono En Las Propiedades Mecánicas y de Durabilidad de Materiales Cementantes. Mater. Constr. 2012, 62, 343–357. [Google Scholar] [CrossRef]

- Wang, T.; Xu, J.; Bai, E.; Lv, Y.; Peng, G. Research on a Sustainable Concrete Synergistic Reinforced with Carbon Fiber and Carbon Nanofiber: Mechanical Properties, Durability and Environmental Evaluation. Int. J. Hydrogen Energy 2023, 48, 35366–35386. [Google Scholar] [CrossRef]

- Dong, H.; Wang, J. Carbon Nanofibers and Polyvinyl-Alcohol Fiber Hybrid-Reinforced High-Performance Concrete: Mechanical Property, Chloride Penetration Resistance, and Material Characterization. Constr. Build. Mater. 2023, 399, 131891. [Google Scholar] [CrossRef]

- Daoust, K.; Vallières, P.L.; Tagnit-Hamou, A.; Claverie, J.P. Carbon Nanofibers Encapsulated by Polyethylene Glycol Increase the Mechanical Properties and Durability of OPC Mortars. Constr. Build. Mater. 2024, 447, 137986. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Mechanical Properties of Ultra-High-Performance Concrete Enhanced with Graphite Nanoplatelets and Carbon Nanofibers. Compos. Part B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Akono, A.T. Nanostructure and Fracture Behavior of Carbon Nanofiber-Reinforced Cement Using Nanoscale Depth-Sensing Methods. Materials 2020, 13, 3837. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Sun, Y.; Du, Y. Influence of Carbon Nanofiber Content on the Fracture Mechanical Properties of Cement-Based Materials: Insights from Three-Point Bending and Nanoindentation Tests. Buildings 2023, 13, 2594. [Google Scholar] [CrossRef]

- Wang, H.; Gao, X.; Wang, R. The Influence of Rheological Parameters of Cement Paste on the Dispersion of Carbon Nanofibers and Self-Sensing Performance. Constr. Build. Mater. 2017, 134, 673–683. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Aza, C.A. Self Sensing Carbon Nanotube (CNT) and Nanofiber (CNF) Cementitious Composites for Real Time Damage Assessment in Smart Structures. Cem. Concr. Compos. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Shareef, K.R.M.; Rawoof, S.A.; Sowjanya, K. A Feasibility Study on Mechanical Properties of Concrete With Graphene Oxide. Int. Res. J. Eng. Technol. 2008, 9001, 218–224. [Google Scholar]

- Lin, Y.; Du, H. Graphene Reinforced Cement Composites: A Review Graphene Reinforced Cement Composites: A Review. Constr. Build. Mater. 2020, 265, 120312. [Google Scholar] [CrossRef]

- Sedaghat, A.; Ram, M.K.; Zayed, A.; Kamal, R.; Shanahan, N. Investigation of Physical Properties of Graphene-Cement Composite for Structural Applications. Open J. Compos. Mater. 2014, 4, 12–21. [Google Scholar] [CrossRef]

- Cao, M.-l.; Zhang, H.-x.; Zhang, C. Effect of Graphene on Mechanical Properties of Cement Mortars. J. Cent. South Univ. 2016, 23, 919–925. [Google Scholar] [CrossRef]

- Dong, W.; Gao, S.; Peng, S.; Shi, L.; Shah, S.P.; Li, W. Graphene Reinforced Cement-Based Triboelectric Nanogenerator for Efficient Energy Harvesting in Civil Infrastructure. Nano Energy 2024, 131, 110380. [Google Scholar] [CrossRef]

- Kjaernsmo, H.; Kakay, S.; Fossa, K.T.; Gronli, J. The Effect of Graphene Oxide on Cement Mortar. IOP Conf. Ser. Mater. Sci. Eng. 2018, 362, 012012. [Google Scholar] [CrossRef]

- Mijowska, S. Nanocomposite of Cement/Graphene Oxide—Impact on Hydration Kinetics and Young’ s Modulus. Constr. Build. Mater. 2015, 78, 234–242. [Google Scholar] [CrossRef]

- E Silva, R.A.; de Castro Guetti, P.; da Luz, M.S.; Rouxinol, F.; Gelamo, R.V. Enhanced Properties of Cement Mortars with Multilayer Graphene Nanoparticles. Constr. Build. Mater. 2017, 149, 378–385. [Google Scholar] [CrossRef]

- Devi, S.C.; Khan, R.A. Effect of Graphene Oxide on Mechanical and Durability Performance of Concrete. J. Build. Eng. 2020, 27, 101007. [Google Scholar] [CrossRef]

- Bai, S.; Jiang, L.; Jiang, Y.; Jin, M.; Jiang, S.; Tao, D. Research on Electrical Conductivity of Graphene/Cement Composites. Adv. Cem. Res. 2020, 32, 45–52. [Google Scholar] [CrossRef]

- Pajarito, B.; Belarmino, A.J.; Calimbas, R.M.; Gonzales, J.R. Graphite Nanoplatelets from Waste Chicken Feathers. Materials 2020, 13, 2109. [Google Scholar] [CrossRef] [PubMed]

- Cataldi, P.; Athanassiou, A.; Bayer, I.S. Graphene Nanoplatelets-Based Advanced Materials and Recent Progress in Sustainable Applications. Appl. Sci. 2018, 8, 1438. [Google Scholar] [CrossRef]

- Huang, S. Multifunctional Graphite Nanoplatelets (Gnp) Reinforced Cementitious Composites. Master’s Thesis, National University of Singapore, Singapore, 2012. [Google Scholar]

- Chen, G.; Yang, M.; Xu, L.; Zhang, Y. Graphene Nanoplatelets Impact on Concrete in Improving Freeze-Thaw Resistance. Appl. Sci. 2019, 9, 3582. [Google Scholar] [CrossRef]

- Wang, B.; Jiang, R.; Wu, Z. Investigation of the Mechanical Properties and Microstructure of Graphene Nanoplatelet-Cement Composite. Nanomaterials 2016, 6, 200. [Google Scholar] [CrossRef]

- Hang, Z.; Fan, Y.; Yang, J.; Feng, C.; Yang, J.; Wang, S. Improved Compressive and Flexural Performances of Functionally Graded Graphene Nanoplatelet Reinforced Cement Composites: Experiments and Modelling. Constr. Build. Mater. 2023, 391, 131828. [Google Scholar] [CrossRef]

- Dalla, P.T.; Tragazikis, I.; Trakakis, G.; Galiotis, C.; Dassios, K.G.; Matikas, T.E. Multifunctional Cement Mortars Enhanced with Graphene Nanoplatelets and Carbon Nanotubes. Sensors 2021, 21, 933. [Google Scholar] [CrossRef]

- Le, J.L.; Du, H.; Pang, S.D. Use of 2-D Graphene Nanoplatelets (GNP) in Cement Composites for Structural Health Evaluation. Compos. Part B Eng. 2014, 67, 555–563. [Google Scholar] [CrossRef]

- Qi, G.; Wang, Q.; Zhang, R.; Guo, Z.; Zhan, D.; Liu, S. Effect of RGO/GNP on the Electrical Conductivity and Piezoresistance of Cement-Based Composite Subjected to Dynamic Loading. Constr. Build. Mater. 2023, 368, 130340. [Google Scholar] [CrossRef]

- ASTM C230/C230M—08; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM: West Conshohocken, PA, USA, 2010; pp. 4–9.

- ASTM Standards C 293-02; Standard Test Method Flexural Strength Concr. (Using Simple Beam with Center-Point Loading). ASTM International: West Conshohocken, PA, USA, 2002; pp. 1–3. [CrossRef]

- Vilela Rocha, V.; Ludvig, P.; Constancio Trindade, A.C.; de Andrade Silva, F. The Influence of Carbon Nanotubes on the Fracture Energy, Flexural and Tensile Behavior of Cement Based Composites. Constr. Build. Mater. 2019, 209, 1–8. [Google Scholar] [CrossRef]

- Luo, J.; Chen, S.; Li, Q.; Liu, C.; Gao, S.; Zhang, J.; Guo, J. Influence of Graphene Oxide on the Mechanical Properties, Fracture Toughness, and Microhardness of Recycled Concrete. Nanomaterials 2019, 9, 325. [Google Scholar] [CrossRef] [PubMed]

- Xie, C.; Cao, M.; Khan, M.; Yin, H.; Guan, J. Review on Different Testing Methods and Factors Affecting Fracture Properties of Fiber Reinforced Cementitious Composites. Constr. Build. Mater. 2020, 273, 121766. [Google Scholar] [CrossRef]

- ASTM-C349-02; Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure)1. ASTM: West Conshohocken, PA, USA, 1957; pp. 4–6. [CrossRef]

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–3. [CrossRef]

- Nam, I.W.; Souri, H.; Lee, H.K. Percolation Threshold and Piezoresistive Response of Multi-Wall Carbon Nanotube/Cement Composites. Smart Struct. Syst. 2016, 18, 217–231. [Google Scholar] [CrossRef]

- Raza, A.; Bhandari, M.; Kim, H.; Son, H.; Huang, B.; Nam, I.-W. A Study on Mechanical Characteristics of Cement Composites Fabricated with Nano-Silica and Carbon Nanotube. Appl. Sci. 2021, 11, 152. [Google Scholar] [CrossRef]

- Gillani, S.S.U.H.; Khitab, A.; Ahmad, S.; Khushnood, R.A.; Ferro, G.A.; Saleem Kazmi, S.M.; Qureshi, L.A.; Restuccia, L. Improving the Mechanical Performance of Cement Composites by Carbon Nanotubes Addition. Procedia Struct. Integr. 2017, 3, 11–17. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Carbon Nanotube Reinforced Cementitious Composites: An Overview. Compos. Part A Appl. Sci. Manuf. 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical Behavior and Microstructure of Cement Composites Incorporating Surface-Treated Multi-Walled Carbon Nanotubes. Carbon N. Y. 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The Influences of Admixtures on the Dispersion, Workability, and Strength of Carbon Nanotube-OPC Paste Mixtures. Cem. Concr. Compos. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Mechanical Properties of Carbon-Nanotube-Reinforced Cementitious Materials: Database and Statistical Analysis. Mag. Concr. Res. 2020, 72, 1047–1071. [Google Scholar] [CrossRef]

- Kim, G.M.; Nam, I.W.; Yang, B.; Yoon, H.N.; Lee, H.K.; Park, S. Carbon Nanotube (CNT) Incorporated Cementitious Composites for Functional Construction Materials: The State of the Art. Compos. Struct. 2019, 227, 111244. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Taha, R.; Abu Taqa, A.; Shaat, A. Optimum Carbon Nanotubes’ Content for Improving Flexural and Compressive Strength of Cement Paste. Constr. Build. Mater. 2017, 150, 395–403. [Google Scholar] [CrossRef]

- Gdoutos, E.E.; Konsta-gdoutos, M.S.; Danoglidis, P.A. Portland Cement Mortar Nanocomposites at Low Carbon Nanotube and Carbon Nanofiber Content: A Fracture Mechanics Experimental Study. Cem. Concr. Compos. 2016, 70, 110–118. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Konsta-Gdoutos, M.S.; Shah, S.P. Carbon Nanofiber Cementitious Composites: Effect of Debulking Procedure on Dispersion and Reinforcing Efficiency. Cem. Concr. Compos. 2013, 36, 25–32. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R. A Review on Nanomaterial Dispersion, Microstructure, and Mechanical Properties of Carbon Nanotube and Nanofiber Reinforced Cementitious Composites. J. Nanomater. 2013, 2013, 710175. [Google Scholar] [CrossRef]

- Tziviloglou, E.; Metaxa, Z.S.; Maistros, G.; Kourkoulis, S.K.; Alexopoulos, N.D. Evaluation of Fracture Toughness in Graphene-Based Cementitious Nanocomposites via Electrical Impedance. Procedia Struct. Integr. 2022, 42, 1700–1707. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, L.; Wang, R.; Zhang, S.; Fu, L.; Li, M.; Xiao, Q. Advances in Monte Carlo Method for Simulating the Electrical Percolation Behavior of Conductive Polymer Composites with a Carbon-Based Filling. Polymers 2024, 16, 545. [Google Scholar] [CrossRef]

- Du, H.; Quek, S.T.; Pang, S.D. Smart Multifunctional Cement Mortar Containing Graphite Nanoplatelet. Sensors Smart Struct. Technol. Civil, Mech. Aerosp. Syst. 2013, 8692, 869238. [Google Scholar] [CrossRef]

- Jin, M.; Li, W.; Ma, Y.; Zeng, H.; Huang, M.; Lu, C.; Yang, G. Investigation on the Electrical Conductivity of Graphene/Cement Composites by Alternating Current Method. Materials 2023, 16, 1436. [Google Scholar] [CrossRef]

| Composite Type | CNM Ratio | SP * (g) | Water (g) | Cement (g) | W/C Ratio | CNM (g) |

|---|---|---|---|---|---|---|

| CNT/cement | 0.1 | 0 | 541.4 | 2165.4 | 0.25 | 2.2 |

| 0.3 | 14 | 6.5 | ||||

| 0.6 | 25 | 13.0 | ||||

| 1 | 82.7 | 21.7 | ||||

| CNF/cement | 0.1 | 0 | 541.4 | 2165.4 | 0.25 | 2.2 |

| 0.3 | 0 | 6.5 | ||||

| 0.6 | 1.8 | 13.0 | ||||

| 1 | 7 | 21.7 | ||||

| Graphene/cement | 0.1 | 0 | 541.4 | 2165.4 | 0.25 | 2.2 |

| 0.3 | 0 | 6.5 | ||||

| 0.6 | 5.7 | 13.0 | ||||

| 1 | 20 | 21.7 | ||||

| GNP/cement | 0.1 | 0 | 541.4 | 2165.4 | 0.25 | 2.2 |

| 0.3 | 0 | 6.5 | ||||

| 0.6 | 0 | 13.0 | ||||

| 1 | 2.3 | 21.7 | ||||

| Cement only | 0 | 0 | 541.4 | 2165.4 | 0.25 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhandari, M.; Yue, J.; Nam, I.-W. Mechanical, Electrical and Fractural Characteristics of Carbon Nanomaterial-Added Cement Composites. Appl. Sci. 2025, 15, 4673. https://doi.org/10.3390/app15094673

Bhandari M, Yue J, Nam I-W. Mechanical, Electrical and Fractural Characteristics of Carbon Nanomaterial-Added Cement Composites. Applied Sciences. 2025; 15(9):4673. https://doi.org/10.3390/app15094673

Chicago/Turabian StyleBhandari, Manan, Jianguang Yue, and Il-Woo Nam. 2025. "Mechanical, Electrical and Fractural Characteristics of Carbon Nanomaterial-Added Cement Composites" Applied Sciences 15, no. 9: 4673. https://doi.org/10.3390/app15094673

APA StyleBhandari, M., Yue, J., & Nam, I.-W. (2025). Mechanical, Electrical and Fractural Characteristics of Carbon Nanomaterial-Added Cement Composites. Applied Sciences, 15(9), 4673. https://doi.org/10.3390/app15094673