Synergistic Evolution and Spatial-Temporal Differences in Green Technological Innovation and Carbon Emission Reduction in the Construction Industry from the Perspective of New Productive Forces

Abstract

:1. Introduction

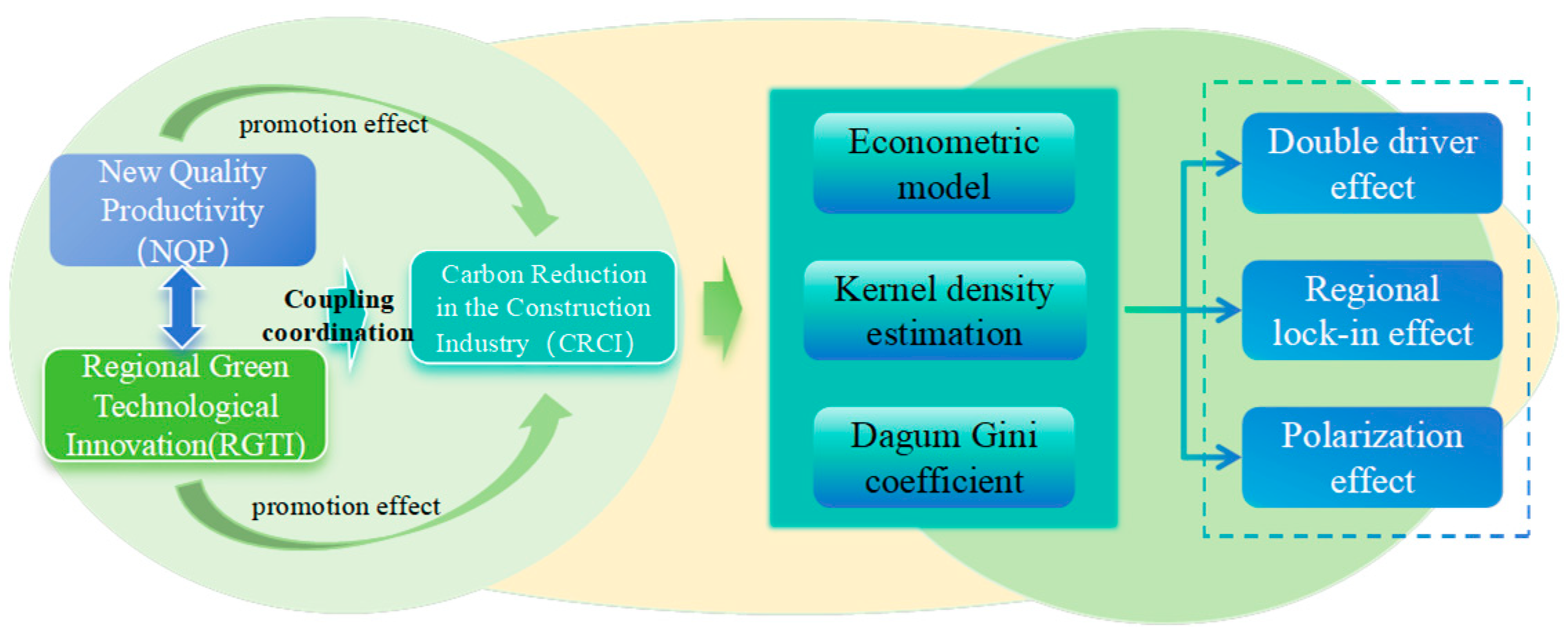

2. Theoretical Analysis and Model Development

3. Method and Data

3.1. Measurement of RGTI, NQP, and CRCI

3.2. Econometric Model

3.3. Coupling Coordination Degree Model

3.4. Analysis of Spatiotemporal Evolutionary Differences

3.5. Data Collection

4. Results

4.1. Measurement Results of RGTI, NQP, and CRCI

4.2. Econometric Results

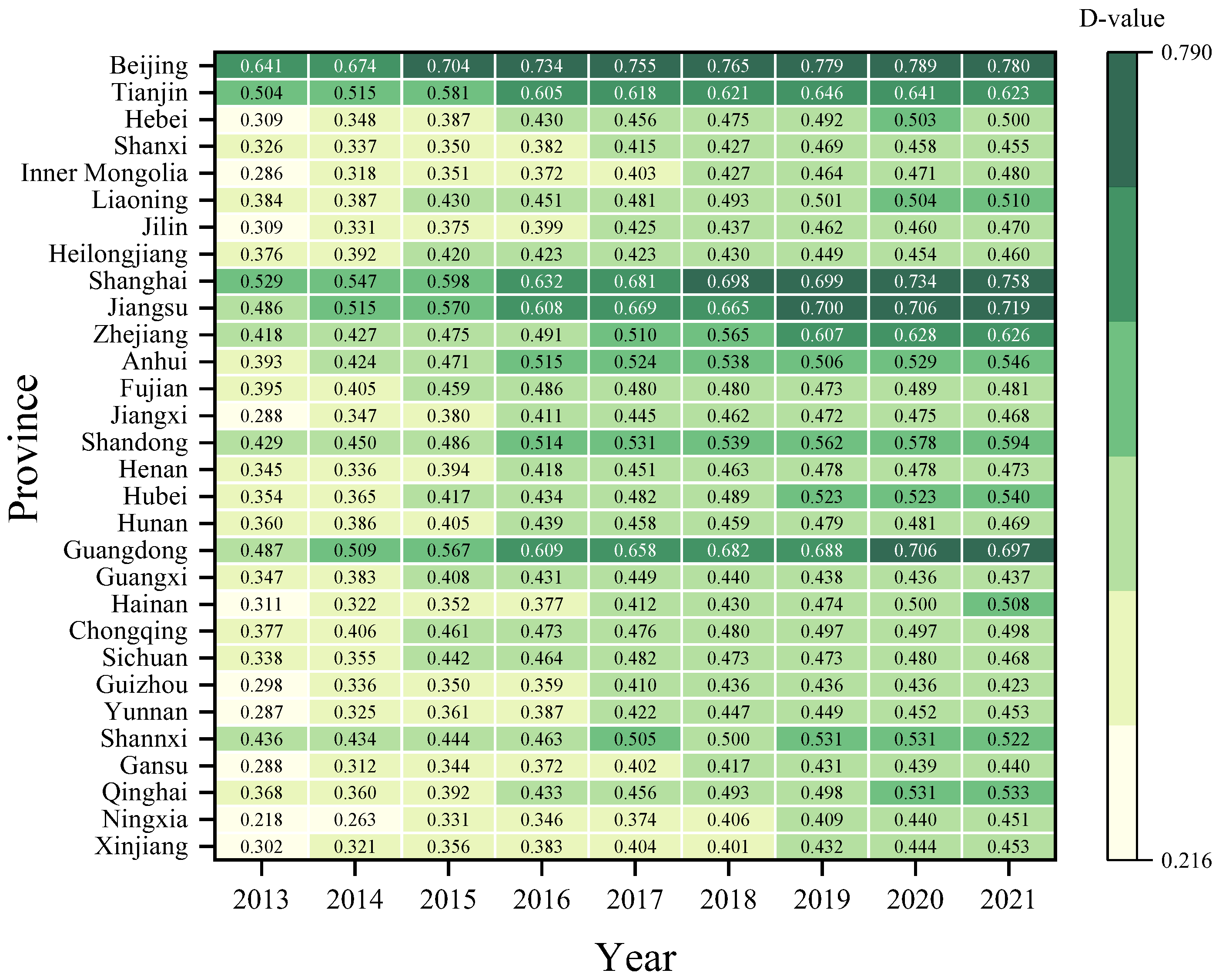

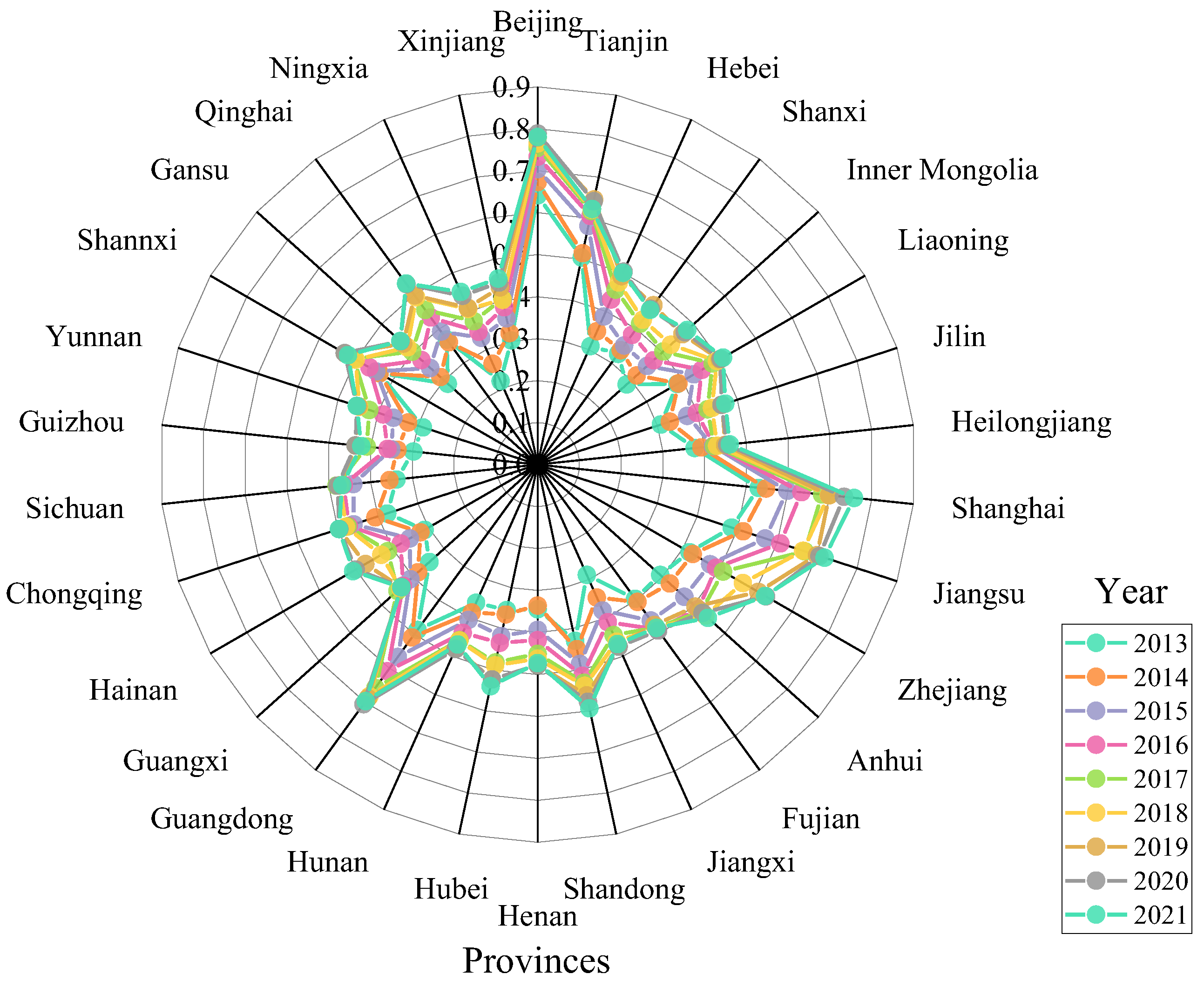

4.3. Co-Evolutionary Results of RGTI, NQP and CRCI

4.4. Results of Spatiotemporal Evolution Analysis

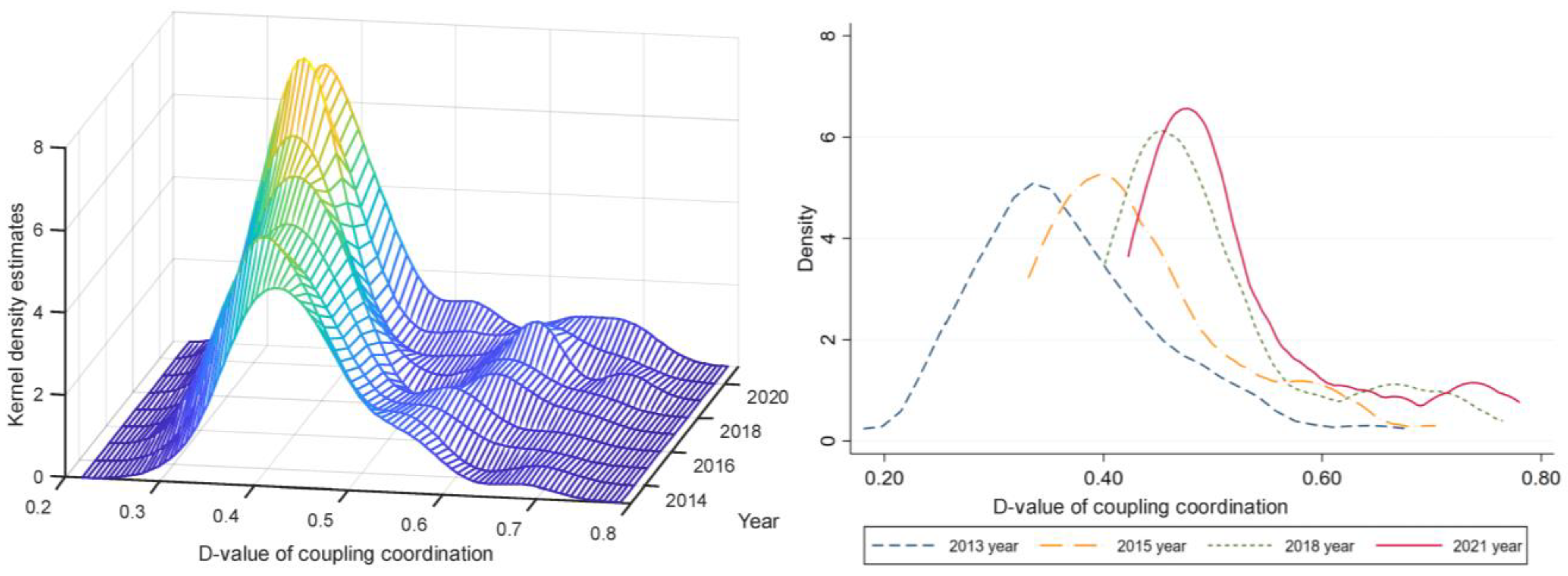

4.4.1. Dynamic Evolution Results

4.4.2. Spatial Variation Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmed Ali, K.; Ahmad, M.I.; Yusup, Y. Issues, impacts, and mitigations of carbon dioxide emissions in the building sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M. Carbon footprint of construction industry: A global review and supply chain analysis. Renew. Sustain. Energy Rev. 2020, 124, 109783. [Google Scholar] [CrossRef]

- Erdogan, S. Dynamic nexus between technological innovation and building sector carbon emissions in the BRICS countries. J. Environ. Manag. 2021, 293, 112780. [Google Scholar] [CrossRef] [PubMed]

- Lai, K.E.; Rahiman, N.A.; Othman, N.; Ali, K.N.; Lim, Y.W.; Moayedi, F.; Dzahir, M.A.M. Quantification process of carbon emissions in the construction industry. Energy Build. 2023, 289, 113025. [Google Scholar] [CrossRef]

- Li, D.; Huang, G.; Zhang, G.; Wang, J. Driving factors of total carbon emissions from the construction industry in Jiangsu Province, China. J. Clean. Prod. 2020, 276, 123179. [Google Scholar] [CrossRef]

- Chen, C.; Bi, L. Study on spatio-temporal changes and driving factors of carbon emissions at the building operation stage—A case study of China. Build. Environ. 2022, 219, 109147. [Google Scholar] [CrossRef]

- Liu, C.; Gao, X.; Ma, W.; Chen, X. Research on regional differences and influencing factors of green technology innovation efficiency of China’s high-tech industry. J. Comput. Appl. Math. 2020, 369, 112597. [Google Scholar] [CrossRef]

- Peng, B.; Zheng, C.; Wei, G.; Elahi, E. The cultivation mechanism of green technology innovation in manufacturing industry: From the perspective of ecological niche. J. Clean. Prod. 2020, 252, 119711. [Google Scholar] [CrossRef]

- Lin, S.; Chen, Z.; He, Z. Rapid transportation and green technology innovation in cities—From the view of the industrial collaborative agglomeration. Appl. Sci. 2021, 11, 8110. [Google Scholar] [CrossRef]

- Zhang, R.; Tang, Y.; Zhang, Y.; Wang, Z. Collaborative relationship discovery in green building technology innovation: Evidence from patents in China’s construction industry. J. Clean. Prod. 2023, 391, 136041. [Google Scholar] [CrossRef]

- Sizirici, B.; Fseha, Y.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A review of carbon footprint reduction in construction industry, from design to operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef]

- Fenner, A.E.; Kibert, C.J.; Woo, J.; Morque, S.; Razkenari, M.; Hakim, H.; Lu, X. The carbon footprint of buildings: A review of methodologies and applications. Renew. Sustain. Energy Rev. 2018, 94, 1142–1152. [Google Scholar] [CrossRef]

- Zhang, J.; Ouyang, Y.; Ballesteros-Pérez, P.; Li, H.; Philbin, S.P.; Li, Z.; Skitmore, M. Understanding the impact of environmental regulations on green technology innovation efficiency in the construction industry. Sustain. Cities Soc. 2021, 65, 102647. [Google Scholar] [CrossRef]

- Li, C.; Qi, L. Can Government Environmental Attention Improve Corporate Carbon Emission Reduction Performance?—Evidence from China A-Share Listed Companies with High-Energy-Consumption. Sustainability 2024, 16, 4660. [Google Scholar] [CrossRef]

- Xu, T.; Yang, G.; Chen, T. The role of green finance and digital inclusive finance in promoting economic sustainable development: A perspective from new quality productivity. J. Environ. Manag. 2024, 370, 122892. [Google Scholar] [CrossRef]

- Liu, Y.; He, Z. Synergistic Industrial Agglomeration, New Quality Productive Forces and High-quality Development of the Manufacturing Industry. Int. Rev. Econ. Financ. 2024, 94, 103373. [Google Scholar] [CrossRef]

- Miao, C.; Fang, D.; Sun, L.; Luo, Q. Natural resources utilization efficiency under the influence of green technological innovation. Resour. Conserv. Recycl. 2017, 126, 153–161. [Google Scholar] [CrossRef]

- Yuan, S.; Pan, X. Inherent mechanism of digital technology application empowered corporate green innovation: Based on resource allocation perspective. J. Environ. Manag. 2023, 345, 118841. [Google Scholar] [CrossRef]

- Xue, L.; Zhang, Q.; Zhang, X.; Li, C. Can digital transformation promote green technology innovation? Sustainability 2022, 14, 7497. [Google Scholar] [CrossRef]

- Dou, Q.; Gao, X. How does the digital transformation of corporates affect green technology innovation? An empirical study from the perspective of asymmetric effects and structural breakpoints. J. Clean. Prod. 2023, 428, 139245. [Google Scholar] [CrossRef]

- Xu, D.; Abbas, S.; Rafique, K.; Ali, N. The race to net-zero emissions: Can green technological innovation and environmental regulation be the potential pathway to net-zero emissions? Technol. Soc. 2023, 75, 102364. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z.; Xu, J.; Zhang, Z. Green baton: How government interventions advance green technological innovation. Environ. Dev. Sustain. 2023, 25, 11121–11152. [Google Scholar] [CrossRef]

- Wang, B.; Chen, H.; Ao, Y.; Liao, F. Spatiotemporal differentiation and influencing factors of green technology innovation efficiency in the construction industry: A case study of chengdu–chongqing urban agglomeration. Buildings 2023, 13, 73. [Google Scholar] [CrossRef]

- Li, X.; Qin, Q.; Yang, Y. The impact of green innovation on carbon emissions: Evidence from the construction sector in China. Energies 2023, 16, 4529. [Google Scholar] [CrossRef]

- Wang, M.; Li, Y.; Li, J.; Wang, Z. Green process innovation, green product innovation and its economic performance improvement paths: A survey and structural model. J. Environ. Manag. 2021, 297, 113282. [Google Scholar] [CrossRef]

- Jiao, J.; Chen, C.; Bai, Y. Is green technology vertical spillovers more significant in mitigating carbon intensity? Evidence from Chinese industries. J. Clean. Prod. 2020, 257, 120354. [Google Scholar] [CrossRef]

- Chen, W.; Ma, Y.; Bai, C. The Impact of Carbon Emission Quota Allocation Regulations on the Investment of Low-Carbon Technology in Electric Power Industry Under Peak-Valley Price Policy. IEEE Trans. Eng. Manag. 2021, 71, 374–391. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A review of low-carbon technologies and projects for the global cement industry. J. Environ. Sci. 2024, 136, 682–697. [Google Scholar] [CrossRef]

- Yao, H.; Xu, P.; Wang, Y.; Chen, R. Exploring the low-carbon transition pathway of China’s construction industry under carbon-neutral target: A socio-technical system transition theory perspective. J. Environ. Manag. 2023, 327, 116879. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Gyamfi, S.; Olanipekun, A.O.; He, B.-J.; Yu, Y. Driving forces for green building technologies adoption in the construction industry: Ghanaian perspective. Build. Environ. 2017, 125, 206–215. [Google Scholar] [CrossRef]

- Agan, B.; Balcilar, M. On the determinants of green technology diffusion: An empirical analysis of economic, social, political, and environmental factors. Sustainability 2022, 14, 2008. [Google Scholar] [CrossRef]

- Hu, S.; Li, S.; Meng, X.; Peng, Y.; Tang, W. Study on regional differences of carbon emission efficiency: Evidence from Chinese construction industry. Energies 2023, 16, 6882. [Google Scholar] [CrossRef]

- Zhang, J.; Shan, Y.; Jiang, S.; Xin, B.; Miao, Y.; Zhang, Y. Study on the coordinated development degree of new quality productivity and manufacturing carbon emission efficiency in provincial regions of China. Environ. Dev. Sustain. 2024, 1–35. [Google Scholar] [CrossRef]

- Zhou, W.; Xu, L. On new quality productivity: Connotative characteristics and important focus. Reform 2023, 10, 1–13. [Google Scholar]

- Hao, X.; Liang, Y.; Yang, C.; Wu, H.; Hao, Y. Can Industrial Digitalization Promote Regional Green Technology Innovation? J. Innov. Knowl. 2024, 9, 100463. [Google Scholar] [CrossRef]

- Li, W.; Sun, W.; Li, G.; Cui, P.; Wu, W.; Jin, B. Temporal and spatial heterogeneity of carbon intensity in China’s construction industry. Resour. Conserv. Recycl. 2017, 126, 162–173. [Google Scholar] [CrossRef]

- Cui, X.; Zhao, T.; Wang, J. Allocation of carbon emission quotas in China’s provincial power sector based on entropy method and ZSG-DEA. J. Clean. Prod. 2021, 284, 124683. [Google Scholar] [CrossRef]

- Song, Q.; Zhou, N.; Liu, T.; Siehr, S.A.; Qi, Y. Investigation of a “coupling model” of coordination between low-carbon development and urbanization in China. Energy Policy 2018, 121, 346–354. [Google Scholar] [CrossRef]

- Sun, Y.; Cui, Y. Evaluating the coordinated development of economic, social and environmental benefits of urban public transportation infrastructure: Case study of four Chinese autonomous municipalities. Transp. Policy 2018, 66, 116–126. [Google Scholar] [CrossRef]

- Liu, X.; Nie, W. Study on the coupling coordination mechanism of green technology innovation, environmental regulation, and green finance. Environ. Sci. Pollut. Res. 2022, 29, 71796–71809. [Google Scholar] [CrossRef]

- Tao, C.-Q.; Yi, M.-Y.; Wang, C.-S. Coupling coordination analysis and Spatiotemporal heterogeneity between data elements and green development in China. Econ. Anal. Policy 2023, 77, 1–15. [Google Scholar] [CrossRef]

- Wang, F.; Zhuang, L.; Cheng, S.; Zhang, Y.; Cheng, S. Spatiotemporal variation and convergence analysis of China’s regional energy security. Renew. Sustain. Energy Rev. 2024, 189, 113923. [Google Scholar] [CrossRef]

- Sun, Y.; Hao, S.; Long, X. A study on the measurement and influencing factors of carbon emissions in China’s construction sector. Build. Environ. 2023, 229, 109912. [Google Scholar] [CrossRef]

- Wang, S.; Chen, F. Can New Quality Productivity Promote the Carbon Emission Performance—Empirical Evidence from China. Sustainability 2025, 17, 567. [Google Scholar] [CrossRef]

- Lu, X.; Lu, Z. How does green technology innovation affect urban carbon emissions? Evidence from Chinese cities. Energy Build. 2024, 325, 115025. [Google Scholar] [CrossRef]

- Shao, Y.; Chen, Z. Can government subsidies promote the green technology innovation transformation? Evidence from Chinese listed companies. Econ. Anal. Policy 2022, 74, 716–727. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, S. Evaluation of green technology innovation efficiency in a regional context: A dynamic network slacks-based measuring approach. Technol. Forecast. Soc. Change 2022, 182, 121836. [Google Scholar] [CrossRef]

- Chen, H.; Yi, J.; Chen, A.; Peng, D.; Yang, J. Green technology innovation and CO2 emission in China: Evidence from a spatial-temporal analysis and a nonlinear spatial durbin model. Energy Policy 2023, 172, 113338. [Google Scholar] [CrossRef]

- Si, R.; Wang, Y.; Cao, M.; Wen, H. Does green technology innovation promote green economic growth?–Examining regional heterogeneity between resource-based and non-resource-based cities. Int. Rev. Econ. Financ. 2024, 94, 103406. [Google Scholar] [CrossRef]

- Grashof, N.; Basilico, S. Divergent paths for green transition: Regional disparities in technology diversification. Reg. Stud. 2025, 59, 2363327. [Google Scholar] [CrossRef]

- Cai, A.; Zheng, S.; Cai, L.; Yang, H.; Comite, U. How does green technology innovation affect carbon emissions? A spatial econometric analysis of China’s provincial panel data. Front. Environ. Sci. 2021, 9, 813811. [Google Scholar] [CrossRef]

- Guo, L.; Tan, W.; Xu, Y.; Tang, Q. Curbing regional carbon emissions through green technology innovation: An empirical analysis in China. Environ. Dev. Sustain. 2024, 1–24. [Google Scholar] [CrossRef]

- Du, K.; Li, P.; Yan, Z. Do green technology innovations contribute to carbon dioxide emission reduction? Empirical evidence from patent data. Technol. Forecast. Soc. Change 2019, 146, 297–303. [Google Scholar] [CrossRef]

- Feng, N.; Yan, M.; Yan, M. Spatiotemporal Evolution and Influencing Factors of New-Quality Productivity. Sustainability 2024, 16, 10852. [Google Scholar] [CrossRef]

- Gao, X.; Li, S. A Dynamic Evolution and Spatiotemporal Convergence Analysis of the Coordinated Development Between New Quality Productive Forces and China’s Carbon Total Factor Productivity. Sustainability 2025, 17, 3137. [Google Scholar] [CrossRef]

- Zhang, X.; He, S.; Shen, J. The Impact of New Quality Productivity on Carbon Emission Intensity: Evidence from China. Front. Earth Sci. 2025, 13, 1546703. [Google Scholar]

- Li, J.; Noorliza, K.; Zhang, X. Enhancing environmental, social, and governance performance through new quality productivity and green innovation. Sustainability 2024, 16, 4843. [Google Scholar] [CrossRef]

| Coordination Type | D-Value Range | Coordination Level |

|---|---|---|

| Coordinated Development | [0.9, 1] | High-quality coordination |

| [0.8, 0.9) | Good coordination | |

| [0.7, 0.8) | Intermediate coordination | |

| Transitional Development | [0.6, 0.7) | Primary coordination |

| [0.5, 0.6) | Barely coordinated | |

| [0.4, 0.5) | On the verge of imbalance | |

| Imbalanced Decline | [0.3, 0.4) | Slight imbalance |

| [0.2, 0.3) | Moderate imbalance | |

| [0.1, 0.2) | Severe imbalance | |

| [0, 0.1) | Extreme imbalance |

| Variables | (1) | (2) | (3) | (4) | (5) | (6) |

|---|---|---|---|---|---|---|

| CEICI | CEICI | CEICI | CEICI | CEICI | NQP | |

| RGTI | −0.478 *** | −0.813 *** | −0.759 *** | 0.250 *** | ||

| (0.171) | (0.212) | (0.240) | (0.032) | |||

| NQP | −0.876 *** | −0.860 ** | −0.215 | |||

| (0.325) | (0.400) | (0.442) | ||||

| ES | 0.228 | 0.233 | 0.231 | 0.012 | ||

| (0.157) | (0.160) | (0.157) | (0.024) | |||

| DGI | −1.287 ** | −0.771 | −1.256 ** | 0.147 * | ||

| (0.566) | (0.561) | (0.571) | (0.086) | |||

| IS | 0.127 ** | 0.037 | 0.117 * | −0.048 *** | ||

| (0.060) | (0.059) | (0.063) | (0.009) | |||

| R&D | −9.151 | −12.425 ** | −9.281 | −0.607 | ||

| (5.695) | (5.737) | (5.711) | (0.861) | |||

| LO | −0.773 ** | −0.484 | −0.815 ** | −0.196 *** | ||

| (0.311) | (0.312) | (0.323) | (0.047) | |||

| LRE | −0.311 ** | −0.209 | −0.297 ** | 0.064 *** | ||

| (0.146) | (0.149) | (0.149) | (0.022) | |||

| Time FE | Yes | Yes | Yes | Yes | Yes | Yes |

| Id FE | Yes | Yes | Yes | Yes | Yes | Yes |

| N | 270 | 270 | 270 | 270 | 270 | 270 |

| Adj R2 | 0.785 | 0.784 | 0.834 | 0.794 | 0.801 | 0.950 |

| Year | Overall Variance G | Intra-Regional Variance | Inter-Regional Variance | Hypervariance Density |

|---|---|---|---|---|

| 2013 | 0.127 | 0.029 | 0.078 | 0.019 |

| 2014 | 0.113 | 0.026 | 0.071 | 0.016 |

| 2015 | 0.108 | 0.024 | 0.068 | 0.016 |

| 2016 | 0.105 | 0.023 | 0.069 | 0.014 |

| 2017 | 0.099 | 0.022 | 0.066 | 0.011 |

| 2018 | 0.095 | 0.020 | 0.065 | 0.009 |

| 2019 | 0.091 | 0.019 | 0.066 | 0.006 |

| 2020 | 0.093 | 0.018 | 0.068 | 0.007 |

| 2021 | 0.094 | 0.019 | 0.068 | 0.008 |

| Average | 0.103 | 0.022 | 0.069 | 0.012 |

| Year | Eastern Region | Central Region | Western Region | Northeastern Region |

|---|---|---|---|---|

| 2013 | 0.118 | 0.047 | 0.051 | 0.095 |

| 2014 | 0.115 | 0.037 | 0.046 | 0.073 |

| 2015 | 0.109 | 0.030 | 0.050 | 0.063 |

| 2016 | 0.104 | 0.049 | 0.028 | 0.061 |

| 2017 | 0.106 | 0.040 | 0.029 | 0.051 |

| 2018 | 0.102 | 0.038 | 0.031 | 0.042 |

| 2019 | 0.095 | 0.021 | 0.025 | 0.042 |

| 2020 | 0.092 | 0.028 | 0.024 | 0.040 |

| 2021 | 0.093 | 0.038 | 0.023 | 0.040 |

| Average | 0.104 | 0.036 | 0.034 | 0.056 |

| Year | E–C | E–W | E–EN | C–W | C–EN | W–EN |

|---|---|---|---|---|---|---|

| 2013 | 0.141 | 0.153 | 0.183 | 0.058 | 0.089 | 0.083 |

| 2014 | 0.138 | 0.142 | 0.165 | 0.048 | 0.068 | 0.066 |

| 2015 | 0.136 | 0.141 | 0.159 | 0.045 | 0.060 | 0.063 |

| 2016 | 0.134 | 0.139 | 0.157 | 0.042 | 0.064 | 0.054 |

| 2017 | 0.125 | 0.139 | 0.149 | 0.043 | 0.054 | 0.045 |

| 2018 | 0.124 | 0.139 | 0.145 | 0.043 | 0.047 | 0.039 |

| 2019 | 0.120 | 0.134 | 0.146 | 0.030 | 0.044 | 0.038 |

| 2020 | 0.127 | 0.142 | 0.148 | 0.033 | 0.042 | 0.037 |

| 2021 | 0.130 | 0.136 | 0.149 | 0.035 | 0.045 | 0.037 |

| Average | 0.131 | 0.141 | 0.156 | 0.042 | 0.057 | 0.051 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, Z.; Xie, Q. Synergistic Evolution and Spatial-Temporal Differences in Green Technological Innovation and Carbon Emission Reduction in the Construction Industry from the Perspective of New Productive Forces. Appl. Sci. 2025, 15, 4720. https://doi.org/10.3390/app15094720

Niu Z, Xie Q. Synergistic Evolution and Spatial-Temporal Differences in Green Technological Innovation and Carbon Emission Reduction in the Construction Industry from the Perspective of New Productive Forces. Applied Sciences. 2025; 15(9):4720. https://doi.org/10.3390/app15094720

Chicago/Turabian StyleNiu, Zihao, and Qingjie Xie. 2025. "Synergistic Evolution and Spatial-Temporal Differences in Green Technological Innovation and Carbon Emission Reduction in the Construction Industry from the Perspective of New Productive Forces" Applied Sciences 15, no. 9: 4720. https://doi.org/10.3390/app15094720

APA StyleNiu, Z., & Xie, Q. (2025). Synergistic Evolution and Spatial-Temporal Differences in Green Technological Innovation and Carbon Emission Reduction in the Construction Industry from the Perspective of New Productive Forces. Applied Sciences, 15(9), 4720. https://doi.org/10.3390/app15094720