Research on Performance of a Dense Graded Ultra-Thin Wearing Course Mixture

Abstract

:1. Introduction

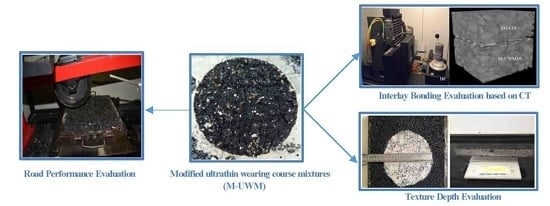

2. Experimental

2.1. Mix Design for Different Asphalt Mixtures

2.2. Test Procedures

2.2.1. Road Performance Evaluation

2.2.2. Texture Depth Evaluation

- After the rectangular specimen with dimensions of 300 × 300 × 50 mm was prepared for the wheel tracking test, its original texture depth (TD) named K0 was measured, as shown in Figure 2a.

- After the silica sands on the specimen surface were washed away, the specimen was submitted to the wheel tracking test for 180 minutes.

- After the wheel tracking test, the rutting area right underneath the wheel loading positions was cut from the tested specimen and then weighed to get its mass m1, as shown in Figure 2b.

- The texture depth K1 for the cut strip specimen, which represents the rutting area under the wheel loading positions after the wheel tracking test, was determined by Equation (1):where s is the top surface area of the cut strip specimen, and is the density of the silica sands.

- By comparing K0 and K1, the degradation degree of the surface texture depth caused by wheel loading can be obtained.

2.2.3. Interlay Bonding Evaluation

3. Result and Discussions

3.1. Road Performance Evaluation

3.2. Texture Depth Evaluation

3.3. Interlay Bonding Evaluation

4. Conclusions

- A dense-graded ultra-thin wearing course mixture with multi-chain polyolefin modifier and SBS modified asphalt was prepared in this paper. It is proved that the designed asphalt mixture has satisfied high-temperature rutting resistance, low-temperature cracking resistance and moisture resistance to bear the traffic loading and environment effects.

- The test results from combined tests of the wheel tracking test and the texture depth test proved that the designed wearing course mixture shows satisfied skidding resistance and wearing resistance. Field texture depth test results confirmed that the designed wearing course mixture is promising to keep long-term skidding resistance during traffic loading.

- Laboratory and field tests based on the test road indicated that the wearing course paved with the designed ultra-thin wearing course mixture can provide satisfied water-proof and interlayer bonding effects, which are helpful to improve the pavement durability.

- Future work will focus on the fatigue resistance of the ultra-thin wearing course mixture.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Luo, Y.L. Brief introduction to application of maintenance technology on ultra-thin wearing course for asphalt pavement of expressway. Guangdong Highway Commun. 2011. [Google Scholar] [CrossRef]

- Pei, P.; Peng, G.J. Application of ultra-thin wear layer technology in expressway maintenance. W. China Commun. Sci. Technol. 2015, 12, 23–26. [Google Scholar] [CrossRef]

- Qiao, X.L. Application of novachip ultra-thin wearing layer in highway maintenance. Transport. Standard. 2013, 18. Available online: http://xueshu.baidu.com/s?wd=paperuri%3A%2832b4e61b2b25b0508cfc06e363ef4551%29&filter=sc_long_sign&tn=SE_xueshusource_2kduw22v&sc_vurl=http%3A%2F%2Fen.cnki.com.cn%2FArticle_en%2FCJFDTOTAL-JTBH201318005.htm&ie=utf-8&sc_us=14205075173698836325 (accessed on 6 August 2017).

- Yang, Y.H.; Shen, Y.; Gao, X.X. Analysis interlayer shear stress of ultra-thin wearing course considering temperature and different interlayer contact conditions. Appl. Mech. Mater. 2014, 505–506, 102–105. [Google Scholar] [CrossRef]

- Tan, Y.Q.; Yao, L.; Wang, H.P.; Bian, X.; Yu-Xiang, Q.I. Performance evaluation indicator of ultra-thin wearing course asphalt mixture. J. Harbin Inst. Tech. 2012, 44, 73–77. [Google Scholar]

- Zhi-Tao, H.U.; Niu, X.X. Application of novachip ultra-thin wearing layer of asphalt pavement on the preventive maintenance engineering of expressways. Guangdong Highway Commun. 2009, 3. Available online: http://xueshu.baidu.com/s?wd=paperuri%3A%2817fe1a1403e497837a8ed55c1959682d%29&filter=sc_long_sign&tn=SE_xueshusource_2kduw22v&sc_vurl=http%3A%2F%2Fen.cnki.com.cn%2FArticle_en%2FCJFDTOTAL-GDGT200903003.htm&ie=utf-8&sc_us=6153204051113523490 (accessed on 6 August 2017).

- Chan, S.; Lane, B.; Kazmierowski, T. Pavement preservation—a solution for sustainability. Transport. Res. Rec. 2011, 47, 36–42. [Google Scholar] [CrossRef]

- Kandhal, P.S.; Lockett, L. Construction and performance of ultrathin asphalt friction course; NCAT Report No. 97-5; National Center for Asphalt Technology of Auburn University: Auburn, AL, USA, September 1997. [Google Scholar]

- Pretorius, F.J.; Wise, J.C.; Henderson, M. Development of application differentiated ultra-thin asphalt friction courses for southern african application. In Proceedings of the 8th Conference on Asphalt Pavements for Southern Africa, Sun City, South Africa, 12–16 September 2004. [Google Scholar]

- Zeng, M.L.; Peng, L.Q.; Chao-Fan, W.U.; Tan, B.Y. Experimental study of the performance of ultrathin asphalt friction course. J. Wuhan Univ. Technol. 2012, 4. U414. [Google Scholar]

- Yang, X.; Ling, J.; Chaofan, W.U.; Zeng, Z. Evaluation of performance of novachip ultrathin asphalt friction course. Highway Eng. 2013, 1. Available online: http://en.cnki.com.cn/Article_en/CJFDTOTAL-ZNGL201301004.htm (accessed on 6 August 2017).

- Ministry of Transport of the People′s Republic of China. Specifications for design of highway asphalt; China Communications Press: Beijing, China, 2006.

- Xiao, F.; Amirkhanian, S.N. Effects of liquid antistrip additives on rheology and moisture susceptibility of water bearing warm mixtures. Constr. Build. Mater. 2010, 24, 1649–1655. [Google Scholar] [CrossRef]

- Wu, S. Assessment of bonding behaviours between ultrathin surface layer and asphalt mixture layer using modified pull test. J. Adhes. Sci. Technol. 2015, 29, 1508–1521. [Google Scholar]

- Rahaman, F.; Musty, H.Y.; Hossain, M. Evaluation of recycled asphalt pavement materials from ultra-thin bonded bituminous surface. In Proceedings of the GeoCongress 2012, Oakland, CA, USA, 25–29 March 2012. [Google Scholar] [CrossRef]

- Yang, Y.H.; Liu, Z.; Gao, J.X.; Zhu, G.S. Bonding characteristics analysis of ultra-thin overlay of asphalt pavement layer. Appl. Mech. Mater. 2012, 178–181, 1245–1249. [Google Scholar] [CrossRef]

- Weidong, C.; Jianrong, S.; Hengchun, H. Introduction of Technology of Ultra-thin Asphalt Friction Course. Petrol. Asphalt 2005, 19, 56–59. [Google Scholar]

- Pasetto, M.; Baldo, N. Influence of the aggregate skeleton design method on the permanent deformation resistance of stone mastic asphalt. Mater. Res. Innovations 2014, 18, S3-96–S3-101. [Google Scholar] [CrossRef]

- Ministry of Transport of the People′s Republic of China. Standard test methods of bitumen and bituminous mixtures for highway engineering; China Communications Press: Beijing, China, 2011.

- Ma, T.; Geng, L.; Ding, X.; Zhang, D.; Huang, X. Experimental study of deicing asphalt mixture with anti-icing additives. Constr. Build. Mater. 2016, 127, 653–662. [Google Scholar] [CrossRef]

- Ministry of Transport of the People′s Republic of China. Standard specification for construction of highway asphalt pavements; China Communications Press: Beijing, China, 2004.

- Ma, T.; Wang, H.; He, L.; Zhao, Y.; Huang, X.; Chen, J. Property characterization of asphalt binders and mixtures modified by different crumb rubbers. J. Mater. Civil Eng. 2017, 29. [Google Scholar] [CrossRef]

| Mixture Type | Asphalt Content (%) | VV (%) | VMA (%) | VFA (%) | Marshall Stability (kN) | Flow Value (0.1 mm) |

|---|---|---|---|---|---|---|

| SMA13 | 6.0 | 4.3 | 18.28 | 76.7 | 8.9 | 26.8 |

| AC13 | 5.1 | 4.8 | 19.90 | 75.9 | 8.52 | 27.4 |

| SMA10 | 6.3 | 4.2 | 18.53 | 77.5 | 10.54 | 28.9 |

| UWM10 | 5.2 | 5.1 | 16.0 | 68.0 | 9.83 | 26 |

| M-UWM10 | 5.2 | 4.7 | 15.6 | 70.1 | 12.00 | 24 |

| Type | x-axis (mm) | y-axis (mm) | z-axis (mm) | 3D-xy-Pixel Size, 3D-z-Pixel Size (mm) |

|---|---|---|---|---|

| Specification | 200 | 420 | 630 | 0.113 |

| Performance Index | Dynamic Stability (cycles/mm) | Failure Strain (µε) | Marshall Stability Ratio (%) | Tensile Strength Ratio (%) |

|---|---|---|---|---|

| Requirements | ≥3000 | ≥2500 | ≥85 | ≥80 |

| Test method | T0719-2011 | T0715-2011 | T0709-2011 | T0729-2000 |

| Type of Wearing Course Mixtures | Original Texture Depth (mm) | Texture Depth after One Year (mm) | Reduced Ratio (%) |

|---|---|---|---|

| M-UWM10 | 0.85 | 0.78 | 8.2 |

| SMA10 | 0.92 | 0.8 | 13.0 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, L.; Ma, T.; Zhang, J.; Huang, X.; Hu, P. Research on Performance of a Dense Graded Ultra-Thin Wearing Course Mixture. Appl. Sci. 2017, 7, 800. https://doi.org/10.3390/app7080800

Geng L, Ma T, Zhang J, Huang X, Hu P. Research on Performance of a Dense Graded Ultra-Thin Wearing Course Mixture. Applied Sciences. 2017; 7(8):800. https://doi.org/10.3390/app7080800

Chicago/Turabian StyleGeng, Lei, Tao Ma, Junhui Zhang, Xiaoming Huang, and Pengsen Hu. 2017. "Research on Performance of a Dense Graded Ultra-Thin Wearing Course Mixture" Applied Sciences 7, no. 8: 800. https://doi.org/10.3390/app7080800

APA StyleGeng, L., Ma, T., Zhang, J., Huang, X., & Hu, P. (2017). Research on Performance of a Dense Graded Ultra-Thin Wearing Course Mixture. Applied Sciences, 7(8), 800. https://doi.org/10.3390/app7080800