Effect of Amphiphilic Polymer/Nano-Silica Composite on Shale Stability for Water-Based Muds

Abstract

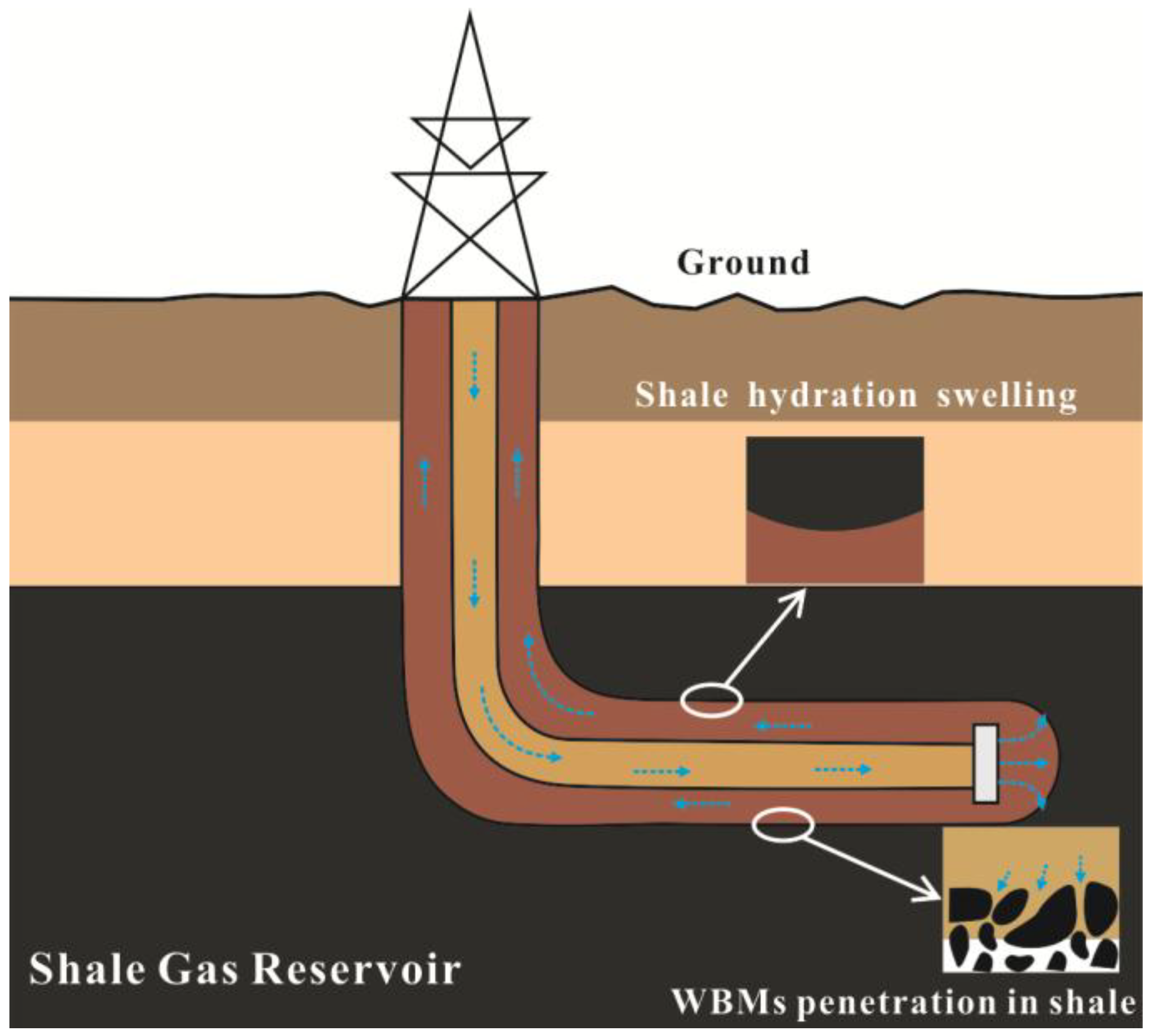

:1. Introduction

2. Materials and Methods

2.1. Materials

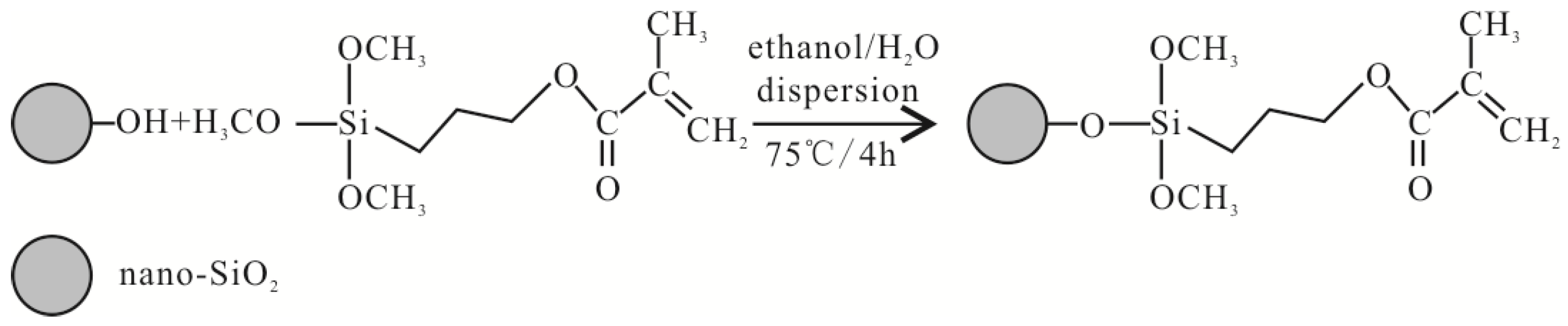

2.2. Preparation of SMA/SiO2

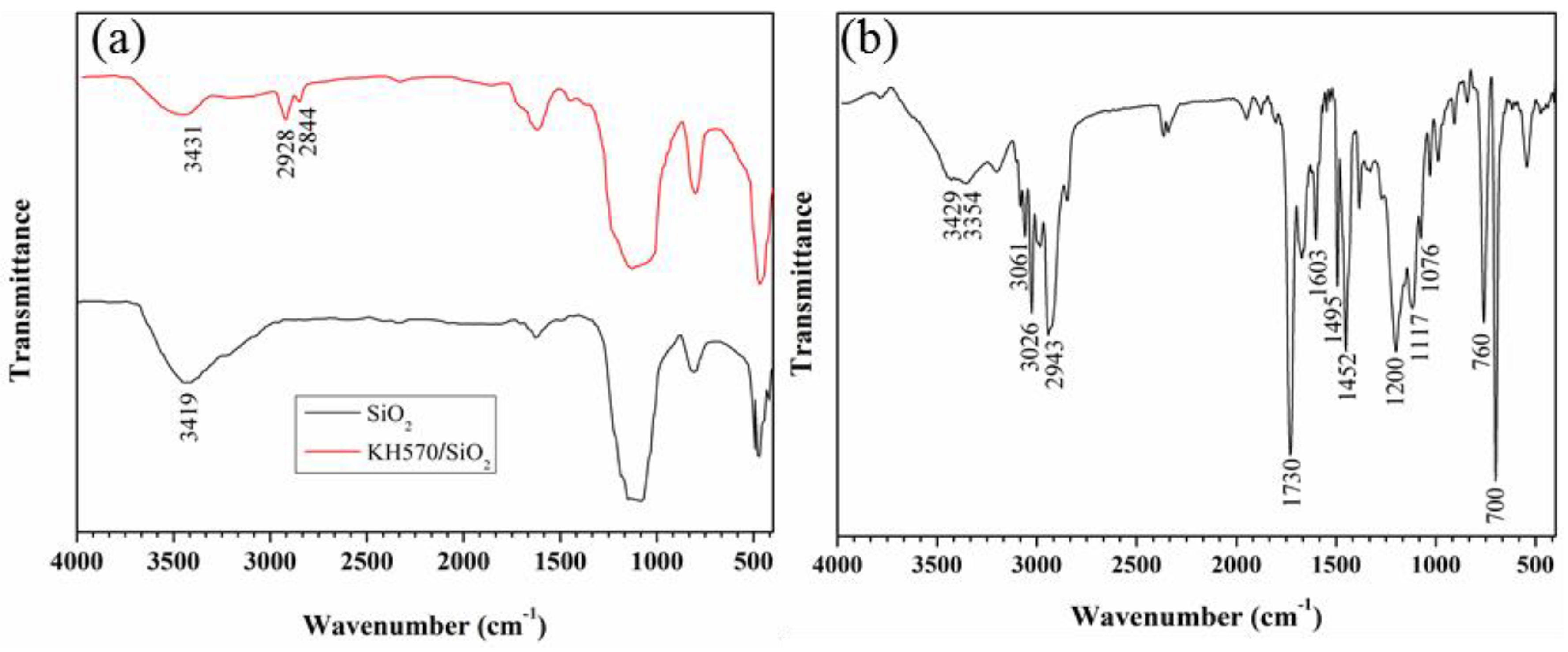

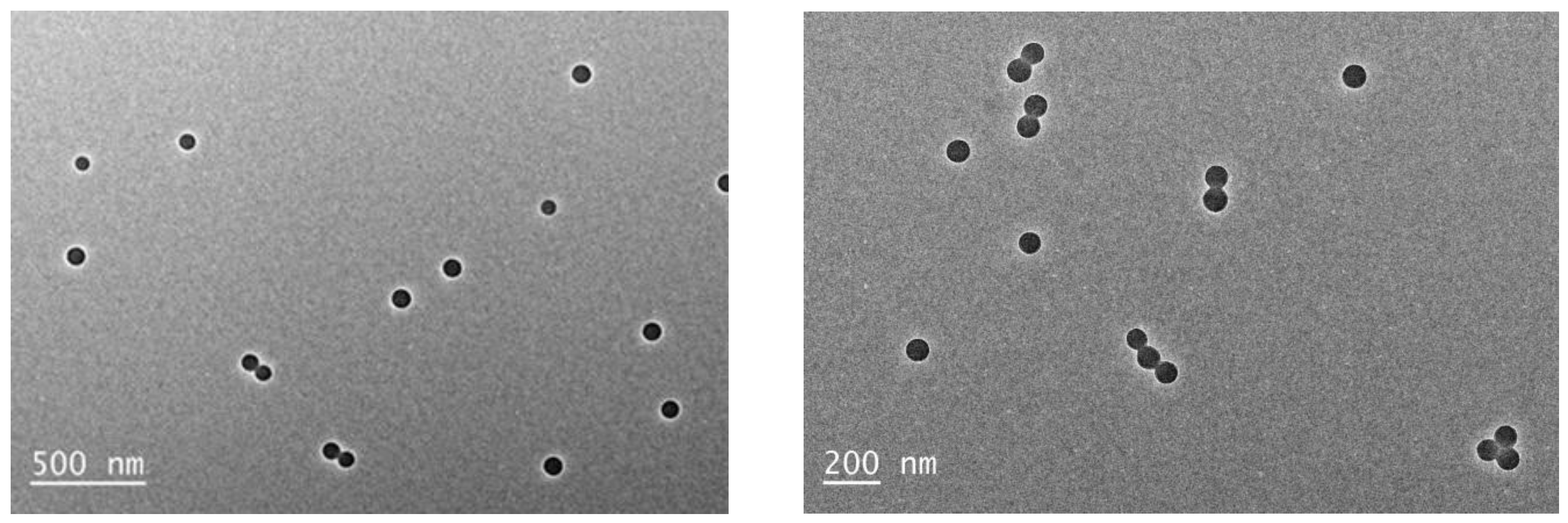

2.3. Characterization of SMA/SiO2

2.4. Pressure Transmission Test

2.5. Pore Structure Characterization of Shale

2.6. Rolling Dispersion Experiment

2.7. Contact Angle Test

2.8. Compatible Test

3. Results and Discussion

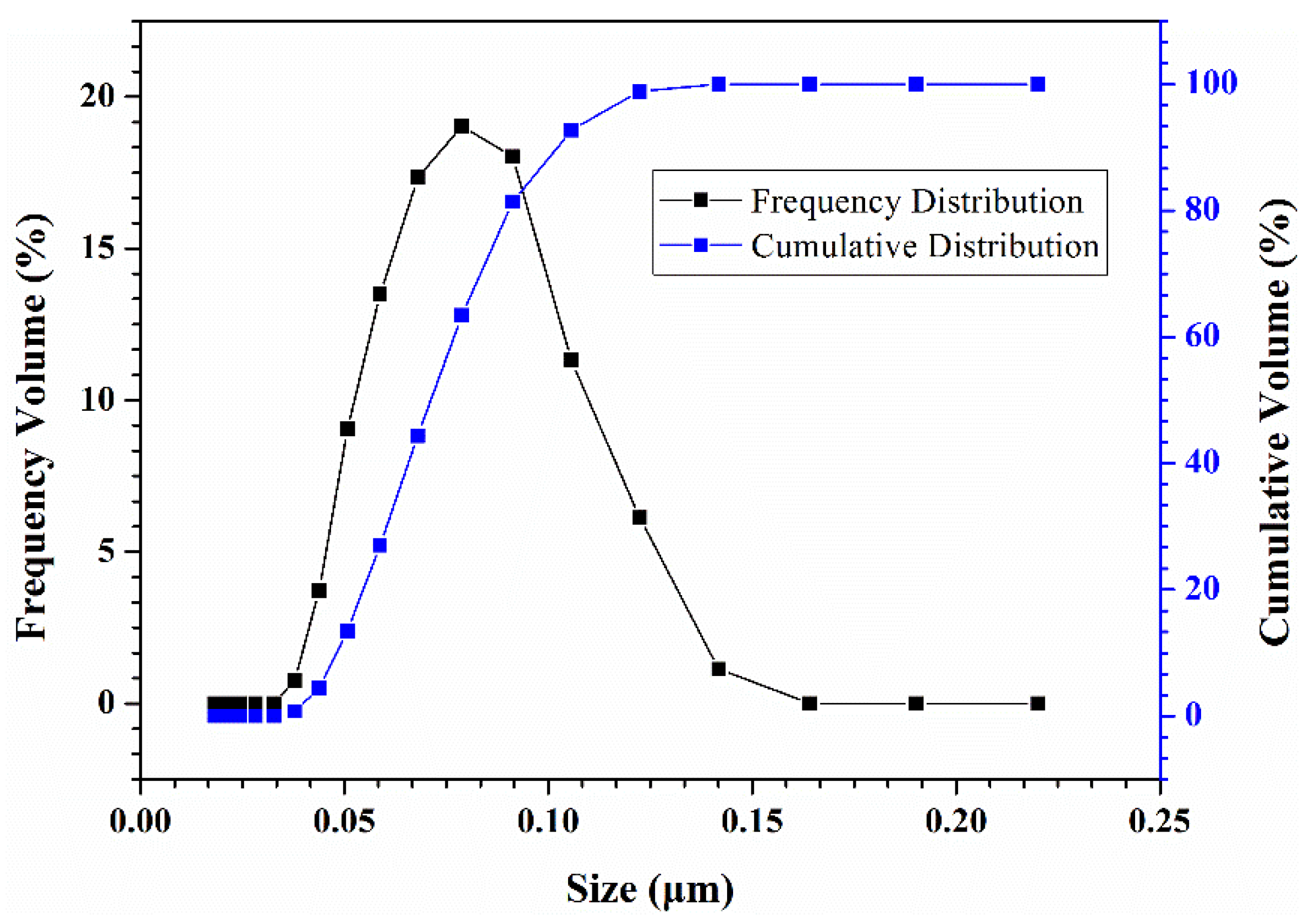

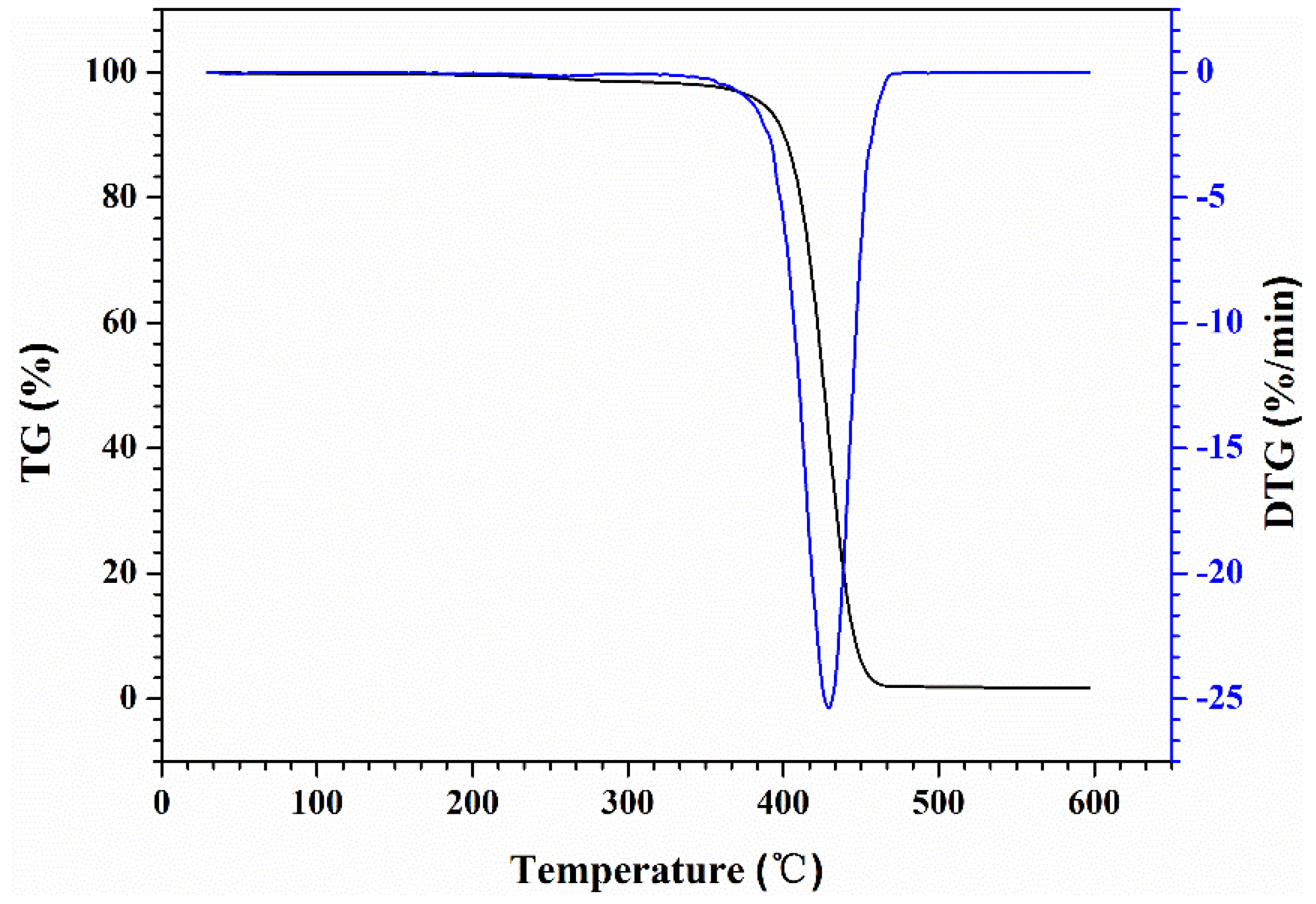

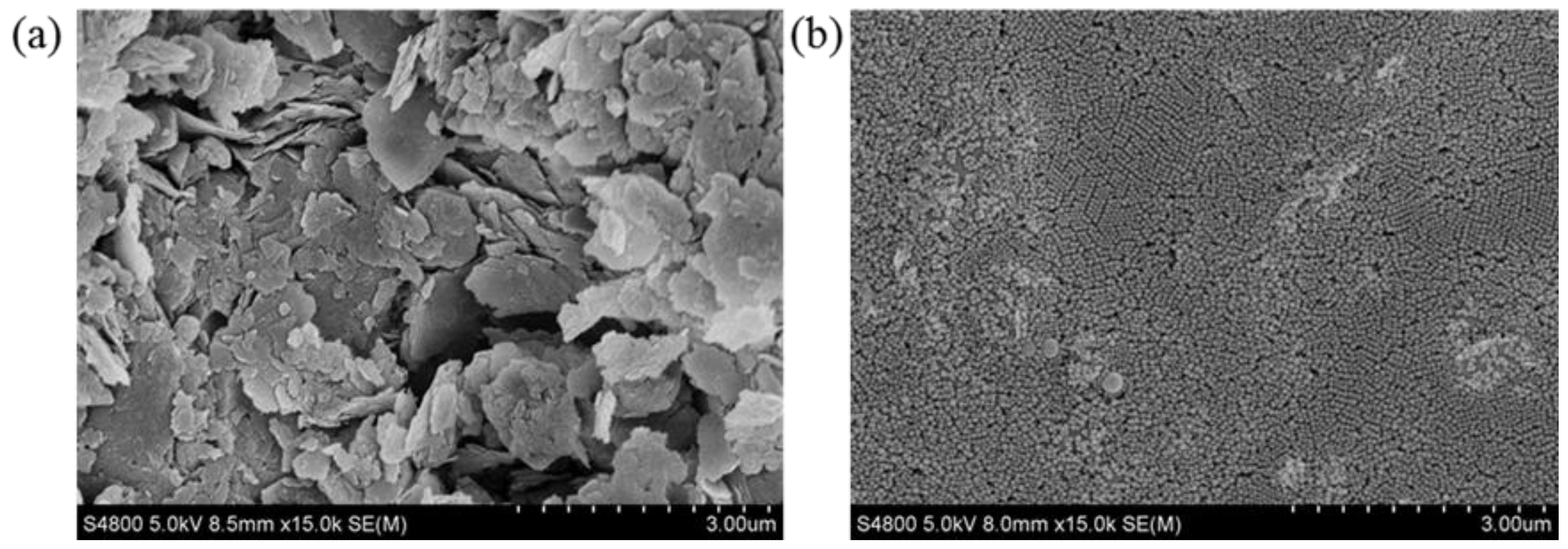

3.1. Characterization of the SMA/SiO2

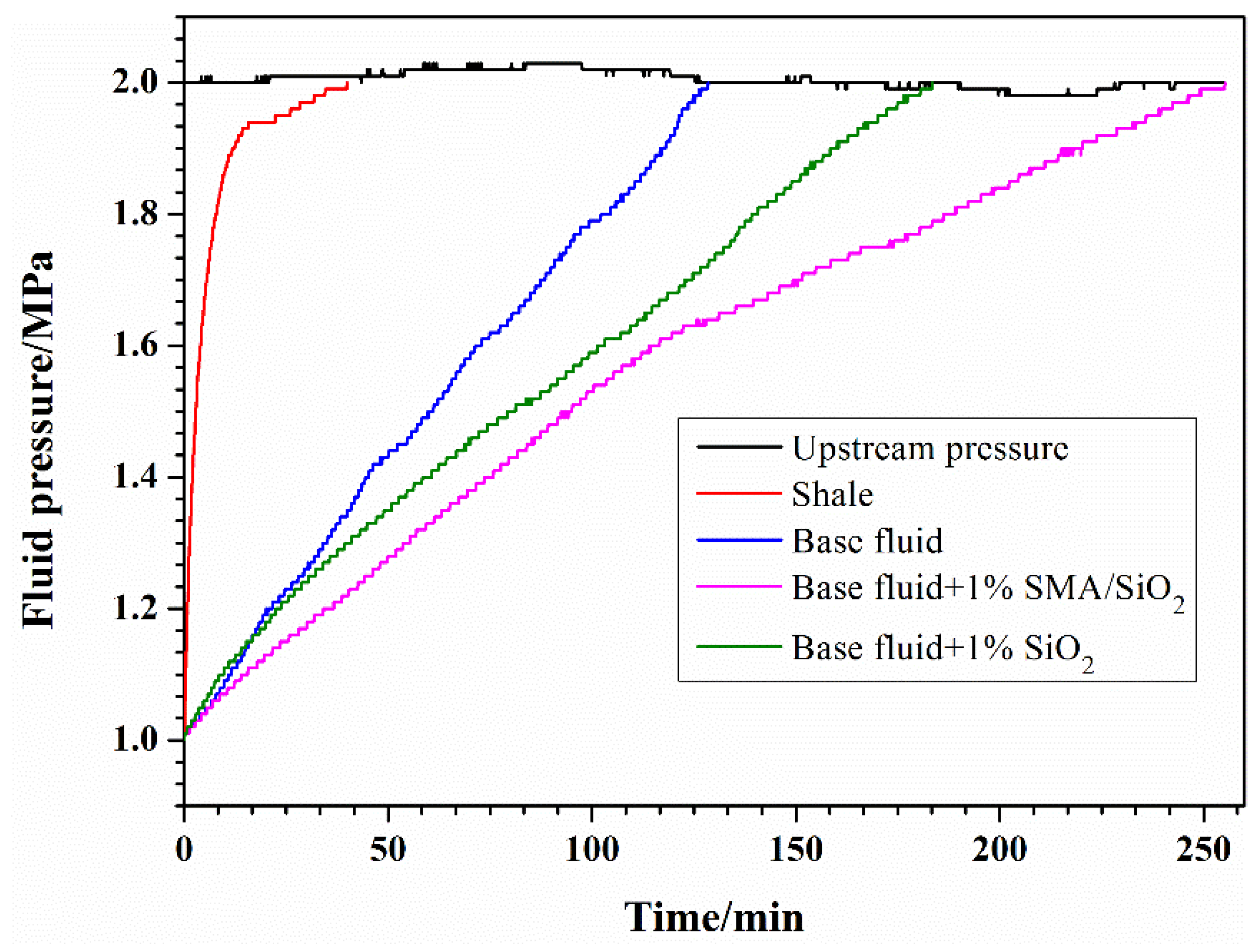

3.2. Pressure Transmission Test

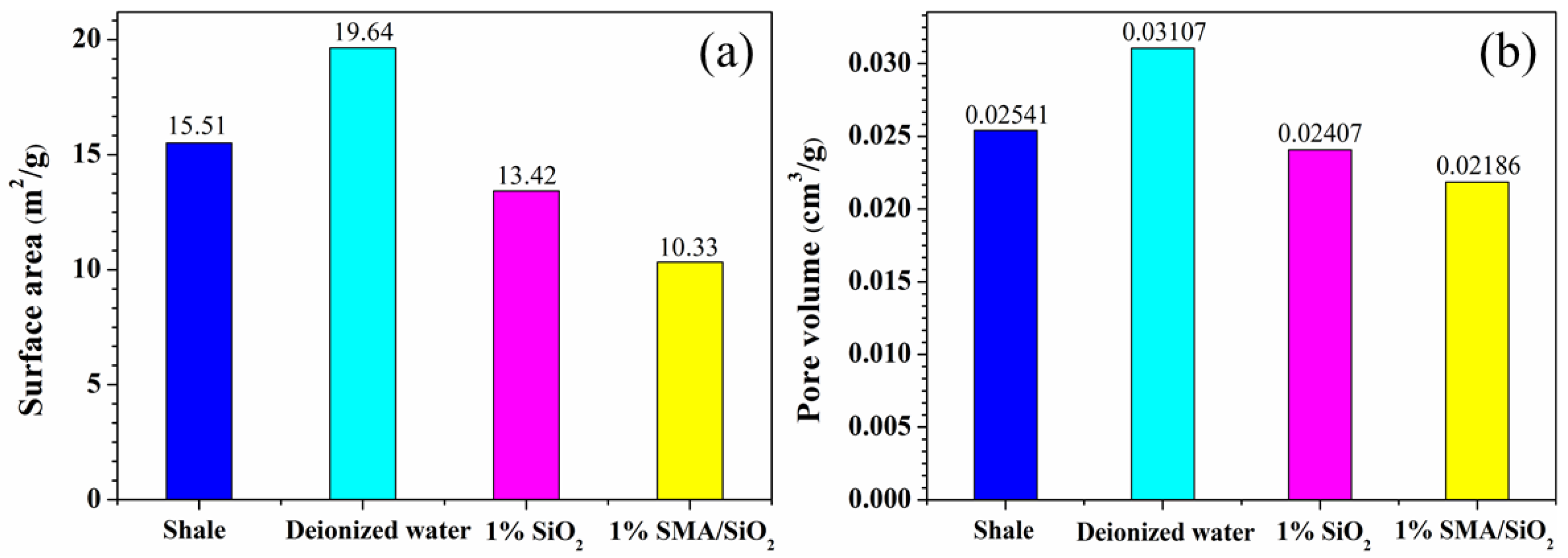

3.3. Pore Structure Characterization of Shale

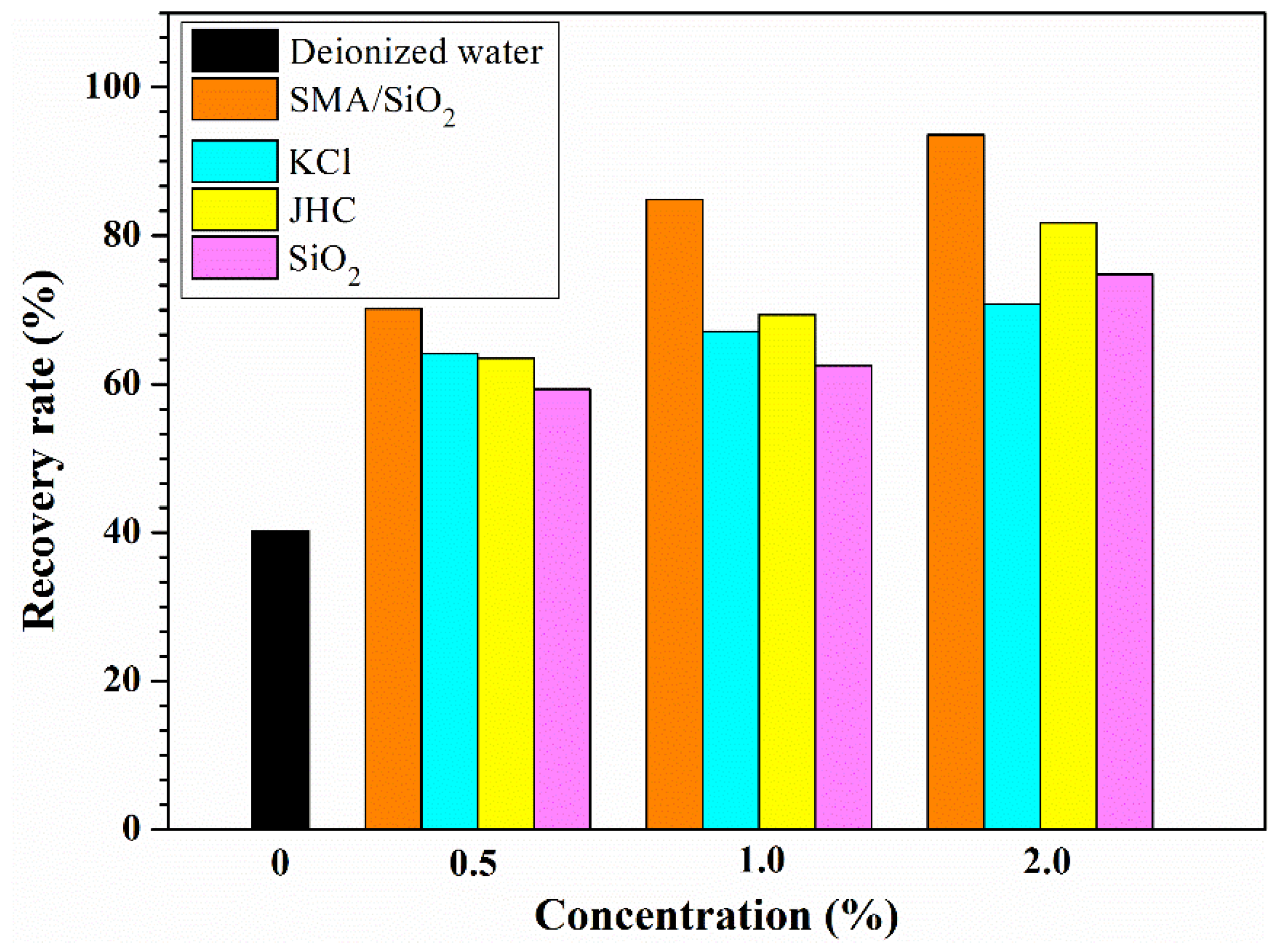

3.4. Rolling Dispersion Experiment

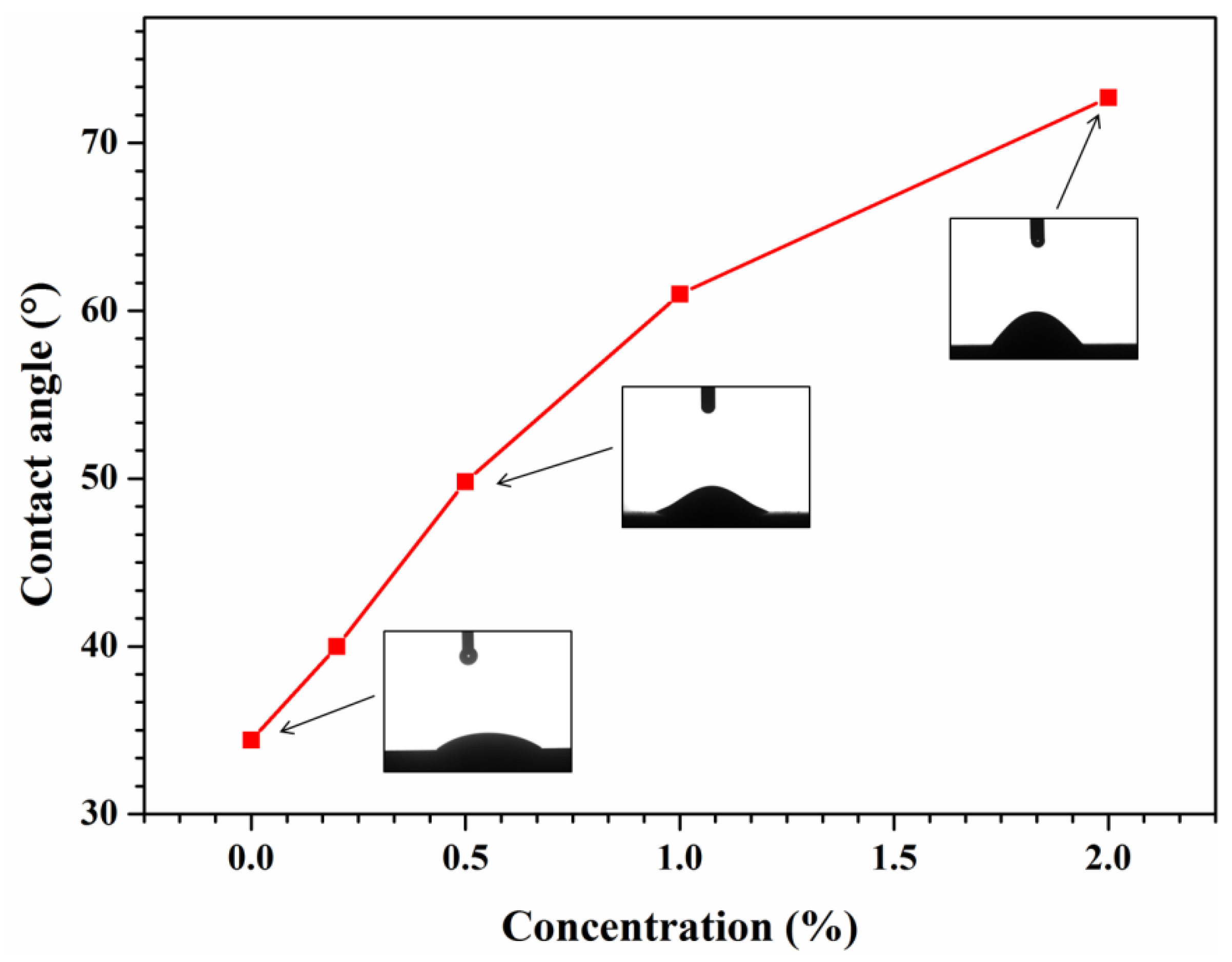

3.5. Contact Angle Test Results

3.6. Probable Shale Stabilization Mechanism

3.7. Compatible Test

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| WBMs | water-based muds |

| St | styrene |

| MMA | methyl methacrylate |

| AM | acrylamide |

| SMA | poly(St-MMA-AM) |

| KH570 | 3-methacryloxypropyltrimethoxysilane |

| SDS | sodium dodecyl sulfate |

| OP-10 | octylphenol polyoxyethylene ether |

| SMA/SiO2 | poly(St-MMA-AM)/nano-SiO2 composite |

| JHC | polymeric alcohol |

| FT-IR | Fourier transform infrared spectra |

| NMR | nuclear magnetic resonance |

| PSD | particle size distribution |

| TEM | transmission electron microscope |

| SEM | scanning electron microscopy |

| TGA | thermogravimetric analysis |

| AV | apparent Viscosity |

| PV | plastic viscosity |

| YP | yield Point |

| API | American Petroleum Institute |

| FLAPI | fluid loss |

| K | shale permeability |

| μ | viscosity of fluids |

| β | static compression ratio of fluids |

| V | enclosed volume |

| L | length of shale core |

| A | cross-sectional area of shale core |

| t | experimental time |

| Pm | upstream pressure |

| Po | initial downstream pressure |

| P(L, t) | realtime downstream pressure |

References

- Razali, S.Z.; Yunus, R.; Rashid, S.A.; Lim, H.N.; Jan, B.M. Review of biodegradable synthetic-based drilling fluid: progression, performance and future prospect. Renew. Sustain. Energy Rev. 2018, 90, 171–186. [Google Scholar] [CrossRef]

- Zhao, X.; Qiu, Z.; Huang, W.; Wang, M. Mechanism and method for controlling low-temperature rheology of water-based drilling fluids in deepwater drilling. J. Pet. Sci. Eng. 2017, 154, 405–416. [Google Scholar] [CrossRef]

- Xu, J.; Qiu, Z.; Zhao, X.; Mou, T.; Zhong, H.; Huang, W. A polymer microsphere emulsion as a high-performance shale stabilizer for water-based drilling fluids. RSC Adv. 2018, 8, 20852–20861. [Google Scholar] [CrossRef]

- Xie, B.; Liu, X. Thermo-thickening behavior of LCST-based copolymer viscosifier for water-based drilling fluids. J. Pet. Sci. Eng. 2017, 154, 244–251. [Google Scholar] [CrossRef]

- Song, K.; Wu, Q.; Li, M.; Ren, S.; Dong, L.; Zhang, X.; Kojima, Y. Water-based bentonite drilling fluids modified by novel biopolymer for minimizing fluid loss and formation damage. Colloids Surf. A 2016, 507, 58–66. [Google Scholar] [CrossRef]

- Wang, L.L.; Zhang, G.Q.; Hallais, S.; Tanguy, A.; Yang, D.S. Swelling of shales: A multiscale experimental investigation. Energy Fuels 2017, 31, 10442–10451. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Zubair, H.A.; Chhabra, A.; Ullah, A. Liquid intake of organic shales. Energy Fuels 2012, 26, 5750–5758. [Google Scholar] [CrossRef]

- Chamkalani, A.; Zendehboudi, S.; Amani, M.; Chamkalani, R.; James, L.; Dusseault, M. Pattern recognition insight into drilling optimization of shaly formations. J. Pet. Sci. Eng. 2017, 156, 322–339. [Google Scholar] [CrossRef]

- Zhao, H.; Firoozabadi, A. Sorption Hysteresis of Light Hydrocarbons and Carbon Dioxide in Shale and Kerogen. Sci. Rep. 2017, 7, 16209. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Kou, Z.; Wang, H.; Zhao, Y.; Dejam, M.; Guo, J.; Du, J. Performance analysis for a model of a multi-wing hydraulically fractured vertical well in a coalbed methane gas reservoir. J. Pet. Sci. Eng. 2018, 166, 104–120. [Google Scholar] [CrossRef]

- Jin, Z.; Firoozabadi, A. Phase Behavior and Flow in Shale Nanopores from Molecular Simulations. Fluid Phase Equilib. 2016, 430, 156–168. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Semi-analytical solution for pressure transient analysis of a hydraulically fractured vertical well in a bounded dual-porosity reservoir. J. Hydrol. 2018, 565, 289–301. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M. Microstructural and geomechanical analysis of Bakken shale at nanoscale. J. Pet. Sci. Eng. 2017, 153, 133–144. [Google Scholar] [CrossRef]

- Ma, F.; Pu, X.; Wang, B.; Li, J.; Cao, C. Preparation and evaluation of polyampholyte inhibitor DAM. RSC Adv. 2017, 7, 49320–49328. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Sheng, J.J.; Shen, Z. Effect of hydration on fractures and permeabilities in Mancos, Eagleford, Barnette and Marcellus shale cores under compressive stress conditions. J. Pet. Sci. Eng. 2017, 156, 917–926. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, J.; Wu, K.; Xu, B.; Zhang, T.; Chang, Y.; Li, X. Transport capacity of gas confined in nanoporous ultra-tight gas reservoirs with real gas effect and water storage mechanisms coupling. Int. J. Heat Mass Transf. 2018, 126, 1007–1018. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Pre-Darcy flow in porous media. Water Resour. Res. 2017, 53, 8187–8210. [Google Scholar] [CrossRef]

- An, Y.; Jiang, G.; Qi, Y.; Huang, X.; He, S. High-performance shale plugging agent based on chemically modified grapheme. J. Nat. Gas Sci. Eng. 2016, 32, 347–355. [Google Scholar]

- Xu, J.; Qiu, Z.; Huang, W.; Zhao, X. Preparation and performance properties of polymer latex SDNL in water-based drilling fluids for drilling troublesome shale formations. J. Nat. Gas Sci. Eng. 2017, 37, 462–470. [Google Scholar] [CrossRef]

- Steiger, R.P.; Leung, P.K. Quantitative determination of the mechanical properties of shales. SPE Drill. Complet. 1992, 7, 181–185. [Google Scholar] [CrossRef]

- Hassani, S.S.; Amrollahi, A.; Rashidi, A.; Soleymani, M.; Rayatdoost, S. The effect of nanoparticles on the heat transfer properties of drilling fluids. J. Pet. Sci. Eng. 2016, 146, 183–190. [Google Scholar] [CrossRef]

- Lau, H.C.; Yu, M.; Nguyen, Q.P. Nanotechnology for oilfield applications: Challenges and impact. J. Pet. Sci. Eng. 2017, 157, 1160–1169. [Google Scholar] [CrossRef]

- Li, Y.; Dai, C.; Zhou, H.; Wang, X.; Lv, W.; Wu, Y. A novel nanofluid based on fluorescent carbon nanoparticles for enhanced oil recovery. Ind. Eng. Chem. Res. 2017, 56, 12464–12470. [Google Scholar] [CrossRef]

- Zoveidavianpoor, M.; Samsuri, A. The use of nano-sized tapioca starch as a natural water-soluble polymer for filtration control in water-based drilling muds. J. Nat. Gas Sci. Eng. 2016, 34, 832–840. [Google Scholar] [CrossRef]

- William, J.K.; Ponmani, M.S.; Samuel, R.; Nagarajan, R.; Sangwai, J.S. Effect of CuO and ZnO nanofluids in xanthan gum on thermal, electrical and high pressure rheology of water-based drilling fluids. J. Pet. Sci. Eng. 2014, 117, 15–27. [Google Scholar] [CrossRef]

- An, Y.; Jiang, G.; Qi, Y.; Ge, Q.; Zhang, L.; Ren, Y. Synthesis of nano-plugging agent based on AM/AMPS/NVP terpolymer. J. Pet. Sci. Eng. 2015, 135, 505–514. [Google Scholar] [CrossRef]

- Cai, J.; Chenevert, M.E.; Sharma, M.M.; Friedheim, J.E. Decreasing water invasion into atoka shale using nonmodified silica nanoparticles. SPE Drill. Complet. 2012, 27, 103–112. [Google Scholar] [CrossRef]

- Jain, R.; Mahto, V.; Sharma, V.P. Evaluation of polyacrylamide-grafted-polyethylene glycol/silica nanocomposite as potential additive in water based drilling mud for reactive shale formation. J. Nat. Gas Sci. Eng. 2015, 26, 526–537. [Google Scholar] [CrossRef]

- Kosynkin, D.V.; Ceriotti, G.; Wilson, K.C.; Lomeda, J.R.; Scorsone, J.T.; Patel, A.D. Graphene oxide as a high-performance fluid-loss-control additive in water-based drilling fluids. ACS Appl. Mater. Interfaces 2012, 4, 222–227. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Qiu, Z.; Zhao, X.; Zhang, Y.; Li, G.; Huang, W. Application of nano-polymer emulsion for inhibiting shale self-imbibition in water-based drilling fluids. J. Surfactants Deterg. 2018, 21, 155–164. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, Z.; Huang, W. Novel latex particles and aluminum complexes as potential shale stabilizers in water-based drilling fluids. J. Pet. Sci. Eng. 2015, 135, 433–441. [Google Scholar] [CrossRef]

- Seright, R.S. How Much Polymer Should Be Injected During a Polymer Flood? Review of Previous and Current Practices. Soc. Pet. Eng. J. 2018, 22, 1–18. [Google Scholar]

- Amirian, E.; Dejam, M.; Chen, Z. Performance forecasting for polymer flooding in heavy oil reservoirs. Fuel 2018, 216, 83–100. [Google Scholar] [CrossRef]

- Saboorian-Jooybari, H.; Dejam, M.; Chen, Z. Heavy oil polymer flooding from laboratory core floods to pilot tests and field applications: Half-century studies. J. Pet. Sci. Eng. 2016, 142, 85–100. [Google Scholar] [CrossRef]

- Mashayekhizadeh, V.; Kord, S.; Dejam, M. EOR potential within Iran. Spec. Top. Rev. Porous Media 2014, 5, 325–354. [Google Scholar] [CrossRef]

- Mao, H.; Qiu, Z.; Shen, Z.; Huang, W. Hydrophobic associated polymer based silica nano particles composite with core–shell structure as a filtrate reducer for drilling fluid at utra-high temperature. J. Pet. Sci. Eng. 2015, 129, 1–14. [Google Scholar] [CrossRef]

- Xu, J.; Qiu, Z.; Zhao, X.; Zhong, H.; Li, G.; Huang, W. Synthesis and characterization of shale stabilizer based on polyethylene glycol grafted nano-silica composite in water-based drilling fluids. J. Pet. Sci. Eng. 2018, 163, 371–377. [Google Scholar] [CrossRef]

- Ferreira, C.C.; Teixeira, G.T.; Lachter, E.R.; Nascimento, R.S.V. Partially hydrophobized hyperbranched polyglycerols as non-ionic reactive shale inhibitors for water-based drilling fluids. Appl. Clay Sci. 2016, 132, 122–132. [Google Scholar] [CrossRef]

- Barati, P.; Keshtkar, S.; Aghajafari, A.; Shahbazi, K.; Momeni, A. Inhibition performance and mechanism of horsetail extract as shale stabilizer. Pet. Explor. Dev. 2016, 43, 522–527. [Google Scholar] [CrossRef]

- Zhong, H.; Qiu, Z.; Sun, D.; Zhang, D.; Huang, W. Inhibitive properties comparison of different polyetheramines in water-based drilling fluid. J. Nat. Gas Sci. Eng. 2015, 26, 99–107. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, G.; Dong, T.; Wang, L.; Li, X.; Wang, G. An amphoteric polymer as a shale borehole stabilizer in water-based drilling fluids. J. Pet. Sci. Eng. 2018, 170, 112–120. [Google Scholar] [CrossRef]

- Xu, J.; Qiu, Z.; Zhao, X.; Huang, W. Hydrophobic modified polymer based silica nanocomposite for improving shale stability in water-based drilling fluids. J. Pet. Sci. Eng. 2017, 153, 325–330. [Google Scholar] [CrossRef]

- Xu, J.F.; Qiu, Z.S.; Lyu, K.H. Pressure transmission testing technology and simulation equipment for hydramechanics coupling of shale. Acta Pet. Sin. 2005, 27, 26–27. [Google Scholar]

- Xu, J.F.; Qiu, Z.S. Simulation test equipment of coupled hydra-mechanics of shales. J. China Univ. Pet. (Ed. Nat. Sci.) 2006, 30, 63–66. [Google Scholar]

- Zhang, P.; Lu, S.; Li, J.; Xue, H.; Li, W.; Zhang, P. Characterization of shale pore system: A case study of Paleogene Xin’gouzui Formation in the Jianghan basin, China. Mar. Pet. Geol. 2017, 79, 321–334. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Kong, L. Multifractal characteristics of Longmaxi Shale pore structures by N2 adsorption: A model comparison. J. Pet. Sci. Eng. 2018, 168, 330–341. [Google Scholar] [CrossRef]

- Liang, L.; Xiong, J.; Liu, X. Experimental study on crack propagation in shale formations considering hydration and wettability. J. Nat. Gas Sci. Eng. 2015, 23, 492–499. [Google Scholar] [CrossRef]

- Huang, W.; Li, X.; Qiu, Z.; Jia, J.; Wang, Y.; Li, X. Inhibiting the surface hydration of shale formation using preferred surfactant compound of polyamine and twelve alkyl two hydroxyethyl amine oxide for drilling. J. Pet. Sci. Eng. 2017, 159, 791–798. [Google Scholar] [CrossRef]

- Hamdia, K.M.; Silani, M.; Zhuang, X.; He, P.; Rabczuk, T. Stochastic analysis of the fracture toughness of polymeric nanoparticle composites using polynomial chaos expansions. Int. J. Fract. 2017, 206, 215–227. [Google Scholar] [CrossRef]

- Vu-Bac, N.; Lahmer, T.; Zhuang, X.; Nguyen-Thoi, T.; Rabczuk, T. A software framework for probabilistic sensitivity analysis for computationally expensive models. Adv. Eng. Softw. 2016, 100, 19–31. [Google Scholar] [CrossRef]

| Component | Content (wt%) | Component of Clay Mineral | Content (wt%) |

|---|---|---|---|

| Quartz | 20 | Illite | 12 |

| Calcite | 28 | Chlorite | 3 |

| Plagioclase | 29 | Kaolinite | 3 |

| Iron dolomite | 2 | Illite/smectite mixed layer | 82 |

| Potassium feldspar | 6 | ||

| Clay mineral | 15 |

| Parameter | Before adding SMA/SiO2 | After adding 2.0% SMA/SiO2 |

|---|---|---|

| θ at 600 rpm (lbf/100 ft2) | 70 | 74 |

| θ at 300 rpm (lbf/100 ft2) | 44 | 46 |

| AV (mPa.s) | 35 | 37 |

| PV (mPa.s) | 26 | 28 |

| YP (Pa) | 9 | 9 |

| YP/PV | 0.35 | 0.32 |

| FLAPI (mL) | 8.2 | 6.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, Z.; Xu, J.; Yang, P.; Zhao, X.; Mou, T.; Zhong, H.; Huang, W. Effect of Amphiphilic Polymer/Nano-Silica Composite on Shale Stability for Water-Based Muds. Appl. Sci. 2018, 8, 1839. https://doi.org/10.3390/app8101839

Qiu Z, Xu J, Yang P, Zhao X, Mou T, Zhong H, Huang W. Effect of Amphiphilic Polymer/Nano-Silica Composite on Shale Stability for Water-Based Muds. Applied Sciences. 2018; 8(10):1839. https://doi.org/10.3390/app8101839

Chicago/Turabian StyleQiu, Zhengsong, Jiangen Xu, Peng Yang, Xin Zhao, Tingbo Mou, Hanyi Zhong, and Weian Huang. 2018. "Effect of Amphiphilic Polymer/Nano-Silica Composite on Shale Stability for Water-Based Muds" Applied Sciences 8, no. 10: 1839. https://doi.org/10.3390/app8101839

APA StyleQiu, Z., Xu, J., Yang, P., Zhao, X., Mou, T., Zhong, H., & Huang, W. (2018). Effect of Amphiphilic Polymer/Nano-Silica Composite on Shale Stability for Water-Based Muds. Applied Sciences, 8(10), 1839. https://doi.org/10.3390/app8101839