Mechanical Properties of Concrete with Bamboo Chips

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.2. Design of Experiments

2.3. Specimen Preparation and Test

3. Experimental Results and Discussion

3.1. Slump Loss

3.2. Compressive Properties

3.2.1. Compressive Strength

3.2.2. Compressive Toughness Ratio

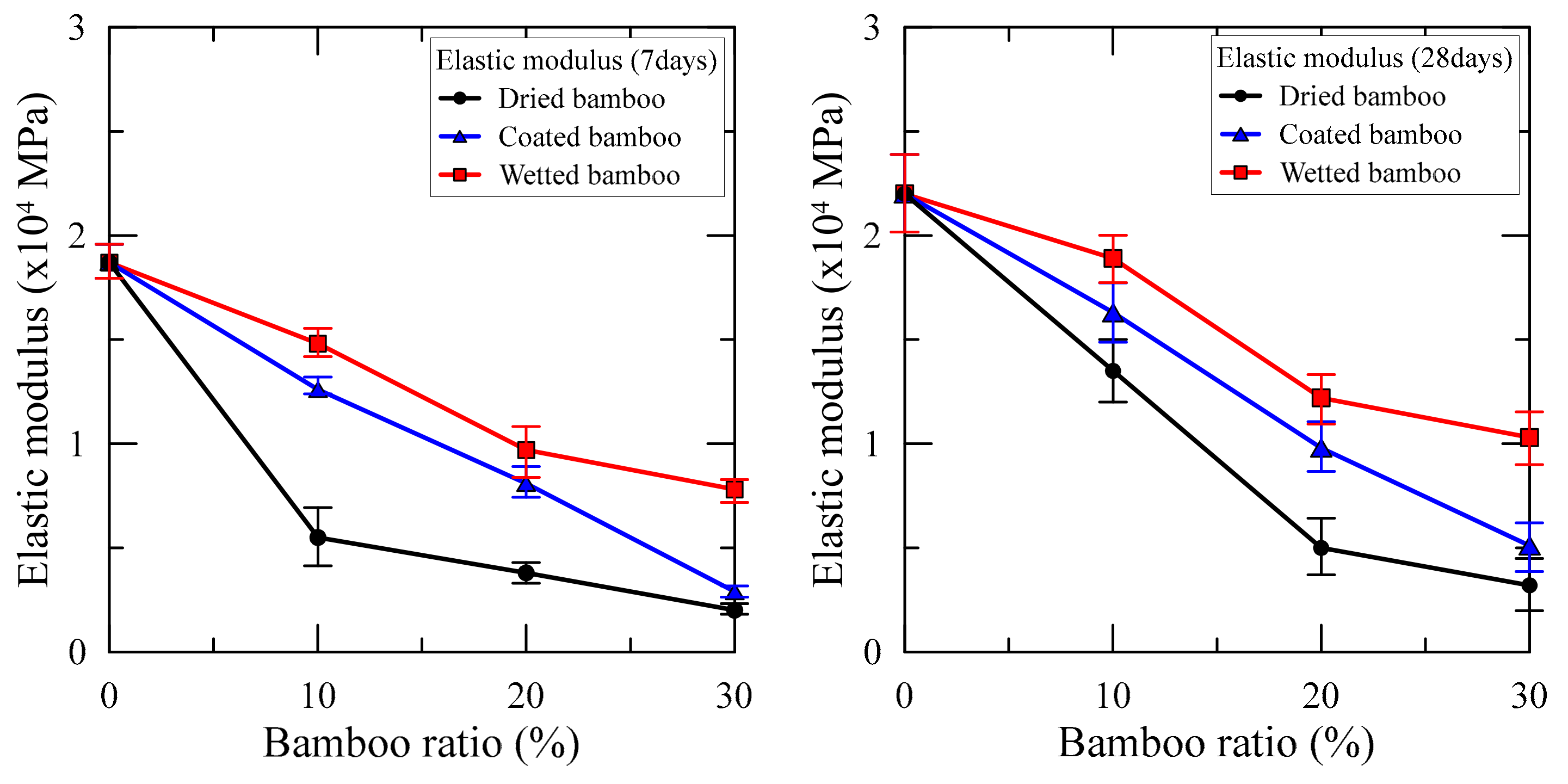

3.2.3. Modulus of Elasticity

3.3. Comparison of Splitting Tensile Strength

4. Conclusions

- Regardless of the bamboo type, both compressive and splitting tensile strengths decreased with increasing BCC. The strength of the specimen with 30% dried bamboo was 87% of the strength associated with ordinary concrete without bamboo. When natural coarse aggregates were replaced entirely with wetted bamboo chips, the compressive and tensile strengths decreased to ~10% of the plain-concrete strength. This results from the fact that the bamboo chip had lower strength and a weaker interface than the natural coarse aggregate.

- The specimen with wetted bamboo exhibited the highest strength, whereas the specimen with coated and then dried bamboo exhibited the lowest strength. During the curing process, the dried bamboo absorbs water, causing the volume to expand, resulting in micro cracks in the concrete and leading to a reduction in the strength of the concrete.

- The elastic modulus decreased from 2.2 × 104 MPa to 0.32 × 104 MPa, when the BCC increased from 0 to 30%. Moreover, except for the toughness ratio of the plain concrete, the toughness ratio decreased slightly with increasing BCC.

Author Contributions

Funding

Conflicts of Interest

References

- Masakazu, T.; Koichi, M. Fracture Behavior and Mechanical Properties of Bamboo Reinforced Concrete Members. Proc. Eng. 2011, 10, 2967–2972. [Google Scholar] [Green Version]

- Agarwal, A.; Nanda, B.; Maity, D. Experimental investigation on chemically treated bamboo reinforced concrete beams and columns. Constr. Build. Mater. 2014, 71, 610–617. [Google Scholar] [CrossRef]

- Karthik, S.; Rao, P.R.M.; Awoyera, P.O. Strength properties of bamboo and steel reinforced concrete containing manufactured sand and mineral admixtures. J. King Saud Univ. Eng. Sci. 2017, 29, 400–406. [Google Scholar] [CrossRef]

- Javadian, A.; Wielopolski, M.; Smith, I.F.; Hebel, D.E. Bond-behavior study of newly developed bamboo-composite reinforcement in concrete. Constr. Build. Mater. 2016, 122, 110–117. [Google Scholar] [CrossRef]

- Rahman, N.; Shing, L.W.; Simon, L.; Philipp, M.; Alireza, J.; Dirk, H.; Ling, C.S.; Wuan, L.H.; Valavan, S.E.; Nee, S.S. Enhanced bamboo composite with protective coating for structural concrete application. Energy Proc. 2017, 143, 167–172. [Google Scholar] [CrossRef]

- Moroz, J.G.; Lissel, S.L.; Hagel, M.D. Performance of bamboo reinforced concrete masonry shear walls. Constr. Build. Mater. 2014, 61, 125–137. [Google Scholar] [CrossRef]

- Ghavami, K. Ultimate load behaviour of bamboo-reinforced lightweight concrete beams. Cement. Concrete. Comp. 1995, 17, 281–288. [Google Scholar] [CrossRef]

- Ghavami, K. Bamboo as reinforcement in structural concrete elements. Cement. Concrete. Comp. 2005, 27, 637–649. [Google Scholar] [CrossRef]

- Endoh, N.; Inose, H.; Ohyama, A.; Kobayashi, K.; Maruyama, K. Mechanical properties for porous concrete mixing with bamboo chip. Rep. Nagano Nat. Inst. Technol. 2012, 46, 1–5. [Google Scholar]

- Dudhatra, B.; Parmar, D.; Patel, P. A study on bamboo as a replacement of aggregates in self compacting concrete. Int. J. Eng. Res. Technol. 2017, 6, 429–432. [Google Scholar]

- ASTM C33/C33M-18. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM C143/C143M-15a. Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C39/C39M-18. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International,: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM C496/C496M-17. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- JSCE. Concrete library International no.3; Japan Society of Civil Engineers: Tokyo, Japan, 1984; pp. 63–66. [Google Scholar]

- Taerwe, L.R. Influence of steel fibers on strain-softening of high-strength concrete. ACI Mater. J. 1993, 89, 54–60. [Google Scholar]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Stress–strain curves for steel-fiber reinforced concrete under compression. Cement. Concrete. Comp. 1999, 21, 383–390. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures. Cement. Concrete. Res. 2004, 34, 2215–2222. [Google Scholar] [CrossRef]

| Type | Size Range (mm) | Fineness Modulus | Specific Gravity | Water Absorption (%) |

|---|---|---|---|---|

| Fine aggregate | 10–20 | 6.5 | 2.58 | 1.1 |

| Coarse aggregate | 0.15–2.0 | 2.65 | 2.67 | 3.2 |

| Bamboo chip | 10 | - | 1.27 | 55.9 |

| TEST ID | Curing Age (day) | Bamboo Chip Type | Bamboo Chip Content, BCC (%) |

|---|---|---|---|

| NB-7 | 7 | No bamboo | 0 |

| DB10-7 | Dried | 10 | |

| DB20-7 | 20 | ||

| DB30-7 | 30 | ||

| CB10-7 | Coated | 10 | |

| CB20-7 | 20 | ||

| CB30-7 | 30 | ||

| WB10-7 | Wetted | 10 | |

| WB20-7 | 20 | ||

| WB30-7 | 30 | ||

| NB-28 | 28 | No bamboo | 0 |

| DB10-28 | Dried | 10 | |

| DB20-28 | 20 | ||

| DB30-28 | 30 | ||

| CB10-28 | Coated | 10 | |

| CB20-28 | 20 | ||

| CB30-28 | 30 | ||

| WB10-28 | Wetted | 10 | |

| WB20-28 | 20 | ||

| WB30-28 | 30 |

| W/C (%) | S/a (%) | Unit Weight (kg/m3) | ||

|---|---|---|---|---|

| OPC | S | G | ||

| 0.45 | 50 | 467 | 804 | 777 |

| TEST ID | Compressive Strength (MPa) | Strain at Peak Stress (%) | Elastic Modulus (×104 MPa) | Compressive Toughness Ratio (%) | Splitting Tensile Strength (MPa) |

|---|---|---|---|---|---|

| NB-7 | 18.00 | 0.22 | 1.87 | 0.26 | 1.89 |

| DB10-7 | 9.40 | 0.30 | 0.55 | 0.34 | 1.15 |

| DB20-7 | 4.28 | 0.33 | 0.38 | 0.68 | 0.82 |

| DB30-7 | 2.37 | 0.35 | 0.20 | 0.59 | 0.37 |

| CB10-7 | 9.84 | 0.28 | 1.26 | 0.45 | 1.39 |

| CB20-7 | 7.94 | 0.35 | 0.81 | 0.51 | 1.11 |

| CB30-7 | 7.33 | 0.33 | 0.29 | 0.44 | 0.74 |

| WB10-7 | 12.52 | 0.27 | 1.48 | 0.73 | 1.63 |

| WB20-7 | 11.26 | 0.30 | 0.97 | 0.71 | 1.52 |

| WB30-7 | 9.51 | 0.29 | 0.78 | 0.58 | 1.35 |

| NB-28 | 30.77 | 0.22 | 2.20 | 0.17 | 2.38 |

| DB10-28 | 13.55 | 0.20 | 1.35 | 0.30 | 1.59 |

| DB20-28 | 5.76 | 0.27 | 0.50 | 0.66 | 0.83 |

| DB30-28 | 3.13 | 0.35 | 0.32 | 0.65 | 0.38 |

| CB10-28 | 15.01 | 0.26 | 1.63 | 0.61 | 1.74 |

| CB20-28 | 14.15 | 0.25 | 0.98 | 0.61 | 1.13 |

| CB30-28 | 8.99 | 0.20 | 0.51 | 0.63 | 0.84 |

| WB10-28 | 23.73 | 0.25 | 1.89 | 0.50 | 2.21 |

| WB20-28 | 19.04 | 0.28 | 1.22 | 0.55 | 1.79 |

| WB30-28 | 17.75 | 0.23 | 1.03 | 0.57 | 1.61 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.-S.; Hou, Y.-l.; Lee, J.-C.; Jeong, S.-W. Mechanical Properties of Concrete with Bamboo Chips. Appl. Sci. 2019, 9, 3367. https://doi.org/10.3390/app9163367

Park S-S, Hou Y-l, Lee J-C, Jeong S-W. Mechanical Properties of Concrete with Bamboo Chips. Applied Sciences. 2019; 9(16):3367. https://doi.org/10.3390/app9163367

Chicago/Turabian StylePark, Sung-Sik, Yao-long Hou, Jun-Cheol Lee, and Sueng-Won Jeong. 2019. "Mechanical Properties of Concrete with Bamboo Chips" Applied Sciences 9, no. 16: 3367. https://doi.org/10.3390/app9163367

APA StylePark, S.-S., Hou, Y.-l., Lee, J.-C., & Jeong, S.-W. (2019). Mechanical Properties of Concrete with Bamboo Chips. Applied Sciences, 9(16), 3367. https://doi.org/10.3390/app9163367