Technical Performance of an Inflatable Solar Dryer for Drying Amaranth Leaves in Kenya

Abstract

:1. Introduction

2. Materials and Methods

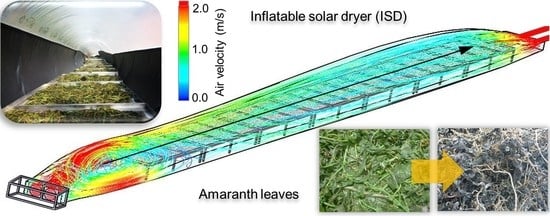

2.1. Inflatable Solar Dryer (ISD)

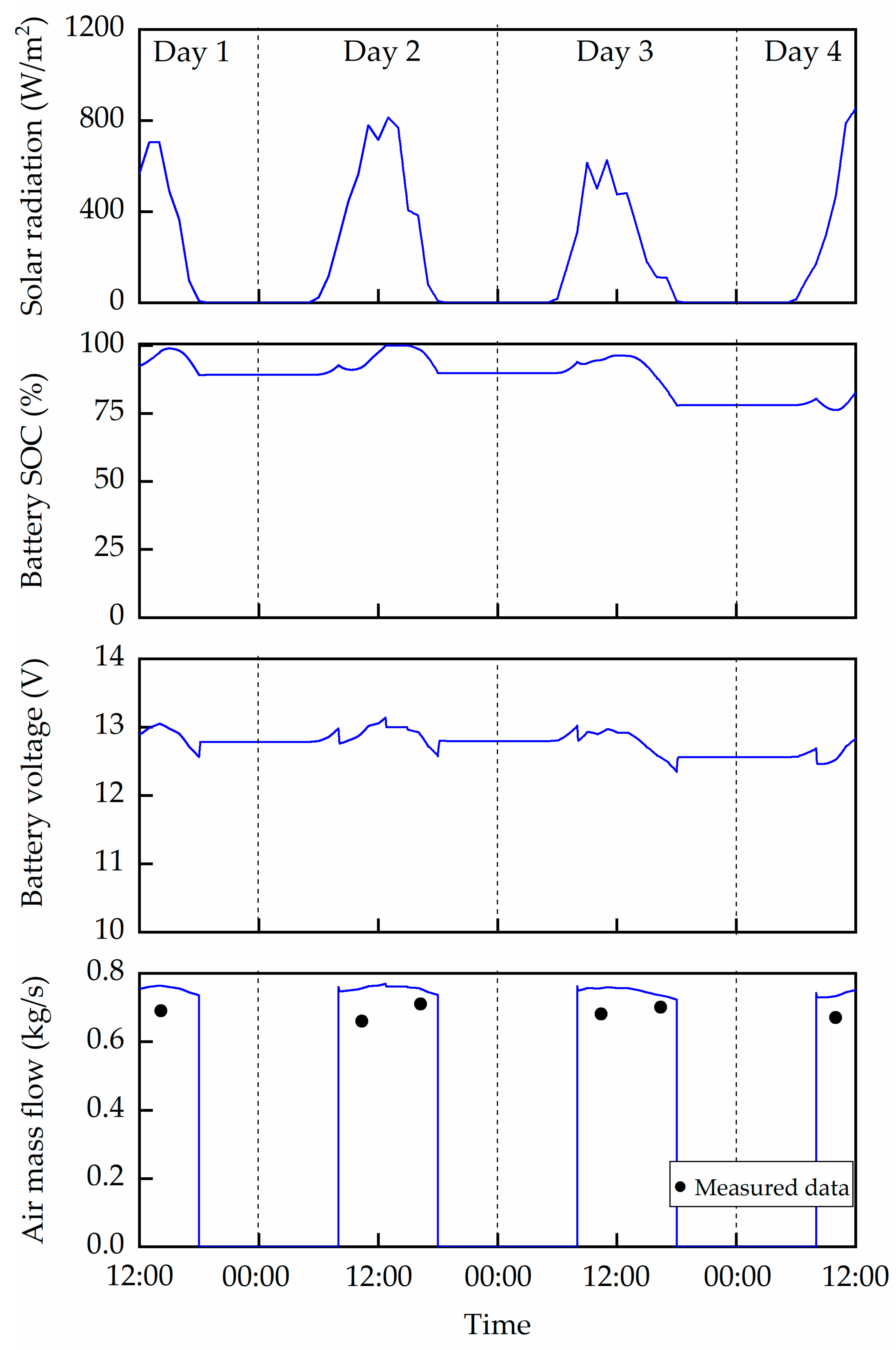

2.2. Simulation of the Photovoltaic Energy Supply System

2.3. Computational Evaluation of Airflow inside the ISD

2.4. Drying Experiments

2.5. Statistical Analysis

3. Results and Discussion

3.1. Estimated Performance of the ISD Solar System

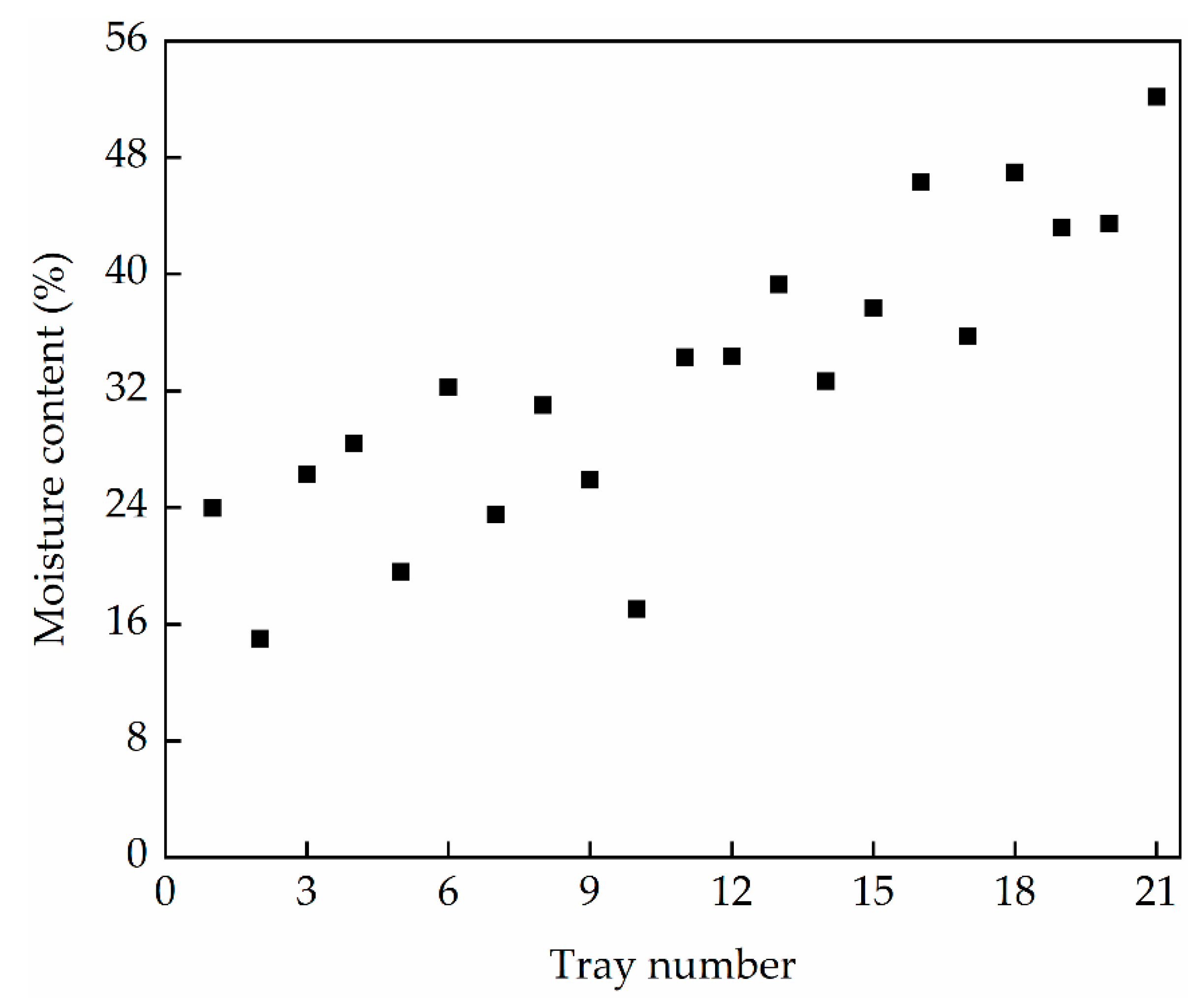

3.2. Simulation of Airflow Distribution in the ISD

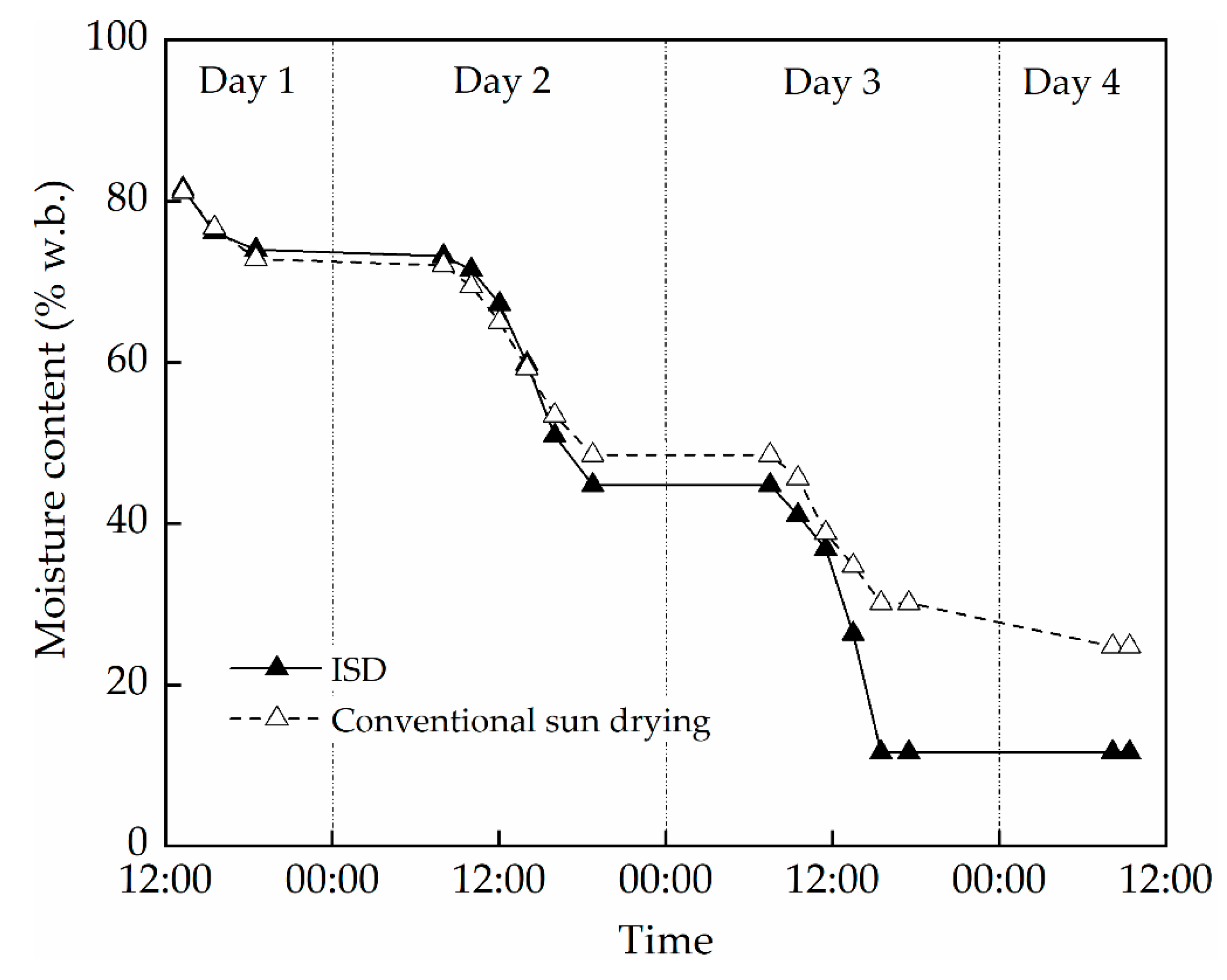

3.3. Drying Performance of the ISD Compared to Conventional Sun Drying

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Grabowski, S.; Ramaswamy, H.S.; Marcotte, M. Drying of fruits, vegetables, and spices. In Handbook of Postharvest Technology: Cereals, Fruits, Vegetables, Tea, and Spices; Ramaswamy, H.S., Raghavan, G.S.V., Chakraverty, A., Mujumdar, A.S., Eds.; Marcel Dekker Inc.: New York, NY, USA, 2003; pp. 653–695. [Google Scholar]

- Janjai, S.; Bala, B.K. Solar Drying Technology. Food Eng. Rev. 2012, 4, 16–54. [Google Scholar] [CrossRef]

- Müller, J.; Mühlbauer, W. Solar drying. In Modern Drying Technology; Tsotsas, E., Mujumdar, A.S., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; pp. 199–243. [Google Scholar]

- Jebur, H.A.; Jabr, A.K.; Jassim, S.Y. Evaluation of thermal efficiency for solar energy storage of agricultural products: A review. Plant Arch. 2019, 19, 17–24. [Google Scholar]

- Sharma, V.K.; Colangelo, A.; Spagna, G. Experimental investigation of different solar dryers suitable for fruit and vegetable drying. Renew. Energy 1995, 6, 413–424. [Google Scholar] [CrossRef]

- Amir, E.J.; Grandegger, K.; Esper, A.; Sumarsono, M.; Djaya, C.; Mühlbauer, W. Development of a multi-purpose solar tunnel dryer for use in humid tropics. Renew. Energy 1991, 1, 167–176. [Google Scholar] [CrossRef]

- Singh, P.; Shrivastava, V.; Kumar, A. Recent developments in greenhouse solar drying: A review. Renew. Sustain. Energy Rev. 2018, 82, 3250–3262. [Google Scholar] [CrossRef]

- Khazimov, M.Z.; Khazimov, K.M.; Urmashev, B.A.; Tazhibayev, T.S.; Sagyndykova, Z.B. Intensification of the Plant Products Drying Process by Improving Solar Dryer Design. J. Eng. Thermophys. 2018, 27, 580–592. [Google Scholar] [CrossRef]

- Sai Krishna Teja, M.; Narasimha Rao, K.V.; Pochont, N.R. Design, development and experimental evaluation of solar dryer. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 949–968. [Google Scholar]

- Noh, A.M.; Mat, S.; Ruslan, M.H. CFD simulation of temperature and air flow distribution inside industrial scale solar dryer. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 45, 156–164. [Google Scholar]

- Orbegoso, E.M.; Saavedra, R.; Marcelo, D.; La Madrid, R. Numerical characterisation of one-step and three-step solar air heating collectors used for cocoa bean solar drying. J. Environ. Manag. 2017, 203, 1080–1094. [Google Scholar] [CrossRef]

- Lutz, K.; Mühlbauer, W. Solar tunnel dryer with integrated collector. Dry. Technol. 1986, 4, 583–603. [Google Scholar] [CrossRef]

- Salvatierra-Rojas, A.; Nagle, M.; Gummert, M.; de Bruin, T.; Müller, J. Development of an inflatable solar dryer for improved postharvest handling of paddy rice in humid climates. Int. J. Agric. Biol. Eng. 2017, 10, 269–282. [Google Scholar]

- Ng’Ang’A, M.N.; Muasya, R.M.; Omami, E.; Ohiokpehai, O. Effect of environment, intercropping systems and harvest intervals on protein and β-carotene contents of leaf Amaranth. Acta Hortic. 2011, 911, 433–436. [Google Scholar]

- Liu, F.; Stützel, H. Leaf water relations of vegetable amaranth (Amaranthus spp.) in response to soil drying. Eur. J. Agron. 2002, 16, 137–150. [Google Scholar] [CrossRef]

- Nzomo, E.M.; Ariyawardana, A.; Sila, D.N.; Sellahewa, J.N. Reaping the potential benefits of amaranth: Value chain challenges ahead for Kenya. In Acta Horticulturae; Mecozzi, M., Srinivasan, R., Keatinge, J.D.H., Eds.; International Society for Horticultural Science: Leuven, Belgium, 2015; Volume 1102, pp. 191–198. [Google Scholar]

- Oliveira, S.M.; Brandão, T.R.S.; Silva, C.L.M. Influence of Drying Processes and Pretreatments on Nutritional and Bioactive Characteristics of Dried Vegetables: A Review. Food Eng. Rev. 2016, 8, 134–163. [Google Scholar] [CrossRef]

- Negi, P.S.; Roy, S.K. Effect of Blanching and Drying Methods on β -Carotene, Ascorbic acid and Chlorophyll Retention of Leafy Vegetables. LWT Food Sci. Technol. 2000, 33, 295–298. [Google Scholar] [CrossRef]

- Oboh, G. Effect of blanching on the antioxidant properties of some tropical green leafy vegetables. LWT Food Sci. Technol. 2005, 38, 513–517. [Google Scholar] [CrossRef]

- Sukamongkol, Y.; Chungpaibulpatana, S.; Ongsakul, W. A simulation model for predicting the performance of a solar photovoltaic system with alternating current loads. Renew. Energy 2002, 27, 237–258. [Google Scholar] [CrossRef]

- Torres-Toledo, V.; Meissner, K.; Täschner, P.; Martınez-Ballester, S.; Müller, J. Design and performance of a small-scale solar ice-maker based on a DC-freezer and an adaptive control unit. Sol. Energy 2016, 139, 433–443. [Google Scholar] [CrossRef]

- Poblete, R.; Cortes, E.; Macchiavello, J.; Bakit, J. Factors influencing solar drying performance of the red algae Gracilaria chilensis. Renew. Energy 2018, 126, 978–986. [Google Scholar] [CrossRef]

- Dassault Systèmes. Technical Reference-Solidworks Flow Simulation 2017; Dassault Systèmes: Vélizy-Villacoublay, France, 2017. [Google Scholar]

- Zogzas, N.P.; Maroulis, Z.B.; Marinos-Kouris, D. Densities, shrinkage and porosity of some vegetables during air drying. Dry. Technol. 1994, 12, 1653–1666. [Google Scholar] [CrossRef]

- DIN CEN/TS 14774-3. Determination of moisture content-oven dry method. In Part 3: Moisture in General Analysis Sample; Deutsches Institut für Normung e.V.: Berlin, Germany, 2004. [Google Scholar]

- Pereira, L.S.; Allen, R.G.; Smith, M.; Raes, D. Crop evapotranspiration estimation with FAO56: Past and future. Agric. Water Manag. 2015, 147, 4–20. [Google Scholar] [CrossRef]

- Sharma, A.; Chen, C.R.; Vu Lan, N. Solar-energy drying systems: A review. Renew. Sustain. Energy Rev. 2009, 13, 1185–1210. [Google Scholar] [CrossRef]

- Sobukola, O.P.; Dairo, O.U.; Sanni, L.O.; Odunewu, A.V.; Fafiolu, B.O. Thin layer drying process of some leafy vegetables under open sun. Food Sci. Technol. Int. 2007, 13, 35–40. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romuli, S.; Schock, S.; Nagle, M.; Chege, C.G.K.; Müller, J. Technical Performance of an Inflatable Solar Dryer for Drying Amaranth Leaves in Kenya. Appl. Sci. 2019, 9, 3431. https://doi.org/10.3390/app9163431

Romuli S, Schock S, Nagle M, Chege CGK, Müller J. Technical Performance of an Inflatable Solar Dryer for Drying Amaranth Leaves in Kenya. Applied Sciences. 2019; 9(16):3431. https://doi.org/10.3390/app9163431

Chicago/Turabian StyleRomuli, Sebastian, Steffen Schock, Marcus Nagle, Christine G. Kiria Chege, and Joachim Müller. 2019. "Technical Performance of an Inflatable Solar Dryer for Drying Amaranth Leaves in Kenya" Applied Sciences 9, no. 16: 3431. https://doi.org/10.3390/app9163431

APA StyleRomuli, S., Schock, S., Nagle, M., Chege, C. G. K., & Müller, J. (2019). Technical Performance of an Inflatable Solar Dryer for Drying Amaranth Leaves in Kenya. Applied Sciences, 9(16), 3431. https://doi.org/10.3390/app9163431