A Stratigraphic Prediction Method Based on Machine Learning

Abstract

:1. Introduction

2. Geostratigraphic Series Simulation Method Based on Machine Learning

2.1. Geostratigraphic Series

2.2. Stratum Data Reconstruction Schemes Based on Machine Learning

2.2.1. Stratum Data Normalization

2.2.2. Drilling Data Segmentation and Equalization

2.2.3. Geostratigraphic Series Filling

2.2.4. Stratum Coding Based on One-Hot Encoding

2.3. Geostratigraphic Series Simulation Based on a Recurrent Neural Network

2.3.1. Establishment of the Sequence Model of the Stratum Type

2.3.2. Establishment of the Series Model of the Stratum Thickness

2.3.3. Establishment of the Geostratigraphic Series Modeling

2.4. Evaluation Method of Stratum Type Series Simulation

- Replace the first “silt” with “sand”;

- Insert “miscellaneous fill” at the beginning of t1;

- Remove the last “clay”;

- Delete the final “silt”.

3. Results and Discussions

3.1. Study of the Regional Geology and Data Reconstruction Schemes

3.2. Machine Learning Simulation Result Analysis

- class CrossLoss(nn.Module):

- def __init__(self,ignore_index = 0):

- super(CrossLoss, self).__init__()

- self.ignore_index = ignore_index

- self.criterion = nn.CrossEntropyLoss(ignore_index = 0)

- def forward(self, input, target):

- ind = (target ! = self.ignore_index).float()

- num_all = torch.sum(ind).data[0]

- #print(target)

- size0 = target.size(0)

- size1 = target.size(1)

- temp = target.cpu().data

- for i in range(size0):

- for j in range(size1):

- temp[i,j] = depthLabel(temp[i,j])

- pred = torch.mul(input,ind).long()

- temp = temp.long()

- loss = self.criterion(pred, temp)

- return loss, num_all

- CPU: Intel Core i7-4790k @ 4.00GHz quad-core;

- Memory: 32 GB;

- VGA card: Nvidia GeForce GTX 770(2GB).

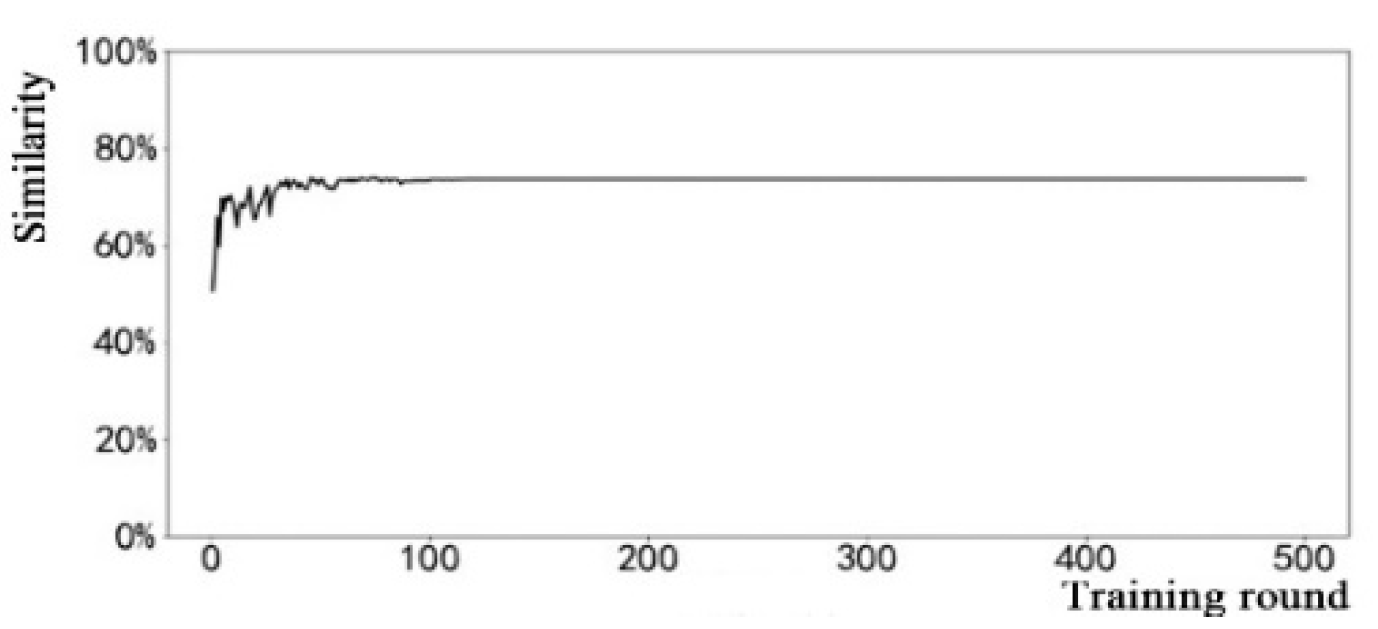

3.2.1. Training and Verification of the Stratum Type Series Model

3.2.2. Training and Verification of the Stratum Thickness Series Model

3.2.3. Verification of the Geostratigraphic Series Model

3.3. Three-Dimensional Geological Modeling and Testing

3.3.1. Three-Dimensional Geological Modeling

3.3.2. Three-Dimensional Geological Model Verification

3.4. Evaluation of 3D Geological Modeling Based on the Geostratigraphic Series Model

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bertoncello, A.; Sun, T.; Li, H.; Mariethoz, G.; Caers, J. Conditioning surface-based geological models to well and thickness data. Math. Geosci. 2013, 45, 873–893. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, C.; Li, M.; Pan, X.; Sun, J. Building 3D solid models of sedimentary stratum systems from borehole data: An automatic method and case studies. Eng. Geol. 2012, 127, 1–13. [Google Scholar] [CrossRef]

- Jones, N.L.; Walker, J.R.; Carle, S.F. Hydrogeologic unit flow characterization using transition probability geostatistics. Groundwater 2005, 43, 285–289. [Google Scholar] [CrossRef]

- Qiao, J.; Pan, M.; Li, Z.; Jin, Y. 3D Geological modeling from DEM, boreholes, cross-sections and geological maps. In Proceedings of the 2011 19th International Conference on Geoinformatics, Shanghai, China, 24–26 June 2011; pp. 1–5. [Google Scholar]

- Lallier, F.; Caumon, G.; Borgomano, J.; Viseur, S.; Royer, J.J.; Antoine, C. Uncertainty assessment in the stratigraphic well correlation of a carbonate ramp: Method and application to the Beausset Basin, SE France. Comptes Rendus Geosci. 2016, 348, 499–509. [Google Scholar] [CrossRef] [Green Version]

- Edwards, J.; Lallier, F.; Caumon, G.; Carpentier, C. Uncertainty management in stratigraphic well correlation and stratigraphic architectures: A training-based method. Comput. Geosci. 2017, 111, 11–17. [Google Scholar] [CrossRef]

- Carr, G.R.; Andrew, A.S.; Denton, G.; Giblin, A.; Korsch, M.; Whitford, D. The “Glass Earth”—Geochemical frontiers in exploration through cover. Aust. Inst. Geosci. Bull. 1999, 28, 33–40. [Google Scholar]

- Molennar, M. A topology for 3D vector maps. ITC J. 1992, 1, 25–33. [Google Scholar]

- Chen, H.; Huang, T. A survey of construction and manipulation of octrees. Comput. Vis. Graph. Image Process. 1988, 43, 409–431. [Google Scholar] [CrossRef]

- Houlding, S.W. 3D Geoscience Modeling—Computer Techniques for Geological Characterization; Springer: New York, NY, USA, 1994; p. 303. [Google Scholar]

- Caumon, G.; Mallet, J.L. 3D Stratigraphic models: Representation and stochastic modelling. In Proceedings of the IAMG 2006, Liège, Belgium, 3–8 September 2006. [Google Scholar]

- Mallet, J.L. Discrete Smooth Interpolation. ACM Trans. Graph. 1989, 8, 121–144. [Google Scholar] [CrossRef]

- Mallet, J.L. Geomodeling; Oxford University Press: New York, NY, USA, 2002; p. 612. [Google Scholar]

- Mallet, J.L. Elements of Mathematical Sedimentary Geology: The GeoChron Model; EAGE: Houten, The Netherlands, 2014. [Google Scholar]

- Randle, C.H.; Bond, C.E.; Lark, R.M.; Monaghan, A.A. Uncertainty in geological interpretations: Effectiveness of expert elicitations. Geosphere 2019, 15, 108–118. [Google Scholar] [CrossRef]

- Carbonell, J. Machine Learning: A Maturing Field. Mach. Learn. 1992, 9, 5–7. [Google Scholar] [CrossRef]

- Langley, P. Machine learning as an experimental science. Mach. Learn. 1988, 3, 5–8. [Google Scholar] [CrossRef] [Green Version]

- Quinlan, J.R. Induction of Decision Trees. Mach. Learn. 1986, 1, 81–106. [Google Scholar] [CrossRef]

- Breiman, L. Statistical modeling: The two cultures (with comments and a rejoinder by the author). Stat. Sci. 2001, 16, 199–231. [Google Scholar] [CrossRef]

- Bachri, I.; Hakdaoui, M.; Raji, M.; Teodoro, A.C.; Benbouziane, A. Machine Learning Algorithms for Automatic Lithological Mapping Using Remote Sensing Data: A Case Study from Souk Arbaa Sahel, Sidi Ifni Inlier, Western Anti-Atlas, Morocco. ISPRS Int. J. Geo-Inf. 2019, 8, 248. [Google Scholar] [CrossRef]

- Chen, L.; Ren, C.; Li, L.; Wang, Y.; Zhang, B.; Wang, Z.; Li, L. A Comparative Assessment of Geostatistical, Machine Learning, and Hybrid Approaches for Mapping Topsoil Organic Carbon Content. ISPRS Int. J. Geo-Inf. 2019, 8, 174. [Google Scholar] [CrossRef]

- Mueller, E.; Sandoval, J.; Mudigonda, S.; Elliott, M. A Cluster-Based Machine Learning Ensemble Approach for Geospatial Data: Estimation of Health Insurance Status in Missouri. ISPRS Int. J. Geo-Inf. 2019, 8, 13. [Google Scholar] [CrossRef]

- Burl, M.C.; Asker, L.; Smyth, P.; Fayyad, U.; Perona, P.; Crumpler, L.; Aubele, J. Learning to Recognize Volcanoes on Venus. Mach. Learn. 1998, 30, 165–194. [Google Scholar] [CrossRef] [Green Version]

- Gonçalves, Í.G.; Kumaira, S.; Guadagnin, F. A machine learning approach to the potential-field method for implicit modeling of geological structures. Comput. Geosci. 2017, 103, 173–182. [Google Scholar] [CrossRef]

- Klump, J.F.; Huber, R.; Robertson, J.; Cox, S.J.; Woodcock, R. Linking descriptive geology and quantitative machine learning through an ontology of lithological concepts. In Proceedings of the AGU Fall Meeting Abstracts 2014, San Francisco, CA, USA, 15–19 December 2004. [Google Scholar]

- Rodriguez-Galiano, V.; Sanchez-Castillo, M.; Chica-Olmo, M.; Chica-Rivas, M. Machine learning predictive models for mineral prospectivity: An evaluation of neural networks, random forest, regression trees and support vector machines. Ore Geol. Rev. 2015, 71, 804–818. [Google Scholar] [CrossRef]

- Porwal, A.; Carranza, E.J.M.; Hale, M. Artificial Neural Networks for Mineral-Potential Mapping: A Case Study from Aravalli Province, Western India. Nat. Resour. Res. 2003, 12, 155–171. [Google Scholar] [CrossRef]

- Zhang, T. The Relationships between Rock Elements and the Igneous Rocks, the Lithologic Discrimination and Mineral Identification of Sedimentary Rocks: A Study Based on the Method of Artificial Neural Network. Ph.D. Thesis, Northwest University, Xi’an, China, 2016. [Google Scholar]

- Zhang, Y.; Su, G.; Yan, L. Gaussian Process Machine Learning Model for Forecasting of Karstic Collapse. In International Conference on Applied Informatics and Communication; Springer: Berlin/Heidelberg, Germany, 2011; pp. 365–372. [Google Scholar]

- Chaki, S.; Routray, A.; Mohanty, W.K. Well-Log and Seismic Data Integration for Reservoir Characterization: A Signal Processing and Machine-Learning Perspective. IEEE Signal Process. Mag. 2018, 35, 72–81. [Google Scholar] [CrossRef]

- Gaurav, A. Horizontal shale well eur determination integrating geology, machine learning, pattern recognition and multivariate statistics focused on the permian basin. In SPE Liquids-Rich Basins Conference-North America; Society of Petroleum Engineers: Richardson, TX, USA, 2017. [Google Scholar]

- Sha, A.; Tong, Z.; Gao, J. Recognition and Measurement of Pavement Disasters Based on Convolutional Neural Networks. China J. Highw. Transp. 2017, 31, 1–10. [Google Scholar]

- Connor, J.T.; Martin, R.D.; Atlas, L.E. Recurrent Neural Networks and Robust Time Series Prediction; IEEE Press: Piscataway Township, NJ, USA, 1994. [Google Scholar]

- Graves, A. Supervised Sequence Labelling with Recurrent Neural Networks; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Lamb, A.M.; Goyal, A.G.; Zhang, Y.; Zhang, S.; Courville, A.C.; Bengio, Y. Professor Forcing: A New Algorithm for Training Recurrent Networks. In Advances in Neural Information Processing Systems, Proceedings of the 30th Annual Conference on Neural Information Processing Systems 2016, Barcelona, Spain, 5–10 December 2016; Curran Associates, Inc.: Red Hook, NY, USA, 2016. [Google Scholar]

- Lin, C.; Hsieh, T.; Liu, Y.; Lin, Y.; Fang, C.; Wang, Y.; Chuang, C. Minority oversampling in kernel adaptive subspaces for class imbalanced datasets. IEEE Trans. Knowl. Data Eng. 2018, 30, 950–962. [Google Scholar] [CrossRef]

- LÞcke, J.; Sahani, M. Maximal causes for non-linear component extraction. J. Mach. Learn. Res. 2008, 9, 1227–1267. [Google Scholar]

- Liu, X. Application of BP neural network in insider rock identification of Taiguyu in Liaohe. Pet. Geol. Eng. 2010, 24, 40–42. [Google Scholar]

- Royer, J.J.; Mejia, P.; Caumon, G.; Collon, P. 3D and 4D Geomodelling Applied to Mineral Resources Exploration—An Introduction. 3D, 4D and Predictive Modelling of Major Mineral Belts in Europe; Springer: Cham, Switzerland, 2015. [Google Scholar]

| Stratum Types | Number | Coding Vector |

|---|---|---|

| clay | 0 | (1, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0) |

| silt | 1 | (0, 1, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0) |

| plain fill | 2 | (0, 0, 1, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0) |

| miscellaneous fill | 3 | (0, 0, 0, 1, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0) |

| silty sand | 4 | (0, 0, 0, 0, 1, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0) |

| silty clay | 5 | (0, 0, 0, 0, 0, 1, 0, 0, 0, 0, 0, 0, 0, 0, 0) |

| mucky soil | 6 | (0, 0, 0, 0, 0, 0, 1, 0, 0, 0, 0, 0, 0, 0, 0) |

| mucky clay | 7 | (0, 0, 0, 0, 0, 0, 0, 1, 0, 0, 0, 0, 0, 0, 0) |

| old city fill | 8 | (0, 0, 0, 0, 0, 0, 0, 0, 1, 0, 0, 0, 0, 0, 0) |

| clay sand inclusion | 9 | (0, 0, 0, 0, 0, 0, 0, 0, 0, 1, 0, 0, 0, 0, 0) |

| mud | 10 | (0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 1, 0, 0, 0, 0) |

| medium sand | 11 | (0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 1, 0, 0, 0) |

| intermediate fine sand | 12 | (0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 1, 0, 0) |

| start mark | 13 | (0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 1, 0) |

| end mark | 14 | (0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 1) |

| Round Number | 50 | 500 |

|---|---|---|

| Loss value | 0.483226 | 0.374167 |

| Cumulative decline | 0.327009 | 0.436068 |

| Cumulative decline | 40.36% | 53.82% |

| Expert Ratio | 0 | 1/3 | 1/2 | 2/3 | 1 |

|---|---|---|---|---|---|

| Maximum value | 61.42% | 63.83% | 64.82% | 63.40% | 64.82% |

| Steady value | 59.86% | 60.00% | 62.41% | 61.13% | 60.42% |

| Expert Ratio | 0 | 1/3 | 1/2 | 2/3 | 1 | |

|---|---|---|---|---|---|---|

| Edit Distance = 0 | Maximum value | 37.2% | 39.6% | 39.2% | 39.6% | 36.4% |

| Steady value | 35.2% | 38% | 38.4% | 38.4% | 35.6% | |

| Edit Distance <= 1 | Maximum value | 76% | 77.2% | 76.4% | 77.2% | 76.4% |

| Steady value | 74% | 75.6% | 75.6% | 75.6% | 73.6% | |

| Expert Ratio | 0 | 1/3 | 1/2 | 2/3 | 1 |

|---|---|---|---|---|---|

| Maximum value | 71.85% | 73.60% | 73.95% | 73.98% | 72.51% |

| Steady value | 70.91% | 72.64% | 73.57% | 73.09% | 71.68% |

| Stratum Thickness Interval | Layer Thickness Type Coding Number | Coded Vector |

|---|---|---|

| <3 m | 0 | [1, 0, 0, 0, 0, 0, 0] |

| 3–5 m | 1 | [0, 1, 0, 0, 0, 0, 0] |

| 5–10 m | 2 | [0, 0, 1, 0, 0, 0, 0] |

| 10–20 m | 3 | [0, 0, 0, 1, 0, 0, 0] |

| 20–30 m | 4 | [0, 0, 0, 0, 1, 0, 0] |

| >30 m | 5 | [0, 0, 0, 0, 0, 1, 0] |

| initiation mark | 6 | [0, 0, 0, 0, 0, 0, 1] |

| Expert Ratio | 0 | 1/3 | 1/2 | 2/3 | 1 |

|---|---|---|---|---|---|

| Maximum value | 65.07% | 73.05% | 80.08% | 75.60% | 70.07% |

| Steady value | 63.53% | 70.07% | 75.05% | 72.62% | 67.94% |

| Number | The Real Borehole Strata | Prediction Results of Machine Learning | ||

|---|---|---|---|---|

| Stratum Type Sequence | Stratum Thickness Sequence (m) | Stratum Type Sequence | Stratum Thickness Sequence (m) | |

| 1 | silt, clay | 0.3, 3.9 | floury soil, clay, plain fill | within 3 m, within 3 m, 3–5 m |

| 2 | clay | 2 | clay | within 3 m |

| 3 | miscellaneous fill | 0.6 | plain fill | 5–10 m |

| 4 | plain fill, clay | 3.1, 9.8 | plain fill, clay | within 3 m, 5–10 m |

| 5 | miscellaneous fill, clay, mucky soil, plain fill, clay | 1.2, 1.3, 1.5, 2.4, 13.3 | miscellaneous fill, plain fill, mucky soil, plain fill, clay | within 3 m, within 3 m, within 3 m, within 3 m, 10–20 m |

| 6 | floury soil, silty clay, plain fill, clay, plain fill, clay | 1.0, 0.5, 2.5, 1.2, 0.3, 3.6 | floury soil, plain fill, clay, plain fill, clay | within 3 m, within 3 m, within 3 m, within 3 m 5–10 m |

| 7 | miscellaneous fill, plain fill, clay | 0.7, 3.0, 4.5 | miscellaneous fill, plain fill, clay | within 3 m, within 3 m, 3–5 m |

| 8 | miscellaneous fill, clay | 0.6, 4.0 | miscellaneous fill | within 3 m |

| 9 | miscellaneous fill, plain fill, clay | 0.5, 1.0, 11.9 | miscellaneous fill, plain fill, clay | within 3 m, within 3 m, 10–20 m |

| 10 | miscellaneous fill, clay | 1.0, 9.8 | miscellaneous fill, clay | within 3 m, 5–10 m |

| 11 | miscellaneous fill, silt, plain fill, clay | 4.1, 11.2, 7.0, 10.0 | miscellaneous fill, plain fill, clay | within 3 m, 10–20 m, 5–10 m |

| 12 | floury soil, plain fill, mucky soil, clay | 0.5, 6.7, 1.2, 8.6 | floury soil, plain fill, plain fill, clay | within 3 m, within 3 m, within 3 m, 5–10 m |

| 13 | silt, clay | 0.4, 6.6 | floury soil, clay | within 3 m, 5–10 m |

| 14 | silt, clay | 0.4, 10.4 | floury soil, clay | within 3 m, 5–10 m |

| 15 | miscellaneous fill, silt, plain fill, clay | 0.7, 1.9, 3.4, 24.0 | miscellaneous fill, floury soil, plain fill, clay | within 3 m, within 3 m, within 3 m, 20–30 m |

| 16 | miscellaneous fill soil, plain fill soil, old city miscellaneous fill soil, clay | 1.2, 2.6, 6.5, 13.0 | miscellaneous fill, floury soil, plain fill, old town fill, clay | within 3 m, within 3 m, within 3 m, 5–10 m, 10–20 m |

| 17 | miscellaneous fill soil, plain fill soil, clay | 0.5, 2.8, 10.2 | miscellaneous fill, plain fill, clay | within 3 m, within 3 m, 10–20 m |

| 18 | miscellaneous fill soil, plain fill soil, clay | 2.1, 0.8, 12.9 | miscellaneous fill, plain fill, clay | within 3 m, within 3 m, 10–20 m, |

| Stratum Type Accuracy | Average Sequence Similarity | Stratum Thickness Accuracy |

|---|---|---|

| 62.98% | 72.16% | 74.04% |

| Number | The Real Borehole Strata | Prediction Results of 3D Geological Modeling | ||

|---|---|---|---|---|

| Stratum Type Sequence | Stratum Thickness Sequence (m) | Stratum Type Sequence | Stratum Thickness Sequence (m) | |

| 1 | silt, clay | 0.3, 3.9 | clay, silt | 0.3, 3.9 |

| 2 | clay | 2 | miscellaneous fill | 2.0 |

| 3 | miscellaneous fill | 0.6 | miscellaneous fill | 0.6 |

| 4 | plain fill, clay | 3.1, 9.8 | miscellaneous fill | 13.5 |

| 5 | miscellaneous fill, clay, mucky soil, plain fill, clay | 1.2, 1.3, 1.5, 2.4, 13.3 | miscellaneous fill, clay, mucky soil, silt | 1.2, 1.3, 3.9, 13.3 |

| 6 | floury soil, silty clay, plain fill, clay, plain fill, clay | 1.0, 0.5, 2.5, 1.2, 0.3, 3.6 | plain fill, silt clay, silt, clay, silt | 1, 0.5, 2.5, 1.2, 3.9 |

| 7 | miscellaneous fill, plain fill, clay | 0.7, 3.0, 4.5 | miscellaneous fill, silt | 0.7, 8.5 |

| 8 | miscellaneous fill, clay | 0.6, 4.0 | miscellaneous fill | 4.6 |

| 9 | miscellaneous fill, plain fill, clay | 0.5, 1.0, 11.9 | miscellaneous fill, silt | 0.5, 0.5 |

| 10 | miscellaneous fill, clay | 1.0, 9.8 | miscellaneous fill | 12.2 |

| 11 | miscellaneous fill, silt, plain fill, clay | 4.1, 11.2, 7.0, 10.0 | miscellaneous fill, silt | 2.8, 25.2 |

| 12 | floury soil, plain fill, mucky soil, clay | 0.5, 6.7, 1.2, 8.6 | plain fill, silt | 0.5, 16.5 |

| 13 | silt, clay | 0.4, 6.6 | plain fill | 7 |

| 14 | silt, clay | 0.4, 10.4 | plain fill | 10.9 |

| 15 | miscellaneous fill, silt, plain fill, clay | 0.7, 1.9, 3.4, 24.0 | miscellaneous fill, plain fill, silt, silt | 0.7, 1.9, 3.4, 24 |

| 16 | miscellaneous fill soil, plain fill soil, old city miscellaneous fill soil, clay | 1.2, 2.6, 6.5, 13.0 | miscellaneous fill, plain fill, old city miscellaneous fill soil | 1.2, 2.6, 22.5 |

| 17 | miscellaneous fill soil, plain fill soil, clay | 0.5, 2.8, 10.2 | miscellaneous fill, plain fill | 0.5, 13 |

| 18 | miscellaneous fill soil, plain fill soil, clay | 2.1, 0.8, 12.9 | miscellaneous fill, silt, clay | 2.1, 0.8, 12.9 |

| Stratum Type Accuracy | Average Sequence Similarity | Stratum Thickness Accuracy |

|---|---|---|

| 30.78% | 32.27% | 64.52% |

| Test Borehole Data | Three-Dimensional Geological Model | |

|---|---|---|

| Average reliability | 0.6293 | 0.3205 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Ouyang, J.; Ming, W.; Zhang, G.; Du, Z.; Liu, Z. A Stratigraphic Prediction Method Based on Machine Learning. Appl. Sci. 2019, 9, 3553. https://doi.org/10.3390/app9173553

Zhou C, Ouyang J, Ming W, Zhang G, Du Z, Liu Z. A Stratigraphic Prediction Method Based on Machine Learning. Applied Sciences. 2019; 9(17):3553. https://doi.org/10.3390/app9173553

Chicago/Turabian StyleZhou, Cuiying, Jinwu Ouyang, Weihua Ming, Guohao Zhang, Zichun Du, and Zhen Liu. 2019. "A Stratigraphic Prediction Method Based on Machine Learning" Applied Sciences 9, no. 17: 3553. https://doi.org/10.3390/app9173553