Investigation on Smoke Flow in Stairwells induced by an Adjacent Compartment Fire in High Rise Buildings

Abstract

1. Introduction

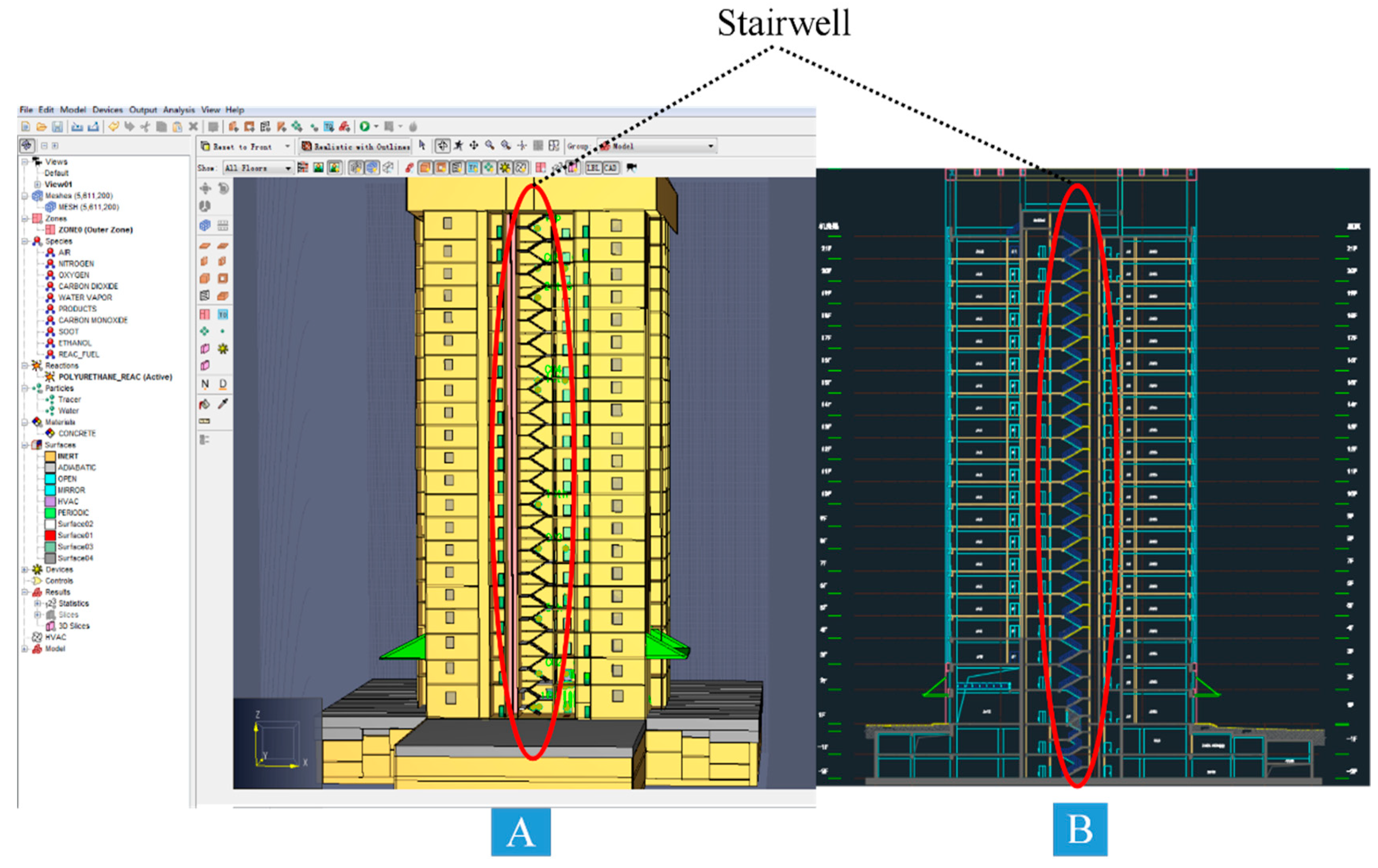

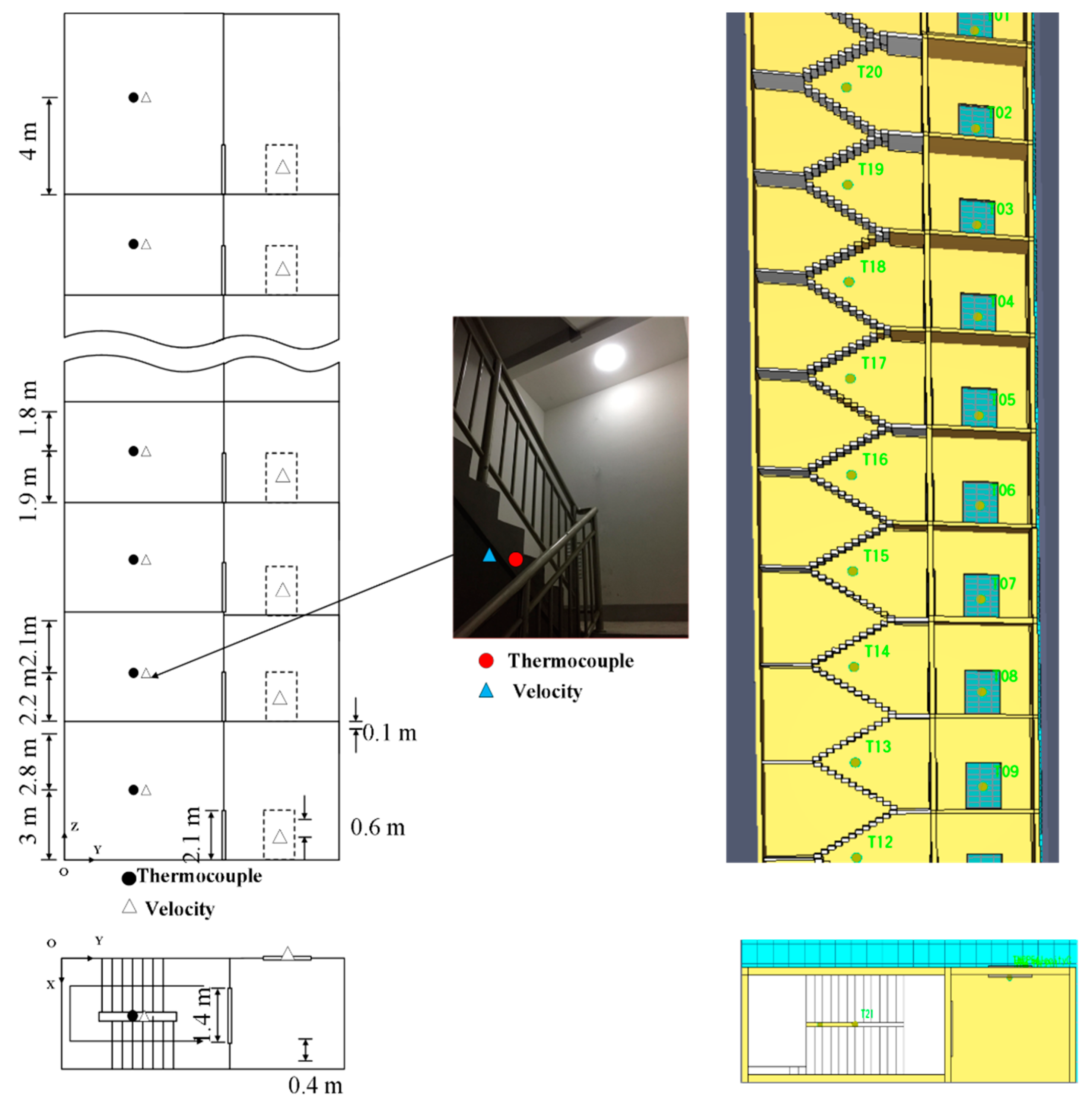

2. Simulation Setup

Simplified Model and Configurations

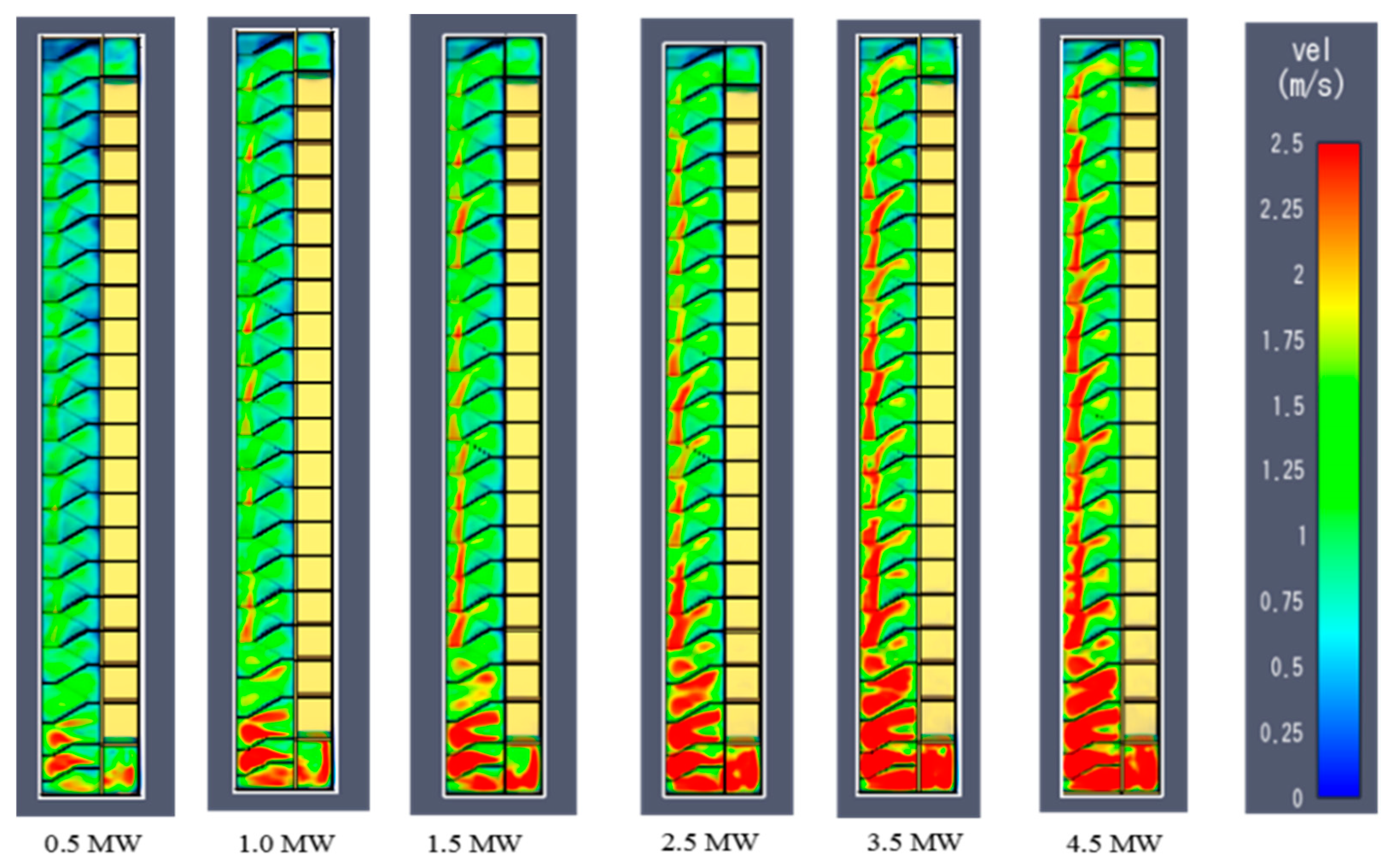

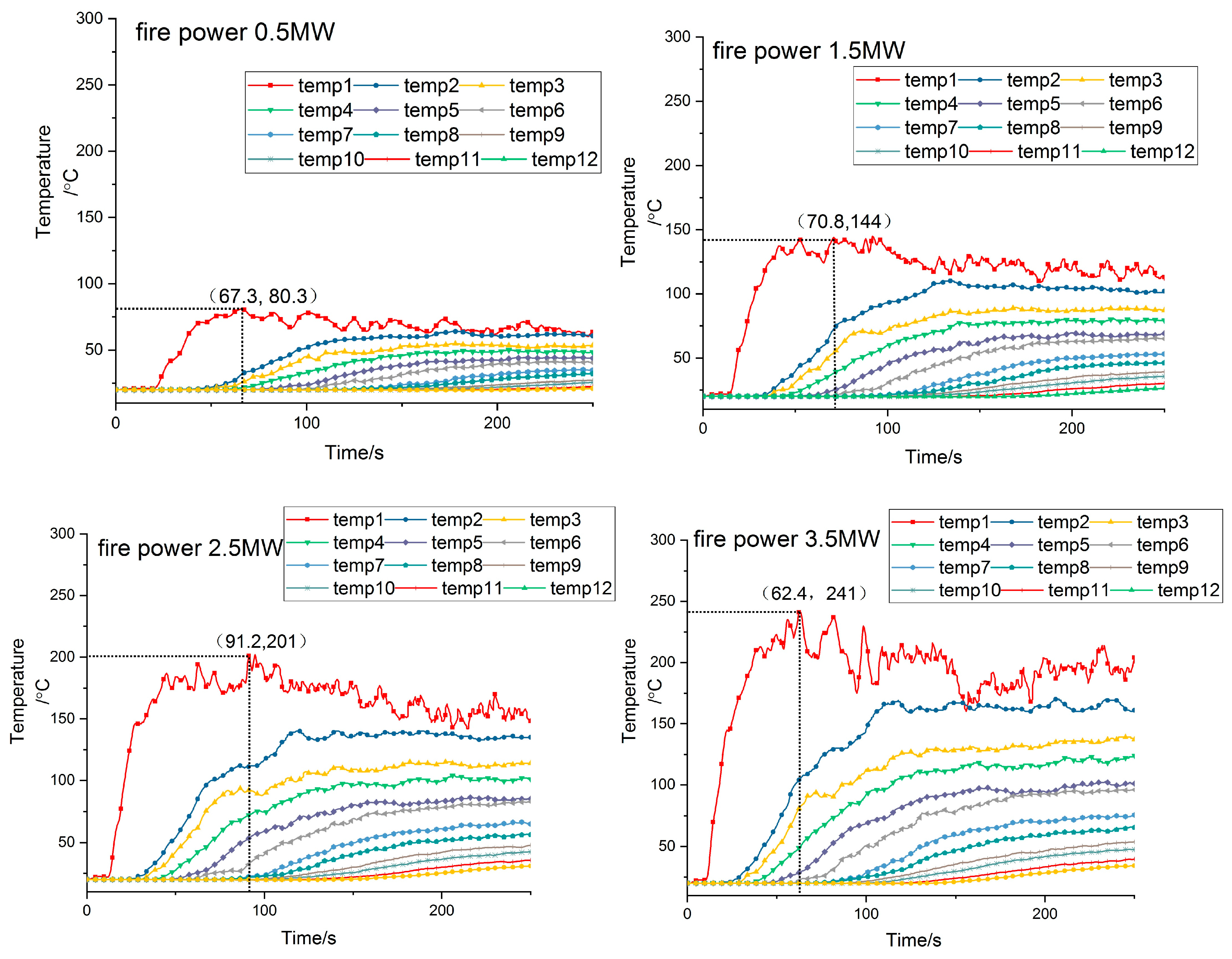

3. Results and Discussion

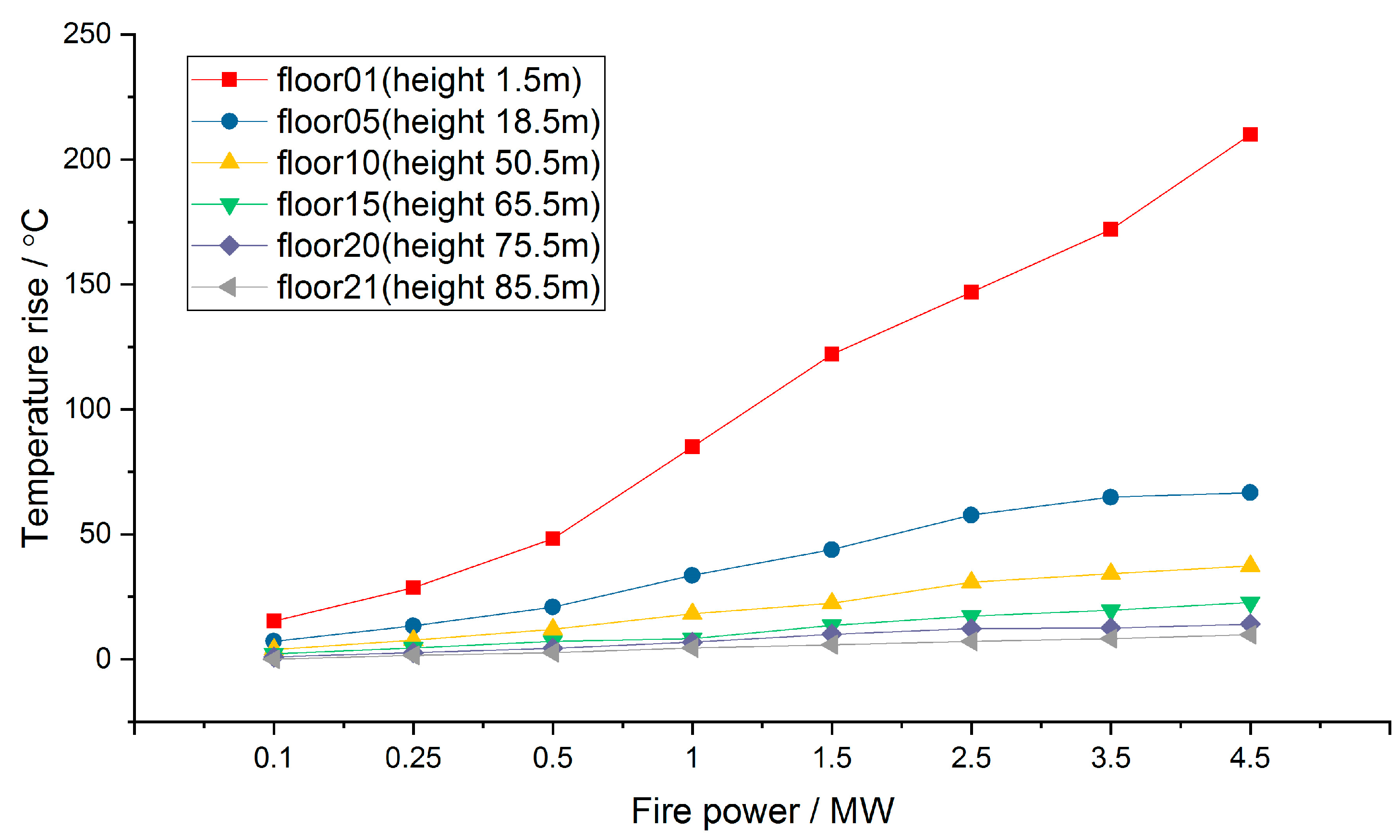

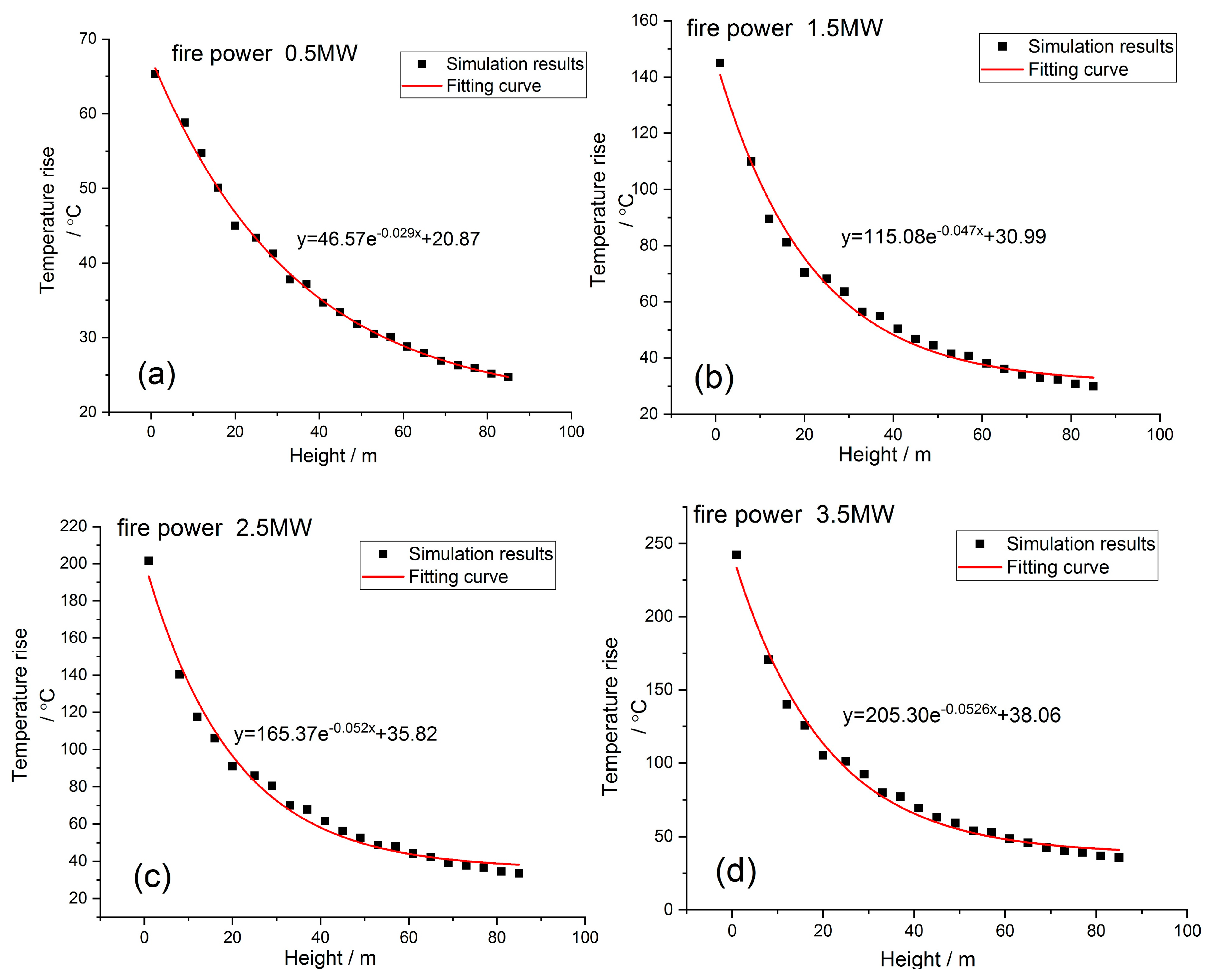

3.1. Effects of Fire Size

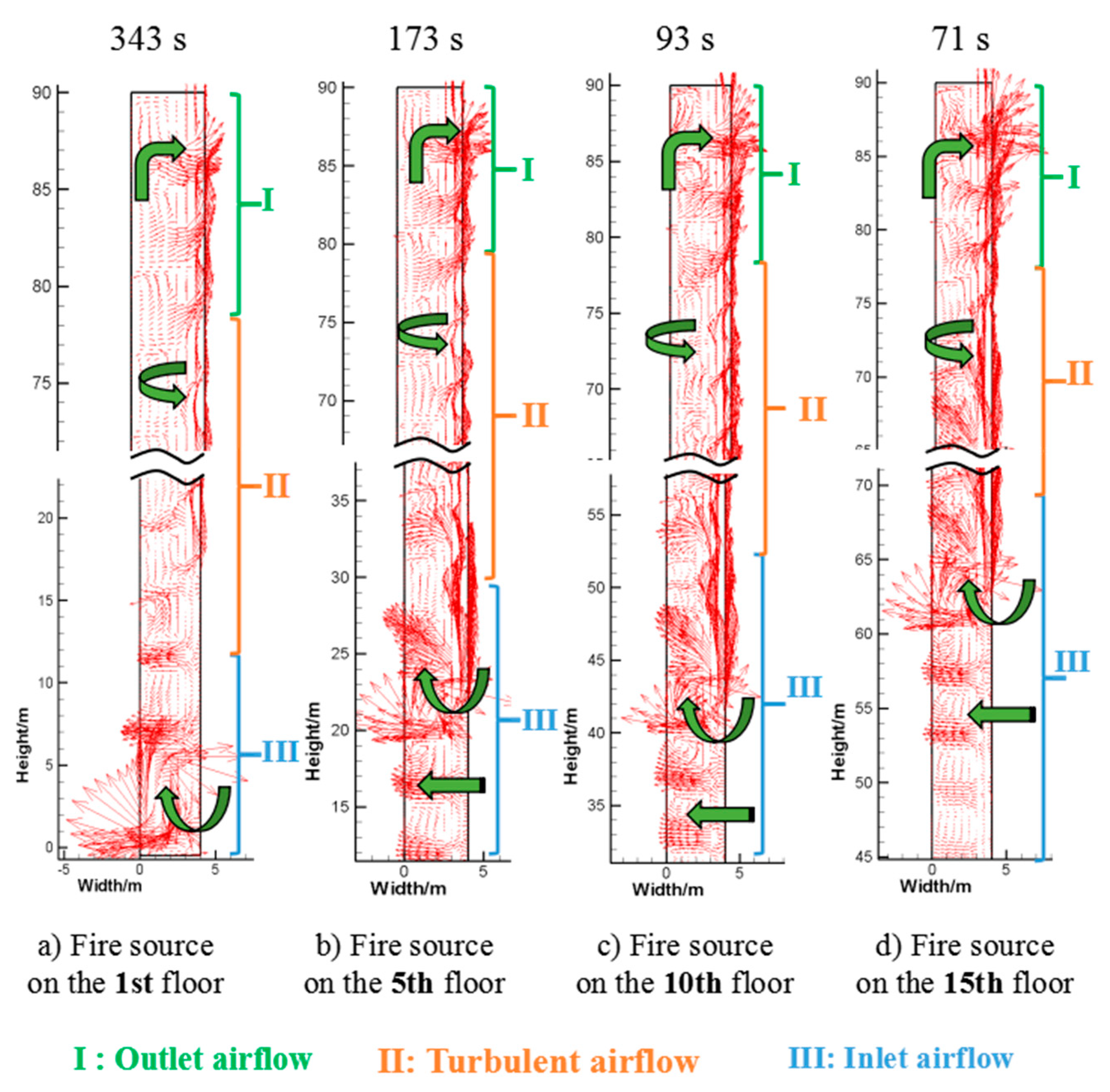

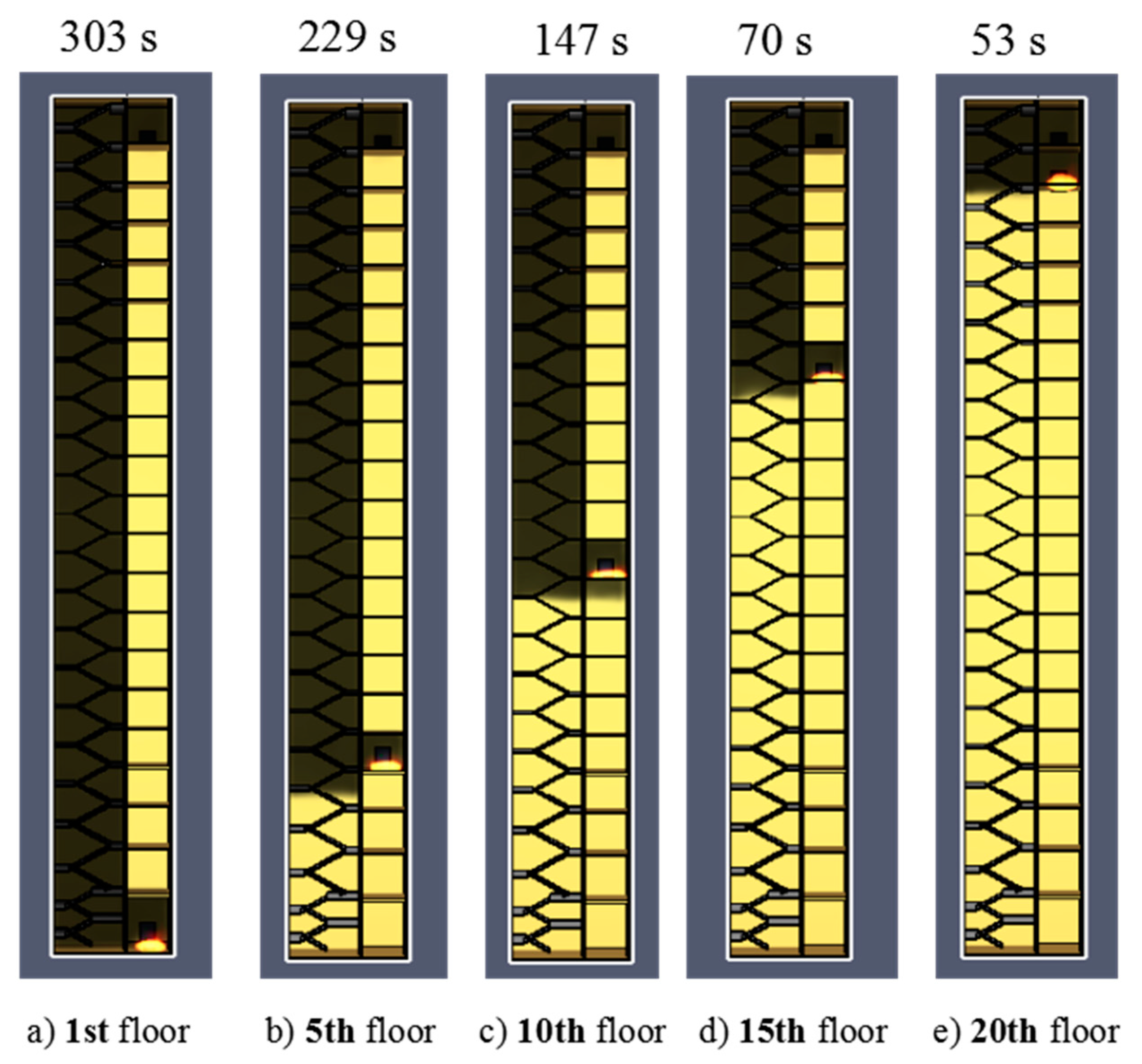

3.2. Effects of Fire Locations

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ahn, C.S.; Bang, B.H.; Kim, M.W.; James, S.C.; Yarin, A.L.; Yoon, S.S. Theoretical, numerical, and experimental investigation of smoke dynamics in high-rise buildings. Int. J. Heat Mass Transf. 2019, 135, 604–613. [Google Scholar] [CrossRef]

- Qi, D.; Wang, L.; Zmeureanu, R. An analytical model of heat and mass transfer through non-adiabatic high-rise shafts during fires. Int. J. Heat Mass Transf. 2014, 72, 585–594. [Google Scholar] [CrossRef]

- Li, M.; Gao, Z.; Ji, J.; Li, K. Modeling of positive pressure ventilation to prevent smoke spreading in sprinklered high-rise buildings. Fire Saf. J. 2018, 95, 87–100. [Google Scholar] [CrossRef]

- Seidu, R.; Robinson, H.; Young, B. Cost of Fire in Highrise Building. Presented at International Conference on Professionalism and Ethics in Construction, London, UK, 21–22 November 2018. [Google Scholar]

- Salankar, S.; Tauseef, S.M.; Sharma, R.K. Need for Better High-Rise Building Evacuation Practices. In Advances in Fire and Process Safety; Springer: Singapore, 2018; pp. 191–205. [Google Scholar]

- Boroń, S.; Węgrzyński, W.; Kubica, P.; Czarnecki, L. Numerical Modelling of the Fire Extinguishing Gas Retention in Small Compartments. Appl. Sci. 2019, 9, 663. [Google Scholar] [CrossRef]

- Alarie, Y. Toxicity of fire smoke. Crit. Rev. Toxicol. 2002, 32, 259–289. [Google Scholar] [CrossRef]

- Giebułtowicz, J.; Rużycka, M.; Wroczyński, P.; Purser, D.A.; Stec, A.A. Analysis of fire deaths in Poland and influence of smoke toxicity. Forensic Sci. Int. 2017, 277, 77–87. [Google Scholar] [CrossRef] [PubMed]

- Alarifi AA, S.; Phylaktou, H.N.; Andrews, G.E. What kills people in a fire? heat or smoke? In Proceedings of the 9th SSC, Birmingham, UK, 13–14 February 2016. [Google Scholar]

- Marshall, N.R. The behaviour of hot gases flowing within a staircase. Fire Saf. J. 1985, 9, 245–255. [Google Scholar] [CrossRef]

- Tamura, G.T. Smoke Movement and Control in High-Rise Buildings. 2008. Available online: https://nrc-publications.canada.ca/eng/view/accepted/?id=af1afd4c-f8d6-4daf-8d2b-0aea9bf0089e (accessed on 20 October 2018).

- Chow, W.K.; Fong, N.K.; Cui, E.; Ho, P.L.; Wong, L.T.; Huo, R.; Fan, W.; Li, Y.; Yuan, L. PolyU/USTC Atrium: A full-scale burning facility—Preliminary experiments. J. Appl. Fire Sci. 1999, 8, 229–241. [Google Scholar]

- Cooper, L.Y. Simulating smoke movement through long vertical shafts in zone-type compartment fire models. Fire Saf. J. 1998, 31, 85–99. [Google Scholar] [CrossRef]

- Zukoski, E.E. Review of Flows Driven by Natural Convection in Adiabatic Shaft; NASA, US Department of Commerce, Technology Administration, National Institute of Standards and Technology: Washington, DC, USA, 1995; (19980017476). [Google Scholar]

- Qin, T.X.; Guo, Y.C.; Chan, C.K.; Lau, K.S.; Lin, W.Y. Numerical simulation of fire-induced flow through a stairwell. Build. Environ. 2005, 40, 183–194. [Google Scholar] [CrossRef]

- Gao, Z.; Yuan, X.; Ji, J.; Li, Y.; Yang, L. Influence of stack effect on flame shapes of gas burner fires. Appl. Therm. Eng. 2017, 127, 1574–1581. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Lu, W.Z.; Huo, R.; Feng, R. A new model for determining neutral-plane location in shaft space of a building under fire situation. Build. Environ. 2008, 43, 1101–1108. [Google Scholar] [CrossRef]

- Ji, J.; Li, M.; Gao, Z.H.; Li, Y.F.; Shi, W.X.; Sun, J.H. Experimental investigation of combustion characteristics under different ventilation conditions in a compartment connected to a stairwell. Appl. Therm. Eng. 2016, 101, 390–401. [Google Scholar] [CrossRef]

- Cengel, Y.A. Fluid Mechanics; Tata McGraw-Hill Education: New York, NY, USA, 2010. [Google Scholar]

- Himoto, K.; Tsuchihashi, T.; Tanaka, Y.; Tanaka, T. Modeling the trajectory of window flames with regard to flow attachment to the adjacent wall. Fire Saf. J. 2009, 44, 250–258. [Google Scholar] [CrossRef]

- Ji, J.; Fan, C.G.; Gao, Z.H.; Sun, J.H. Effects of vertical shaft geometry on natural ventilation in urban road tunnel fires. J. Civ. Eng. Manag. 2014, 20, 466–476. [Google Scholar] [CrossRef]

- Fan, C.G.; Ji, J.; Gao, Z.H.; Sun, J.H. Experimental study on transverse smoke temperature distribution in road tunnel fires. Tunn. Undergr. Space Technol. 2013, 37, 89–95. [Google Scholar] [CrossRef]

- Harrison, R.; Spearpoint, M. Physical scale modelling of adhered spill plume entrainment. Fire Saf. J. 2010, 45, 149–158. [Google Scholar] [CrossRef]

- Li, D.; Zhou, T.; Liu, Z.; Wang, J. Transport phenomena of fire-induced smoke flow in a semi-open vertical shaft. Int. J. Numer. Methods Heat Fluid Flow 2018, 28, 2664–2680. [Google Scholar] [CrossRef]

- Jones, K. Density of Concrete, The Physics Factbook, Retrieved 7 January 2015. Available online: https://hypertextbook.com/facts/1999/KatrinaJones.shtml (accessed on 20 October 2018).

- Washer, G.; Fuchs, P.; Graybeal, B. Elastic properties of reactive powder concrete. In Proceedings of the International Symposium on Non-Destrconreteuctive Testing in Civil Engineering (NDT-CE 2003), Berlin, Germany, 16–19 September 2003. [Google Scholar]

- Doroudiani, S.; Omidian, H. Environmental, health and safety concerns of decorative mouldings made of expanded polystyrene in buildings. Build. Environ. 2010, 45, 647–654. [Google Scholar] [CrossRef]

- Xu, Q.; Jin, C.; Griffin, G.; Jiang, Y. Fire safety evaluation of expanded polystyrene foam by multi-scale methods. J. Therm. Anal. Calorim. 2014, 115, 1651–1660. [Google Scholar] [CrossRef]

- An, W.; Jiang, L.; Sun, J.; Liew, K.M. Correlation analysis of sample thickness, heat flux, and cone calorimetry test data of polystyrene foam. J. Therm. Anal. Calorim. 2015, 119, 229–238. [Google Scholar] [CrossRef]

- Wang, S.; Chen, H.; Liu, N. Ignition of expandable polystyrene foam by a hot particle: An experimental and numerical study. J. Hazard. Mater. 2015, 283, 536–543. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Xiao, H.; Zhou, Y.; An, W.; Yan, W.; He, J.; Sun, J. Theoretical and experimental study of width effects on horizontal flame spread over extruded and expanded polystyrene foam surfaces. J. Fire Sci. 2014, 32, 193–209. [Google Scholar] [CrossRef]

- Ji, J.; Li, L.J.; Shi, W.X.; Fan, C.G.; Sun, J.H. Experimental investigation on the rising characteristics of the fire-induced buoyant plume in stairwells. Int. J. Heat Mass Transf. 2013, 64, 193–201. [Google Scholar] [CrossRef]

- Atallah, S.; Allan, D.S. Safe separation distances from liquid fuel fires. Fire Technol. 1971, 7, 47–56. [Google Scholar] [CrossRef]

- Thomas, P.H. Rates of spread of some wind-driven fires. For. Int. J. For. Res. 1971, 44, 155–175. [Google Scholar] [CrossRef]

- Guan, J.; Fang, J.; Zhang, D.; Wang, J.; Zhang, Y. Experiment study of oil tank fire characteristics dependent on the opening of tank top. Procedia Eng. 2013, 62, 932–939. [Google Scholar] [CrossRef]

- You, D.; Wang, X.Z.; Chen, W.J.; Wu, G.X. Numerical Simulation Analysis of Smoke Control and Flow for Large Building Fire. In Applied Mechanics and Materials; Trans Tech Publications China: Beijing, China, 2014; Volume 608, pp. 61–65. [Google Scholar]

- Wang, Y.; Wang, Q.; Sun, J.; He, L.; Liew, K.M. Thermal performance of exposed framing glass façades in fire. Mater. Struct. 2016, 49, 2961–2970. [Google Scholar] [CrossRef]

- Hasemi, Y.; Shigekawa, K. Radiation Tolerance Criterion of People in Big Fire. Bull. Jpn. Assoc. Fire Sci. Eng. 1981, 31, 7–14. [Google Scholar]

- Raj, P.K. A review of the criteria for people exposure to radiant heat flux from fires. J. Hazard. Mater. 2008, 159, 61–71. [Google Scholar] [CrossRef] [PubMed]

- Martin, R.E.; Cushwa, C.T.; Miller, R.L. Fire as a physical factor in wildland management. In Proceedings of the Annual [9th] Tall Timbers Fire Ecology Conference, Tallahassee, FL, USA, 10–11 April 1969; pp. 10–11. [Google Scholar]

- Hadjisophocleous, G.; Jia, Q. Comparison of FDS prediction of smoke movement in a 10-storey building with experimental data. Fire Technol. 2009, 45, 163–177. [Google Scholar] [CrossRef]

- Zhao, G.; Beji, T.; Merci, B. Study of FDS simulations of buoyant fire-induced smoke movement in a high-rise building stairwell. Fire Saf. J. 2017, 91, 276–283. [Google Scholar] [CrossRef]

- Byström, A.; Cheng, X.; Wickström, U.; Veljkovic, M. Full-scale experimental and numerical studies on compartment fire under low ambient temperature. Build. Environ. 2012, 51, 255–262. [Google Scholar] [CrossRef]

- Peppes, A.A.; Santamouris, M.; Asimakopoulos, D.N. Experimental and numerical study of buoyancy-driven stairwell flow in a three storey building. Build. Environ. 2002, 37, 497–506. [Google Scholar] [CrossRef]

| Floor | Room Height (m) | Size of Stairwell (m) (Length × Width × Height) | Size of Compartment Room (m) (Length × Width × Height) |

|---|---|---|---|

| 1 | 6.0 | 6.75 × 2.9 × 6 | 4.2 × 2.9 × 6 |

| 2–3 | 4.5 | 6.75 × 2.9 × 4.5 | 4.2 × 2.9 × 4.5 |

| 4–20 | 3.9 | 6.75 × 2.9 × 3.9 | 4.2 × 2.9 × 3.9 |

| 21 | 8.0 | 6.75 × 2.9 × 8 | 4.2 × 2.9 × 8 |

| Subject | Content | |

|---|---|---|

| The type of action | Polyurethane reaction (C = 1.0, H = 1.7, O = 0.3, N = 0.08, CO Yield = 0.042, Soot Yield = 0.12) | |

| Simulation time | 600 s | |

| Initial conditions | Ambient temperature | 20.0 °C |

| Ambient pressure | 1.01325 Pa | |

| Relative humidity | 40.0% | |

| Group | Test | Fire HRR (MW) | Atria Fire Location | Opening Locations | |

|---|---|---|---|---|---|

| I. Varied fire size | 1 | 0.1 | 1 F | 1F, 21F | |

| 2 | 0.25 | 1 F | 1F, 21F | ||

| 3 | 0.5 | 1 F | 1F, 21F | ||

| 4 | 1 | 1 F | 1F, 21F | ||

| 5 | 1.5 | 1 F | 1F, 21F | ||

| 6 | 2.5 | 1 F | 1F, 21F | ||

| 7 | 3.5 | 1 F | 1F,21F | ||

| II. Varied fire location | Uniform opening in side direction | 1 | 1.5 | 1 F | All open |

| 2 | 1.5 | 5 F | All open | ||

| 3 | 1.5 | 10 F | All open | ||

| 4 | 1.5 | 15 F | All open | ||

| Non-uniform opening in side direction | 5 | 1.5 | 1 F | 1F, 21F | |

| 6 | 1.5 | 5 F | 5F, 21F | ||

| 7 | 1.5 | 10 F | 8F, 21F | ||

| 8 | 1.5 | 15 F | 15F, 21F | ||

| 9 | 1.5 | 19 F | 19F, 21F | ||

| Figure | Fire HRR (MW) | Coefficient A | Coefficient B | Coefficient C | Correlation Coefficient R |

|---|---|---|---|---|---|

| Figure 7a | 0.5 | 46.57 | 0.029 | 20.87 | 0.9972 |

| Figure 7b | 1.5 | 115.08 | 0.047 | 30.99 | 0.9893 |

| Figure 7c | 2.5 | 165.37 | 0.052 | 35.82 | 0.9879 |

| Figure 7d | 3.5 | 205.30 | 0.053 | 38.06 | 0.9896 |

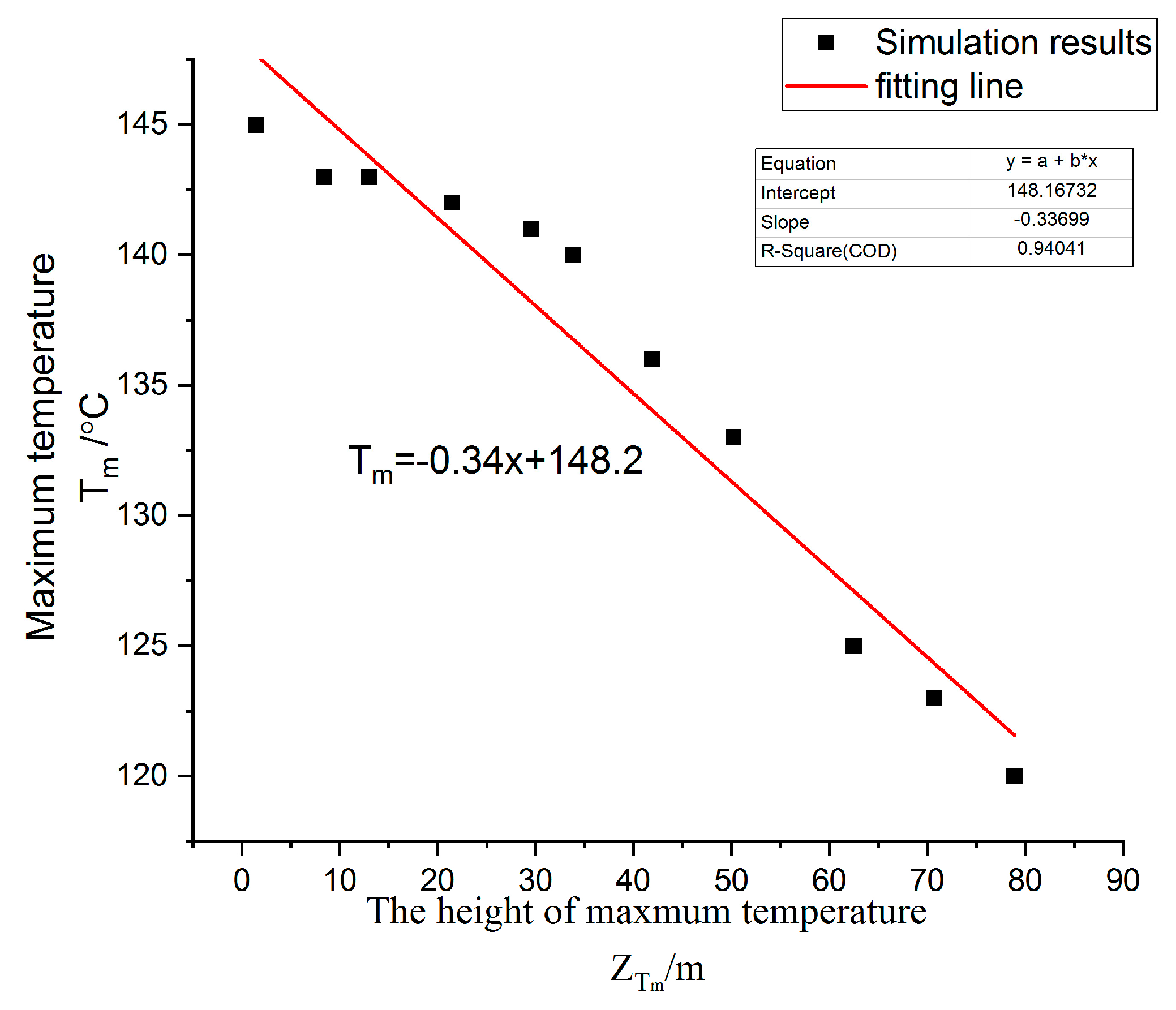

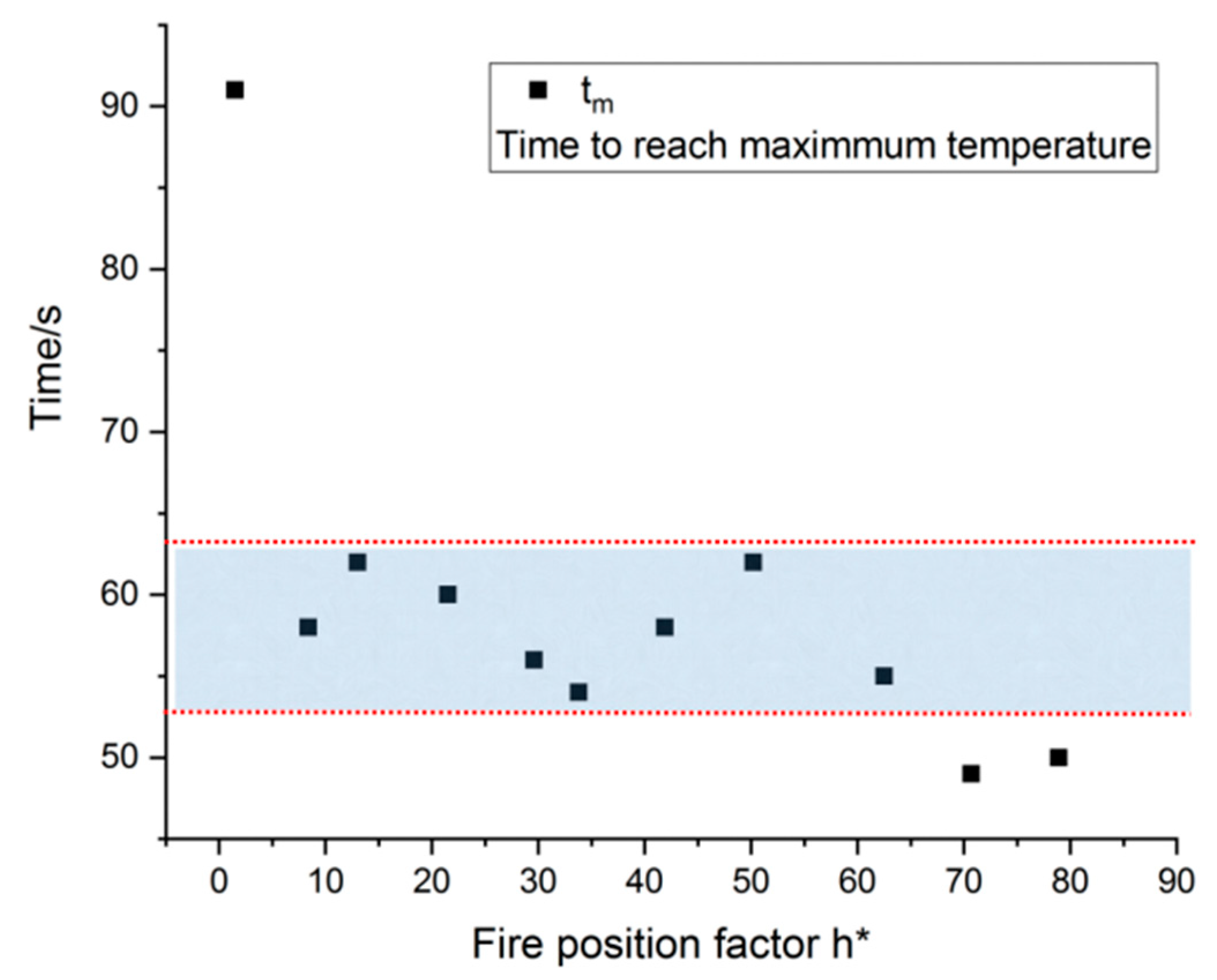

| Test | Fire Location h (m) | Fire Location Factor h* | Maximum Temperature of Measuring Points Tm (°C) | Time Required to Reach Maximum Temperature tm (s) | Height of Maximum Temperature ZTm (m) |

|---|---|---|---|---|---|

| 1 | 0.2 | 0.002 | 145 | 91 | 1.5 |

| 2 | 6.0 | 0.067 | 143 | 58 | 8.4 |

| 3 | 10.8 | 0.121 | 143 | 62 | 13.0 |

| 4 | 19.5 | 0.218 | 142 | 60 | 21.5 |

| 5 | 27.6 | 0.309 | 141 | 56 | 29.6 |

| 6 | 31.7 | 0.350 | 140 | 54 | 33.8 |

| 7 | 40.0 | 0.448 | 136 | 58 | 41.9 |

| 8 | 48.1 | 0.539 | 133 | 62 | 50.2 |

| 9 | 60.5 | 0.677 | 125 | 55 | 62.5 |

| 10 | 68.6 | 0.768 | 123 | 49 | 70.7 |

| 11 | 76.8 | 0.860 | 120 | 50 | 78.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Weng, J.; Zhou, T.; Ouyang, D.; Chen, Q.; Wei, R.; Wang, J. Investigation on Smoke Flow in Stairwells induced by an Adjacent Compartment Fire in High Rise Buildings. Appl. Sci. 2019, 9, 1431. https://doi.org/10.3390/app9071431

Zhang J, Weng J, Zhou T, Ouyang D, Chen Q, Wei R, Wang J. Investigation on Smoke Flow in Stairwells induced by an Adjacent Compartment Fire in High Rise Buildings. Applied Sciences. 2019; 9(7):1431. https://doi.org/10.3390/app9071431

Chicago/Turabian StyleZhang, Jun, Jingwen Weng, Tiannian Zhou, Dongxu Ouyang, Qinpei Chen, Ruichao Wei, and Jian Wang. 2019. "Investigation on Smoke Flow in Stairwells induced by an Adjacent Compartment Fire in High Rise Buildings" Applied Sciences 9, no. 7: 1431. https://doi.org/10.3390/app9071431

APA StyleZhang, J., Weng, J., Zhou, T., Ouyang, D., Chen, Q., Wei, R., & Wang, J. (2019). Investigation on Smoke Flow in Stairwells induced by an Adjacent Compartment Fire in High Rise Buildings. Applied Sciences, 9(7), 1431. https://doi.org/10.3390/app9071431