Enhancing Wheat Sprout Attributes Using “Intensification of Vaporization by Decompression to the Vacuum”, an Innovative Drying–Texturizing Technology

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Germination Process

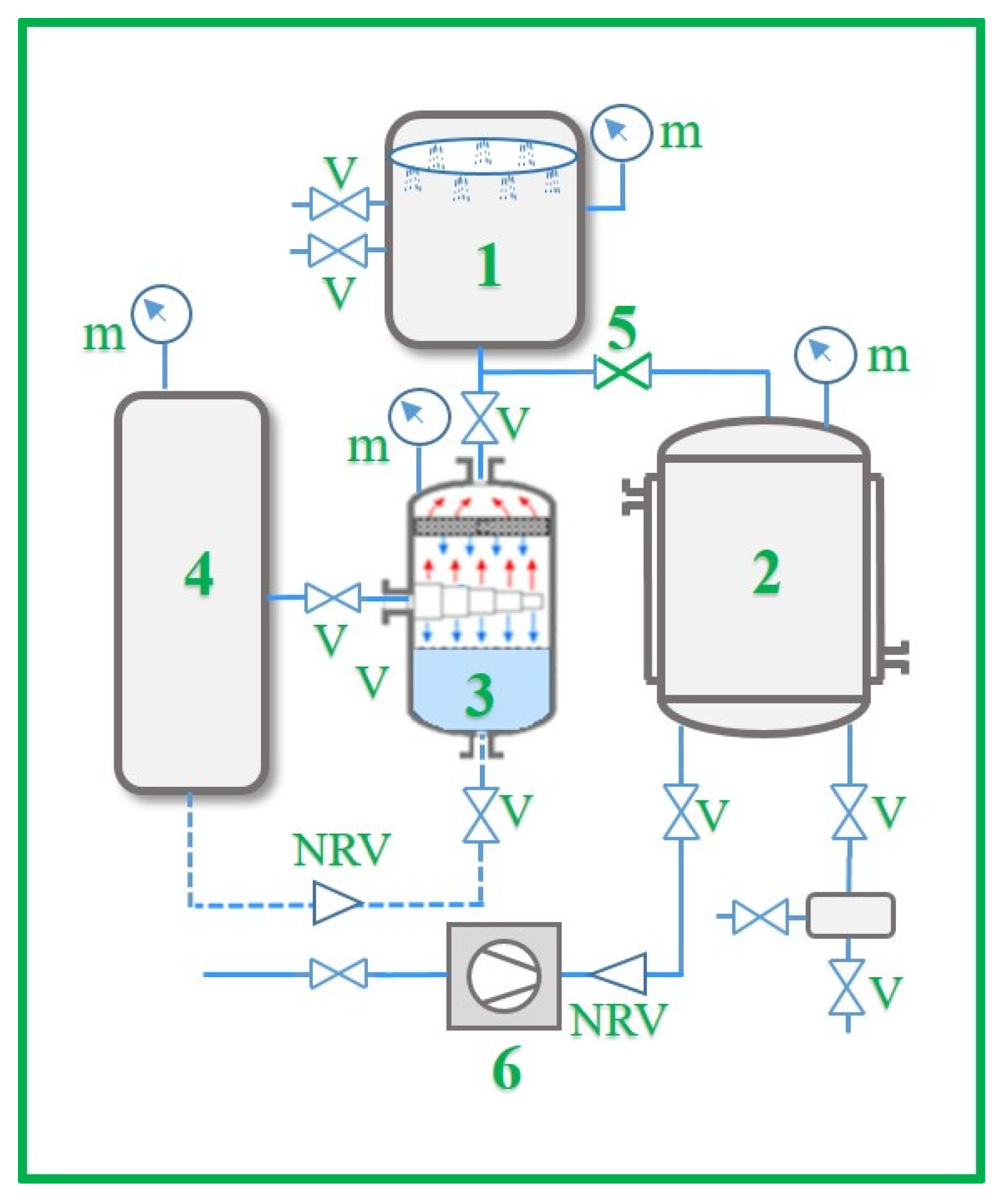

2.3. Hot-Air Drying and IVDV Treatment

- Once the partially dried sprouts are introduced into the treatment chamber, a preliminary vacuum is established, allowing a direct contact between the surface of the product and the water vapor.

- An ultra-rapid steam generator creates a rapid increase in saturated steam pressure (in less than a second).

- The samples are subjected to high pressure P of saturated steam (high temperature) for a short time t (few seconds), to the point at which the product reaches the thermal and rheological stages required for its expansion.

- During this phase, a sudden drop in pressure towards vacuum induces a fast evaporation of a part of the residual water inside the product. Within the product, this induces mechanical stresses of viscoelastic behavior, leading to its expansion and giving it a porous structure. It also leads to a very rapid cooling of the product, which is accompanied by a simultaneous injection of atmospheric (ambient) air, while maintaining the vacuum. This considerably limits the thermal degradation of the product and makes it possible to avoid shrinkage by freezing it in its expanded state.

- A return to atmospheric pressure is ensured before opening the treatment chamber and withdrawing the expanded product.

2.4. RSM Experimental Design

2.5. Nutritional and Textural Analysis

- mMS, the mass of dry matter, is obtained by the determination of the initial water content after incubating the samples in triplicate in a ventilated oven at 105 °C for 24 h.

- mw, the mass of water, is equal to the mass of the product at the time “t” minus the mass of dry matter (mMS).

3. Results and Discussion

3.1. Response Parameters

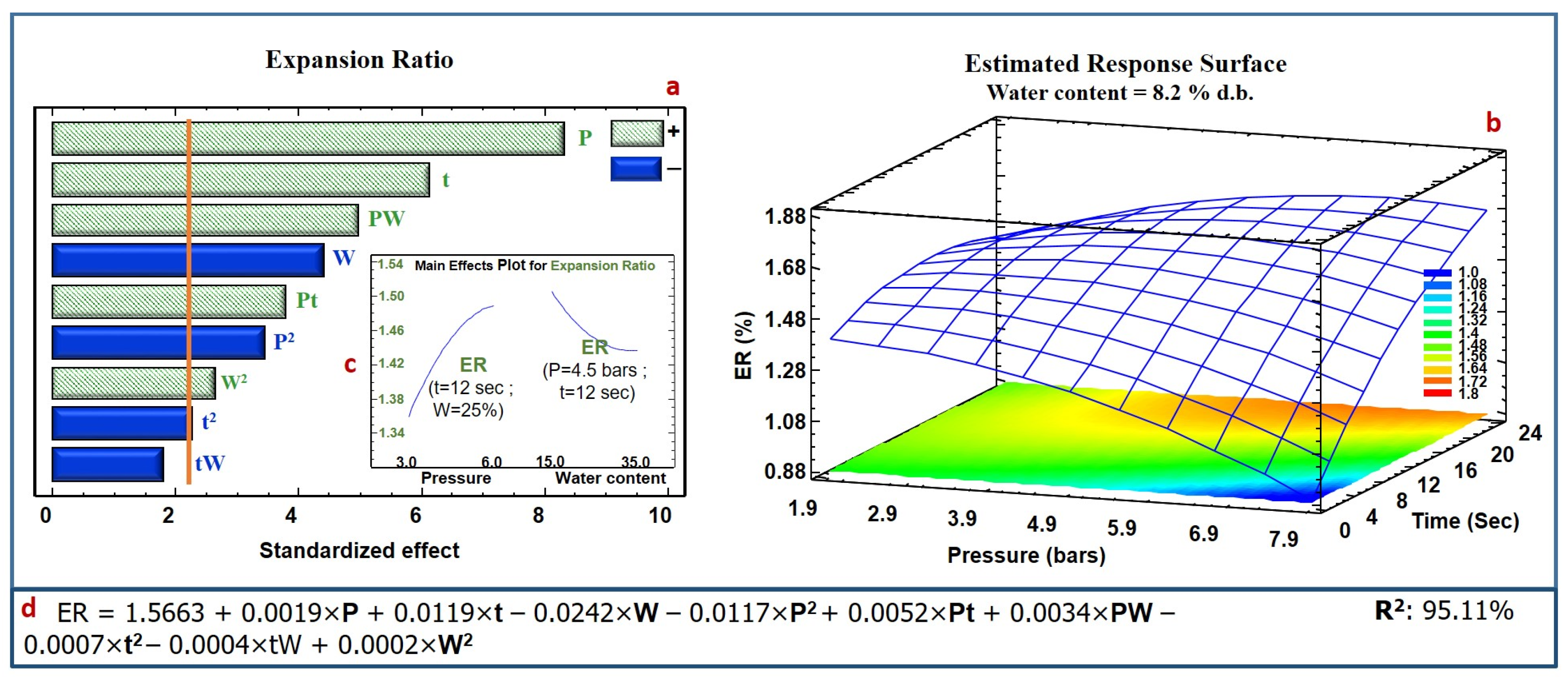

3.1.1. Expansion Ratio

3.1.2. Vitamins

3.1.3. Crude Proteins and Lipids

3.2. Effects of Factors on Different Responses

3.2.1. Effect of Saturated Steam Pressure (P)

3.2.2. Effect of Initial Water Content (W)

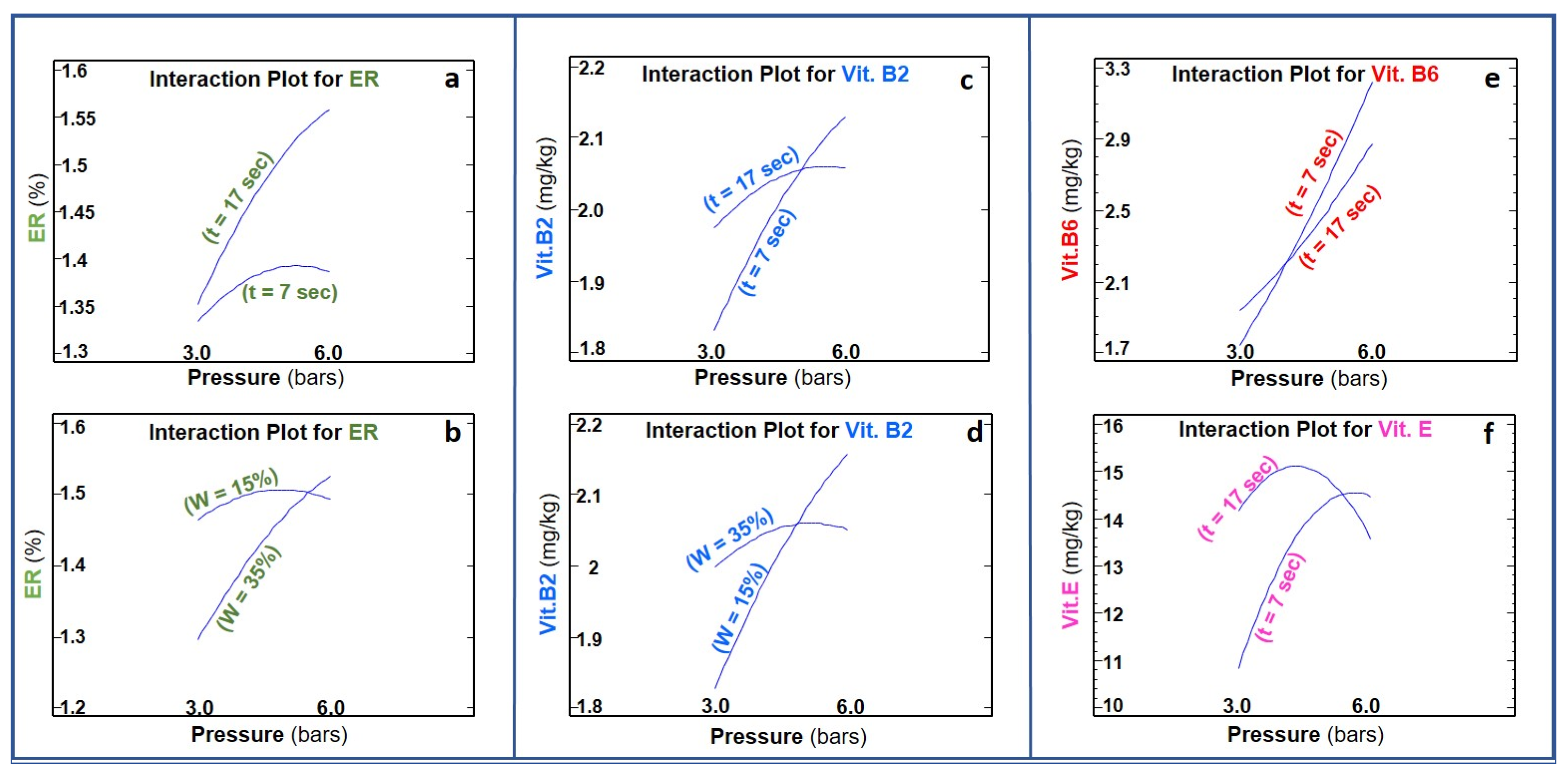

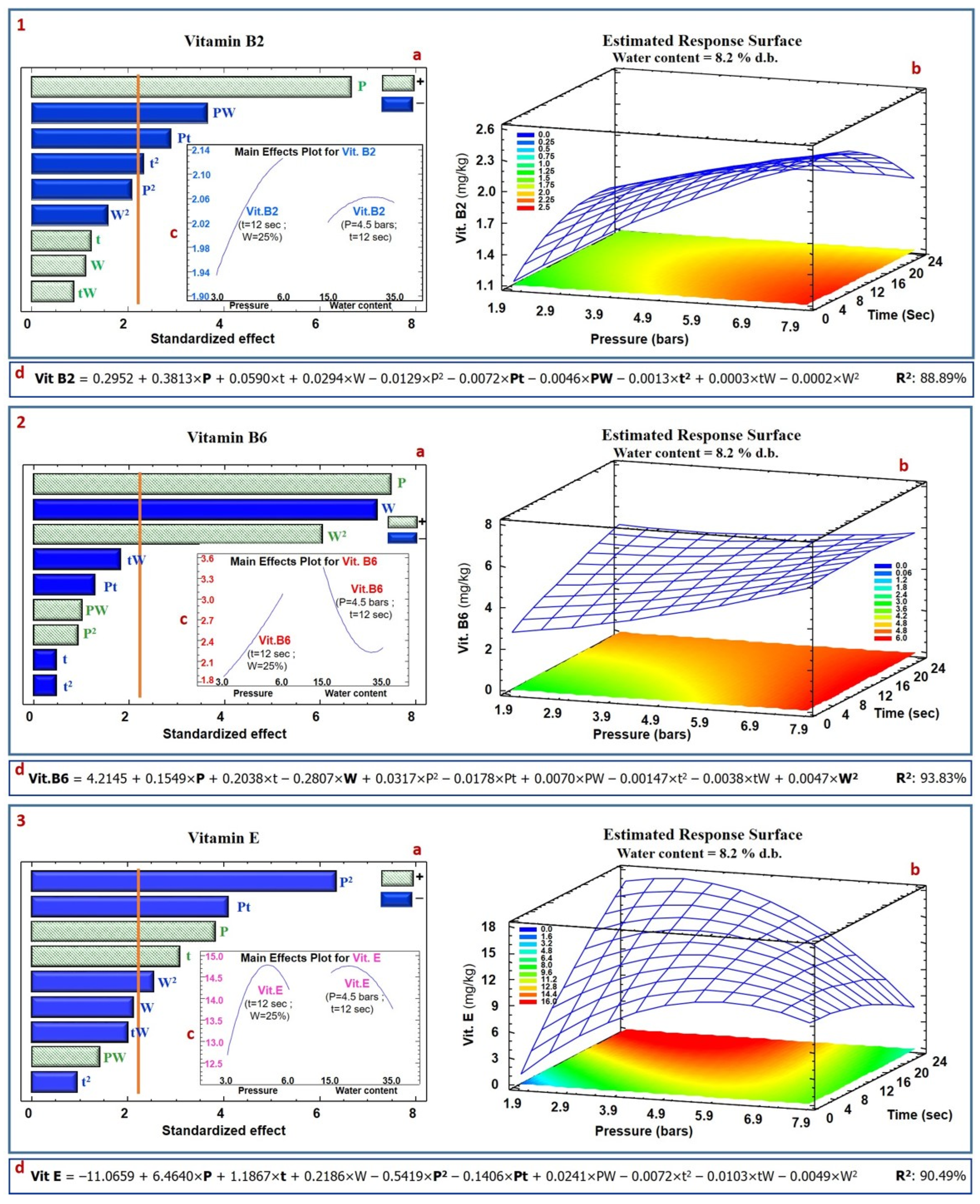

- For vitamin B2 (Figure 5(1)), W had no effect, with levels ranging only between 2.02 and 2.05 mg/kg.

- For vitamin B6, levels decreased from 3.46 to 2.30 mg/kg as water content increased from 15% to 25% (Figure 5(2)), a trend similar to that of the expansion. Afterwards, the levels of vitamin B6 stabilized, proving the positive quadratic effect of W.

- For vitamin E (Figure 5(3)), levels were initially stable, at around 14.6 mg/kg (for W between 15 and 28%), but decreased to 13.7 mg/kg as W reached 35%, correlating with a decrease in expansion. This reflected the negative quadratic effect of W.

3.2.3. Effect of Processing Time (t)

3.2.4. Effects of Significant Interactions

- Effect of Pressure and Time Interaction (Pt)

- Effect of Pressure and Water Content Interaction (PW)

3.3. Optimization and Model Validation

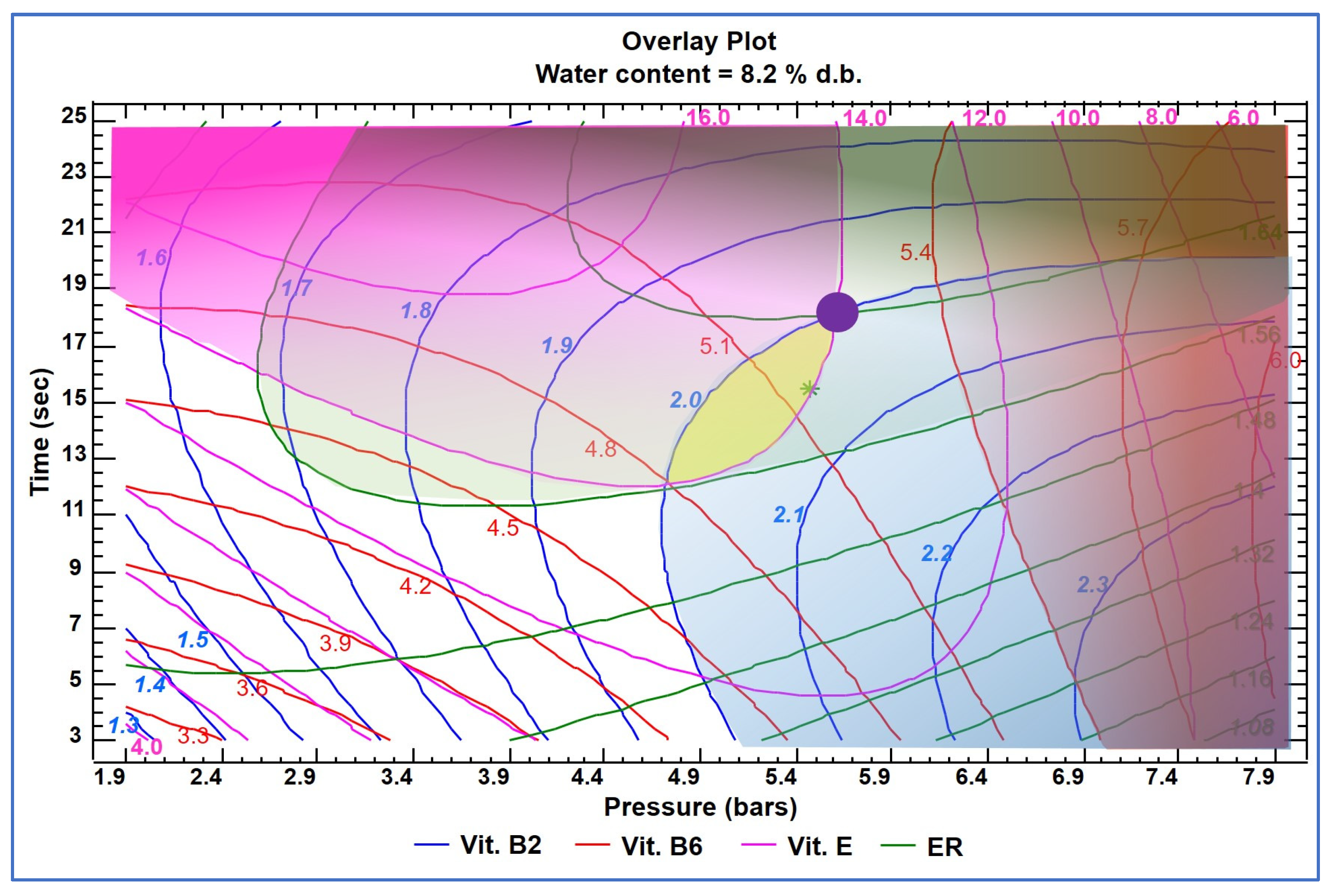

- Optimization: The examination of results allowed us to define various processing conditions tailored to the particular response or responses to be enhanced. In single-response optimization, the objective was to focus on one particular response, enabling the selection of the best operational conditions for each response variable. Table 4, provided below, summarizes the optimal responses recommended by the Statgraphics processing software for each factor, along with the values of the related parameters.

- Model validation: To validate the model defined by the software, three repetitions of the IVDV treatment were conducted under conditions of total multiple optimization (Table 4). The values of various responses were then compared to those predicted by the model. Table 5 compiles the predicted results, experimental mean values, and the absolute error for each of the responses studied. Given that the predicted and observed values varied within the margin of the average absolute error, we can conclude that the defined model is consistent with the experimental results, and the equations effectively model the process.

3.4. Drying Kinetics

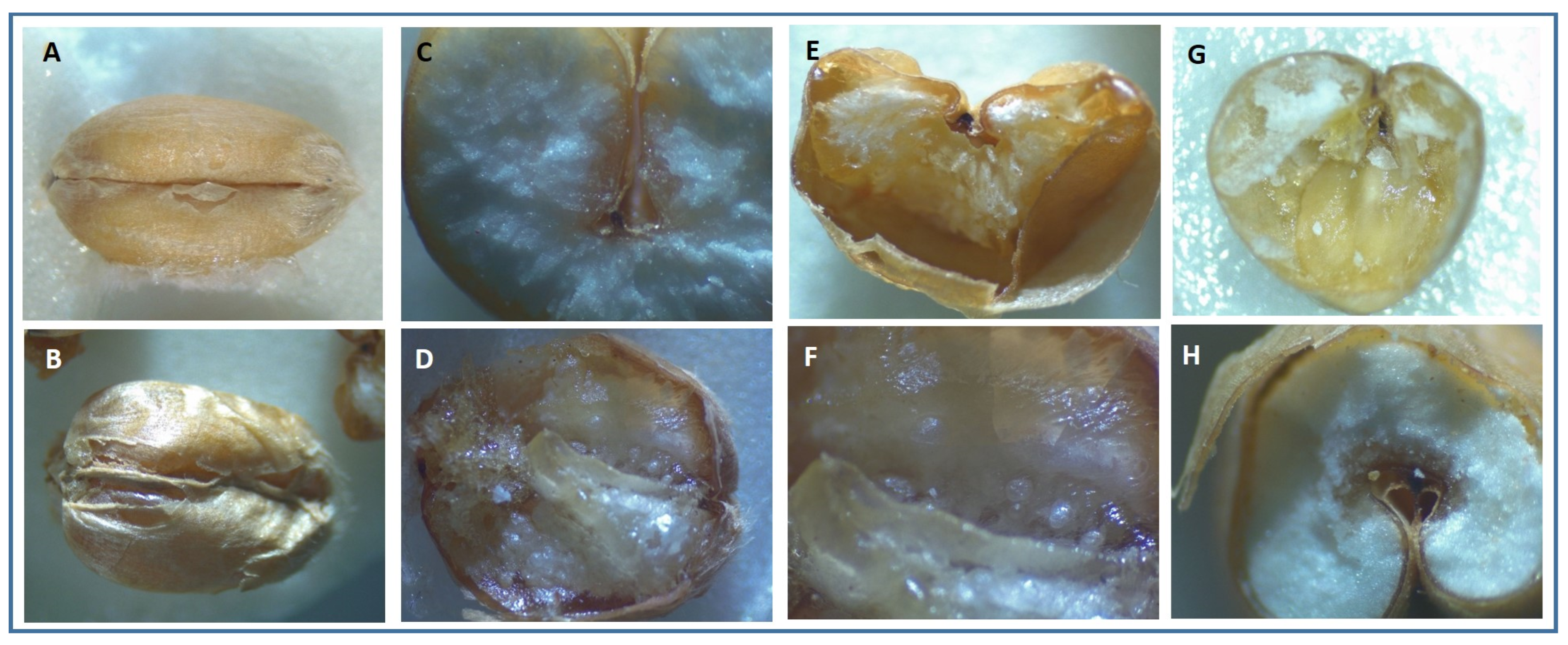

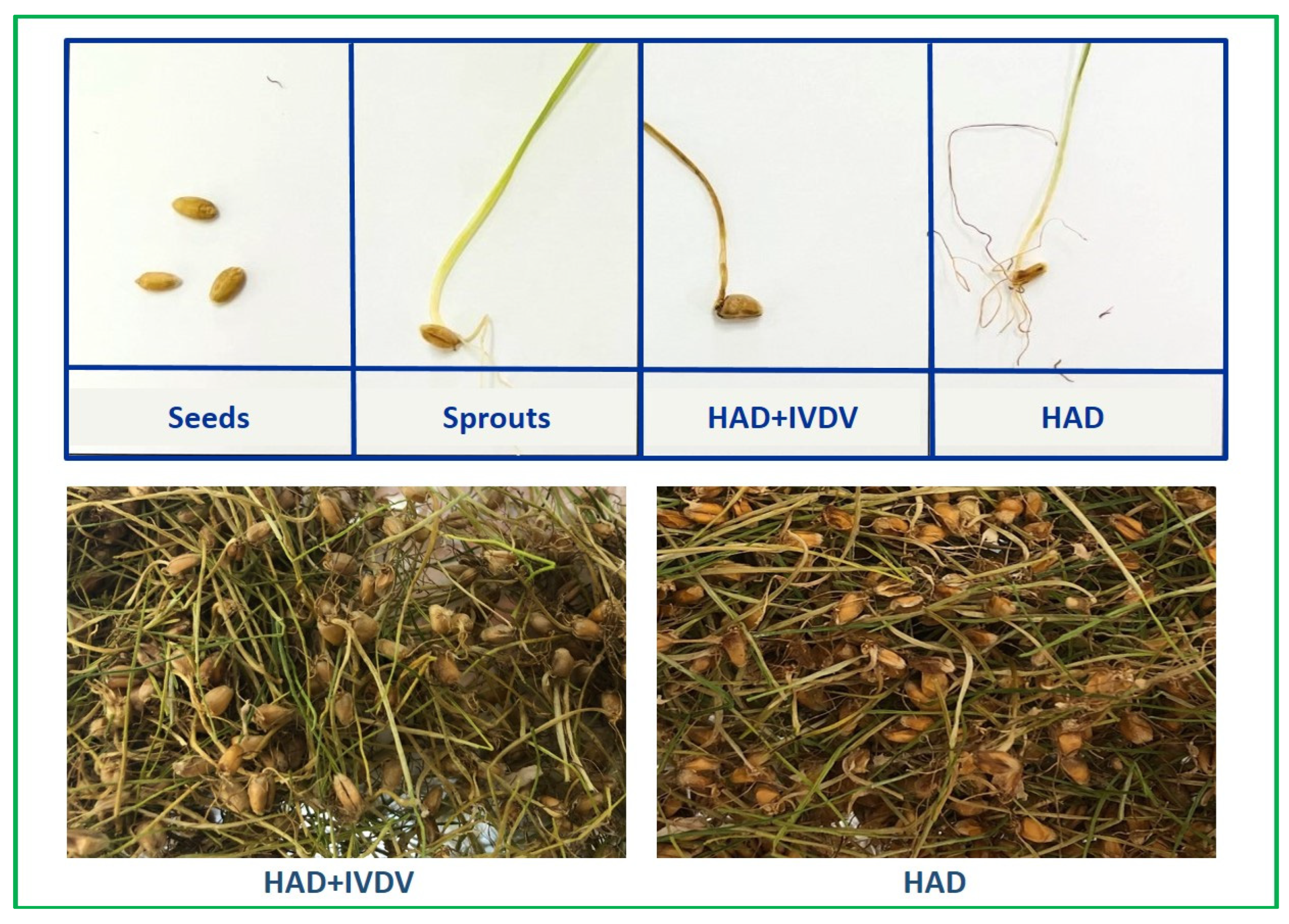

3.5. Nutritional and Aspect Comparison of the Treatment Effect on Wheat Sprouts

4. Conclusions

5. Patent

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Technavio. Packaged Sprouts Market Research Report, Size, Growth, Trends, Opportunity Analysis, Industry Forecast—2022–2026. Available online: https://www.technavio.com/report/packaged-sprouts-market-industry-analysis (accessed on 15 February 2024).

- Global Industry Analysts. Worldwide Pre-Packaged Greens Sector Analysis. 2024. Available online: https://www.reportlinker.com/p05957628/Global-Packaged-Sprouts-Industry.html?utm_source=GNW (accessed on 15 February 2024).

- Lemmens, E.; Moroni, A.V.; Pagand, J.; Heirbaut, P.; Ritala, A.; Karlen, Y.; Kim-Anne, L.; Van den Broeck, H.C.; Brouns, F.J.P.H.; De Brier, N.; et al. Impact of Cereal Seed Sprouting on Its Nutritional and Technological Properties: A Critical Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 305–328. [Google Scholar] [CrossRef] [PubMed]

- Marton, M.; Mandoki, Z.; Csapo-Kiss, Z.; Csapo, J. The Role of Sprouts in Human Nutrition. A Review. Aliment. Hung. Univ. Transylvania 2010, 3, 81–117. [Google Scholar]

- Falcinelli, B.; Famiani, F.; Paoletti, A.; D’egidio, S.; Stagnari, F.; Galieni, A.; Benincasa, P. Phenolic Compounds and Antioxidant Activity of Sprouts from Seeds of Citrus Species. Agriculture 2020, 10, 33. [Google Scholar] [CrossRef]

- Donkor, O.N.; Stojanovska, L.; Ginn, P.; Ashton, J.; Vasiljevic, T. Germinated Grains—Sources of Bioactive Compounds. Food Chem. 2012, 135, 950–959. [Google Scholar] [CrossRef] [PubMed]

- Penãs, E.; Martínez-Villaluenga, C. Advances in Production, Properties and Applications of Sprouted Seeds. Foods 2020, 9, 790. [Google Scholar] [CrossRef] [PubMed]

- Curtis, B.C. Wheat in the World. In Bread Wheat Improvement and Production, Plant Production and Protection Series 30; FAO: Roma, Italy, 2002; pp. 1–18. [Google Scholar]

- Kim, M.; Park, J.; Kim, K.M.; Kim, Y.; Kang, C.S.; Son, J.; Ko, J.; Kim, K.H. Low-Temperature Effects on the Growth and Phytochemical Properties of Wheat Sprouts. Agriculture 2022, 12, 745. [Google Scholar] [CrossRef]

- Koehler, P.; Wieser, H. Chemistry of Cereal Grains. In Handbook on Sourdough Biotechnology; Gobbetti, M., Gänzle, M., Eds.; Springer: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Plaza, L.; de Ancos, B.; Cano, P.M. Nutritional and Health-Related Compounds in Sprouts and Seeds of Soybean (Glycine max), Wheat (Triticum aestivum L.) and Alfalfa (Medicago sativa) Treated by a New Drying Method. Eur. Food Res. Technol. 2003, 216, 138–144. [Google Scholar] [CrossRef]

- Yang, F.; Basu, T.K.; Ooraikul, B. Studies on Germination Conditions and Antioxidant Contents of Wheat Grain. Int. J. Food Sci. Nutr. 2001, 52, 319–330. [Google Scholar] [CrossRef]

- Van Hung, P.; Hatcher, D.W.; Barker, W. Phenolic Acid Composition of Sprouted Wheats by Ultra-Performance Liquid Chromatography (UPLC) and Their Antioxidant Activities. Food Chem. 2011, 126, 1896–1901. [Google Scholar] [CrossRef]

- Miyahira, R.F.; Antunes, A.E.C. Bacteriological Safety of Sprouts: A Brief Review. Int. J. Food Microbiol. 2021, 352, 109266. [Google Scholar] [CrossRef]

- Cheng, L.; Sun, D.W.; Zhu, Z.; Zhang, Z. Emerging Techniques for Assisting and Accelerating Food Freezing Processes: A Review of Recent Research Progresses. Crit. Rev. Food Sci. Nutr. 2017, 57, 769–781. [Google Scholar] [CrossRef] [PubMed]

- James, C.; Purnell, G.; James, S.J. A Review of Novel and Innovative Food Freezing Technologies. Food Bioprocess Technol. 2015, 8, 1616–1634. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Altunakar, B.; Mejia-Lorio, D.J. Freezing of Fruits and Vegetables: An Agribusiness Alternative for Rural and Semi-Rural Areas; FAO: Roma, Italy, 2005; Available online: https://www.fao.org/3/y5979e/y5979e00.htm (accessed on 15 February 2024).

- Sutariya, S.G.; Sunkesula, V. Food Freezing: Emerging Techniques for Improving Quality and Process Efficiency a Comprehensive Review. In Innovative Food Processing Technologies: A Comprehensive Review; Elsevier: Amsterdam, The Netherlands, 2020; pp. 36–63. [Google Scholar] [CrossRef]

- Marin, M.; Rene, F. Lyophilisation. 2000. Available online: https://www.techniques-ingenieur.fr/base-documentaire/procedes-chimie-bio-agro-th2/operations-unitaires-en-agroalimentaire-42430210/lyophilisation-f3240/#:~:text=La%20lyophilisation%2C%20appel%C3%A9e%20autrefois%20cryodessication,de%20l'eau%20du%20produit (accessed on 15 February 2024).

- Ratti, C. Hot Air and Freeze-Drying of High-Value Foods: A Review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Jribi, S.; Chabbouh, M.; Sassi, K.; Sfayhi, D.; Marzoughi, S.; Amara, H.; Ebbahi, H. Sprouting, a Bioprocess Supporting Food Industry. J. New Sci. 2018, 57, 3725–3737. [Google Scholar]

- Kenghe, R.N.; Yewale, M.V.; Kanawade, V.L. Effect of Different Drying Techniques on Dehydration of Sprouted Moth Bean (Vigna Acontilifolia). Legume Genom. Genet. 2016, 7, 2016. [Google Scholar] [CrossRef]

- Dziki, D.; Gawlik-dziki, U. 4. Processing of Germinated Grains. In Sprouted Grains Nutritional Value, Production and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 9780128115251. [Google Scholar]

- Dziki, D.; Habza-Kowalska, E.; Gawlik-Dziki, U.; Miś, A.; Rózyło, R.; Krzysiak, Z.; Hassoon, W.H. Drying Kinetics, Grinding Characteristics, and Physicochemical Properties of Broccoli Sprouts. Processes 2020, 8, 97. [Google Scholar] [CrossRef]

- Mattioli, S.; Dal Bosco, A.; Castellini, C.; Falcinelli, B.; Sileoni, V.; Marconi, O.; Mancinelli, A.C.; Cotozzolo, E.; Benincasa, P. Effect of Heat- and Freeze-Drying Treatments on Phytochemical Content and Fatty Acid Profile of Alfalfa and Flax Sprouts. J. Sci. Food Agric. 2019, 99, 4029–4035. [Google Scholar] [CrossRef] [PubMed]

- Jribi, S.; Gliguem, H.; Szaloki-Dorko, L.; Naar, Z.; Kheriji, O.; Debbabi, H. Impact of Drying Method on Bioactive Compounds, Functional and Thermal Properties of Durum Wheat (Triticum Durum) Sprouts. Ann. Univ. Dunarea Galati Fascicle VI-Food Technol. 2022, 46, 79–92. [Google Scholar] [CrossRef]

- Hefni, M.; Witthöft, C.M. Effect of Germination and Subsequent Oven-Drying on Folate Content in Different Wheat and Rye Cultivars. J. Cereal Sci. 2012, 56, 374–378. [Google Scholar] [CrossRef]

- Nader, J.; Afif, C.; Louka, N. Expansion of Partially Defatted Peanuts by a New Texturizing Process Called “Intensification of Vaporization by Decompression to the Vacuum” (IVDV). Innov. Food Sci. Emerg. Technol. 2017, 41, 179–187. [Google Scholar] [CrossRef]

- Abi-Khattar, A.M.; Rajha, H.N.; Abdel-Massih, R.M.; Habchi, R.; Maroun, R.G.; Debs, E.; Louka, N. “Intensification of Vaporization by Decompression to the Vacuum” (IVDV), a Novel Technology Applied as a Pretreatment to Improve Polyphenols Extraction from Olive Leaves. Food Chem. 2021, 342, 128236. [Google Scholar] [CrossRef]

- Mrad, R.; Debs, E.; Saliba, R.; Maroun, R.G.; Louka, N. Multiple Optimization of Chemical and Textural Properties of Roasted Expanded Purple Maize Using Response Surface Methodology. J. Cereal Sci. 2014, 60, 397–405. [Google Scholar] [CrossRef]

- Louka, N.; Allaf, K. New Process for Texturizing Partially Dehydrated Biological Products Using Controlled Sudden Decompression to the Vacuum: Application on Potatoes. J. Food Sci. 2002, 67, 3033–3038. [Google Scholar] [CrossRef]

- Mounir, S.; Allaf, T.; Mujumdar, A.S.; Allaf, K. Swell Drying: Coupling Instant Controlled Pressure Drop DIC to Standard Convection Drying Processes to Intensify Transfer Phenomena and Improve Quality—An Overview. Dry. Technol. 2012, 30, 1508–1531. [Google Scholar] [CrossRef]

- Francis, H.; Koubaa, M.; Alrayess, Z.; Maroun, R.G.; Louka, N. Sprouts Use as Functional Foods. Optimization of Germination of Wheat (Triticum aestivum L.), Alfalfa (Medicago sativa L.), and Radish (Raphanus sativus L.) Seeds Based on Their Nutritional Content Evolution. Foods 2022, 11, 1460. [Google Scholar] [CrossRef]

- Louka, N.; Allaf, K. Expansion Ratio and Color Improvement of Dried Vegetables Texturized by a New Process “Controlled Sudden Decompression to the Vacuum”. J. Food Eng. 2004, 65, 233–243. [Google Scholar] [CrossRef]

- Maache-Rezzoug, Z.; Zarguili, I.; Loisel, C.; Doublier, J.L.; Buléon, A. Investigation on Structural and Physicochemical Modifications of Standard Maize, Waxy Maize, Wheat and Potato Starches after DIC Treatment. Carbohydr. Polym. 2011, 86, 328–336. [Google Scholar] [CrossRef]

- Hefni, M.; Witthöft, C.M. Increasing the Folate Content in Egyptian Baladi Bread Using Germinated Wheat Flour. LWT—Food Sci. Technol. 2011, 44, 706–712. [Google Scholar] [CrossRef]

- Świeca, M.; Dziki, D. Improvement in Sprouted Wheat Flour Functionality: Effect of Time, Temperature and Elicitation. Int. J. Food Sci. Technol. 2015, 50, 2135–2142. [Google Scholar] [CrossRef]

| Variable | Low (−1) | Medium (0) | High (+1) |

|---|---|---|---|

| Pressure (bars) | 3 | 4.5 | 6 |

| Processing time (s) | 7 | 12 | 17 |

| Water content (% d.b.) | 15 | 25 | 35 |

| Run | Process Parameters | Response Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| P (bars) | t (s) | W (% d.b.) | Lip. (% d.b.) | Prot. (% d.b.) | Vit.B2 (mg/kg) | Vit.B6 (mg/kg) | Vit.E (mg/kg) | ER (%) | |

| 1 | 3[−1] | 7[−1] | 15[−1] | 3.29 | 12.69 | 1.79 | 2.55 | 11.84 | 1.42 |

| 2 | 6[+1] | 7[−1] | 15[−1] | 3.50 | 11.98 | 2.13 | 3.89 | 13.80 | 1.35 |

| 3 | 3[−1] | 17[+1] | 15[−1] | 3.90 | 12.45 | 1.85 | 3.16 | 15.18 | 1.44 |

| 4 | 6[+1] | 17[+1] | 15[−1] | 3.33 | 11.74 | 2.09 | 3.79 | 13.86 | 1.58 |

| 5 | 3[−1] | 7[−1] | 35[+1] | 3.04 | 12.59 | 1.87 | 1.82 | 10.28 | 1.29 |

| 6 | 6[+1] | 7[−1] | 35[+1] | 3.54 | 12.51 | 2.05 | 3.40 | 14.63 | 1.47 |

| 7 | 3[−1] | 17[+1] | 35[+1] | 3.53 | 12.23 | 2.11 | 1.48 | 12.49 | 1.29 |

| 8 | 6[+1] | 17[+1] | 35[+1] | 3.20 | 11.19 | 1.95 | 2.71 | 11.68 | 1.58 |

| 9 | 1.98[−α] | 12[0] | 25[0] | 3.87 | 12.44 | 1.76 | 1.68 | 9.12 | 1.26 |

| 10 | 7[+α] | 12[0] | 25[0] | 3.42 | 11.45 | 2.18 | 3.73 | 12.75 | 1.48 |

| 11 | 4.5[0] | 3.6[−α] | 25[0] | 3.15 | 11.85 | 1.94 | 2.40 | 12.21 | 1.31 |

| 12 | 4.5[0] | 20.4[+α] | 25[0] | 3.61 | 11.50 | 1.99 | 2.40 | 15.54 | 1.49 |

| 13 | 4.5[0] | 12[0] | 8.2[−α] | 3.28 | 11.40 | 1.97 | 5.02 | 13.03 | 1.60 |

| 14 | 4.5[0] | 12[0] | 41.8[+α] | 3.19 | 12.29 | 2.02 | 2.68 | 12.97 | 1.41 |

| 15 | 4.5[0] | 12[0] | 25[0] | 3.53 | 10.09 | 2.04 | 2.46 | 14.42 | 1.47 |

| 16 | 4.5[0] | 12[0] | 25[0] | 3.33 | 10.36 | 2.02 | 2.24 | 14.79 | 1.44 |

| 17 | 4.5[0] | 12[0] | 25[0] | 3.49 | 10.65 | 2.03 | 2.02 | 14.62 | 1.41 |

| 18 | 4.5[0] | 12[0] | 25[0] | 3.69 | 10.16 | 2.07 | 2.93 | 14.86 | 1.45 |

| 19 | 4.5[0] | 12[0] | 25[0] | 3.58 | 10.31 | 2.15 | 2.09 | 14.71 | 1.46 |

| 20 | 4.5[0] | 12[0] | 25[0] | 3.61 | 10.55 | 2.05 | 2.69 | 14.68 | 1.47 |

| HAD | 2.77 | 11.90 | 2.13 | 0.98 | 9.91 | 1.00 | |||

| Response Parameter | R2 (%) | R2 Adjusted (%) | Lack of Fit |

|---|---|---|---|

| ER | 95.1 | 90.7 | 0.15 |

| Vit.B2 | 88.9 | 80.0 | 0.33 |

| Vit.B6 | 93.8 | 88.3 | 0.83 |

| Vit.E | 90.5 | 82.0 | <0.05 |

| Response | Optimal Value | IVDV Conditions | |||

|---|---|---|---|---|---|

| P (bars) | t (sec) | W (% d.b.) | |||

| Single optimization | ER (%) | 1.67 | 5.8 | 20.4 | 8.18 |

| Vit.B2 (mg/kg) | 2.32 | 7.02 | 4.23 | 8.18 | |

| Vit.B6 (mg/kg) | 5.59 | 7.02 | 9.01 | 8.18 | |

| Vit.E (mg/kg) | 16.5 | 3.52 | 20.4 | 9.44 | |

| Multiple optimization | ER (%) | 1.60 | 5.48 | 15.4 | 8.8 |

| Vit.B2 (mg/kg) | 2.05 | ||||

| Vit.B6 (mg/kg) | 5.02 | ||||

| Vit.E (mg/kg) | 14.08 | ||||

| Response Parameter | Predicted Value | Observed Value | Mean Absolute Error |

|---|---|---|---|

| ER (%) | 1.6 | 1.58 | 0.02 |

| Vit.B2 (mg/kg) | 2.05 | 2.03 | 0.03 |

| Vit.B6 (mg/kg) | 5.02 | 5.11 | 0.17 |

| Vit.E (mg/kg) | 14.08 | 14.23 | 0.38 |

| Proteins (%) | Lipids (%) | Vit.B2 (mg/kg) | Vit.B6 (mg/kg) | Vit.E (mg/kg) | |

|---|---|---|---|---|---|

| Seeds | 9.48 a | 2.65 a | 0.47 a | 2.51 a | 6.11 a |

| Sprouts | 13.85 b | 3.65 b | 7.24 b | 9.49 b | 22.39 b |

| HAD + IVDV | 12.33 c | 2.97 a | 2.03 c | 5.11 c | 14.23 c |

| HAD | 11.90 c | 2.77 a | 2.19 c | 0.98 d | 9.91 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Francis, H.; Debs, E.; Maroun, R.G.; Louka, N. Enhancing Wheat Sprout Attributes Using “Intensification of Vaporization by Decompression to the Vacuum”, an Innovative Drying–Texturizing Technology. Agriculture 2024, 14, 515. https://doi.org/10.3390/agriculture14040515

Francis H, Debs E, Maroun RG, Louka N. Enhancing Wheat Sprout Attributes Using “Intensification of Vaporization by Decompression to the Vacuum”, an Innovative Drying–Texturizing Technology. Agriculture. 2024; 14(4):515. https://doi.org/10.3390/agriculture14040515

Chicago/Turabian StyleFrancis, Helga, Espérance Debs, Richard G. Maroun, and Nicolas Louka. 2024. "Enhancing Wheat Sprout Attributes Using “Intensification of Vaporization by Decompression to the Vacuum”, an Innovative Drying–Texturizing Technology" Agriculture 14, no. 4: 515. https://doi.org/10.3390/agriculture14040515

APA StyleFrancis, H., Debs, E., Maroun, R. G., & Louka, N. (2024). Enhancing Wheat Sprout Attributes Using “Intensification of Vaporization by Decompression to the Vacuum”, an Innovative Drying–Texturizing Technology. Agriculture, 14(4), 515. https://doi.org/10.3390/agriculture14040515