Preliminary Evaluation of Bioactive Collagen–Polyphenol Surface Nanolayers on Titanium Implants: An X-ray Photoelectron Spectroscopy and Bone Implant Study

Abstract

1. Introduction

- -

- The first point involves the actual structure of the surface layer. The driving force for building multilayers involving polyphenols and collagen is not just that of charge interaction, as in most conventional layer-by-layer (LBL) systems [31]. It is well known that polyphenols act as chemical cross-linkers of collagen, as exploited in leather tanning for centuries [32]. Thus, we should not expect to build a simple layered structure on the surface; rather, the different layers will interplay according to relevant chemistry. The first aim of this work is to try to understand the arrangement of collagen and polyphenols on top of titanium through surface analysis.

- -

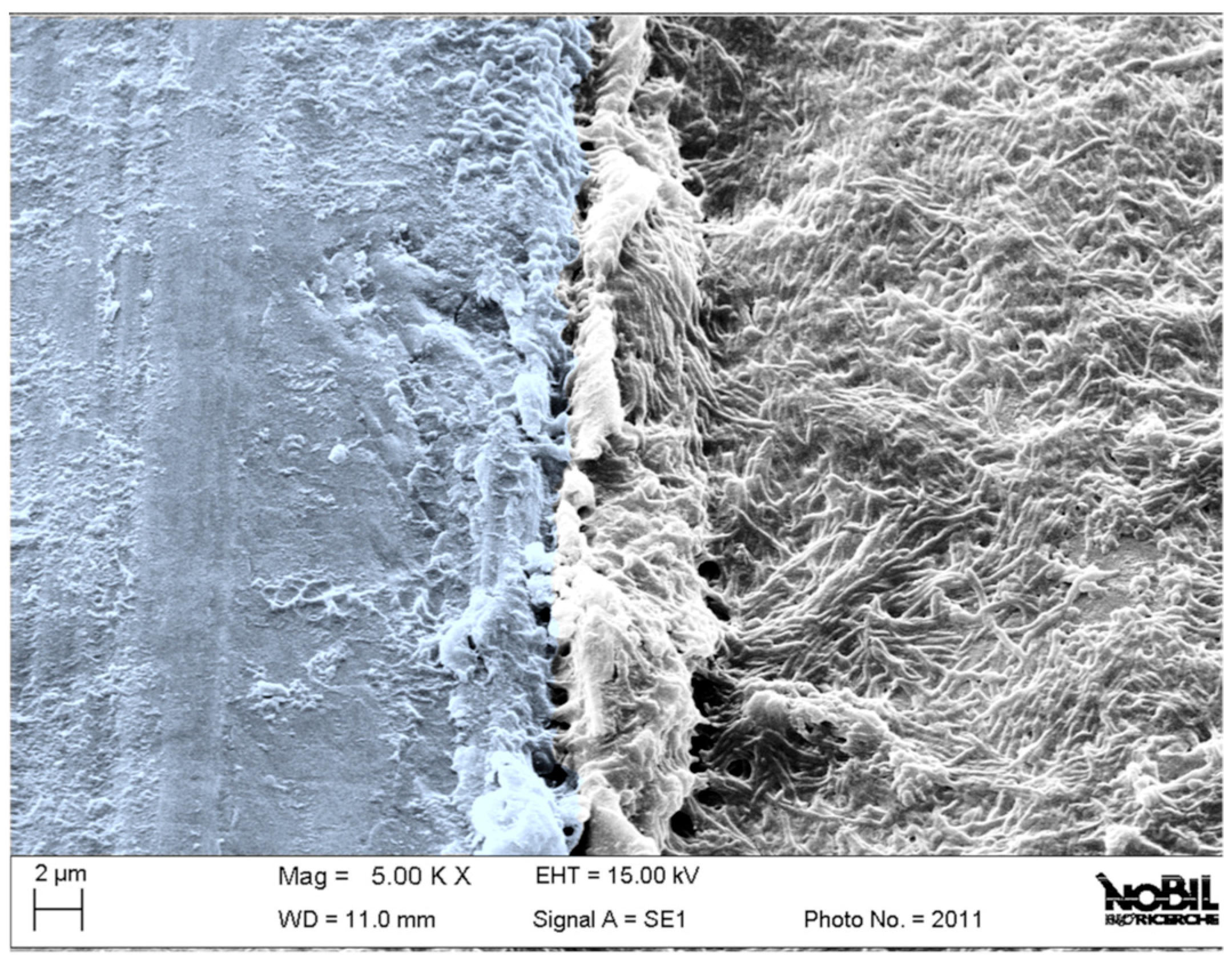

- Then, the surface layer is intended to enhance the device response at the “battlefront” shown in Figure 1. Thus, from a practical point of view, in a production setting, it is much more convenient to apply it to the whole implant surface, confined to a reaction in the liquid environment to a specific area rather cumbersome and expensive. It is then mandatory to evaluate the effects of the surface layer on conventional osteointegration to ascertain that it is not delayed or impaired by the chemistry of the layered structure.

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Polyphenols Rich Pomace Extracts (PRPE)

2.3. Preparation of Ti Samples for XPS Analysis and In Vivo Study

- -

- Ti-machined (Ti mach), which represents the control surface of the in vivo study;

- -

- Ti-etched (Ti rough);

- -

- Ti-machined functionalized with all three steps of functionalization (Ticpc mach);

- -

- Ti-etched functionalized with all three steps of functionalization (Ticpc rough).

2.4. X-ray Photoelectron Analysis of Treated Disks

2.5. In Vivo Study

2.5.1. Bone Sample Harvesting and Processing

2.5.2. Statistical Analysis

3. Results

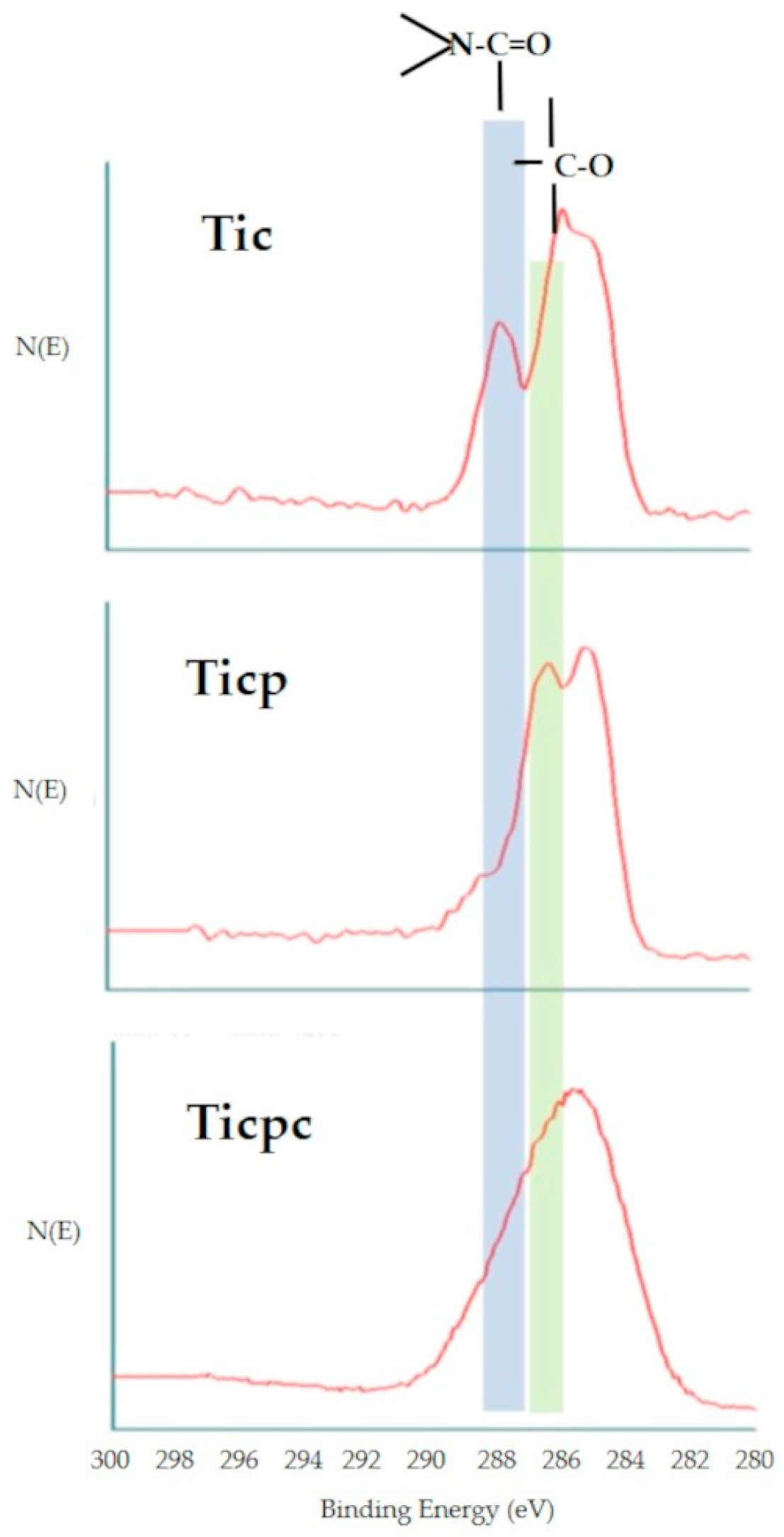

3.1. XPS Analysis

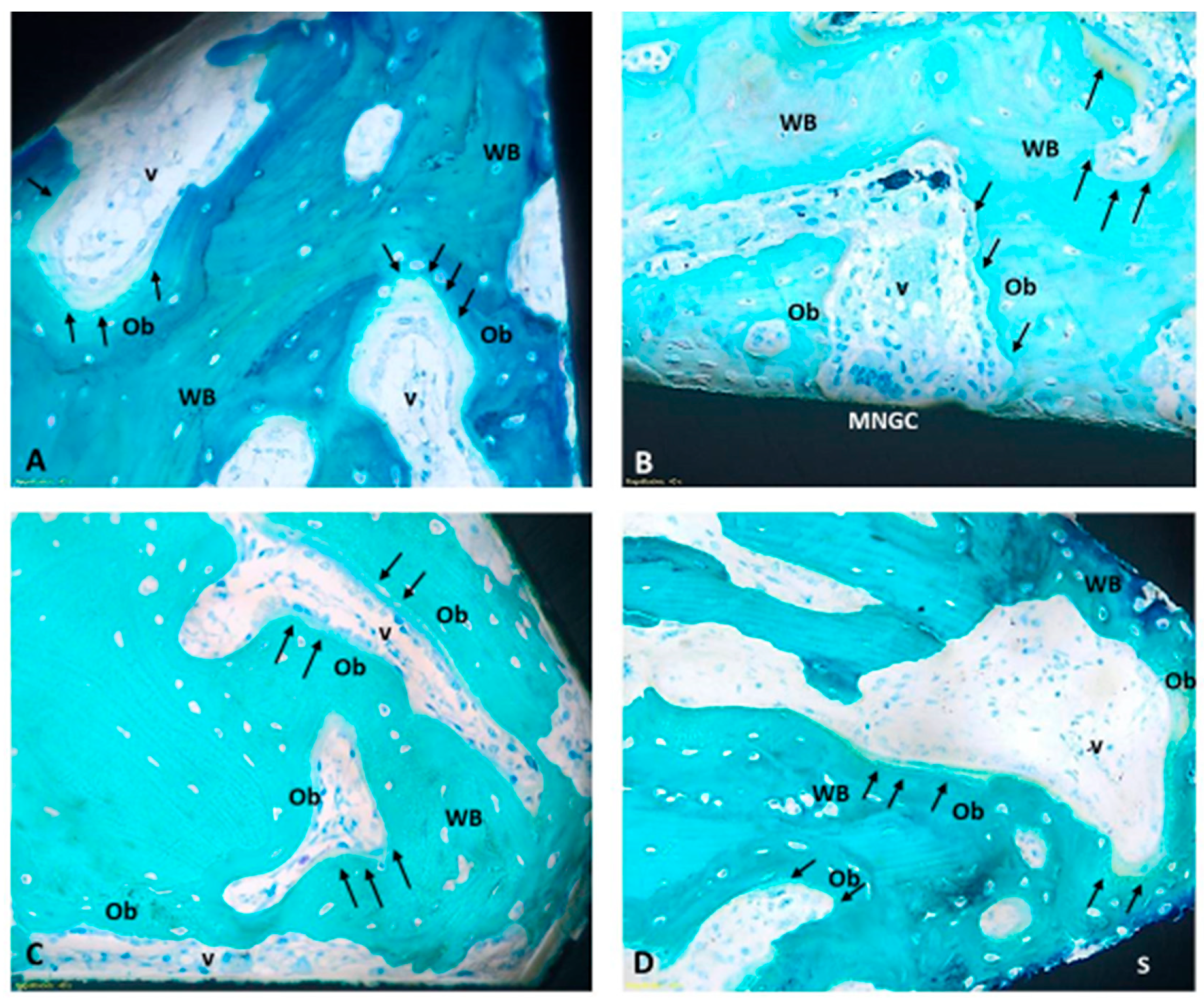

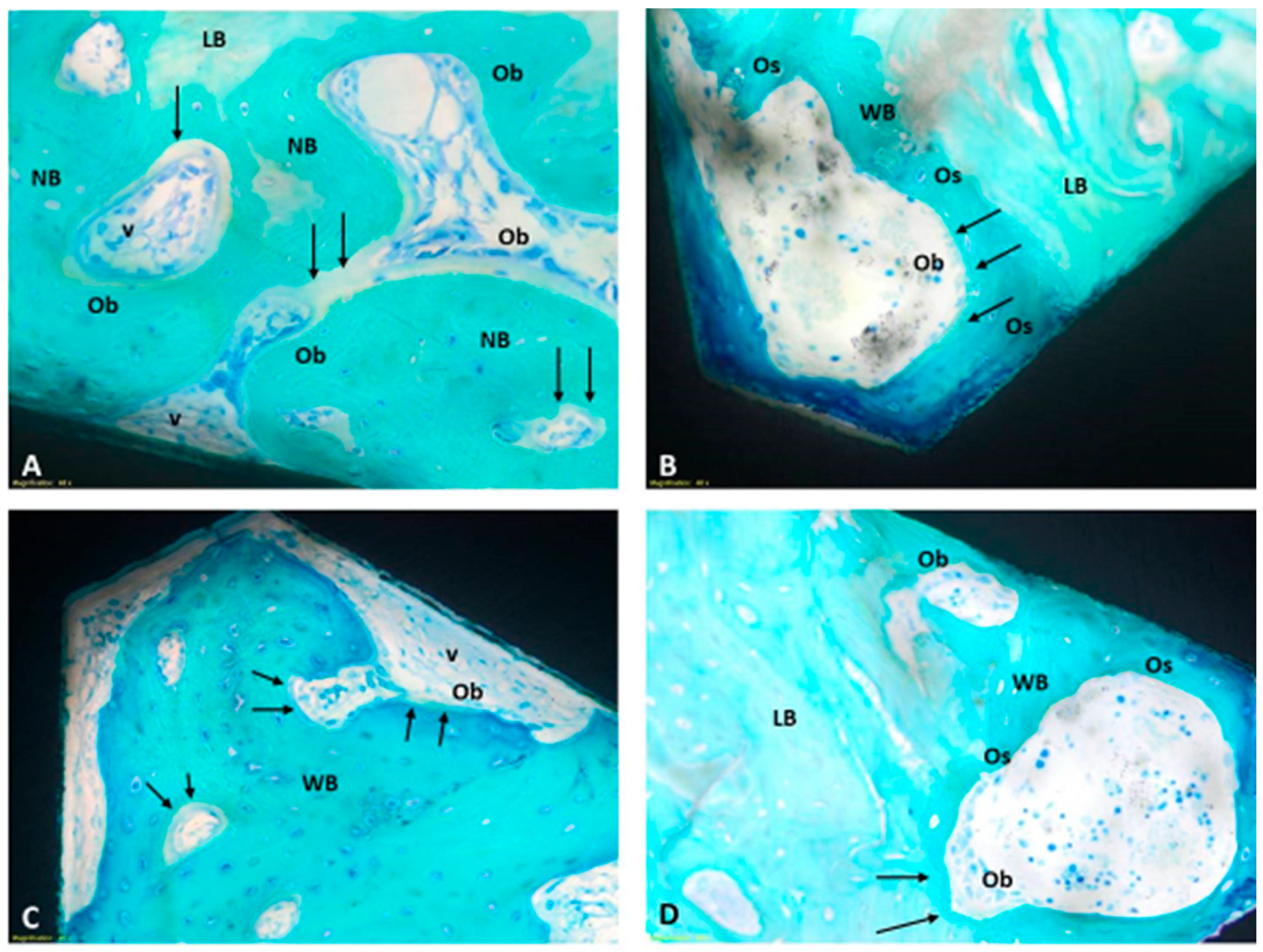

3.2. In Vivo Studies

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Brånemark, P.I. Osseointegration and its experimental background. J. Prosthet. Dent. 1983, 50, 399–410. [Google Scholar] [CrossRef] [PubMed]

- Brånemark, P.I.; Hansson, B.O.; Adell, R.; Breine, U.; Lindström, J.; Hallén, O.; Ohman, A. Osseointegrated implants in the treatment of the edentulous jaw. Experience from a 10-year period. Scand. J. Plast. Reconstr. Surg. Suppl. 1977, 16, 1–132. [Google Scholar] [PubMed]

- Profeta, A.C. Brånemark’s legacy. Eur. Arch. Otorhinolaryngol. 2016, 273, 1329–1330. [Google Scholar] [CrossRef] [PubMed]

- Balkin, B.E. Implant dentistry: Historical overview with current perspective. J. Dent. Educ. 1988, 52, 683–685. [Google Scholar] [CrossRef] [PubMed]

- Giusto, E.; Blunn, G.; de Godoy, R.F.; Liu, C.; Pendegrass, C. Optimising soft tissue in-growth in vivo in additive layer manufactured osseointegrated transcutaneous implants. Biomater. Transl. 2022, 3, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Saremi, L.; Shafizadeh, M.; Esmaeilzadeh, E.; Ghaffari, M.E.; Mahdavi, M.H.; Amid, R.; Kadkhodazadeh, M. Assessment of IL-10, IL-1ß and TNF-α gene polymorphisms in patients with peri-implantitis and healthy controls. Mol. Biol. Rep. 2021, 48, 2285–2290. [Google Scholar] [CrossRef] [PubMed]

- Rahnama-Hezavah, M.; Mertowska, P.; Mertowski, S.; Skiba, J.; Krawiec, K.; Łobacz, M.; Grywalska, E. How Can Imbalance in Oral Microbiota and Immune Response Lead to Dental Implant Problems? Int. J. Mol. Sci. 2023, 24, 17620. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Monje, A.; Kan, J.Y.; Borgnakke, W. Impact of local predisposing/precipitating factors and systemic drivers on peri-implant diseases. Clin. Implant. Dent. Relat. Res. 2023, 25, 640–660. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.A.; de Oliveira Alves, R.; Nascimento, I.M.; Hidalgo, M.A.R.; Scarel-Caminaga, R.M.; Cristina Pigossi, S. Pro- and anti-inflammatory cytokines and osteoclastogenesis-related factors in peri-implant diseases: Systematic review and meta-analysis. BMC Oral Health 2023, 23, 420. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Albrektsson, T.; Tengvall, P.; Amengual-Peñafiel, L.; Coli, P.; Kotsakis, G.; Cochran, D.L. Implications of considering peri-implant bone loss a disease, a narrative review. Clin. Implant. Dent. Relat. Res. 2022, 24, 532–543. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Albrektsson, T.; Tengvall, P.; Amengual, L.; Coli, P.; Kotsakis, G.A.; Cochran, D. Osteoimmune regulation underlies oral implant osseointegration and its perturbation. Front. Immunol. 2023, 13, 1056914. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Sartori, M.; Borsari, V.; Maglio, M.; Brogini, S.; Bragonzoni, L.; Zaffagnini, S.; Fini, M. Skin adhesion to the percutaneous component of direct bone anchored systems: Systematic review on preclinical approaches and biomaterials. Biomater. Sci. 2021, 9, 7008–7023. [Google Scholar] [CrossRef] [PubMed]

- Alghamdi, H.S.; Jansen, J.A. The development and future of dental implants. Dent. Mater. J. 2020, 39, 167–172. [Google Scholar] [CrossRef] [PubMed]

- Hasan, J.; Bright, R.; Hayles, A.; Palms, D.; Zilm, P.; Barker, D.; Vasilev, K. Preventing Peri-Implantitis: The Quest for a Next Generation of Titanium Dental Implants. ACS Biomater. Sci. Eng. 2022, 8, 4697–4737. [Google Scholar] [CrossRef] [PubMed]

- Milleret, V.; Lienemann, P.S.; Gasser, A.; Bauer, S.; Ehrbar, M.; Wennerberg, A. Rational Design and in Vitro Characterization of Novel Dental Implant and Abutment Surfaces for Balancing Clinical and Biological Needs. Clin. Implant. Dent. Relat. Res. 2019, 21, 15–24. [Google Scholar] [CrossRef] [PubMed]

- Barão, V.A.R.; Costa, R.C.; Shibli, J.A.; Bertolini, M.; Souza, J.G.S. Emerging titanium surface modifications: The war against polymicrobial infections on dental implants. Braz. Dent. J. 2022, 33, 1–12. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Abdulghafor, M.A.; Mahmood, M.K.; Tassery, H.; Tardivo, D.; Falguiere, A.; Lan, R. Biomimetic Coatings in Implant Dentistry: A Quick Update. J. Funct. Biomater. 2023, 15, 15. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Torre, E.; Iviglia, G.; Cassinelli, C.; Morra, M.; Russo, N. Polyphenols from grape pomace induce osteogenic differentiation in mesenchymal stem cells. Int. J. Mol. Med. 2020, 45, 1721–1734. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Iviglia, G.; Morra, M. Engineering Interfacial Environment of Epigallocatechin Gallate Coated Titanium for Next-Generation Bioactive Dental Implant Components. Int. J. Mol. Sci. 2023, 24, 2661. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Scalbert, A.; Johnson, I.T.; Saltmarsh, M. Polyphenols: Antioxidants and Beyond. Am. J. Clin. Nutr. 2005, 81, 215S–217S. [Google Scholar] [CrossRef] [PubMed]

- Vermerris Wilfred, R.N. Phenolic Compound Biochemistry; Springer: Dordrecht, The Netherlands, 2006; ISBN 978-1-4020-5163-0. [Google Scholar]

- Torre, E. Molecular Signaling Mechanisms behind Polyphenol-Induced Bone Anabolism. Phytochem. Rev. 2017, 16, 1183–1226. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.; Kim, J.H.; Lee, C.K.; Oh, C.H.; Song, H.J. The Antimicrobial Activity of (-)-Epigallocatehin-3-Gallate and Green Tea Extracts against Pseudomonas Aeruginosa and Escherichia Coli Isolated from Skin Wounds. Ann. Dermatol. 2014, 26, 564. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Takagi, S.; Ando, T.; Yoneyama, H.; Ito, K.; Mizugai, H.; Isogai, E. Antimicrobial Activity of Tea Catechin against Canine Oral Bacteria and the Functional Mechanisms. J. Vet. Med. Sci. 2016, 78, 1439–1445. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Brown, A.C. Applications of Catechins in the Treatment of Bacterial Infections. Pathogens 2021, 10, 546. [Google Scholar] [CrossRef] [PubMed]

- Cajiao Checchin, V.C.; Gonzalez, A.; Bertuola, M.; Fernández Lorenzo de Mele, M.A. Multifunctional Coatings of Phenolic Phytocompounds of Medical Interest: Assembly Methods and Applications. Prog. Org. Coat. 2022, 172, 107068. [Google Scholar] [CrossRef]

- Rahim, M.A.; Björnmalm, M.; Bertleff-Zieschang, N.; Ju, Y.; Mettu, S.; Leeming, M.G.; Caruso, F. Multiligand Metal-Phenolic Assembly from Green Tea Infusions. ACS Appl. Mater. Interfaces 2018, 10, 7632–7639. [Google Scholar] [CrossRef] [PubMed]

- Torre, E.; Morra, M.; Cassinelli, C.; Iviglia, G. Antibacterial and Anti-inflammatory effect of a Polyphenols-coating bone filler. Submitted. April 2024. [Google Scholar]

- Chattopadhyay, S.; Raines, R.T. Review collagen-based biomaterials for wound healing. Biopolymers 2014, 101, 821–833. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Sharma, S.; Rai, V.K.; Narang, R.K.; Markandeywar, T.S. Collagen-based formulations for wound healing: A literature review. Life Sci. 2022, 290, 120096, Erratum in: Life Sci. 2022, 297, 120436. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zeng, J.; Groll, J.; Matsusaki, M. Layer-by-layer assembly methods and their biomedical applications. Biomater. Sci. 2022, 10, 4077–4094. [Google Scholar] [CrossRef] [PubMed]

- Falcão, L.; Araújo, M.E.M. Vegetable Tannins Used in the Manufacture of Historic Leathers. Molecules 2018, 23, 1081. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Fadley, C.S. Angle-resolved x-ray photoelectron spectroscopy. Prog. Surf. Sci. 1984, 16, 275–388. [Google Scholar] [CrossRef]

- Sartori, M.; Giavaresi, G.; Parrilli, A.; Ferrari, A.; Aldini, N.N.; Morra, M.; Cassinelli, C.; Bollati, D.; Fini, M. Collagen type I coating stimulates bone regeneration and osteointegration of titanium implants in the osteopenic rat. Int. Orthop. 2015, 39, 2041–2052. [Google Scholar] [CrossRef] [PubMed]

- Morra, M.; Cassinelli, C.; Cascardo, G.; Mazzucco, L.; Borzini, P.; Fini, M.; Giavaresi, G.; Giardino, R. Collagen I-coated titanium surfaces: Mesenchymal cell adhesion and in vivo evaluation in trabecular bone implants. J. Biomed Mater. Res. A 2006, 78, 449–458. [Google Scholar] [CrossRef]

- Davies, J.E. Understanding peri-implant endosseous healing. J. Dent. Educ. 2003, 67, 932–949. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, V.; Krithica, N.; Madhan, B.; Sehgal, P.K. Preparation and Properties of Tannic Acid Cross-Linked Collagen Scaffold and Its Application in Wound Healing. J. Biomed. Mater. Res. Part. B Appl. Biomater. 2013, 101, 560–567. [Google Scholar] [CrossRef] [PubMed]

- Shavandi, A.; Bekhit, A.E.D.A.; Saeedi, P.; Izadifar, Z.; Bekhit, A.A.; Khademhosseini, A. Polyphenol Uses in Biomaterials Engineering. Biomaterials 2018, 167, 91–106. [Google Scholar] [CrossRef] [PubMed]

- Norde, W.; Lyklema, J. Why proteins prefer interfaces. J. Biomater. Sci. Polym. Ed. 1991, 2, 183–202. [Google Scholar] [CrossRef] [PubMed]

- Morra, M. Biochemical modification of titanium surfaces: Peptides and ECM proteins. Eur. Cell Mater. 2006, 12, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Stewart, C.; Akhavan, B.; Wise, S.G.; Bilek MM, M. A review of biomimetic surface functionalization for bone-integrating orthopedic implants: Mechanisms, current approaches, and future directions. Prog. Mater. Sci. 2019, 106, 100588. [Google Scholar] [CrossRef]

- He, L.; Mu, C.; Shi, J.; Zhang, Q.; Shi, B.; Lin, W. Modification of collagen with a natural cross-linker, procyanidin. Int. J. Biol. Macromol. 2011, 48, 354–359. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Bai, X.; Li, S.; Liu, Y.; Keightley, A.; Wang, Y. Molecular weight and galloylation affect grape seed extract constituents' ability to cross-link dentin collagen in clinically relevant time. Dent. Mater. 2015, 31, 814–821. [Google Scholar] [CrossRef] [PubMed] [PubMed Central][Green Version]

- Wu, L.; Shao, H.; Fang, Z.; Zhao, Y.; Cao, C.Y.; Li, Q. Mechanism and Effects of Polyphenol Derivatives for Modifying Collagen. ACS Biomater. Sci. Eng. 2019, 5, 4272–4284. [Google Scholar] [CrossRef] [PubMed]

- Hass, V.; Liu, H.; Cook, W.; Walker, M.P.; Wang, Y. Distinct effects of polyphenols and solvents on dentin collagen crosslinking interactions and biostability. Dent. Mater. 2021, 37, 1794–1805. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Baldion, P.A.; Betancourt, D.E. Dataset on the effect of flavonoids on the stabilization of the resin-dentin interface. Data Brief. 2021, 35, 106984. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Wang, Y.; Zhou, J.; Tian, X.; Bai, L.; Ma, C.; Chen, Y.; Li, Y.; Wang, W. Effects of Covalent or Noncovalent Binding of Different Polyphenols to Acid-Soluble Collagen on Protein Structure, Functionality, and Digestibility. J. Agric. Food Chem. 2023, 71, 19020–19032. [Google Scholar] [CrossRef] [PubMed]

- Green, B.; Yao, X.; Ganguly, A.; Xu, C.; Dusevich, V.; Walker, M.P.; Wang, Y. Grape seed proanthocyanidins increase collagen biodegradation resistance in the dentin/adhesive interface when included in an adhesive. J. Dent. 2010, 38, 908–915. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Reis, M.; Zhou, B.; Alania, Y.; Leme-Kraus, A.A.; Jing, S.; McAlpine, J.B.; Chen, S.N.; Pauli, G.F.; Bedran-Russo, A.K. Unveiling structure-activity relationships of proanthocyanidins with dentin collagen. Dent. Mater. 2021, 37, 1633–1644. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Liu, Y.; Chen, M.; Yao, X.; Xu, C.; Zhang, Y.; Wang, Y. Enhancement in dentin collagen's biological stability after proanthocyanidins treatment in clinically relevant time periods. Dent. Mater. 2013, 29, 485–492. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Vidal, C.M.; Zhu, W.; Manohar, S.; Aydin, B.; Keiderling, T.A.; Messersmith, P.B.; Bedran-Russo, A.K. Collagen-collagen interactions mediated by plant-derived proanthocyanidins: A spectroscopic and atomic force microscopy study. Acta Biomater. 2016, 41, 110–118. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Wang, R.; Stanley, T.; Yao, X.; Liu, H.; Wang, Y. Collagen stabilization by natural cross-linkers: A qualitative and quantitative FTIR study on ultra-thin dentin collagen model. Dent. Mater. J. 2022, 41, 440–450. [Google Scholar] [CrossRef] [PubMed]

- Coroaba, A. Contributions Regarding the Use of XPS in the Investigation of Organic and Inorganic Materials. Ph.D. Thesis, Romanian Academy, Petru Poni Institut of Macromolecular Chemistry, Iași, Romania, 2015. Available online: https://icmpp.ro/doctorate/rezumat/REZUMAT_teza_doctorat_Adina_Coroaba.pdf (accessed on 27 January 2024).

- Morra, M.; Cassinelli, C.; Cascardo, G.; Bollati, D.; Rodriguez YBaena, R. Multifunctional implant surfaces: Surface characterization and bone response to acid-etched Ti implants surface-modified by fibrillar collagen I. J. Biomed Mater. Res. A 2010, 94, 271–279. [Google Scholar] [CrossRef] [PubMed]

- Scarano, A.; Lorusso, F.; Orsini, T.; Morra, M.; Iviglia, G.; Valbonetti, L. Biomimetic Surfaces Coated with Covalently Immobilized Collagen Type I: An X-Ray Photoelectron Spectroscopy, Atomic Force Microscopy, Micro-CT and Histomorphometrical Study in Rabbits. Int. J. Mol. Sci. 2019, 20, 724. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

| Sample | O | Ti | N | C |

|---|---|---|---|---|

| Ti | 48.4 | 19.5 | 0.4 | 31.7 |

| Tic | 22.5 | 1.7 | 13.9 | 61.9 |

| Ticp | 26.4 | 0.4 | 5.2 | 68.0 |

| Ticpc | 21.6 | - | 11.8 | 66.5 |

| Take Off Angle | Sample | O | Ti | N | C |

|---|---|---|---|---|---|

| 15 | Tic | 18.2 | 0.8 | 12.8 | 68.2 |

| 45 | Tic | 22.5 | 1.7 | 13.9 | 61.9 |

| 75 | Tic | 26.0 | 3.2 | 14.0 | 56.8 |

| 15 | Ticp | 24.9 | - | 4.9 | 70.2 |

| 45 | Ticp | 26.4 | 0.4 | 5.2 | 68.0 |

| 75 | Ticp | 28.4 | 0.8 | 5.5 | 65.3 |

| 15 | Ticpc | 20.6 | - | 13.1 | 66.2 |

| 45 | Ticpc | 21.6 | - | 11.8 | 66.5 |

| 75 | Ticpc | 20.8 | - | 15.5 | 63.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morra, M.; Iviglia, G.; Cassinelli, C.; Sartori, M.; Cavazza, L.; Martini, L.; Fini, M.; Giavaresi, G. Preliminary Evaluation of Bioactive Collagen–Polyphenol Surface Nanolayers on Titanium Implants: An X-ray Photoelectron Spectroscopy and Bone Implant Study. J. Funct. Biomater. 2024, 15, 170. https://doi.org/10.3390/jfb15070170

Morra M, Iviglia G, Cassinelli C, Sartori M, Cavazza L, Martini L, Fini M, Giavaresi G. Preliminary Evaluation of Bioactive Collagen–Polyphenol Surface Nanolayers on Titanium Implants: An X-ray Photoelectron Spectroscopy and Bone Implant Study. Journal of Functional Biomaterials. 2024; 15(7):170. https://doi.org/10.3390/jfb15070170

Chicago/Turabian StyleMorra, Marco, Giorgio Iviglia, Clara Cassinelli, Maria Sartori, Luca Cavazza, Lucia Martini, Milena Fini, and Gianluca Giavaresi. 2024. "Preliminary Evaluation of Bioactive Collagen–Polyphenol Surface Nanolayers on Titanium Implants: An X-ray Photoelectron Spectroscopy and Bone Implant Study" Journal of Functional Biomaterials 15, no. 7: 170. https://doi.org/10.3390/jfb15070170

APA StyleMorra, M., Iviglia, G., Cassinelli, C., Sartori, M., Cavazza, L., Martini, L., Fini, M., & Giavaresi, G. (2024). Preliminary Evaluation of Bioactive Collagen–Polyphenol Surface Nanolayers on Titanium Implants: An X-ray Photoelectron Spectroscopy and Bone Implant Study. Journal of Functional Biomaterials, 15(7), 170. https://doi.org/10.3390/jfb15070170