High-Quality Single Crystalline Sc0.37Al0.63N Thin Films Enabled by Precise Tuning of III/N Atomic Flux Ratio during Molecular Beam Epitaxy

Abstract

:1. Introduction

2. Experimental Details

3. Results and Discussion

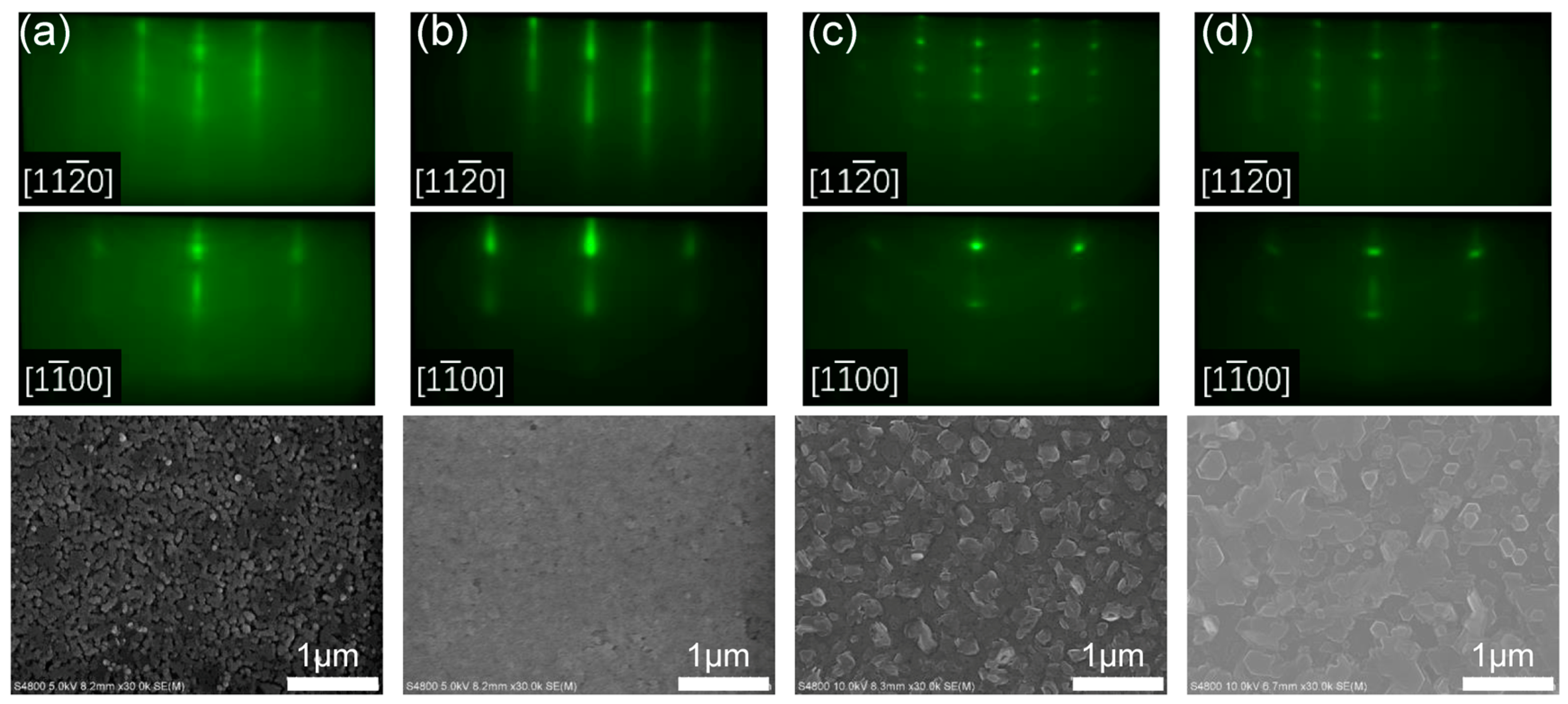

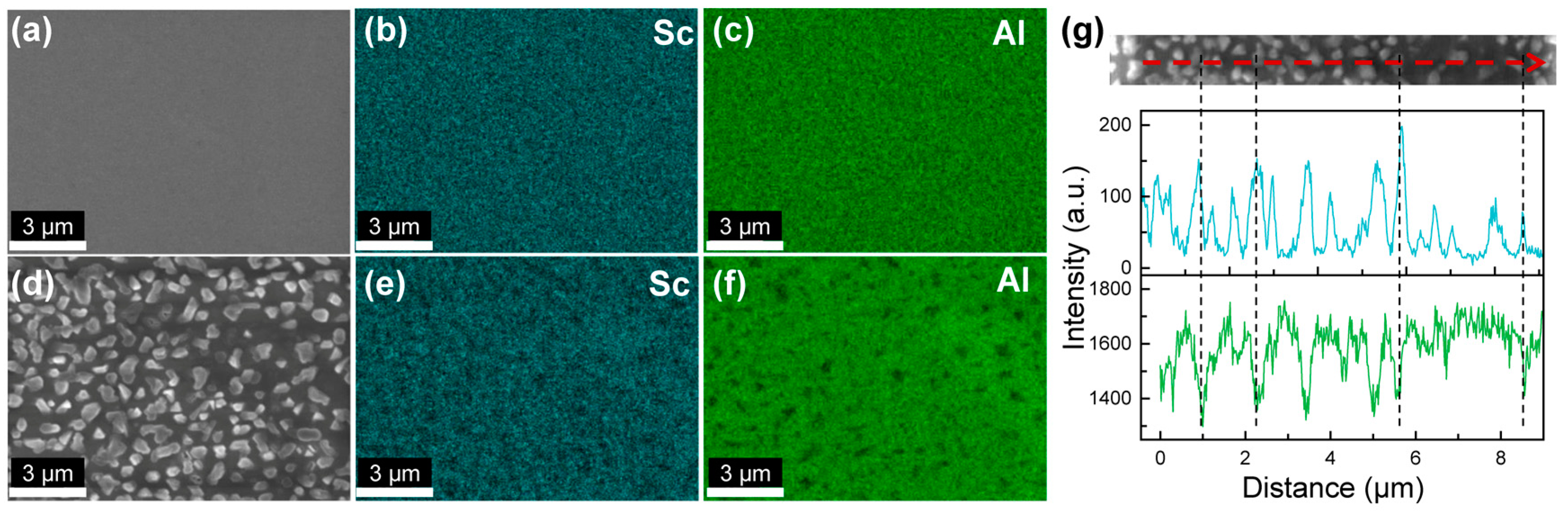

3.1. Effect of III/N Atomic Flux Ratio on Sc0.18Al0.82N Growth

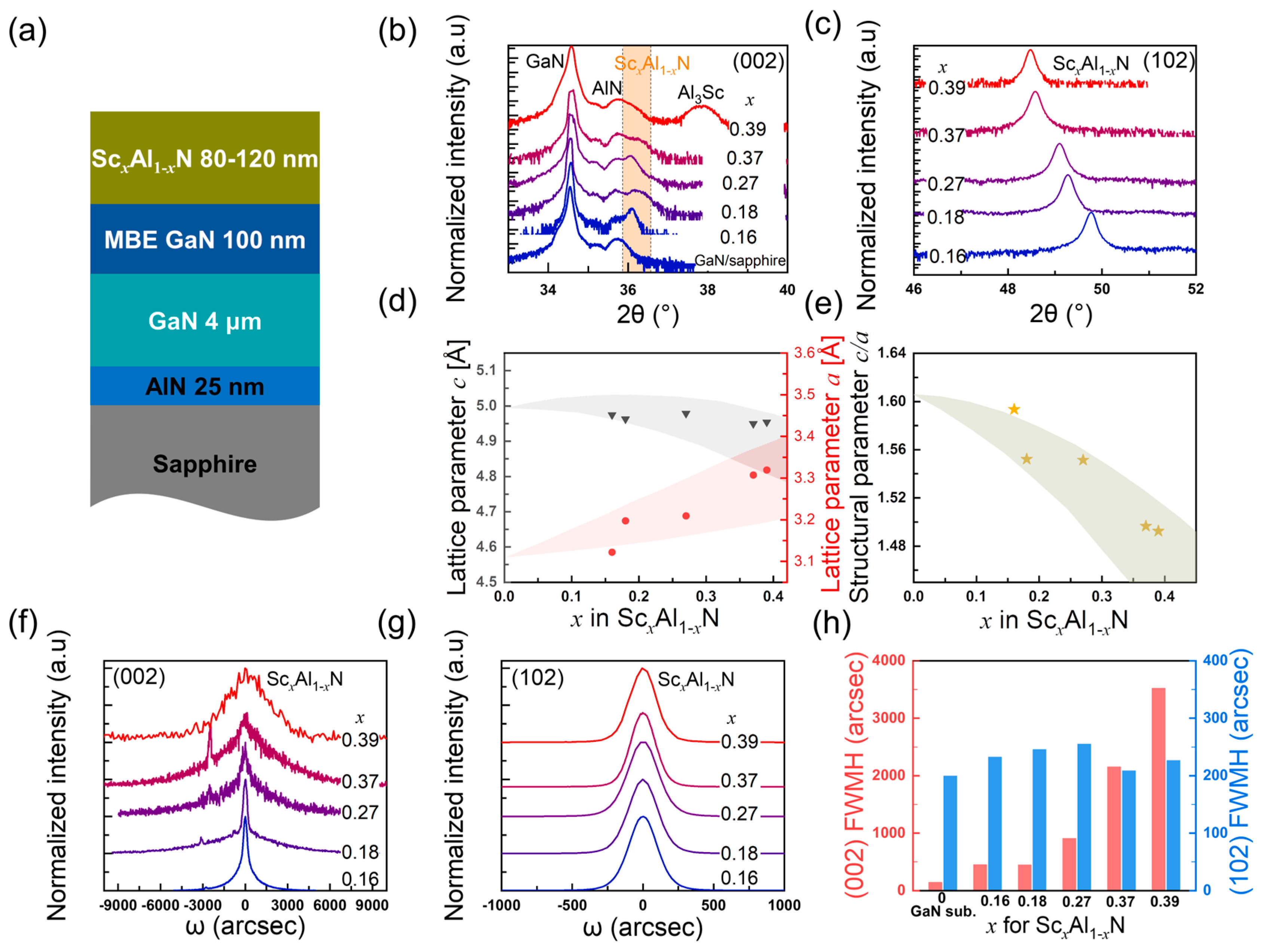

3.2. Characterization of Sc Composition and Crystal Quality of ScxAl1−xN Films

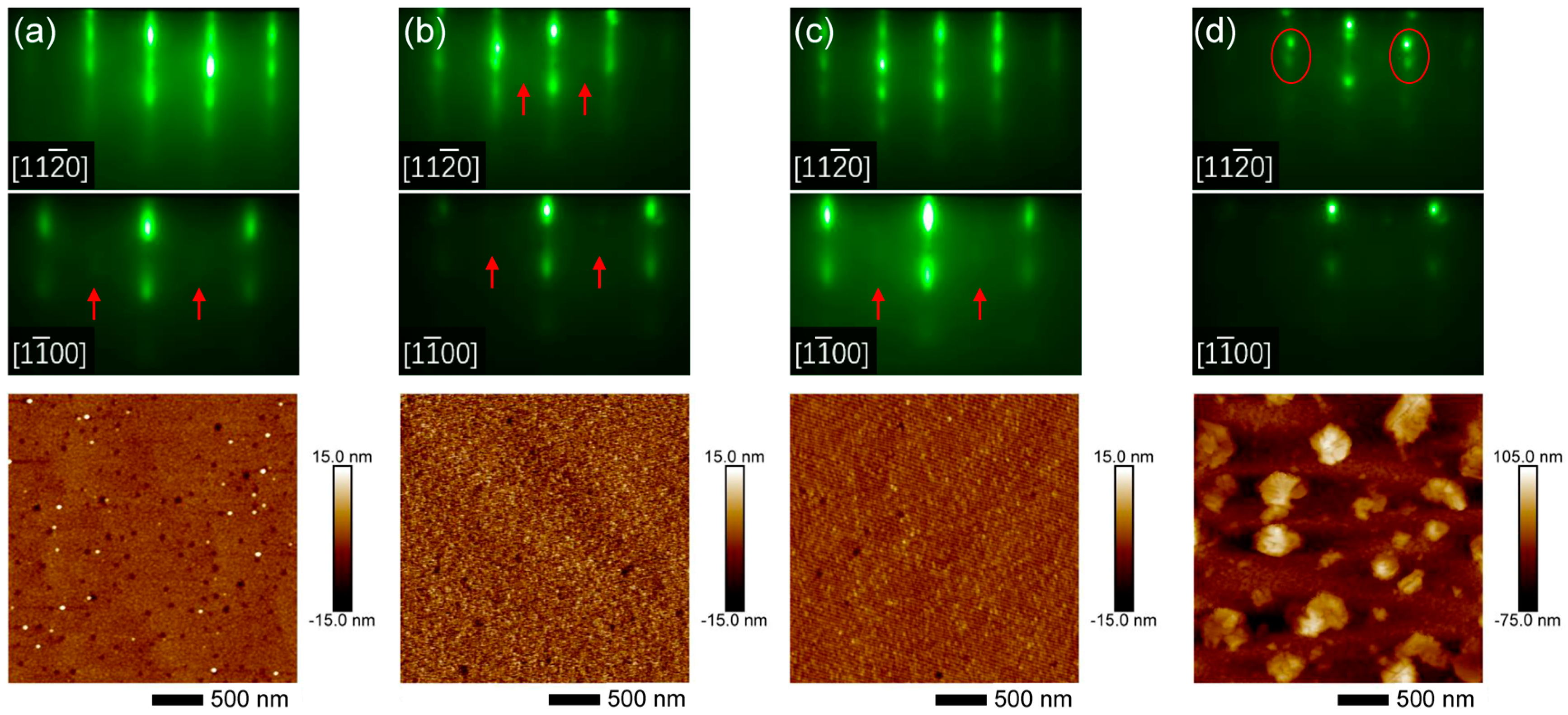

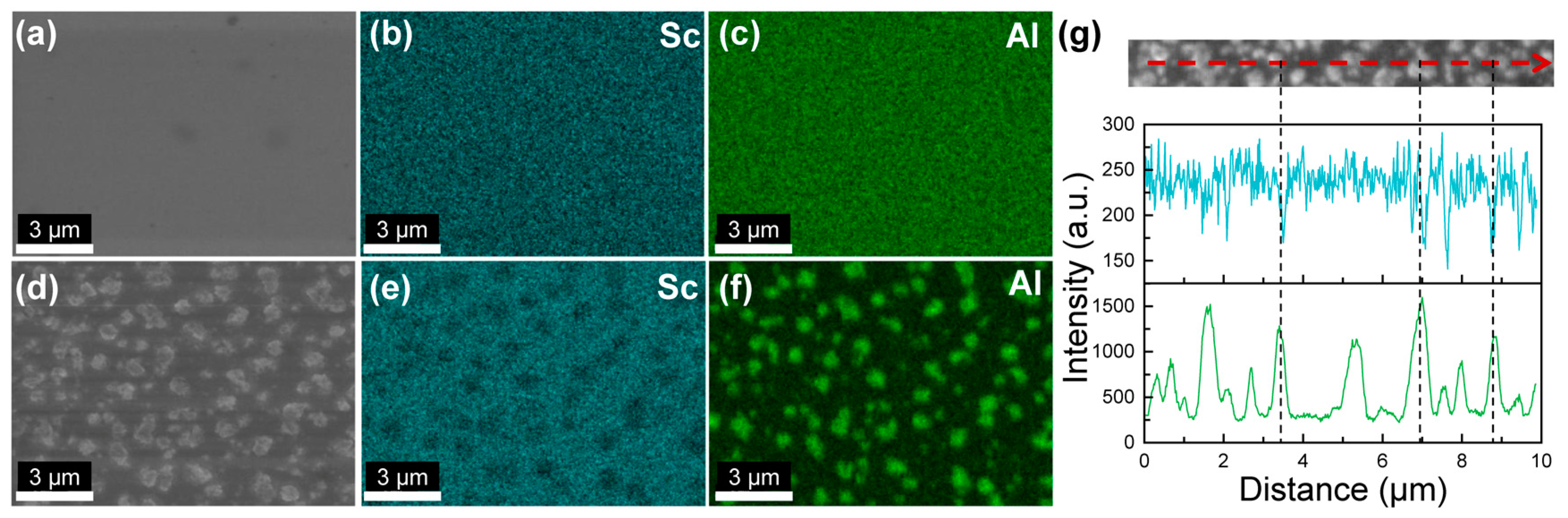

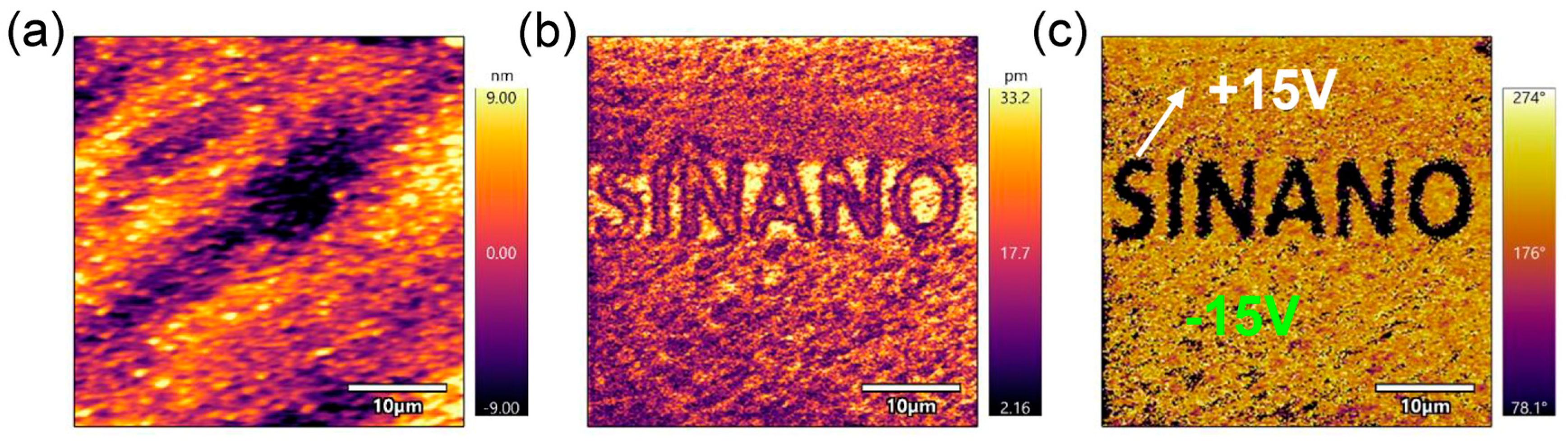

3.3. High Sc-Content ScxAl1−xN Films and Phase Separation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tasnádi, F.; Alling, B.; Höglund, C.; Wingqvist, G.; Birch, J.; Hultman, L.; Abrikosov, I.A. Origin of the Anomalous Piezoelectric Response in Wurtzite ScxAl(1−x)N Alloys. Phys. Rev. Lett. 2010, 104, 137601. [Google Scholar] [CrossRef]

- Akiyama, M.; Kano, K.; Teshigahara, A. Influence of growth temperature and scandium concentration on piezoelectric response of scandium aluminum nitride alloy thin films. Appl. Phys. Lett. 2009, 95, 162107. [Google Scholar] [CrossRef]

- Akiyama, M.; Kamohara, T.; Kano, K.; Teshigahara, A.; Takeuchi, Y.; Kawahara, N. Enhancement of Piezoelectric Response in Scandium Aluminum Nitride Alloy Thin Films Prepared by Dual Reactive Cosputtering. Adv. Mater. 2009, 21, 593–596. [Google Scholar] [CrossRef]

- Yanagitani, T.; Suzuki, M. Electromechanical coupling and gigahertz elastic properties of ScAlN films near phase boundary. Appl. Phys. Lett. 2014, 105, 122907. [Google Scholar] [CrossRef]

- Farrer, N.; Bellaiche, L. Properties of hexagonal ScN versus wurtzite GaN and InN. Phys. Rev. B 2002, 66, 201203. [Google Scholar] [CrossRef]

- Ambacher, O.; Christian, B.; Feil, N.; Urban, D.F.; Elsässer, C.; Prescher, M.; Kirste, L. Wurtzite ScAlN, InAlN, and GaAlN crystals, a comparison of structural, elastic, dielectric, and piezoelectric properties. J. Appl. Phys. 2021, 130, 045102. [Google Scholar] [CrossRef]

- Fichtner, S.; Wolff, N.; Lofink, F.; Kienle, L.; Wagner, B. AlScN: A III-V semiconductor based ferroelectric. J. Appl. Phys. 2019, 125, 114103. [Google Scholar] [CrossRef]

- Wang, D.; Wang, P.; Mondal, S.; Mohanty, S.; Ma, T.; Ahmadi, E.; Mi, Z. An Epitaxial Ferroelectric ScAlN/GaN Heterostructure Memory. Adv. Electron. Mater. 2022, 8, 2200005. [Google Scholar] [CrossRef]

- Yazawa, K.; Drury, D.; Zakutayev, A.; Brennecka, G.L. Reduced coercive field in epitaxial thin film of ferroelectric wurtzite Al0.7Sc0.3N. Appl. Phys. Lett. 2021, 118, 162903. [Google Scholar] [CrossRef]

- Casamento, J.; Nguyen, T.-S.; Cho, Y.; Savant, C.; Vasen, T.; Afroz, S.; Hannan, D.; Xing, H.; Jena, D. Transport properties of polarization-induced 2D electron gases in epitaxial AlScN/GaN heterojunctions. Appl. Phys. Lett. 2022, 121, 192101. [Google Scholar] [CrossRef]

- Wang, P.; Wang, D.; Wang, B.; Mohanty, S.; Diez, S.; Wu, Y.; Sun, Y.; Ahmadi, E.; Mi, Z. N-polar ScAlN and HEMTs grown by molecular beam epitaxy. Appl. Phys. Lett. 2021, 119, 082101. [Google Scholar] [CrossRef]

- Frei, K.; Trejo-Hernández, R.; Schütt, S.; Kirste, L.; Prescher, M.; Aidam, R.; Müller, S.; Waltereit, P.; Ambacher, O.; Fiederle, M. Investigation of growth parameters for ScAlN-barrier HEMT structures by plasma-assisted MBE. Jpn. J. Appl. Phys. 2019, 58, SC1045. [Google Scholar] [CrossRef]

- Hardy, M.T.; Downey, B.P.; Nepal, N.; Storm, D.F.; Katzer, D.S.; Meyer, D.J. Epitaxial ScAlN grown by molecular beam epitaxy on GaN and SiC substrates. Appl. Phys. Lett. 2017, 110, 162104. [Google Scholar] [CrossRef]

- Hardy, M.T.; Jin, E.N.; Nepal, N.; Katzer, D.S.; Downey, B.P.; Gokhale, V.J.; Storm, D.F.; Meyer, D.J. Control of phase purity in high scandium fraction heteroepitaxial ScAlN grown by molecular beam epitaxy. Appl. Phys. Express 2020, 13, 065509. [Google Scholar] [CrossRef]

- Mertin, S.; Heinz, B.; Rattunde, O.; Christmann, G.; Dubois, M.-A.; Nicolay, S.; Muralt, P. Piezoelectric and structural properties of c-axis textured aluminium scandium nitride thin films up to high scandium content. Surf. Coat. Technol. 2018, 343, 2–6. [Google Scholar] [CrossRef]

- Knisely, K.; Douglas, E.; Mudrick, J.; Rodriguez, M.; Kotula, P. Thickness dependence of Al0.88Sc0.12N thin films grown on silicon. Thin Solid Films 2019, 675, 66–72. [Google Scholar] [CrossRef]

- Park, M.; Wang, J.; Dargis, R.; Clark, A.; Ansari, A. Super high-frequency scandium aluminum nitride crystalline film bulk acoustic resonators. In Proceedings of the 2019 IEEE International Ultrasonics Symposium (IUS), Glasgow, UK, 6–9 October 2019; pp. 1689–1692. [Google Scholar]

- Sandu, C.S.; Parsapour, F.; Mertin, S.; Pashchenko, V.; Matloub, R.; LaGrange, T.; Heinz, B.; Muralt, P. Abnormal Grain Growth in AlScN Thin Films Induced by Complexion Formation at Crystallite Interfaces. Phys. Status Solidi A 2019, 216, 1800569. [Google Scholar] [CrossRef]

- Mishin, S.; Oshmyansky, Y. Optimizing high concentration Scandium Aluminum Nitride films. In Proceedings of the 2023 IEEE International Ultrasonics Symposium (IUS), Montreal, QC, Canada, 3–8 September 2023; pp. 1–3. [Google Scholar]

- Hardy, M.T.; Lang, A.C.; Jin, E.N.; Nepal, N.; Downey, B.P.; Gokhale, V.J.; Scott Katzer, D.; Wheeler, V.D. Nucleation control of high crystal quality heteroepitaxial Sc0.4Al0.6N grown by molecular beam epitaxy. J. Appl. Phys. 2023, 134, 105301. [Google Scholar] [CrossRef]

- Höglund, C.; Birch, J.; Alling, B.; Bareño, J.; Czigány, Z.; Persson, P.O.Å.; Wingqvist, G.; Zukauskaite, A.; Hultman, L. Wurtzite structure ScxAl(1−x)N solid solution films grown by reactive magnetron sputter epitaxy: Structural characterization and first-principles calculations. J. Appl. Phys. 2010, 107, 123515. [Google Scholar] [CrossRef]

- Höglund, C.; Bareño, J.; Birch, J.; Alling, B.; Czigány, Z.; Hultman, L. Cubic ScxAl(1−x)N solid solution thin films deposited by reactive magnetron sputter epitaxy onto ScN(111). J. Appl. Phys. 2009, 105, 113517. [Google Scholar] [CrossRef]

- Hirata, K.; Shobu, K.; Yamada, H.; Uehara, M.; Anggraini, S.; Akiyama, M. Thermodynamic assessment of the Al–Sc–N ternary system and phase-separated region of the strained wurtzite phase. J. Eur. Ceram. Soc. 2020, 40, 5410–5422. [Google Scholar] [CrossRef]

- Gund, V.; Davaji, B.; Lee, H.; Casamento, J.; Xing, H.G.; Jena, D.; Lal, A. Towards Realizing the Low-Coercive Field Operation of Sputtered Ferroelectric ScxAl(1-x)N. In Proceedings of the 2021 21st International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Orlando, FL, USA, 20–24 June 2021; pp. 1064–1067. [Google Scholar]

- Engel, Z.; Motoki, K.; Matthews, C.M.; Doolittle, W.A. Overcoming metal-rich surface chemistry limitations of ScAlN for high electrical performance heterostructures. J. Appl. Phys. 2022, 132, 185302. [Google Scholar] [CrossRef]

- Wang, P.; Wang, B.; Laleyan, D.A.; Pandey, A.; Wu, Y.; Sun, Y.; Liu, X.; Deng, Z.; Kioupakis, E.; Mi, Z. Oxygen defect dominated photoluminescence emission of ScxAl(1−x)N grown by molecular beam epitaxy. Appl. Phys. Lett. 2021, 118, 032102. [Google Scholar] [CrossRef]

- Casamento, J.; Chang, C.S.; Shao, Y.-T.; Wright, J.; Muller, D.A.; Xing, H.; Jena, D. Structural and piezoelectric properties of ultra-thin ScxAl(1−x)N films grown on GaN by molecular beam epitaxy. Appl. Phys. Lett. 2020, 117, 112101. [Google Scholar] [CrossRef]

- Hunter, D.A.; Lavery, S.P.; Edwards, P.R.; Martin, R.W. Assessing the Impact of Secondary Fluorescence on X-Ray Microanalysis Results from Semiconductor Thin Films. Microsc. Microanal. 2022, 28, 1472–1483. [Google Scholar] [CrossRef]

- Bryan, I.; Bryan, Z.; Mita, S.; Rice, A.; Tweedie, J.; Collazo, R.; Sitar, Z. Surface kinetics in AlN growth: A universal model for the control of surface morphology in III-nitrides. J. Cryst. Growth 2016, 438, 81–89. [Google Scholar] [CrossRef]

- Heying, B.; Smorchkova, I.; Poblenz, C.; Elsass, C.; Fini, P.; Den Baars, S.; Mishra, U.; Speck, J.S. Optimization of the surface morphologies and electron mobilities in GaN grown by plasma-assisted molecular beam epitaxy. Appl. Phys. Lett. 2000, 77, 2885–2887. [Google Scholar] [CrossRef]

- Heying, B.; Averbeck, R.; Chen, L.F.; Haus, E.; Riechert, H.; Speck, J.S. Control of GaN surface morphologies using plasma-assisted molecular beam epitaxy. J. Appl. Phys. 2000, 88, 1855–1860. [Google Scholar] [CrossRef]

- Österlund, E.; Ross, G.; Caro, M.A.; Paulasto-Kröckel, M.; Hollmann, A.; Klaus, M.; Meixner, M.; Genzel, C.; Koppinen, P.; Pensala, T.; et al. Stability and residual stresses of sputtered wurtzite AlScN thin films. Phys. Rev. Mater. 2021, 5, 035001. [Google Scholar] [CrossRef]

- Ambacher, O.; Mihalic, S.; Yassine, M.; Yassine, A.; Afshar, N.; Christian, B. Review: Structural, elastic, and thermodynamic properties of cubic and hexagonal ScxAl(1−x)N crystals. J. Appl. Phys. 2023, 134, 160702. [Google Scholar] [CrossRef]

- King-Smith, R.D.; Vanderbilt, D. Theory of polarization of crystalline solids. Phys. Rev. B 1993, 47, 1651–1654. [Google Scholar] [CrossRef] [PubMed]

- Zoroddu, A.; Bernardini, F.; Ruggerone, P.; Fiorentini, V. First-principles prediction of structure, energetics, formation enthalpy, elastic constants, polarization, and piezoelectric constants of AlN, GaN, and InN: Comparison of local and gradient-corrected density-functional theory. Phys. Rev. B 2001, 64, 045208. [Google Scholar] [CrossRef]

- Fan, S.; Liu, R.; Huang, Y.; Liu, J.; Zhan, X.; Sun, X.; Feng, M.; Yin, Y.; Sun, Q.; Yang, H. Observation of threading dislocations and misfit dislocation half-loops in GaN/AlGaN heterostructures grown on Si using electron channeling contrast imaging. J. Appl. Phys. 2022, 132, 105302. [Google Scholar] [CrossRef]

- Deng, R.; Evans, S.R.; Gall, D. Bandgap in Al(1−x)ScxN. Appl. Phys. Lett. 2013, 102, 112103. [Google Scholar] [CrossRef]

- Zywitzki, O.; Modes, T.; Barth, S.; Bartzsch, H.; Frach, P. Effect of scandium content on structure and piezoelectric properties of AlScN films deposited by reactive pulse magnetron sputtering. Surf. Coat. Technol. 2017, 309, 417–422. [Google Scholar] [CrossRef]

- Mayrhofer, P.M.; Eisenmenger-Sittner, C.; Stöger-Pollach, M.; Euchner, H.; Bittner, A.; Schmid, U. The impact of argon admixture on the c-axis oriented growth of direct current magnetron sputtered ScxAl(1−x)N thin films. J. Appl. Phys. 2014, 115, 193505. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Wu, Z.; Gao, M.; Lou, L. Characterization of AlN thin film piezoelectric coefficient d31 using Piezoelectric Micromachined Ultrasonic Transducers (PMUTs). J. Phys. Conf. Ser. 2023, 2483, 012067. [Google Scholar] [CrossRef]

- Wurm, C.; Ahmadi, E.; Wu, F.; Hatui, N.; Keller, S.; Speck, J.; Mishra, U. Growth of high-quality N-polar GaN on bulk GaN by plasma-assisted molecular beam epitaxy. Solid State Commun. 2020, 305, 113763. [Google Scholar] [CrossRef]

- Casamento, J.; Wright, J.; Chaudhuri, R.; Xing, H.; Jena, D. Molecular beam epitaxial growth of scandium nitride on hexagonal SiC, GaN, and AlN. Appl. Phys. Lett. 2019, 115, 172101. [Google Scholar] [CrossRef]

- Satoh, S.; Ohtaka, K.; Shimatsu, T.; Tanaka, S. Crystal structure deformation and phase transition of AlScN thin films in whole Sc concentration range. J. Appl. Phys. 2022, 132, 025103. [Google Scholar] [CrossRef]

- Wang, D.; Wang, P.; Mondal, S.; Liu, J.; Hu, M.; He, M.; Nam, S.; Peng, W.; Yang, S.; Wang, D.; et al. Controlled ferroelectric switching in ultrawide bandgap AlN/ScAlN multilayers. Appl. Phys. Lett. 2023, 123, 103506. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Y.; Liu, R.; Zhao, H.; Fan, S.; Zhang, J.; Li, S.; Sun, Q.; Yang, H. High-Quality Single Crystalline Sc0.37Al0.63N Thin Films Enabled by Precise Tuning of III/N Atomic Flux Ratio during Molecular Beam Epitaxy. Nanomaterials 2024, 14, 1459. https://doi.org/10.3390/nano14171459

Yin Y, Liu R, Zhao H, Fan S, Zhang J, Li S, Sun Q, Yang H. High-Quality Single Crystalline Sc0.37Al0.63N Thin Films Enabled by Precise Tuning of III/N Atomic Flux Ratio during Molecular Beam Epitaxy. Nanomaterials. 2024; 14(17):1459. https://doi.org/10.3390/nano14171459

Chicago/Turabian StyleYin, Yuhao, Rong Liu, Haiyang Zhao, Shizhao Fan, Jianming Zhang, Shun Li, Qian Sun, and Hui Yang. 2024. "High-Quality Single Crystalline Sc0.37Al0.63N Thin Films Enabled by Precise Tuning of III/N Atomic Flux Ratio during Molecular Beam Epitaxy" Nanomaterials 14, no. 17: 1459. https://doi.org/10.3390/nano14171459

APA StyleYin, Y., Liu, R., Zhao, H., Fan, S., Zhang, J., Li, S., Sun, Q., & Yang, H. (2024). High-Quality Single Crystalline Sc0.37Al0.63N Thin Films Enabled by Precise Tuning of III/N Atomic Flux Ratio during Molecular Beam Epitaxy. Nanomaterials, 14(17), 1459. https://doi.org/10.3390/nano14171459