Depth-Resolved Phase Analysis of Expanded Austenite Formed in Austenitic Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

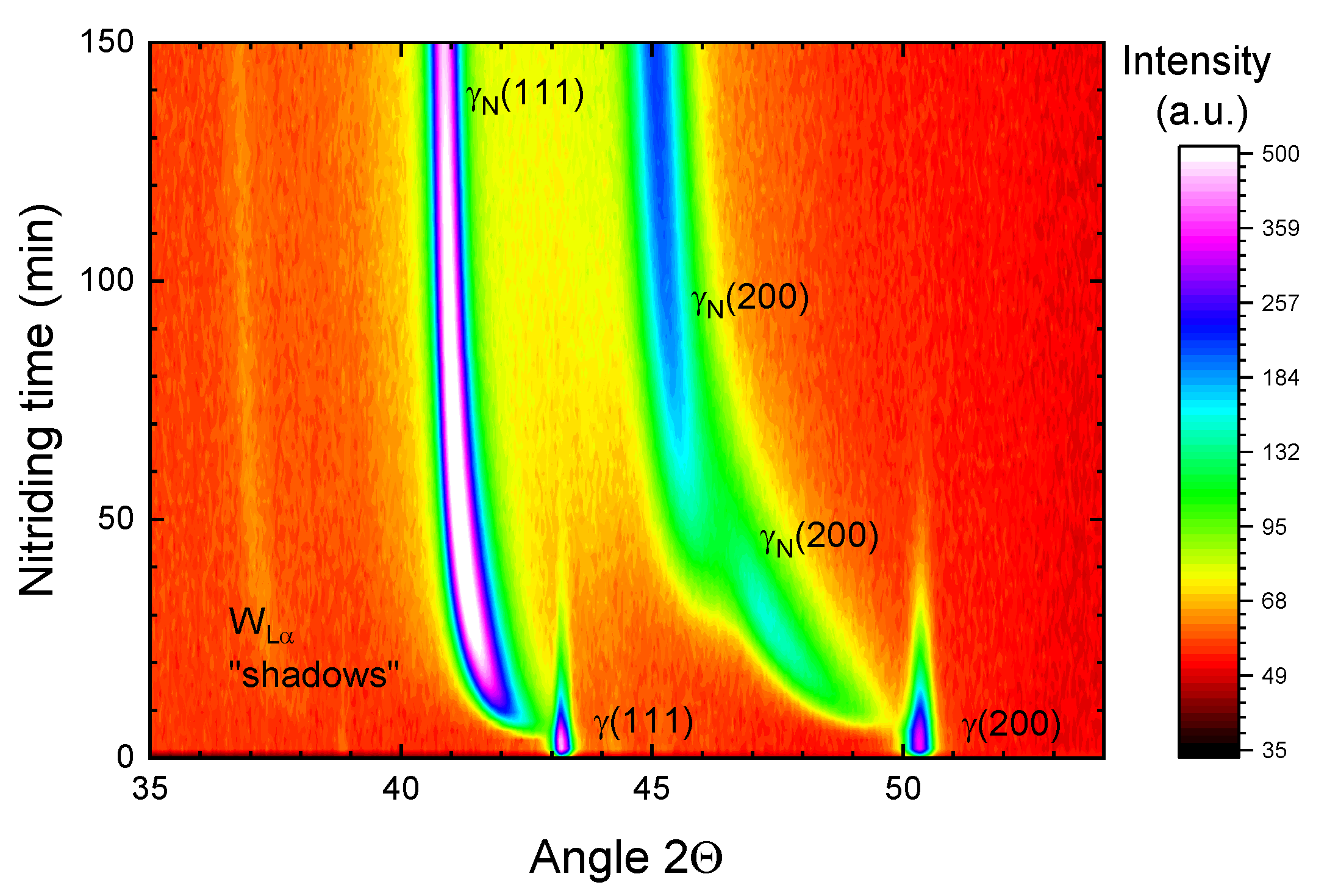

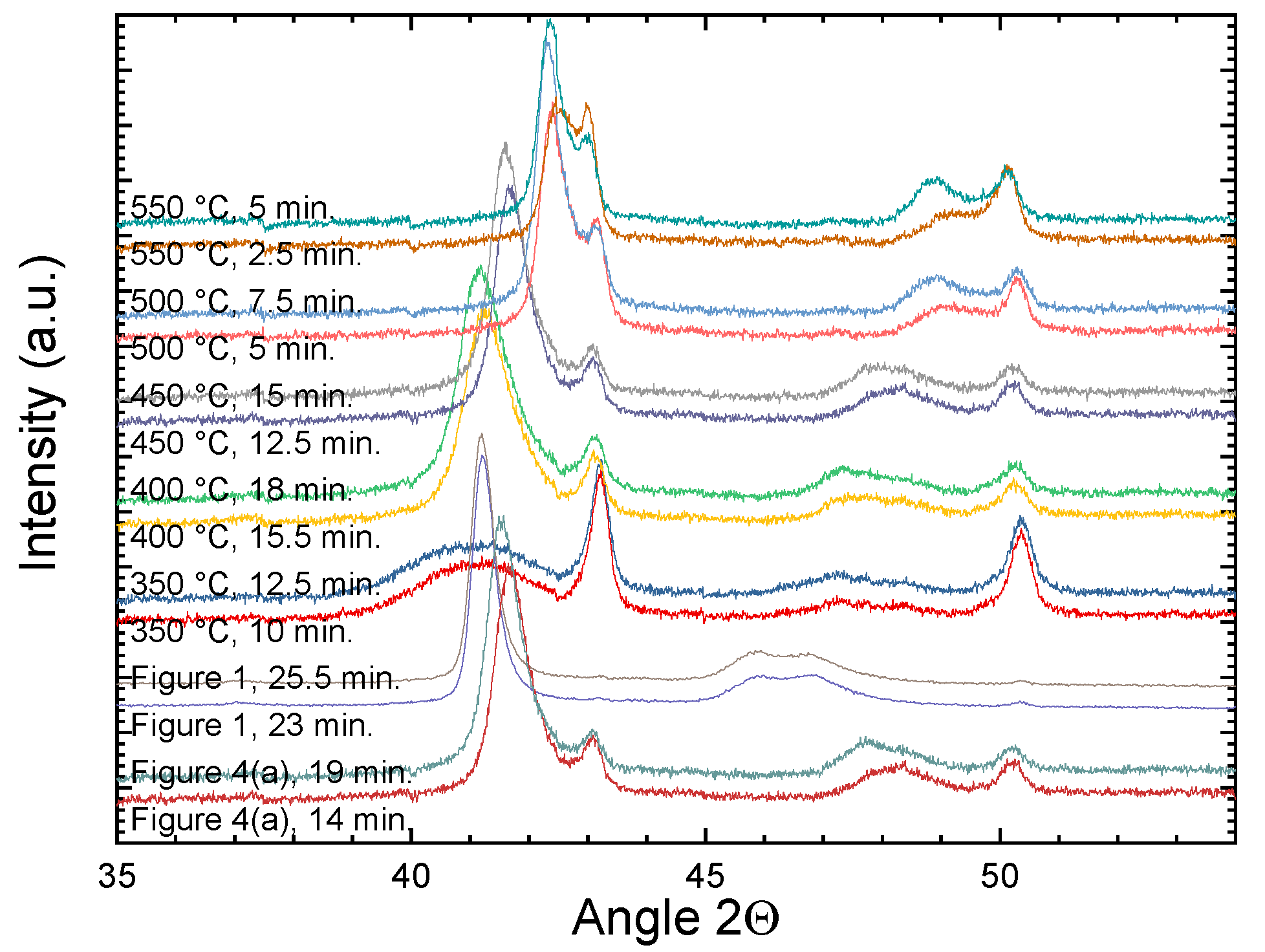

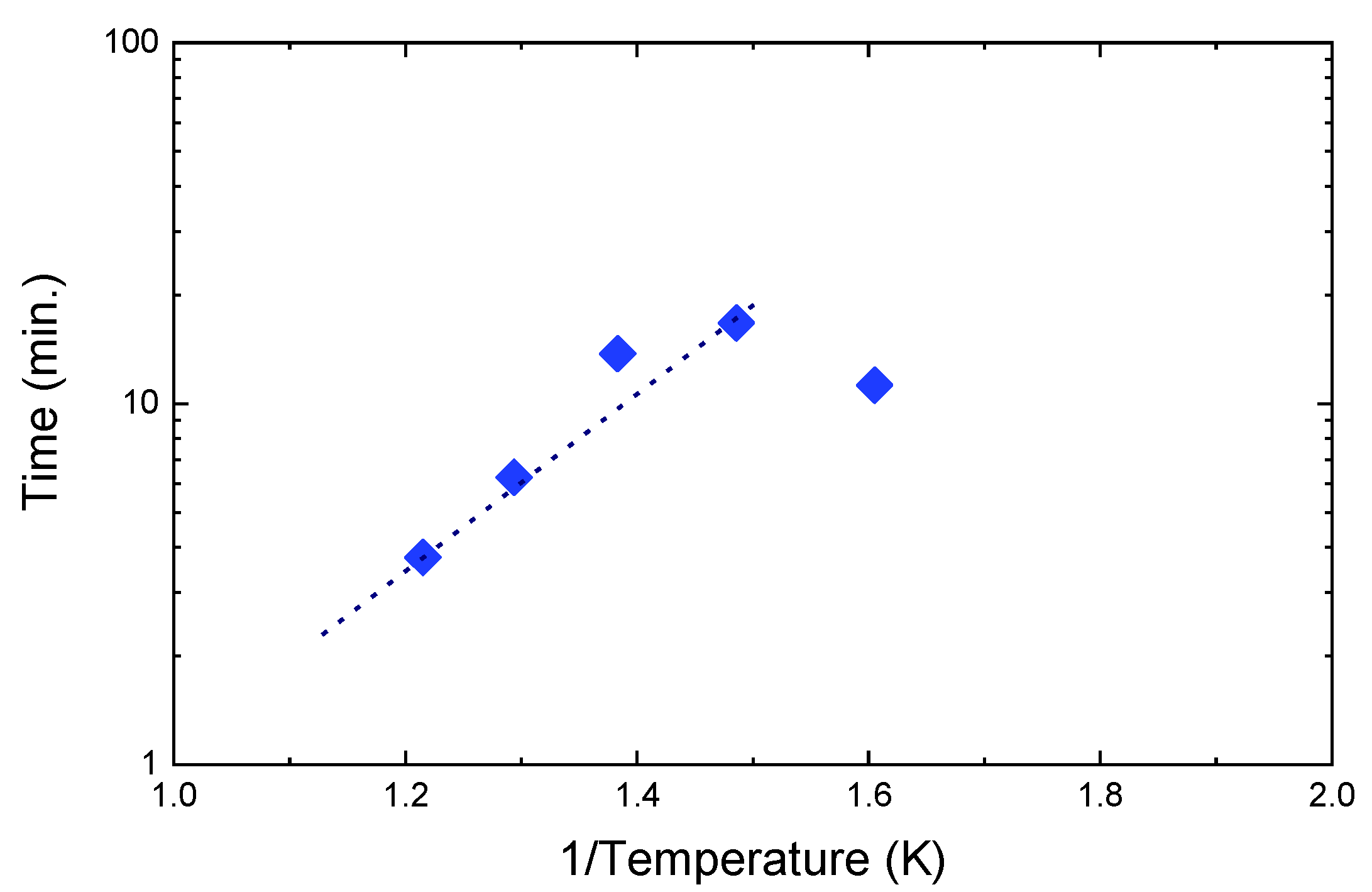

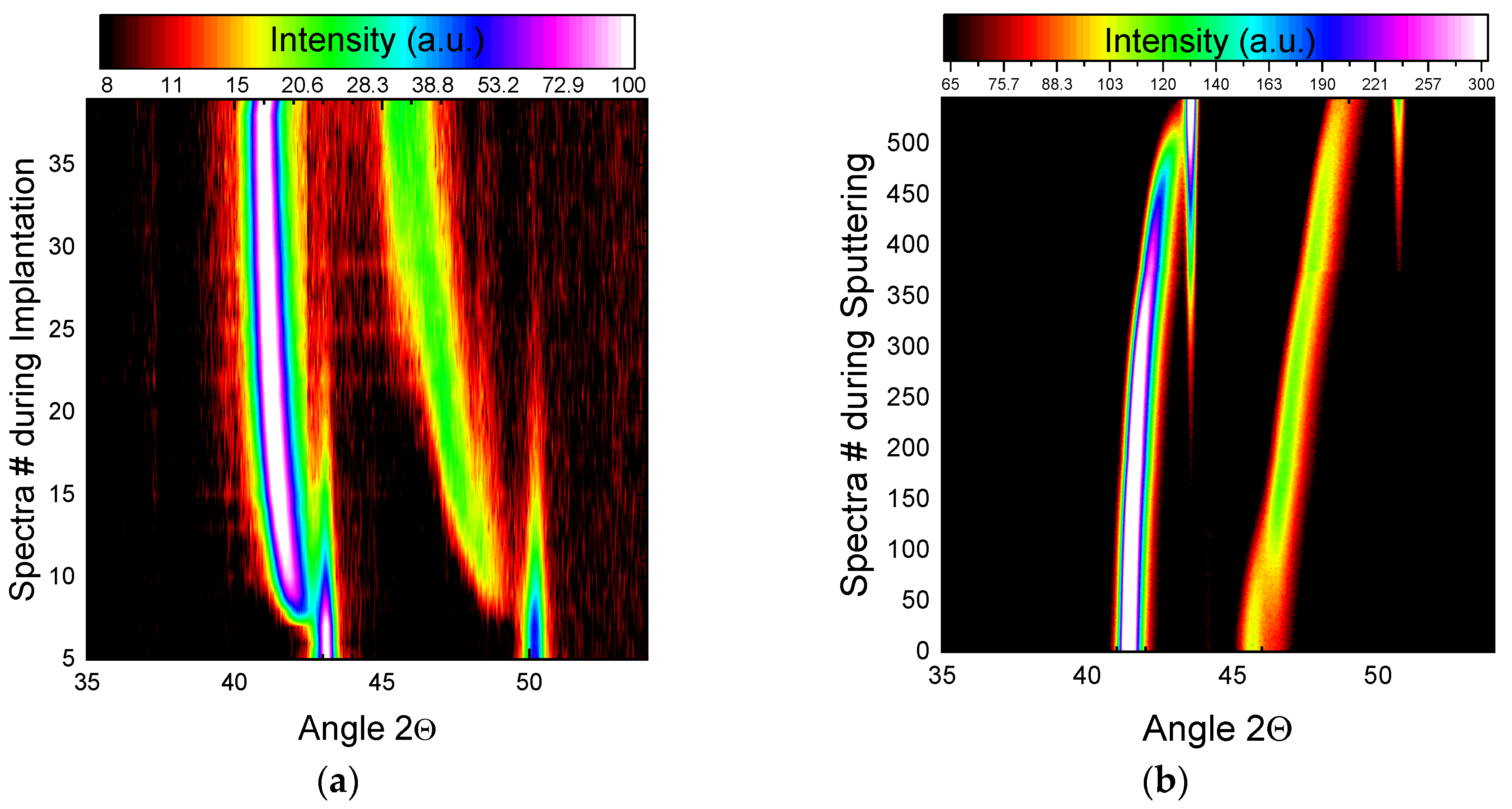

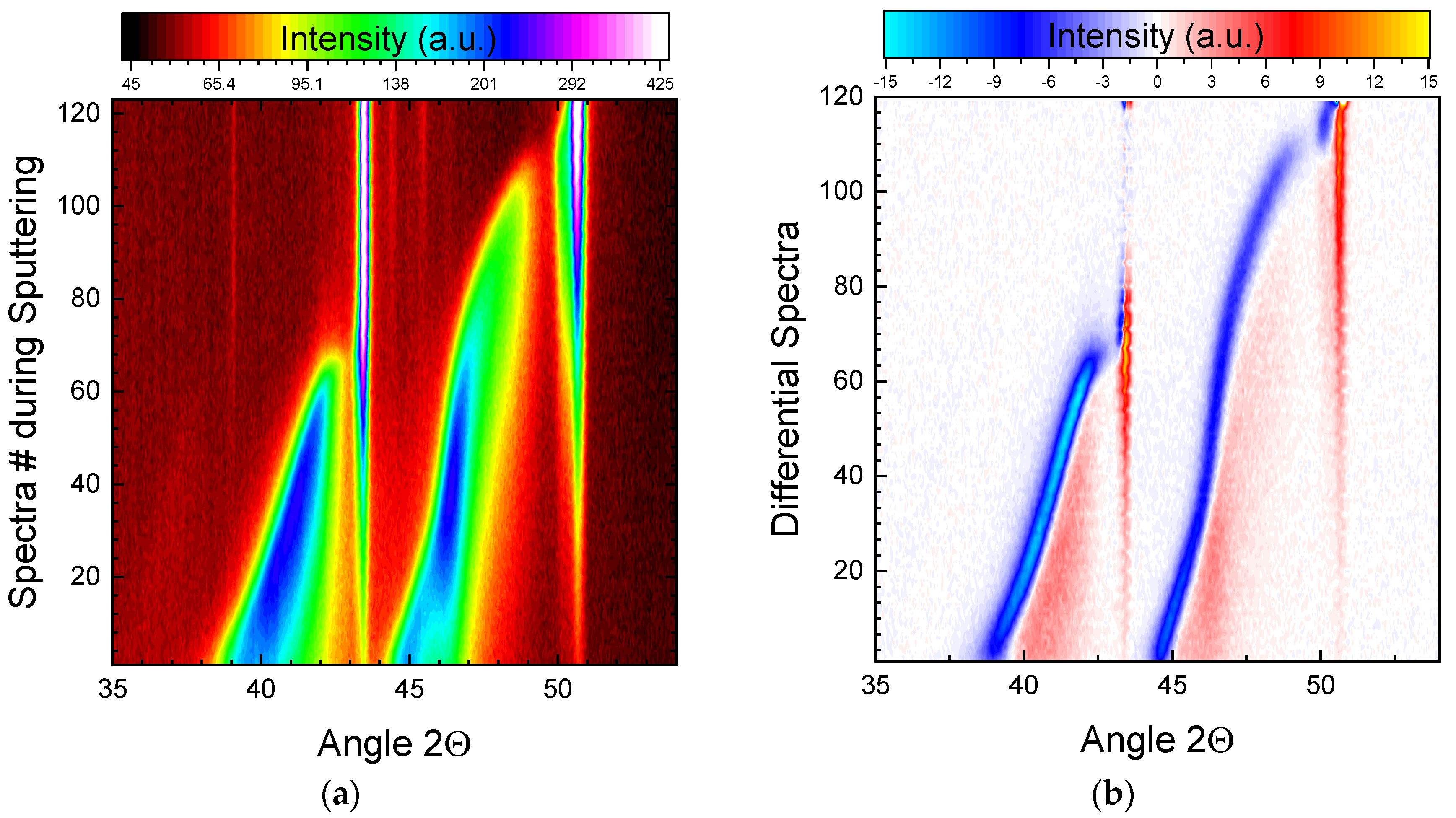

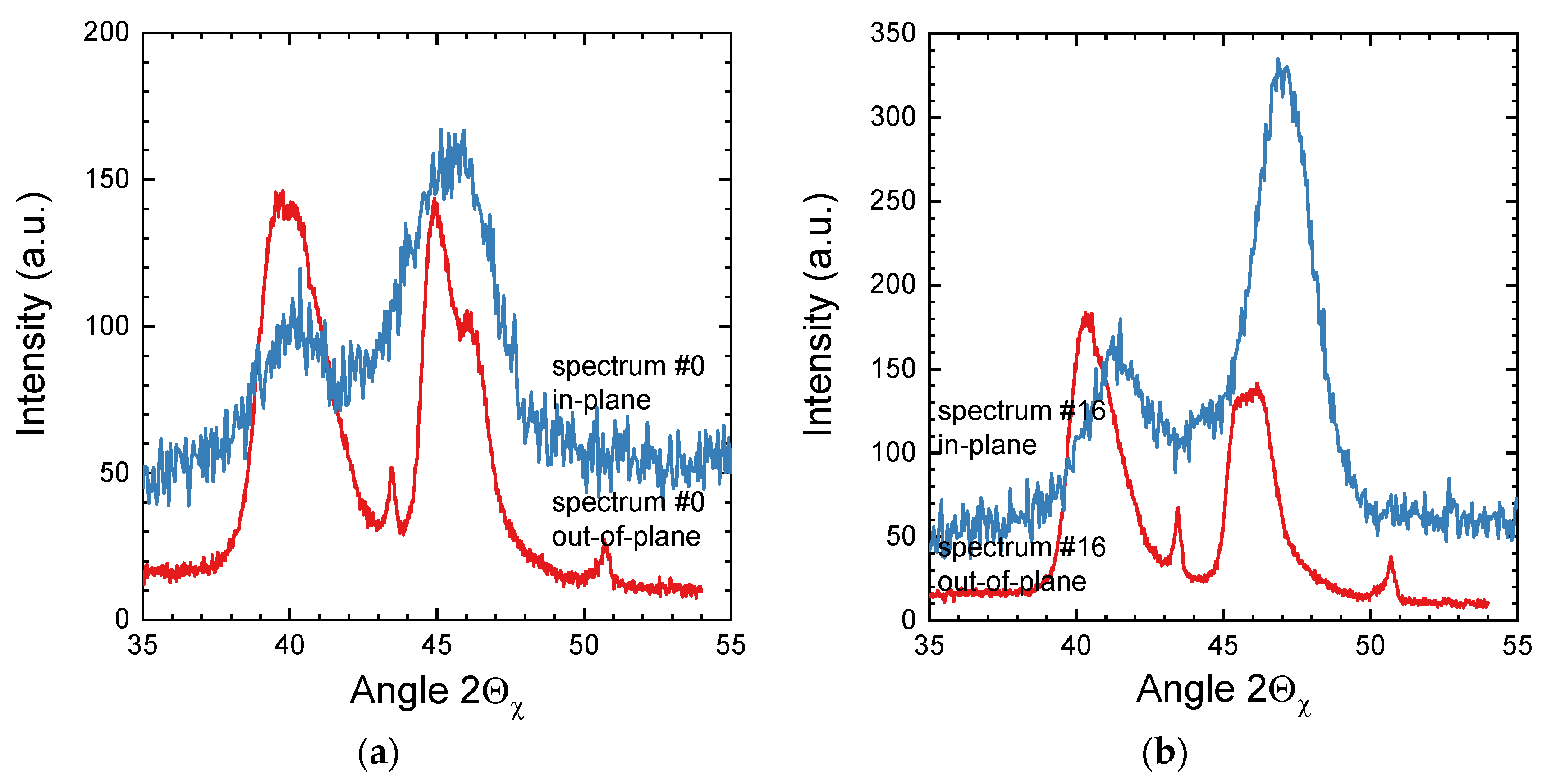

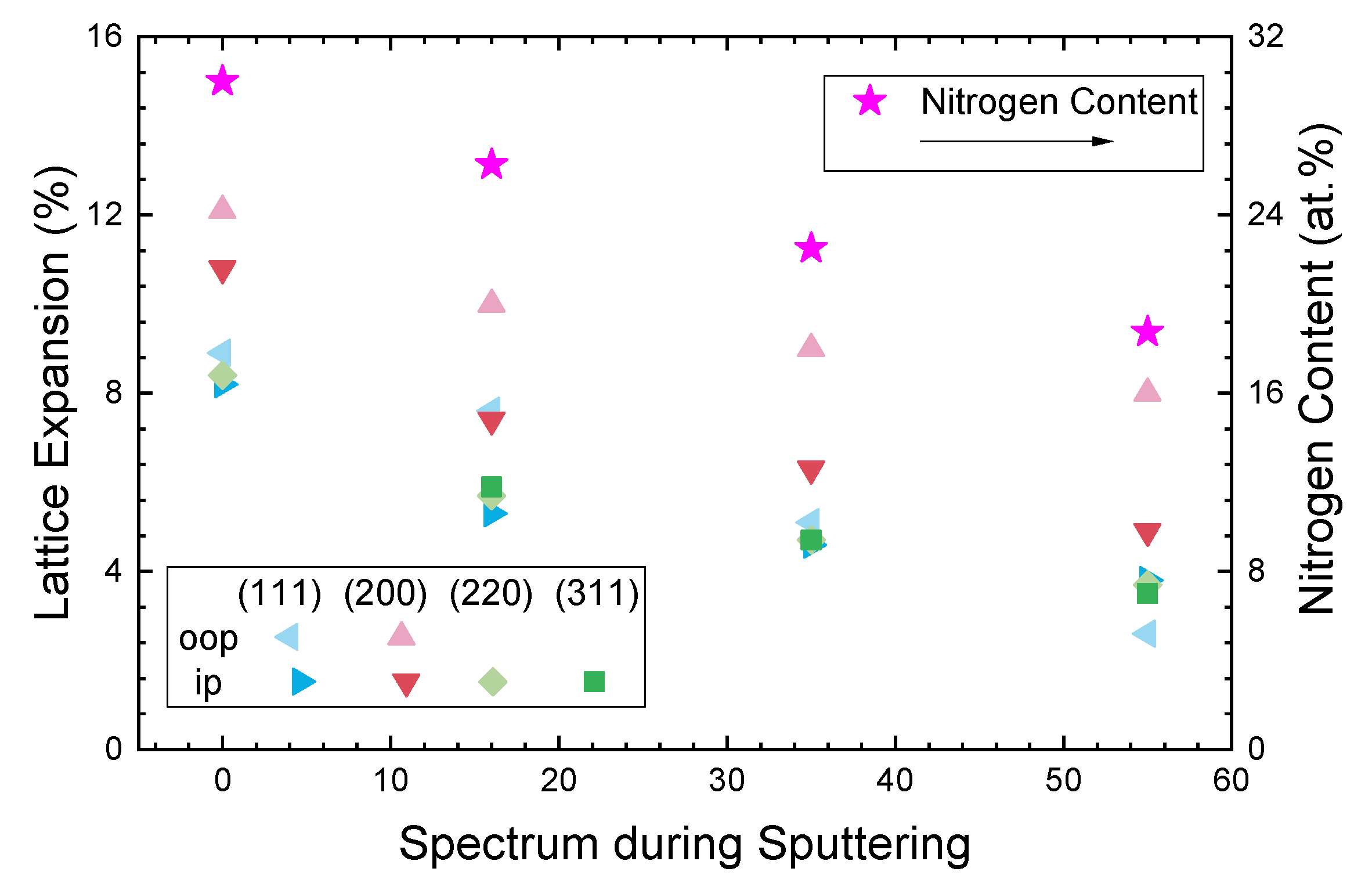

3. Results

3.1. Peculiarities of (200) Reflection for the Expanded Phase

3.2. Depth-Dependent Investigations

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Washko, S.D.; Aggen, G. Wrought Stainless Steels. In ASM Handbook; ASM International: Materials Park, OH, USA, 1997; Volume 1, pp. 841–907. [Google Scholar]

- McGuire, M.F. Stainless Steels for Design Engineers; ASM International: Materials Park, OH, USA, 2008; ISBN 978-0-87170-717-8. [Google Scholar]

- Lerner, R.M. Glow-discharge nitriding of Nitralloy 135M and AISI304 stainless steel. J. Iron Steel Inst. 1972, 210, 631–632. [Google Scholar]

- Lebrun, J.-P.; Michel, H.; Gantois, M. Nitruration par bombardement ionique des aciers inoxydables 18-10. Mémoires Sci. La Rev. Métallurgie 1972, 69, 727–738. [Google Scholar]

- Somers, M.A.J.; Christiansen, T.L. Low temperature surface hardening of stainless steel. In Thermochemical Surface Engineering of Steels; Mittemeijer, E.J., Somers, M.A.J., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 557–579. ISBN 978-0-85709-592-3. [Google Scholar] [CrossRef]

- Ichii, K.; Fujimura, K.; Takase, T. Microstructure, corrosion resistance, and hardness of the surface layer in ion nitrided 18-8 stainless steel. Netsu Shori 1985, 25, 191–195. [Google Scholar]

- Sun, Y.; Haruman, E. Low temperature plasma surface alloying of austenitic stainless steels. Solid State Phenom. 2006, 118, 85–90. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Bell, T. Structure and corrosion resistance of plasma nitrided stainless steel. Surf. Eng. 1985, 1, 131–136. [Google Scholar] [CrossRef]

- Borgioli, F. From austenitic stainless steel to expanded austenite-s phase: Formation, characteristics and properties of an elusive metastable phase. Metals 2020, 10, 187. [Google Scholar] [CrossRef]

- Czerwiec, T.; He, H.; Marcos, G.; Thiriet, T.; Weber, S.; Michel, H. Fundamental and innovations in plasma assisted diffusion of nitrogen and carbon in austenitic stainless steels and related alloys. Plasma Process. Polym. 2009, 6, 401–409. [Google Scholar] [CrossRef]

- Fewell, M.P.; Priest, J.M. High-order diffractometry of expanded austenite using synchrotron radiation. Surf. Coat. Technol. 2008, 202, 1802–1815. [Google Scholar] [CrossRef]

- Mändl, S.; Rauschenbach, B. Anisotropic strain in nitrided austenitic stainless steel. J. Appl. Phys. 2000, 88, 3323–3329. [Google Scholar] [CrossRef]

- Velterop, L.; Delhez, R.; de Keijser, T.H.; Mittemeijer, E.J.; Reefman, D. X-ray diffraction analysis of stacking and twin faults in f.c.c. metals: A revision and allowance for texture and non-uniform fault probabilities. J. Appl. Crystallogr. 2000, 33, 296–306. [Google Scholar] [CrossRef]

- Brink, B.K.; Ståhl, K.; Christiansen, T.L.; Oddershede, J.; Winther, G.; Somers, M.A.J. On the elusive crystal structure of expanded austenite. Scr. Mater. 2017, 131, 59–62. [Google Scholar] [CrossRef]

- Christiansen, T.; Somers, M.A.J. Avoiding ghost stress on reconstruction of stress-and composition-depth profiles from destructive X-ray diffraction depth profiling. Mater. Sci. Eng. A 2006, 424, 181–189. [Google Scholar] [CrossRef]

- Sienz, S.; Mändl, S.; Rauschenbach, B. In-situ stress measurements during low energy nitriding of stainless steel. Surf. Coat. Technol. 2002, 156, 185–189. [Google Scholar] [CrossRef]

- Christiansen, T.L.; Hummelshøj, T.S.; Somers, M.A.J. Expanded austenite, crystallography and residual stress. Surf. Eng. 2010, 26, 242–247. [Google Scholar] [CrossRef]

- Lutz, J.; Manova, D.; Gerlach, J.W.; Störmer, M.; Mändl, S. Interpretation of glancing angle and bragg-brentano XRD Measurements for CoCr alloy and austenitic stainless steel after PIII nitriding. IEEE Trans. Plasma Sci. 2011, 39, 3056–3060. [Google Scholar] [CrossRef]

- Manova, D.; Mändl, S. Perspectives: In-situ XRD measurements to explore phase formation near surface region. J. Appl. Phys. 2019, 126, 200901. [Google Scholar] [CrossRef]

- Henke, B.L.; Gullikson, E.M.; Davis, J.C. X-ray interactions: Photoabsorption, scattering, transmission, and reflection at E = 50–30000 eV, Z = 1–92. Data Nucl. Data Tables 1993, 54, 181–342. [Google Scholar] [CrossRef]

- Manova, D.; Mändl, S.; Gerlach, J.W.; Hirsch, D.; Neumann, H.; Rauschenbach, B. In situ X-ray diffraction investigations during low energy ion nitriding of austenitic stainless steel grade 1.4571. J. Phys. D Appl. Phys. 2014, 47, 365301. [Google Scholar] [CrossRef]

- Mändl, S. Nitriding of stainless steel: PIII or low energy nitriding? Plasma Proc. Polym. 2007, 4, 239–245. [Google Scholar] [CrossRef]

- Neumann, H.; Tartz, M.; Scholze, F.; Chassé, T.; Kersten, H.; Leiter, H. Broad beam ion sources for electrostatic space propulsion and surface modification processes: From roots to present applications. Contrib. Plasma Phys. 2007, 47, 487–497. [Google Scholar] [CrossRef]

- Brink, B.; Ståhl, K.; Christiansen, T.L.; Somers, M.A.J. Thermal expansion and phase transformations of nitrogen-expanded austenite studied with in situ synchrotron X-ray diffraction. J. Appl. Crystallogr. 2014, 47, 819–826. [Google Scholar] [CrossRef]

- Dienelt, J.; Zimmer, K.; Scholze, F.; Dathe, B.; Neumann, H. Generation of a pulsed ion beam with a tuned electronic beam switch. Plasma Sources Sci. Technol. 2003, 12, 489–494. [Google Scholar] [CrossRef]

- Manova, D.; Lutz, J.; Mändl, S. Sputtering effects during plasma immersion ion implantation of metals. Surf. Coat. Technol. 2010, 204, 2875–2880. [Google Scholar] [CrossRef]

- Williamson, D.L.; Davis, J.A.; Wilbur, P.J. Effect of austenitic stainless steel composition on low-energy, high-flux, nitrogen ion beam processing. Surf. Coat. Technol. 1998, 103, 178–184. [Google Scholar] [CrossRef]

- Blawert, C.; Weisheit, A.; Mordike, B.L.; Knoop, F.M. Plasma immersion ion implantation of stainless steel: Austenitic stainless steel in comparison to austenitic-ferritic stainless steel. Surf. Coat. Technol. 1996, 85, 15–27. [Google Scholar] [CrossRef]

- Manova, D.; Günther, C.; Bergmann, A.; Mändl, S.; Neumann, H.; Rauschenbach, B. Influence of temperature on layer growth as measured by in-situ XRD observation of nitriding austenitic stainless steel. Nucl. Instrum. Methods B 2013, 307, 310–314. [Google Scholar] [CrossRef]

- Williamson, D.L.; Ozturk, O.; Wei, R.; Wilbur, P.J. Metastable phase formation and enhanced diffusion in f.c.c. alloys under high dose, high flux nitrogen implantation at high and low ion energies. Surf. Coat. Technol. 1994, 65, 15–27. [Google Scholar] [CrossRef]

- Manova, D.; Díaz, C.; Pichon, L.; Abrasonis, G.; Mändl, S. Comparability and accuracy of nitrogen depth profiling in nitrided austenitic stainless steel. Nucl. Instrum. Methods B 2015, 349, 106–113. [Google Scholar] [CrossRef]

- Blawert, C.; Mordike, B.L.; Collins, G.A.; Short, K.T.; Jirásková, Y.; Schneeweiss, O.; Perina, V. Characterisation of duplex layer structures produced by simultaneous implantation of nitrogen and carbon into austenitic stainless steel X5CrNi189. Surf. Coat. Technol. 2000, 128, 219–225. [Google Scholar] [CrossRef]

- Mändl, S.; Dunkel, R.; Hirsch, D.; Manova, D. Intermediate stages of CrN precipitation during PIII nitriding of stainless steel. Surf. Coat. Technol. 2014, 258, 722–726. [Google Scholar] [CrossRef]

- Manova, D.; Lotnyk, A.; Mändl, S.; Neumann, H.; Rauschenbach, B. CrN precipitation and elemental segregation during the decay of expanded austenite. Mater. Res. Express 2016, 3, 066502. [Google Scholar] [CrossRef]

- Martinavičius, A.; Abrasonis, G.; Möller, W.; Templier, C.; Rivière, J.P.; Declémy, A.; Chumlyakov, Y. Anisotropic ion-enhanced diffusion during ion nitriding of single crystalline austenitic stainless steel. J. Appl. Phys. 2009, 105, 93502. [Google Scholar] [CrossRef]

- Christiansen, T.; Somers, M. Controlled dissolution of colossal quantities of nitrogen in stainless steel. Met. Mater. Trans. 2006, 37A, 675–682. [Google Scholar] [CrossRef]

- Ledbetter, H.M.; Austin, M.W. Dilation of an fcc Fe–Cr–Ni alloy by interstitial carbon and nitrogen. Mater. Sci. Technol. 1987, 3, 101–104. [Google Scholar] [CrossRef]

- Manova, D.; Lutz, J.; Gerlach, J.W.; Neumann, H.; Mändl, S. Relation between lattice expansion and nitrogen content in expanded phase after nitrogen insertion in austenitic stainless steel and CoCr alloys. Surf. Coat. Technol. 2011, 205, S290–S293. [Google Scholar] [CrossRef]

- Wu, D.; Kahn, H.; Dalton, J.C.; Michal, G.M.; Ernst, F.; Heuer, A.H. Orientation dependence of nitrogen supersaturation in austenitic stainless steel during low-temperature gas-phase nitriding. Acta Mater. 2014, 79, 339–350. [Google Scholar] [CrossRef]

- Fonović, M.; Leineweber, A.; Robach, O.; Jägle, E.A.; Mittemeijer, E. The nature and origin of “double expanded austenite” in Ni-based Ni–Ti alloys developing upon low temperature gaseous nitriding. J. Met. Mater. Trans. 2015, 46, 4115–4131. [Google Scholar] [CrossRef]

- Jafarpour, S.M.; Puth, A.; Dalke, A.; Böcker, J.; Pipa, A.V.; Röpcke, J.; van Helden, J.-P.; Biermann, H. Solid carbon active screen plasma nitrocarburizing of AISI 316L stainless steel in cold wall reactor: Influence of plasma conditions. J. Mater. Res. Technol. 2020, 9, 9195–9205. [Google Scholar] [CrossRef]

- Manova, D.; Hirsch, D.; Gerlach, J.W.; Mändl, S.; Neumann, H.; Rauschenbach, B. In-situ Investigation of phase formation during low energy ion nitriding of Ni80Cr20 alloy. Surf. Coat. Technol. 2014, 259, 434–441. [Google Scholar] [CrossRef]

- Gai, Z.; Lin, W.; Burton, J.; Fuchigami, K.; Snijders, P.C.; Ward, T.Z.; Tsymbal, E.Y.; Shen, J.; Jesse, S.; Kalinin, S.V.; et al. Chemically induced Jahn–Teller ordering on manganite surfaces. Nat. Commun. 2014, 5, 4528. [Google Scholar] [CrossRef]

- Panigrahi, P.; Hussain, T.; Araujo, C.M.; Ahuja, R. Hole induced Jahn Teller distortion ensuing ferromagnetism in Mn-MgO: Bulk, surface and one dimensional structures. J. Phys. Condens Matter. 2014, 26, 265801. [Google Scholar] [CrossRef] [PubMed]

| Spectra # | Comment |

|---|---|

| 0 | surface |

| 16 | transition in (200) exp. phase |

| 35 | bulk of exp. phase |

| 55 | end of (111) exp. phase |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manova, D.; Schlenz, P.; Gerlach, J.W.; Mändl, S. Depth-Resolved Phase Analysis of Expanded Austenite Formed in Austenitic Stainless Steel. Coatings 2020, 10, 1250. https://doi.org/10.3390/coatings10121250

Manova D, Schlenz P, Gerlach JW, Mändl S. Depth-Resolved Phase Analysis of Expanded Austenite Formed in Austenitic Stainless Steel. Coatings. 2020; 10(12):1250. https://doi.org/10.3390/coatings10121250

Chicago/Turabian StyleManova, Darina, Patrick Schlenz, Jürgen W. Gerlach, and Stephan Mändl. 2020. "Depth-Resolved Phase Analysis of Expanded Austenite Formed in Austenitic Stainless Steel" Coatings 10, no. 12: 1250. https://doi.org/10.3390/coatings10121250

APA StyleManova, D., Schlenz, P., Gerlach, J. W., & Mändl, S. (2020). Depth-Resolved Phase Analysis of Expanded Austenite Formed in Austenitic Stainless Steel. Coatings, 10(12), 1250. https://doi.org/10.3390/coatings10121250