Effects of Tool Coatings on Energy Consumption in Micro-Extrusion of Aluminum Alloy 6063

Abstract

:1. Introduction

2. Materials and Methods

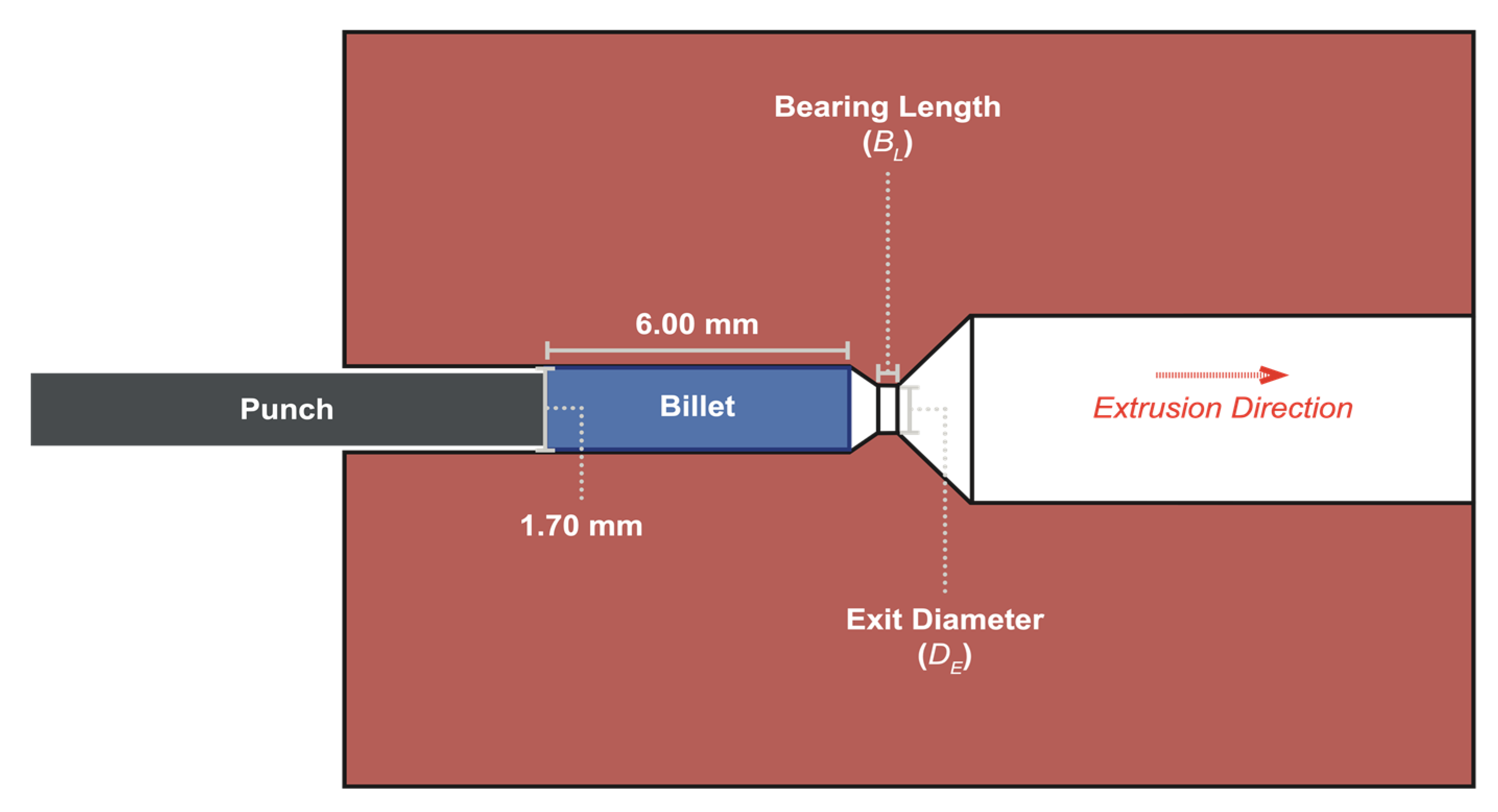

2.1. Micro-Extrusion Experiment

2.2. Materials

2.3. Considered Factors

2.4. Finite Element Simulation

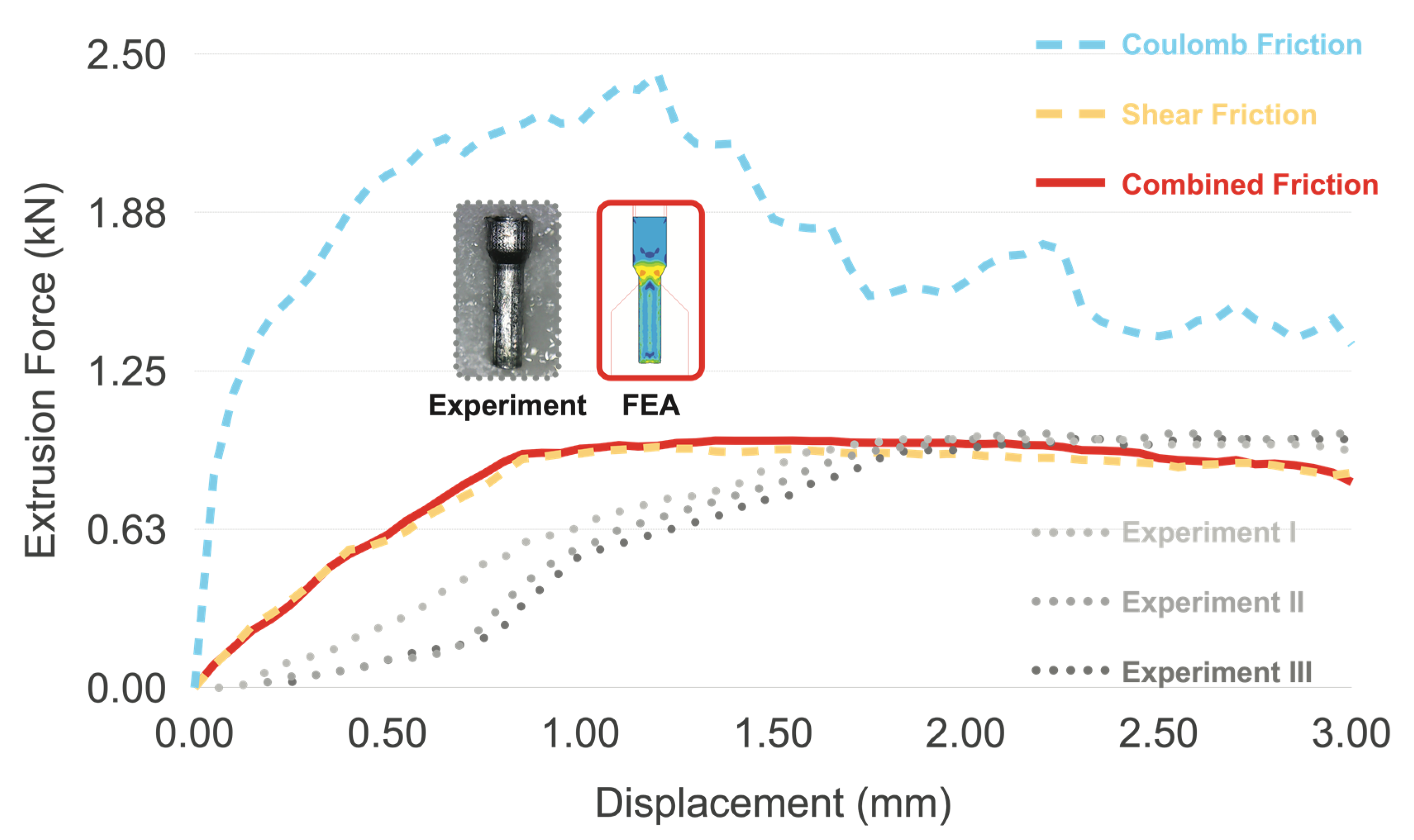

2.4.1. Coulomb Friction Model

2.4.2. Shear Friction Model

2.4.3. Combined Friction Model

- (1)

- The wear rate per cycle would be used to predict the number of cycles prior to tool wear (coating thickness depletion). Thus, the final part geometry could be precisely controlled, and the tool could be adequately maintained, lowering the production cost.

- (2)

- The energy consumption per extrusion cycle would be used to predict the energy cost by using each considered tool coating. Each extrusion energy cycle would be multiplied by the predicted number of cycles from (1) to obtain the total energy consumption.

3. Results

4. Discussion

5. Conclusions

- (1)

- Increasing bearing lengths from 0.5 mm to 3.0 mm led to the increase in tool wear rate of 40% and energy consumption of 10%–30% for all the coating types.

- (2)

- Reducing the coefficient of frictions from 0.45 to 0.11 led to a decrease in energy consumption of 50%.

- (3)

- High hardness values of the tool surface and low bearing lengths are critical to tool life extension.

- (4)

- Low coefficient of friction values of the tool-billet interface and low bearing lengths are critical to energy consumption.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cullen, M.; Allwood, J. Mapping the global flow of aluminum: From liquid aluminum to end-use goods. Environ. Sci. Technol. 2013, 47, 3057–3064. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gronostajski, Z.; Pater, Z.; Madej, L.; Surdacki, P.; Lisiecki, L.; Lukaszek-Solek, A.; Łuksza, J.; Mróz, S.; Muskalski, Z.; Muzykiewicz, W.; et al. Recent development trends in metal forming. Arch. Civ. Mech. Eng. 2019, 19, 898–941. [Google Scholar] [CrossRef]

- Alting, L.; Kimura, F.; Hansen, H.N.; Bissacco, G. Micro engineering. CIRP Ann. 2003, 52, 635–657. [Google Scholar] [CrossRef]

- Cowley, A.; Woodward, B. A healthy future: Platinum in medical applications. Platin. Metals Rev. 2011, 55, 98–107. [Google Scholar] [CrossRef]

- Vollertsen, F.; Friedrich, S.; Kuhfuß, B.; Maaß, P.; Thomy, C.; Zoch, H.-W. Micro forming processes. In Cold Micro Metal Forming. Lecture Notes in Production Engineering; Vollertsen, F., Friedrich, S., Kuhfuß, B., Maaß, P., Thomy, C., Zoch, H.W., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Rosochowski, A.; Presz, W.; Olejnik, L.; Richert, M. Micro-extrusion of ultra-fine grained aluminium. Int. J. Adv. Manuf. Technol. 2007, 33, 137–146. [Google Scholar] [CrossRef]

- Mahayotsanun, N.; Lee, H.C.; Cheng, T.J.; Chuang, Y.; Tu, K.Y.; Ehmann, K.; Cao, J. Development of the High-Speed Micro-Extrusion machine to investigate strain rate and size effects. In Proceedings of the 2009 International Conference of Micro-Manufacturing (4M/ICOMM 2009), Karlsruhe, Germany, 23–25 September 2009; pp. 383–386. [Google Scholar]

- Kuhfuss, B. Bulk metal forming. In Micro Metal Forming; Springer: Berlin, Germany, 2013; pp. 103–133. [Google Scholar]

- Li, Y.; Bushby, A.J.; Dunstan, D.J. The Hall–Petch effect as a manifestation of the general size effect. Proc. R. Soc. A 2016, 472, 20150890. [Google Scholar] [CrossRef] [PubMed]

- Justinger, H.; Hirt, G. Estimation of grain size and grain orientation influence in microforming processes by Taylor factor considerations. J. Manuf. Process. 2011, 13, 153–159. [Google Scholar] [CrossRef]

- Parasız, S.A.; Kinsey, B.L.; Mahayotsanun, N.; Cao, J. Effect of specimen size and grain size on deformation in microextrusion. J. Manuf. Process. 2009, 209, 2111–2121. [Google Scholar] [CrossRef]

- Chan, W.L.; Fu, M.W.; Yang, B. Study of size effect in micro-extrusion process of pure copper. Mater Des. 2011, 32, 3772–3782. [Google Scholar] [CrossRef]

- Fu, M.W.; Chan, W.L. Size effects in micro-scaled plastic deformation. In Micro-scaled Products Development via Microforming; Springer: London, UK, 2014; pp. 9–55. [Google Scholar]

- Rajenthirakumar, D.; Sridhar, R.; Abenethiri, R.; Kartik, R.; Bagri, D. Experimental investigations of grain size effects in forward microextrusion. Int. J. Adv. Manuf. Technol. 2016, 85, 2257–2264. [Google Scholar] [CrossRef]

- Wang, C.; Wang, C.; Xu, J.; Zhang, P.; Shan, D.; Gao, B. Interactive effect of microstructure and cavity dimension on filling behavior in micro coining of pure nickel. Sci. Rep. 2016, 6, 23895. [Google Scholar] [CrossRef] [PubMed]

- Engel, U. Tribology in microforming. Wear 2006, 260, 265–273. [Google Scholar] [CrossRef]

- Dixit, U.S.; Yadav, V.; Narayanan, G.R.; Bhardwaj, N. Friction in micromanufacturing. J. Micromanufacturing 2018, 1, 76–91. [Google Scholar] [CrossRef]

- Yao, Z.; Mei, D.; Shen, H.; Chen, Z. A friction evaluation method based on barrel compression test. Tribol. Lett. 2013, 51, 525–535. [Google Scholar] [CrossRef]

- Zhou, F.; Suh, C.-M.; Kim, S.-S.; Murakami, R.-I. Sliding-wear behavior of TiN- and CrN-coated 2024 aluminum alloy against an Al2O3 ball. Tribol. Lett. 2002, 13, 173–178. [Google Scholar] [CrossRef]

- Eriksen, R.; Calaon, M.; Arentoft, M.; Bay, N. Benchmarking of direct and indirect friction tests in micro forming. Key Eng. Mater. 2012, 504–506, 581–586. [Google Scholar] [CrossRef]

- Groche, P.; Muller, C.; Jahn, A. Effects of the tool lubrication in cold forging. Tribol. Lett. 2014, 53, 599–605. [Google Scholar] [CrossRef]

- Groche, P.; Kramer, P.; Zang, Z.; Rezanov, V. Prediction of the evolution of the surface roughness in dependence of the lubrication system for cold forming processes. Tribol. Lett. 2015, 59, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Osakada, K.; Matsumoto, R. Fundamental study of dry metal forming with coated tools. CIRP Ann. Manuf. Technol. 2000, 49, 161–164. [Google Scholar] [CrossRef]

- Biswas, S.K.; Singh, R.A. Wear of metals—Influence of some primary material properties. Tribol. Lett. 2002, 13, 203–207. [Google Scholar] [CrossRef]

- Wang, S.Q.; Wei, M.X.; Wang, F.; Cui, X.H.; Dong, C. Transition of mild wear to severe wear in oxidative wear of H21 steel. Tribol. Lett. 2008, 32, 67–72. [Google Scholar] [CrossRef]

- Prieske, M.; Hasselbruch, H.; Mehner, A.; Vollertsen, F. Friction and wear performance of different carbon coatings for use in dry aluminium forming processes. Surf. Coat. Technol. 2019, 357, 1048–1059. [Google Scholar] [CrossRef]

- Hilda, R.; Bergsa, T.; Mattfelda, P.; Trautha, D.; Klockea, F.; Hoffmannb, D.C.; Kruppeb, N.C.; Brögelmannb, T.; Bobzinb, K. Analysis of wear phenomena during forward extrusion under dry friction conditions. Wear 2019, 426–427, 1362–1370. [Google Scholar] [CrossRef]

- Ahmad, F.; Zhang, L.; Zheng, J.; Sidra, I.; Zhang, S. Characterization of AlCrN and AlCrON coatings deposited on plasma nitrided AISI H13 steels using ion-source-enhanced arc ion plating. Coatings 2020, 10, 306. [Google Scholar] [CrossRef] [Green Version]

- Abrashov, A.; Grigoryan, N.; Vagramyan, T.; Asnis, N. On the mechanism of formation of conversion titanium-containing coatings. Coatings 2020, 10, 328. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Shan, D.; Guo, B. DLC-Coated tools for micro-forming. In Micromanufacturing Engineering and Technology, 2nd ed.; Qin, Y., Ed.; William Andrew: Amsterdam, The Netherlands, 2015; pp. 487–512. [Google Scholar]

- Yang, M.; Shimizu, T.; Hu, J.; Shiratori, T. An integrated precise engineering for micro forming. MATEC Web Conf. 2018, 190, 01003. [Google Scholar] [CrossRef] [Green Version]

- Evaristo, M.; Fernandes, F.; Cavaleiro, A. Room and high temperature tribological behaviour of W-DLC coatings produced by DCMS and hybrid DCMS-HiPIMS configuration. Coatings 2020, 10, 319. [Google Scholar] [CrossRef] [Green Version]

- Kanda, K.; Suzuki, S.; Niibe, M.; Hasegawa, T.; Suzuki, T.; Saitoh, H. Local structure analysis on Si-containing DLC films based on the measurement of C K-Edge and Si K-Edge X-ray absorption spectra. Coatings 2020, 10, 330. [Google Scholar] [CrossRef] [Green Version]

- Atta, A.M.; Ahmed, M.A.; Al-Lohedan, H.A.; El-Faham, A. Multi-Functional cardanol triazine schiff base polyimine additives for self-healing and super-hydrophobic epoxy of steel coating. Coatings 2020, 10, 327. [Google Scholar] [CrossRef] [Green Version]

- Funazuka, T.; Takatsuji, N.; Dohda, K.; Mahayotosanun, N. Effect of Die angle and friction condition on formability in micro extrusion—Research on micro forward-backward extrusion of aluminum alloy 2nd report. J. Jpn. Soc. Technol. Plast. 2018, 59, 7–12. [Google Scholar]

- Saboori, M.; Bakhshi-Jooybari, M.; Noorani-Azad, M.; Gorji, A. Experimental and numerical study of energy consumption in forward and backward rod extrusion. J. Mater. Process. Technol. 2006, 177, 612–616. [Google Scholar] [CrossRef]

- Zhang, B.; Dodaran, M.; Ahmed, S.; Shao, S.; Meng, W.J.; Juul, K.J.; Nielsen, K.L. Grain-size affected mechanical response and deformation behavior in microscale reverse extrusion. Materialia 2019, 6, 100272. [Google Scholar] [CrossRef]

- Ghassemali, E.; Tan, M.J.; Jarfors, A.E.W.; Lim, S.C.V. Progressive microforming process: Towards the mass production of micro-parts using sheet metal. Int. J. Adv. Manuf. Technol. 2012, 66, 5–8. [Google Scholar] [CrossRef]

- Murakawa, M.; Takeuchi, S. Evaluation of tribological properties of DLC films used in sheet forming of aluminum sheet. Surf. Coat. Technol. 2003, 163–164, 561–565. [Google Scholar] [CrossRef]

| Parameters | CrN | TiN | DLC-CVD | DLC-PVD |

|---|---|---|---|---|

| Coating Hardness (HV) | 1700 | 2100 | 4000 | 7000 |

| Coating Thickness (μm) | 2.0 | 1.0 | 1.0 | 0.7 |

| Coefficient of Friction (COF) | 0.45 | 0.55 | 0.11 | 0.11 |

| Parameters | Level 1 (Initial) | Level 2 (Low) | Level 3 (Medium) | Level 4 (High) |

|---|---|---|---|---|

| Bearing Length (BL) | 0.50 mm | 1.00 mm | 2.50 mm | 3.00 mm |

| Parameters | Level 1 (Low) | Level 2 (High) |

|---|---|---|

| Exit Diameter (DE) | 1.09 mm | 0.55 mm |

| Extrusion Ratio (ER) | 2.43 | 9.55 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sucharitpwatskul, S.; Mahayotsanun, N.; Bureerat, S.; Dohda, K. Effects of Tool Coatings on Energy Consumption in Micro-Extrusion of Aluminum Alloy 6063. Coatings 2020, 10, 381. https://doi.org/10.3390/coatings10040381

Sucharitpwatskul S, Mahayotsanun N, Bureerat S, Dohda K. Effects of Tool Coatings on Energy Consumption in Micro-Extrusion of Aluminum Alloy 6063. Coatings. 2020; 10(4):381. https://doi.org/10.3390/coatings10040381

Chicago/Turabian StyleSucharitpwatskul, Sedthawatt, Numpon Mahayotsanun, Sujin Bureerat, and Kuniaki Dohda. 2020. "Effects of Tool Coatings on Energy Consumption in Micro-Extrusion of Aluminum Alloy 6063" Coatings 10, no. 4: 381. https://doi.org/10.3390/coatings10040381