Preparation of the Surface of Long-Dimensional Rods of Hydro-Cylinders for Thermal Spraying Using an Abrasive Jet

Abstract

:1. Introduction

- -

- Adhesive method (film material lags behind completely);

- -

- Cohesive method (the film is stratified, destroyed);

- -

- Mixed method (partial peeling of the film from the surface of the substrate occurs, and partially tearing off the film itself).

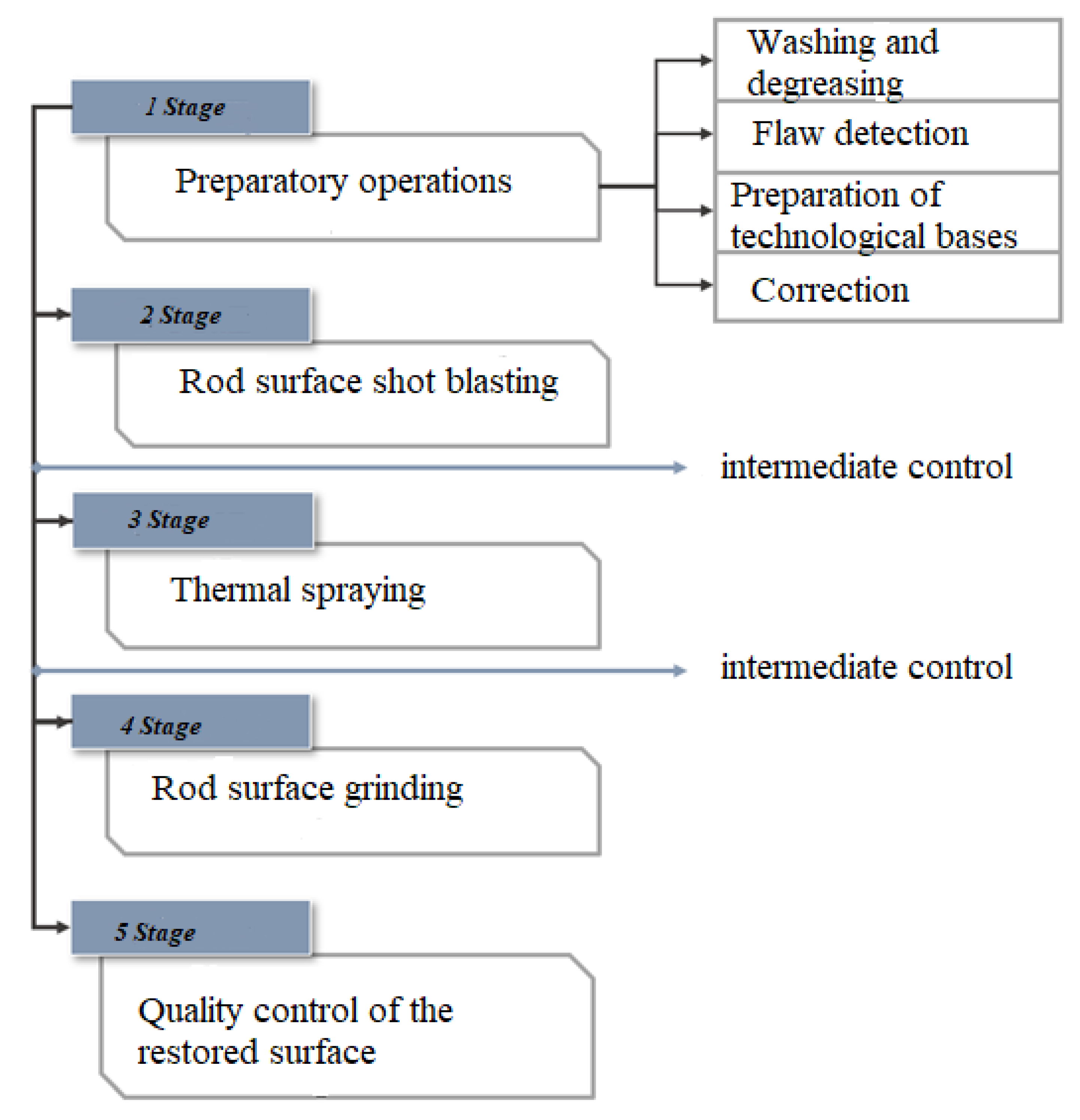

2. Materials and Methods

- -

- Shot type—DSK-0.3 according to GOST 11964-81;

- -

- Microhardness—500 HV;

- -

- Density—not less than 7200 kg/m3;

- -

- Allowable residue content on sieve No. 3—not less than 65%.

- -

- Diameter of the shot blasting nozzle—4.5 mm;

- -

- Type of abrasive particles—DSK-03 according to GOST 11964-81;

- -

- Rod rotation frequency—63 rpm.

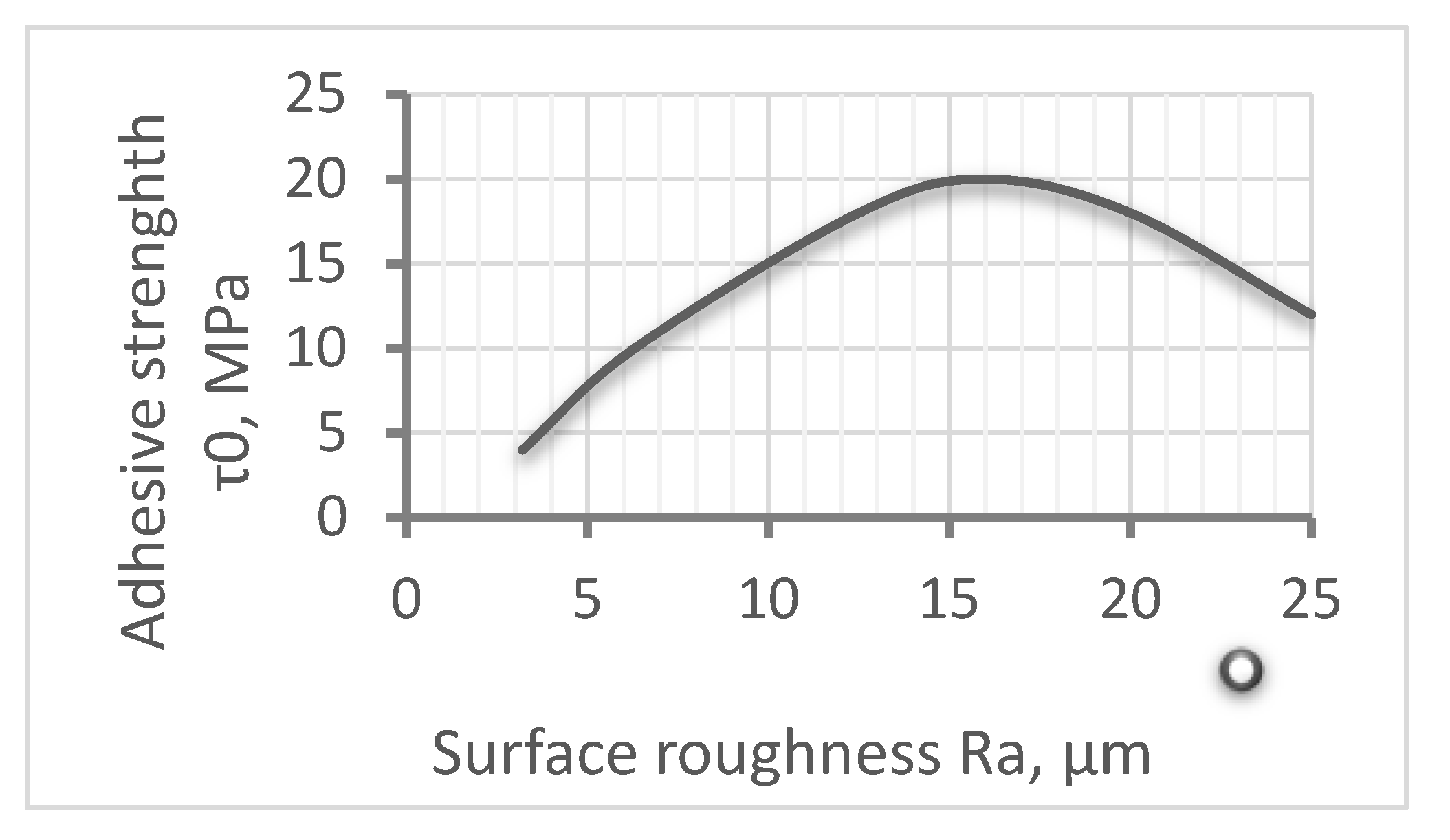

3. Results and Discussion

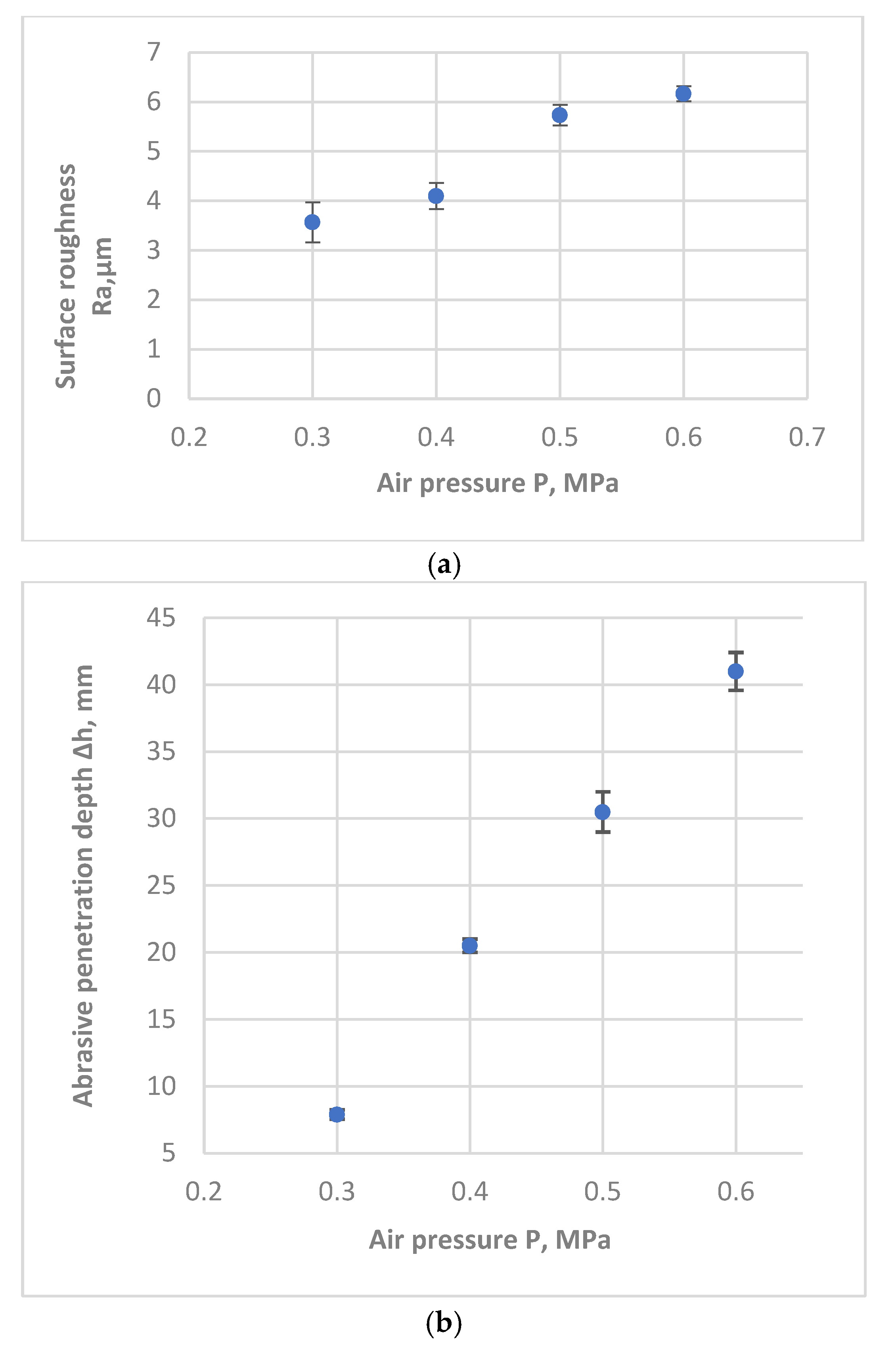

3.1. Investigation of the Dependence of Surface Quality Parameters on Air Pressure

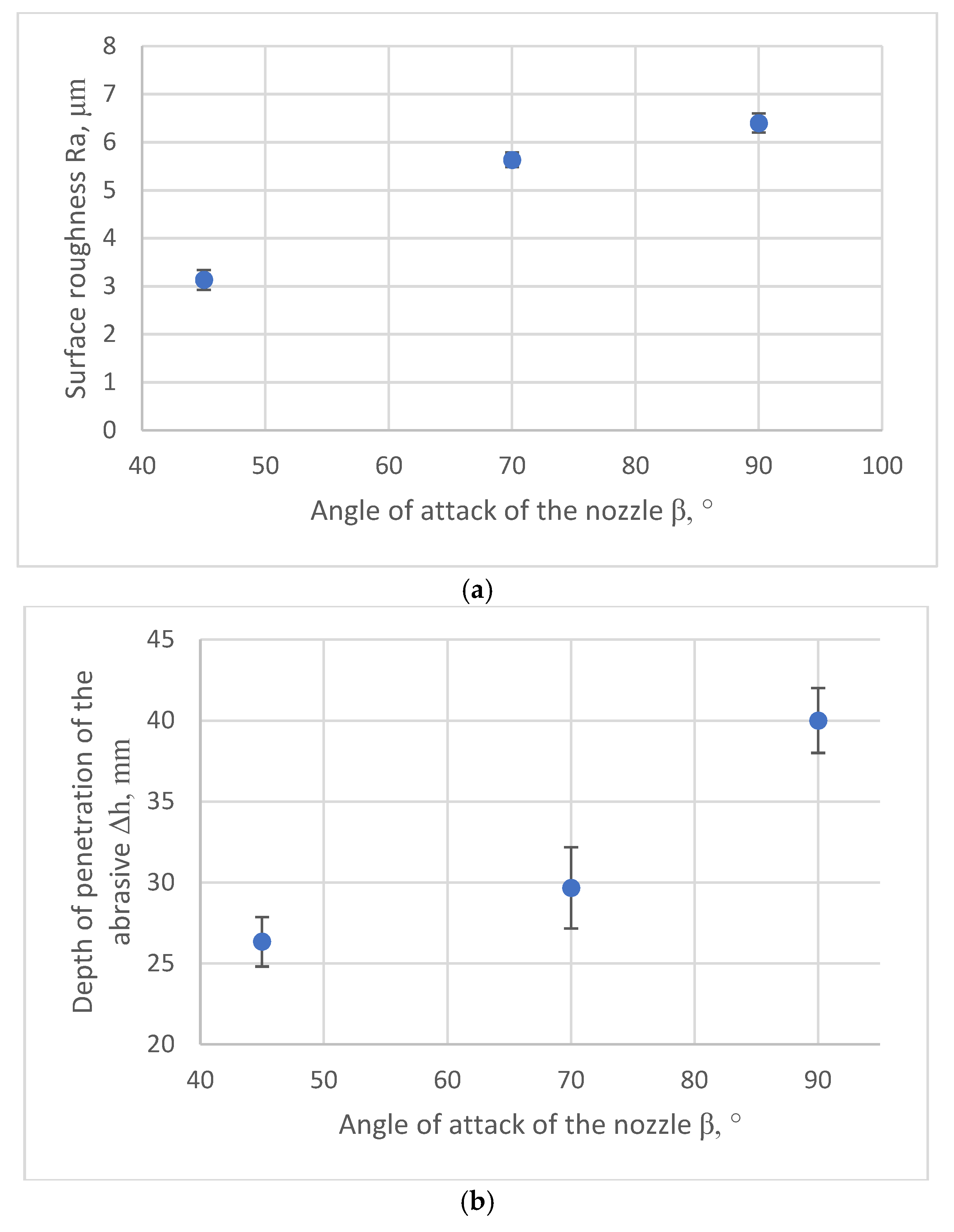

3.2. Investigation of the Dependence of Surface Quality Parameters on the Angle of Attack of the Nozzle

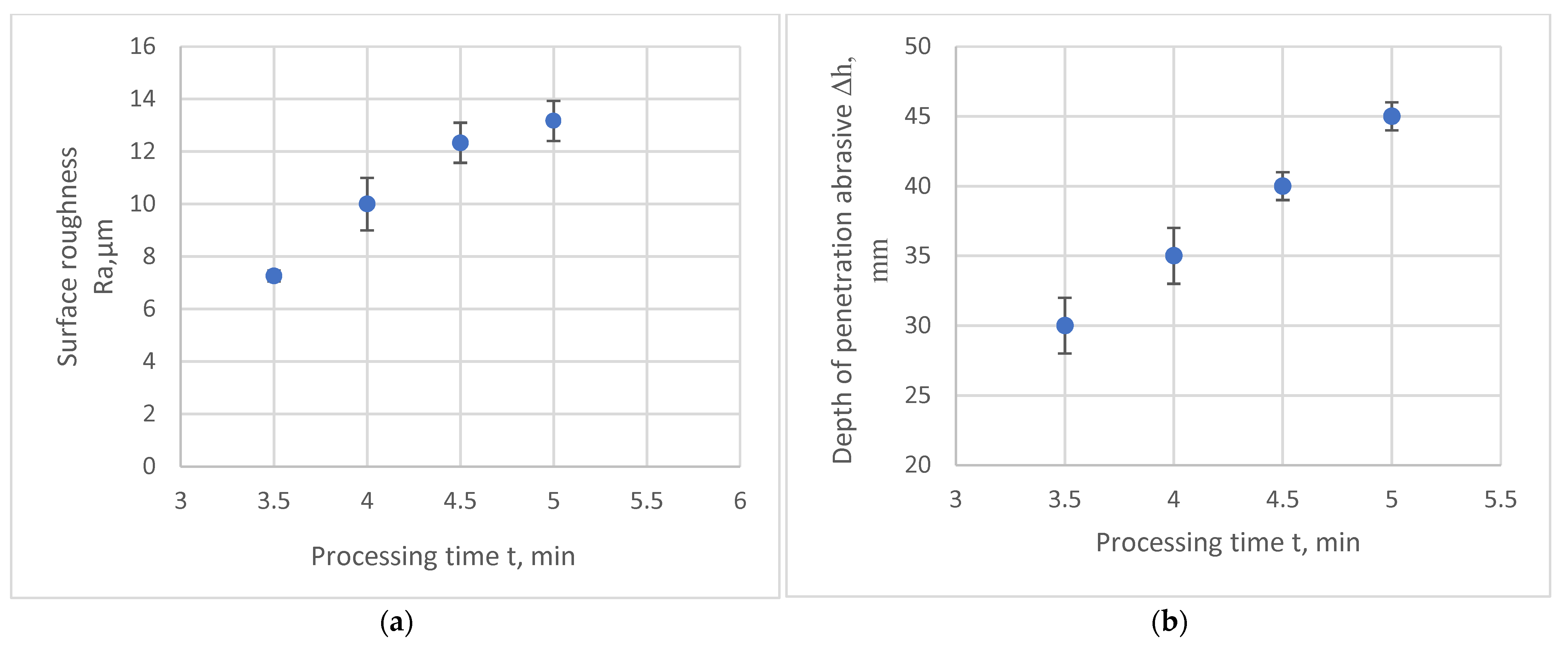

3.3. Investigation of the Dependence of Surface Quality Parameters on

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Belenkiy, U.; Kretinin, V.; Sokolova, V.; Parfenopulo, G. Features of formation of gas-thermal coatings with equal thickness on flat surfaces. IOP Conf. Ser. Mater. Sci. Eng. 2020, 786, 012025. [Google Scholar] [CrossRef]

- Radionov, A. Application of Gas-Thermal Coatings on Low-Alloyed Steel Surfaces. Solid State Phenom. 2018, 284, 1284–1290. [Google Scholar]

- Tejero-Martin, D.; Rezvani Rad, M.; McDonald, A.; Hussain, T. Beyond Traditional Coatings: A Review on Thermal-Sprayed Functional and Smart Coatings. J. Therm. Spray Technol. 2019, 28, 598–644. [Google Scholar] [CrossRef] [Green Version]

- Yin, S.; Cizek, J.; Suo, X.; Li, W.; Liao, H. Thermal Spray Technology. Adv. Mater. Sci. Eng. 2019, 2019, 8654764. [Google Scholar] [CrossRef] [Green Version]

- Astanin, V.K.; Pukhov, E.V.; Stekolnikov, Y.A.; Golikova, O.A. Hardening parts by chrome plating in manufacture and repair. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 032008. [Google Scholar] [CrossRef]

- Semchuk, G.I. Methods of restoration and hardening of agricultural machinery parts. Technol. Audit Prod. Reserves 2013, 5, 57–59. [Google Scholar] [CrossRef] [Green Version]

- Dudnikov, A.; Dudnikov, I.; Dudnyk, V.; Mykhailichnko, V.; Burlaka, O.; Kanivets, O. Increasing the resource of agricultural machines. Technol. Audit Prod. Reserves 2021, 5, 6–11. [Google Scholar] [CrossRef]

- Dinesh Babu, P.; Balasubramanian, K.R.; Buvanashekaran, G. Laser surface hardening: A review. Int. J. Surf. Sci. Eng. 2011, 5, 131–151. [Google Scholar] [CrossRef]

- Espallargas, N. Introduction to thermal spray coatings, Future Development of Thermal Spray Coatings; Woodhead Publishing: Sawston, UK, 2015; pp. 1–13. [Google Scholar] [CrossRef]

- Kuznetsov, Y.A.; Selemenev, M.F.; Kravchenko, I.N.; Spasibin, A.V.; Pankov, G.B. Theoretical Justification of Coating Adhesion during Gas-Thermal Spraying. Mater. Res. Proc. 2022, 21, 161–168. [Google Scholar]

- Zhetessova, G.; Zharkevich, O.; Pleshakova, Y.; Yurchenko, V.; Platonova, Y.; Buzauova, T. Building mathematical model for gas-thermal process of coating evaporation. Metalurgija 2016, 55, 63–66. [Google Scholar]

- Aurich, J.C.; Kirscha, B.; Settia, D.; Axinte, D.; Beaucamp, A.; Butler-Smith, P.; Yamaguchi, H. Abrasive processes for micro parts and structures. CIRP Ann. 2019, 68, 653–676. [Google Scholar] [CrossRef]

- Müller, M.; Levytskyi, A.; Svobodová, J.; Lebedev, P. Abrasive-free Ultrasonic Finishing of Metals. Manuf. Technol. 2014, 14, 366–370. [Google Scholar] [CrossRef]

- John, M.; Ralls, A.M.; Dooley, S.C.; Thazhathidathil, A.K.V.; Perka, A.K.; Kuruveri, U.B.; Menezes, P.L. Ultrasonic Surface Rolling Process: Properties, Characterization, and Applications. Appl. Sci. 2021, 11, 10986. [Google Scholar] [CrossRef]

- Du, Z.; Wen, S.; Wang, J.; Yin, C.; Yu, D.; Luo, J. The Review of Powder Coatings. J. Mater. Sci. Chem. Eng. 2016, 4, 54–59. [Google Scholar] [CrossRef] [Green Version]

- Bidulsky, R.; Gobber, F.S.; Bidulska, J.; Grande, M.A. Coated Metal Powders for Laser Powder Bed Fusion (L-PBF) Processing: A Review. Metals 2021, 11, 1831. [Google Scholar] [CrossRef]

- Matarneh, M.; Al Quran, F.; Andilakhay, A.A.; Haddad, J. Speed of abrasive particles in the process of abrasive blasting by submerged jets. Int. J. Acad. Res. 2014, 6, 240–245. [Google Scholar] [CrossRef]

- Draganovská, D.; Ižaríková, G.; Guzanová, A.; Brezinová, J. General Regression Model for Predicting Surface Topography after Abrasive Blasting. Metals 2018, 8, 938. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharyya, B.; Doloi, B. Chapter Seven—Micromachining Processes. In Modern Machining Technology Advanced, Hybrid, Micro Machining and Super Finishing Technology; Elsevier: Amsterdam, The Netherlands, 2020; pp. 593–673. [Google Scholar]

- Vipindas, K.; Kuriachen, B.; Mathew, J. Chapter 13—An Insight on Ultrasonic Machining Technology. In Handbooks in Advanced Manufacturing, Advanced Machining and Finishing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 451–478. [Google Scholar]

- Barrôso Vieira, Á.S.; Antunes, L.; Cople Maia, L.; Guimarães Primo, L. Ultrasonic Abrasion: An Alternative for Cavity Preparation. Pesqui. Bras. Odontopediatr. Clín. Integr. 2007, 7, 181–186. [Google Scholar]

- Kohli, R. Chapter 14—Microabrasive Technology for Precision Cleaning and Processing. In Developments in Surface Contamination and Cleaning: Applications of Cleaning Techniques; Elsevier: Amsterdam, The Netherlands, 2016; pp. 627–666. [Google Scholar]

- Koivuluoto, H.; Hartikainen, E.; Niemelä-Anttonen, H. Thermally Sprayed Coatings: Novel Surface Engineering Strategy Towards Icephobic Solutions. Materials 2020, 13, 1434. [Google Scholar] [CrossRef] [Green Version]

- Škamat, J.; Černašėjus, O.; Zhetessova, G.; Nikonova, T.; Zharkevich, O.; Višniakov, N. Effect of laser processing parameters on microstructure, hardness and tribology of NiCrCoFeCBSi/Wc coatings. Materials 2021, 14, 6034. [Google Scholar] [CrossRef]

- Aiman, S.; Bhargav, R.S.; Vikhyath, V.; Darshan, K.A.; Ashitraj, V.; Nanjundeswaraswamy, T.S. Process Characteristics of Abrasive Jet Machining. Int. J. Eng. Res. Technol. 2019, 8, 593–597. [Google Scholar]

- Doreswamy, D.; Shivamurthy, B.; Anjaiah, D.; Sharma, N.Y. An Investigation of Abrasive Water Jet Machining on Graphite/Glass/Epoxy Composite. Int. J. Manuf. Eng. 2015, 2015, 627218. [Google Scholar] [CrossRef] [Green Version]

- Zaytzev, A.N.; Aleksandrova, Y.P.; Yagopolskiy, A.G. Comparative Analysis of Methods for Assessing Adhesion Strength of Thermal Spray Coatings. Proc. High. Educ. Inst. Mach. Build. 2021, 5, 48–57. [Google Scholar] [CrossRef]

- Kinlock, E. Adhesion and Adhesives: Science and Technology; Springer: Berlin/Heidelberg, Germany, 1991; 484p. [Google Scholar]

- Burov, V.; Yanpolskiy, V.; Rakhimyanov, K. Technological Aspects of Forming the Surface Microrelief of Low-Wear Coatings after Electro-Diamond Grinding. IOP Conf. Ser. Mater. Sci. Eng. 2016, 126, 012018. [Google Scholar] [CrossRef]

- Łatka, L.; Pawłowski, L.; Winnicki, M.; Sokołowski, P.; Małachowska, A.; Kozerski, S. Review of Functionally Graded Thermal Sprayed Coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Dorfman, M.R. Chapter 22—Thermal Spray Coatings. In Handbook of Environmental Degradation of Materials, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 469–488. [Google Scholar]

- Wang, T.; Ning, W.; Li, Y.; Yunshan, W. Study on preparation technologies of thermal barrier coatings. Surf. Rev. Lett. 2016, 24, 1730004. [Google Scholar] [CrossRef]

- Wang, J.; Chen, M.; Wang, Y.; Li, B.; Yu, Y.; Tian, Y.; Liu, B.; Jing, Q. Preparation and thermo-physical properties of La2AlTaO7 ceramic for thermal barrier coating application. Mater. Chem. Phys. 2022, 289, 126465. [Google Scholar] [CrossRef]

- Olt, J.; Maksarov, V.; Krasnyy, V. Provision of adhesion strength of gas-thermal coatings on piston rings of quarry transport engines. J. Min. Inst. 2018, 229, 77–83. [Google Scholar]

- Ibatov, M.K.; Zhetessova, G.S.; Nikonova, T.Y.; Zharkevich, O.M.; Olegas, Č.; Škamat, J.; Yurchenko, V.V.; Kalinin, A.A.; Dandybaev, E.S. Support for Horizontal Mobility of Device for Gas-Flame Spraying of Long Components (Patent for Utility Model)б No. 6901. 2021. Available online: https://gosreestr.kazpatent.kz/Utilitymodel/Details?docNumber=349139 (accessed on 31 August 2022).

- Nikonova, T.Y.; Zhetesova, G.S.; Yurchenko, V.V.; Zharkevich, O.M.; Zhunuspekov, D.S.; Kalinin, A.A. Calculation of Technological Parameters of Coating Application during Gas Thermal Treatment (Certificate for an Object Protected by the Law of the Republic of Kazakhstan), No. 27846. 2022. Available online: https://copyright.kazpatent.kz/?!.iD=zXkt (accessed on 31 August 2022).

- Bae, S.H.; Kim, S.; Yi, S.H.; Son, I.; Kim, K.T.; Chung, H. Effect of Surface Roughness and Electroless Ni–P Plating on the Bonding Strength of Bi–Te-based Thermoelectric Modules. Coatings 2019, 9, 213. [Google Scholar] [CrossRef] [Green Version]

- Oksa, M.; Turunen, E.; Suhonen, T.; Varis, T.; Hannula, S.-P. Optimization and Characterization of High Velocity Oxy-fuel Sprayed Coatings: Techniques, Materials, and Applications. Coatings 2011, 1, 17–52. [Google Scholar] [CrossRef]

| Method Name | Technical Process | Application Area |

|---|---|---|

| Shotblasting | Supply to the surface of metal cast iron chips or shot with a particle size of 1.5–2 mm at an air pressure of 0.5–0.6 MPa | For large flat workpieces |

| Sandblasting | Blowing the surface of parts from a gun in a special chamber with quartz sand with a grain size of 0.5–2.5 mm under an excess air pressure of 1–6 atm | For parts of complex shape, when repairing cracks in cast iron parts, for parts with sliding fit, as well as in preparation for applying heat-resistant and decorative coatings with a layer thickness of 0.02 to 3 mm |

| Name of Indicator | Indicator Value |

|---|---|

| Developed pressure range, MPa | 0.3–0.7 |

| Air consumption, m³/min | 1.5–2.5 |

| Abrasive tank capacity, L | 2 |

| The range of fractions of the used abrasive, mm | 0.3–1.4 |

| Installation nozzle diameter, mm | 4.5 |

| Maximum width of the cleaned strip in one pass, mm | 32 |

| The principle of operation of shot blasting | ejector, dust-free |

| Overall dimensions (length × width × height), m | 0.6 × 0.2 × 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhetessova, G.; Nikonova, T.; Gierz, Ł.; Zhunuspekov, D.; Yurchenko, V.; Zharkevich, O. Preparation of the Surface of Long-Dimensional Rods of Hydro-Cylinders for Thermal Spraying Using an Abrasive Jet. Coatings 2022, 12, 1514. https://doi.org/10.3390/coatings12101514

Zhetessova G, Nikonova T, Gierz Ł, Zhunuspekov D, Yurchenko V, Zharkevich O. Preparation of the Surface of Long-Dimensional Rods of Hydro-Cylinders for Thermal Spraying Using an Abrasive Jet. Coatings. 2022; 12(10):1514. https://doi.org/10.3390/coatings12101514

Chicago/Turabian StyleZhetessova, Gulnara, Tatyana Nikonova, Łukasz Gierz, Darkhan Zhunuspekov, Vassiliy Yurchenko, and Olga Zharkevich. 2022. "Preparation of the Surface of Long-Dimensional Rods of Hydro-Cylinders for Thermal Spraying Using an Abrasive Jet" Coatings 12, no. 10: 1514. https://doi.org/10.3390/coatings12101514

APA StyleZhetessova, G., Nikonova, T., Gierz, Ł., Zhunuspekov, D., Yurchenko, V., & Zharkevich, O. (2022). Preparation of the Surface of Long-Dimensional Rods of Hydro-Cylinders for Thermal Spraying Using an Abrasive Jet. Coatings, 12(10), 1514. https://doi.org/10.3390/coatings12101514