Effect of La2O3 on Microstructure and Properties of Laser Cladding SMA Coating on AISI 304 Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Design

2.2. Sample Characterization

3. Results and Discussion

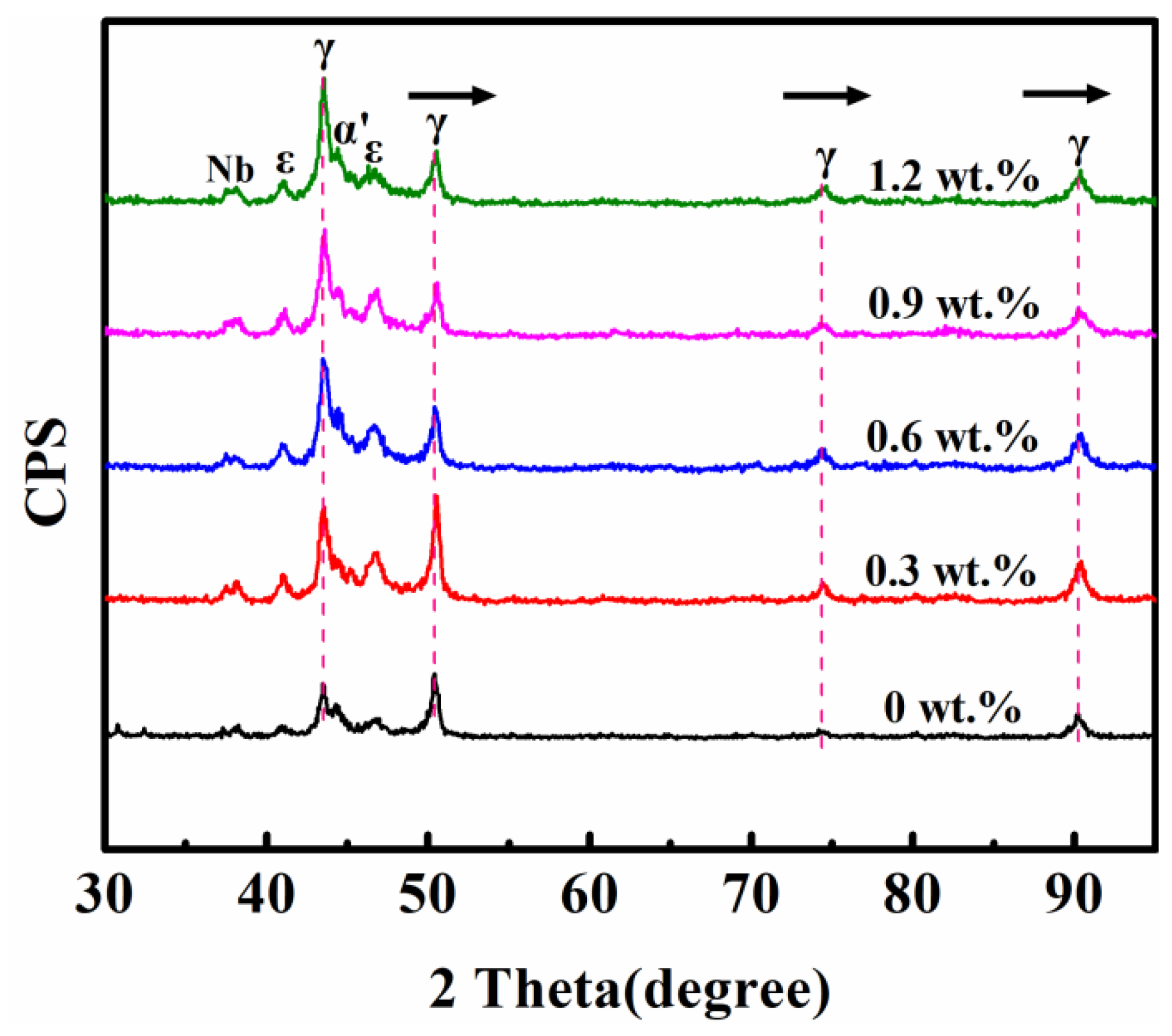

3.1. Phases Analysis

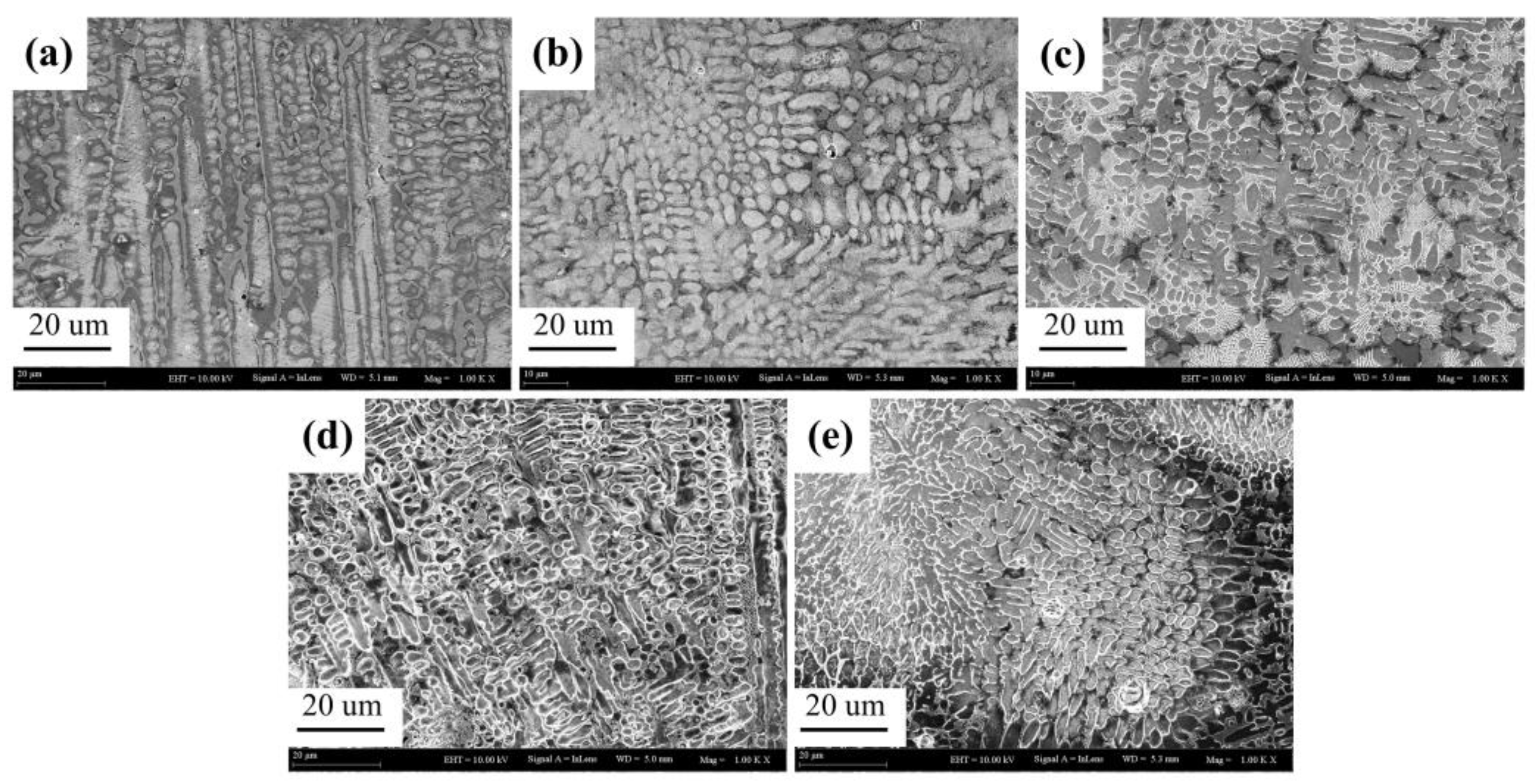

3.2. Microstructure

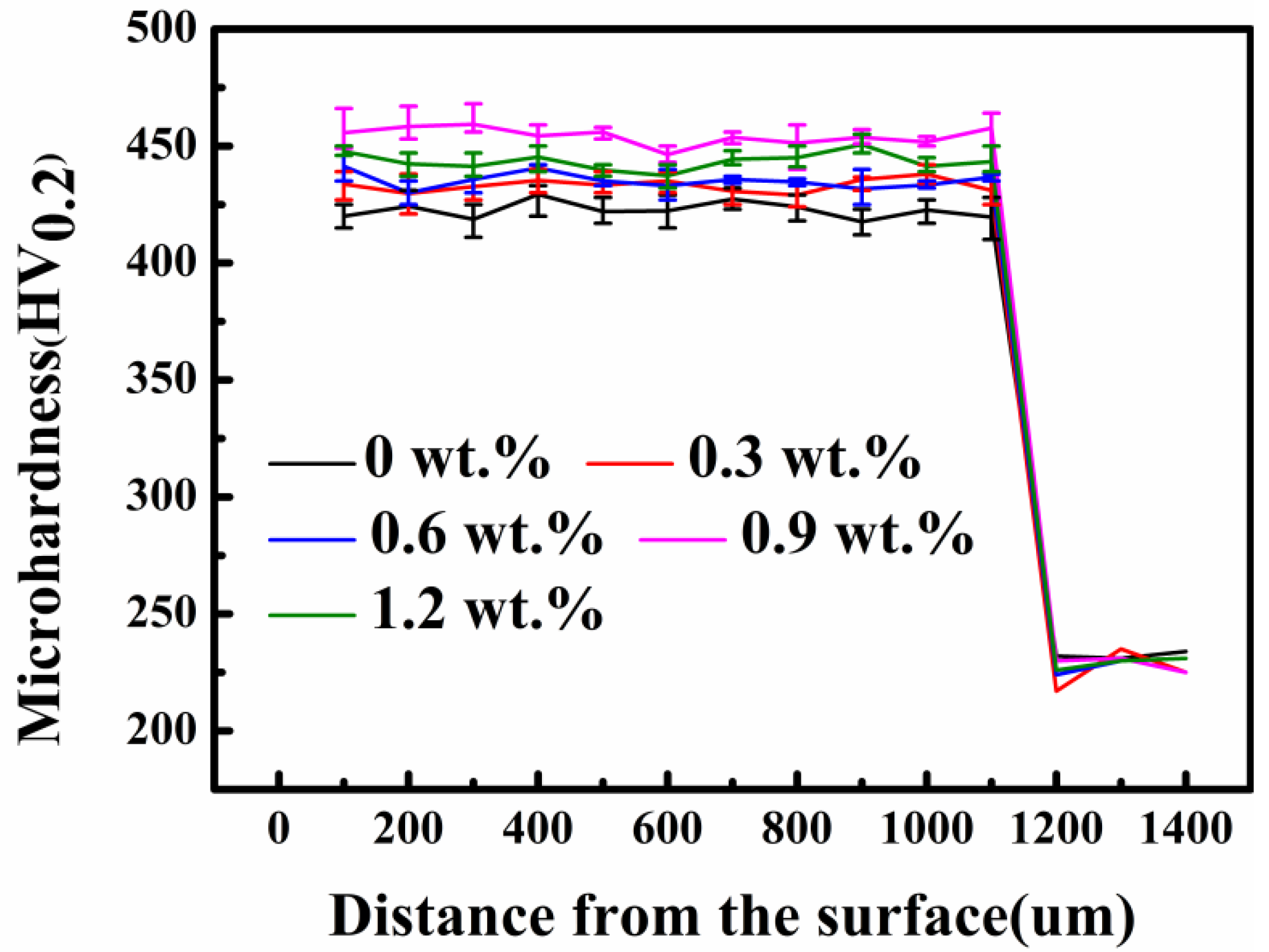

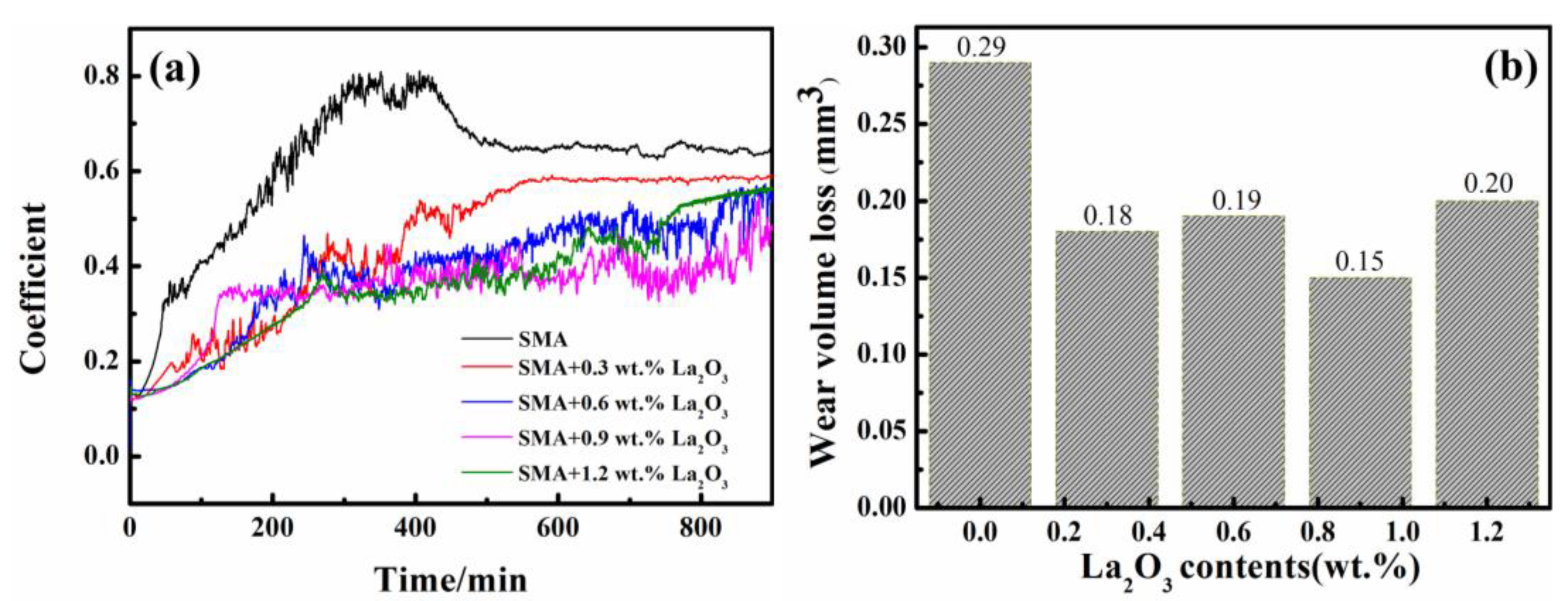

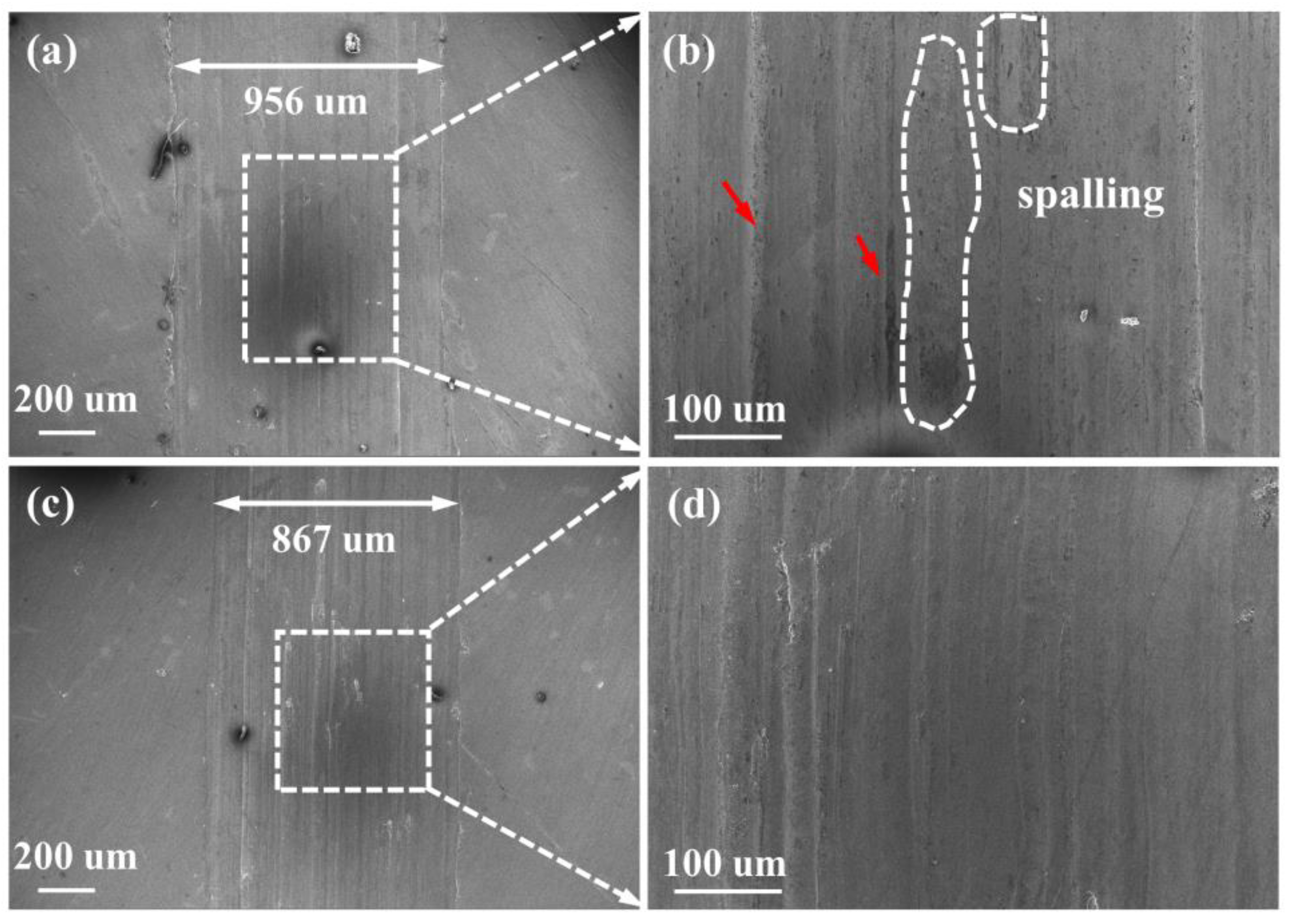

3.3. Microhardness and Wear Resistance

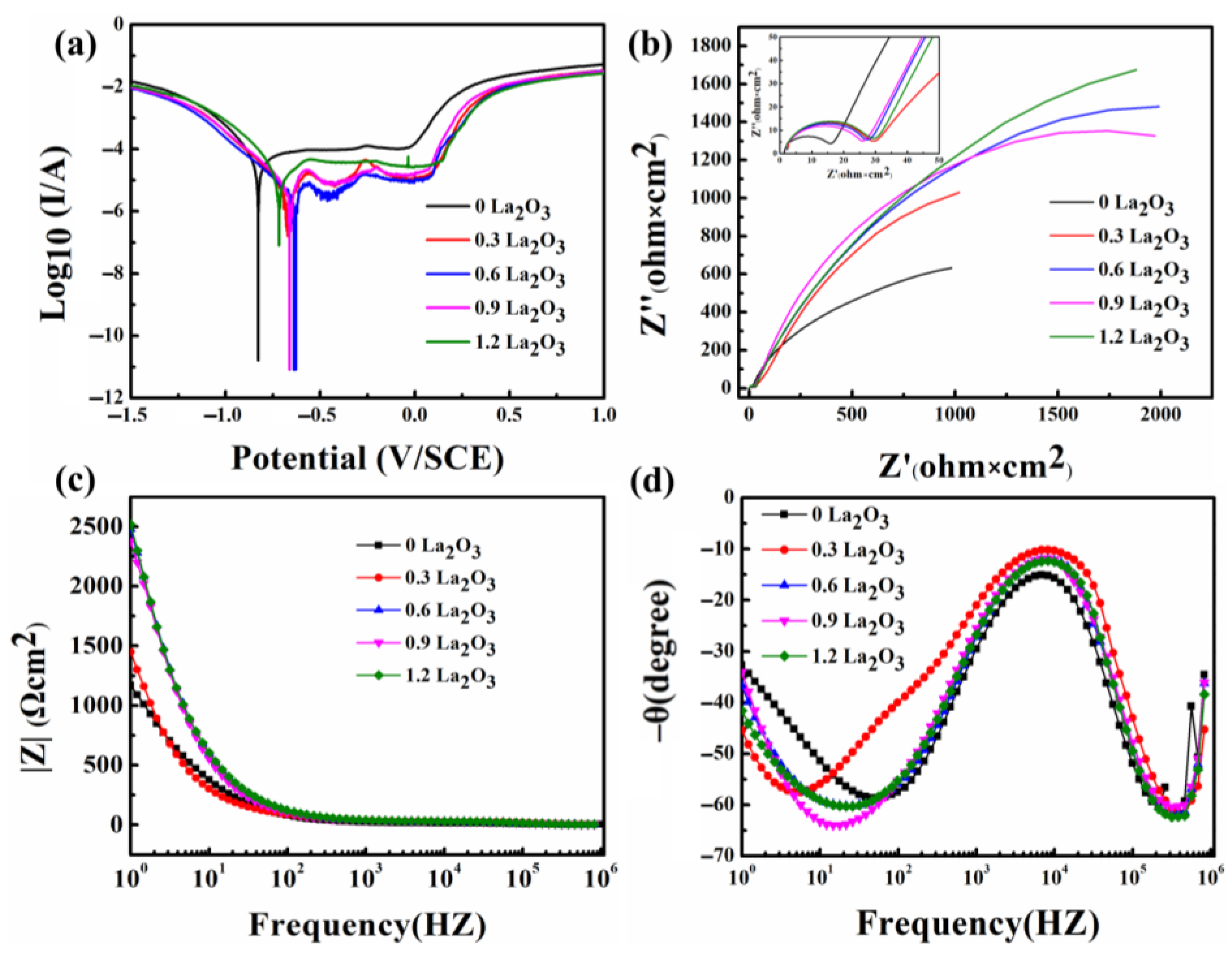

3.4. Corrosion Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pathania, A.; Kumar, S.A.; Nagesha, B.K.; Barad, S.; Suresh, T.N. Reclamation of titanium alloy based aerospace parts using laser based metal deposition methodology. Mater. Today 2021, 45, 4886–4892. [Google Scholar] [CrossRef]

- Avery, D.Z.; Cleek, C.E.; Phillips, B.J.; Rekha, M.Y.; Kinser, R.P.; Rao, H.M.; Brewer, L.N.; Allison, P.G.; Jordon, J.B. Evaluation of Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy Repaired via Additive Friction Stir Deposition. J. Eng. Mater. Technol. 2022, 144, 031003. [Google Scholar] [CrossRef]

- Liu, Y.N.; Ding, Y.; Yang, L.J.; Sun, R.L.; Zhang, T.G.; Yang, X.J. Research and progress of laser cladding on engineering alloys: A review. J. Manuf. Process. 2021, 66, 341–363. [Google Scholar] [CrossRef]

- Smurov, I. Laser cladding and laser assisted direct manufacturing. Surf. Coat. Technol. 2008, 202, 4496–4502. [Google Scholar] [CrossRef]

- Calleja, A.; Tabernero, I.; Celaya, A.; Lamikiz, A.; De Lacalle, L.L. Improvement of strategies and parameters for multi-axis laser cladding operations. Opt. Laser Eng. 2014, 56, 113–120. [Google Scholar] [CrossRef]

- Liu, C.Y.; Xu, P.; Zheng, D.Y.; Liu, Q.B. Study on microstructure and properties of a Fe-based SMA/PZT composite coating produced by laser cladding. J. Alloy. Compd. 2020, 831, 154813. [Google Scholar] [CrossRef]

- Robinson, J.S.; Pirling, T.; Truman, C.E.; Panzner, T. Residual stress relief in the aluminium alloy 7075. Mater. Sci. Technol. 2017, 33, 1765–1775. [Google Scholar] [CrossRef]

- Tang, F.; Lu, A.L.; Mei, J.F.; Fang, H.Z.; Luo, X.J. Research on residual stress reduction by a low frequency alternating magnetic field. J. Mater. Process. Technol. 1998, 74, 255–258. [Google Scholar] [CrossRef]

- Park, S.J.; Muraishi, S.J. Influence of Residual Stress around Constituent Particles on Recrystallization and Grain Growth in Al-Mn-Based Alloy during Annealing. Materials 2021, 14, 1701. [Google Scholar] [CrossRef]

- Roehling, J.D.; Smith, W.L.; Roehling, T.T.; Vrancken, B.; Guss, G.M.; McKeown, J.T.; Hill, M.R.; Matthews, M.J. Reducing residual stress by selective large-area diode surface heating during laser powder bed fusion additive manufacturing. Addit. Manuf. 2019, 28, 228–235. [Google Scholar] [CrossRef]

- Xu, P.; Ju, H.; Lin, C.X.; Zhou, C.Y.; Pan, D.W. In-situ synthesis of Fe-Mn-Si-Cr-Ni shape memory alloy functional coating by Laser cladding. Chin. Opt. Lett. 2014, 12, 041403. [Google Scholar]

- Ferretto, I.; Kim, D.; Della Ventur, N.M.; Shahverdi, M.; Lee, W.; Leinenbach, C. Laser powder bed fusion of a Fe-Mn-Si shape memory alloy. Addit. Manuf. 2021, 46, 102071. [Google Scholar] [CrossRef]

- Tian, J.Y.; Xu, P.; Chen, J.H.; Liu, Q.B. Microstructure and phase transformation behaviour of a Fe/Mn/Si/Cr/Ni alloy coating by laser cladding. Opt. Lasers Eng. 2019, 122, 97–104. [Google Scholar] [CrossRef]

- Liu, C.Y.; Xu, P.; Zha, G.Q.; Ouyang, Z. Microstructure and properties of a Ti doped Fe based SMA coating produced by laser cladding. J. Mater. Res. Technol. 2021, 14, 2441–2450. [Google Scholar] [CrossRef]

- Balaram, V. Rare earth elements: A review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci. Front. 2019, 10, 1285–1303. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, M.; He, C.; Qi, F.; Wang, D.; Peng, S.; Shuai, C. Rare earth improves strength and creep resistance of additively manufactured Zn implants. Compos. Part B Eng. 2021, 216, 108882. [Google Scholar] [CrossRef]

- Du, M.Z.; Wang, L.L.; Gao, Z.N.; Yang, X.Y.; Liu, T.; Zhan, X.H. Microstructure and element distribution characteristics of Y2O3 modulated WC reinforced coating on Invar alloys by laser cladding. Opt. Laser Technol. 2022, 153, 108205. [Google Scholar] [CrossRef]

- Wang, C.L.; Gao, Y.; Wang, R.; Wei, D.Q.; Cai, M.; Fu, Y.K. Microstructure of laser-clad Ni60 cladding layers added with different amounts of rare-earth oxides on 6063 Al alloys. J. Alloy. Compd. 2018, 740, 1099–1107. [Google Scholar] [CrossRef]

- Liu, Y.N.; Sun, R.L.; Wei, N.; Zhang, T.G.; Lei, Y.W. Effects of CeO2 on microstructure and properties of TiC/Ti2Ni reinforced Ti-based laser cladding composite coatings. Opt. Laser Eng. 2019, 120, 84–94. [Google Scholar]

- Yin, P.M.; Liu, Z.Y.; Wei, X.B.; Cao, X.Q.; Ding, Q.; Lu, Z.B.; Zhang, G.A. Improving the corrosion resistance of a-C:H film by a top a-C:H:Si:O layer. Ceram. Int. 2022, 48, 21451–21458. [Google Scholar] [CrossRef]

- Tian, J.Y.; Xu, P.; Liu, Q.B. Effects of stress-induced solid phase transformations on residual stress in laser cladding a Fe-Mn-Si-Cr-Ni alloy coating. Mater. Des. 2020, 193, 108824. [Google Scholar] [CrossRef]

- Chen, Y.C.; Molnárová, O.; Tyc, O.; Kadeřávek, L.; Heller, L.; Šittner, P. Recoverability of large strains and deformation twinning in martensite during tensile deformation of NiTi shape memory alloy polycrystals. Acta Mater. 2019, 180, 243–259. [Google Scholar] [CrossRef]

- Wang, H.Z.; Cheng, Y.H.; Yang, J.Y.; Wang, Q.Q. Microstructure and properties of laser clad Fe-based amorphous alloy coatings containing Nb powder. J. Non Cryst. Solids. 2020, 550, 120351. [Google Scholar] [CrossRef]

- Quazi, M.M.; Fazal, M.A.; Haseeb, A.S.M.A.; Yusof, F.; Masjuki, H.H.; Arslan, A. Effect of rare earth elements and their oxides on tribo-mechanical performance of laser claddings: A review. J. Rare Earth. 2016, 34, 549–564. [Google Scholar] [CrossRef]

- Das, A.K. Effect of rare earth oxide additive in coating deposited by laser cladding: A review. Mater. Today Proc. 2022, 52, 1558–1564. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, J.; Niu, W.J.; Li, Y.Y.; Zhang, K.; Mao, X.; Wang, Y.G. Effect of La2O3 on the Microstructure and Properties of Laser Cladding Fe-based JG-8 Alloy. Rare Met. Mater. Eng. 2021, 50, 2125–2133. [Google Scholar]

- Zhang, T.G.; Zhuang, H.F.; Zhang, Q.; Yao, B.; Yang, F. Influence of Y2O3 on the microstructure and tribological properties of Tibased wear-resistant laser-clad layers on TC4 alloy. Ceram. Int. 2020, 46, 13711–13723. [Google Scholar] [CrossRef]

- He, F.; Wang, Z.J.; Cheng, P.; Wang, Q.; Li, J.J.; Dang, Y.Y.; Wang, J.C.; Liu, C.T. Designing eutectic high entropy alloys of CoCrFeNiNbx. J. Alloy. Compd. 2016, 656, 284–289. [Google Scholar] [CrossRef]

- Yang, C.; Kang, L.M.; Li, X.X.; Zhang, W.W.; Zhang, D.T.; Fu, Z.Q.; Li, Y.Y.; Zhang, L.C.; Lavernia, E.J. Bimodal titanium alloys with ultrafine lamellar eutectic structure fabricated by semi-solid sintering. Acta Mater. 2017, 132, 491–502. [Google Scholar] [CrossRef]

- Naik, S.N.; Walley, S.M. The Hall–Petch and inverse Hall–Petch relations and the hardness of nanocrystalline metals. J. Mater. Sci. 2020, 55, 2661–2681. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.A.; Aitken, Z.H.; Wu, Z.X.; Yu, Z.G.; Banerjee, R.; Zhang, Y.W. Hall-Petch and inverse Hall-Petch relations in high-entropy CoNiFeAlxCu1-x alloys. Mater. Sci. Eng. A 2020, 773, 138873. [Google Scholar] [CrossRef]

- Du, Y.; Pei, X.H.; Tang, Z.W.; Zhang, F.; Zhou, Q.; Wang, H.F.; Liu, W.M. Mechanical and tribological performance of CoCrNiHfx eutectic medium-entropy alloys. J. Mater. Sci. Technol. 2021, 90, 194–204. [Google Scholar] [CrossRef]

- Mohammadnejad, A.; Bahrami, A.; Tafaghodi Khajavi, L. Microstructure and Mechanical Properties of Spark Plasma Sintered Nanocrystalline TiAl-xB Composites (0.0 < x < 1.5 at.%) Containing Carbon Nanotubes. J. Mater. Eng. Perform. 2021, 30, 4380–4392. [Google Scholar]

- Rahimi, H.; Mozaffarinia, R.; Najafabadi, A.H. Corrosion and Wear Resistance Characterization of Environmentally Friendly Solegel Hybrid Nanocomposite Coating on AA5083. J. Mater. Sci. Technol. 2013, 29, 603–608. [Google Scholar] [CrossRef]

- Mohammadnejad, A.; Bahrami, A.; Goli, M.; Nia, D.H.; Taheri, P. Wear Induced Failure of Automotive Disc Brakes—A Case Study. Materials 2019, 12, 4214. [Google Scholar] [CrossRef] [Green Version]

- Najafabadi, A.H.; Mozaffarinia, R.; Rahimi, H.; Razavi, R.S.; Paimozd, E. Mechanical property evaluation of corrosion protection sol-gel nanocomposite coatings. Surf. Eng. 2013, 29, 249–254. [Google Scholar] [CrossRef]

- Guo, W.; Li, J.; Qi, M.; Xu, Y.; Ezatpour, H.R. Effects of heat treatment on the microstructure, wear behavior and corrosion resistance of AlCoCrFeNiSi high-entropy alloy. Intermetallics 2021, 138, 107324. [Google Scholar] [CrossRef]

- Kim, K.M.; Al-Zain, Y.; Yamamoto, A.; Daher, A.H.; Mansour, A.T.; Al Ajlouni, J.M.; Aloweidi, A.S.; Al-Abbadi, M.A.; Kim, H.Y.; Miyazaki, S.C. Synthesis and Characterization of a Ti-Zr-Based Alloy with Ultralow Young’s Modulus and Excellent Biocompatibility. Adv. Eng. Mater. 2022, 24, 2100776. [Google Scholar] [CrossRef]

- Burduhos-Nergis, D.P.; Vizureanu, P.; Sandu, A.V.; Bejinariu, C. Phosphate Surface Treatment for Improving the Corrosion Resistance of the C45 Carbon Steel Used in Carabiners Manufacturing. Materials 2020, 13, 3410. [Google Scholar] [CrossRef]

- Xu, P.Z.; Zhou, J.; Li, G.G.; Wang, P.G.; Wang, P.; Li, F.; Zhang, B.H.; Chi, H. Corrosion inhibition efficiency of compound nitrite with D-sodium gluconate on carbon steel in simulated concrete pore solution. Constr. Build. Mater. 2021, 288, 123101. [Google Scholar] [CrossRef]

- Ju, S.C.; Kang, H.J.; Jun, J.H.; Son, S.; Park, J.; Kim, W.; Lee, H. Periodic Micropillar-Patterned FTO/BiVO4 with Superior Light Absorption and Separation Efficiency for Efficient PEC Performance. Small 2021, 17, 2006558. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Song, R.G.; Kong, D.J. Microstructure and corrosion behaviours of composite coatings on S355 offshore steel prepared by laser cladding combined with micro-arc oxidation. Appl. Surf. Sci. 2019, 497, 143703. [Google Scholar] [CrossRef]

- Dong, S.H.; Yang, Y.; Liang, T.T.; Ma, R.N.; Du, A.; Yang, M.X.; Fan, Y.Z.; Zhao, X.; Gao, X.M. Construction and corrosion resistance of Ni-B4C superhydrophobic composite coatings on Q235 steel. Surf. Coat. Technol. 2021, 422, 127551. [Google Scholar] [CrossRef]

- Wang, Y.B.; Yuan, Z.Y.; Zhang, Z.K.; Xin, Y.C.; Fujita, T.; Wei, Y.Z. In situ one-step fabrication of superhydrophobic layered double hydroxide on Al alloys for anti-corrosion. Appl. Surf. Sci. 2022, 593, 153400. [Google Scholar] [CrossRef]

- Trdan, U.; Grum, J. SEM/EDS characterization of laser shock peening effect on localized corrosion of Al alloy in a near natural chloride environment. Corros. Sci. 2014, 82, 328–338. [Google Scholar] [CrossRef]

| Coatings | Fe (wt.%) | Ni (wt.%) | Mn (wt.%) | Cr (wt.%) | Si (wt.%) | Nb (wt.%) | La2O3 (wt.%) |

|---|---|---|---|---|---|---|---|

| 304 SS | Bal | 8–15 | ≤2.00 | 18–20 | ≤1.00 | 0 | 0 |

| SMA | 49.4 | 2.85 | 30.4 | 3.8 | 8.55 | 5 | 0 |

| SMA/La2O3 | 49.4 | 2.85 | 30.4 | 3.8 | 8.55 | 5 | 0.3 |

| 49.4 | 2.85 | 30.4 | 3.8 | 8.55 | 5 | 0.6 | |

| 49.4 | 2.85 | 30.4 | 3.8 | 8.55 | 5 | 0.9 | |

| 49.4 | 2.85 | 30.4 | 3.8 | 8.55 | 5 | 1.2 |

| Elements | Fe | Mn | Si | Cr | Ni | Nb | C | O | La |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 42.02 | 20.25 | 7.83 | 2.37 | 2.55 | 19.65 | 3.35 | 1.76 | 0.22 |

| wt.% | Ecorr | Icorr | Rate (gram/hr) | Rate (mil/year) |

|---|---|---|---|---|

| 0 | −0.81 | 4.733 × 10−5 | 3.296 × 10−5 | 29.52 |

| 0.3 | −0.67 | 4.710 × 10−6 | 3.280 × 10−6 | 2.937 |

| 0.6 | −0.64 | 4.556 × 10−6 | 3.173 × 10−6 | 2.842 |

| 0.9 | −0.65 | 1.462 × 10−5 | 1.018 × 10−5 | 9.118 |

| 1.2 | −0.72 | 1.345 × 10−5 | 9.367 × 10−6 | 8.388 |

| Parameters | Rs (Ω·cm2) | Cf (F cm−2) | CPE1 (Ω−1 cm−2 sn) | Rf (Ω·cm2) | Cdl (F cm−2) | CPE2 (Ω−1 cm−2 sn) | Rct (Ω·cm2) | ||

|---|---|---|---|---|---|---|---|---|---|

| Q | n | Q | n | ||||||

| 0 | 1.323 | 2.06 × 10−7 | 2.34 × 10−7 | 0.99 | 15.01 | 2.33 × 10−3 | 1.10 × 10−4 | 0.7557 | 1603 |

| 0.3 | 1.640 | 5.94 × 10−8 | 8.86 × 10−8 | 0.97 | 28.09 | 2.67 × 10−4 | 2.00 × 10−4 | 0.6884 | 9465 |

| 0.6 | 1.505 | 8.72 × 10−8 | 1.13 × 10−7 | 0.98 | 26.67 | 4.57 × 10−5 | 6.65 × 10−5 | 0.7670 | 4366 |

| 0.9 | 1.376 | 9.67 × 10−8 | 1.62 × 10−7 | 0.96 | 25.52 | 4.55 × 10−5 | 6.44 × 10−5 | 0.7953 | 4010 |

| 1.2 | 1.512 | 8.50 × 10−8 | 1.10 × 10−7 | 0.98 | 28.63 | 5.10 × 10−5 | 7.08 × 10−5 | 0.7548 | 5152 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Qiao, Y.; Xu, P. Effect of La2O3 on Microstructure and Properties of Laser Cladding SMA Coating on AISI 304 Stainless Steel. Coatings 2022, 12, 1004. https://doi.org/10.3390/coatings12071004

Liu L, Qiao Y, Xu P. Effect of La2O3 on Microstructure and Properties of Laser Cladding SMA Coating on AISI 304 Stainless Steel. Coatings. 2022; 12(7):1004. https://doi.org/10.3390/coatings12071004

Chicago/Turabian StyleLiu, Linlin, Yueqi Qiao, and Peng Xu. 2022. "Effect of La2O3 on Microstructure and Properties of Laser Cladding SMA Coating on AISI 304 Stainless Steel" Coatings 12, no. 7: 1004. https://doi.org/10.3390/coatings12071004

APA StyleLiu, L., Qiao, Y., & Xu, P. (2022). Effect of La2O3 on Microstructure and Properties of Laser Cladding SMA Coating on AISI 304 Stainless Steel. Coatings, 12(7), 1004. https://doi.org/10.3390/coatings12071004