Preparation of Mortar with Fe2O3 Nanoparticles for Radiation Shielding Application

Abstract

:1. Introduction

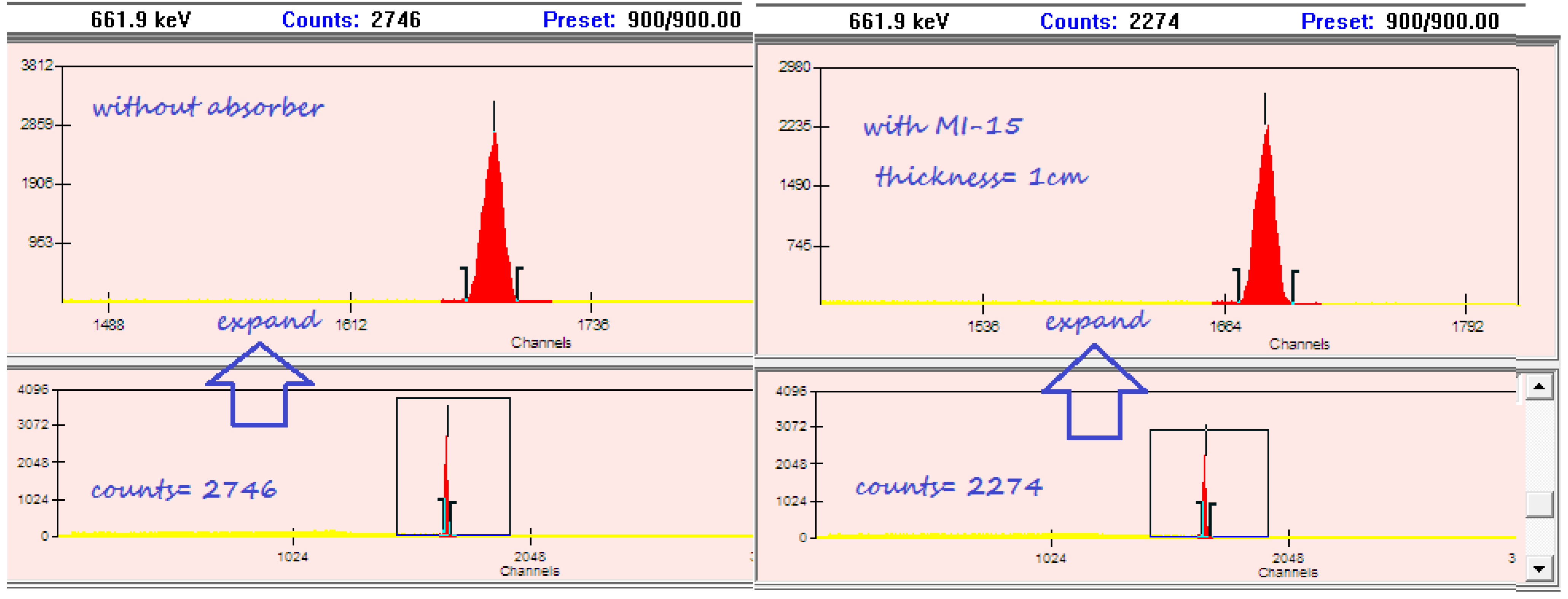

2. Materials and Methods

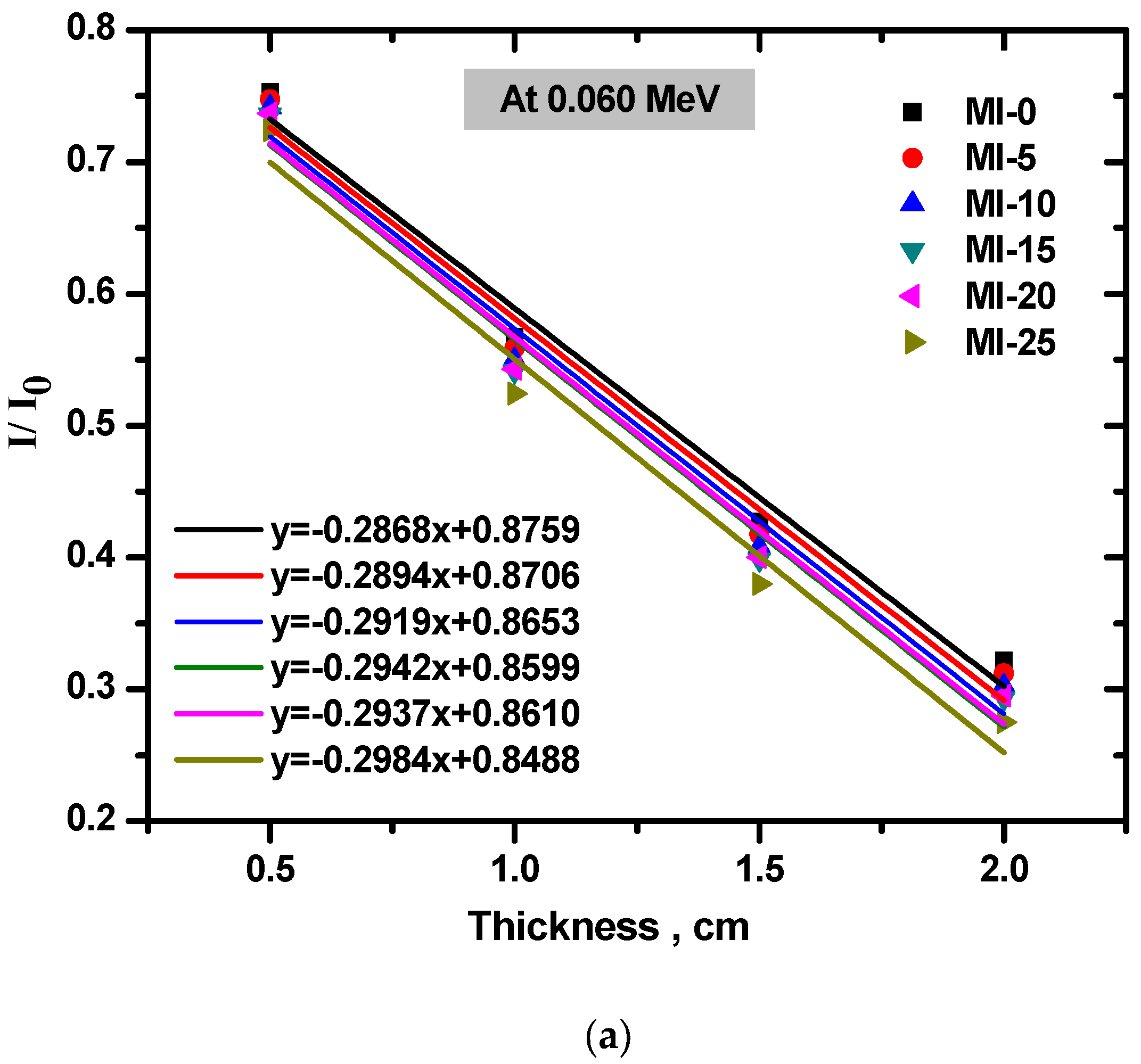

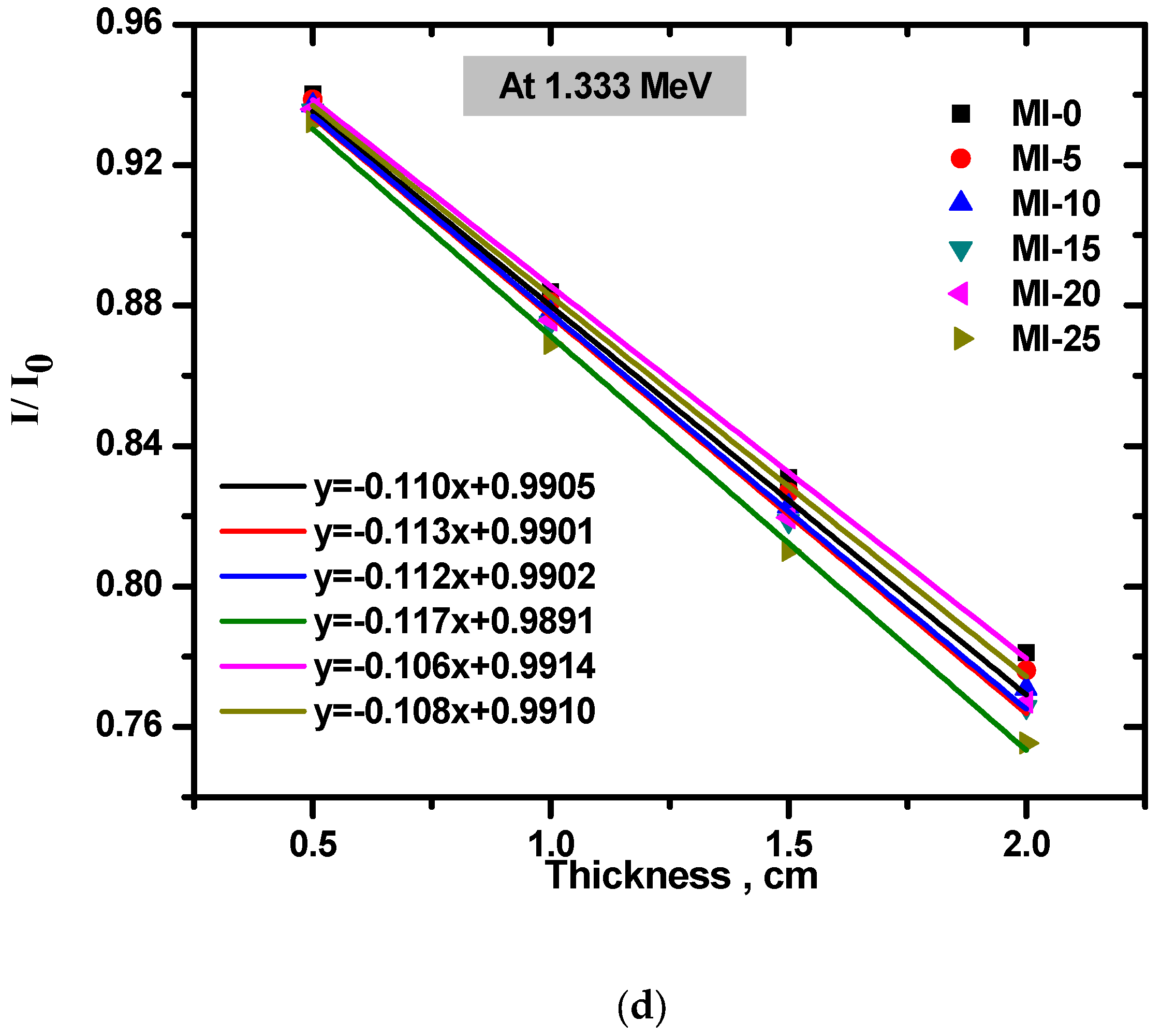

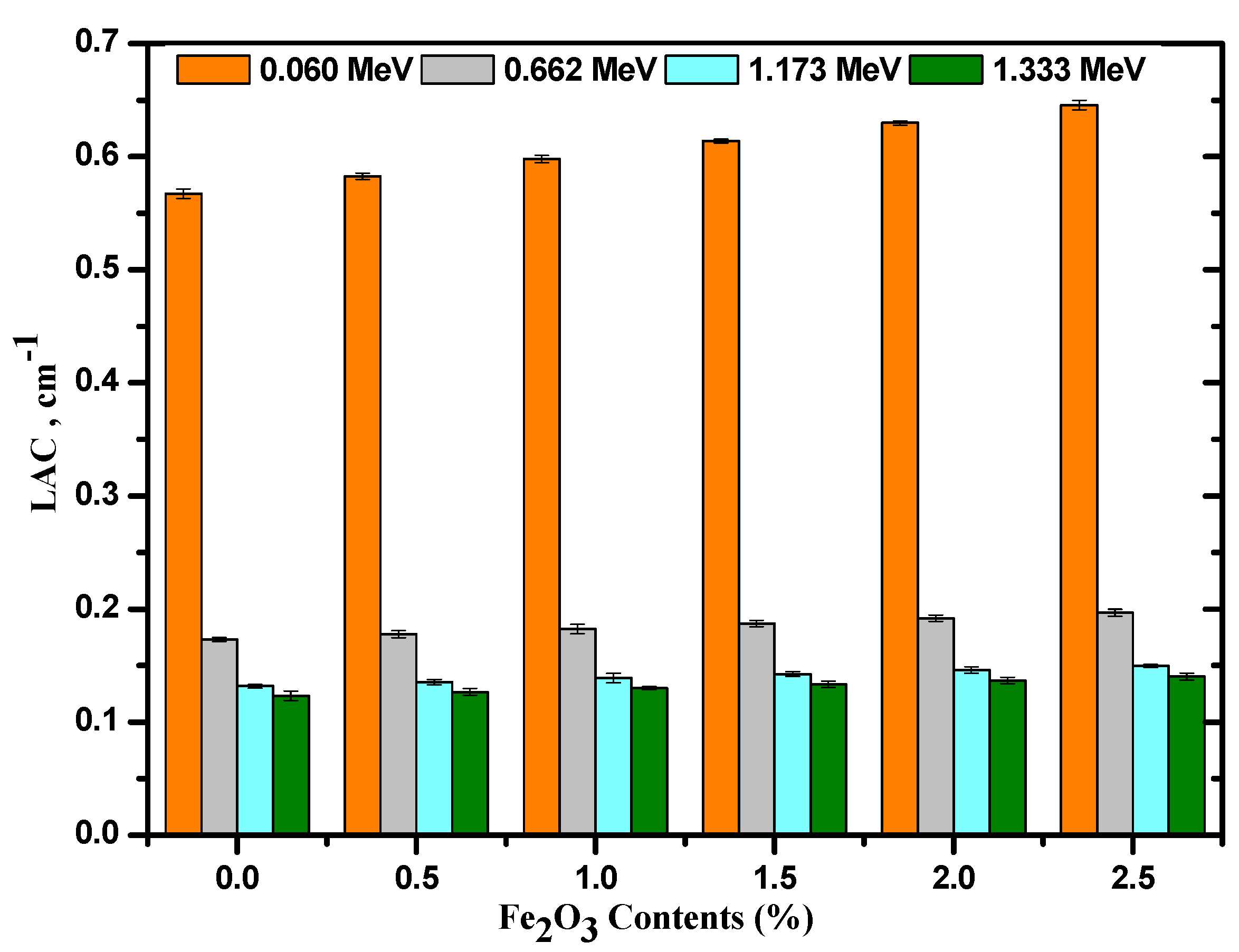

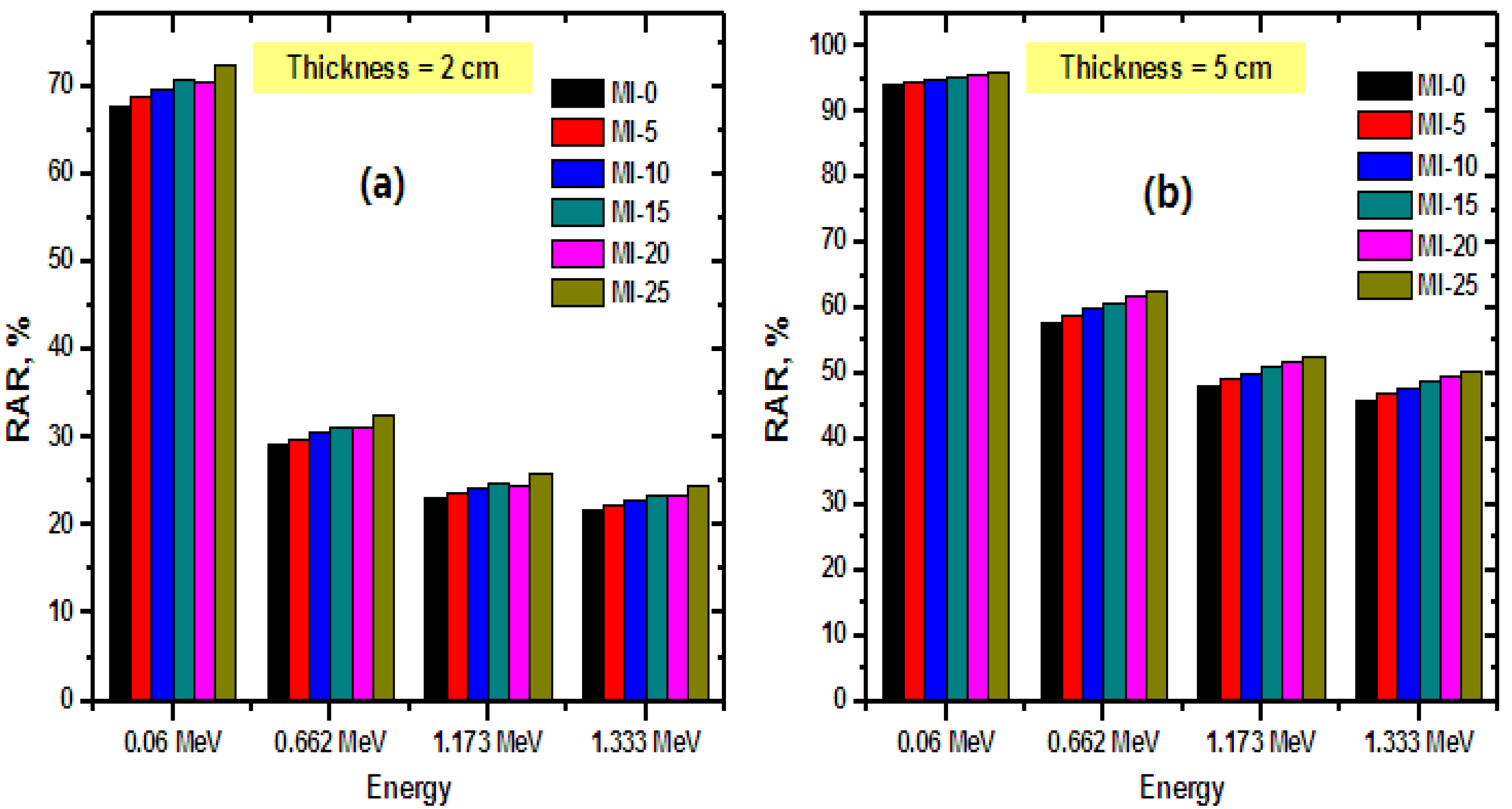

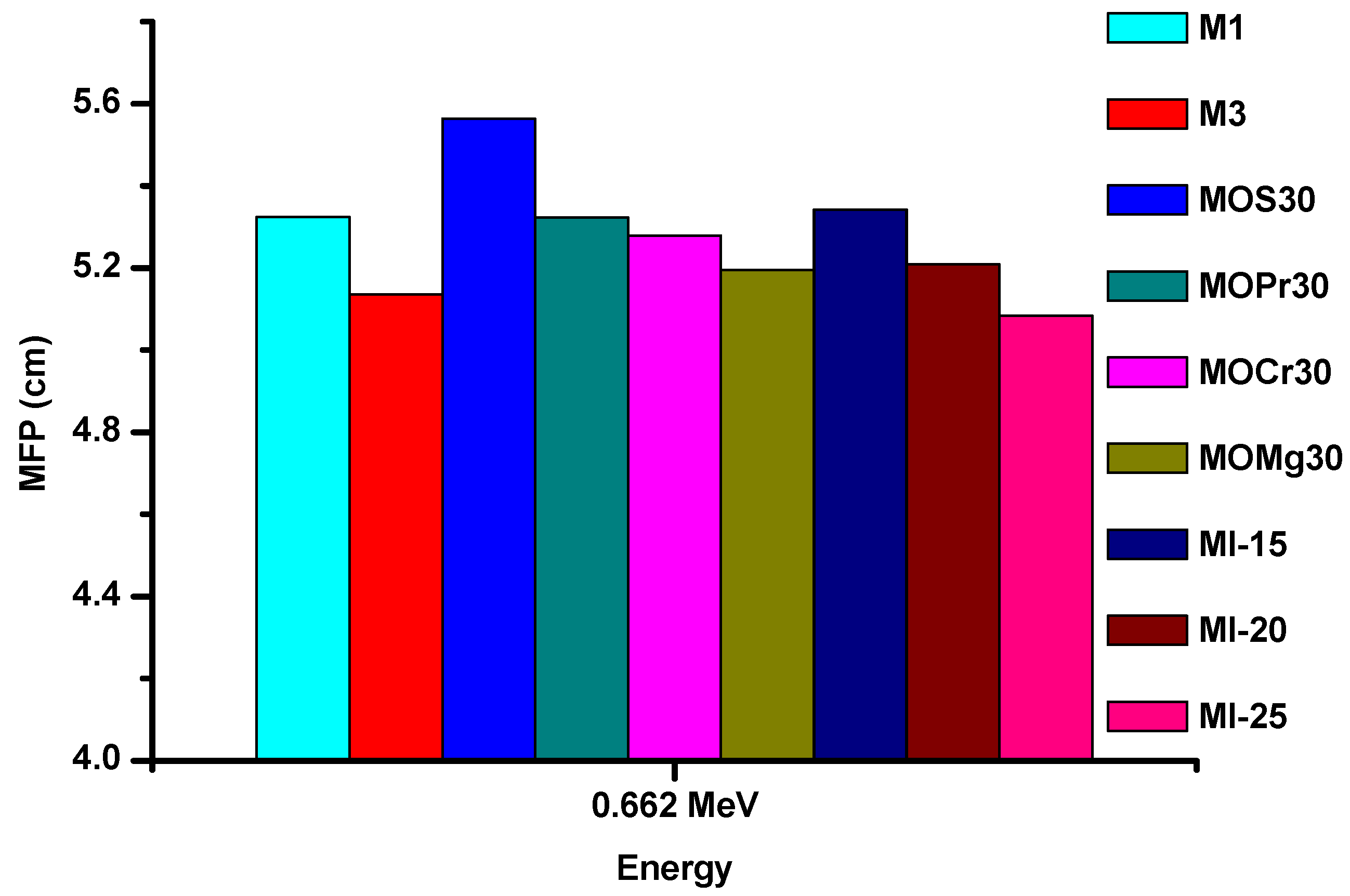

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aygün, B. Neutron and gamma radiation shielding Ni based new type super alloys development and production by Monte Carlo Simulation technique. Radiat. Phys. Chem. 2021, 188, 109630. [Google Scholar] [CrossRef]

- Kamislioglu, M. An investigation into gamma radiation shielding parameters of the (Al:Si) and (Al + Na):Si-doped international simple glasses (ISG) used in nuclear waste management, deploying Phy-X/PSD and SRIM software. J. Mater. Sci. Mater. Electron. 2021, 32, 12690–12704. [Google Scholar] [CrossRef]

- Abouhaswa, A.S.; Kavaz, E. Bi2O3 effect on physical, optical, structural and radiation safety characteristics of B2O3-Na2O-ZnO-CaO glass system. J. Non Cryst. Solids 2020, 535, 119993. [Google Scholar] [CrossRef]

- Dong, M.; Xue, X.; Yang, H.; Li, Z. Highly cost-effective shielding composite made from vanadium slag and boron-rich slag and its properties. Radiat. Phys. Chem. 2017, 141, 239–244. [Google Scholar] [CrossRef]

- Dong, M.; Xue, X.; Yang, H.; Liu, D.; Wang, C.; Li, Z. A novel comprehensive utilization of vanadium slag: As gamma ray shielding material. J. Hazard. Mater. 2016, 318, 751–757. [Google Scholar] [CrossRef] [PubMed]

- Dong, M.; Zhou, S.; Xue, X.; Sayyed, M.; Tishkevich, D.; Trukhanov, A.; Wang, C. Study of comprehensive shielding behaviors of chambersite deposit for neutron and gamma ray. Prog. Nucl. Energy 2022, 146, 104155. [Google Scholar] [CrossRef]

- Aygün, B. High alloyed new stainless steel shielding material for gamma and fast neutron radiation. Nucl. Eng. Technol. 2019, 52, 647–653. [Google Scholar] [CrossRef]

- Rajesh, M.; Kavaz, E.; Deva, B.; Raju, P. Photoluminescence, radiative shielding properties of Sm3+ ions doped fluoroborosilicate glasses for visible (reddish-orange) display and radiation shielding applications. Mater. Res. Bull. 2021, 142, 111383. [Google Scholar] [CrossRef]

- Al-Yousef, H.A.; Alotiby, M.; Hanfi, M.Y.; Alotaibi, B.M.; Mahmoud, K.A.; Sayyed, M.I.; Al-Hadeethi, Y. Effect of the Fe2O3 addition on the elastic and gamma-ray shielding features of bismuth sodium-borate glass system. J. Mater. Sci. Mater. Electron. 2021, 32, 6942–6954. [Google Scholar] [CrossRef]

- Albarzan, B.; Hanfi, M.Y.; Almuqrin, A.H.; Sayyed, M.I.; Alsafi, H.M.; Mahmoud, K.A. The Influence of Titanium Dioxide on Silicate-Based Glasses: An Evaluation of the Mechanical and Radiation Shielding Properties. Materials 2021, 14, 3414. [Google Scholar] [CrossRef]

- Naseer, K.; Sathiyapriya, G.; Marimuthu, K.; Piotrowski, T.; Alqahtani, M.S.; Yousef, E.S. Optical, elastic, and neutron shielding studies of Nb2O5 varied Dy3+ doped barium-borate glasses. Optik 2021, 251, 168436. [Google Scholar] [CrossRef]

- Zayed, A.M.; Masoud, M.A.; Shahien, M.G.; Gökçe, H.S.; Sakr, K.; Kansouh, W.A.; El-Khayatt, A.M. Physical, mechanical and radiation attenuation properties of serpentine concrete containing boric acid. Constr. Build. Mater. 2021, 272, 121641. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Öztürk, B.C.; Çam, N.F.; Andiç-Çakır, Ö. Gamma-ray attenuation coefficients and transmission thickness of high consistency heavyweight concrete containing mineral admixture. Cem. Concr. Compos. 2018, 92, 56–69. [Google Scholar] [CrossRef]

- Abbas, M.I.; El-Khatib, A.M.; Dib, M.F.; Mustafa, H.E.; Sayyed, M.I.; Elsafi, M. The Influence of Bi2O3 Nanoparticle Content on the γ-ray Interaction Parameters of Silicon Rubber. Polymers 2022, 14, 1048. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Rafiee, A.; Dezhampanah, S.; Mehdipour, S.; Mohebbi, R.; Moghadam, H.H.; Sadrmomtazi, A. Effect of high temperature on the radiation shielding properties of cementitious composites containing nano-Bi2O. J. Mater. Res. Technol. 2020, 9, 11135–11153. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Mohebbi, R.; Dezhampanah, S.; Mehdipour, S.; Mohammadi, R.; Nejat, T. Gamma ray shielding properties of heavy-weight concrete containing Nano-TiO. Radiat. Phys. Chem. 2019, 162, 157–167. [Google Scholar] [CrossRef]

- El-Sayed, T.A. Performance of heavy weight concrete incorporating recycled rice straw ash as radiation shielding material. Prog. Nucl. Energy 2021, 135, 103693. [Google Scholar] [CrossRef]

- El-Sayed, A.A.; Fathy, I.N.; Tayeh, B.A.; Almeshal, I. Using artificial neural networks for predicting mechanical and radiation shielding properties of different nano-concretes exposed to elevated temperature. Constr. Build. Mater. 2022, 324, 126663. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.; El-Hosiny, F.; El-Gamal, S.; Amin, M.; Ramadan, M. Gamma radiation shielding, fire resistance and physicochemical characteristics of Portland cement pastes modified with synthesized Fe2O3 and ZnO nanoparticles. Constr. Build. Mater. 2018, 173, 687–706. [Google Scholar] [CrossRef]

- Seifan, M.; Mendoza, S.; Berenjian, A. Mechanical properties and durability performance of fly ash based mortar containing nano- and micro-silica additives. Constr. Build. Mater. 2020, 252, 119121. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Antolik, A.; Gawlicki, M. Evaluation of compatibility of neutron-shielding boron aggregates with Portland cement in mortar. Constr. Build. Mater. 2018, 164, 731–738. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Elsafi, M.; Almuqrin, A.H.; Cornish, K.; Elkhatib, A.M. Novel Shielding Mortars for Radiation Source Transportation and Storage. Sustainability 2022, 14, 1248. [Google Scholar] [CrossRef]

- Sayyed, M.; Hamad, M.K.; Mhareb, M.; Kurtulus, R.; Dwaikat, N.; Saleh, M.; Elsafi, M.; Taki, M.M.; Kavas, T.; Ziq, K.; et al. Assessment of radiation attenuation properties for novel alloys: An experimental approach. Radiat. Phys. Chem. 2022, 110152. [Google Scholar] [CrossRef]

- Şensoy, A.T.; Gökçe, H.S. Simulation and optimization of gamma-ray linear attenuation coefficients of barite concrete shields. Constr. Build. Mater. 2020, 253, 119218. [Google Scholar] [CrossRef]

- Demir, I.; Gümüş, M.; Gökçe, H.S. Gamma ray and neutron shielding characteristics of polypropylene fiber-reinforced heavyweight concrete exposed to elevated temperatures. Constr. Build. Mater. 2020, 257, 119596. [Google Scholar] [CrossRef]

- Kaewjaeng, S.; Kothan, S.; Chaiphaksa, W.; Chanthima, N.; Rajaramakrishna, R.; Kim, H.J.; Kaewkhao, J. High transparency La2O3-CaO-B2O3-SiO2 glass for diagnosis x-rays shielding material application. Radiat. Phys. Chem. 2019, 160, 41–47. [Google Scholar] [CrossRef]

- D’Souza, A.N.; Sayyed, M.; Karunakara, N.; Al-Ghamdi, H.; Almuqrin, A.H.; Elsafi, M.; Khandaker, M.U.; Kamath, S.D. TeO2–SiO2–B2O3 glasses doped with CeO2 for gamma radiation shielding and dosimetry application. Radiat. Phys. Chem. 2022, 110233. [Google Scholar] [CrossRef]

- Kaewjaeng, S.; Chanthima, N.; Thongdang, J.; Reungsri, S.; Kothan, S.; Kaewkhao, J. Synthesis and radiation properties of Li2O-BaO-Bi2O3-P2O5 glasses. Mater. Today Proc. 2021, 43, 2544–2553. [Google Scholar] [CrossRef]

- Chanthima, N.; Kaewkhao, J.; Limkitjaroenporn, P.; Tuscharoen, S.; Kothan, S.; Tungjai, M.; Kaewjaeng, S.; Sarachai, S.; Limsuwan, P. Development of BaO–ZnO–B2O3 glasses as a radiation shielding material. Radiat. Phys. Chem. 2017, 137, 72–77. [Google Scholar] [CrossRef]

- Tijani, S.A.; Al-Hadeethi, Y.F. The use of isophthalic-bismuth polymer composites as radiation shielding barriers in nuclear medicine. Mater. Res. Express 2019, 6, 055323. [Google Scholar] [CrossRef]

- Cheewasukhanont, W.; Limkitjaroenporn, P.; Kothan, S.; Kedkaew, C.; Kaewkhao, J. The effect of particle size on radiation shielding properties for bismuth borosilicate glass. Radiat. Phys. Chem. 2020, 172, 108791. [Google Scholar] [CrossRef]

- Hannachi, E.; Sayyed, M.I.; Slimani, Y.; Almessiere, M.A.; Baykal, A.; Elsafi, M. Synthesis, characterization, and performance assessment of new composite ceramics towards radiation shielding applications. J. Alloys Compd. 2022, 899, 163173. [Google Scholar] [CrossRef]

- Elsafi, M.; Koraim, Y.; Almurayshid, M.; Almasoud, F.I.; Sayyed, M.I.; Saleh, I.H. Investigation of Photon Radiation Attenuation Capability of Different Clay Materials. Materials 2021, 14, 6702. [Google Scholar] [CrossRef]

- Elsafi, M.; Dib, M.F.; Mustafa, H.E.; Sayyed, M.I.; Khandaker, M.U.; Alsubaie, A.; Almalki, A.S.A.; Abbas, M.I.; El-Khatib, A.M. Enhancement of Ceramics Based Red-Clay by Bulk and Nano Metal Oxides for Photon Shielding Features. Materials 2021, 14, 7878. [Google Scholar] [CrossRef]

- Elsafi, M.; El-Nahal, M.A.; Alrashedi, M.F.; Olarinoye, O.I.; Sayyed, M.I.; Khandaker, M.U.; Osman, H.; Alamri, S.; Abbas, M.I. Shielding Properties of Some Marble Types: A Comprehensive Study of Experimental and XCOM Results. Materials 2021, 14, 4194. [Google Scholar] [CrossRef]

- Agar, O.; Sayyed, M.I.; Tekin, H.O.; Kaky, K.M.; Baki, S.O.; Kityk, I. An investigation on shielding properties of BaO, MoO3 and P2O5 based glasses using MCNPX code. Results Phys. 2019, 12, 629–634. [Google Scholar] [CrossRef]

- Baltas, H.; Sirin, M.; Celik, A.; Ustabas, İ.; El-Khayatt, A.M. Radiation shielding properties of mortars with minerals and ores additives. Cem. Concr. Compos. 2019, 97, 268–278. [Google Scholar] [CrossRef]

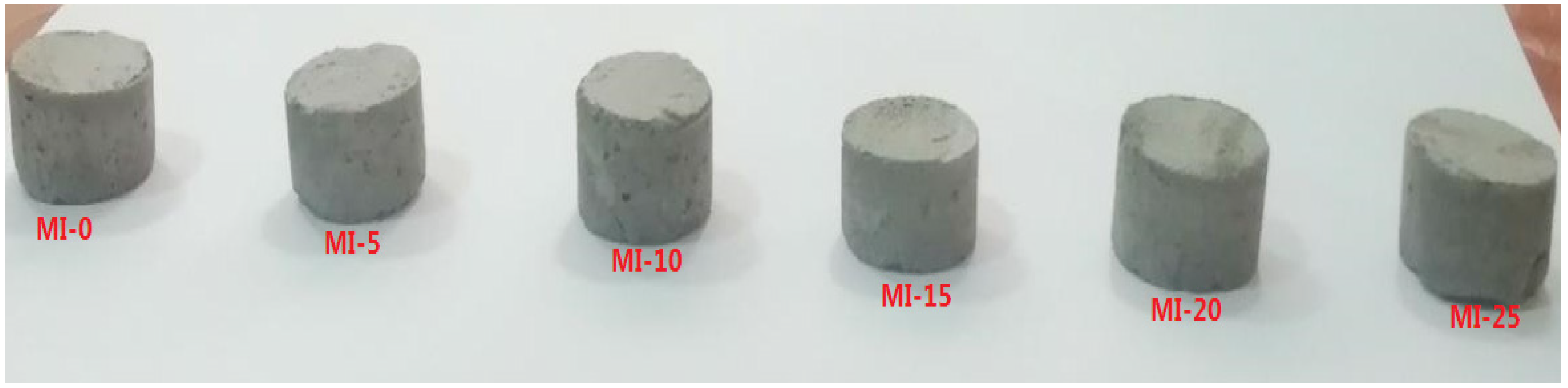

| Codes | Composition, Kg/m3 | Density, g/cm−3 | |||

|---|---|---|---|---|---|

| Cement | Water | Sand | Fe2O3 Nanoparticles | ||

| MI-0 | 500 | 250 | 1375 | — | 2.241 |

| MI-5 | 500 | 250 | 1375 | 25 | 2.256 |

| MI-10 | 500 | 250 | 1375 | 50 | 2.270 |

| MI-15 | 500 | 250 | 1375 | 75 | 2.285 |

| MI-20 | 500 | 250 | 1375 | 100 | 2.300 |

| MI-25 | 500 | 250 | 1375 | 125 | 2.314 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayyed, M.I.; Almousa, N.; Elsafi, M. Preparation of Mortar with Fe2O3 Nanoparticles for Radiation Shielding Application. Coatings 2022, 12, 1329. https://doi.org/10.3390/coatings12091329

Sayyed MI, Almousa N, Elsafi M. Preparation of Mortar with Fe2O3 Nanoparticles for Radiation Shielding Application. Coatings. 2022; 12(9):1329. https://doi.org/10.3390/coatings12091329

Chicago/Turabian StyleSayyed, M. I., Nouf Almousa, and Mohamed Elsafi. 2022. "Preparation of Mortar with Fe2O3 Nanoparticles for Radiation Shielding Application" Coatings 12, no. 9: 1329. https://doi.org/10.3390/coatings12091329

APA StyleSayyed, M. I., Almousa, N., & Elsafi, M. (2022). Preparation of Mortar with Fe2O3 Nanoparticles for Radiation Shielding Application. Coatings, 12(9), 1329. https://doi.org/10.3390/coatings12091329