Flow Characteristics and Hydraulic Lift of Coandă Effect-Based Pick-Up Method for Polymetallic Nodule

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mass and Momentum Balance

2.2. Effect of Wall Curvature on the Growth Rate

2.3. Prediction of Particle Lift in Jet Flows on Logarithmic Spirals

3. Results

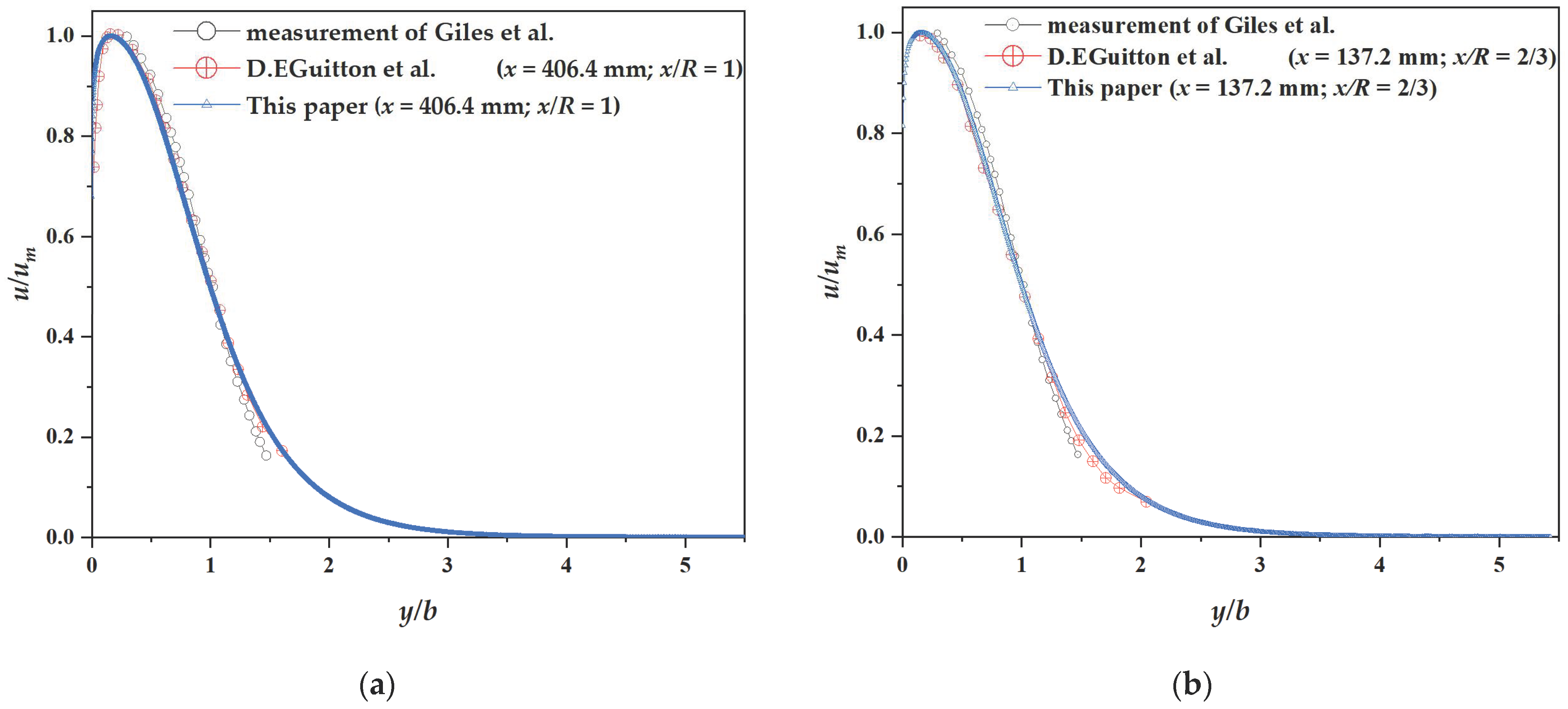

3.1. Validation

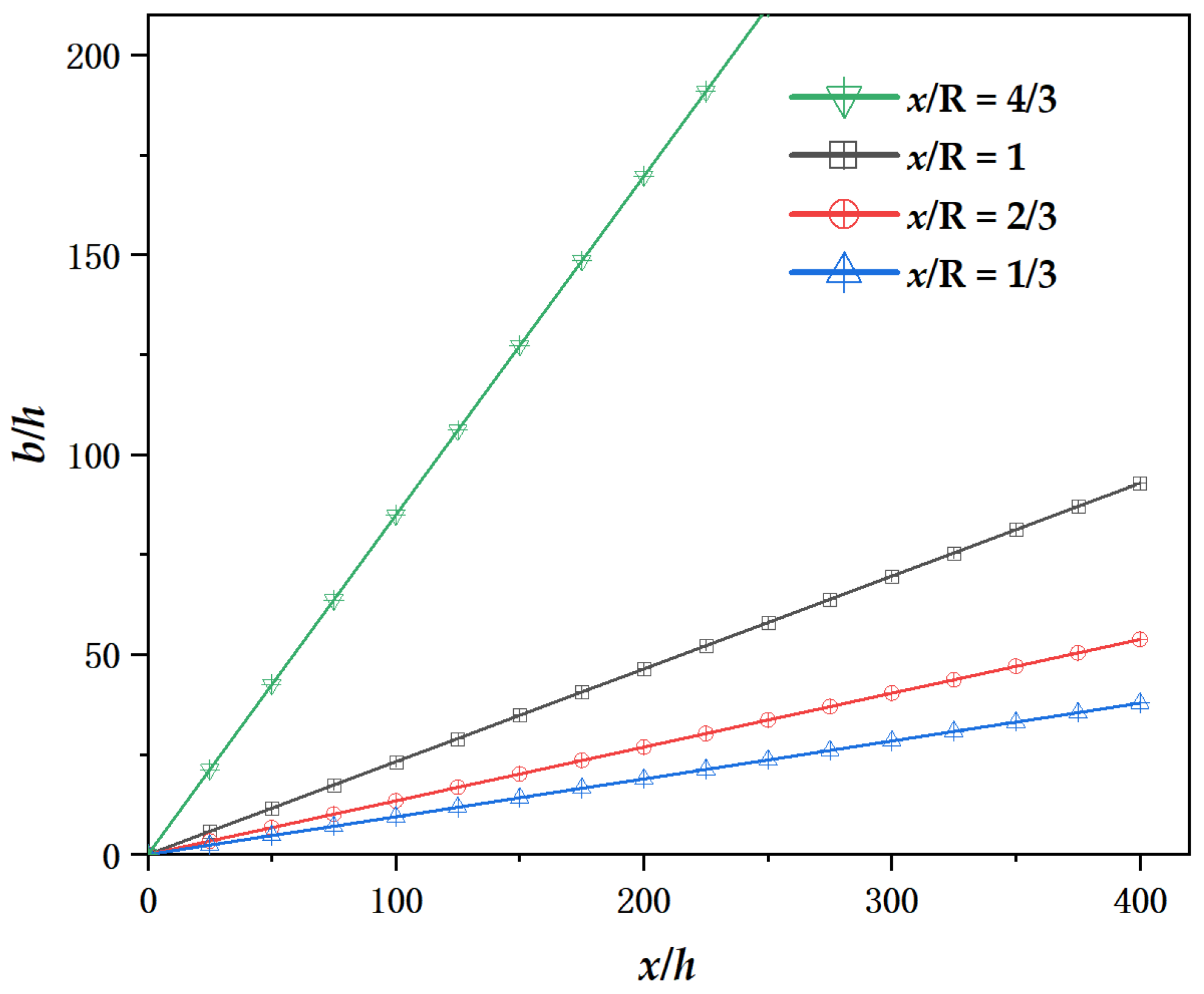

3.2. Growth Rate

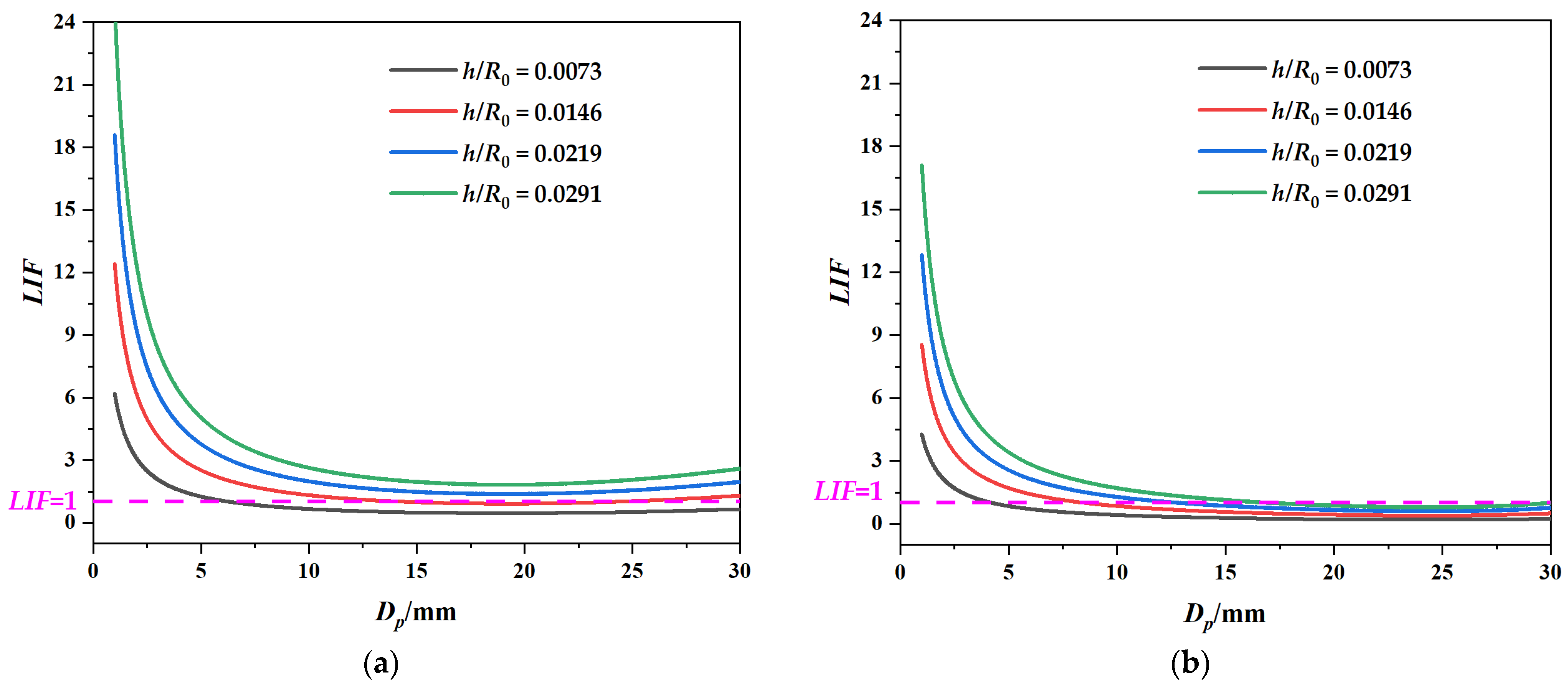

3.3. Parameters Affect the Jet Flow and Lift Index on Logarithmic Spirals

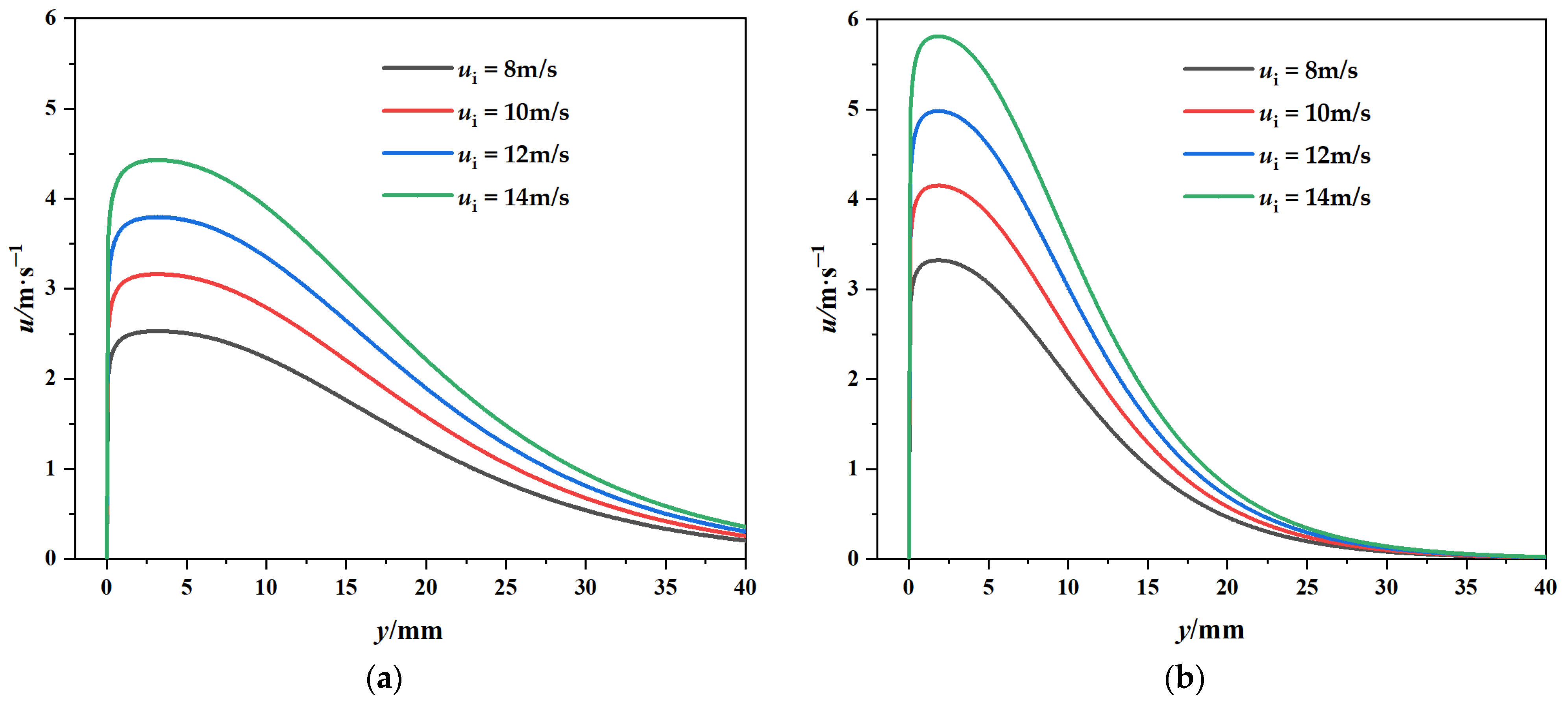

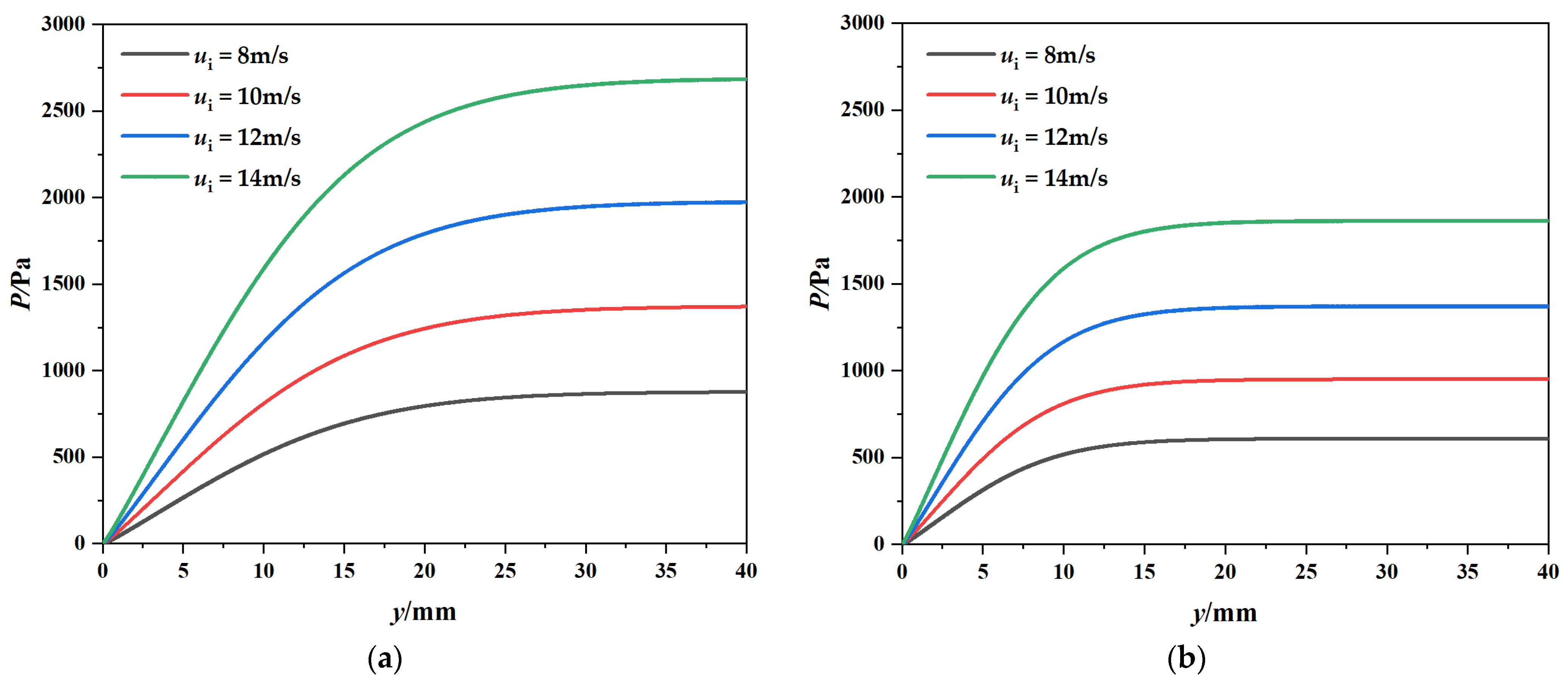

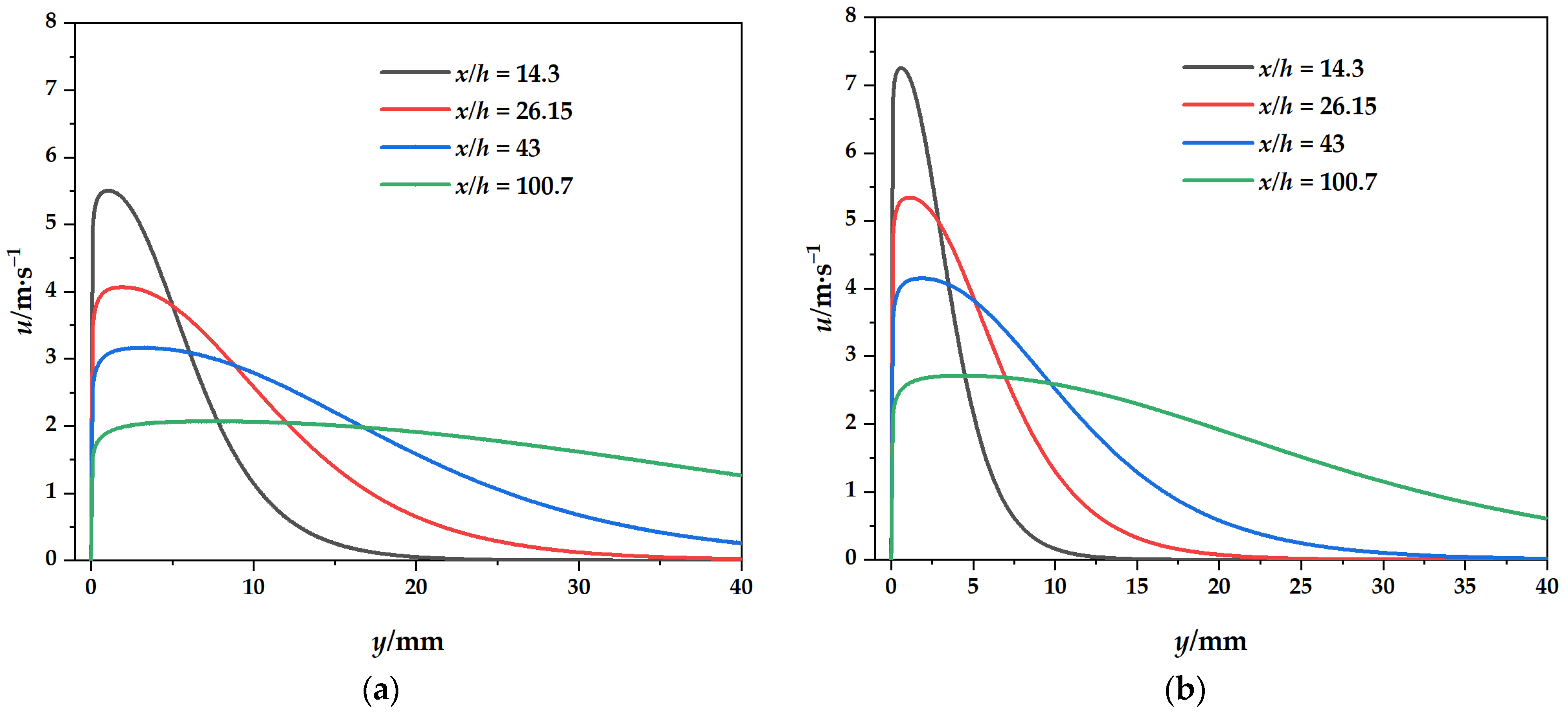

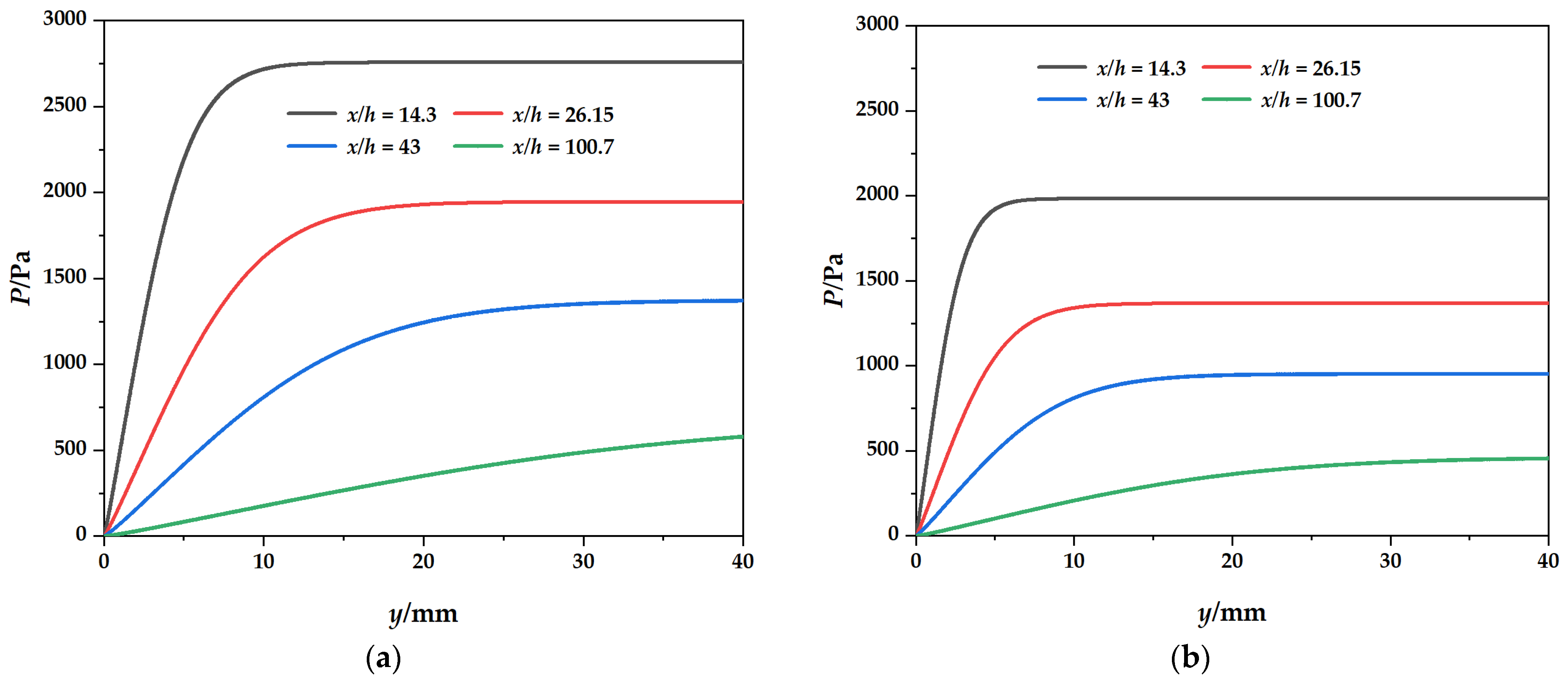

3.3.1. Jet Exit Velocity ui

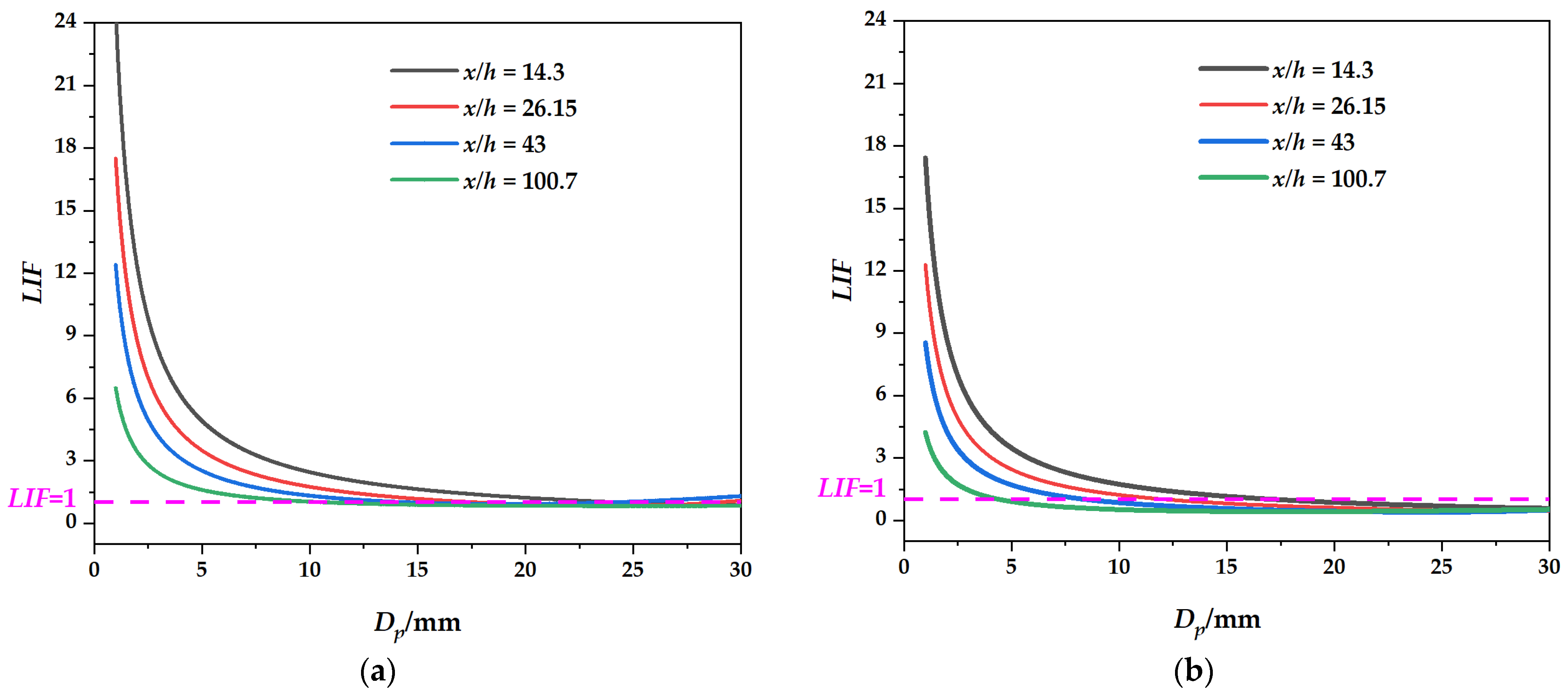

3.3.2. Jet Downstream Distance x/h

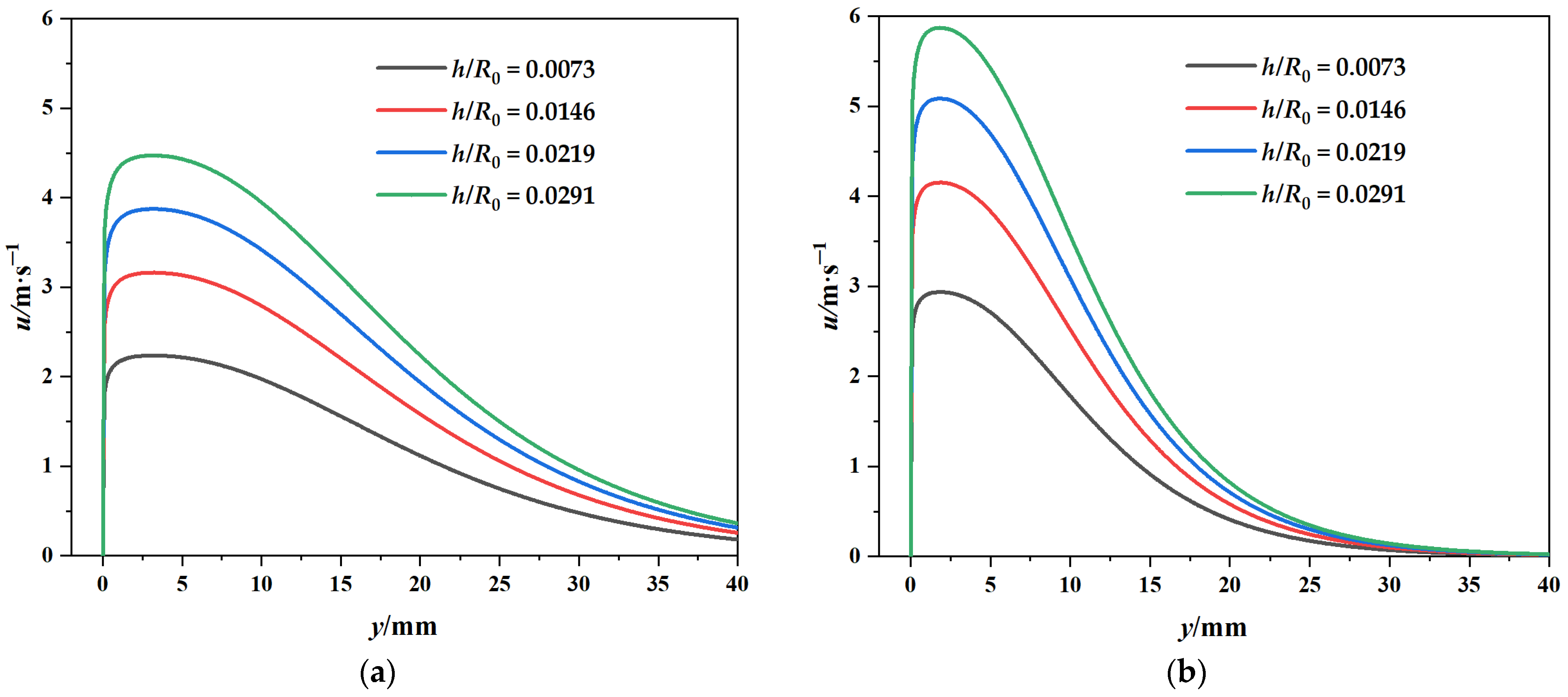

3.3.3. Non-Dimensional Slot Height h/R0

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Handschuh, R.; Grebe, H.; Panthel, J.; Schulte, E.; Ravindran, M. Innovative deep ocean mining concept based on flexible riser and self-propelled mining machines. In Proceedings of the Fourth Isope Ocean Mining Symposium, Szczecin, Poland, 23–27 September 2001. [Google Scholar]

- Jia, H.; Wang, Y.; Zhu, Z.; Su, X.; Tang, Z. Coarse particle motion characteristics in a double-stage slurry pump considering leakage flow. Shock Vib. 2021, 2021, 5904446. [Google Scholar] [CrossRef]

- Kim, S.; Cho, S.G.; Kim, J.; Lee, T.H.; Chi, S.B. Reliability-based design optimization of a pick-up device of a manganese nodule miner using correlated and grouped manganese nodule data. In Proceedings of the 13th World Congress of Structural and Multidisciplinary Optimization (WCSMO-13), Beijing, China, 20–24 May 2019. [Google Scholar]

- Oebius, H.U.; Becker, H.J.; Rolinski, S.; Jankowski, J.A. Parametrization and evaluation of marine environmental impacts produced by deep-sea manganese nodule mining. Deep Sea Res. Part II Top. Stud. Oceanogr. 2001, 48, 3453–3467. [Google Scholar] [CrossRef]

- Cho, S.G.; Park, S.; Oh, J.; Min, C.; Kim, H.; Hong, S.; Jang, J.; Lee, T.H. Design optimization of deep-seabed pilot miner system with coupled relations between constraints. J. Terramech. 2019, 83, 25–34. [Google Scholar] [CrossRef]

- Jia, H.; Yang, J.; Su, X.; Xia, Q.; Wu, K. Theoretical prediction on hydraulic lift of a coandă effect-based mining collector for manganese nodule. Energies 2022, 15, 6345. [Google Scholar] [CrossRef]

- Yue, Z.; Zhao, G.; Xiao, L.; Liu, M. Comparative study on collection performance of three nodule collection methods in seawater and sediment-seawater mixture. Appl. Ocean Res. 2021, 110, 102606. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, G.; Xiao, L.; Liu, M. Experimental investigation on characteristics of flow field in ‘suck-up-based’ and ‘coandă-effect-based’ nodule pick-up devices. In Proceedings of the The 30th International Ocean and Polar Engineering Conference, Virtual, 11–16 October 2020. [Google Scholar]

- Kim, M.; Kim, H.D.; Yeom, E.; Kyung, K.C. Flow characteristics of three-dimensional curved wall jets on a cylinder. J. Fluids Eng. Trans. ASME 2018, 140, 041201. [Google Scholar] [CrossRef]

- Roberts, L. A theory for turbulent curved wall jets. In Proceedings of the 25th AIAA Aerospace Sciences Meeting, Reno, NV, USA, 24–26 March 1987. [Google Scholar]

- Rodman, L.C.; Wood, N.J.; Roberts, L. Experimental investigation of straight and curved annular wall jets. AIAA J. 1989, 27, 1059–1067. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.U.; Hong, S.; Choi, J.S.; Kim, H.W.; Yeu, T.K.; Min, C.H.; Cho, S.G.; Lee, T.H. Design optimization of a hydraulic deep-sea manganese pick-up device using coanda effect. In Proceedings of the KSME 2013 Spring Annual Meeting, Busan, Republic of Korea, 23–24 May 2013; pp. 1660–1665. [Google Scholar]

- Guitton, D.E.; Newman, B.G. Self-preserving turbulent wall jets over convex surfaces. J. Fluid Mech. 1977, 81, 155–185. [Google Scholar] [CrossRef]

- Giles, J.A.; Hays, A.P.; Sawyer, R.A. Turbulent wall jets on logarithmic spiral surfaces. Aeronaut. Q. 1966, 17, 201–215. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, H.; Yang, J.; Su, X.; Wang, Y.; Wu, K. Flow Characteristics and Hydraulic Lift of Coandă Effect-Based Pick-Up Method for Polymetallic Nodule. Coatings 2023, 13, 271. https://doi.org/10.3390/coatings13020271

Jia H, Yang J, Su X, Wang Y, Wu K. Flow Characteristics and Hydraulic Lift of Coandă Effect-Based Pick-Up Method for Polymetallic Nodule. Coatings. 2023; 13(2):271. https://doi.org/10.3390/coatings13020271

Chicago/Turabian StyleJia, Hao, Jian Yang, Xianghui Su, Yapeng Wang, and Kexin Wu. 2023. "Flow Characteristics and Hydraulic Lift of Coandă Effect-Based Pick-Up Method for Polymetallic Nodule" Coatings 13, no. 2: 271. https://doi.org/10.3390/coatings13020271

APA StyleJia, H., Yang, J., Su, X., Wang, Y., & Wu, K. (2023). Flow Characteristics and Hydraulic Lift of Coandă Effect-Based Pick-Up Method for Polymetallic Nodule. Coatings, 13(2), 271. https://doi.org/10.3390/coatings13020271