Evaluation of Curing Effects on Bitumen Emulsion-Based Cold In-Place Recycling Mixture Considering Field-Water Evaporation and Heat-Transfer Conditions

Abstract

:1. Introduction

2. Materials and Experimental Program

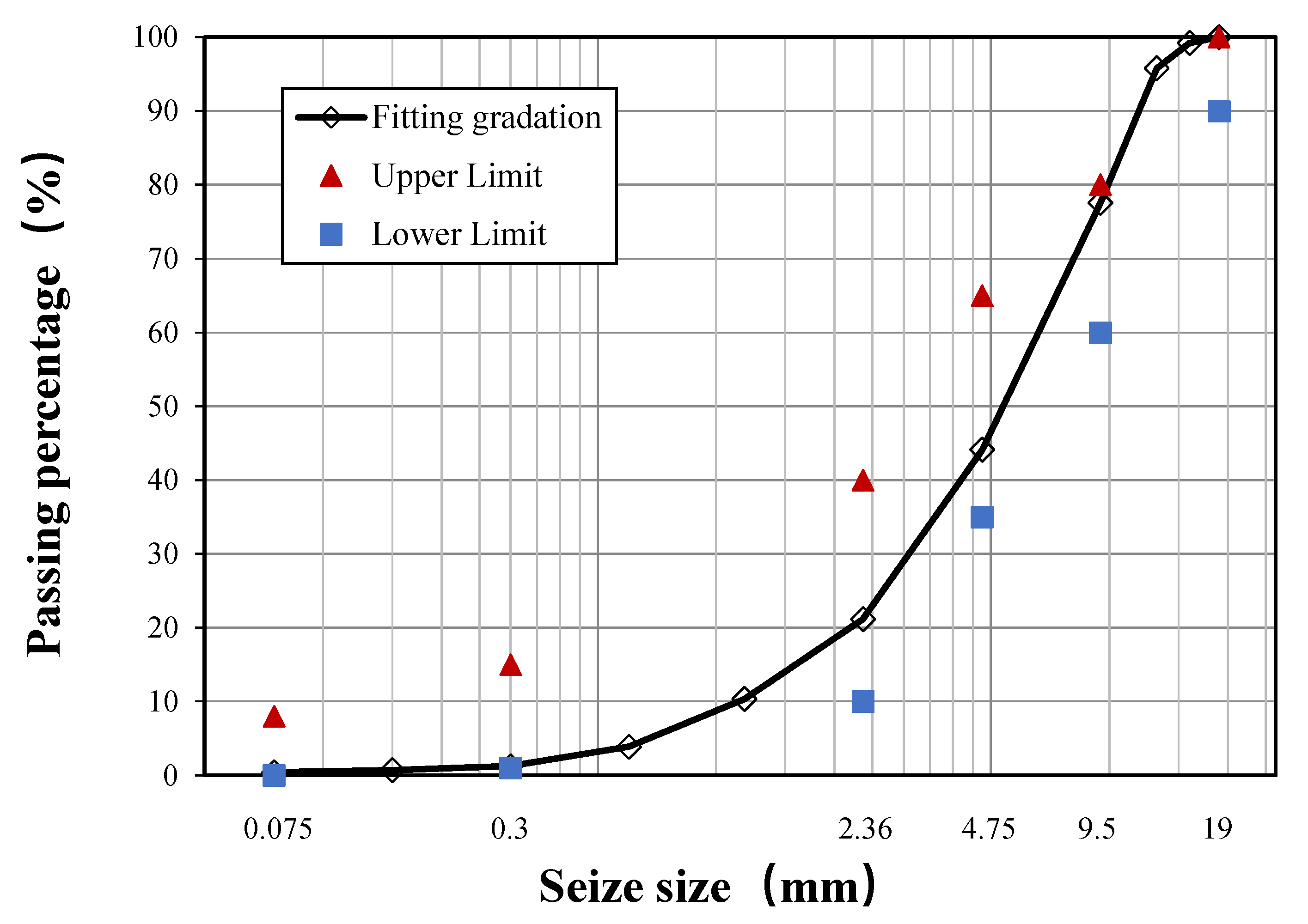

2.1. Mix Design

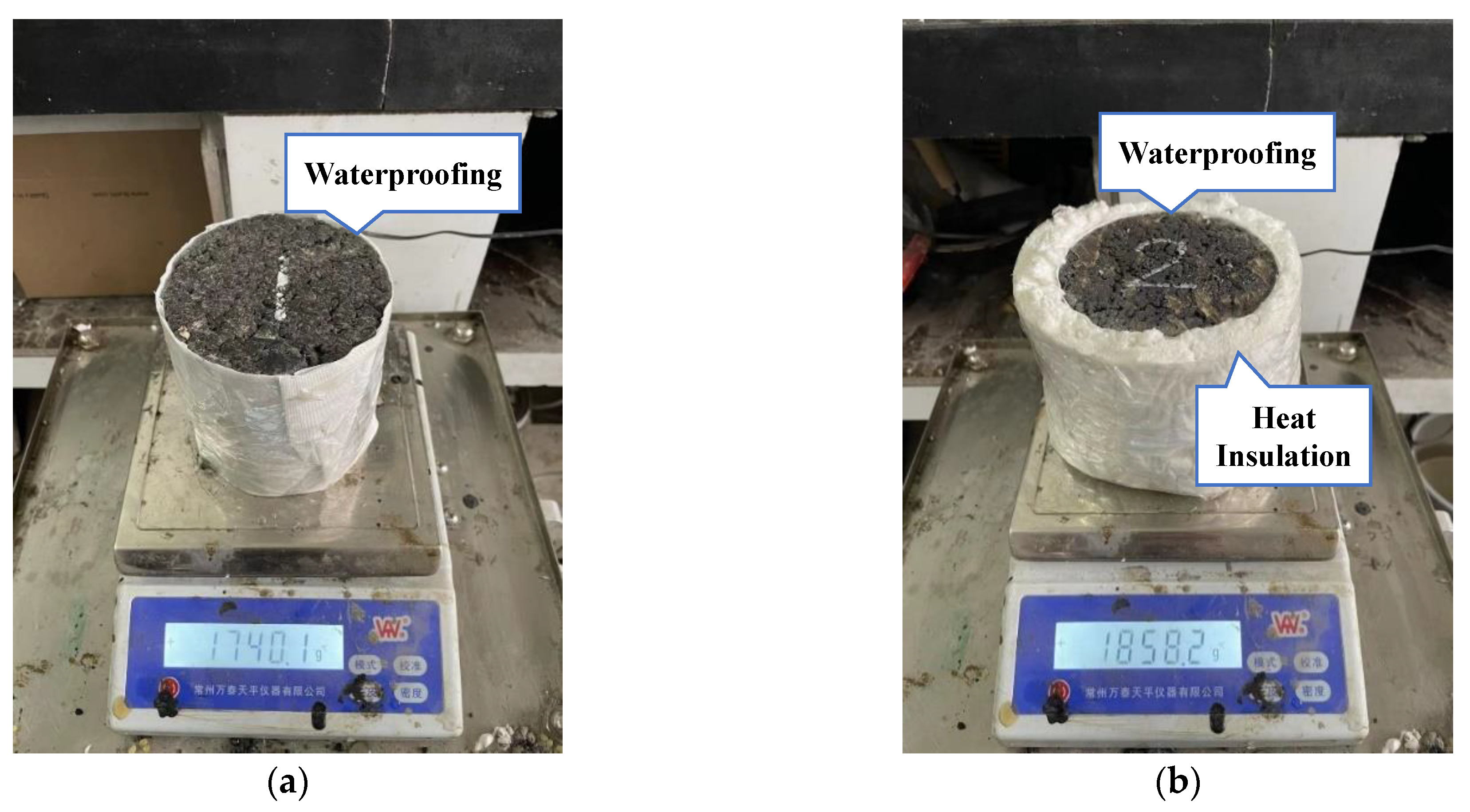

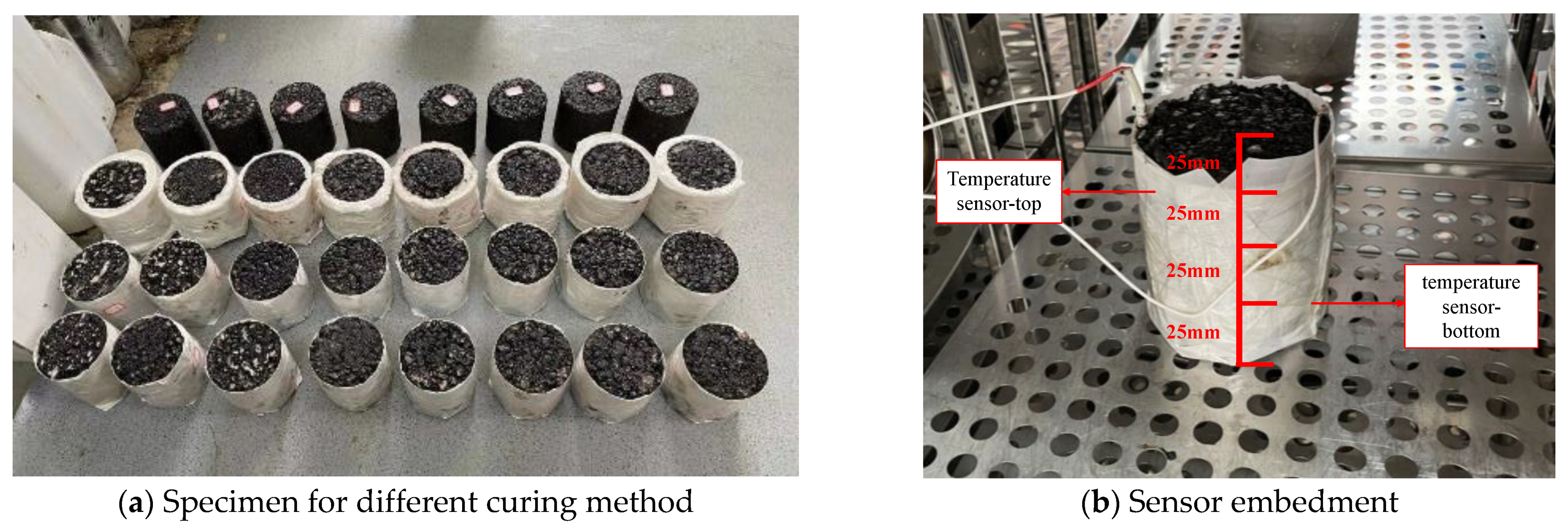

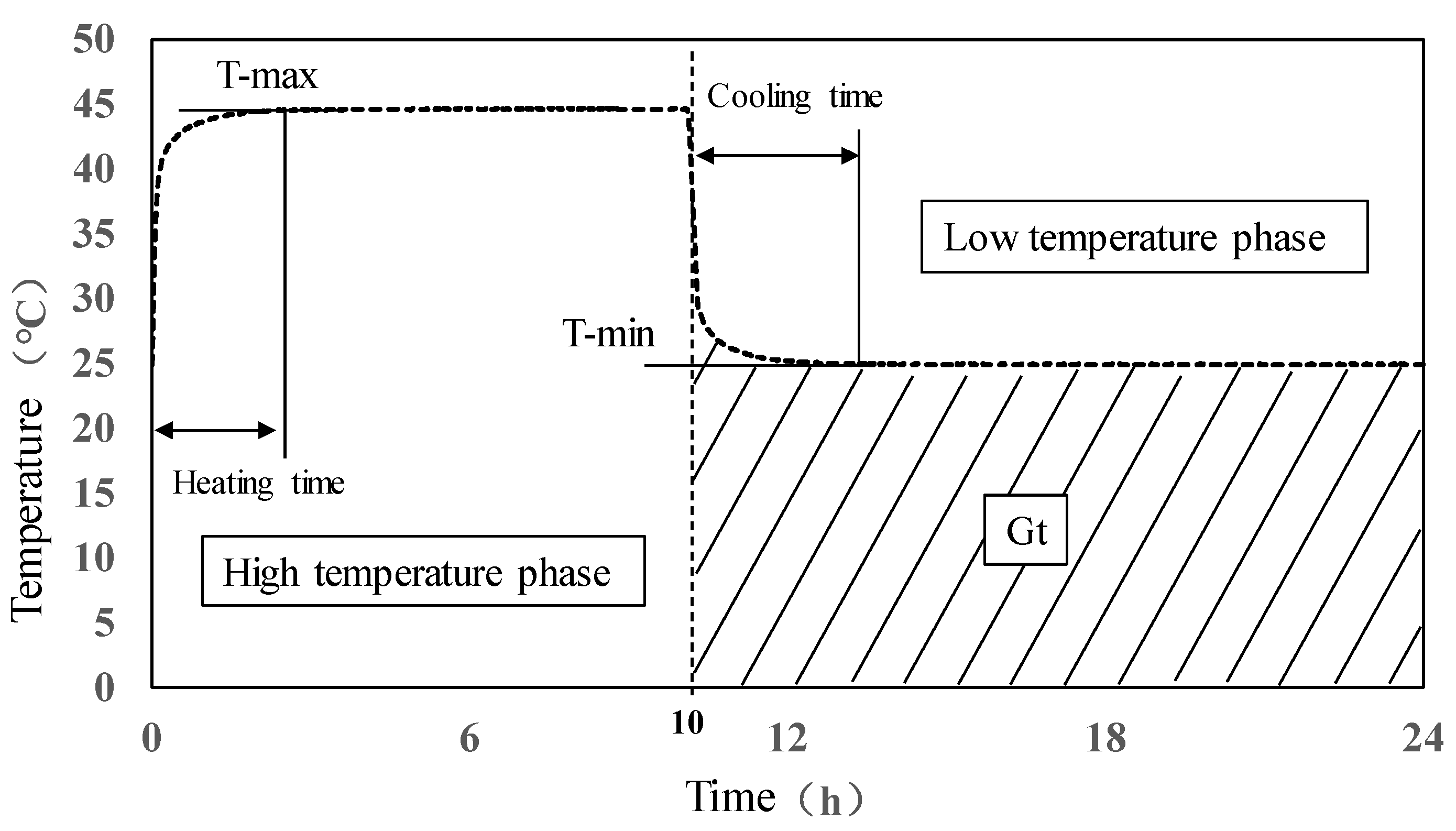

2.2. Curing Method Design

2.3. Test Program

3. Results Analysis

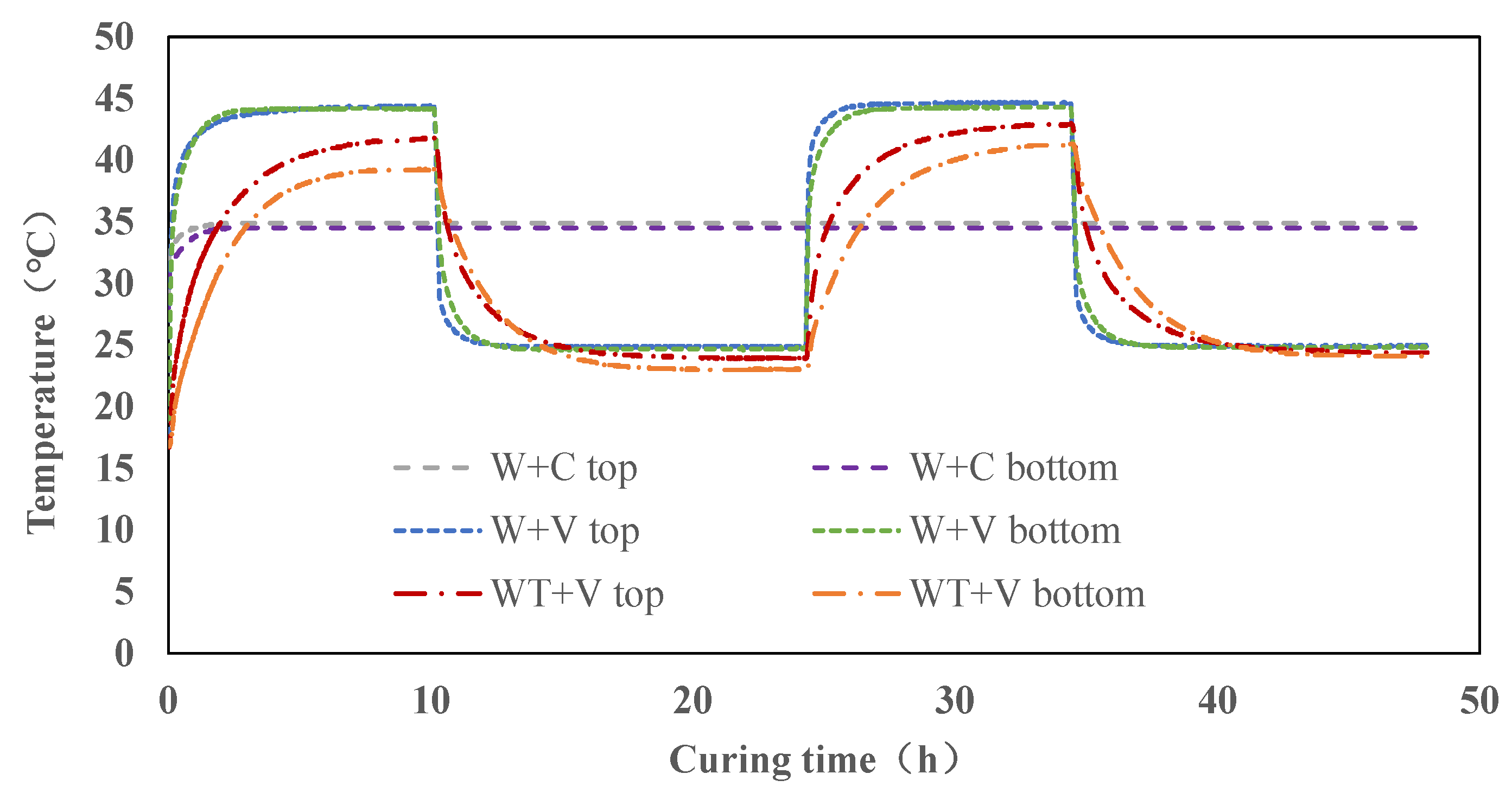

3.1. Analysis of Temperature Variation

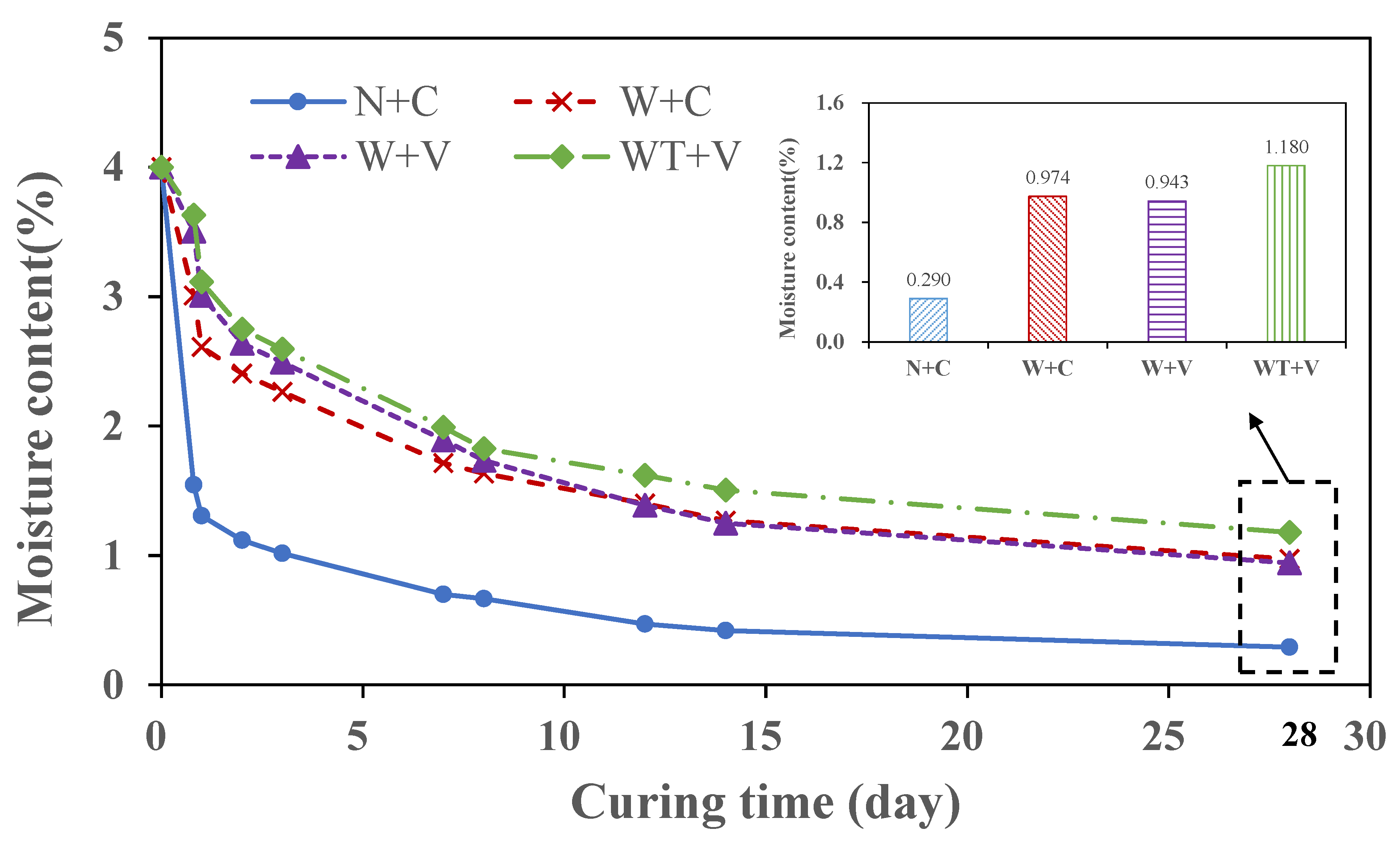

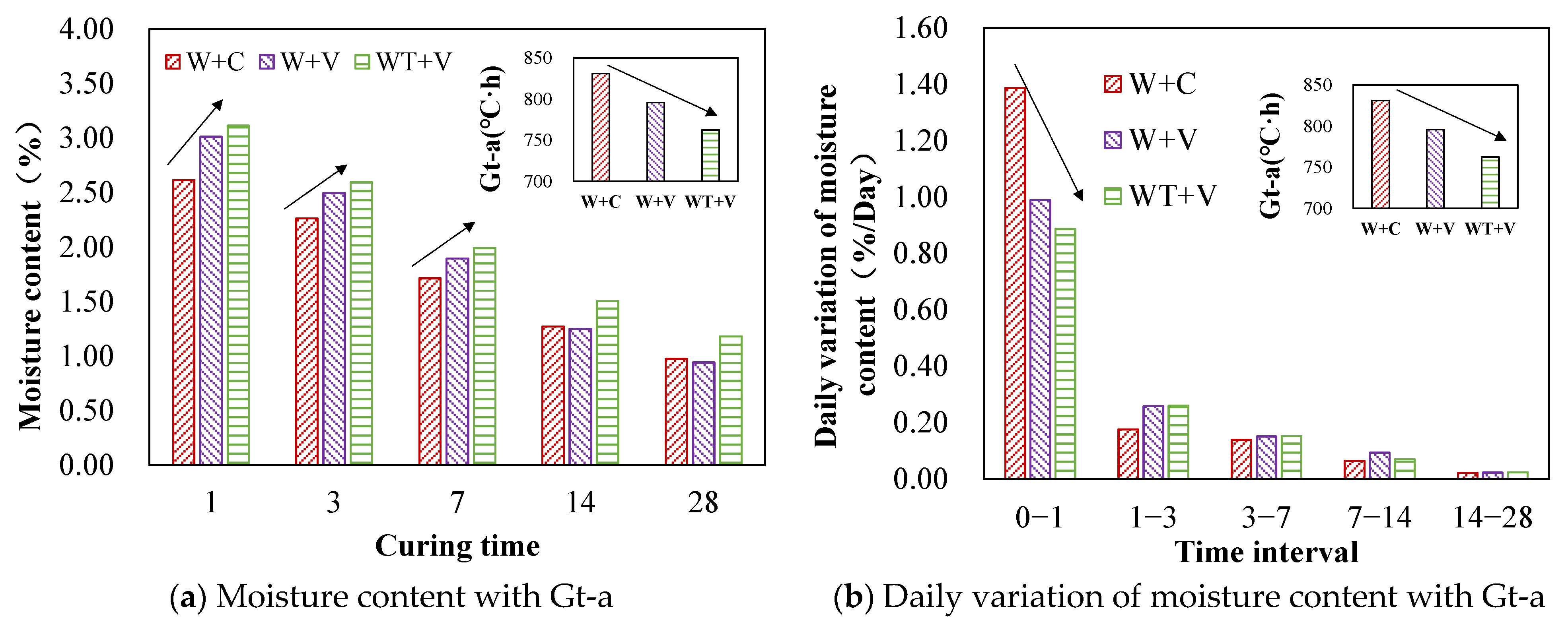

3.2. Moisture Variation Analysis

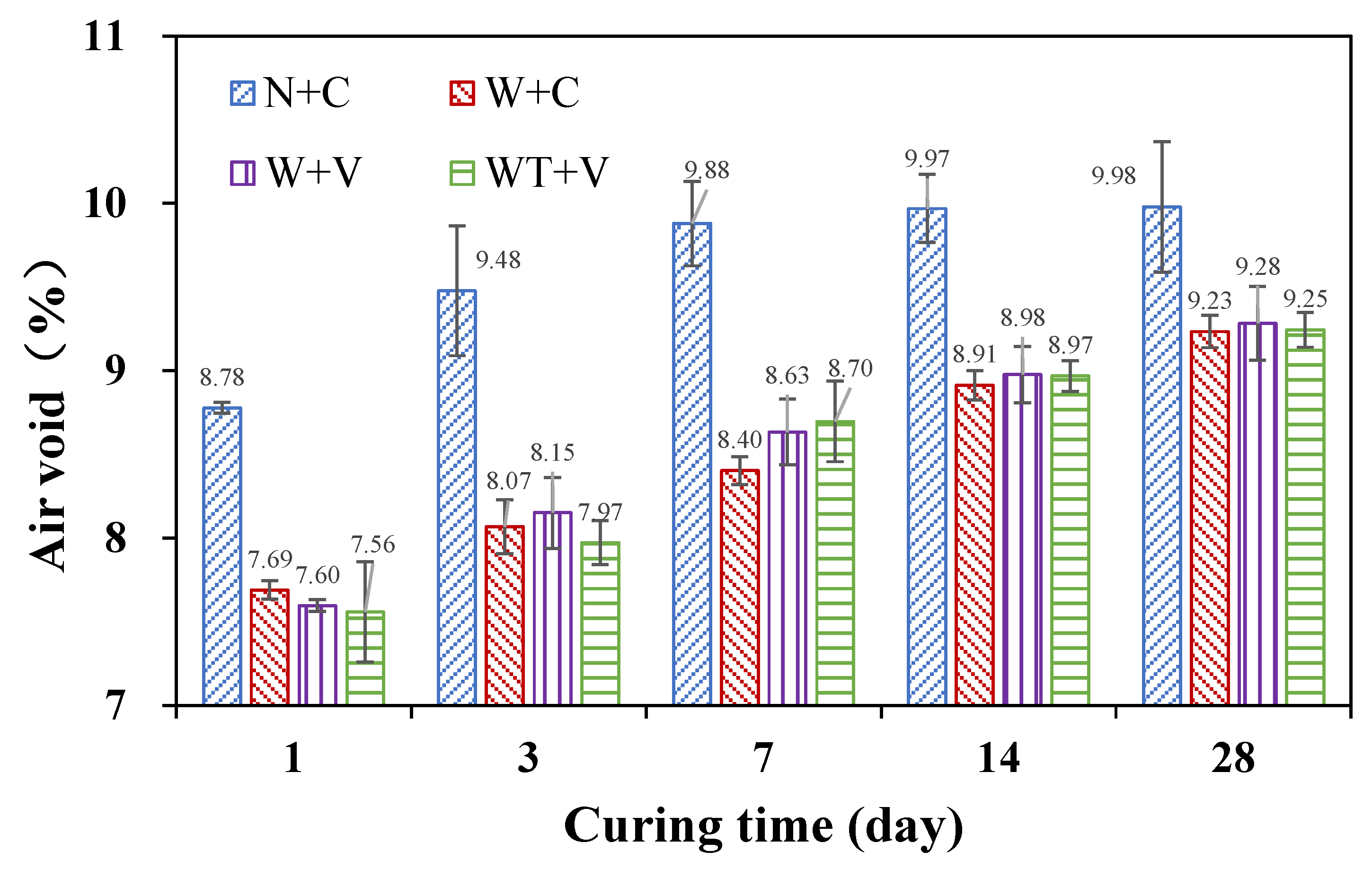

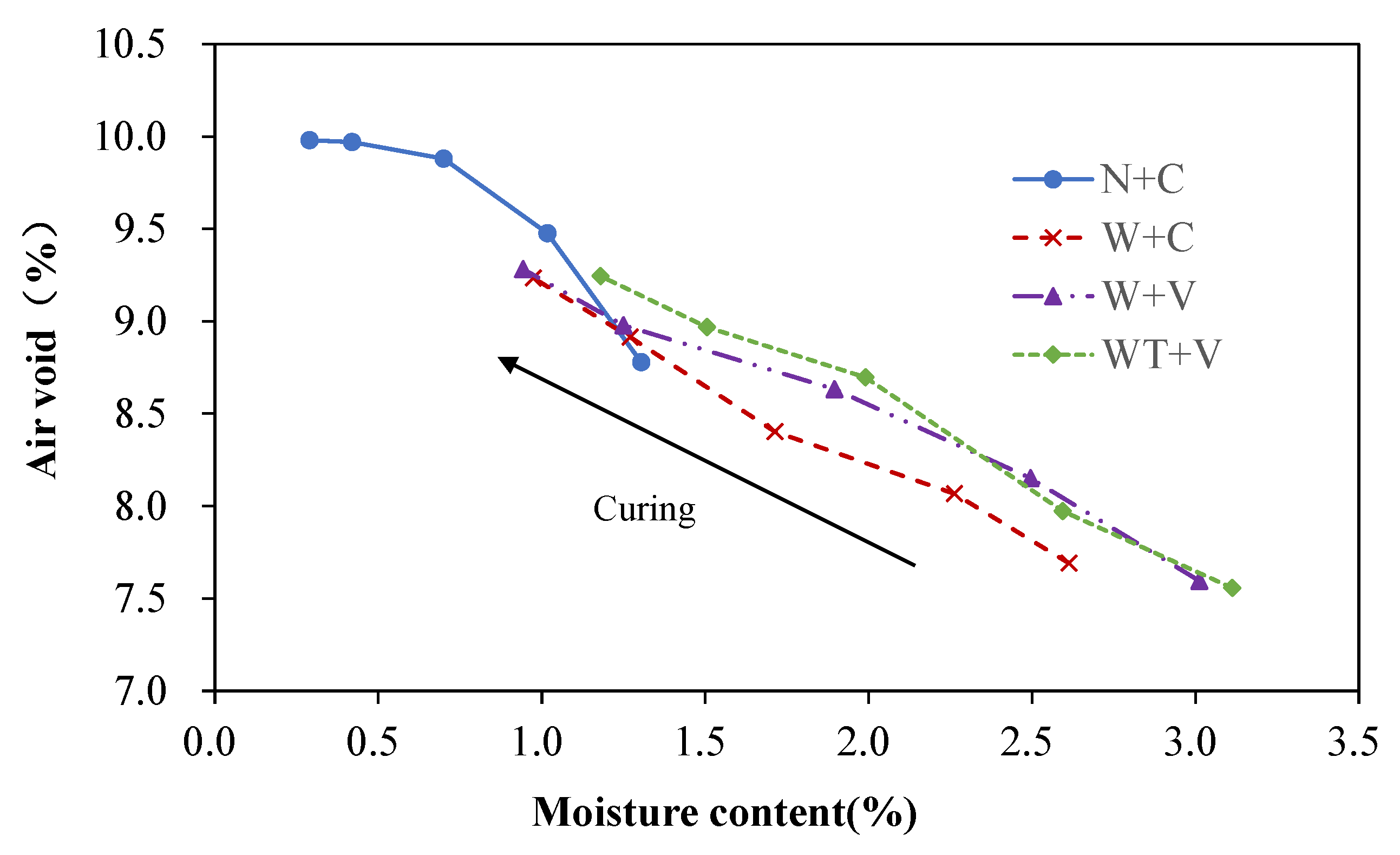

3.3. Analysis of the Changing Air Void Content

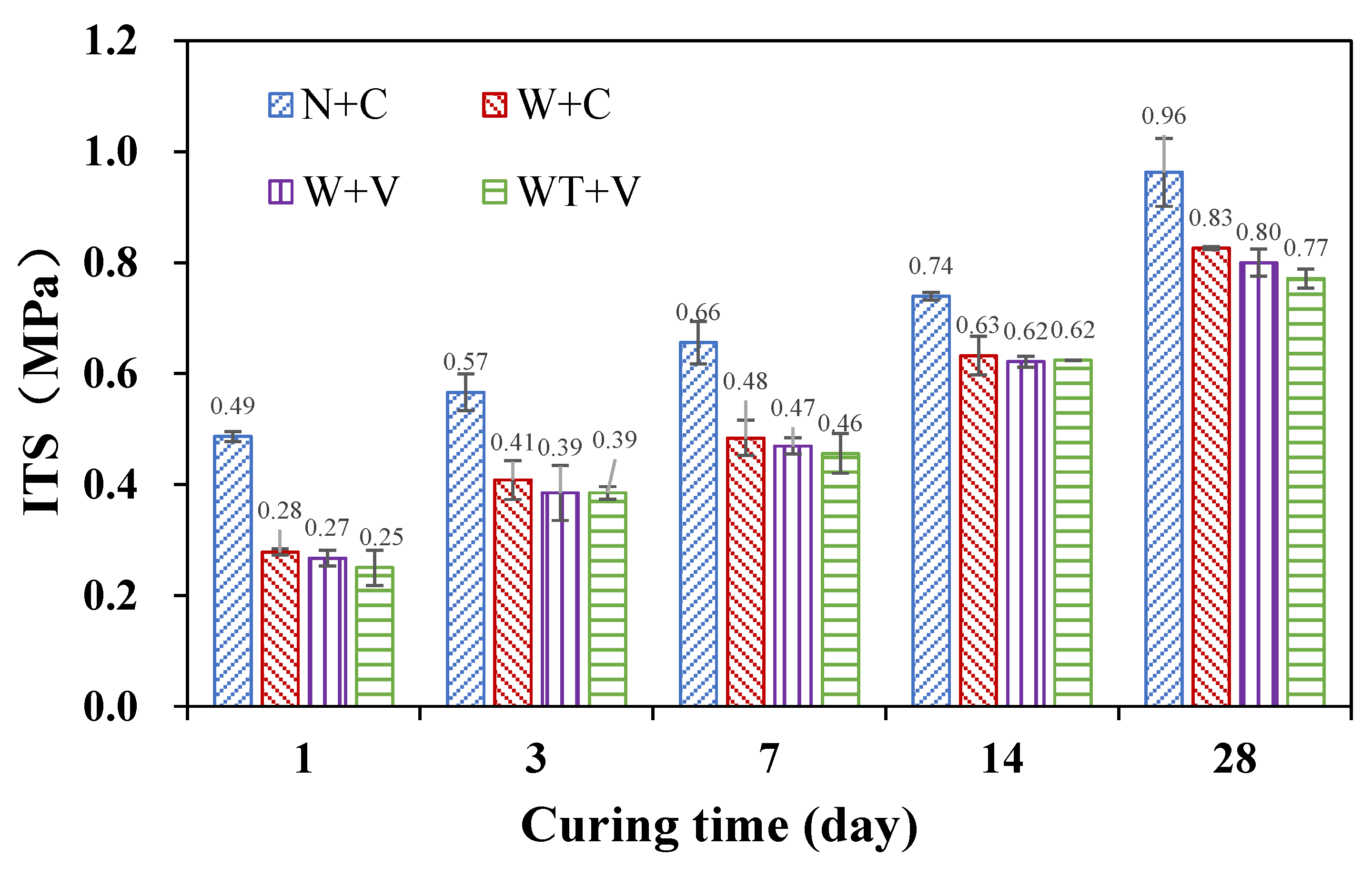

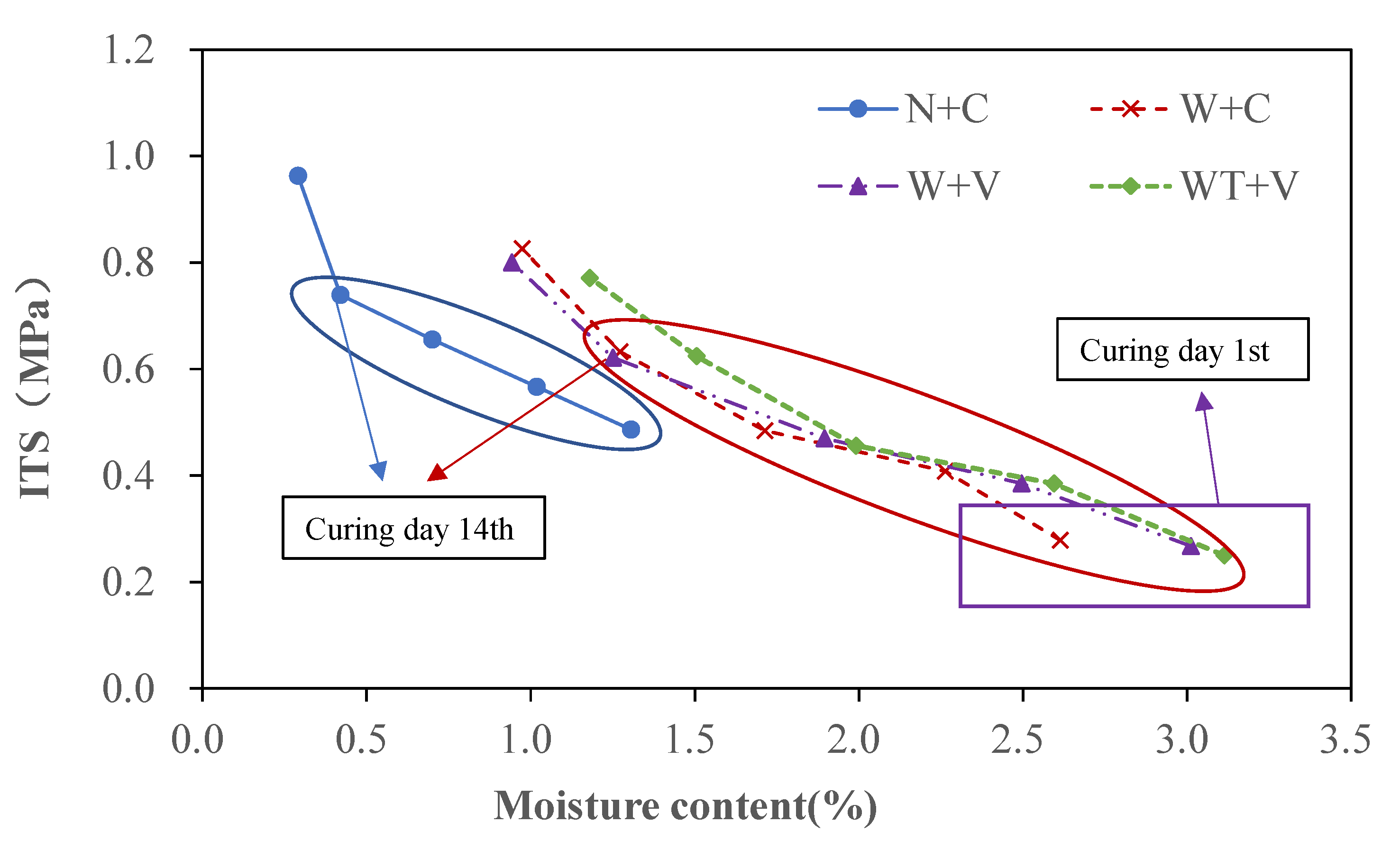

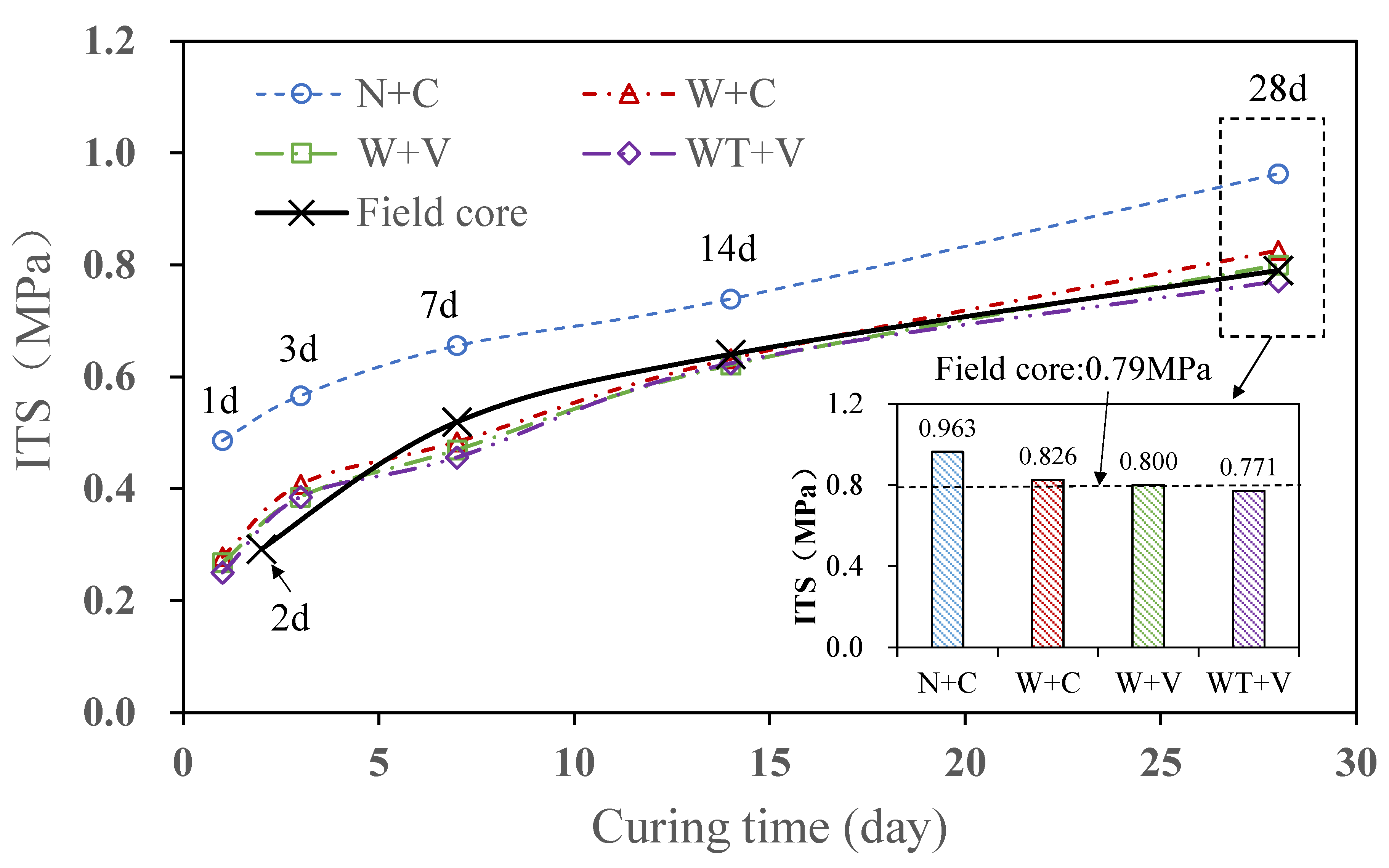

3.4. Analysis of the ITS

4. Mutual Influence of Indicators

4.1. Effect of Temperature Indexes on Moisture Content

4.2. Relationship between Moisture Content and Air Void

4.3. Effect of Moisture Content on ITS

5. Comparison with Field Cores

6. Findings and Conclusions

- (1)

- The performance development of the BE-CIR mixture cured in the method considering the field-water evaporation condition had significant differences from that with no treatment (N + C), which was manifested as higher moisture content, lower air void, and ITS under the same curing time. This indicates that the higher water content within the mix may inhibit the hydration of the cement and, thus, lead to a lower strength.

- (2)

- Comparing curing methods considering different heat-transfer conditions, the moisture content showed a rank of W + C < W + V < WT + V, and the ITS had similar regularity. The temperature energy (Gt-a) was better aligned with this ranking than the average temperature. In addition, the differences between the three methods were much smaller than the differences considering water evaporation.

- (3)

- The internal temperature of the mixture was the main factor affecting the variation in moisture content, especially on the first curing day. The air void of the mixture had a strong linear relationship with the moisture content. The relationship between water content and ITS can be divided into two stages. In the first stage, the ITS increased linearly with the decrease in moisture content, indicating that the water dispersion had a significant influence on the strength growth of the BE-CIR mixture. In the second stage, the moisture content decreased slightly and ITS increased rapidly, implying that the free water basically evaporated, and the development of strength was mainly caused by the continuous hydration of cement.

- (4)

- Compared with the results of field cores, N + C had the largest difference in both moisture content and ITS due to the quick water loss rate. The waterproofing and variable temperature mode can better simulate the in situ environmental conditions and delay the water-loss rate of the specimen to a reasonable value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, F.; Ma, W.Y.; West, R.C.; Taylor, A.J.; Zhang, Y.Q. Structural performance and sustainability assessment of cold central-plant and in-place recycled asphalt pavements: A case study. J. Clean. Prod. 2019, 208, 1513–1523. [Google Scholar] [CrossRef] [Green Version]

- Modarres, A.; Rahimzadeh, M.; Zarrabi, M. Field investigation of pavement rehabilitation utilizing cold in-place recycling. Resour. Conserv. Recycl. 2014, 83, 112–120. [Google Scholar] [CrossRef]

- Hussein, Z.; Yaacob, H.; Idham, M.; Abdulrahman, S.; Choy, L.; Jaya, R. Rejuvenation of hot mix asphalt incorporating high RAP content: Issues to consider. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; p. 012009. [Google Scholar]

- Turk, J.; Pranjic, A.M.; Mladenovic, A.; Cotic, Z.; Jurjavcic, P. Environmental comparison of two alternative road pavement rehabilitation techniques: Cold-in-place-recycling versus traditional reconstruction. J. Clean. Prod. 2016, 121, 45–55. [Google Scholar] [CrossRef]

- Alkins, A.E.; Lane, B.; Kazmierowski, T.; Environmental, S.P. Economic, and Social Benefits of In Situ Pavement Recycling. Transp. Res. Rec. 2008, 2084, 100–103. [Google Scholar] [CrossRef] [Green Version]

- Xiao, F.; Yao, S.; Wang, J.; Li, X.; Amirkhanian, S. A literature review on cold recycling technology of asphalt pavement. Constr. Build. Mater. 2018, 180, 579–604. [Google Scholar] [CrossRef]

- Wang, Z.C.; Wang, Q.; Jia, C.X.; Bai, J.R. Thermal evolution of chemical structure and mechanism of oil sands bitumen. Energy 2022, 244, 123190. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Katman, H.Y.; Satar, M.K.I.M.; Bilema, M.; Jaya, R.P.; Eltwati, A.S.; Radeef, H.R.J.S. A review on the durability of recycled asphalt mixtures embraced with rejuvenators. Sustainability 2021, 13, 8970. [Google Scholar] [CrossRef]

- Mohammad, L.N.; Abu-Farsakh, M.Y.; Wu, Z.; Abadie, C. Louisiana experience with foamed recycled asphalt pavement base materials. Transp. Res. Rec. 2003, 1832, 17–24. [Google Scholar] [CrossRef]

- Kuna, K.; Airey, G.; Thom, N. Mix design considerations of foamed bitumen mixtures with reclaimed asphalt pavement material. Int. J. Pavement Eng. 2017, 18, 902–915. [Google Scholar] [CrossRef]

- Konitufe, C.; Abubakar, A.; Baba, A.S.J.C. Influence of Aggregate Size and Shape on the Compressive Strength of Concrete. Construction 2023, 3, 15–22. [Google Scholar] [CrossRef]

- Flores, G.; Gallego, J.; Miranda, L.; Marcobal, J.R. Cold asphalt mix with emulsion and 100% rap: Compaction energy and influence of emulsion and cement content. Constr. Build. Mater. 2020, 250, 118804. [Google Scholar] [CrossRef]

- Deb, P.; Singh, K.L. Mix design, durability and strength enhancement of cold mix asphalt: A state-of-the-art review. Innov. Infrastruct. Solut. 2021, 7, 61. [Google Scholar] [CrossRef]

- Du, S.W. The Optimum Pre-mixing Water Content in Asphalt Emulsion Mixture with Cement. J. Test. Eval. 2021, 49, 4560–4575. [Google Scholar] [CrossRef]

- Lin, J.; Wei, T.; Hong, J.; Zhao, Y.; Liu, J. Research on development mechanism of early-stage strength for cold recycled asphalt mixture using emulsion asphalt. Constr. Build. Mater. 2015, 99, 137–142. [Google Scholar] [CrossRef]

- Golian, M.; Katibeh, H.; Singh, V.P.; Ostad-Ali-Askari, K.; Rostami, H.T. Prediction of tunnelling impact on flow rates of adjacent extraction water wells. Q. J. Eng. Geol. Hydrogeol. 2020, 53, 236–251. [Google Scholar] [CrossRef]

- Yang, Y.H.; Wang, H.B.; Yang, Y.; Zhang, H.Z. Evaluation of the evolution of the structure of cold recycled mixture subjected to wheel tracking using digital image processing. Constr. Build. Mater. 2021, 304, 124680. [Google Scholar] [CrossRef]

- Cardone, F.; Grilli, A.; Bocci, M.; Graziani, A. Curing and temperature sensitivity of cement-bitumen treated materials. Int. J. Pavement Eng. 2015, 16, 868–880. [Google Scholar] [CrossRef]

- Graziani, A.; Godenzoni, C.; Cardone, F.; Bocci, M. Effect of curing on the physical and mechanical properties of cold-recycled bituminous mixtures. Mater. Des. 2016, 95, 358–369. [Google Scholar] [CrossRef]

- Graziani, A.; Iafelice, C.; Raschia, S.; Perraton, D.; Carter, A. A procedure for characterizing the curing process of cold recycled bitumen emulsion mixtures. Constr. Build. Mater. 2018, 173, 754–762. [Google Scholar] [CrossRef]

- Fu, P.C.; Jones, D.; Harvey, J.T.; Halles, F.A. Investigation of the Curing Mechanism of Foamed Asphalt Mixes Based on Micromechanics Principles. J. Mater. Civ. Eng. 2010, 22, 29–38. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.; Im, S. Examination of Curing Criteria for Cold In-Place Recycling; Technical Report for Iowa Highway Research Board, University of Iowa: Iowa City, IA, USA, 2008. [Google Scholar]

- Pasetto, M.; Pasquini, E.; Baliello, A.; Raschia, S.; Rahmanbeiki, A.; Carter, A.; Perraton, D.; Preti, F.; Gouveia, B.C.S.; Tebaldi, G. Influence of curing on the mechanical properties of cement-bitumen treated materials using foamed bitumen: An interlaboratory test program. In Proceedings of the 9th International Conference on Maintenance and Rehabilitation of Pavements—Mairepav9, Zurich, Switzerland, 1–3 July 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 55–65. [Google Scholar]

- Kim, Y.; Im, S.; Lee, H.D. Impacts of curing time and moisture content on engineering properties of cold in-place recycling mixtures using foamed or emulsified asphalt. J. Mater. Civ. Eng. 2011, 23, 542–553. [Google Scholar] [CrossRef]

- Tebaldi, G.; Dave, E.V.; Marsac, P.; Muraya, P.; Hugener, M.; Pasetto, M.; Graziani, A.; Grilli, A.; Bocci, M.; Marradi, A.J.R.M.; et al. Synthesis of standards and procedures for specimen preparation and in-field evaluation of cold-recycled asphalt mixtures. J. Mater. Civ. Eng. 2014, 15, 272–299. [Google Scholar] [CrossRef]

- Kuna, K.; Airey, G.; Thom, N.J.C.; Materials, B. Development of a tool to assess in-situ curing of Foamed Bitumen Mixtures. Constr. Build. Mater. 2016, 124, 55–68. [Google Scholar] [CrossRef]

- Yang, W.; Ouyang, J.; Meng, Y.; Han, B.; Sha, Y.J.C.; Materials, B. Effect of curing and compaction on volumetric and mechanical properties of cold-recycled mixture with asphalt emulsion under different cement contents. Constr. Build. Mater. 2021, 297, 123699. [Google Scholar] [CrossRef]

- Ma, X.Y.; Dong, Z.J.; Quan, W.W.; Dong, Y.K.; Tan, Y.Q. Real-time assessment of asphalt pavement moduli and traffic loads using monitoring data from Built-in Sensors: Optimal sensor placement and identification algorithm. Mech. Syst. Signal Process. 2023, 187, 109930. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Jiang, S.C. A Laboratory and Field Universal Estimation Method for Tire-Pavement Interaction Noise (TPIN) Based on 3D Image Technology. Sustainability 2022, 14, 12066. [Google Scholar] [CrossRef]

- Zhao, Z.L.; Jiang, J.W.; Chen, Z.W.; Ni, F.J. Moisture migration of bitumen emulsion-based cold in-place recycling pavement after compaction: Real-time field measurement and laboratory investigation. J. Clean. Prod. 2022, 360, 132213. [Google Scholar] [CrossRef]

- DOT, J.P. Applied Manual for Asphalt Emulsion Cold In-Place Recycling Technology; Department of Transport of Jiangsu province: Nanjing, China, 2010. (In Chinese) [Google Scholar]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011. (In Chinese)

- JTG/T 5521-2019; Technical Specifications for Highway Asphalt Pavement Recycling. Ministry of Transport of the People’s Republic of China: Beijing, China, 2019. (In Chinese)

- AASHTO T 269; Standard Method of Test for Percent Air Voids in Compacted Dense and Open Asphalt Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

| Characteristics of the Emulsified Bitumen | Result |

|---|---|

| Residual content (%) | 64 |

| Penetration (25 °C; 0.1 mm) | 59.1 |

| Softening point (°C) | 59.9 |

| Ductility (15 °C; cm) | 110 |

| Sieve residue (1.18 mm; %) | 0.03 |

| Storage stability (5 d, 25 °C; %) | 1.47 |

| Storage stability (1 d, 25 °C; %) | 0.42 |

| Properties of Mixture Design | Results |

|---|---|

| Optimal emulsified bitumen content (%) | 3.3 |

| Cement content (%) | 2.2 |

| Optimal moisture content (%) | 4.01 |

| Bulk density (g/cm3) | 2.184 |

| Target air voids (%) | 10.0 |

| Curing Method | Specimen-Preparation Method | Temperature-Control Mode |

|---|---|---|

| N + C | No Treatment | Constant 35 °C |

| W + C | Waterproofing | Constant 35 °C |

| W + V | Waterproofing | Variable 10 h (45 °C) + 14 h (25 °C) |

| WT + V | Waterproofing + Heat Insulation | Variable 10 h (45 °C) + 14 h (25 °C) |

| Property | W + C-Top | W + C-Bottom | W + V-Top | W + V-Bottom | WT + V-Top | WT + V-Bottom |

|---|---|---|---|---|---|---|

| High-temperature phase (0–10 h) | ||||||

| T-max (°C) | 34.9 | 34.5 | 44.7 | 44.6 | 43 | 41.3 |

| Heating time (h) | 2 | 2.1 | 2.5 | 3.3 | 7.9 | 8.5 |

| Gt-h (°C·h) | 348.07 | 343.28 | 442.88 | 436.95 | 405.44 | 377.50 |

| Low-temperature phase (11–24 h) | ||||||

| T-min (°C) | 34.9 | 34.5 | 24.9 | 24.8 | 24.4 | 24.1 |

| Cooling time (h) | - | - | 3.2 | 3.9 | 10.6 | 11 |

| Gt-l (°C·h) | 488.21 | 482.62 | 355.29 | 356.20 | 368.13 | 374.01 |

| Full cycle | ||||||

| T-a (°C) | 34.84 | 34.41 | 32.86 | 32.65 | 33.35 | 32.34 |

| Gt-a (°C·h) | 836.28 | 825.90 | 798.17 | 793.15 | 773.58 | 751.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Ni, F.; Zheng, J.; Cheng, Z.; Xie, S. Evaluation of Curing Effects on Bitumen Emulsion-Based Cold In-Place Recycling Mixture Considering Field-Water Evaporation and Heat-Transfer Conditions. Coatings 2023, 13, 1204. https://doi.org/10.3390/coatings13071204

Zhao Z, Ni F, Zheng J, Cheng Z, Xie S. Evaluation of Curing Effects on Bitumen Emulsion-Based Cold In-Place Recycling Mixture Considering Field-Water Evaporation and Heat-Transfer Conditions. Coatings. 2023; 13(7):1204. https://doi.org/10.3390/coatings13071204

Chicago/Turabian StyleZhao, Zili, Fujian Ni, Junqiu Zheng, Zhiqiang Cheng, and Shengjia Xie. 2023. "Evaluation of Curing Effects on Bitumen Emulsion-Based Cold In-Place Recycling Mixture Considering Field-Water Evaporation and Heat-Transfer Conditions" Coatings 13, no. 7: 1204. https://doi.org/10.3390/coatings13071204

APA StyleZhao, Z., Ni, F., Zheng, J., Cheng, Z., & Xie, S. (2023). Evaluation of Curing Effects on Bitumen Emulsion-Based Cold In-Place Recycling Mixture Considering Field-Water Evaporation and Heat-Transfer Conditions. Coatings, 13(7), 1204. https://doi.org/10.3390/coatings13071204