Investigation of the Influence of the Oxygen Flow Rate on the Mechanical, Structural and Operational Properties of 86WC-10Co-4Cr Coatings, as Determined Using the High-Velocity Oxyfuel Spraying Method

Abstract

1. Introduction

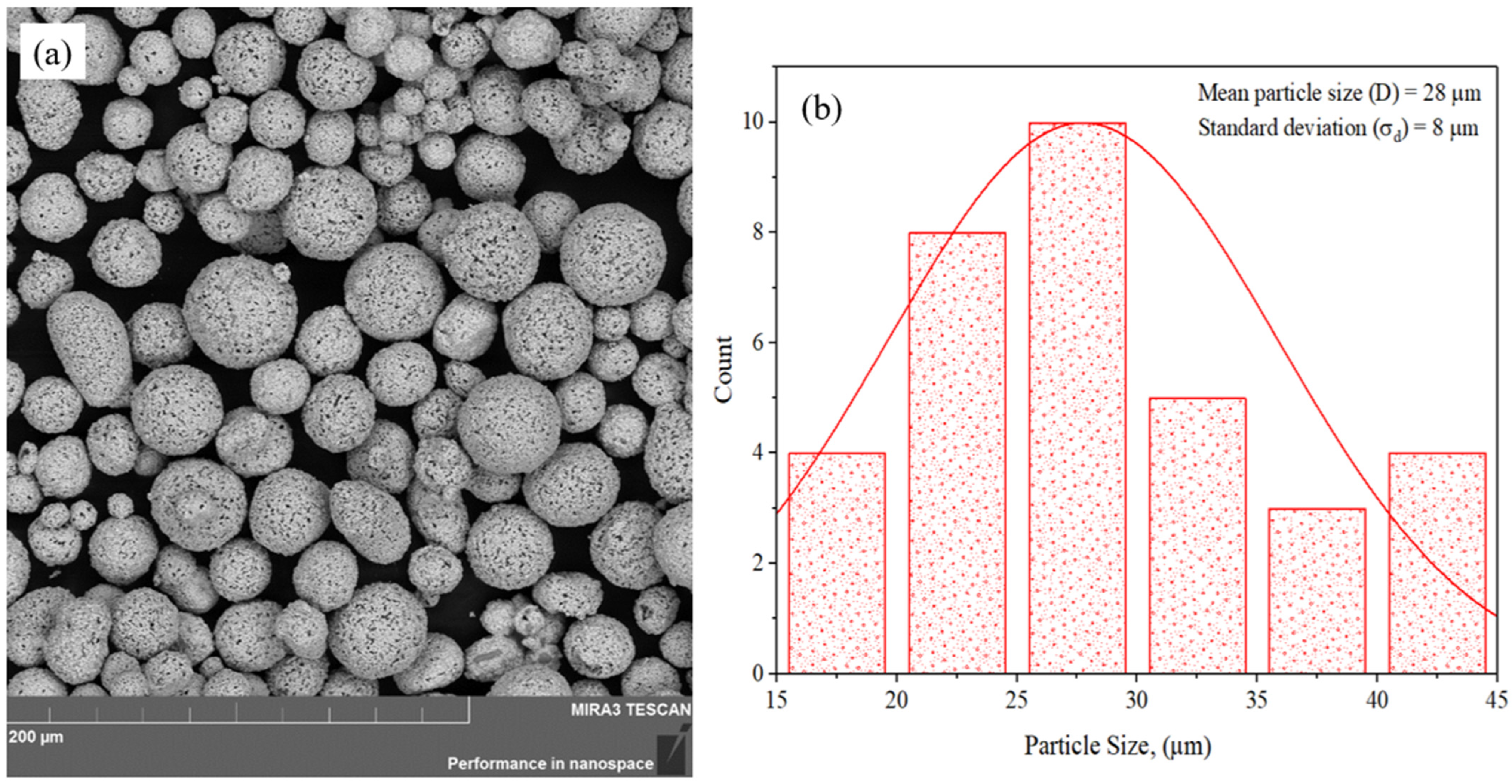

2. Materials and Methods

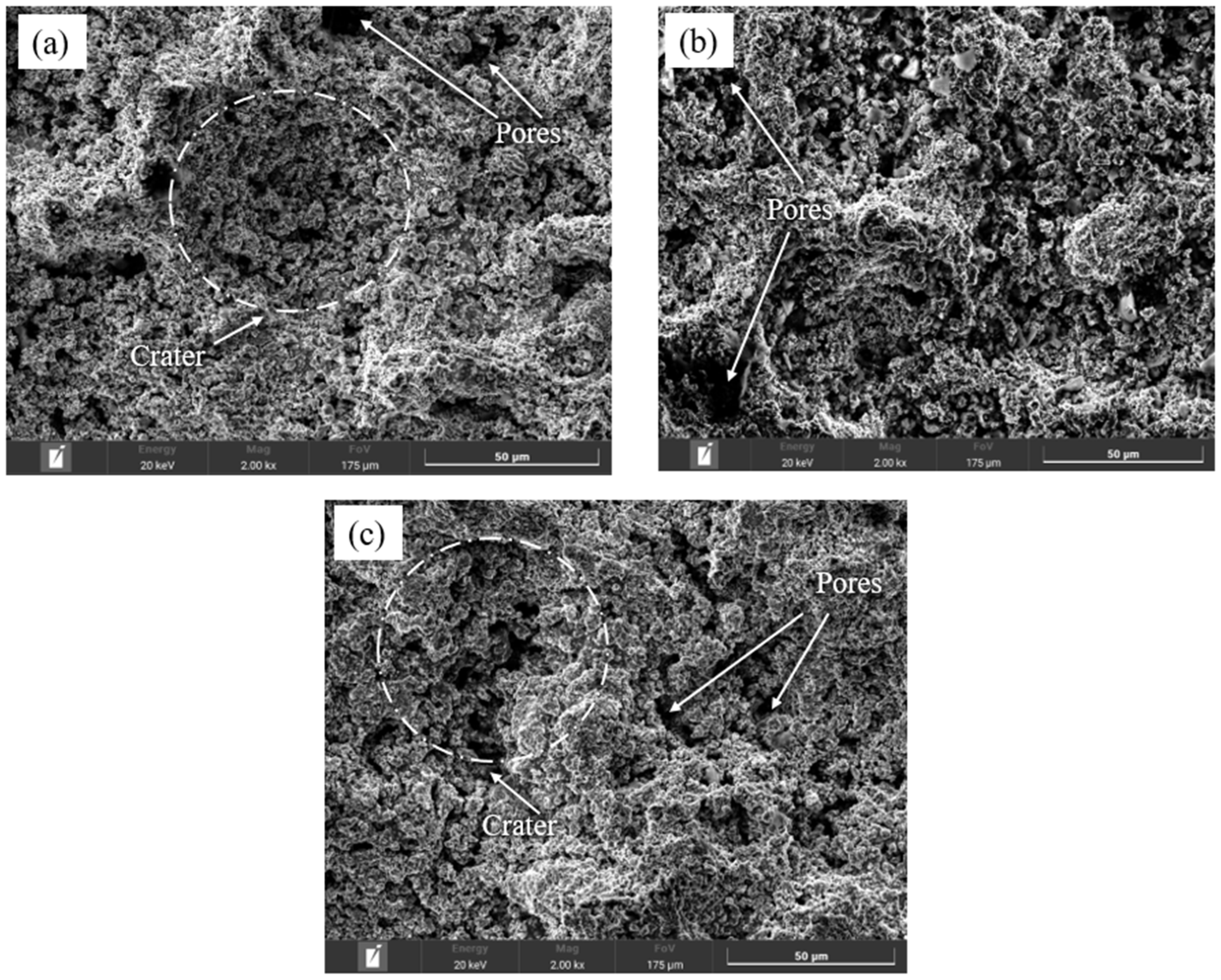

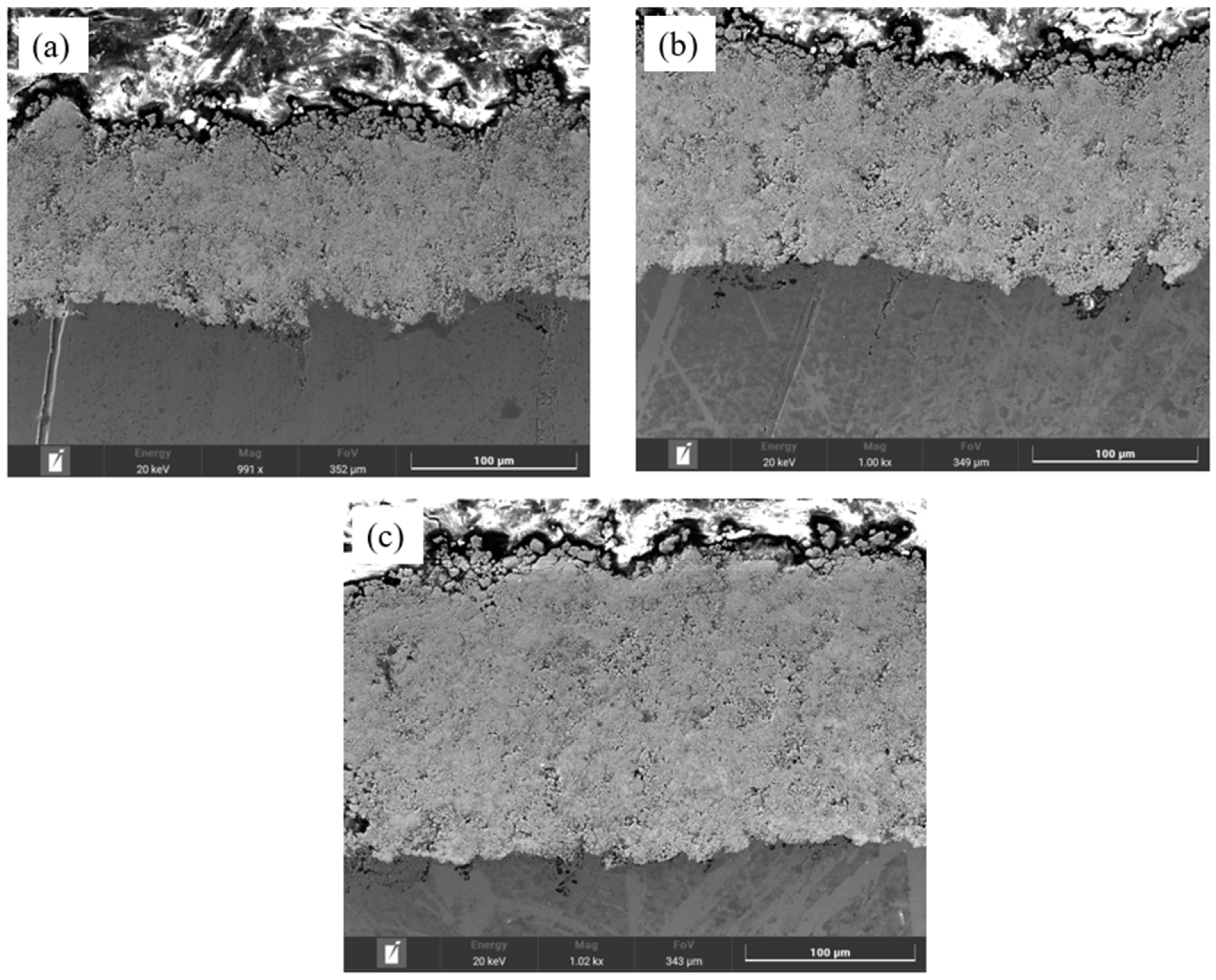

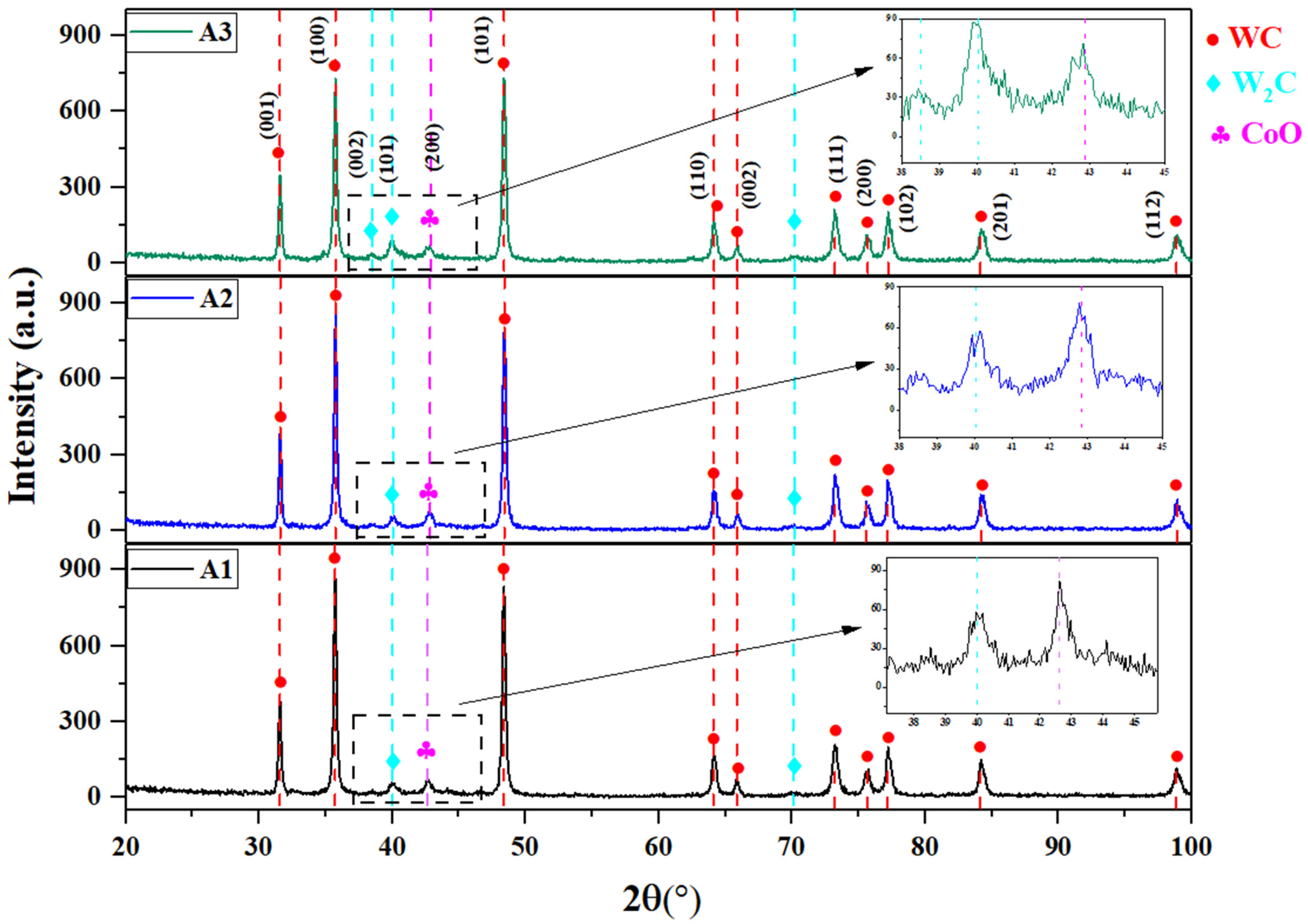

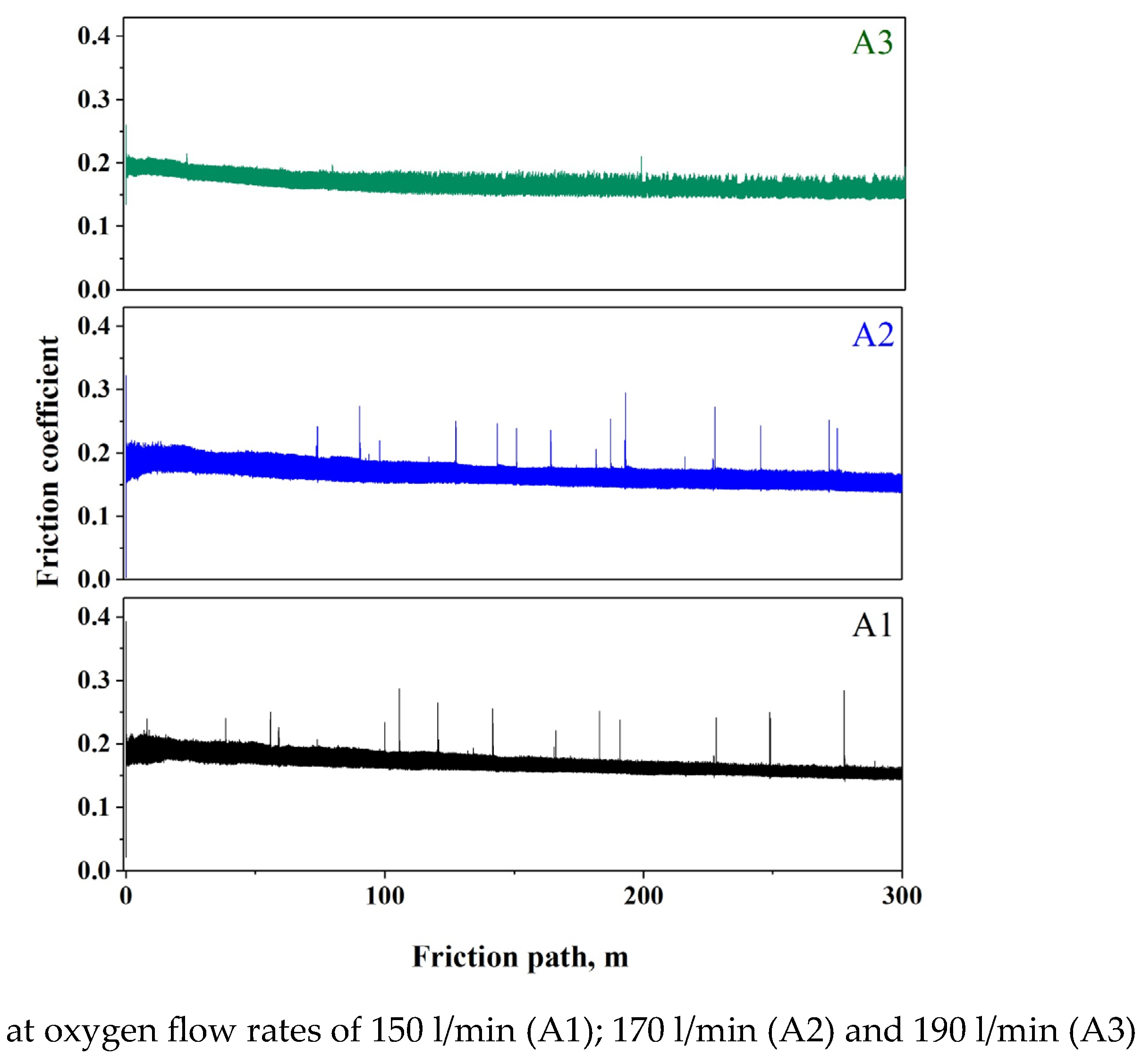

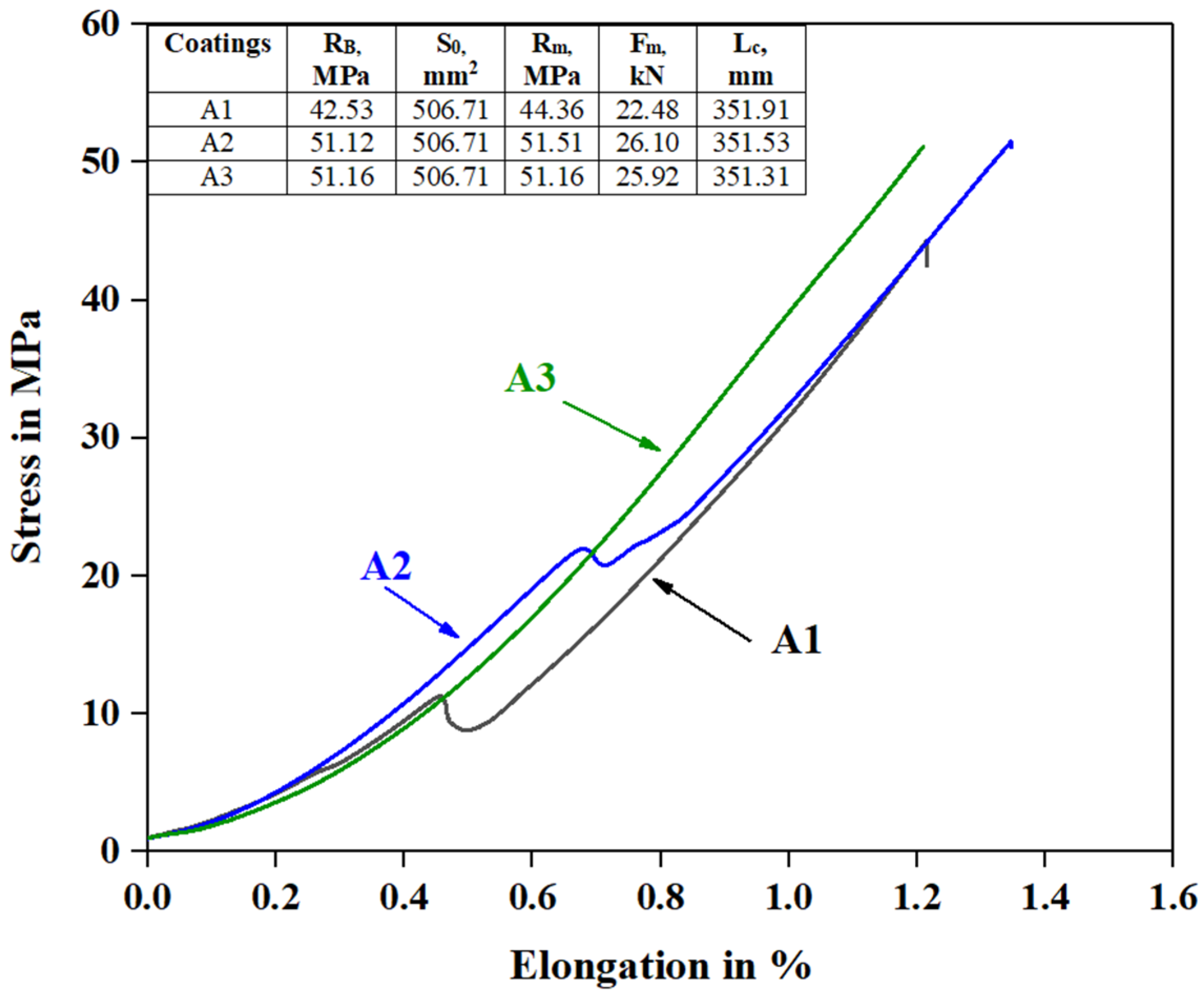

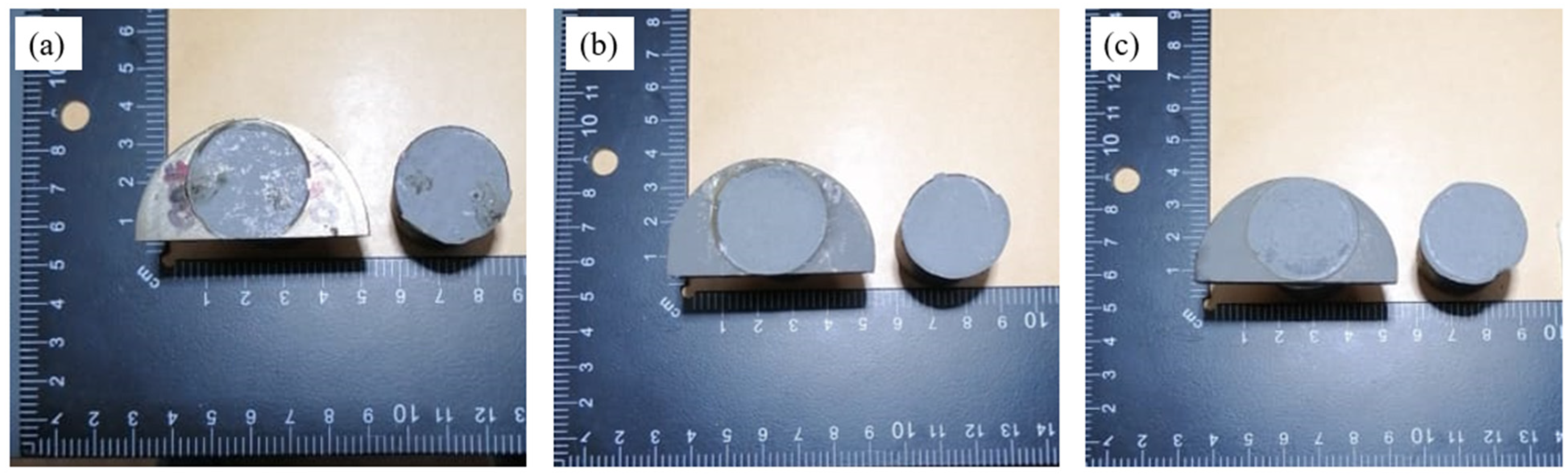

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Efimova, A.; Panchenko, E.; Lopa, I. Longitudinal stability of retractable spindles of pipeline gates taking into account the supporting influence of the gland. Izv. Tula State Univ. Tech. Sci. 2012, 2, 312–318. (In Russian) [Google Scholar]

- Rakhadilov, B.; Muktanova, N.; Kakimzhanov, D.; Satbayeva, Z.; Kassenova, L.; Magazov, N. Investigation of the Influence of Powder Fraction on Tribological and Corrosion Characteristics of 86WC-10Co-4Cr Coating Obtained by HVOF Method. Coatings 2024, 14, 651. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Muktanova, N.; Kakimzhanov, D.; Adilkanova, M.; Kurbanbekov, S.; Abdulina, S. Influence of Varying the Spraying Distance on the Structural-Phase State and Mechanotribological Properties of 86WC-10Co-4Cr-Based Coatings Obtained by the HVOF Method. Coatings 2024, 14, 264. [Google Scholar] [CrossRef]

- Kengesbekov, A.; Rakhadilov, B.; Sagdoldina, Z.; Buitkenov, D.; Dosymov, Y.; Kylyshkanov, M. Improving the Efficiency of Air Plasma Spraying of Titanium Nitride Powder. Coatings 2022, 12, 1644. [Google Scholar] [CrossRef]

- Druzhnova, Y. Development of methods of gas-thermal spraying of hardening coatings based on tungsten and chromium carbides (review). Proc. VIAM 2022, 10, 100–115. (In Russian) [Google Scholar]

- Rakhadilov, B.; Buitkenov, D.; Sagdoldina, Z.; Idrisheva, Z.; Zhamanbayeva, M.; Kakimzhanov, D. Preparation and Characterization of NiCr/NiCr-Al2O3/Al2O3 Multilayer Gradient Coatings by Gas Detonation Spraying. Coatings 2021, 11, 1524. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Kakimzhanov, D.; Dautbekov, M.; Sagdoldina, Z.; Adylkanova, M.; Abylkalykova, R. Influence of Spraying Parameters on the Structure and Tribological Properties of Cr3C2-NiCr Detonation Coatings. Adv. Tribol. 2023, 2023, e6684656. [Google Scholar] [CrossRef]

- Abd Malek, M.; Saad, N.; Abas, S.; Shah, N. Thermal arc spray overview. IOP Conf. Ser. Mater. Sci. Eng. 2013, 46, 012028. [Google Scholar] [CrossRef]

- Skakov, M.; Ocheredko, I.; Tuyakbayev, B.; Bayandinova, M.; Nurizinova, M. Development and Studying of the Technology for Thermal Spraying of Coatings Made from Ultra-High-Molecular-Weight Polyethylene. Coatings 2023, 13, 698. [Google Scholar] [CrossRef]

- Qiao, L.; Wu, Y.; Hong, S.; Cheng, J.; Wei, Z. Influence of the High-Velocity Oxygen-Fuel Spray Parameters on the Porosity and Corrosion Resistance of Iron-Based Amorphous Coatings. Surf. Coat. Technol. 2019, 366, 296–302. [Google Scholar] [CrossRef]

- Picas, J.A.; Punset, M.; Baile, M.T.; Martín, E.; Forn, A. Effect of Oxygen/Fuel Ratio on the in-Flight Particle Parameters and Properties of HVOF WC-CoCr Coatings. Surf. Coat. Technol. 2011, 205, S364–S368. [Google Scholar] [CrossRef]

- Kumar, M.S.S.; Arulshri, K.P.; Thirumoorthy, C. HVOF Spray Parameter Optimization to Obtain Maximum Hardness and Minimum Porosity in WC-Co-Cr Coatings on AISI 304 Stainless Steel. Int. J. Appl. Eng. Res. 2015, 10, 38753–38765. [Google Scholar]

- Liu, J.; Chen, T.; Yuan, C.; Bai, X. Performance Analysis of Cavitation Erosion Resistance and Corrosion Behavior of HVOF-Sprayed WC-10Co-4Cr, WC-12Co, and Cr3C2-NiCr Coatings. J. Therm. Spray Technol. 2020, 29, 798–810. [Google Scholar] [CrossRef]

- Erne, M.; Kolar, D. Thermal Spraying of Oxide Ceramic and Ceramic Metallic Coatings. In Ceramic Coatings—Applications in Engineering; Shi, F., Ed.; InTech: London, UK, 2012; ISBN 978-953-51-0083-6. [Google Scholar]

- Dejun, K.; Tianyuan, S. Wear Behaviors of HVOF Sprayed WC-12Co Coatings by Laser Remelting under Lubricated Condition. Opt. Laser Technol. 2017, 89, 86–91. [Google Scholar] [CrossRef]

- Yifu, J.; Weicheng, K.; Tianyuan, S.; Ruihong, Z.; Dejun, K. Effect of Load on Friction-Wear Behavior of HVOF-Sprayed WC-12Co Coatings. J. Mater. Eng. Perform. 2017, 26, 3465–3473. [Google Scholar] [CrossRef]

- Ji, G.-C.; Li, C.-J.; Wang, Y.-Y.; Li, W.-Y. Microstructural Characterization and Abrasive Wear Performance of HVOF Sprayed Cr3C2–NiCr Coating. Surf. Coat. Technol. 2006, 200, 6749–6757. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Espallargas, N.; Suegama, P.H.; Benedetti, A.V. Comparative Study of Cr3C2–NiCr Coatings Obtained by HVOF and Hard Chromium Coatings. Corros. Sci. 2006, 48, 2998–3013. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, K.; Li, Y.; Deng, C.; Zeng, K. High Temperature Wear Performance of HVOF-Sprayed Cr3C2-WC-NiCoCrMo and Cr3C2-NiCr Hardmetal Coatings. Appl. Surf. Sci. 2017, 416, 33–44. [Google Scholar] [CrossRef]

- Murugan, K.; Ragupathy, A.; Balasubramanian, V.; Sridhar, K. Optimizing HVOF Spray Process Parameters to Attain Minimum Porosity and Maximum Hardness in WC–10Co–4Cr Coatings. Surf. Coat. Technol. 2014, 247, 90–102. [Google Scholar] [CrossRef]

- Kumar, R.K.; Kamaraj, M.; Seetharamu, S.; Pramod, T.; Sampathkumaran, P. Effect of Spray Particle Velocity on Cavitation Erosion Resistance Characteristics of HVOF and HVAF Processed 86WC-10Co4Cr Hydro Turbine Coatings. J. Therm. Spray Technol. 2016, 25, 1217–1230. [Google Scholar] [CrossRef]

- Caltaru, M.; Badicioiu, M.; Ripeanu, R.G. Establishing the Tribological Behaviour of HVOF Hardfacing Applied at Petroleum Gate Valves. J. Balk. Tribol. Assoc. 2013, 19, 448–460. [Google Scholar]

- Kumar, H.; Chittosiya, C.; Shukla, V.N. HVOF Sprayed WC Based Cermet Coating for Mitigation of Cavitation, Erosion & Abrasion in Hydro Turbine Blade. Mater. Today Proc. 2018, 5, 6413–6420. [Google Scholar] [CrossRef]

- Thakur, L.; Arora, N. Sliding and Abrasive Wear Behavior of WC-CoCr Coatings with Different Carbide Sizes. J. Mater. Eng. Perform. 2013, 22, 574–583. [Google Scholar] [CrossRef]

- Wheeler, D.W.; Wood, R.J.K. Erosion of Hard Surface Coatings for Use in Offshore Gate Valves. Wear 2005, 258, 526–536. [Google Scholar] [CrossRef]

- Tarragó, J.M.; Ferrari, C.; Reig, B.; Coureaux, D.; Schneider, L.; Llanes, L. Mechanics and Mechanisms of Fatigue in a WC–Ni Hardmetal and a Comparative Study with Respect to WC–Co Hardmetals. Int. J. Fatigue 2015, 70, 252–257. [Google Scholar] [CrossRef]

- Cho, J.E.; Hwang, S.Y.; Kim, K.Y. Corrosion Behavior of Thermal Sprayed WC Cermet Coatings Having Various Metallic Binders in Strong Acidic Environment. Surf. Coat. Technol. 2006, 200, 2653–2662. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Wang, X.; Ryu, T.; Hwang, K.S.; Sohn, H.Y. Synthesis, Sintering, and Mechanical Properties of Nanocrystalline Cemented Tungsten Carbide—A Review. Int. J. Refract. Met. Hard Mater. 2009, 27, 288–299. [Google Scholar] [CrossRef]

- Wood, R.J.K.; Herd, S.; Thakare, M.R. A Critical Review of the Tribocorrosion of Cemented and Thermal Sprayed Tungsten Carbide. Tribol. Int. 2018, 119, 491–509. [Google Scholar] [CrossRef]

- Asl, S.K.; Beyragh, M.R.S.; Noori, N.F. Study of Corrosion Behavior of Conventional and Nanostructured WC-Ni High Velocity Oxy Fuel (HVOF) Sprayed Coatings. Mater. Sci. Forum 2011, 673, 167–172. [Google Scholar] [CrossRef]

- Karimi, A.; Verdon, C.; Barbezat, G. Microstructure and Hydroabrasive Wear Behaviour of High Velocity Oxy-Fuel Thermally Sprayed WC-Co(Cr) Coatings. Surf. Coat. Technol. 1993, 57, 81–89. [Google Scholar] [CrossRef]

- Govande, A.R.; Chandak, A.; Sunil, B.R.; Dumpala, R. Carbide-Based Thermal Spray Coatings: A Review on Performance Characteristics and Post-Treatment. Int. J. Refract. Met. Hard Mater. 2022, 103, 105772. [Google Scholar] [CrossRef]

- Balki, M.K.; Sayin, C.; Sarıkaya, M. Optimization of the Operating Parameters Based on Taguchi Method in an SI Engine Used Pure Gasoline, Ethanol and Methanol. Fuel 2016, 180, 630–637. [Google Scholar] [CrossRef]

- Vignesh, S.; Shanmugam, K.; Balasubramanian, V.; Sridhar, K. Identifying the Optimal HVOF Spray Parameters to Attain Minimum Porosity and Maximum Hardness in Iron Based Amorphous Metallic Coatings. Def. Technol. 2017, 13, 101–110. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, S.L.; Zheng, Y.G.; Ke, W.; Sun, W.H.; Chang, X.C.; Hou, W.L.; Wang, J.Q. Effect of processing parameters on the microstructures and corrosion behaviour of high-velocity oxy-fuel (HVOF) sprayed Fe-based amorphous metallic coatings. Mater. Corros. 2013, 64, 801–810. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, Y.; Hou, G.; An, Y.; Liu, G. The Effect of High-Velocity Oxy-Fuel Spraying Parameters on Microstructure, Corrosion and Wear Resistance of Fe-Based Metallic Glass Coatings. J. Non-Cryst. Solids 2014, 406, 37–44. [Google Scholar] [CrossRef]

- Kumari, S.; Satyanarayana, D.V.V.; Srinivas, M. Failure Analysis of Gas Turbine Rotor Blades. Eng. Fail. Anal. 2014, 45, 234–244. [Google Scholar] [CrossRef]

- Huang, Y.; Ding, X.; Yuan, C.-Q.; Yu, Z.-K.; Ding, Z.-X. Slurry Erosion Behaviour and Mechanism of HVOF Sprayed Micro-Nano Structured WC-CoCr Coatings in NaCl Medium. Tribol. Int. 2020, 148, 106315. [Google Scholar] [CrossRef]

- Li, C.; Gao, X.; Zhang, D.; Gao, H.; Han, X.; Zhang, B. Numerical investigation on the flame characteristics and particle behaviors in a HVOF spray process using kerosene as fuel. J. Therm. Spray Technol. 2021, 30, 725–738. [Google Scholar] [CrossRef]

- Zois, D.; Lekatou, A.; Vardavoulias, M.; Vaimakis, T.; Karantzalis, A.E. Partially Amorphous Stainless Steel Coatings: Microstructure, Annealing Behavior and Statistical Optimization of Spray Parameters. Surf. Coat. Technol. 2011, 206, 1469–1483. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.; Wang, B.; Zheng, Y.; Gao, W.; Li, G. High-Velocity Oxygen-Fuel Spray Parameter Optimization of Nanostructured WC–10Co–4Cr Coatings and Sliding Wear Behavior of the Optimized Coating. Mater. Des. 2014, 55, 286–291. [Google Scholar] [CrossRef]

- Li, M.; Christofides, P.D. Modeling and Analysis of HVOF Thermal Spray Process Accounting for Powder Size Distribution. Chem. Eng. Sci. 2003, 58, 849–857. [Google Scholar] [CrossRef]

- Ghasemi, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. Comparison of Microstructure and Mechanical Properties of Plasma-Sprayed Nanostructured and Conventional Yttria Stabilized Zirconia Thermal Barrier Coatings. Ceram. Int. 2013, 39, 8805–8813. [Google Scholar] [CrossRef]

- Schweda, M.; Beck, T.; Offermann, M.; Singheiser, L. Thermographic Analysis and Modelling of the Delamination Crack Growth in a Thermal Barrier Coating on Fecralloy Substrate. Surf. Coat. Technol. 2013, 217, 124–128. [Google Scholar] [CrossRef][Green Version]

- Ghasemi, R.; Vakilifard, H. Plasma-Sprayed Nanostructured YSZ Thermal Barrier Coatings: Thermal Insulation Capability and Adhesion Strength. Ceram. Int. 2017, 43, 8556–8563. [Google Scholar] [CrossRef]

- Ly, S.; Rubenchik, A.M.; Khairallah, S.A.; Guss, G.; Matthews, M.J. Metal Vapor Micro-Jet Controls Material Redistribution in Laser Powder Bed Fusion Additive Manufacturing. Sci. Rep. 2017, 7, 4085. [Google Scholar] [CrossRef]

- Zhang, P.; Bi, Z.; Yu, H.; Wang, R.; Sun, G.; Zhang, S. Effect of Particle Surface Roughness on the Flowability and Spreadability of Haynes 230 Powder during Laser Powder Bed Fusion Process. J. Mater. Res. Technol. 2023, 26, 4444–4454. [Google Scholar] [CrossRef]

- Wesmann, J.; Kuroda, S.; Espallargas, N. The role of oxide tribofilms on friction and wear of different thermally sprayed WC-CoCr. J. Therm. Spray Technol. 2017, 26, 492–502. [Google Scholar] [CrossRef]

- Magnani, M.; Suegama, P.; Recco, A.; Guilemany, J.; Fugivara, C.; Benedetti, A. WC-CoCr coatings sprayed by high velocity oxygen-fuel (HVOF) flame on AA7050 aluminum alloy: Electrochemical behavior in 3.5% NaCl solution. Mater. Res. 2007, 10, 377–385. [Google Scholar] [CrossRef]

- Kuznetsova, G. Qualitative X-ray Phase Analysis. Course of Lectures. 2005. Available online: https://portal.tpu.ru/SHARED/l/LOGVINENKOOV/subj/Tab/Tab/01_kachestven_rentgenophazn_analys.pdf (accessed on 11 September 2024). (In Russian).

| Coatings Code Example | 86WC-10Co-4Cr (A1) | 86WC-10Co-4Cr (A2) | 86WC-10Co-4Cr (A3) | |

|---|---|---|---|---|

| Application Process Parameters | ||||

| Propane flow rate, L/min | 35 | |||

| Oxygen flow rate, L/min | 150 | 170 | 190 | |

| Spraying distance, mm | 300 | |||

| Powder feed rate, g/min | 100 | |||

| Propane pressure | 0.39 MPa | |||

| Oxygen pressure | 0.88 MPa | |||

| Nitrogen pressure | 0.5 MPa | |||

| Sample | Detected Phases | Phase Content, wt% | Lattice Parameters, (Å) | CSR Size, nm | Δd/d × 10−3 |

|---|---|---|---|---|---|

| A1 coating | WC | 53 | a = 2.9005 c = 2.8330 | 35 | 0.61 |

| W2C | 4 | a = 2.9614 c = 4.6884 | 15 | 2.364 | |

| CoO | 43 | a = 4.2507 | 10 | 3.504 | |

| A2 coating | WC | 50 | a = 2.9011 c = 2.8328 | 38 | 0.482 |

| W2C | 4 | a = 2.9554 c = 4.6641 | 27 | 7.302 | |

| CoO | 46 | a = 4.2451 | 13 | 6.518 | |

| A3 coating | WC | 53 | a = 2.9027 c = 2.8345 | 30 | 1.02 |

| W2C | 7 | a = 2.9624 c = 4.6924 | 13 | 0.894 | |

| CoO | 40 | a = 4.2506 | 10 | 1.682 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakhadilov, B.; Muktanova, N.; Seitkhanova, A.; Kakimzhanov, D.; Dautbekov, M. Investigation of the Influence of the Oxygen Flow Rate on the Mechanical, Structural and Operational Properties of 86WC-10Co-4Cr Coatings, as Determined Using the High-Velocity Oxyfuel Spraying Method. Coatings 2024, 14, 1275. https://doi.org/10.3390/coatings14101275

Rakhadilov B, Muktanova N, Seitkhanova A, Kakimzhanov D, Dautbekov M. Investigation of the Influence of the Oxygen Flow Rate on the Mechanical, Structural and Operational Properties of 86WC-10Co-4Cr Coatings, as Determined Using the High-Velocity Oxyfuel Spraying Method. Coatings. 2024; 14(10):1275. https://doi.org/10.3390/coatings14101275

Chicago/Turabian StyleRakhadilov, Bauyrzhan, Nazerke Muktanova, Ainur Seitkhanova, Dauir Kakimzhanov, and Merkhat Dautbekov. 2024. "Investigation of the Influence of the Oxygen Flow Rate on the Mechanical, Structural and Operational Properties of 86WC-10Co-4Cr Coatings, as Determined Using the High-Velocity Oxyfuel Spraying Method" Coatings 14, no. 10: 1275. https://doi.org/10.3390/coatings14101275

APA StyleRakhadilov, B., Muktanova, N., Seitkhanova, A., Kakimzhanov, D., & Dautbekov, M. (2024). Investigation of the Influence of the Oxygen Flow Rate on the Mechanical, Structural and Operational Properties of 86WC-10Co-4Cr Coatings, as Determined Using the High-Velocity Oxyfuel Spraying Method. Coatings, 14(10), 1275. https://doi.org/10.3390/coatings14101275