Fatigue-Healing Performance Analysis of Warm-Mix Rubber Asphalt Mastic Using the Simplified Viscoelastic Continuum Damage Theory

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. Modified Asphalt

2.2.2. Asphalt Mastic

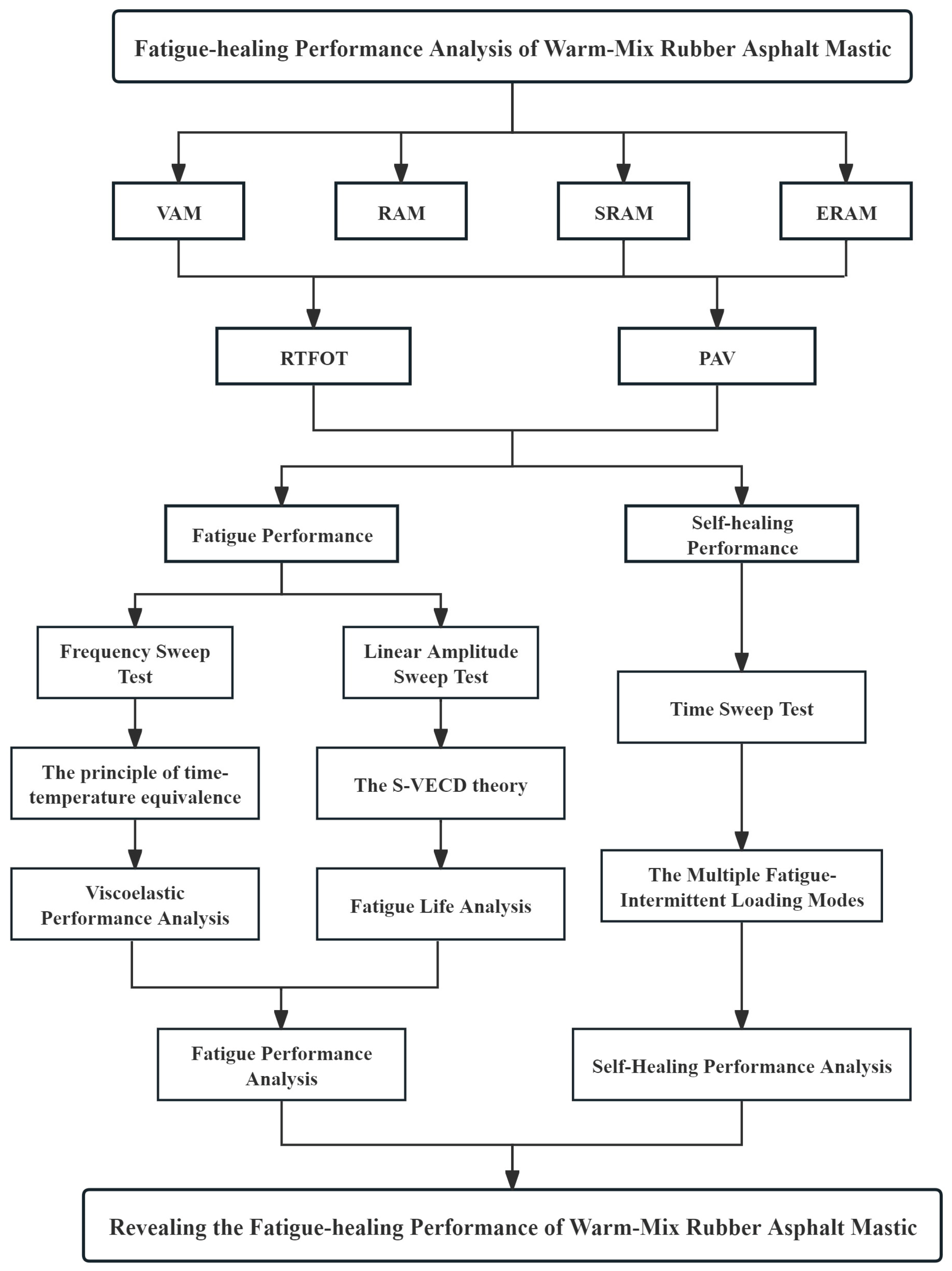

2.3. Methods

2.3.1. Aging Test

2.3.2. Frequency Sweep Test

2.3.3. Linear Amplitude Sweep Test

2.3.4. Time Sweep Test

3. Results and Analysis

3.1. Results and Analysis of Fatigue Performance Tests

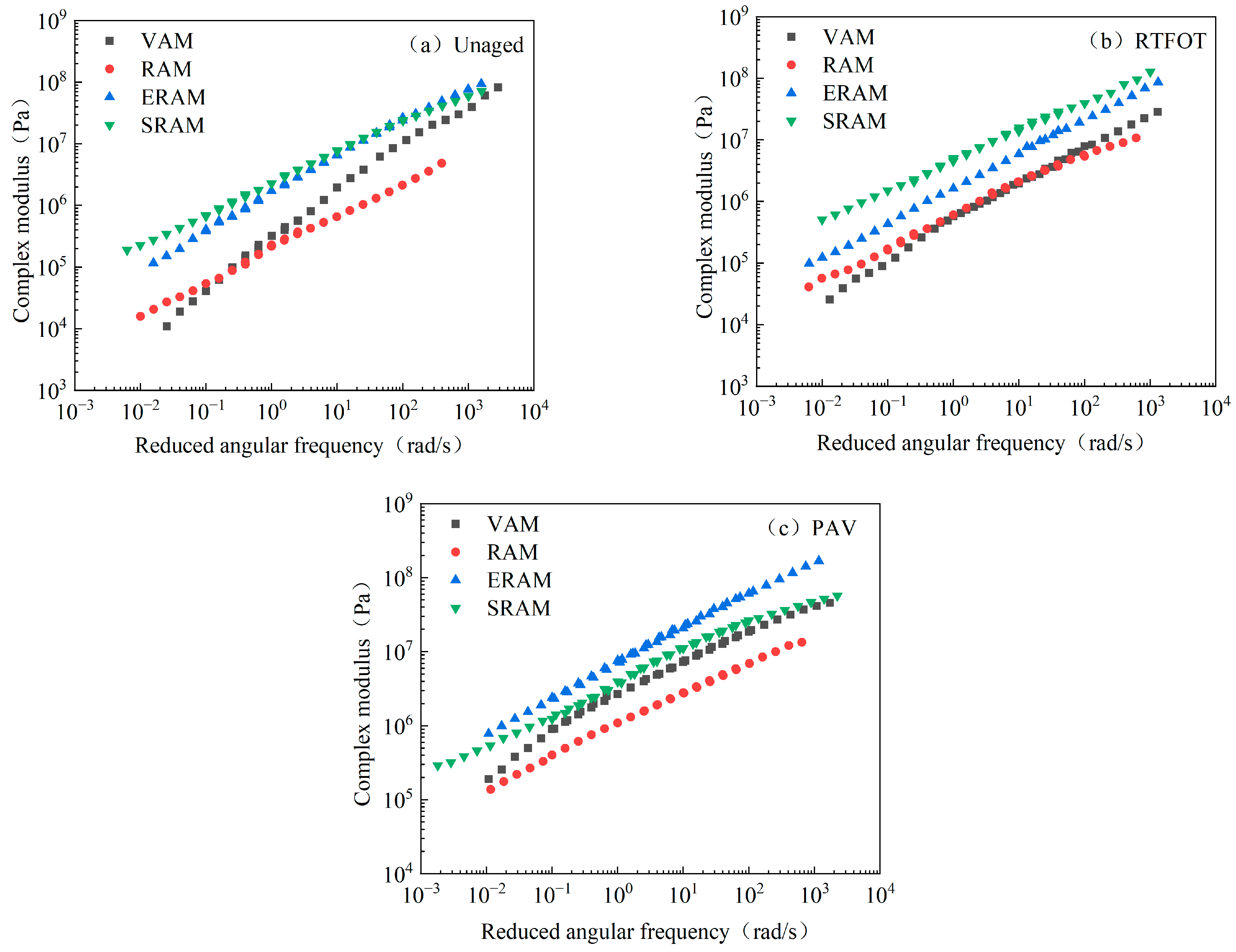

3.1.1. Dynamic Modulus Master Curve

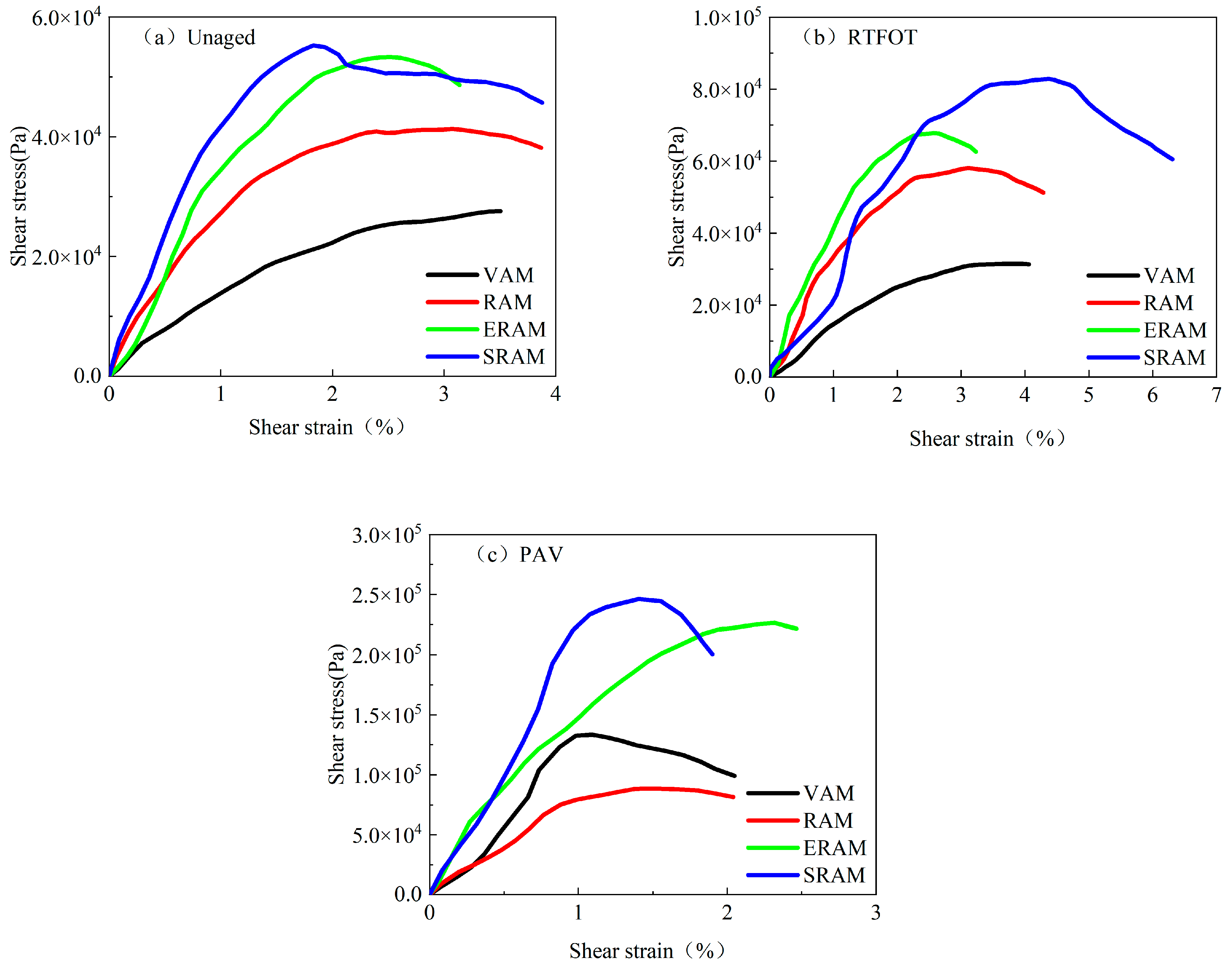

3.1.2. Stress–Strain Curves

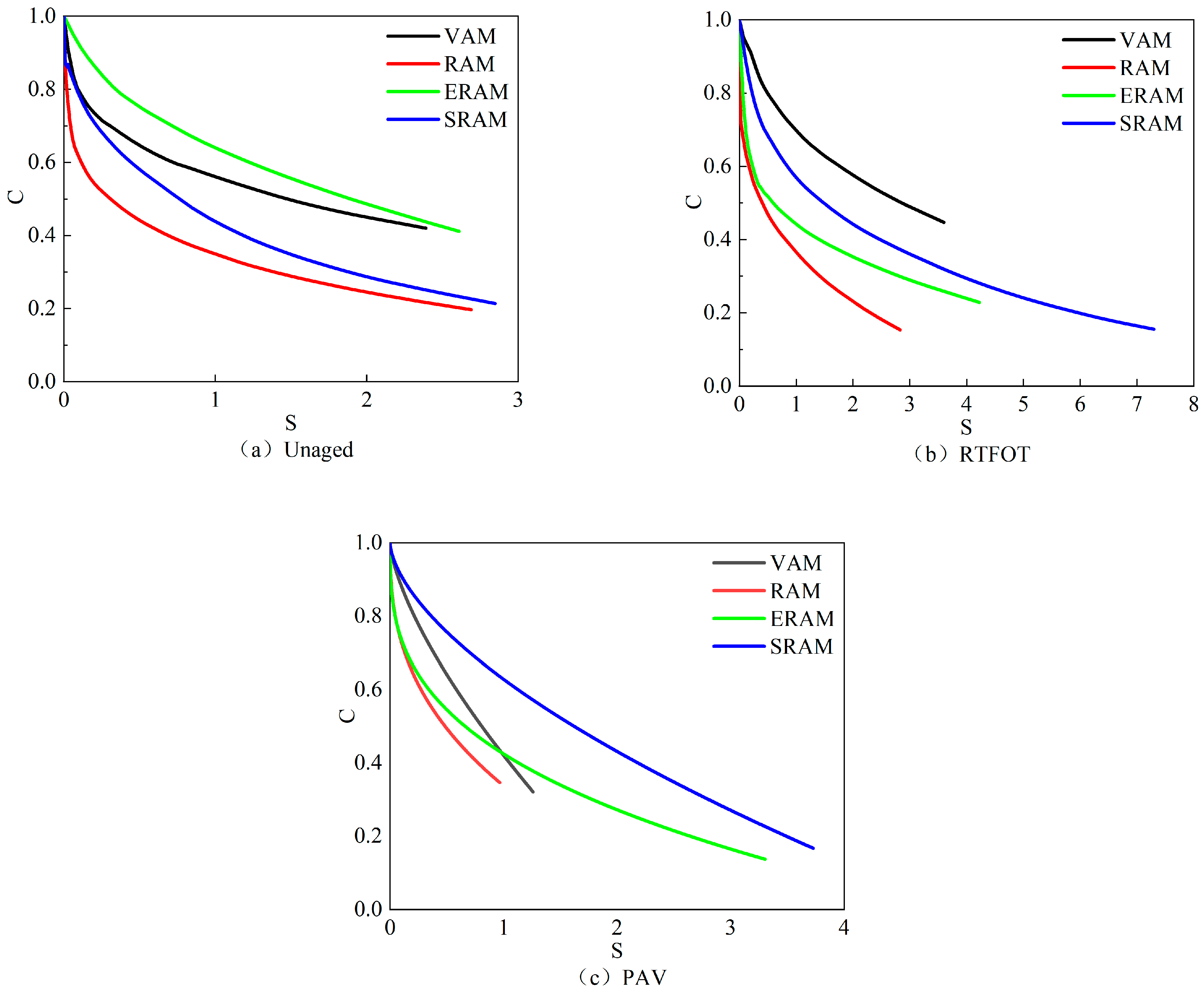

3.1.3. Damage Characterization Curves

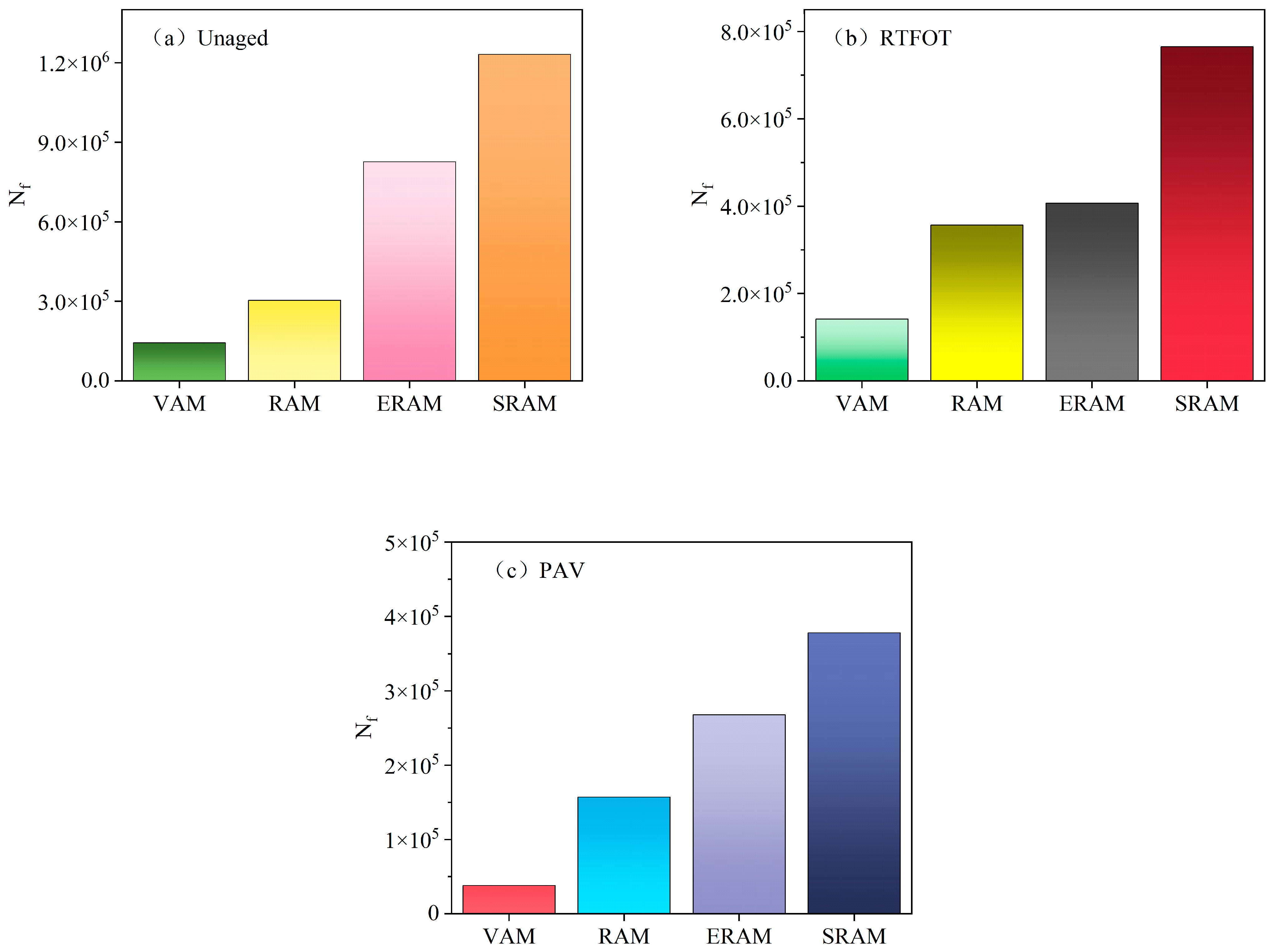

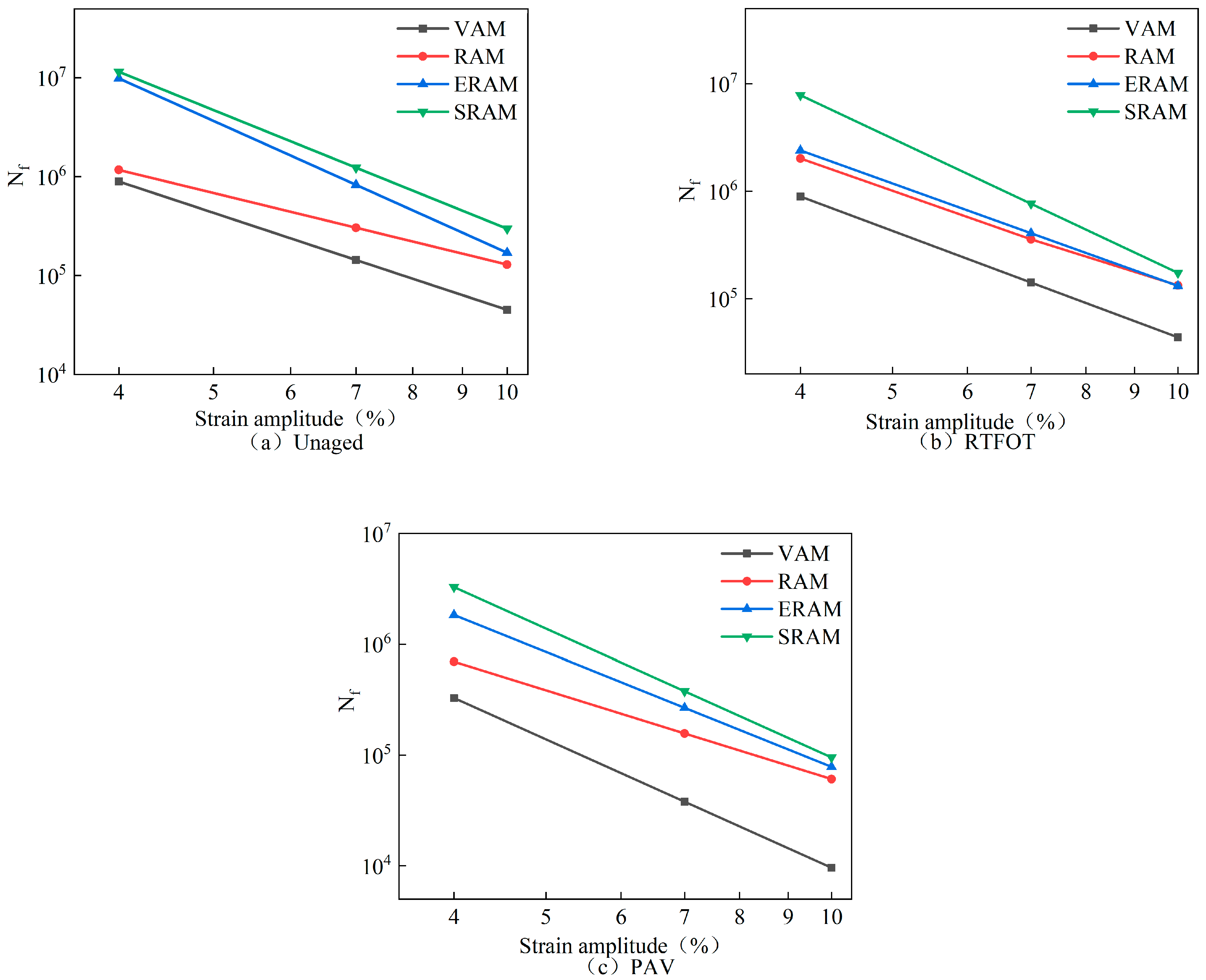

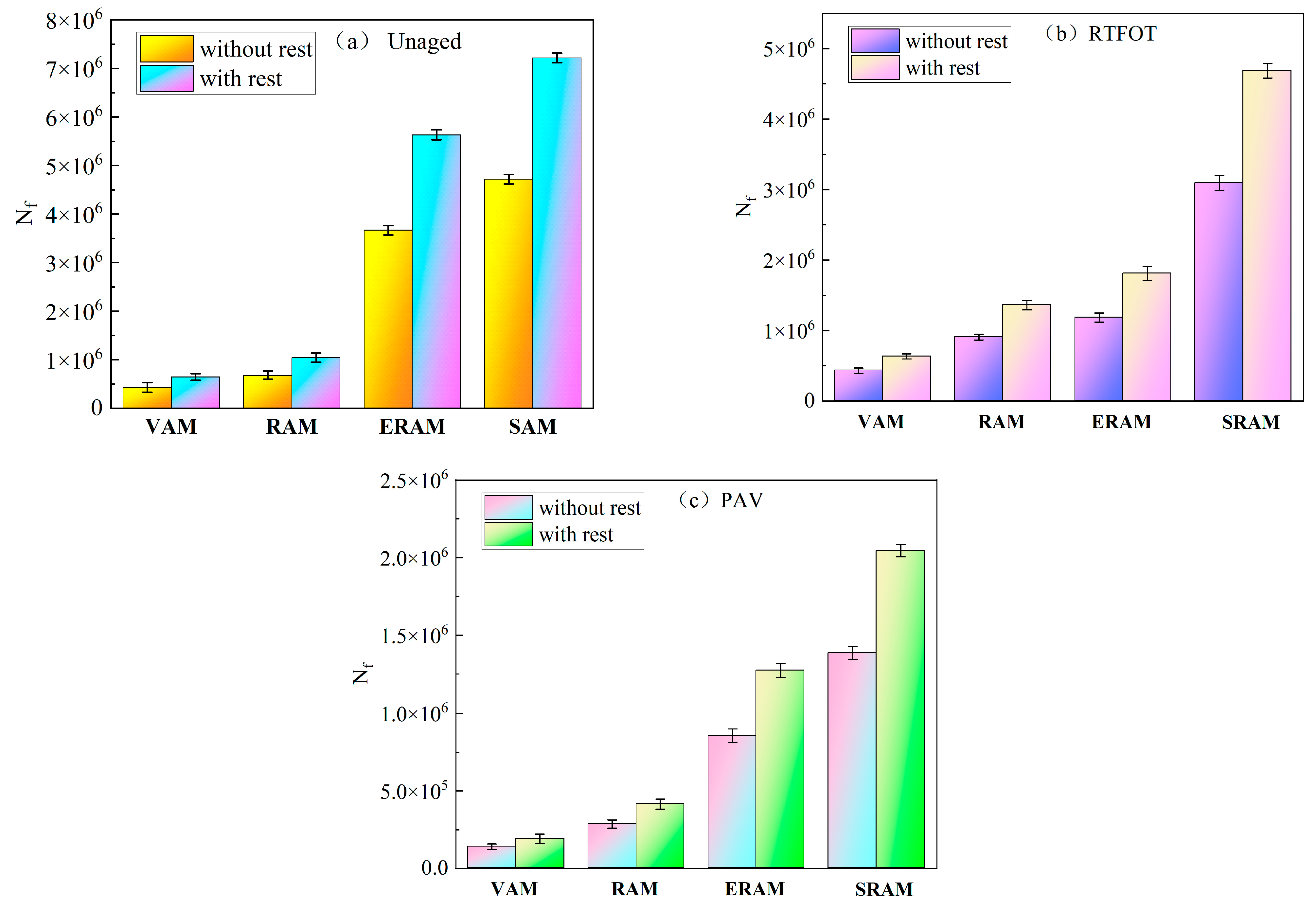

3.1.4. Fatigue Life Analysis

3.2. Results and Analysis of Self-Healing Performance Tests

3.2.1. Cumulative Increase in the Number of Self-Healing Loading Cycles

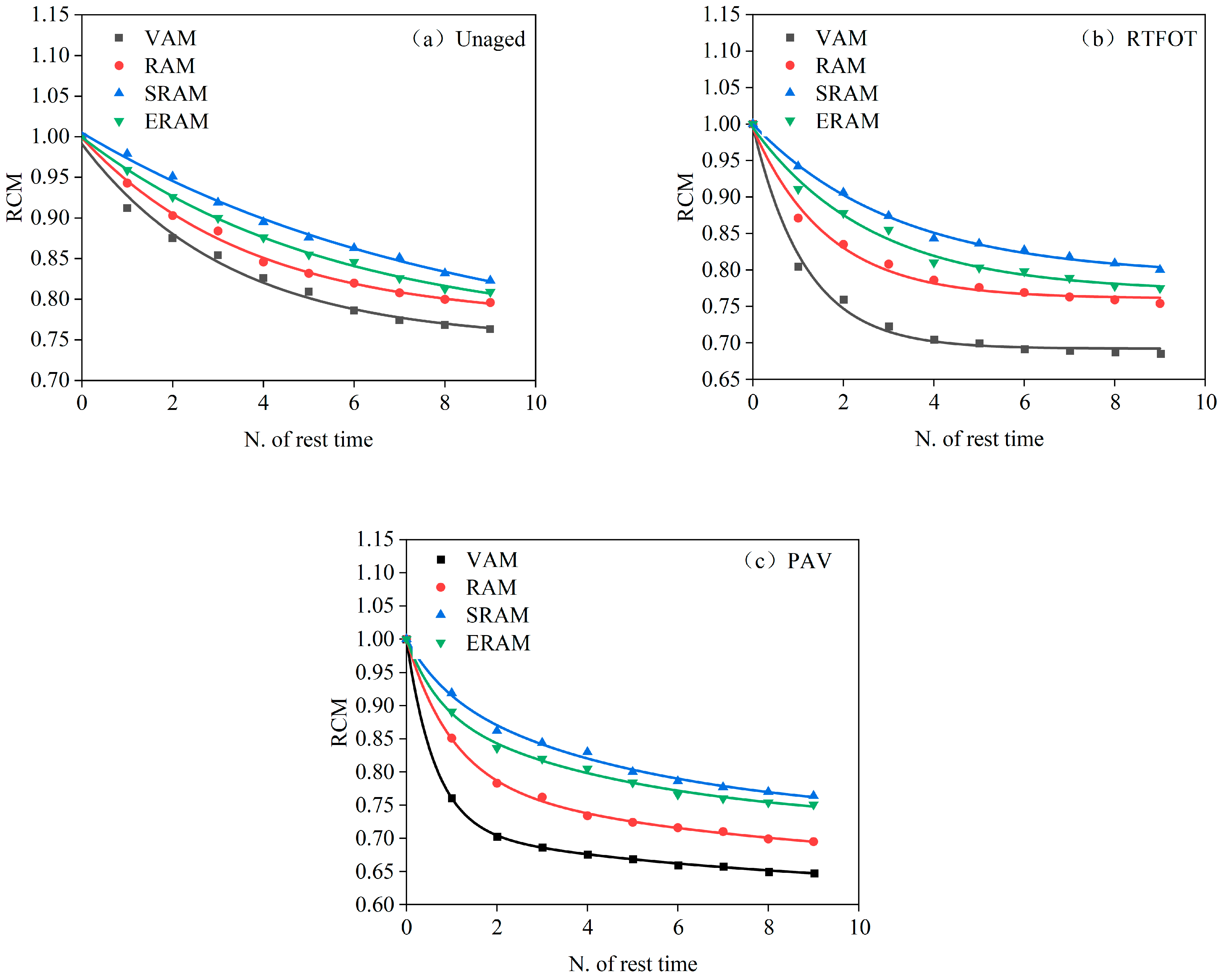

3.2.2. The Recovery Rate of Complex Shear Modulus

3.3. Fatigue Life Analysis Considering the Effect of Self-Healing

4. Conclusions

- (1)

- Both Sasobit and Evotherm can significantly enhance the fatigue performance of asphalt mastics, thereby extending their fatigue life. This is due to the fact that the former can form a solid lattice structure in the bitumen, while the latter can effectively increase the bond between the bitumen and the mineral powder. Specifically, under the long-term aging condition of 7% strain, the fatigue life of SRAM is 9.9 times as long as that of VAM and 2.4 times as long as that of RAM; the fatigue life of ERAM is 8.7 times as long as that of VAM and 1.7 times as long as that of RAM. In addition, SRAM shows better fatigue performance.

- (2)

- The self-healing properties of four asphalt mastics under different aging states were tested and analyzed by multiple intermittent loading TS tests based on and RCM. In particular, after ten fatigue intermittent loadings in the long-term aging condition, the for VAM is only 43.2% of the for SRAM and 48.2% of the for ERAM, while the for RAM is only 76.1% of the N for SRAM and 84.8% of the for ERAM. Moreover, the values of RCM for long-term aging VAM and RAM after ten fatigue intermittent loading tests are 0.65 and 0.70, respectively, which are lower than the values of RCM for SRAM. This indicates that adding a warm-mix agent can improve the self-healing properties of asphalt mastic.

- (3)

- The fatigue life of asphalt mastic at a 5% strain level before and after considering the effect of self-healing was calculated by the fatigue life conversion factor μ. A comparison reveals that the fatigue life of asphalt mastic is significantly prolonged after considering self-healing, which indicates that the self-healing property of asphalt mastic significantly enhances its fatigue performance.

- (4)

- This indicates that aging has some adverse effects on fatigue performance and self-healing performance, and the deeper the aging, the more pronounced the adverse effects. This is because aging hardens the asphalt and reduces its fluidity, which affects the road’s life and the asphalt’s self-healing performance. At a 7% strain, the fatigue life of SRAM after long-term aging is only 30.7% of the fatigue life in the unaged state and 49.4% of the fatigue life in the short-term aging state. Moreover, after ten fatigue intermittent loads in the long-term aging state, the of the SRAM is only 53.2% of the in the unaged state and 58.8% of the in the short-term aging state.

- (5)

- The comprehensive results of the study concluded that Sasobit has a better effect on improving the fatigue and self-healing performances of rubber asphalt mastic. Therefore, Sasobit warm mix is preferable in practical applications to improve the performance of rubber asphalt pavements. This study can provide a theoretical basis for the promotion and application of WMRA pavements and contribute to the sustainable development of road construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, M.; Zhang, L.; Li, A.; Irfan, M.; Du, Y.; Di, W. Comparative pyrolysis behaviors of tire tread and side wall from waste tire and characterization of the resulting chars. J. Environ. Manag. 2019, 232, 364–371. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Zhao, M.; Tang, N. Characterization of crumb tire rubber lightly pyrolyzed in waste cooking oil and the properties of its modified bitumen. Constr. Build. Mater. 2019, 195, 10–18. [Google Scholar] [CrossRef]

- Zheng, G.; Zhang, N.; Lv, S. Experimental Study on Dynamic Modulus of High Content Rubber Asphalt Mixture. Buildings 2024, 14, 434. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Su, J.; Li, P.; Zhu, G.; Wang, X.; Dong, S. Interface Interaction of Waste Rubber–Asphalt System. Buildings 2024, 14, 1868. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Zhou, Z.; Shih, K.; Xiao, F.; Gao, Z. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. J. Clean. Prod. 2017, 141, 336–345. [Google Scholar] [CrossRef]

- Topal, A.; Oner, J.; Sengoz, B.; Dokandari, P.A.; Özdemir, D.K. Evaluation of Rutting Performance of Warm Mix Asphalt. Int. J. Civ. Eng. 2017, 15, 705–714. [Google Scholar] [CrossRef]

- Sharma, A.; Mir, M.S.; Farooq, M.A. Performance of WMA Additives Under Freeze–thaw Action. Road Mater. Pavement Des. 2019, 20, 1468–1480. [Google Scholar] [CrossRef]

- Cheraghian, G.; Falchetto, A.C.; You, Z.; Chen, S.; Kim, S.Y.; Westerhoff, J.; Moon, K.H.; Wistuba, M.P. Warm Mix Asphalt Technology: An up to Date Review. J. Clean. Prod. 2020, 268, 122–128. [Google Scholar] [CrossRef]

- Guo, J.; Chang, C.; Wang, L. Low-Temperature Crack Resistance of High-Content Rubber-Powder-Modified Asphalt Mixture under Freeze–Thaw Cycles. Polymers 2024, 16, 402. [Google Scholar] [CrossRef]

- Gui, W.; Liang, L.; Wang, L.; Zhang, F. Cracking Resistance of Recycled Rubber Asphalt Binder Composed of Warm-Mix Additives. Materials 2022, 15, 4389. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Review of warm mix rubberized asphalt concrete: Towards a sustainable paving technology. J. Clean. Prod. 2018, 177, 302–314. [Google Scholar] [CrossRef]

- Shi, J.; Li, J.; Li, C.; Wang, T.; Liu, J.; Cao, A. Effect of Organic Viscosity-Reducing Warm-Mix Agent on the Performance of Rubber Asphalt. Coatings 2022, 12, 152. [Google Scholar] [CrossRef]

- Bilema, M.; Wah Yuen, C.; Alharthai, M.; Hazim Al-Saffar, Z.; Oleiwi Aletba, S.R.; Md Yusoff, N.I. Influence of Warm Mix Asphalt Additives on the Physical Characteristics of Crumb Rubber Asphalt Binders. Appl. Sci. 2023, 13, 10337. [Google Scholar] [CrossRef]

- Deng, H.B.; Ma, X.; Deng, D.Y.; Tan, L. Fatigue properties of rubber modified SMA asphalt mixture. In Proceedings of the 1st International Conference on Advances in Civil Engineering and Materials (ACEM)/1st World Symposium on Sustainable Bio-Composite Materials and Structures (SBMS), Nanjing, China, 9–11 November 2019; Volume 275. [Google Scholar]

- Yuan, J.; Lv, S.; Peng, X.; You, L.; Borges Cabrera, M. Investigation of strength and fatigue life of rubber asphalt mixture. Materials 2020, 13, 3325. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, X.; van de Ven, M.; Lu, G.; Erkens, S.; Skarpas, A. Fatigue performance of long-term aged crumb rubber modified bitumen containing warm-mix additives. Constr. Build. Mater. 2020, 239, 117824. [Google Scholar] [CrossRef]

- Xiao, F.; Zhao, W.; Amirkhanian, S.N. Laboratory Investigation of Fatigue Characteristics of Rubberized Asphalt Mixtures Containing Warm Asphalt Warm Asphalt Additives at A Low Temperature. J. Test. Eval. 2011, 39, 290–295. [Google Scholar] [CrossRef]

- Kumar, A.; Choudhary, R.; Kandhal, P.S.; Julaganti, A.; Behera, O.P.; Singh, A.; Kumar, R. Fatigue characterisation of modified asphalt binders containing warm mix asphalt additives. Road Mater. Pavement Des. 2020, 21, 519–541. [Google Scholar] [CrossRef]

- Wang, D.; Li, D.; Yan, J.; Leng, Z.; Wu, Y.; Yu, J.; Yu, H. Rheological and chemical characteristic of warm asphalt rubber binders and their liquid phases. Constr. Build. Mater. 2018, 193, 547–556. [Google Scholar] [CrossRef]

- Wang, H.; Yuan, M.; Wu, J.; Wan, P.; Liu, Q. Self-Healing Properties of Asphalt Concrete with Calcium Alginate Capsules Containing Different Healing Agents. Materials 2022, 15, 5555. [Google Scholar] [CrossRef]

- Zhang, F.; Sun, Y.; Kong, L.; Cannone Falchetto, A.; Yuan, D.; Wang, W. Study on Multiple Effects of Self-Healing Properties and Thermal Characteristics of Asphalt Pavement. Buildings 2024, 14, 1313. [Google Scholar] [CrossRef]

- Xu, H.; Xu, W.; Zheng, X.; Cao, K. A Multistage Analysis of Asphalt Binder Nanocrack Generation and Self-Healing Behavior Based on Molecular Dynamics. Polymers 2022, 14, 3581. [Google Scholar] [CrossRef] [PubMed]

- Hasheminejad, N.; Vuye, C.; Margaritis, A.; Ribbens, B.; Jacobs, G.; Blom, J.; Van den bergh, W.; Dirckx, J.; Vanlanduit, S. Investigation of Crack Propagation and Healing of Asphalt Concrete Using Digital Image Correlation. Appl. Sci. 2019, 9, 2459. [Google Scholar] [CrossRef]

- He, L.; Zhou, Z.; Ling, F.; Alexiadis, A.; Van den Bergh, W.; Cannone Falchetto, A.; Balieu, R.; Zhu, J.; Valentin, J.; Kowalski, K.J.; et al. A Coarse-Grained Molecular Model for Simulating Self-Healing of Bitumen. Appl. Sci. 2022, 12, 10360. [Google Scholar] [CrossRef]

- Ma, X.; Kan, J.; Liu, S.; Tu, M.; Wang, D. Investigation of the Effect of Filler on Cohesive Bond Strength of Asphalt Mastic Using Binder Bond Strength (BBS) Test. Coatings 2023, 13, 1001. [Google Scholar] [CrossRef]

- E, G.; Zhang, J.; Shen, Q.; Ji, P.; Wang, J.; Xiao, Y. Influence of Filler Type and Rheological Properties of Asphalt Mastic on the Asphalt Mastic–Aggregate Interaction. Materials 2023, 16, 574. [Google Scholar] [CrossRef] [PubMed]

- Russo, F.; Veropalumbo, R.; Oreto, C.; Biancardo, S.A.; Abbondati, F.; Viscione, N. Verifying the Mechanical Performance of Cold and Hot Asphalt Mastics Containing Jet Grouting Waste as a Filler. Coatings 2021, 11, 751. [Google Scholar] [CrossRef]

- Ge, D.; Yan, K.; You, L.; Wang, Z. Modification mechanism of asphalt modified with Sasobit and Polyphosphoric acid (PPA). Constr. Build. Mater. 2017, 143, 419–428. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, W.; Shen, S.; Li, X.; Muhunthan, B.; Mohammad, L.N. Field-aged asphalt binder performance evaluation for Evotherm warm mix asphalt: Comparisons with hot mix asphalt. Constr. Build. Mater. 2017, 156, 574–583. [Google Scholar] [CrossRef]

- Lu, D.X.; Saleh, M. Laboratory evaluation of warm mix asphalt incorporating high RAP proportion by using evotherm and sylvaroad additives. Constr. Build. Mater. 2016, 114, 580–587. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Lv, S.; Ge, D.; Cao, S.; Liu, D.; Zhang, W.; Li, C.-H.; Borges Cabrera, M. Development of a Framework for Assessing Bitumen Fatigue Cracking Performance under Different Temperatures and Aging Conditions. Buildings 2024, 14, 311. [Google Scholar] [CrossRef]

- Klug, A.; Ng, A.; Faxina, A. Application of the Viscoelastic Continuum Damage Theory to Study the Fatigue Performance of Asphalt Mixtures—A Literature Review. Sustainability 2022, 14, 4973. [Google Scholar] [CrossRef]

- AASHTO T 315-19; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO: Washington, DC, USA, 2019.

- Huo, W.; Zhuang, Y.; Wang, Z.; Kang, X.; Wang, R. The Microscopic Mechanism and Rheological Properties of SBS-Modified Asphalt with Warm Mixing Fast-Melting. Materials 2023, 16, 5690. [Google Scholar] [CrossRef]

- AASHTO TP 101-14; Standard Method of Test for Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep. AASHTO: Washington, DC, USA, 2014.

- Zhou, H.-Y.; Dou, H.-B.; Chen, X.-H. Rheological Properties of Graphene/Polyethylene Composite Modified Asphalt Binder. Materials 2021, 14, 3986. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, X.; Apostolidis, P.; Gard, W.; van de Ven, M.; Erkens, S.; Jing, R. Chemical and Rheological Evaluation of Aged Lignin-Modified Bitumen. Materials 2019, 12, 4176. [Google Scholar] [CrossRef]

- Yue, M.; Yue, J.; Wang, R.; Xiong, Y. Evaluating the fatigue characteristics and healing potential of asphalt binder modified with Sasobit® and polymers using linear amplitude sweep test. Constr. Build. Mater. 2021, 289, 123054. [Google Scholar] [CrossRef]

- Luo, X.; Xie, K.; Zhao, S.; Yao, Q.; Qin, Y. Study of the Molecular Components and Rheological Properties of Asphalt after Long-Term Aging under the Action of Moisture. Sustainability 2022, 14, 9080. [Google Scholar] [CrossRef]

- Men, B.; Li, X.; Sha, T.; Guo, F.; Tang, G.; Yue, J. Research on Fatigue Performance of Fast-Melting SBS/Epoxy Resin Composite-Modified Asphalt. Coatings 2024, 14, 789. [Google Scholar] [CrossRef]

- Wang, H.; Du, Z.; Liu, G.; Luo, X.; Yang, C. Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene–Butadiene–Styrene-Modified Bio-Blend Bitumen. Polymers 2023, 15, 2911. [Google Scholar] [CrossRef]

- Izadi, A.; Motamedi, M.; Alimi, R.; Nafar, M. Effect of aging conditions on the fatigue behavior of hot and warm mix asphalt. Constr. Build. Mater. 2018, 188, 119–129. [Google Scholar] [CrossRef]

- Li, Z. Research on the Performance Experiment and Application of Evotherm Warm Mix Asphalt Mixtures. Masters’s Thesis, Hebei University of Technology, Tianjin, China, 2011. [Google Scholar] [CrossRef]

- Mannan, U.A.; Tarefder, R.A. Investigating different fatigue failure criteria of asphalt binder with the consideration of healing. Int. J. Fatigue 2018, 114, 198–205. [Google Scholar] [CrossRef]

- Kose, S.; Guler, M.; Bahia, H.U.; Masad, E. Distribution of strains within hot-mix asphalt binders: Applying imaging and finite-element techniques. Transp. Res. Rec. 2000, 1728, 21–27. [Google Scholar] [CrossRef]

- Bahia, H.; Tabatabaee, H.A.; Mandal, T.; Faheem, A. Field Evaluation of Wisconsin Modified Binder Selection Guidelines—Phase II; Technical report; University of Wisconsin-Madison: Madison, WI, USA, 2013. [Google Scholar]

- Deef-Allah, E.; Abdelrahman, M. Thermal, chemical and rheological properties of asphalt binders extracted from field cores. Innov. Infrastruct. Solut. 2022, 7, 235. [Google Scholar] [CrossRef]

| Technical Indicator | Test Value | Technical Requirement | Unit |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 70.9 | 60–80 | 0.1 mm |

| Softening point | 54.6 | ≥46 | °C |

| Ductility (15 °C, 5 cm/min) | >100 | ≥100 | cm |

| Technical Indicators | Test Value | Unit |

|---|---|---|

| Particle size | 60 | mesh |

| Moisture content | 0.69 | % |

| Relative density | 1.35 | - |

| Technical Indicators | Test Value | Unit |

|---|---|---|

| Melting point | 101 | °C |

| Density (25 °C) | 0.94 | g/cm3 |

| Flash point | 293 | °C |

| Brinell rotational viscosity (135 °C) | 5.46 × 10−3 | Pa·s |

| Technical Indicators | Test Value | Unit |

|---|---|---|

| Density (25 °C) | 8.07 | lbs/gal |

| Proportion (25 °C) | 0.968 | - |

| Viscosity (20 °C) | 660–1225 | mPa·s |

| Type of Asphalt Mastic | Aging Status |

|---|---|

| VAM | Unaged |

| RTFOT | |

| PAV | |

| RAM | Unaged |

| RTFOT | |

| PAV | |

| SRAM | Unaged |

| RTFOT | |

| PAV | |

| ERAM | Unaged |

| RTFOT | |

| PAV |

| Type of Asphalt | Unaged | RTFOT | PAV |

|---|---|---|---|

| VAM | 1.500896 | 1.469959 | 1.370156 |

| RAM | 1.527895 | 1.500586 | 1.449185 |

| ERAM | 1.529193 | 1.515128 | 1.474655 |

| SRAM | 1.535672 | 1.529622 | 1.491847 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Li, X.; Yu, S.; Sun, L.; Yue, J.; Li, R. Fatigue-Healing Performance Analysis of Warm-Mix Rubber Asphalt Mastic Using the Simplified Viscoelastic Continuum Damage Theory. Coatings 2024, 14, 914. https://doi.org/10.3390/coatings14070914

Li P, Li X, Yu S, Sun L, Yue J, Li R. Fatigue-Healing Performance Analysis of Warm-Mix Rubber Asphalt Mastic Using the Simplified Viscoelastic Continuum Damage Theory. Coatings. 2024; 14(7):914. https://doi.org/10.3390/coatings14070914

Chicago/Turabian StyleLi, Ping, Xiao Li, Shangjun Yu, Linhao Sun, Jinchao Yue, and Ruixia Li. 2024. "Fatigue-Healing Performance Analysis of Warm-Mix Rubber Asphalt Mastic Using the Simplified Viscoelastic Continuum Damage Theory" Coatings 14, no. 7: 914. https://doi.org/10.3390/coatings14070914

APA StyleLi, P., Li, X., Yu, S., Sun, L., Yue, J., & Li, R. (2024). Fatigue-Healing Performance Analysis of Warm-Mix Rubber Asphalt Mastic Using the Simplified Viscoelastic Continuum Damage Theory. Coatings, 14(7), 914. https://doi.org/10.3390/coatings14070914