Study on the Refining Behavior of Al-Si Alloys Doped with Al-Ti-C Intermediate Alloys at Different B Doping Temperatures

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- (1)

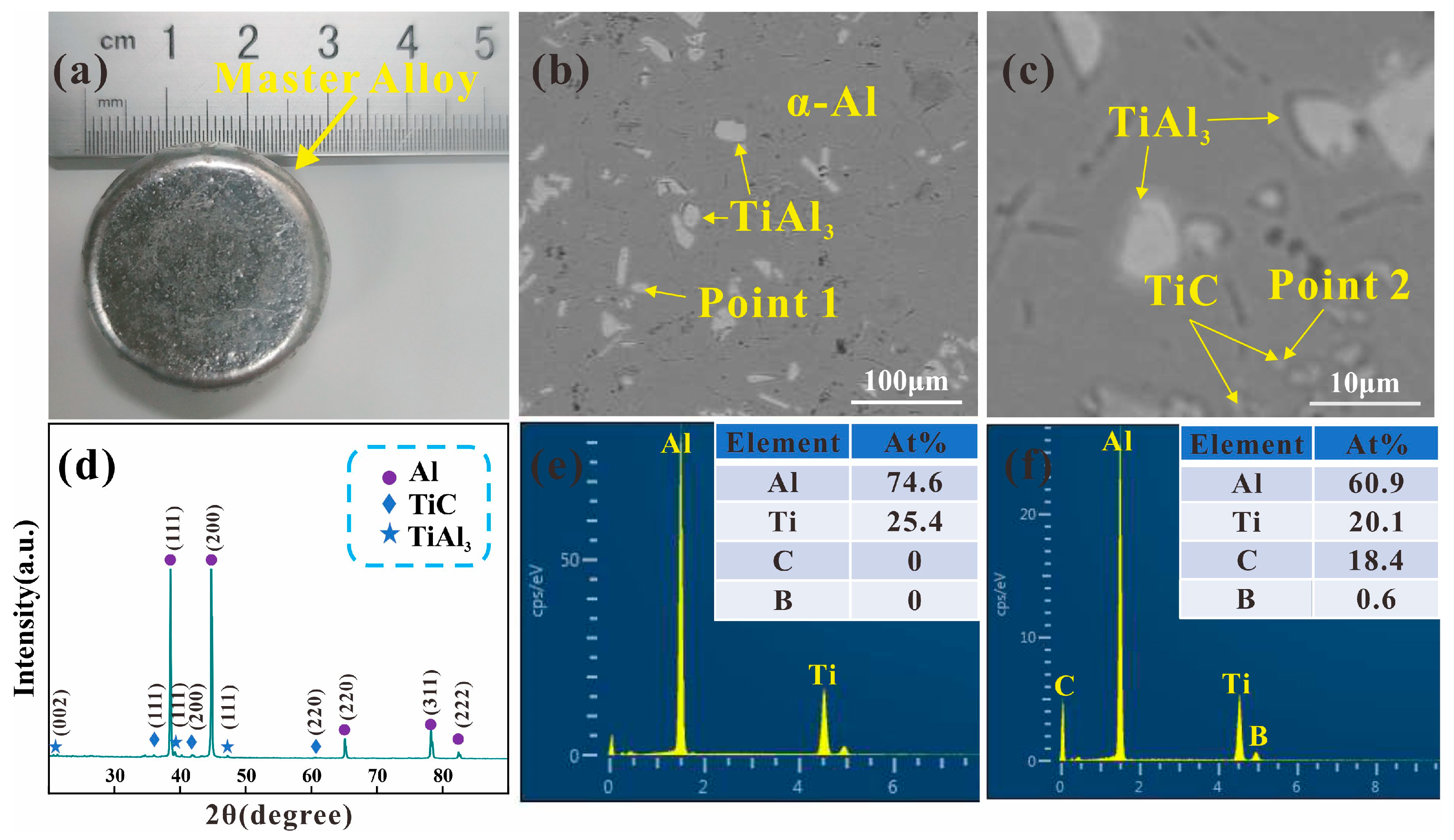

- The average diameters of TiAl3 and TiC were 8 μm ± 2 μm and 3 μm ± 1 μm, respectively, which were uniformly distributed on the α–Al matrix;

- (2)

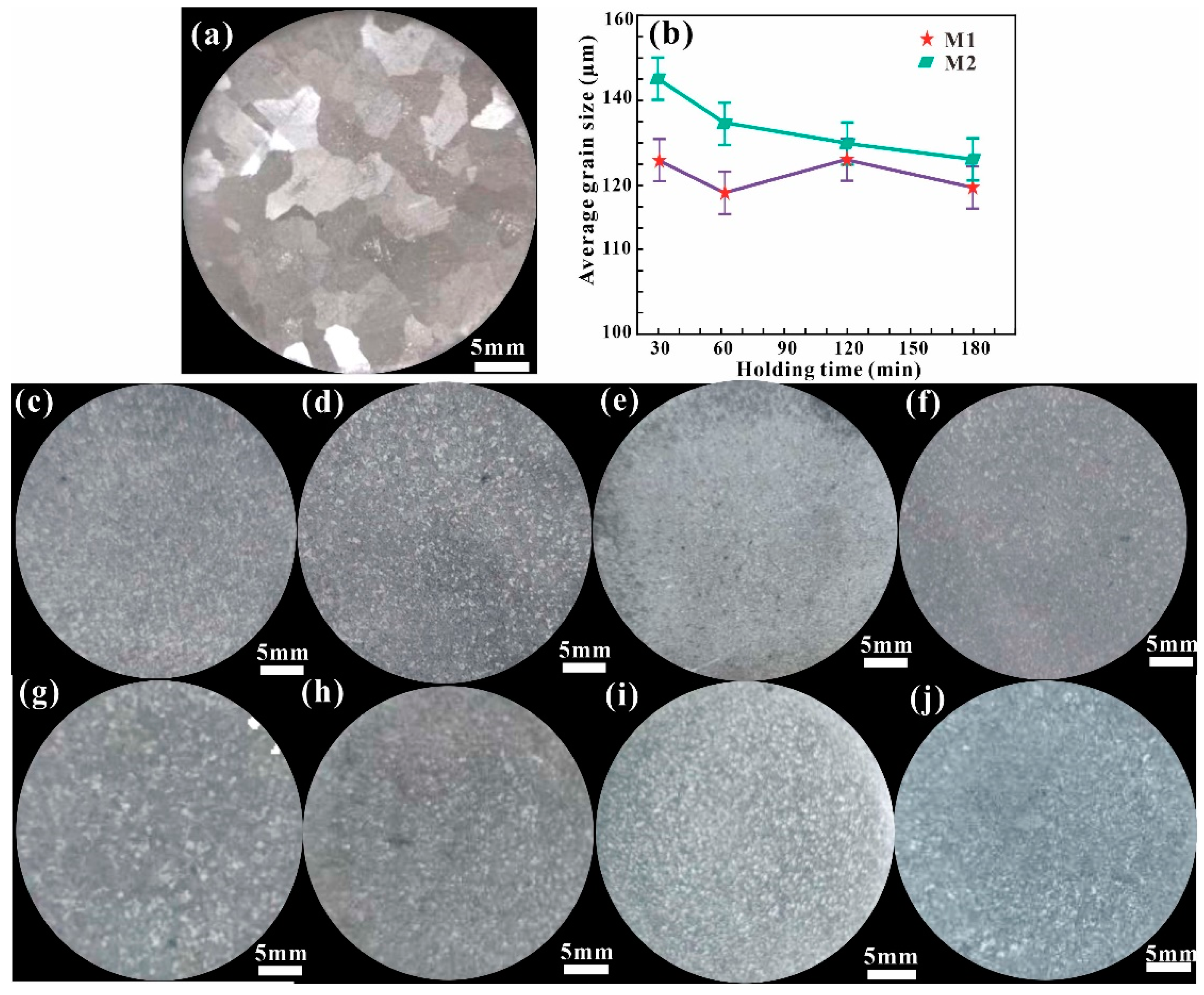

- The blocky TiAl3 generated at low temperature became acicular or elongated with the increase in temperature, slowing the response speed and increasing the time required to achieve the ideal refinement effect;

- (3)

- By adding 0.15 wt.% Al-5Ti-0.3C-0.2B intermediate alloy, the grain size of A356 alloy was refined to 120 μm ± 5 μm and maintained for 180 min without recession.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hirsch, J.; Al-Samman, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- Lian, P.; Mao, H.; Wei, Q.; Ma, R.; Li, C.; Xu, H. Tailoring the strength and corrosion resistance of Al-7Si: Eutectic Si modification by Sr and Sc. Mater. Lett. 2023, 348, 134505. [Google Scholar] [CrossRef]

- Li, Q.; Xia, T.; Lan, Y.; Li, P.; Fan, L. Effects of rare earth Er addition on microstructure and mechanical properties of hypereutectic Al–20% Si alloy. Mater. Sci. Eng. A 2013, 588, 97–102. [Google Scholar] [CrossRef]

- Rakhmonov, J.; Timelli, G.; Bonollo, F.; Arnberg, L. Influence of grain refiner addition on the precipitation of Fe-rich phases in secondary AlSi7Cu3Mg alloys. Int. J. Metalcast. 2017, 11, 294–304. [Google Scholar] [CrossRef]

- Mallapur, D.; Udupa, K.R.; Kori, S. Studies on the influence of grain refining and modification on microstructure and mechanical properties of forged A356 alloy. Mater. Sci. Eng. A 2011, 528, 4747–4752. [Google Scholar] [CrossRef]

- Li, J.; Zarif, M.; Albu, M.; McKay, B.; Hofer, F.; Schumacher, P. Nucleation kinetics of entrained eutectic Si in Al–5Si alloys. Acta Mater. 2014, 72, 80–98. [Google Scholar] [CrossRef]

- Basavakumar, K.; Mukunda, P.; Chakraborty, M. Influence of grain refinement and modification on microstructure and mechanical properties of Al–7Si and Al–7Si–2.5 Cu cast alloys. Mater. Charact. 2008, 59, 283–289. [Google Scholar] [CrossRef]

- Qiu, D.; Taylor, J.; Zhang, M.; Kelly, P. A mechanism for the poisoning effect of silicon on the grain refinement of Al–Si alloys. Acta Mater. 2007, 55, 1447–1456. [Google Scholar] [CrossRef]

- Zhu, M.; Jian, Z.; Yang, G.; Zhou, Y. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2012, 36, 243–249. [Google Scholar] [CrossRef]

- Kori, S.; Murty, B.; Chakraborty, M. Development of an efficient grain refiner for Al–7Si alloy and its modification with strontium. Mater. Sci. Eng. A 2000, 283, 94–104. [Google Scholar] [CrossRef]

- López, V.H.; Scoles, A.; Kennedy, A.R. The thermal stability of TiC particles in an Al7wt.%Si alloy. Mater. Sci. Eng. A 2003, 356, 316–325. [Google Scholar] [CrossRef]

- Vallauri, D.; Atías Adrián, I.C.; Chrysanthou, A. TiC–TiB2 composites: A review of phase relationships, processing and properties. J. Eur. Ceram. Soc. 2008, 28, 1697–1713. [Google Scholar] [CrossRef]

- Li, P.; Liu, S.; Zhang, L.; Liu, X. Grain refinement of A356 alloy by Al–Ti–B–C master alloy and its effect on mechanical properties. Mater. Des. 2013, 47, 522–528. [Google Scholar] [CrossRef]

- Li, D.; Yan, X.; Fan, Y.; Liu, G.; Nie, J.; Liu, X.; Liu, S. An anti Si/Zr-poisoning strategy of Al grain refinement by the evolving effect of doped complex. Acta Mater. 2023, 249, 118812. [Google Scholar] [CrossRef]

- Banerji, A.; Reif, W. Development of Al-Ti-C grain refiners containing TiC. Metall. Trans. A 1986, 17, 2127–2137. [Google Scholar] [CrossRef]

- Small, C.; Prangnell, P.; Hayes, F.; Hardman, A. In Microstructure and grain refining efficiency of TiC particles in Al-Ti-C grain refining master alloys. In Proceedings of the ICAA-6: 6th International Conference on Aluminium Alloys, Toyohashi, Japan, 5–10 July 1998; pp. 213–218. [Google Scholar]

- Ding, W.; Chen, T.; Zhao, X.; Cheng, Y.; Liu, X.; Gou, L. Investigation of microstructure of Al-5Ti-0.62 C system and synthesis mechanism of TiC. Materials 2020, 13, 310. [Google Scholar] [CrossRef] [PubMed]

- Ding, W.; Zhao, X.; Zhao, W.; Guo, T.; Tang, X.; Qiao, J.; Xia, T. Effects of Al–Ti–C–Ce Master Alloy on Microstructure and Mechanical Properties of Hypoeutectic Al–7%Si Alloy. Int. J. Metalcast. 2018, 13, 426–437. [Google Scholar] [CrossRef]

- Gomez, I.V. Influence of Nano-Particles of Alumina (Al2O3) and Titanium di-boride (TiB2) on the Microstructure and Properties of the Alloy Al-Cu3-Fe1-Si9 for Foundry Applications to High Pressure. Ph.D. Thesis, Université Sciences et Technologies-Bordeaux I, Talence, France, 2011. [Google Scholar]

- Vicario, I.; Poulon-Quintin, A.; Lagos, M.A.; Silvain, J.-F. Effect of material and process atmosphere in the preparation of Al-Ti-B grain refiner by SHS. Metals 2015, 5, 1387–1396. [Google Scholar] [CrossRef]

| Si | Mg | Fe | Ti | Sr | Al | |

|---|---|---|---|---|---|---|

| A356 | 6.34 | 0.33 | 0.07 | 0.12 | 0.024 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Liang, M.; Yin, B.; Yang, C.; Li, Y.; Yang, Y. Study on the Refining Behavior of Al-Si Alloys Doped with Al-Ti-C Intermediate Alloys at Different B Doping Temperatures. Coatings 2024, 14, 1102. https://doi.org/10.3390/coatings14091102

Liu X, Liang M, Yin B, Yang C, Li Y, Yang Y. Study on the Refining Behavior of Al-Si Alloys Doped with Al-Ti-C Intermediate Alloys at Different B Doping Temperatures. Coatings. 2024; 14(9):1102. https://doi.org/10.3390/coatings14091102

Chicago/Turabian StyleLiu, Xiaodong, Mengtian Liang, Bingbing Yin, Chuanlong Yang, Yuhao Li, and Yi Yang. 2024. "Study on the Refining Behavior of Al-Si Alloys Doped with Al-Ti-C Intermediate Alloys at Different B Doping Temperatures" Coatings 14, no. 9: 1102. https://doi.org/10.3390/coatings14091102