Study of the Impact of Surface Topography on Wear Resistance

Abstract

:1. Introduction

2. Modelling and Simulation

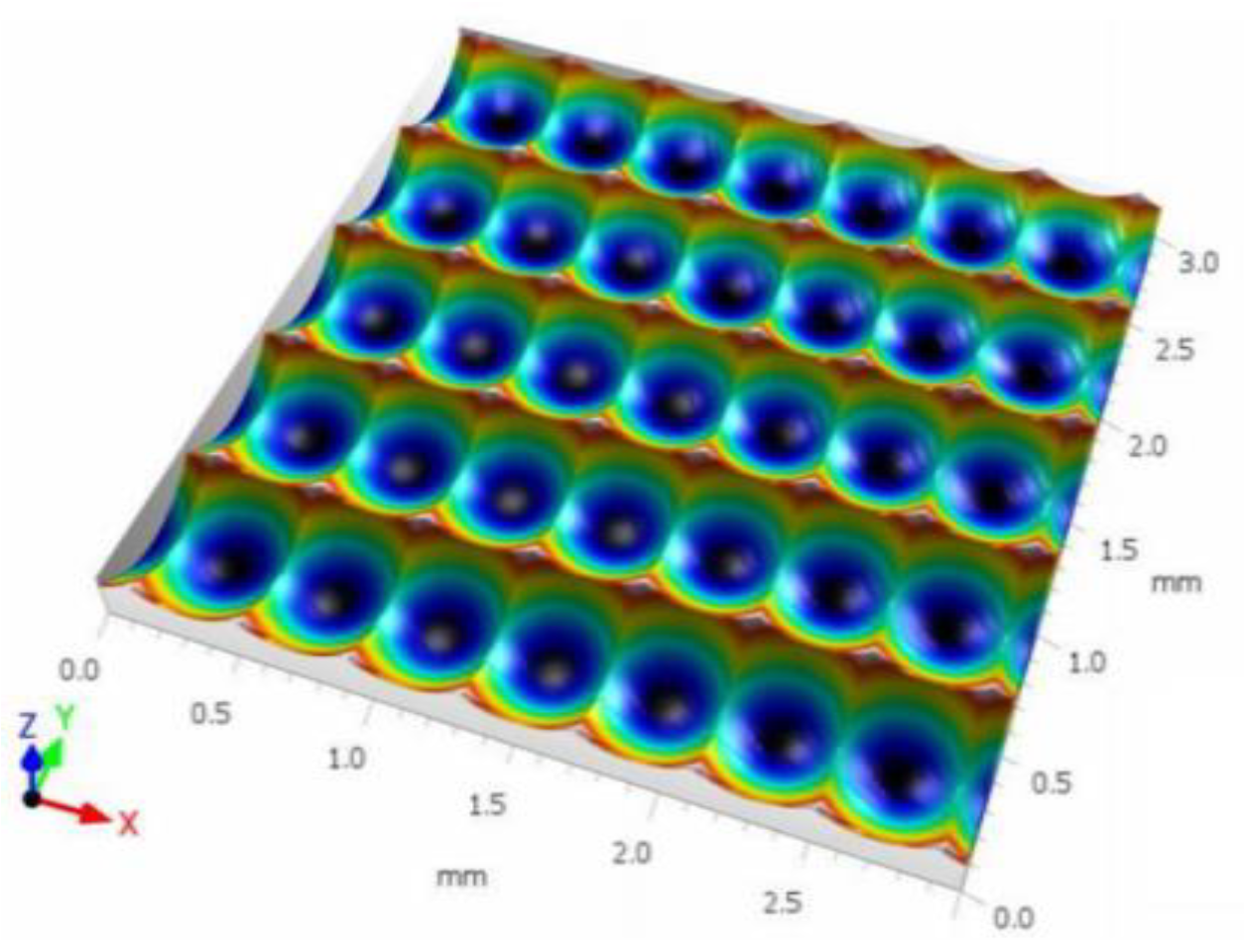

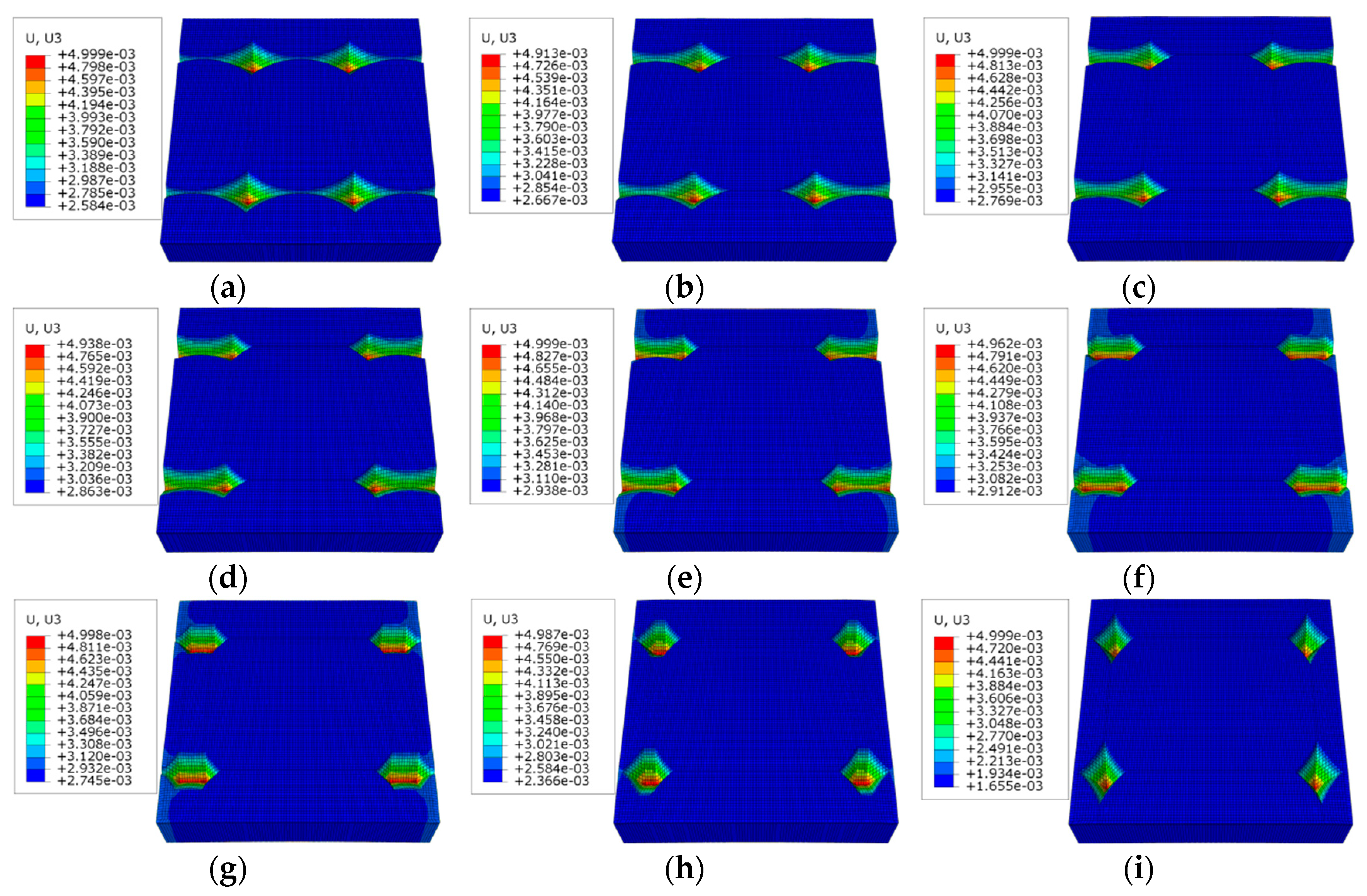

2.1. Three-Dimensional Simulation Model of Surface Topography

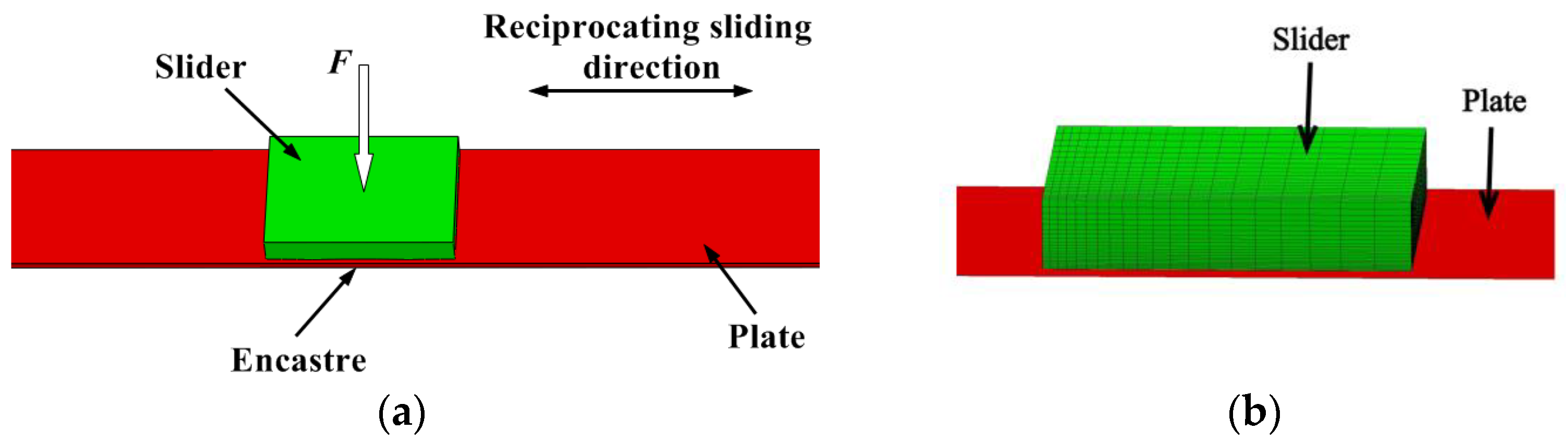

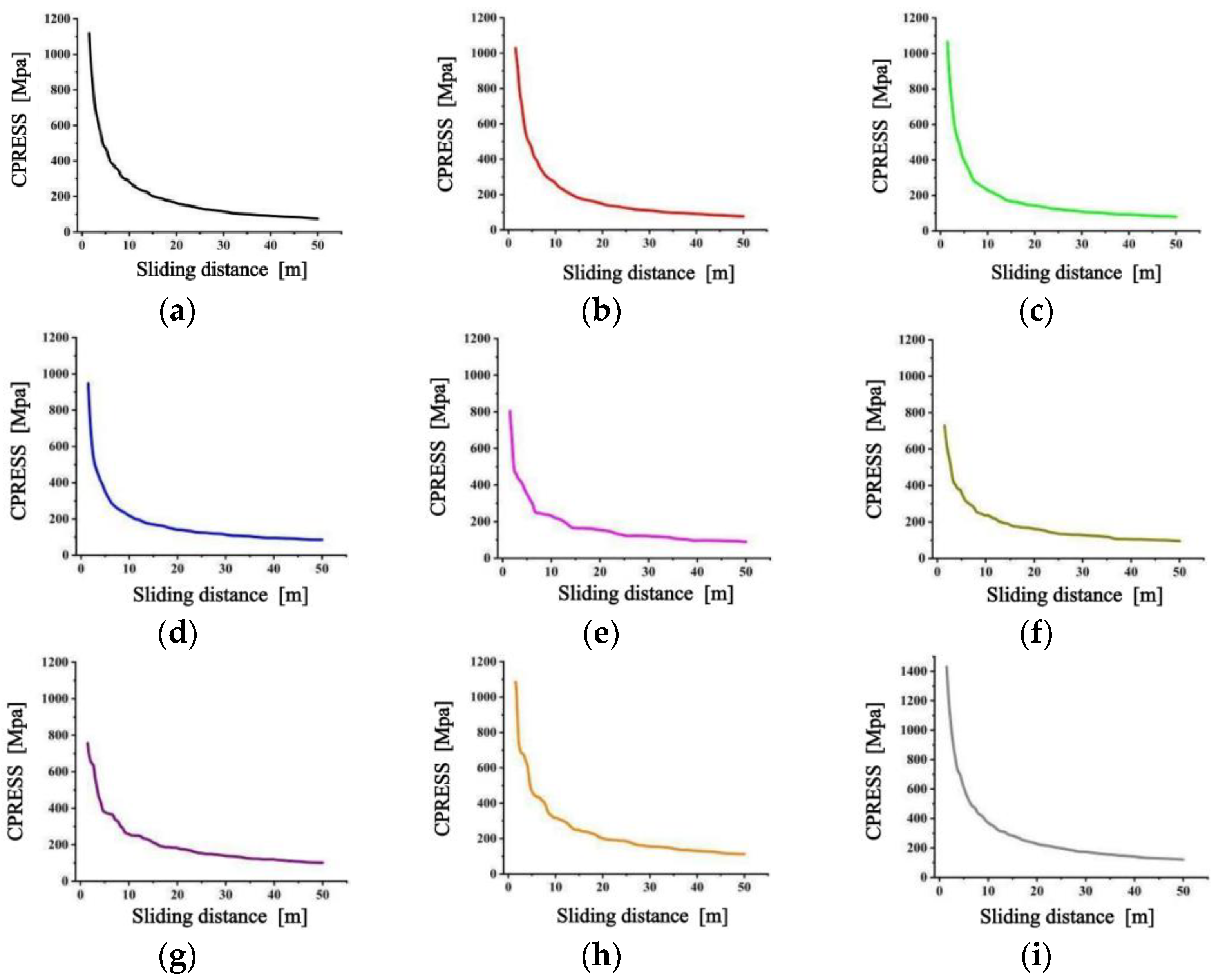

2.2. Finite Element Simulation of Sliding Wear Process

3. Correlation Analysis and Predictive Models

3.1. Improved Relational Grade

3.2. Grey Prediction Model

4. Results and Discussion

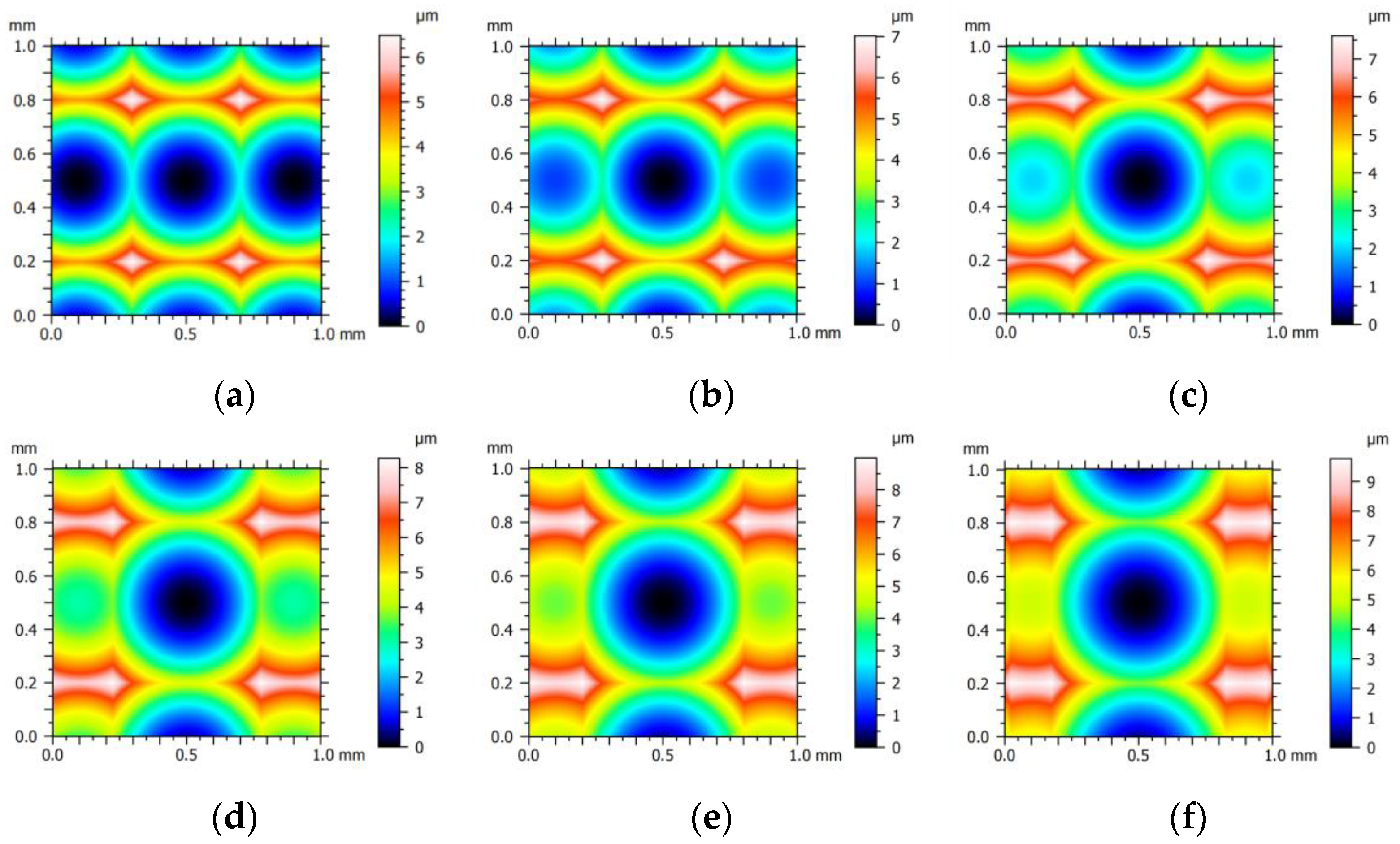

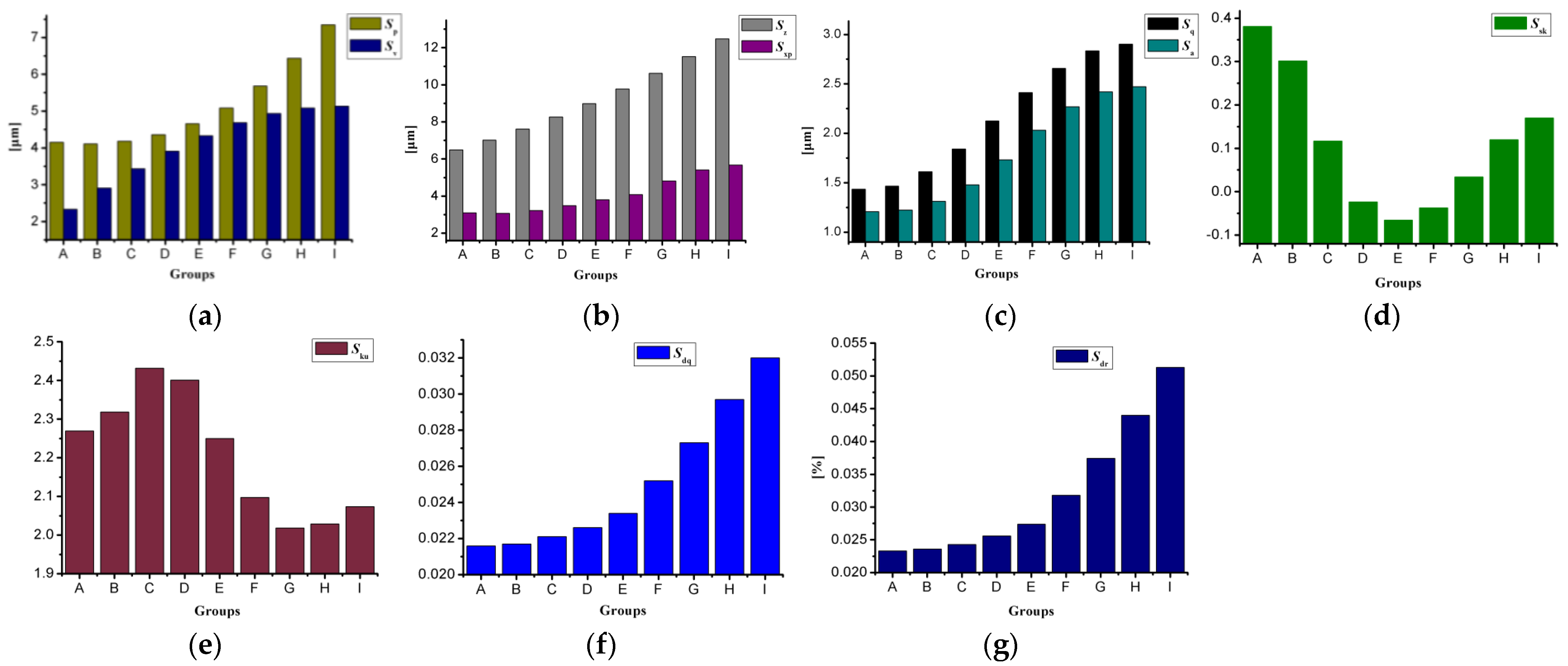

4.1. Surface Texture Parameters

4.2. Correlation Analysis between Surface Texture Parameters

4.3. Sliding Wear

4.4. Predictive Analysis of Wear Characteristics

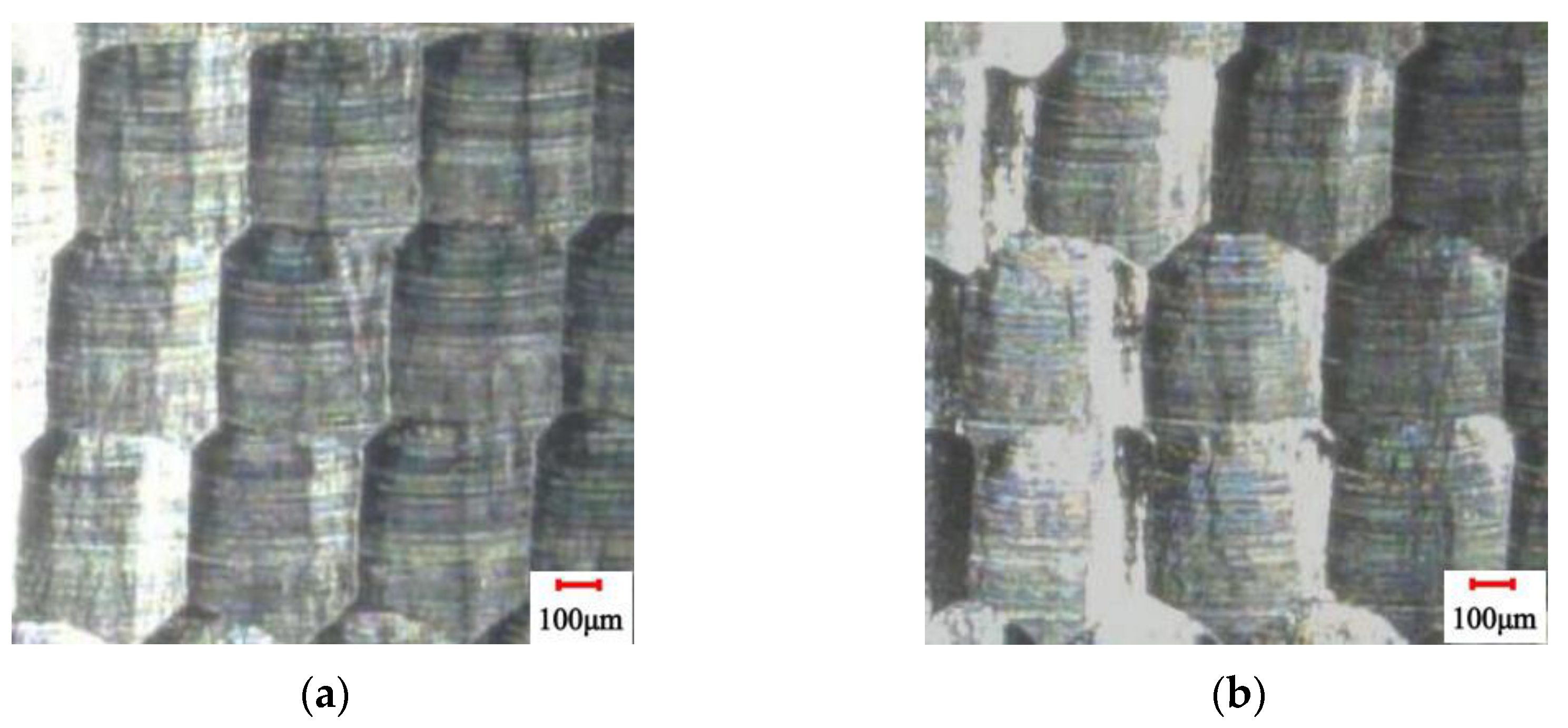

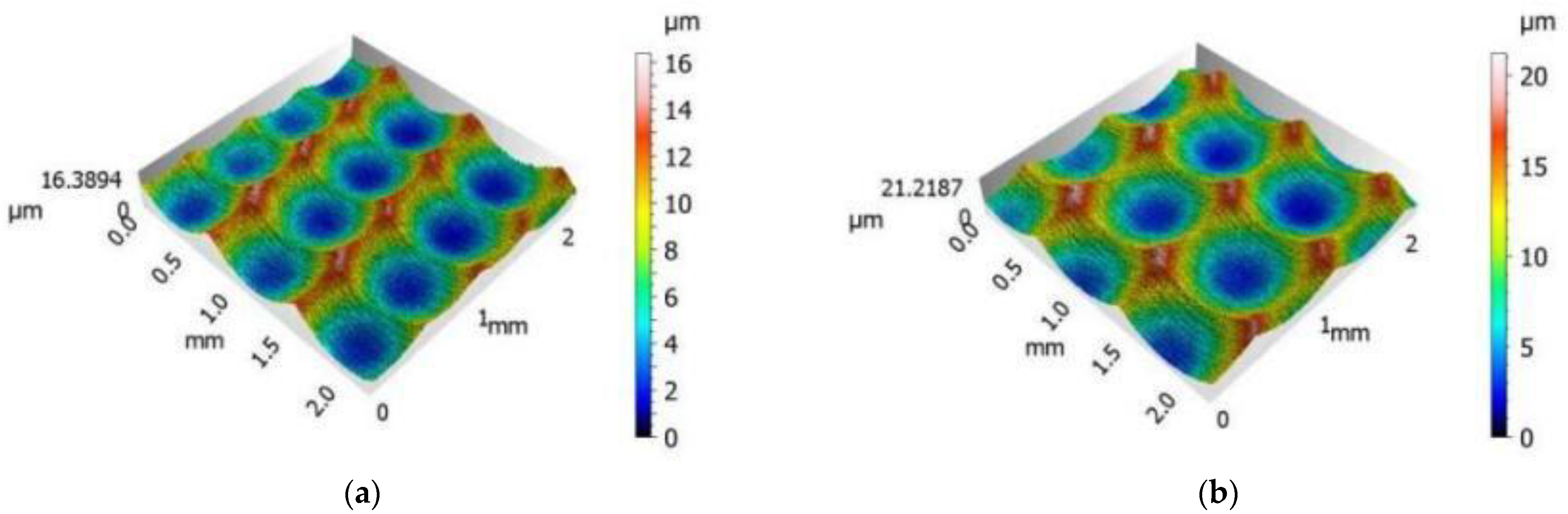

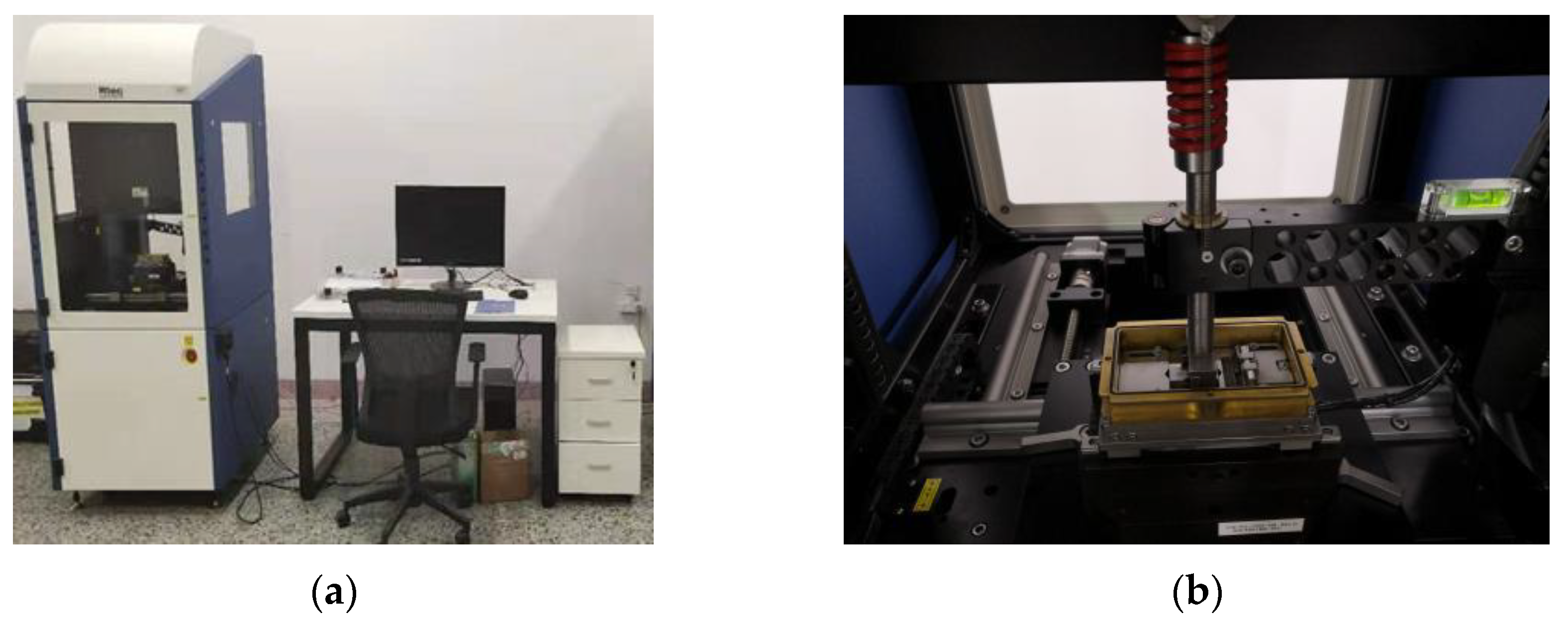

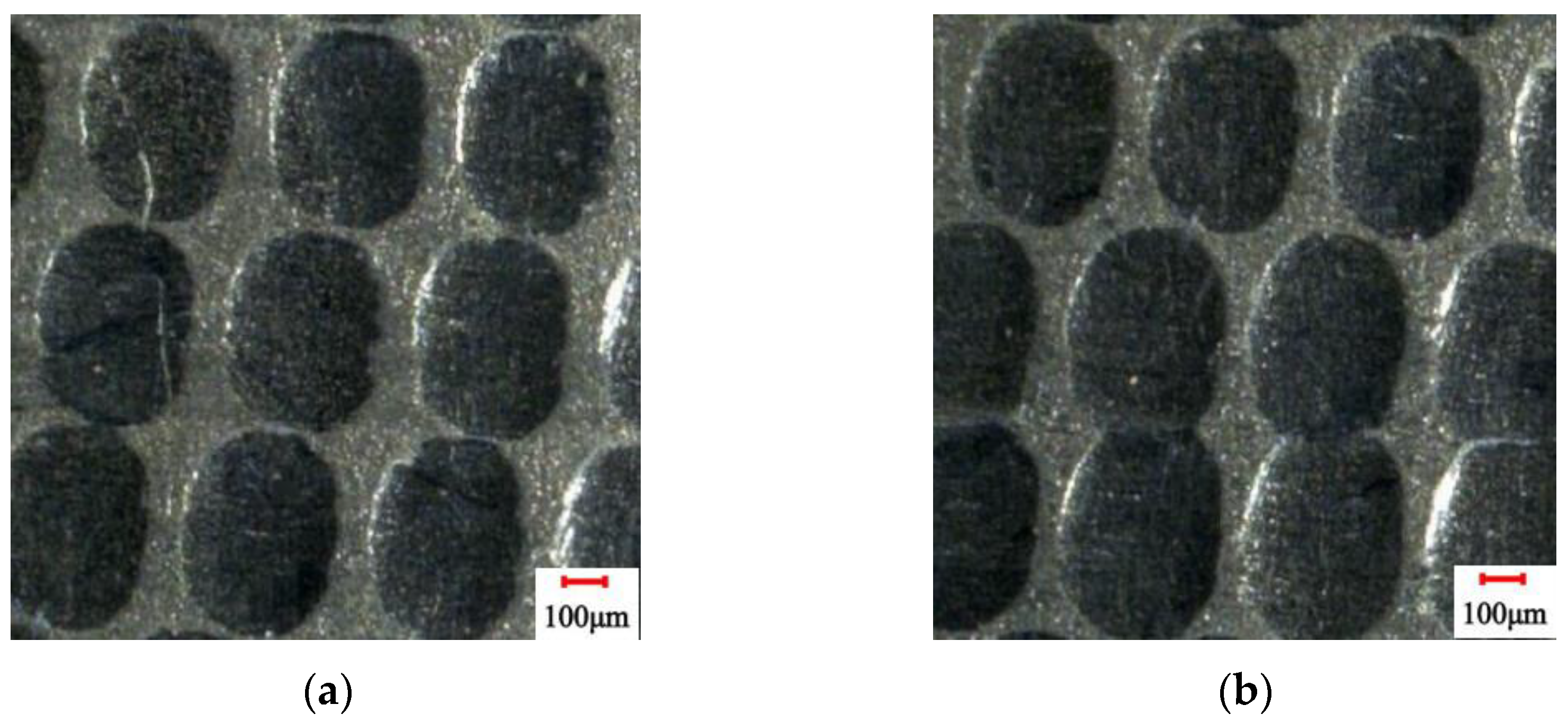

5. Experimental Verification

6. Conclusions

- It is found that the peaks and valleys of the surface topography are more and more significant along with the gradual increase in the t-value, and the surface texture parameters Sp, Sv, Sz, Sxp, Sa, Sq, Sdq, and Sdr are gradually increased.

- An improved correlation analysis model is developed, and the correlations between surface texture parameters are analysed. Extremely strong correlations are found between the parameters Sq and Sa and between Sp, Sdq, and Sdr.

- The evaluation parameter KV for surface wear characteristics was proposed, and it was found that the correlation between the surface texture parameters and KV was in order from strongest to weakest: Sku, Sa, Sq, Sxp, Sp, Sdq, Ssk, Sdr, Sv, Sz.

- A prediction model for the wear feature evaluation parameter KV was established based on Sku, Sa, Sxp, Sp, and Ssk, and the wear resistance prediction analysis based on the surface texture parameter was realised. The correctness of the model was verified by experiments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| t | Vibration difference of adjacent teeth during ball-end milling. |

| Sa | Arithmetical mean height. |

| Sq | Root mean square height. |

| Sp | Largest peak height. |

| Sv | Largest pit height. |

| Sz | Largest height. |

| Ssk | Skewness. |

| Sku | Kurtosis. |

| Sxp | Difference in height between the 2.5% and 50% material ratio. |

| Sdq | Root mean square gradient. |

| Sdr | Developed interfacial area ratio. |

References

- Zhang, N.; Zhan, X.; Li, Z.; Liu, Y.; Ma, J.; Gao, J. Effect of squamous textured SiC on the dry-sliding tribological properties of graphite asperities. Wear 2024, 544, 205297. [Google Scholar] [CrossRef]

- Kang, J.; Lu, Y.; Yang, X.; Zhao, X.; Zhang, Y.; Xing, Z. Modeling and experimental investigation of wear and roughness for honed cylinder liner during running-in process. Tribol. Int. 2022, 171, 107531. [Google Scholar] [CrossRef]

- Lu, G.; Lu, W.; Shi, X.; Zhang, J.; Yang, Z.; Chen, W. Effects of Ni3Al matrix bio-inspired shell-like composite surface structure on interfacial tribological behaviors. Tribol. Int. 2022, 170, 107522. [Google Scholar] [CrossRef]

- Kaya, S.; Yılan, F.; Urtekin, L. Influences of Cr on the microstructural, wear and mechanical performance of high-chromium white cast iron grinding balls. J. Mater. Manuf. 2022, 1, 23–30. [Google Scholar] [CrossRef]

- Chen, H.; Xu, C.; Xiao, G.; Chen, Z.; Yi, M. Ultralow friction between steel surfaces achieved by lubricating with liquid crystal after a running-in process with acetylacetone. Tribol. Lett. 2018, 66, 68. [Google Scholar] [CrossRef]

- Chen, H.; Xu, C.; Xiao, G.; Yi, M.; Chen, Z.; Zhang, J. Analysis of the relationship between roughness parameters of wear surface and tribology performance of 5CB liquid crystal. J. Mol. Liq. 2022, 352, 118711. [Google Scholar] [CrossRef]

- Dzierwa, A.; Pawlus, P.; Zelasko, W. The influence of disc surface topography after vapor blasting on wear of sliding pairs under dry sliding conditions. Coatings 2020, 10, 102. [Google Scholar] [CrossRef]

- Duo, Y.; Tang, J.; Zhao, Z.; You, S.; Li, G.; Zhu, G. Discrimination of wear performance based on surface roughness parameters arithmetic mean height (Sa) and skewness (Ssk). Wear 2024, 548, 205397. [Google Scholar] [CrossRef]

- Dzierwa, A. Influence of surface preparation on surface topography and tribological behaviours. Arch. Civ. Mech. Eng. 2017, 17, 502–510. [Google Scholar] [CrossRef]

- Grabon, W.; Pawlus, P.; Woś, S.; Koszela, W.; Wieczorowski, M. Effects of honed cylinder liner surface texture on tribological properties of piston ring-liner assembly in short time tests. Tribol. Int. 2017, 113, 137–148. [Google Scholar] [CrossRef]

- Kaplan, M. A Study of Erosion Wear Behavior of Inconel-718 Nickel Based Superalloy at Different Impingement Angles. J. Mater. Manuf. 2023, 2, 10–19. [Google Scholar]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional importance of surface texture parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef] [PubMed]

- Pawlus, P.; Reizer, R.; Wieczorowski, M.; Królczyk, G. Parametric description of one-process surface texture. Measurement 2022, 204, 112066. [Google Scholar] [CrossRef]

- Duo, Y.; Tang, J.; Fujia, X.; Wei, Z. Surface roughness characterization and inversion of ultrasonic grinding parameters based on support vector machine. J. Tribol. 2022, 144, 094501. [Google Scholar] [CrossRef]

- Korzynski, M.; Dudek, K.; Palczak, A.; Kruczek, B.; Kocurek, P. Experimental models and correlations between surface parameters after slide diamond burnishing. Meas. Sci. Rev. 2018, 18, 123–129. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, J.; Zhao, H.; Feng, G.; Zhang, Y.; Kong, M.; Liu, E. Study on the Ball-End Milling Cutter Design and the Performance of Milling SiCp/Al. Integr. Ferroelectr. 2023, 235, 106–125. [Google Scholar] [CrossRef]

- Yang, S.; Liu, L.; He, C. Study on milling behavior of TiAlN coated tool with variable distribution density micro-texture. Machining Science and Technology 2024, 28, 74–97. [Google Scholar] [CrossRef]

- Zheng, M.; Wang, B.; Zhang, W.; Cui, Y.; Zhang, L.; Zhao, S. Analysis and prediction of surface wear resistance of ball-end milling topography. Surf. Topogr. Metrol. Prop. 2020, 8, 025032. [Google Scholar] [CrossRef]

- Wang, B.; Zheng, M.; Zhang, W. Analysis and prediction of wear performance of different topography surface. Materials 2020, 13, 5056. [Google Scholar] [CrossRef]

- Li, S.; Dong, Y.; Li, Y.; Li, P.; Yang, Z.; Landers, R.G. Geometrical simulation and analysis of ball-end milling surface topography. Int. J. Adv. Manuf. Technol. 2019, 102, 1885–1900. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Archard, J.F. Wear Theory and Mechanisms. In Wear Control Handbook; Peterson MB & Winer WO, The American Society of Mechanical Engineers, United Engineering Center: New York, NY, USA, 1980; pp. 35–80. [Google Scholar]

- Chen, H.; Jin, L.; Li, X. Grey Systems: Theory and Application. Grey Syst. Theory Appl. 2011, 4883, 44–45. [Google Scholar] [CrossRef]

- Akkus, H. Experimental and statistical investigations of surface roughness, vibration, and energy consumption values of titanium alloy during machining using response surface method and grey relational analysis. Sci. Iran. 2022, 29, 109–119. [Google Scholar] [CrossRef]

- Marakini, V.; Pai, S.; Bhat, U.; Singh, D.; Achar, B. High speed machining for enhancing the AZ91 magnesium alloy surface characteristics: Influence and optimisation of machining parameters. Def. Sci. J. 2022, 72, 105–113. [Google Scholar] [CrossRef]

- Liu, S.; Forrest, J. Grey Systems: Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- PN-EN 25178-2:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2012.

| Groups | A | B | C | D | E | F | G | H | I |

|---|---|---|---|---|---|---|---|---|---|

| t (μm) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Material | Density (g/mm3) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| Cr12MoV | 7700 × 10−6 | 218 | 0.28 |

| A | B | C | D | E | F | G | H | I | |

|---|---|---|---|---|---|---|---|---|---|

| Sp (μm) | 4.1529 | 4.1112 | 4.1814 | 4.3606 | 4.655 | 5.0864 | 5.6805 | 6.4365 | 7.3459 |

| Sv (μm) | 2.3314 | 2.9068 | 3.4325 | 3.908 | 4.3338 | 4.6842 | 4.9350 | 5.0859 | 5.1374 |

| Sz (μm) | 6.4843 | 7.0179 | 7.6139 | 8.2686 | 8.9888 | 9.7706 | 10.6154 | 11.5224 | 12.4833 |

| Sxp (μm) | 3.0937 | 3.0718 | 3.2187 | 3.4862 | 3.8019 | 4.0853 | 4.8201 | 5.4114 | 5.667 |

| Sq (μm) | 1.4344 | 1.4663 | 1.6112 | 1.8424 | 2.1264 | 2.4132 | 2.6584 | 2.8345 | 2.9042 |

| Sa (μm) | 1.2064 | 1.2229 | 1.3119 | 1.479 | 1.7309 | 2.0303 | 2.2701 | 2.4201 | 2.4712 |

| Ssk | 0.3812 | 0.3013 | 0.1167 | −0.0234 | −0.0656 | −0.0375 | 0.0339 | 0.1198 | 0.1696 |

| Sku | 2.2693 | 2.318 | 2.4315 | 2.4007 | 2.2502 | 2.0968 | 2.0182 | 2.0284 | 2.0737 |

| Sal (mm) | 0.1260 | 0.1303 | 0.1514 | 0.1873 | 0.2212 | 0.2361 | 0.2408 | 0.2431 | 0.2441 |

| Sdq | 0.0216 | 0.0217 | 0.0221 | 0.0226 | 0.0234 | 0.0252 | 0.0273 | 0.0297 | 0.0320 |

| Sdr (%) | 0.0233 | 0.0236 | 0.0243 | 0.0256 | 0.0274 | 0.0318 | 0.0374 | 0.0440 | 0.0513 |

| Sp | Sv | Sz | Sxp | Sq | Sa | Ssk | Sku | Sdq | Sdr | |

|---|---|---|---|---|---|---|---|---|---|---|

| Sp | 1 | 0.7937 | 0.6323 | 0.8362 | 0.7402 | 0.7503 | 0.8104 | 0.6501 | 0.9090 | 0.9192 |

| Sv | 1 | 0.7252 | 0.7462 | 0.7049 | 0.6978 | 0.6889 | 0.6027 | 0.8469 | 0.8471 | |

| Sz | 1 | 0.6362 | 0.6393 | 0.6301 | 0.5851 | 0.5629 | 0.6562 | 0.6577 | ||

| Sxp | 1 | 0.7907 | 0.7954 | 0.7910 | 0.7073 | 0.8194 | 0.8016 | |||

| Sq | 1 | 0.9241 | 0.7070 | 0.7294 | 0.7398 | 0.7124 | ||||

| Sa | 1 | 0.7209 | 0.7453 | 0.7508 | 0.7237 | |||||

| Ssk | 1 | 0.7142 | 0.7723 | 0.7697 | ||||||

| Sku | 1 | 0.6436 | 0.6285 | |||||||

| Sdq | 1 | 0.9516 | ||||||||

| Sdr | 1 |

| A | B | C | D | E | F | G | H | I | |

|---|---|---|---|---|---|---|---|---|---|

| V (×10−5 mm3) | 8.29208 | 8.29219 | 8.29233 | 8.29252 | 8.29287 | 8.29191 | 8.29192 | 8.29209 | 8.29222 |

| Vs (×10−9 mm2) | 1.658416 | 1.658438 | 1.658466 | 1.658504 | 1.658574 | 1.658382 | 1.658384 | 1.658418 | 1.658444 |

| KV (×10−9 mm2) | 1 | 1.052885 | 1.120192 | 1.211538 | 1.379808 | 0.918269 | 0.923077 | 1.004808 | 1.067308 |

| Sp | Sv | Sz | Sxp | Sq | Sa | Ssk | Sku | Sdq | Sdr | |

|---|---|---|---|---|---|---|---|---|---|---|

| ε | 0.6210 | 0.5968 | 0.5693 | 0.6263 | 0.6753 | 0.6924 | 0.6149 | 0.7172 | 0.6154 | 0.6021 |

| Groups | Real Data | Simulated Value KV | Relative Error (%) | |

|---|---|---|---|---|

| B | 1.052885 | 2.063901 | 1.063901 | 1.05 |

| C | 1.120192 | 3.126701 | 1.073816 | 4.14 |

| D | 1.211538 | 4.458296 | 1.285219 | 6.08 |

| E | 1.379808 | 5.719717 | 1.335102 | 3.24 |

| F | 0.918269 | 6.678347 | 0.913924 | 0.47 |

| G | 0.923077 | 7.622564 | 0.939872 | 1.82 |

| H | 1.004808 | 8.604838 | 0.999069 | 0.57 |

| I | 1.067308 | 9.678936 | 1.068359 | 0.10 |

| Groups | fz (μm) | ae (μm) | ap (μm) | S (r/min) |

|---|---|---|---|---|

| M | 0.4 | 0.6 | 0.3 | 8000 |

| N | 0.4 | 0.6 | 0.3 | 10,000 |

| Groups | Sku | Sa | Sxp | Sp | Ssk |

|---|---|---|---|---|---|

| M | 2.3829 | 2.4933 | 6.8284 | 10.0332 | 0.5191 |

| N | 2.4397 | 3.1024 | 8.0198 | 12.2234 | 0.3095 |

| Groups | m0 (g) | m1 (g) | T (s) | s (mm) | ΔV (×10−3 mm3/mm) |

|---|---|---|---|---|---|

| M | 22.1410 | 22.0856 | 1800 | 72,000 | 0.2803 |

| N | 22.6872 | 22.4635 | 1800 | 72,000 | 0.4035 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Zhang, W.; Liu, Z. Study of the Impact of Surface Topography on Wear Resistance. Coatings 2024, 14, 1128. https://doi.org/10.3390/coatings14091128

Wang B, Zhang W, Liu Z. Study of the Impact of Surface Topography on Wear Resistance. Coatings. 2024; 14(9):1128. https://doi.org/10.3390/coatings14091128

Chicago/Turabian StyleWang, Ben, Wei Zhang, and Zhongxun Liu. 2024. "Study of the Impact of Surface Topography on Wear Resistance" Coatings 14, no. 9: 1128. https://doi.org/10.3390/coatings14091128

APA StyleWang, B., Zhang, W., & Liu, Z. (2024). Study of the Impact of Surface Topography on Wear Resistance. Coatings, 14(9), 1128. https://doi.org/10.3390/coatings14091128