Oxide Electric Field-Induced Degradation of SiC MOSFET for Heavy-Ion Irradiation

Abstract

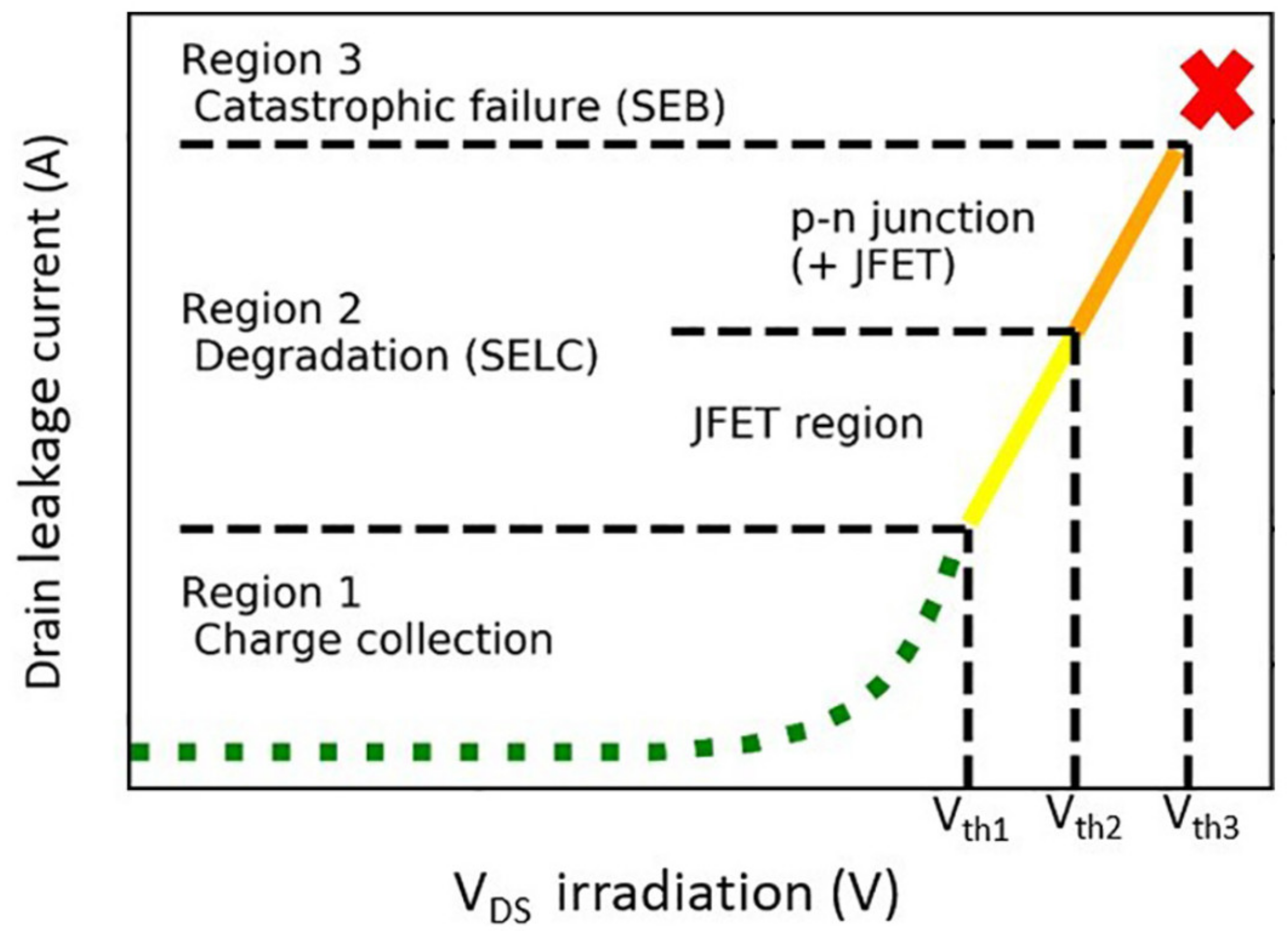

:1. Introduction

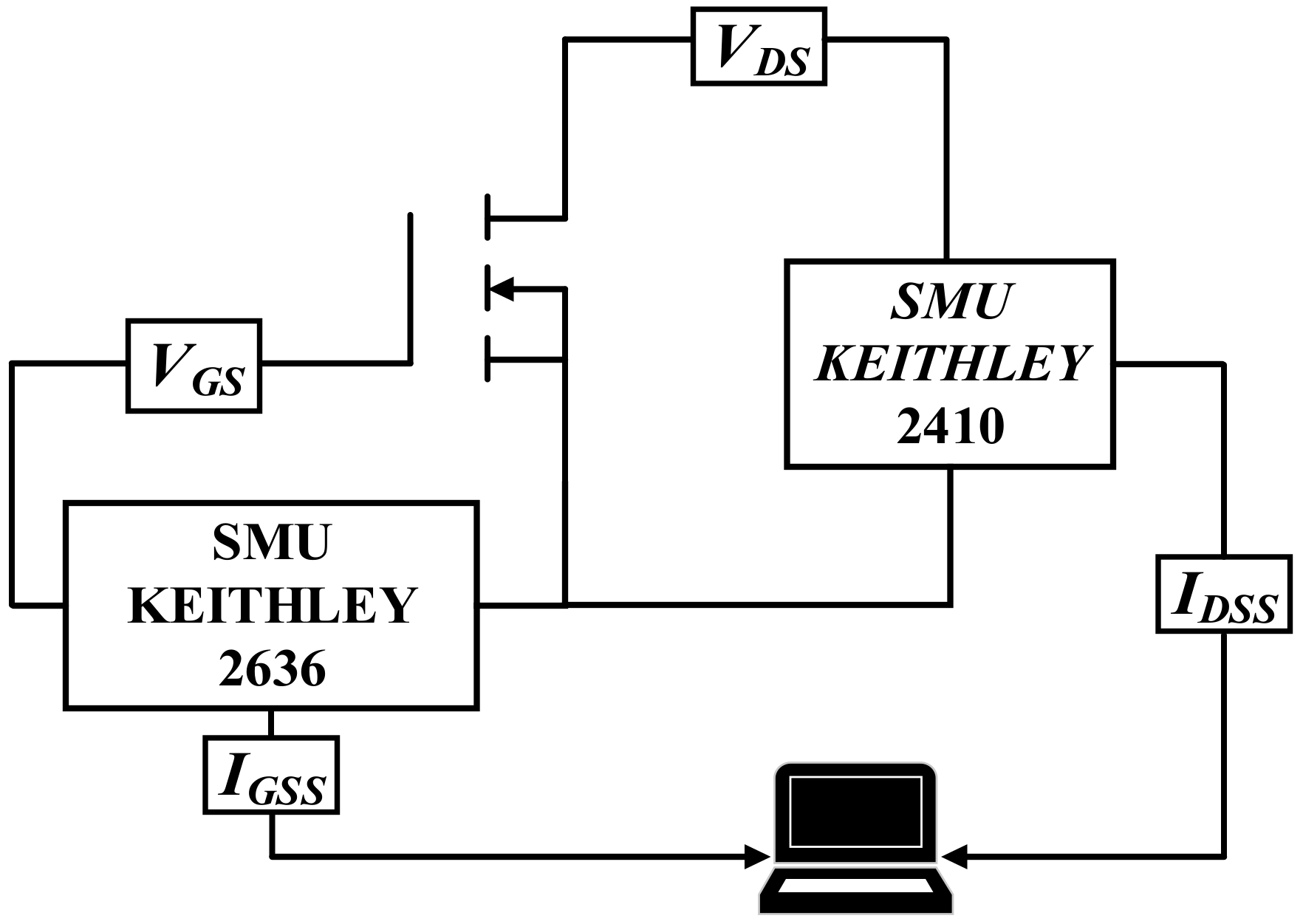

2. Experimental Setup

3. Results and Analysis

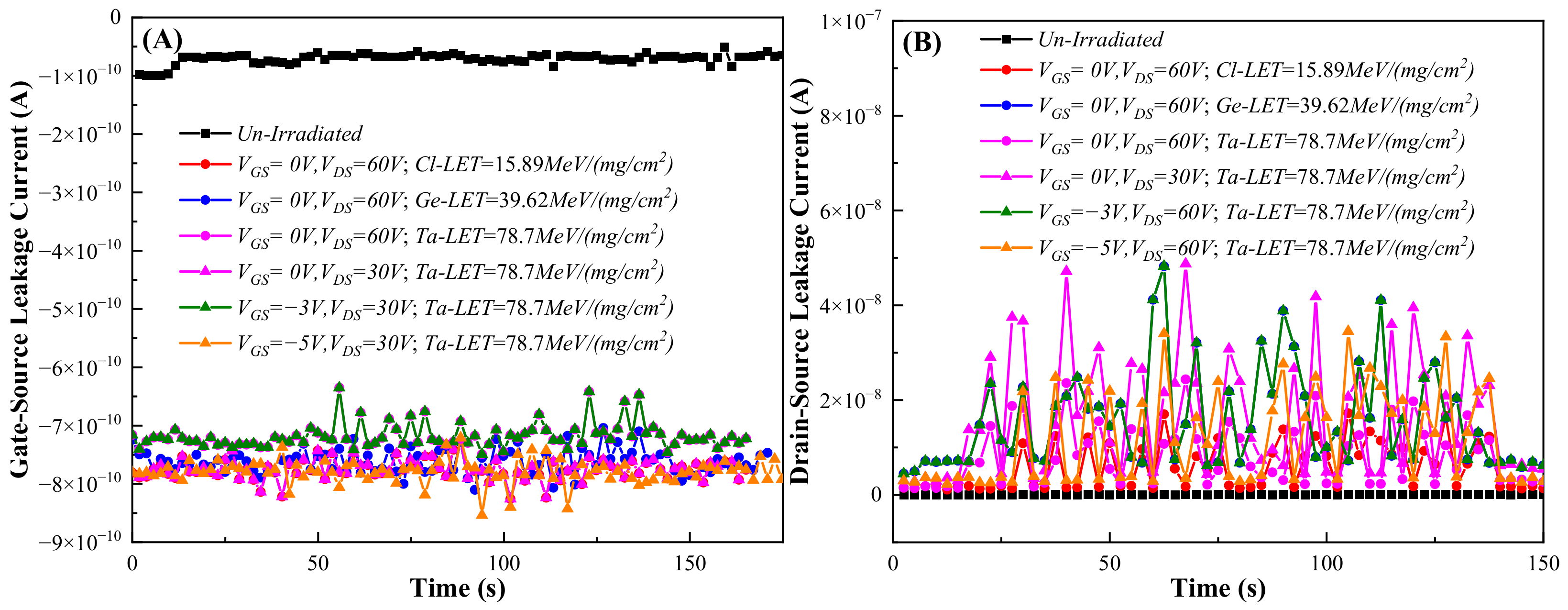

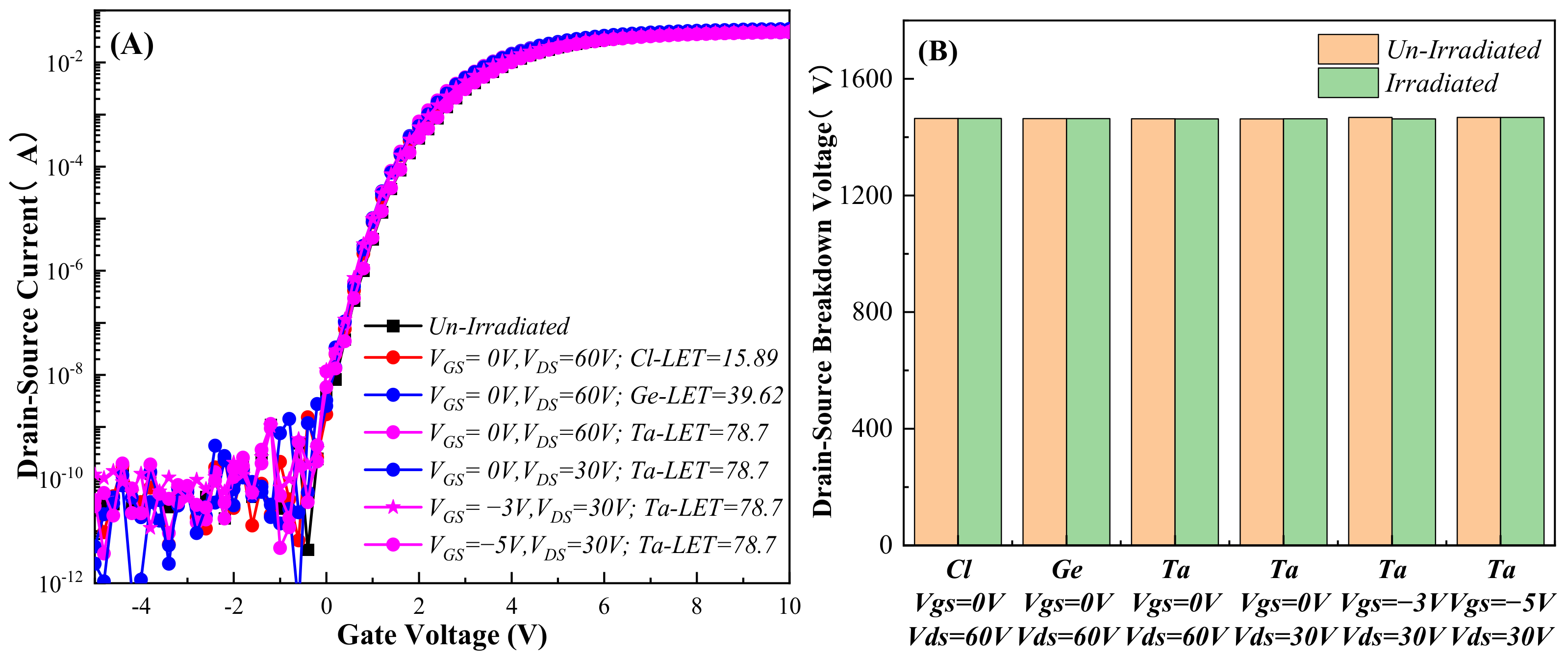

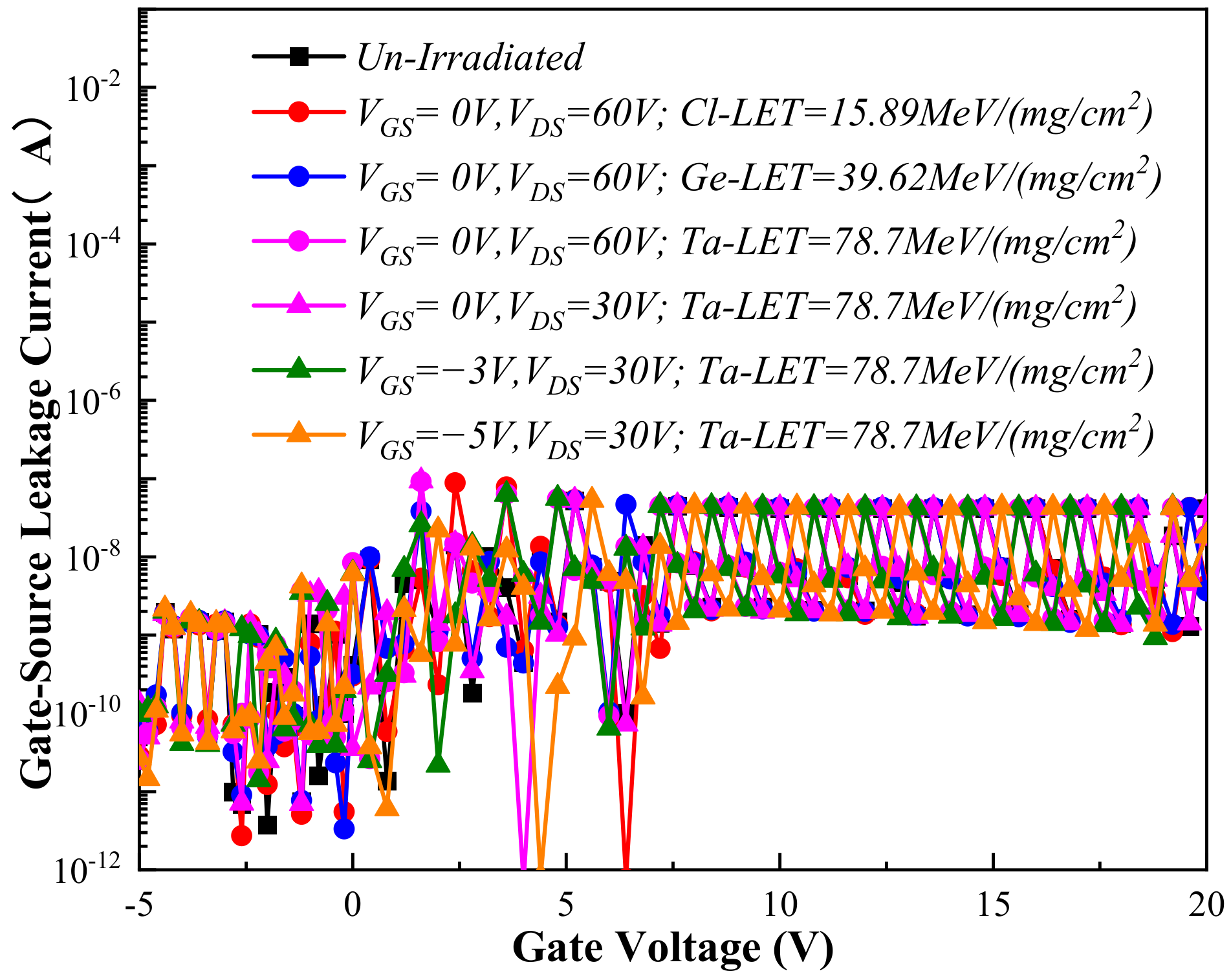

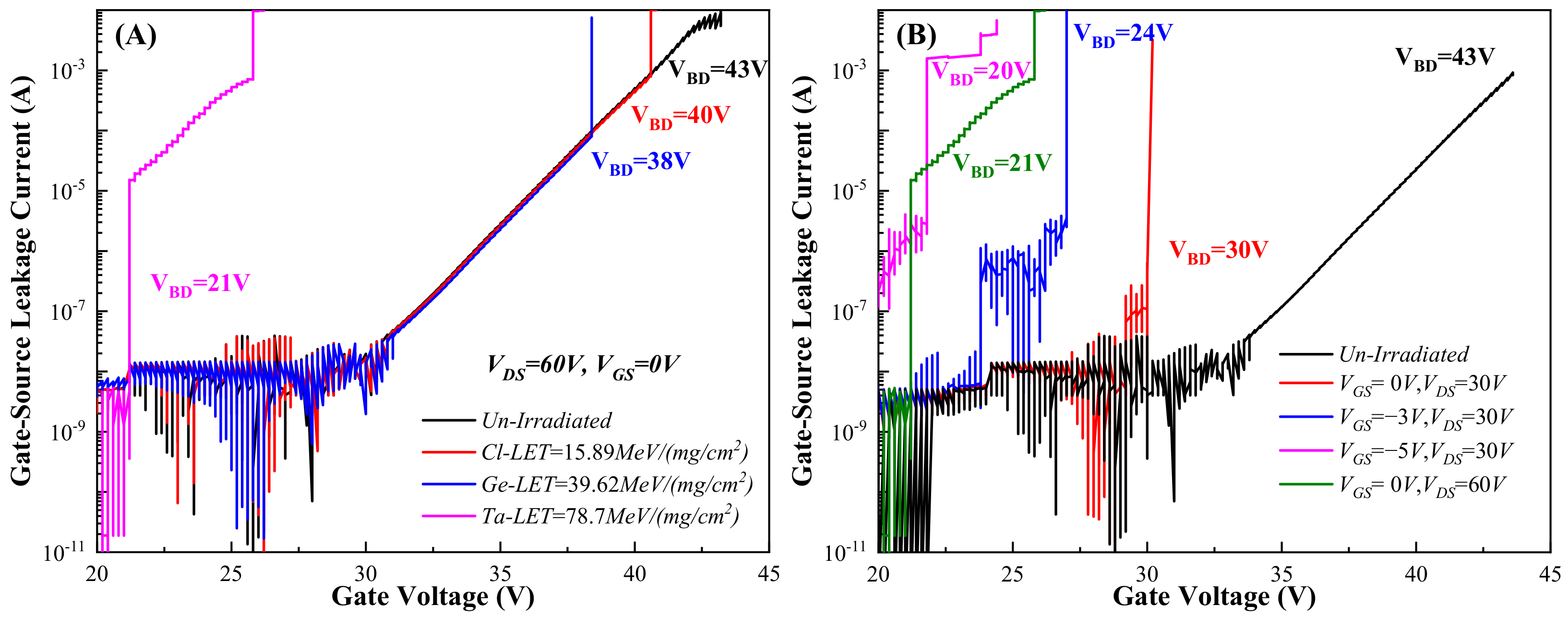

3.1. Heavy-Ion Experiment Results

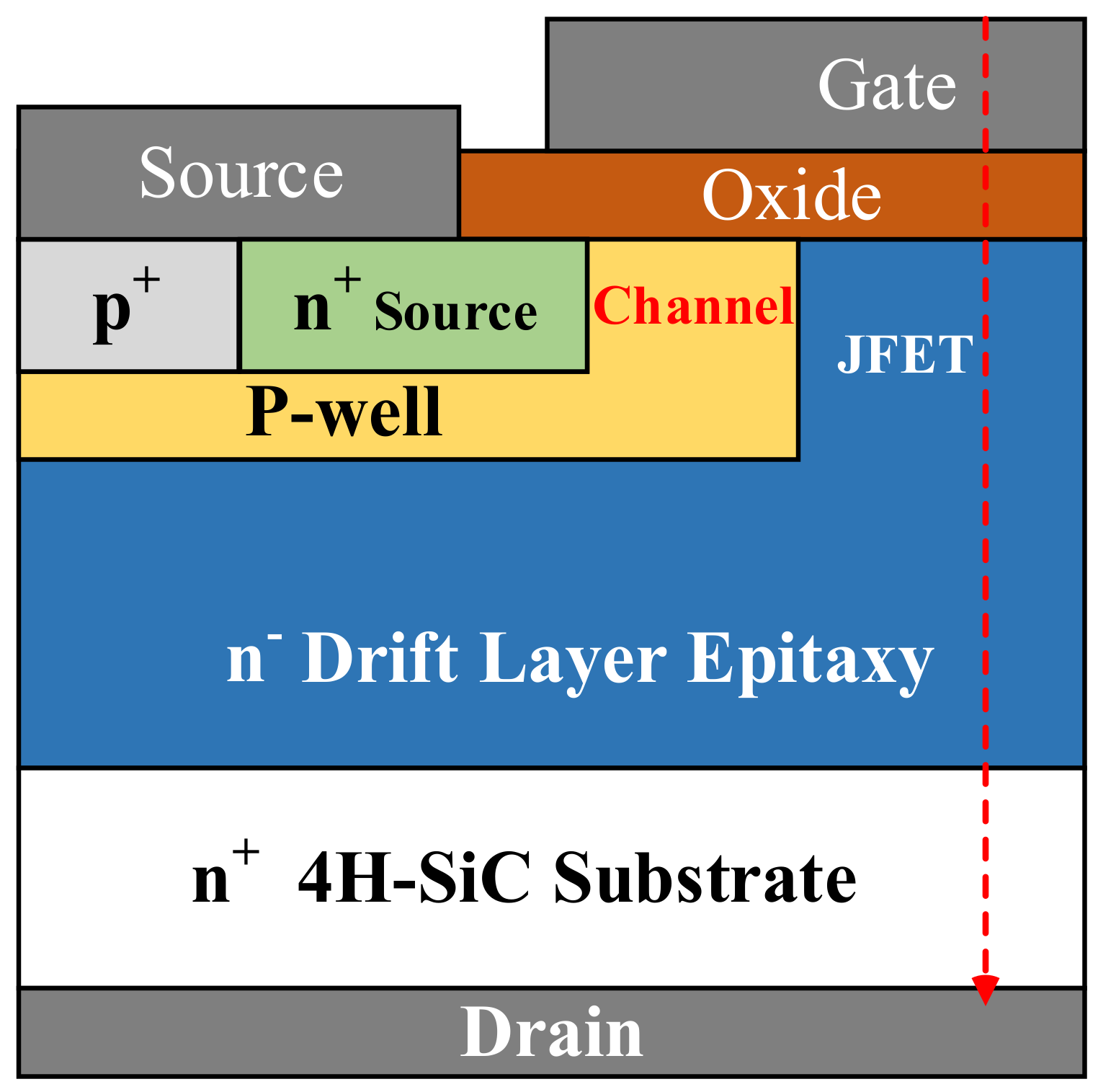

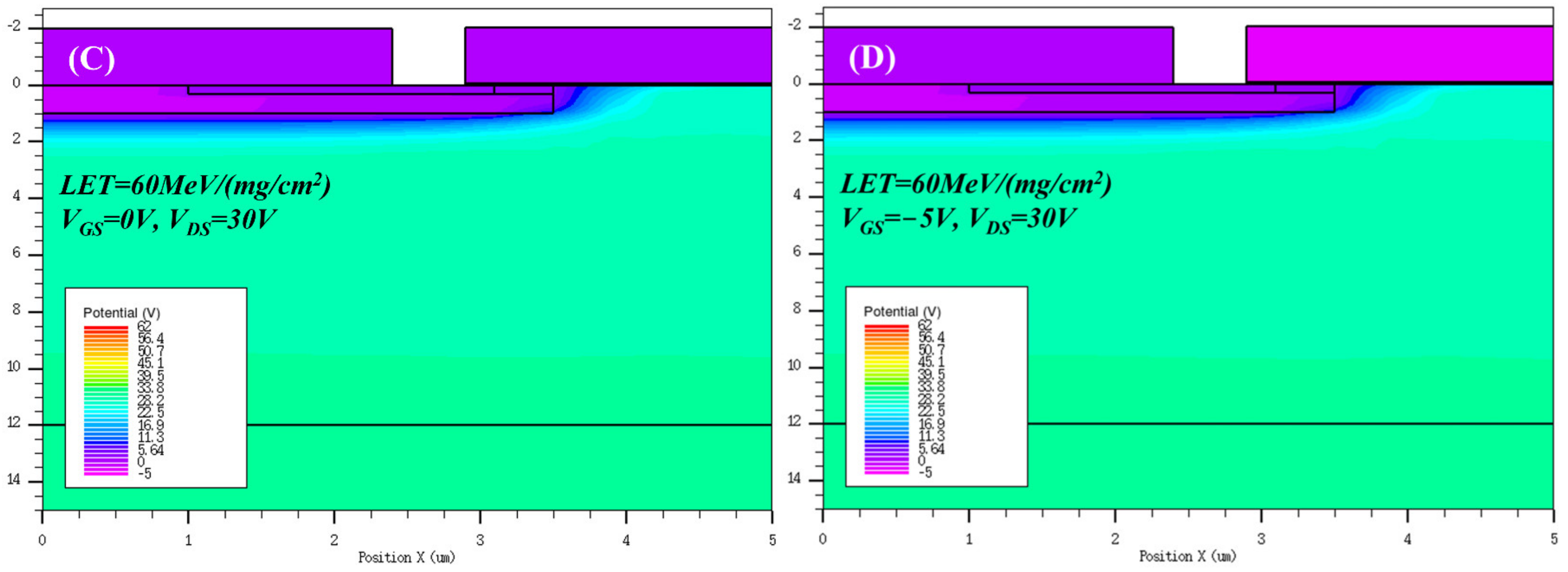

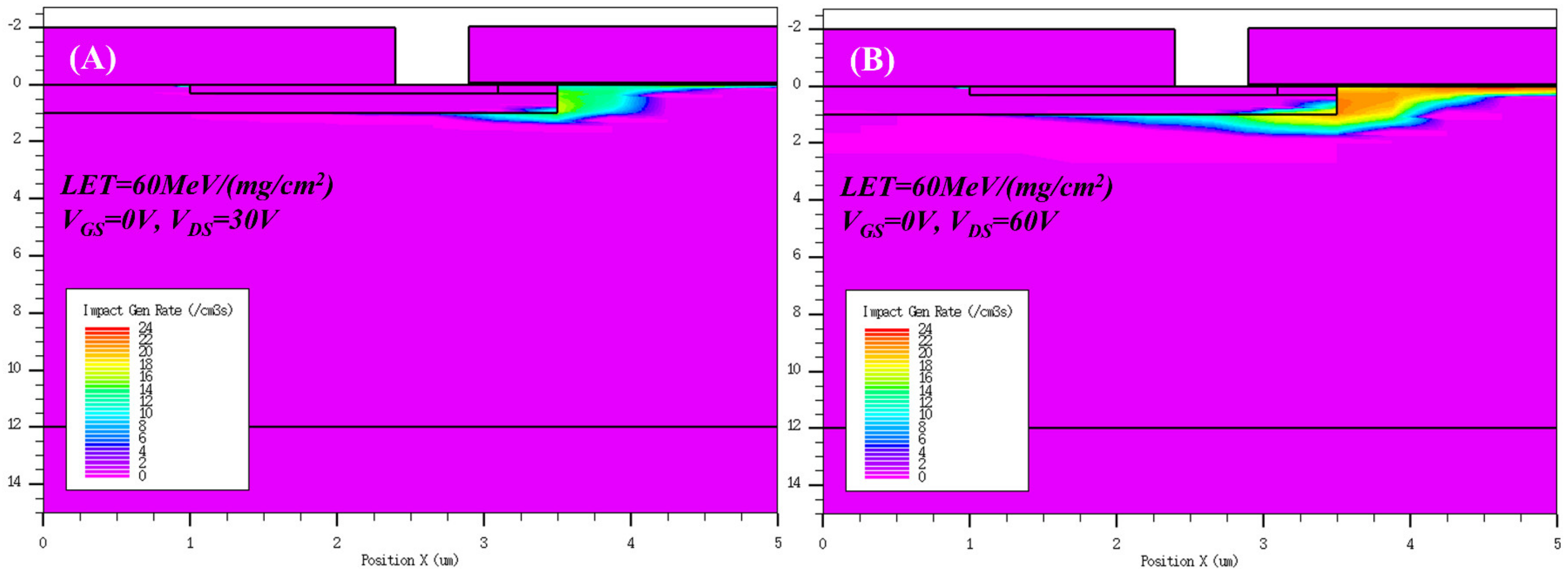

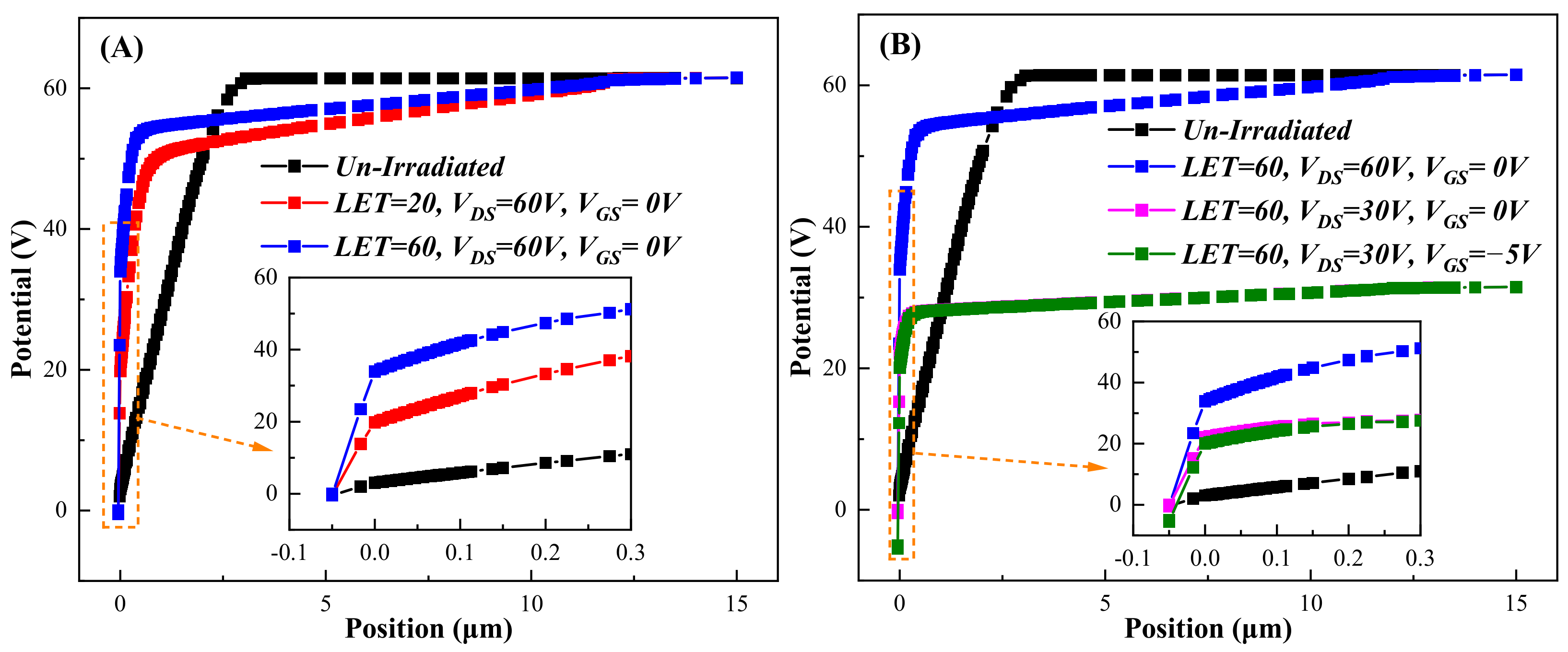

3.2. Degradation Mechanism of Oxide Reliability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- She, X.; Huang, A.Q.; Lucia, O.; Ozpineci, B. Review of Silicon Carbide Power Devices and Their Applications. IEEE Trans. Ind. Electron. 2017, 64, 8193–8205. [Google Scholar] [CrossRef]

- Roccaforte, F.; Fiorenza, P.; Greco, G.; Nigro, R.L.; Giannazzo, F.; Iucolano, F.; Saggio, M. Emerging Trends in Wide Band Gap Semiconductors (SiC and GaN) Technology for Power Devices. Microelectron. Eng. 2018, 187–188, 66–77. [Google Scholar] [CrossRef]

- Li, J.; Igarashi, S.; Fujishima, N. SiC Power Devices and Application to Power Electronics. In Proceedings of the PCIM Asia 2022, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Shanghai, China, 26–27 October 2022. [Google Scholar]

- Boomer, K.; Lauenstein, J.M.; Hammoud, A. Body of Knowledge for Silicon Carbide Power Electronics; NASA: Washington, DC, USA, 2016. [Google Scholar]

- Jie, X.; Qing, K.; Xuan, Z.; Feng, L. Application Prospect of SiC Power Semiconductor Devices in Spacecraft Power Systems. In Proceedings of the 2017 IEEE 13th International Conference on Electronic Measurement & Instruments (ICEMI), Yangzhou, China, 20–22 October 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Lauenstein, J.M. Wide Bandgap Power SiC, GaN Radiation Reliability. In Proceedings of the IEEE Nuclear and Space Radiation Effects Conference (NSREC), Santa Fe, NM, USA, 30 November 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Akturk, A.; McGarrity, J.M.; Potbhare, S.; Goldsman, N. Radiation Effects in Commercial 1200 V 24 A Silicon Carbide Power MOSFETs. IEEE Trans. Nucl. Sci. 2012, 59, 3258–3264. [Google Scholar] [CrossRef]

- Schwank, J.R.; Shaneyfelt, M.R.; Fleetwood, D.M.; Felix, J.A.; Dodd, P.E.; Paillet, P.; Ferlet-Cavrois, V. Radiation Effects in MOS Oxides. IEEE Trans. Nucl. Sci. 2008, 55, 1833–1853. [Google Scholar] [CrossRef]

- Asai, H.; Nashiyama, I.; Sugimoto, K.; Shiba, K.; Sakaide, Y.; Ishimaru, Y.; Okazaki, Y.; Noguchi, K.; Morimura, T. Tolerance Against Terrestrial Neutron-Induced Single-Event Burnout in SiC MOSFETs. IEEE Trans. Nucl. Sci. 2014, 61, 3109–3114. [Google Scholar] [CrossRef]

- Shoji, T.; Nishida, S.; Hamada, K.; Tadano, H. Analysis of neutron-induced single-event burnout in SiC power MOSFETs. Microelectron. Reliab. 2015, 55, 1517–1521. [Google Scholar] [CrossRef]

- Witulski, A.F.; Ball, D.R.; Galloway, K.F.; Javanainen, A.; Lauenstein, J.-M.; Sternberg, A.L.; Schrimpf, R.D. Single-Event Burnout Mechanisms in SiC Power MOSFETs. IEEE Trans. Nucl. Sci. 2018, 65, 1951–1955. [Google Scholar] [CrossRef]

- Ball, D.R.; Galloway, K.F.; Johnson, R.A.; Alles, M.L.; Sternberg, A.L.; Sierawski, B.D.; Witulski, A.F.; Reed, R.A.; Schrimpf, R.D.; Hutson, J.M.; et al. Ion-Induced Energy Pulse Mechanism for Single-Event Burnout in High-Voltage SiC Power MOSFETs and Junction Barrier Schottky Diodes. IEEE Trans. Nucl. Sci. 2020, 67, 22–28. [Google Scholar] [CrossRef] [Green Version]

- Peng, C.; Lei, Z.; Chen, Z.; Yue, S.; Zhang, Z.; He, Y.; Huang, Y. Experimental and Simulation Studies of Radiation-Induced Single Event Burnout in SiC-Based Power MOSFETs. IET Power Electron. 2020, 14, 1700–1712. [Google Scholar] [CrossRef]

- Abbate, C.; Busatto, G.; Tedesco, D.; Sanseverino, A.; Silvestrin, L.; Velardi, F.; Wyss, J. Gate Damages Induced in SiC Power MOSFETs During Heavy-Ion Irradiation—Part Ⅰ. IEEE Trans. Electron. Devices 2019, 66, 4235–4242. [Google Scholar] [CrossRef]

- Busatto, G.; Di Pasquale, A.; Marciano, D.; Palazzo, S.; Sanseverino, A.; Velardi, F. Physical mechanisms for gate damage induced by heavy ions in SiC power MOSFET. Microelectron. Reliab. 2020, 114, 113903. [Google Scholar] [CrossRef]

- Lauenstein, J.M.; Casey, M.C.; Ladbury, R.L.; Kim, H.S.; Phan, A.M.; Topper, A.D. Space Radiation Effects on SiC Power Device Reliability. In Proceedings of the 2021 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 21–25 March 2021; IEEE: Piscataway, NJ, USA, 2021. [Google Scholar]

- Single-Event Burnout and Single-Event Gate Rupture, Mil-Std-750e, Method 1080 [S]. 2006. Available online: http://everyspec.com/MIL-STD/MIL-STD-0700-0799/MIL-STD-750E_15413/ (accessed on 18 June 2023).

- Martinella, C.; Ziemann, T.; Stark, R.; Tsibizov, A.; Voss, K.O.; Alia, R.G.; Kadi, Y.; Grossner, U.; Javanainen, A. Heavy-Ion Microbeam Studies of Single-Event Leakage Current Mechanism in SiC VD-MOSFETs. IEEE Trans. Nucl. Sci. 2020, 67, 1381–1389. [Google Scholar] [CrossRef]

- Martinella, C.; Natzke, P.; Alia, R.; Kadi, Y.; Niskanen, K.; Rossi, M.; Jaatinen, J.; Kettunen, H.; Tsibizov, A.; Grossner, U.; et al. Heavy-ion induced single event effects and latent damages in SiC power MOSFETs. Microelectron. Reliab. 2022, 128, 114423. [Google Scholar] [CrossRef]

- Abbate, C.; Busatto, G.; Tedesco, D.; Sanseverino, A.; Silvestrin, L.; Velardi, F.; Wyss, J. Gate Damages Induced in SiC Power MOSFETs During Heavy-Ion Irradiation—Part Ⅱ. IEEE Trans. Electron. Devices 2019, 66, 4243–4250. [Google Scholar] [CrossRef]

- Zhou, X.; Pang, H.; Jia, Y.; Hu, D.; Wu, Y.; Zhang, S.; Li, Y.; Li, X.; Wang, L.; Fang, X.; et al. Gate Oxide Damage of SiC MOSFETs Induced by Heavy-Ion Strike. IEEE Trans. Electron. Devices 2021, 68, 4010–4015. [Google Scholar] [CrossRef]

- Pintacuda, F.; Massett, S.; Vitanza, E.; Muschitiello, M.; Cantarella, V. SEGR and PIGS Failure Analysis of SiC MOSFET. In Proceedings of the IEEE 2019 European Space Power Conference (ESPC), Juan-les-Pins, France, 30 September–4 October 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Cheung, K.P. SiC Power MOSFET Gate Oxide Breakdown Reliability—Current Status. In Proceedings of the 2018 IEEE International Reliability Physics Symposium (IRPS), Burlingame, CA, USA, 11–15 March 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Matocha, K.; Ji, I.H.; Zhang, X.; Chowdhury, S. SiC Power MOSFETs: Designing for Reliability in Wide-Bandgap Semiconductors. In Proceedings of the 2019 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 31 March–4 April 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Lichtenwalner, D.J.; Hull, B.; Van Brunt, E.; Sabri, S.; Gajewski, D.A.; Grider, D.; Allen, S.; Palmour, J.W.; Akturk, A.; McGarrity, J. Reliability Studies of SiC Vertical Power MOSFETs. In Proceedings of the 2018 IEEE International Reliability Physics Symposium (IRPS), Burlingame, CA, USA, 11–15 March 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Stathis, J.H. Physical and Predictive Models of Ultra Thin Oxide Reliability in CMOS Devices Circuits. IEEE Trans. Device Mater. Reliab. 2001, 1, 43–59. [Google Scholar] [CrossRef]

- Zhou, X.; Jia, Y.; Hu, D.; Wu, Y. A Simulation-Based Comparison between Si and SiC MOSFETs on Single-Event Burnout Susceptibility. IEEE Trans. Electron. Devices 2019, 66, 2551–2556. [Google Scholar] [CrossRef]

- Li, Q.; Chen, X.; Luo, H.; Li, X.; Ma, X.; Tao, L.; Qian, J.; Tan, C. Study on Single-Event Burnout of SiC VDMOSFET Failure Mechanism and Influence Factors. In Proceedings of the 2019 20th International Conference on Electronic Packaging Technology (ICEPT), Hong Kong, China, 12–15 August 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Kimoto, T.; Cooper, J.A. Fundamentals of Silicon Carbide Technology: Growth, Characterization, Devices and Applications; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

| Ions | Energy MeV | LET in SiC MeV/(mg/cm2) | Depth in SiC μm | Flux ions/cm2/s | Fluence ions/cm2 | Irradiation Bias |

|---|---|---|---|---|---|---|

| Cl | 110 | 15.89 | 20.31 | 104 | 106 | VGS = 0 V, VDS = 60 V |

| Ge | 210 | 39.6 | 20.19 | VGS = 0 V, VDS = 60 V | ||

| 181Ta | 2005.5 | 78.7 | 79.29 | VGS = 0 V, VDS = 60 V | ||

| VGS = 0 V, VDS = 30 V | ||||||

| VGS = −3 V, VDS = 30 V | ||||||

| VGS = −5 V, VDS = 30 V |

| Parameter | Value |

|---|---|

| N-Epi Doping/Depth | 1 × 1016 cm−3, 10 μm |

| N+ Substrate | 1 × 1019 cm−3 |

| Body Doping/Depth | 2 × 1017 cm−3, 1.5 μm |

| N+ Drain Doping | 1019 cm−3 |

| Oxide Thickness | 50 nm |

| Ion Track Radius/Length | 50 nm, 15 μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, X.; Feng, H.; Xiang, Y.; Sun, J.; Wei, Y.; Zhang, D.; Li, Y.; Feng, J.; Yu, X.; Guo, Q. Oxide Electric Field-Induced Degradation of SiC MOSFET for Heavy-Ion Irradiation. Electronics 2023, 12, 2886. https://doi.org/10.3390/electronics12132886

Liang X, Feng H, Xiang Y, Sun J, Wei Y, Zhang D, Li Y, Feng J, Yu X, Guo Q. Oxide Electric Field-Induced Degradation of SiC MOSFET for Heavy-Ion Irradiation. Electronics. 2023; 12(13):2886. https://doi.org/10.3390/electronics12132886

Chicago/Turabian StyleLiang, Xiaowen, Haonan Feng, Yutang Xiang, Jing Sun, Ying Wei, Dan Zhang, Yudong Li, Jie Feng, Xuefeng Yu, and Qi Guo. 2023. "Oxide Electric Field-Induced Degradation of SiC MOSFET for Heavy-Ion Irradiation" Electronics 12, no. 13: 2886. https://doi.org/10.3390/electronics12132886